Page 1

SERVICE BULLETIN

SB-2-582

Replaces SB-2-582

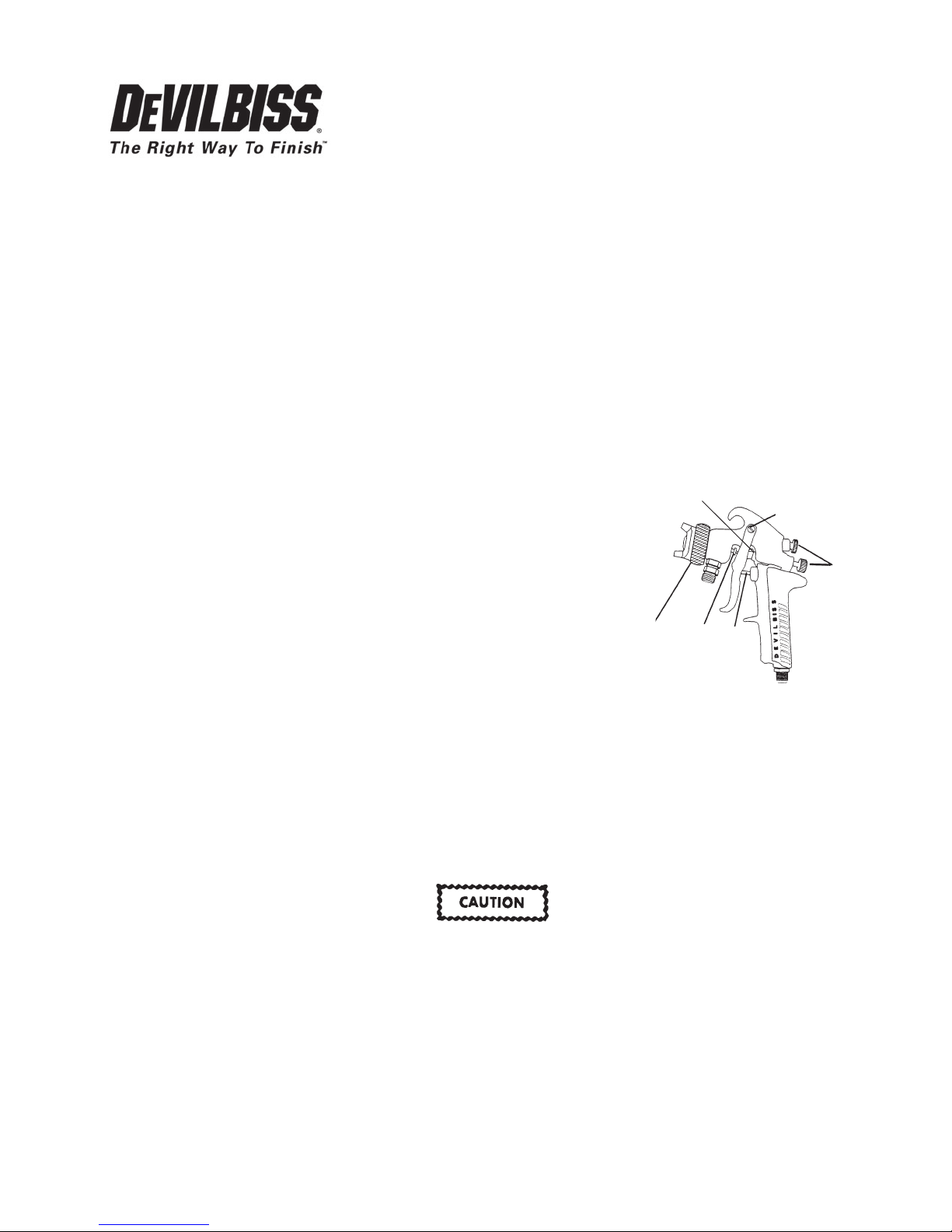

JGA-510-DEC DECORATOR SPRAY GUN

IMPORTANT: Before using this equipment, read all safety precautions and

instructions. Retain for future use.

DESCRIPTION

The JGA-510-DEC is a gun that can

apply decorative spatter effects to

wood furniture, metal panels, etc.

Finish may be changed from a fine

mist to larger droplet size particles.

Simply adjust fluid pressure and/or

air pressure

The JGA-510-DEC comes with the flatend AV-447 spatter cap assembly.

Small spatter dots are the result of

coarse atomization when using the

standard spatter cap assembly (2).

OPERATION

Note

This gun may be used with

chlorinated solvents. Aluminum is not used in the fluid

passage areas.

Mix material according to manufacturer's

instructions. It may be necessary to strain

material.

A greater than normal gun distance

provides a more uniform particle size.

Particle spacing is determined by speed

of movement and degree of overlap.

Particle size is dependent on the material consistency. Specially formulated

spatter materials are available, although

standard paints may be used. Apply

standard paints using very little or no

reduction.

Pressure on cup or tank controls

material flow. Begin with the fluid

needle adjusting screw (32) wide open.

Use fluid needle adjusting screw (32)

to regulate material flow under

abnormally low material pressure or

material viscosity conditions.

Adjust atomization air to get desired

particle size. It should be high enough

to carry particles to surface. Spatter

dot size increases with pressure reduction, and decreases with pressure increase. Pressure used depends on

material viscosity being sprayed and

desired operation speed.

PREVENTIVE MAINTENANCE

To clean gun passages, blow back

paint to material supply source and

flush fluid passage with clean solvent.

Model HD-503 Gun/Hose Cleaner is a

very fast and effective way of cleaning

(See Accessories). Wipe gun clean

with solvent soaked cloth.

If slots of ring (4) become clogged,

clean by soaking cap in solvent and

scrubbing with a gun cleaning brush.

Note

When replacing the fluid tip or

fluid needle, replace both at

the same time. Using worn

parts can cause fluid leakge.

Also, replace the needle packing at this time.

Using SSL-10 gun lube, lightly lubricate the threads of the fluid tip before

reassembling. Torque to 12-15 ft. lbs.

To prevent damage to the fluid

tip (7) or fluid needle (28), be

sure to either 1) pull the trigger

and hold while tightening the

fluid tip or 2) remove fluid

needle adjusting screw to relieve spring pressure.

Spray Gun Lubrication

For best results, lubricate the points

indicated, daily. Use SSL-10 Spray

Gun Lube to lubricate.

A. Trigger Points

B. Packings

C. Adjusting Valves

D. Air Baffle Threads

B

D

B

A

A

C

Page 2

Page 2 SB-2-582

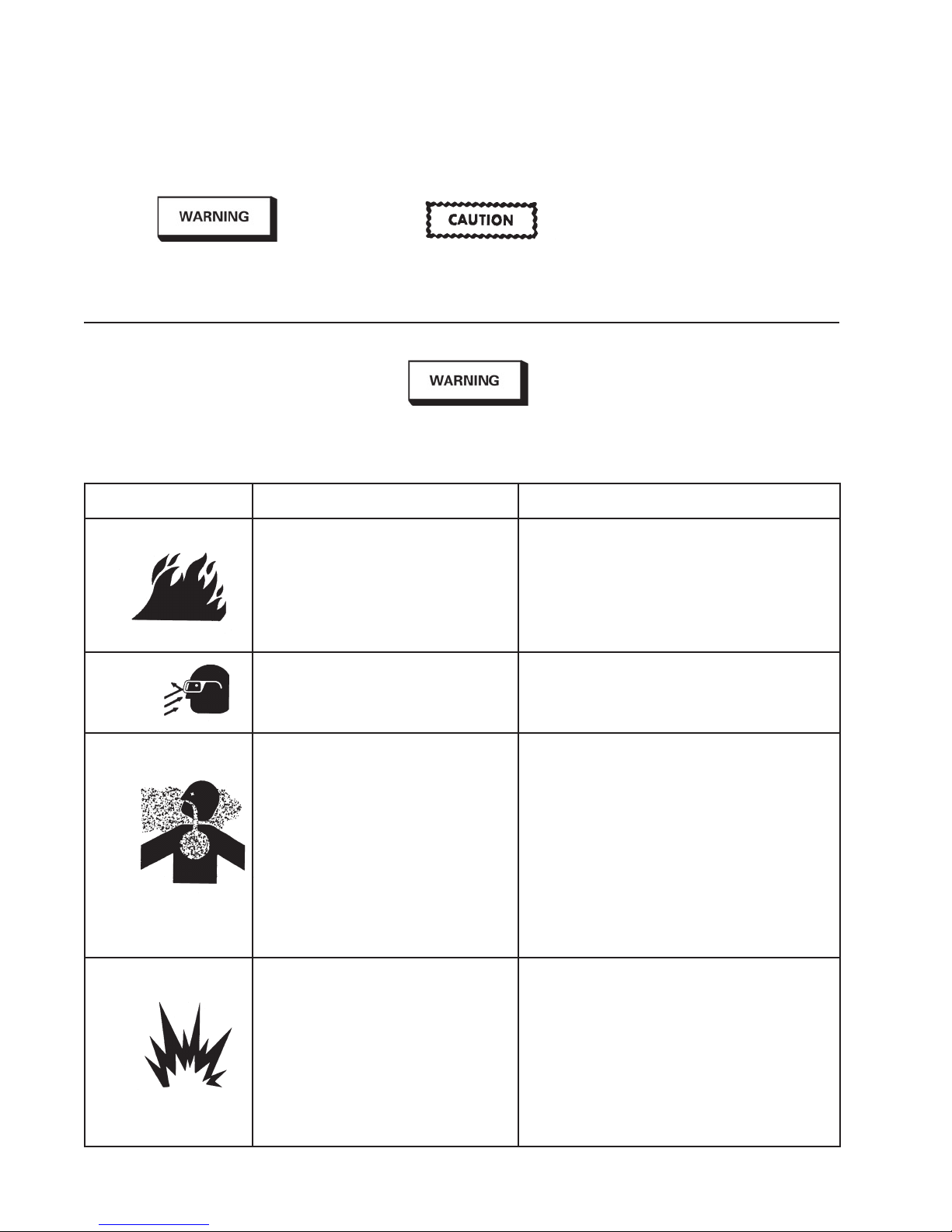

SAFETY PRECAUTIONS

This manual contains information that is improtant for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

Note

Important safety information - A hazard

that may cause serious injury or loss of

life.

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire Solvent and coatings can be highly Adequate exhaust must be provided to keep

flammable or combustible, especially air free of accumulations of flammable vapors.

when sprayed.

Solvent Spray During cleaning and flushing, sol- Wear eye protection.

vents can be forcefully expelled

from fluid and air passages. Some

solvents can cause eye injury.

Important information that tells how to

prevent damage to equipment, or how

to avoid a situation that may cause

minor inury.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present

in the spray area.

Information that you should pay special attention to.

Inhaling Toxic Substances Certain materials may be harmful Follow the requirements of the Material Safety

if inhaled, or if there is contact Data Sheet supplied by your coating material

with the skin. manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienst or safety

expert, and be NIOSH approved.

Explosion Hazard - Halogenated hydrocarbon solvents This gun can be used with these solvents.

- for example; methylene chloride However, aluminum is widely used in other spray

and 1, 1, 1 - Trichloroethane can application equipment - such as, material pumps,

chemically react with aluminum. cups, regulators, valves, etc. Check all other equipThe chemical reaction caused by ment items before use and make sure they can

these solvents reacting with aluminum also be used safely with these solvents. Read the

can become violent and lead to an label or material data sheet for the material you

equipment explosion. intend to spray. If in doubt as to whether or not a

coating or cleaning material is compatible, contact

your material supplier.

Page 3

PARTS LIST

Ref. Individual

No. Part No. Description Parts Req.

1 MBC-231 Retaining Nut 1

2 AV-447 Spatter Cap Assembly (Flat) 1

3 --- Cap 1

4 --- Ring 1

5 --- Gasket 1

6 MSV-3-K10 Gasket, PTFE (Blue) (Kit of 10) 1

7 JGA-4040-VF Fluid Tip and Needle, Matched 1

8 --- Lock Nut 1

9 --- Fluid Inlet Adapter 1

10 JGA-4044 Fluid Inlet and Nut Kit 1

•11 JGV-463-K3 Needle Packing (Kit of 3) 1

12

34411-122-K10

13 --- Trigger Bearing Stud 1

•14 --- Screw 1

15 JGS-478 Stud and Screw Kit 1

16 JGA-477 Trigger, Stud and Screw Kit 1

•17 JGA-14-K25 Snap Ring (Kit of 25) 1

•18 JGA-15-K25 Washer (Kit of 25) 1

•19 JGS-26-K25 U Cup Seal (Kit of 25) 1

•20 JGS-431-K25 Air Valve (Kit of 25) 1

•21 MBD-12-K25 Spring (Kit of 25) 1

•22 JGS-72-K10 Gasket (Kit of 10) 2

23 JGS-449-1 Air Valve Assembly 1

24 JGA-132 Plug 2

(Includes Item 28)

Packing Gland (Kit of 10) 1

(3 studs and 5 screws in kit)

(Kit includes 1 each)

SB-2-582 Page 3

Ref. Individual

No. Part No. Description Parts Req.

25 P-MB-51 Nipple 1

•26 GTI-33-K5 Seal Kit (Kit of 5) 1

27 JGA-4074 Baffle Assembly 1

28 --- Fluid Needle (Included with

29 --- Bushing 1

•30 MBD-19-K10 Spring (Kit of 10) 1

•31 --- Spring Pad (Included

32 JGS-16 Fluid Needle Adjusting Screw 1

33 JGA-4041 Bushing, Spring & Knob Kit 1

•These parts are included in Repair Kit KK-4987-2 and should be

kept on hand for service convenience.

Suffixes - K5, K10 designate kits of multiple parts.

(Example) JGV-463-K3 is a kit of 3 packings.

+Inner PTFE

Piece

Outer U.H.M.W.

Poly. Piece

Item 7) 1

with Item 30) 1

(Ref. No. 11) Needle

Fluid Packing

Nut

▲

Packing (2 piece packing) covered by U.S.

Patent No. 5,209,501.

+Tapered edge faces out

towards packing nut.

Fluid

Needle

33

28

22

29

30

31

32

1

Note

*Apply QH-130 (Loctite #242,

med. strength blue) sealing compound onto the threads and

screw into place with 170-180 in/

lb. torque.

17

2

18

19

See GTI-33 Baffle Seal Replacement

instructions on page 4.

Torque to

12-15 ft. lbs.

3

4 5

7

27

24

26

6

8

9

*

▲

11

12

*

10

Torque to

20-25 ft. lbs.

13

24

25

14

15

20

21

22

23

16

Page 4

Page 4 SB-2-582

GTI-33 Baffle Seal Replacement (26)

1. Remove fluid tip (7).

2. Remove baffle (27).

3. Remove seal (26) from baffle.

4. Assemble seal to baffle with angled

side up as shown at right.

NOTE

The seal should be a tight fit

on the baffle. If it is a loose fit

on the baffle, assure that it is

assembled with the angled

side up.

ACCESSORIES

WR-103 WRENCH

Contains all necessary

tip, hose and nut sizes

used on or with gun.

Millennium 3000

Twin Cartridge,

Paint Spray

Respirator

42884-214-K5 3/8"

42884-215-K10 5/8"

CLEANING BRUSHES

These brushes are helpful in cleaning threads

and recesses of gun

body.

HAF-507

Whirlwind™

In-Line Air Filter

5. Install baffle on gun.

6. Install fluid tip (7) and tighten to 12-15

ft-lbs.

The seal is designed to be a tight fit

on the baffle. The seal should be

able to be removed using your

fingers. If you are unable to remove the seal using your fingers,

insert a small screwdriver between the outer lip and the back of

the baffle and pry the seal off.

HD-503

SOLVENT SAVER™

GUN/HOSE CLEANER

2 qt. Hose/Gun Cleaner

used to clean the inside

of hose, fluid passageways of gun and other

paint equipment.

KB-555 Alum. &

KB-545-SS

Stainless Steel 2 Qt.

Pressure Feed Cups

NOTE

SPRAY GUN LUBE

SSL-10-K12

(2 oz. bottle)

Compatible with all paint

materials: contains no silicone or petroleum distillates to contaminate paint

An MSDS Sheet is available upon request.

29-3100 Scrubs

Hand Cleaner Towels

Pry here if

necessary

®

ANGLED SIDE

THICK SIDE

HAV-500 OR

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

HAV-500 does not have

pressure gauge. Use to

control air usage at gun.

SEAL

BAFFLE

HARG-510 AIR

REGULATOR

Use to maintain nearly

constant outlet pressure

despite changes in inlet

pressure and downstream flow.

®

Scrubs

are a pre-

NIOSH-Certified

(TC-84A-1623) for

respiratory protection in atmospheres

not immediately

dangerous to life.

Removes water,

oil, and debris

from the air line.

Includes a 0-30 psi

gauge.

moistened hand

cleaner towel for

painters, body men

and mechanics that

go where you go

and no water is

needed.

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

2/08 ©2008 Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...