Page 1

CA UTION– Federal (U.S.A.) law restricts this

device to sale by, or on the order of a physician.

D e V ilb is s® In t e lliP A P™P A P D e v ic e

D e V ilb is s

®

S le e p Cu b e™P A P D e v ic e

Model D V54

Serv ice Manu al

Page 2

2

LT-2 027

Page 3

3

LT-2 0 27

EN

Tab le o f C o n te n ts

1. General Information ......................................... 4

A. Safeguards ............................................................ 4

B. Initial Inspection ................................................... 4

C. T ravel ................................................................... 5

D. DC Power ........................................................... 5

E. Setting Pressures and Features ............................ 5

F. Images: DeVilbiss DV54 PAP ................................. 5

2. Description of Normal Operation .................... 6

3. Cleaning and Disinfecting ................................. 7

A. R outine Cleaning--Patient .................................... 7

B. Disinfecting .......................................................... 7

4. Maintenance ...................................................... 10

A. Initial Inspection—Equipment Provider .............. 10

B. R outine Maintenance—Patient ............................ 10

C. R equired 2-year Maintenance—

Equipment Provider ......................................... 10

5. Testing ............................................................... 11

A. Pressure Accuracy T est ........................................ 11

B. Flow Accuracy T est .............................................. 11

C. K eypad T est ......................................................... 12

D. Auto-ON / Auto-OFF T est .................................. 12

E. Backlight T est for LCD and K eypad ..................... 12

6. Alerts and Device Faults ................................... 13

A. Alerts Visible to Patients ...................................... 13

B. Device Faults Visible to Patients ......................... 13

C. R eading and Clearing the Last Device Fault Code 13

7. Calibration......................................................... 14

A. Manual Calibration ............................................... 14

B. Calibration Errors ................................................ 15

C. Auto-Calibration ................................................. 15

D. Details on T c Serial Command ............................ 15

8. Troubleshooting ................................................ 16

9. Service Instructions .......................................... 18

A. Cover R emoval ................................................... 18

B. Cover R eplacement ............................................. 18

C. Control PC Board R emoval ................................. 18

D. Control PC Board R eplacement .......................... 19

E. Power Supply Board R emoval .............................. 20

F. Power Supply Board R eplacement ........................ 20

G. Blower R emoval .................................................. 21

H. Blower R eplacement ........................................... 21

I. K eyPad & LCD Display R emoval and R eplacement ......... 22

J. Firmware installation ............................................. 22

10. Unit Specifi cations ............................................ 23

11. General Information- DV5HH .......................... 24

A. Safeguards ............................................................ 24

B. T ravel .................................................................... 24

C. DC Power ........................................................... 24

D. Product Description ............................................ 24

12. Description of Normal Operation- DV5HH ..... 25

13. Maintenance and Testing- DV5HH ................... 26

A. Cleaning and Disinfection .................................... 26

B. Maintenance ......................................................... 26

C. T esting .................................................................. 26

14. Troubleshooting- DV5HH .................................. 27

15. Service Instructions- DV5HH ........................... 28

A. R emoving the DV5HH base cover ....................... 28

B. R eplacing the DV5HH base cover ........................ 28

C. R emoving and replacing silicone manifold ................ 29

D. R emoving and replacing the latch ........................ 29

16. Unit Specifi cations- DV5HH ............................. 30

17. Ordering and R eturning Parts .......................... 31

A. Ordering Non-W arranty R eplacement Parts ....... 31

B. Ordering W arranty R eplacement Parts ............... 31

C. R eturning W arranty Defective Parts .................... 31

D. Placing orders ...................................................... 31

18. Parts List ........................................................... 32

19. W arranties ......................................................... 33

Page 4

4

LT-2 0 27

EN

1 . G en eral Inf o rm at ion

A. SAFEGU ARDS

When servicing electrical products, basic safety precautions

should always be followed. Important safety information in

this manual is highlighted by the following terms.

DANGER: Urgent safety information for hazards that

will cause serious injury or death.

WARNING: Important safety information for hazards

that might cause serious injury.

CAUTION: Information for preventing damage to the

product.

NOTE: Information to which you should pay

special attention.

PLEASE READ ALL INSTRUCTIONS

BEFORE USING THIS DEVICE.

DANGER!

• ELECTRIC SHOCK HAZARD – Do not use while

bathing.

• ELECTRIC SHOCK HAZARD – Do not immerse

this device into water or any other liquid.

• ELECTRIC SHOCK HAZARD – Do not attempt

to open or remove the enclosure. There are no

user-serviceable internal components. If service is

required, return the product to your home care

provider. Opening or tampering with the product will

void the warranty.

WARNING!

• The DeVilbiss IntelliPAP™ and SleepCube™ should be

used only with masks recommended by DeVilbiss, your

physician or respiratory therapist.

• To avoid rebreathing of exhaled air, do not use a CPAP

mask unless the device is turned on and providing a supply of air. Venting in the mask should never be blocked.

When the device is turned on and providing a fresh

supply of air, exhaled air is fl ushed out of the mask vent.

However, when the device is not operating, exhaled

air may be rebreathed. Rebreathing of exhaled air for

longer than several minutes can in some circumstances

lead to suffocation. This warning applies to most CPAP

devices.

• The DeVilbiss IntelliPAP and SleepCube devices

are not life support devices and may stop operating

with certain device faults or with a power failure. It

is intended to be used on spontaneously breathing

individuals weighing 66 lbs/30 Kg or greater.

• To avoid electric shock, always unplug power cord

from wall outlet power source when performing

cleaning.

• Use only accessories recommended by DeVilbiss.

CAUTION– The circular data port connector located on

the back of the is used to attach accessories to the

device. The connector must only be used with accessories approved for use by DeVilbiss. Do not attempt

to attach any other device to this connector as it may

damage the CPAP or the accessory device.

CAUTION– Never rinse or place the device in water. Never

allow liquids to get into or around any of the ports,

switches or air fi lter; doing so will result in device

damage. If this occurs, discontinue use and remove

the power cord from the power source. Allow the

device to completely dry before use.

CAUTION– Do not place the IntelliPAP or SleepCube device

where it can be bumped onto the fl oor or where the

power cord may create a trip hazard.

CAUTION– Only the DeVilbiss DV5 series Heated Hu-

midifi er system is recommended for use with the

IntelliPAP and SleepCube devices. Other humidifi er

systems may prevent the device from detecting snoring and may cause inappropriate pressure levels in

the mask.

CAUTION– Oxygen is a prescription gas and should only be

administered under the supervision of a physician.

B. INITIAL INSPECTION

DeVilbiss recommends equipment inspection upon delivery

R Power up the DV54 PAP using AC power.

R Test pressure accuracy using an outlet cap (DV51D-

620), a calibrated pressure gauge and the procedures

listed under Pressure Accuracy Test.

R Test the keys on the keypad using the procedures

listed under Keypad Test.

Page 5

5

LT-2 0 27

1.

C. TRAVEL

The DeVilbiss DV54 PAP

• Automatically adjusts for altitudes between sea level

and 9000 ft (2750 m)

• Automatically accepts line voltages of 100-240 V,

50/60 Hz

• Needs power cord appropriate for area

o USA DV51D-606

o Europe, except UK DV51D-607

o UK DV51D-608

o Australia DV51D-609

o Set of 3 (UK, Europe, Australia) DV51D-611

D. DC POWER

The DeVilbiss DV54 PAP

• Automatically accepts 12V DC power

• Operates on DC power only if AC power is not

present

• Operates on AC power if both DC and AC power

are present

• Optional 12V, 60 amp hour, deep cycle marine battery

• Optional DC to AC inverter:

minimum 200 watts @ 100/120 VAC

minimum 400 watts @ 220 VAC

• Needs appropriate DC power cord

o DV51D-619 DC accessory cable for DC plug-in

adapters

o DV51D-696 DC battery clamp-on adaptor for

stand-alone battery

E. SETTING PRESSURES AND FEATURES

Use the following steps to enter Clinical/Setup mode:

1. Apply AC power to the unit

2. Verify that LCD displays OFF

3. Press and hold the Down Arrow key and the Delay

key.

4. While holding two keys, press the ON/OFF key.

5. The blower will begin operating and the LCD will

display ‘Clinical Menu’.

6. Use the Left and Right Arrow keys to scroll through

the options

7. Use the Up and Down Arrow keys to select the

option’s value.

8. Press the ON/OFF key at any time to exit Clinical Mode.

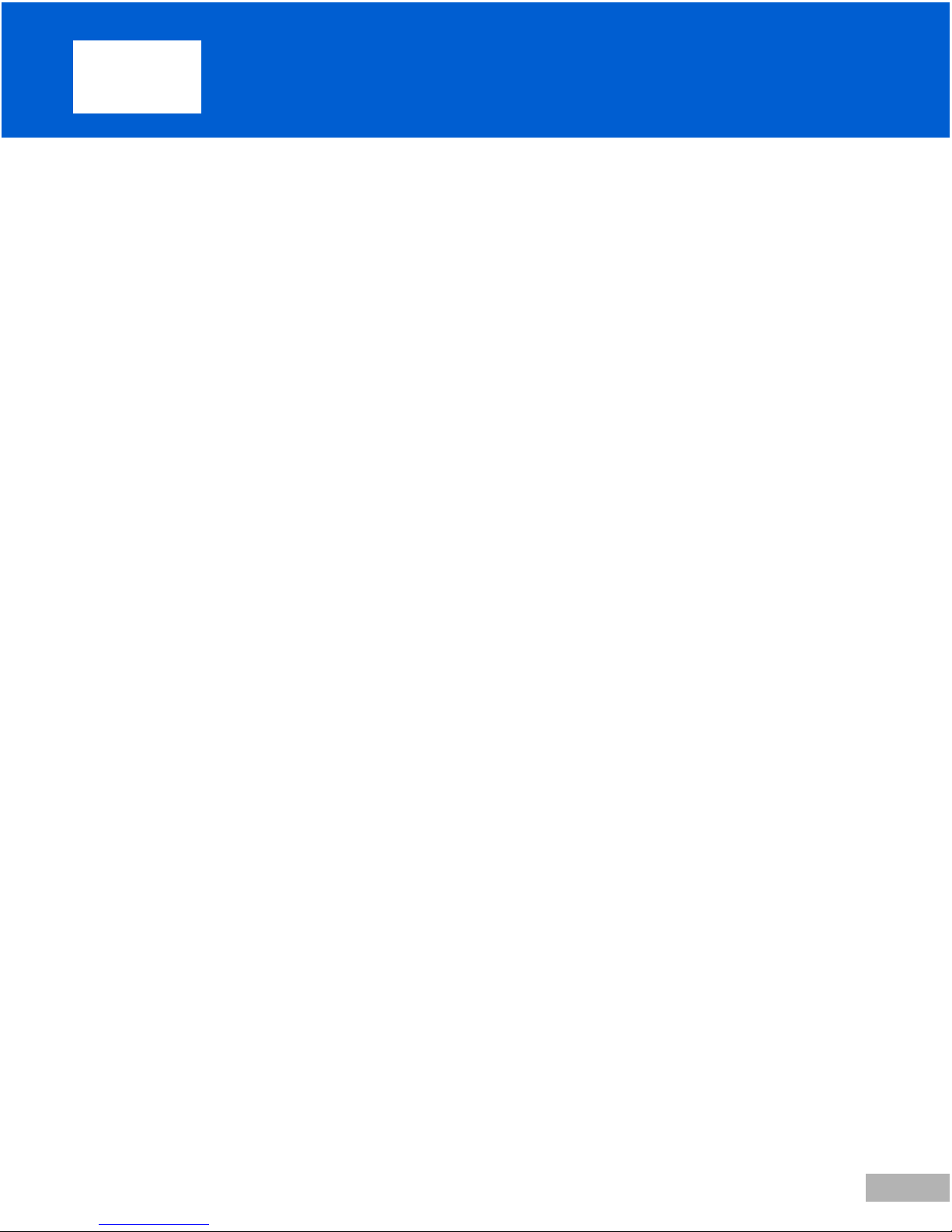

F. IMAGES: DEVILBISS DV54 PAP

Figures A and B:

DV54 Device Back and Bottom Views

1. Air supply port

on back of

device

2. Air supply port

on bottom of

device

(for optional

humidifi er)

3. Air supply port

plug

4. Heater power

connector

(for optional

humidifi er)

5. AC power

connector

6. DC power

connector

7. Data port

8. Air inlet fi lter

opening

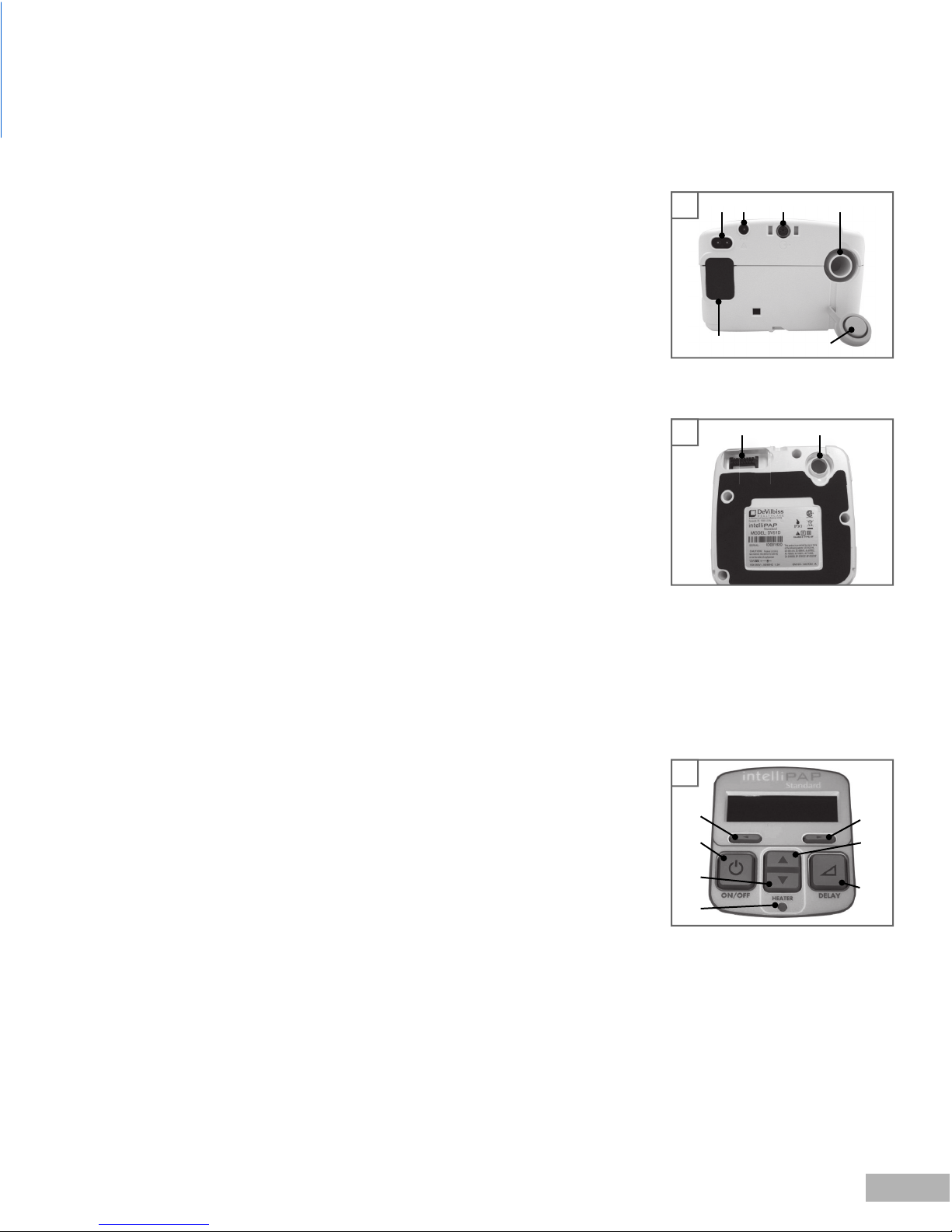

Figure C: Keypad

1. ON/OFF

2. Previous item

3. Next item

4. Delay

5. Decrease value

6. Increase value

7. Heater power

LED

(for optional

humidifi er)

B

2

4

A

1

3

5 6 7

8

C

5

1

2

4

6

3

7

Page 6

6

LT-2 027

EN

An AC line cord (100-240 VAC, 50/60 Hz) or a DC line cord (12 VDC) supplies electrical

power to the DV54 PAP. The PAP converts the AC input voltage to DC voltage by means

of an internal switch mode power supply and uses the DC voltage to power the internal

electronics of the unit, such as microcontroller, motor control circuitry, blower, LCD

display, etc. NOTE: The heated humidifi er will not operate when the PAP uses external

DC power.

The PAP produces positive pressure by spinning a reverse-curved impeller with a brushless DC motor. Room air is drawn through a fi lter into the blower, pressurized in the

blower, optionally passed through a heated humidifi er chamber, and then discharged

through a 22mm-ID, smooth-bore tube. Pressure regulation is achieved using measured

pressure and fl ow as feedback.

The DV54 PAP senses patient breathing by monitoring the fl ow transducer signal which

detects the fl uctuations caused by inhalation and exhalation. The fl ow transducer signal also

triggers mask-OFF alerts and auto-ON / auto-OFF functionality.

In AutoAdjust mode, the DV54 software analyzes the fl ow transducer signal to detect

respiratory events such as apneas, hypopneas, mixed apneas, snoring, and exhale puffing as defi ned by programmable settings. An onboard algorithm evaluates the detected

respiratory events and adjusts the pressure as follows: The DV54 PAP increases output

pressure when it detects apneas, hypopneas, and snoring events; it maintains pressure

when it detects mixed events; and it decreases pressure on a regular timed interval as

the number of recent respiratory events decreases.

2. D escrip tion of N ormal O p eration

Page 7

7

LT-2 027

EN

A. ROUTINE CLEANING--PATIENT

• Unplug the DV54 PAP and wipe enclosure with a clean, damp cloth every few

days to keep dust free. Allow the device to dry completely before returning to

power source.

• Check the air-inlet fi lter every 10 days. Wash the dark outer foam fi lter in a solution of warm water and mild detergent. Rinse with water. Allow the fi lter to dry

completely before returning to the device.

• Check the optional fi ne particle fi lter every 10 days and replace if dirty or damaged.

• Clean the air supply tubing every day. Remove the tubing from the device and

mask and wash the inside of the tubing in a solution of warm water and mild detergent. Rinse with water and allow to air dry before replacing device and mask.

• Clean the mask and headgear according to the manufacturer’s instructions.

B. DISINFECTING

CAUTION– Always work in an ESD (electro static discharge) safe environment when as-

sembling or disassembling electronic components.

NOTE– DeVilbiss does not require disinfection as part of unit maintenance. If disinfection

is desired, the following procedure is recommended.

NOTE– Parts needed to perform the disinfection procedure are NOT covered under the

DV54 PAP warranty as listed in this manual.

NOTE– Follow manufacturer’s instructions for cleaning and disinfection solutions.

NOTE– Disinfection requires the following parts sold in Disinfection Kit, DV51D-682.

• Blower assembly, balanced

• Blower isolator-silicone

• Grommet-silicone

• 1/4 inch blower wrap foam

• 3 1/2 inch silicone tubing

• Air-inlet fi lter

• 5 1/2 inch silicone tubing

• Tubing/Humidifi er air supply support plug

• 1/2 inch blower mount foam-round

• 1/2 inch top blower foam

• 1/8 inch inside bottom cover foam

• 5 inch silicone tubing

• Fine particle fi lter (optional)

3. Cleaning and Disinfecting

Page 8

8

LT-2 0 27

Disinfection Procedure for the

DV Series PAP

1. Make certain that the device is not connected to a power source.

2. Dispose of the mask, headgear, air supply tubing, gray air inlet fi lter and white fi ne

particle fi lter, if applicable.

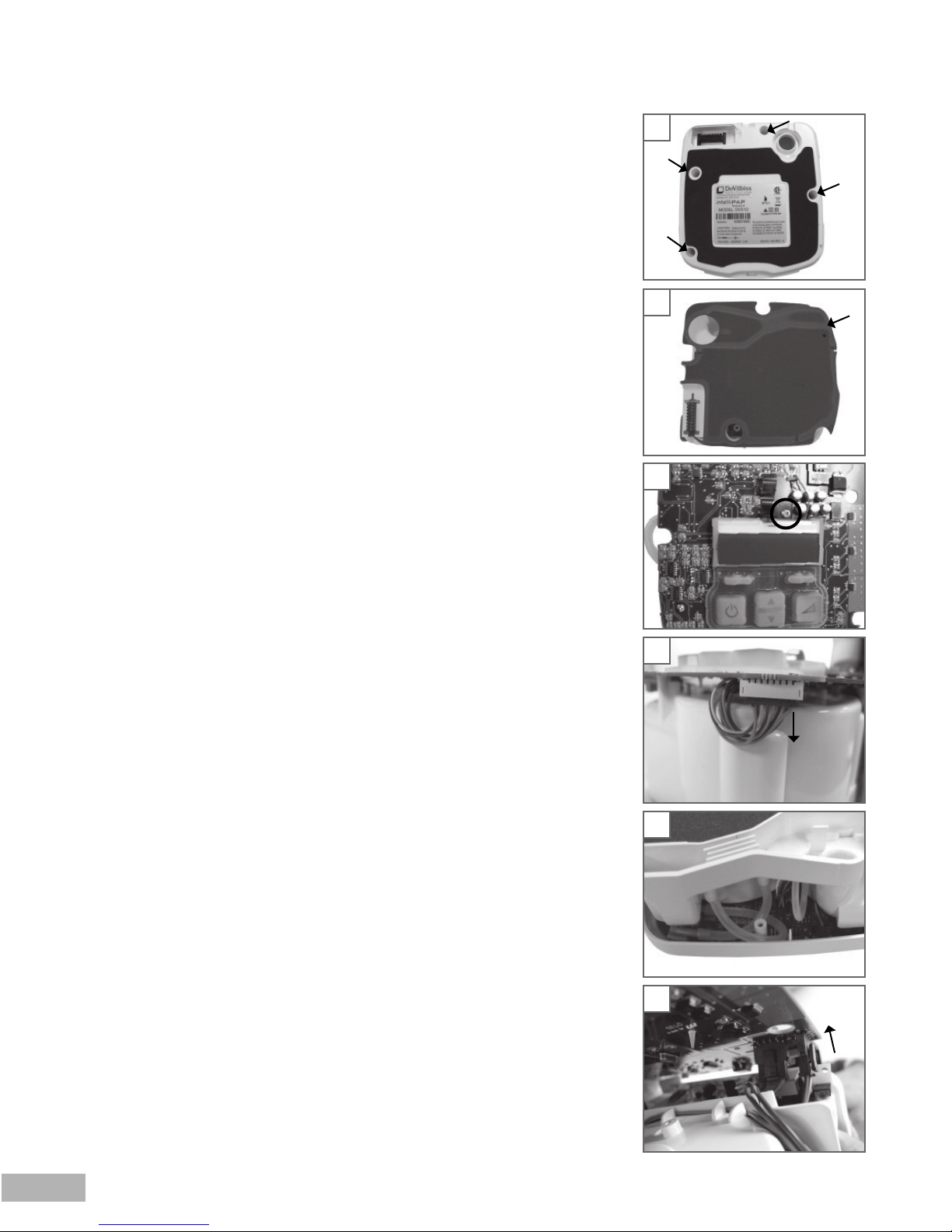

3. Place the unit, top side down, onto a clean work surface. Remove the four (4)

screws from the bottom cover and remove the bottom cover from the unit.

(Fig. 1)

4. Remove the black 1/8 inch inside bottom cover foam from the bottom cover assembly and discard. This foam may stick to the chassis of the main unit. (Fig. 2)

5. Remove the black 1/2 inch top blower foam from the chassis assembly and

discard.

6. Turn the unit top side up and remove the top cover.

7. Using a T-15 driver, remove the screw holding the PC board to the chassis.

(Fig. 3)

8. Disconnect the 8-conductor blower wire harness from the underside of the PC

board. (Fig. 4)

9. Disconnect the three (3) pieces of tubing and discard. (Fig. 5)

NOTE– Pull the tubing straight off the connectors to prevent damaging the chassis.

10. With the ports side of the chassis toward you, tilt the PC board and its respective wire harnesses upward, and remove the wire connections. Lift the PC board

slowly so that you can assist any wires that may become hung up on the chassis or

power supply. (Fig. 6)

3.

2

3

5

1

4

6

Page 9

9

LT-2 0 27

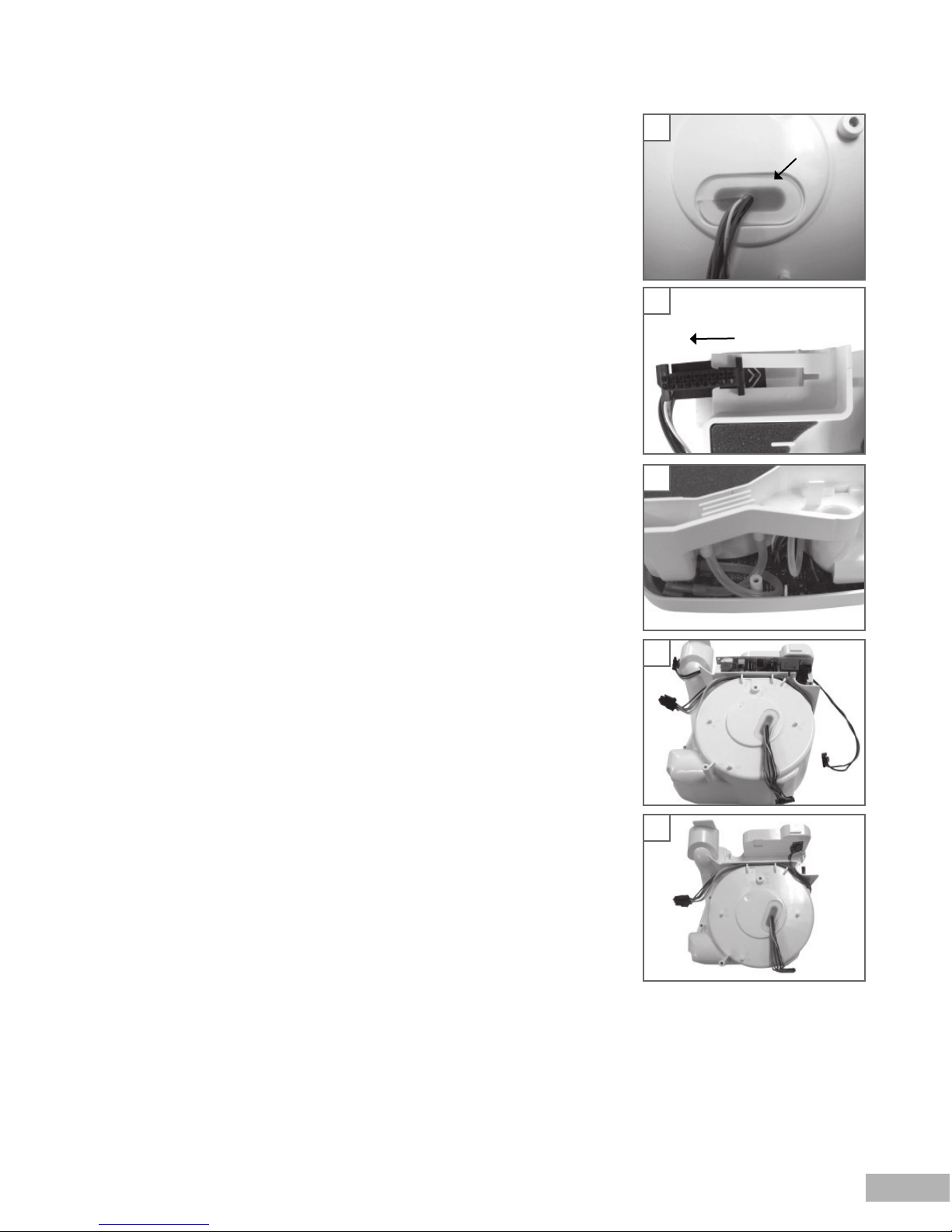

11. Remove the grommet that seals the blower’s wire harness. (Fig. 7)

12. Remove the heater wire harness connector from the bottom of the chassis by

sliding the connector outward while pulling the top retaining tab upward slightly.

(Fig. 8)

13. Remove the 1/4” blower wrap foam, the blower, and the silicone isolator from

the underside of the chassis.

14. Carefully spray, wipe or soak the air intake, fl ow path and blower chassis inside

and outside using a 2% glutaraldehyde solution.

15. Wipe the power cord and the outside of both halves of the PAP case with the

same solution.

16. Let all components fully dry.

17. Reassemble the unit using parts from the Disinfection Kit—DV51D-682.

NOTES:

• Route the silicone tubing correctly, as shown, and ensure that there are no

kinks. (Fig. 9)

• Ensure that the silicone isolator is fully seated in the chassis and the blower.

• Ensure that the grommet is fully seated around the blower wire harness.

• Route the wire harnesses properly, using the provided strain reliefs on the chassis.

(Fig. 11)

• Secure the power supply board within the mount clips on the chassis before

replacing the unit covers. (Fig. 10)

3.

7

8

9

10

11

Page 10

10

LT-2 0 27

EN

4. M ain te n an c e

A. INITIAL INSPECTION—EQ UIPMENT PROVIDER

DeVilbiss recommends equipment inspection upon delivery

R Power up the DV54 PAP using AC power.

R Test pressure accuracy using an outlet cap (DV51D-620), a calibrated pressure

gauge and the procedures listed under Pressure Accuracy Test.

R Test the keys on the keypad using the procedures listed under Keypad Test.

B. ROUTINE MAINTENANCE—PATIENT

R Wipe case with damp cloth every few days

R Check air-inlet fi lter every 10 days and clean as needed

R Clean air supply tubing daily

R Clean mask and headgear per manufacturer’s instructions.

C. REQ UIRED 2-YEAR MAINTENANCE—

EQ UIPMENT PROVIDER

DeVilbiss requires the following maintenance from the equipment provider:

R Test pressure accuracy using procedures listed under Pressure Accuracy Test. If

the device is out of calibration, follow corrective procedures as listed.

R Instruct patient on fi lter maintenance described in Instruction Guide:

Standard Filter Optional Fine Particle Filter

o Inspect fi lter every ten days o Inspect fi lter every ten days

o Clean as needed o Replace if dirty

o Change every 6 months o Change every 30 days

R Optional: Test fl ow accuracy using procedures listed under Flow Accuracy Test.

Page 11

11

LT-2 027

EN

The following test procedures verify correct operation of the

DV54 PAP and should be performed on all repaired units.

NOTE– Verify that the DV54 PAP contains the latest fi rm-

ware release before conducting maintenance or

repairs. Go to http://www.devilbisshealthcare.com/

Products to download the latest fi rmware update.

Download and installation instructions are provided

on the web site.

A. PRESSURE ACCURACY TEST

Additional equipment required: outlet cap (DV51D-620), a

calibrated pressure gauge (0-30 cmH2O, accuracy ±0.25

cmH2O)

1. Connect the pressure gauge to the unit outlet port.

2. Apply AC power to the unit. If the blower is running,

press the ON/OFF key on the keypad so that the

blower stops and the LCD displays ‘OFF’.

3. While pressing both the Down Arrow and Delay

keys, press the ON/OFF key to start the blower and

enter clinical mode.

4. Press the Next Item (right arrow) key to move to the

Operating Mode screen. Use the Up Arrow or Down

Arrow keys to place the unit in CPAP mode.

5. Press the Next Item key until Set Pressure is displayed. Use the Up and Down Arrow keys to adjust

the pressure to 12 cmH2O. Wait at least 30 seconds

for the pressure to stabilize.

6. Verify that the displayed pressure matches the pressure measured on the gauge (pressure setting ±0.5

cmH2O). Accuracy at other pressure settings can be

checked if needed.

7. If the pressure is out of calibration, turn the blower

OFF for approximately 1 minute to allow auto-calibration to occur. Turn the blower back ON and allow 30

seconds for the pressure to stabilize. If the pressure is

still out of calibration, perform a full calibration using

the Manual Calibration Procedure.

8. If manual calibration does not improve pressure accuracy, there may be a problem with the fl ow path or

control board. Refer to Troubleshooting.

5. Testing

B. FLOW ACCURACY TEST

Additional equipment required: PAP to PC cable (DV51D-

615), a calibrated volumetric mass fl ow meter (range 0 to150

L/Min, accuracy ± 3 L/Min), a fl ow control valve #DV51D621 (or equivalent) to adjust fl ow, and a terminal program

(Microsoft Windows HyperTerminal or equivalent).

1. Perform pressure accuracy test fi rst to ensure that

pressure is correct.

2. Connect the volumetric mass fl ow meter and fl ow

control valve to the unit outlet port and close the

valve.

3. Apply AC power to the unit and connect the unit to

the terminal program via the PAP to PC cable.

4. If the blower is running, press the ON/OFF key on

the keypad so that the blower stops and the LCD

displays ‘OFF’.

5. While pressing both the Down Arrow and Delay

keys, press the ON/OFF key to start the blower and

enter clinical mode.

6. Press the Next Item (right arrow) key to move to the

Operating Mode screen. Use the Up Arrow or Down

Arrow keys to place the unit in CPAP mode.

7. Press the Next Item key until Set Pressure is displayed. Use the Up and Down Arrow keys to adjust

the pressure to 12 cmH2O. Wait at least 30 seconds

for the pressure to stabilize.

8. Adjust the fl ow control valve to achieve 60 lpm on

the fl ow meter. Wait at least 30 seconds for the fl ow

to stabilize.

9. Verify that the leak fl ow (terminal command: Fl)

matches the fl ow meter reading (set value ±10 lpm).

Accuracy at other fl ow settings can be checked if

needed.

10. If the fl ow is out of calibration, turn the blower OFF

for approximately 1 minute to allow auto-calibration

to occur. Turn the blower back ON and allow 30 seconds for the pressure and fl ow to stabilize. If the fl ow

is still out of calibration, perform a full calibration using

the Manual Calibration Procedure.

11. If manual calibration does not improve fl ow accuracy,

there may be a problem with the fl ow path or control board. Refer to Troubleshooting.

Page 12

12

LT-2 0 27

C. KEYPAD TEST

No additional equipment required.

1. Apply AC power to the unit. If the blower is running,

press the ON/OFF key on the keypad so that the

blower stops and the LCD displays ‘OFF’.

2. While pressing both the Down Arrow and Delay

keys, press the ON/OFF key to start the blower and

enter clinical mode.

3. Press the Next Item key until Delay Time is shown

on the LCD display.

4. Note the Delay Time; then change it by pressing the

Up and Down arrow keys. Use the arrows keys to

return the Delay Time back to the original setting.

5. Use the Previous Item key to return to the Set Pressure screen.

6. If any of the keypad keys did not function correctly

during this test, replace the PC control board using

Service Instructions.

D. AUTO-ON / AUTO-OFF TEST

Additional equipment required: 6 ft x 22 mm smooth bore

tubing.

1. Apply AC power to the unit. If the blower is running,

press the ON/OFF key on the keypad so that the

blower stops and the LCD displays ‘OFF’.

2. While pressing both the Down Arrow and Delay

keys, press the ON/OFF key to start the blower and

enter clinical mode.

3. Press the Next Item key until Enable Menu is displayed, and then press the Down Arrow key to enter

the sub-menu.

4. Press the Next Item key until the Auto-ON setting

is displayed. Use the Up or Down Arrow keys to set

the value to Enabled.

5. Press the Next Item key until the Auto-OFF setting

is displayed. Use the Up or Down Arrow keys to set

the value to Enabled.

6. Press the ON/OFF key on the keypad so that the

blower stops and OFF is displayed on the LCD.

7. Connect the 6 ft x 22 mm smooth bore tubing to the

CPAP and block the airfl ow with your hand or a plug.

8. Turn the blower ON by pressing the ON/OFF key on

the keypad.

9. Keep the airfl ow blocked for two minutes. Verify that

the blower continues running and no mask alerts appear.

10. Unblock the smooth bore tubing to open the unit’s

airfl ow.

11. Verify that after approximately 10 seconds the LCD

5.

shows ‘Mask OFF’. If the mask alert did not appear,

go to step 14.

12. After another 20 seconds the blower should turn

OFF via the Auto-OFF feature. Wait approximately

two minutes after the blower turns OFF. Verify that

the blower does not turn back ON without breathing

present.

13. Tap the palm of your hand on and off the end of the

smooth bore tubing to simulate breathing and verify that

the blower turns ON via the Auto-ON feature.

14. If any of the Auto-OFF or Auto-ON features do not

work correctly, perform a full calibration using the

Manual Calibration Procedure.

E. BACKLIGHT TEST FOR LCD AND

KEYPAD

No additional equipment required.

1. Apply AC power to the unit. If the blower is running,

press the ON/OFF key on the keypad so that the

blower stops and the LCD displays OFF.

2. Press the ON/OFF key and verify that the LCD and

keypad backlight are lit.

3. Wait one minute and verify that the LCD and keypad

backlights reduce intensity.

4. Press any keypad key, except ON/OFF, and verify

that the LCD and keypad backlights return to full

intensity.

5. If the LCD or keypad backlights did not function

correctly during this test, replace the LCD, keypad

and/or PC control board.

Page 13

13

LT-2 0 27

EN

6. A le r ts an d D ev ic e F au l ts

A. ALERTS VISIBLE TO PATIENTS

Alert Description

Delay running

XX minutes left

Comfort Delay is active

Mask leak = XX%. Check

fit.

High airfl ow for at least 10%

of previous use time (Poor

mask fi t) (actual percentage

is listed)

Mask off. Please check

mask fit.

High airfl ow during use

(Poor mask fi t or mask

removed)

Device Fault E0X. Call

provider.

Device error (See next

table.)

B. DEVICE FAULTS VISIBLE TO PATIENTS

Only device faults classifi ed as critical are visible to the patient

on the LCD display. These faults can be corrected by a service

technician.

Device

Fault

Description

E01

Read Setting Error. Stored prescription

settings are corrupted. Unit is in fail-safe state

(blower off) when this error displays. See

Troubleshooting and Service Instructions to

correct fault, or return unit for repair.

E03

Motor Error. Unit attempts to drive the

motor, but the blower is not spinning (zero

motor speed). See Troubleshooting and Service

Instructions to correct fault, or return unit for

repair.

E04

Locked Rotor Error. Average motor speed is

low, while the motor current is high, for several

seconds. See Troubleshooting and Service

Instructions to correct fault, or return unit for

repair.

E06

Motor Runaway Error. Motor speed is high

and the pressure and total fl ow are low (close

to zero) for a fi xed period of time. See Troubleshooting and Service Instructions to correct

fault, or return unit for repair.

E07

Motor Fault Error. The motor control chip

fault output goes active low for a fi xed period of time. See Troubleshooting and Service

Instructions to correct fault, or return unit for

repair.

C. READING AND CLEARING THE LAST

DEVICE FAULT CODE

NOTE– The last device fault code is stored in EEPROM to

assist in fi eld service of the unit.

Additional equipment: IBM or Compatible PC with a free serial port, PAP to PC cable (DV51D-615), a terminal program

(Microsoft Windows HyperTerminal or equivalent).

1. Connect the DV54 PAP to the PC serial port with

PAP to PC cable.

2. Apply AC power to the unit. If the blower is running,

press the ON/OFF key on the keypad so that the

blower stops and the LCD displays ‘OFF’.

3. Use a terminal program (such as Windows HyperTerminal, or equivalent) with COM settings 9600 baud,

no parity, 8 data bits, 1 stop bit, and Flow Control set

to none.

4. When connection is established with the PAP, the

terminal program will show: ‘RH;’ every 0.5 seconds.

This display indicates that the PAP is waiting for a

handshake.

5. Type ‘rh’ (all commands are case sensitive) and press

Enter. The PAP should respond with the fi rmware

version in the form “V0.XX mm/dd/yyyy.”

Repeat this step if necessary to complete the handshake.

6. Request the last alert code and date by typing ‘El’

and pressing Enter. The return value will be in the

form ‘Exx dd/mm/yyyy’. Exx is the alert code and

dd/mm/yyyy is the date the error occurred.

7. Clear the last alert code by typing ‘Ec’ and pressing

Enter. The PAP will respond with ‘OK’.

Page 14

14

LT-2 0 27

EN

A. MANUAL CALIBRATION

DeVilbiss recommends calibrating the DV54 PAP if replacing the PC

control board or when testing or troubleshooting indicate calibration

is required. The manual calibration procedure accesses a terminal

program via the unit’s communication port to calibrate the internal

pressure sensor, fl ow conditioning circuitry, and the motor current

circuitry. Progress and confi rmation messages display on the terminal

screen throughout the procedure. If a failure occurs during calibration, the error displays as well. See Calibration Errors below.

Additional equipment: IBM or Compatible PC with a free serial

port, PAP to PC cable (DV51D-615), a terminal program (Microsoft Windows HyperTerminal or equivalent) and a calibrated

pressure gauge (0 to 30 cmH2O), a calibrated volumetric fl ow

meter (0 to 150 lpm) and a ball valve or equivalent to adjust the

PAP fl ow.

Please read all steps before beginning this process.

NOTE– Details on the Tc serial commands used in this proce-

dure are listed in Section D.

1. Use the PAP to PC cable to connect the DV54 PAP

to a PC serial port and apply AC power to the PAP.

2. Use a terminal program (such as Windows HyperTerminal, or equivalent) with COM settings 9600 baud,

no parity, 8 data bits, 1 stop bit, Flow Control set to

none.

3. When connection is established with the PAP, the

terminal program will show: ‘RH;’ every 0.5 seconds.

This display indicates that the PAP is waiting for a

handshake.

4. Type ‘rh’ (all DV54 commands are case sensitive)

and press ENTER. The PAP will respond with the

fi rmware version in the form ‘V0.XX dd/mm/

yyyy’. Repeat this step if necessary to complete the

handshake.

5. Start the calibration process by typing ‘Tc=s’ and

pressing ENTER. The PAP will respond with ‘Cali-

bration Started’. If the unit responds with

‘WF’, resend the ‘Tc=s’ command.

6. The PAP will begin sending messages and prompting

for responses to complete the calibration. NOTE: If

a calibration failure is encountered at any stage during the procedure, the PAP will respond with ‘Cal

failed: EXX’, where XX is a two digit error code.

a. PAP sends ‘Waiting for blower to

stop spinning’.

7. C ali br a t io n

b. PAP sends ‘Cal press offset’ when spin-

ning is stopped.

During this stage of the procedure the PAP stops

the blower and saves the pressure sensor and

motor current offsets and adjusts the fl ow balance digital potentiometer. After a short delay,

the PAP increases the pressure to approximately

20 cmH2O.

c. PAP sends ‘Set pressure to 20 cmH2O

using Tw+, Tw-, or Tw=’ ‘Send Tc=y

when ready’

d. Connect the pressure gauge to the PAP outlet

(the outlet should be in a deadhead or zero fl ow

condition) and, using the computer keyboard

(‘Tw+’ followed by ENTER increases the pressure and ‘Tw-’ followed by ENTER decreases

the pressure), adjust the PAP pressure to 20

cmH2O (± 0.1 cmH2O), then type ‘Tc=y’ followed by ENTER.

e. PAP sends ‘Reading and saving pressure hi cal’

after confi rming that the pressure is correct.

During this stage of the procedure, the PAP calibrates the pressure sensor by reading and saving

the high pressure calibration value.

NOTE– As an alternative to steps d and e, the current PAP

pressure gauge reading can be sent to the PAP from

the terminal. Perform the following steps for this option.

Use the ‘Tw+’, ‘Tw-’, or ‘Tw=X’ (where X is a number

between 0 and 1023 to adjust the pressure to a value

between 15 and 30 cmH2O. If the pressure is already

within this range no adjustment is needed. NOTE: A

more accurate calibration will be obtained, if the value

is close to 20 cmH2O.

7. Send the pressure to the PAP in the format

‘Tc=yxxxxx’, where xxxxx is the gauge pressure in

cmH2O multiplied by 1000 (Example: 20 cmH2O is

sent as ‘Tc=y20000’.)

8. Connect a calibrated fl ow meter to the PAP and use

a ball valve (or equivalent) to adjust the volumetric

fl ow to 110 lpm (+/- 1 lpm),.

9. After a short delay, the PAP will respond with ‘Set

flow to 110 lpm’ and ‘type Tc=y when

ready’. Press Enter after receiving those messages.

10. After a short delay the PAP will respond with ‘cal

successful’. Calibration is now complete. Please

check PAP pressure and fl ow for accuracy.

Page 15

15

LT-2 0 27

B. CALIBRATION ERRORS

Code Description

E95

Calibrate Motor Stop Error. The blower did not

stop during device calibration. This error only occurs during the calibration procedure.

E96

Calibrate Flow Balance Error. The fl ow balance

digital potentiometer did not adjust during device

calibration. This error only occurs during the calibration procedure.

E97

Calibrate Flow Gain Error. The flow gain digital potentiometer did not adjust during device calibration. This

error only occurs during the calibration procedure.

C. AUTO-CALIBRATION

The DV54 PAP automatically adjusts calibration to maintain

accuracy over time and under varying operating conditions.

Each time the blower is turned OFF, the PC control board

reads and saves the offset voltages from the pressure transducer and the fl ow transducer. The PAP uses these voltages to

maintain calibration accuracy as the unit is used over time.

D. DETAILS ON TC SERIAL COMMAND

Tc serial commands are used in the manual calibration procedure listed in Section A. The ‘Tc’ command on the terminal

program reads the unit’s current calibration values, starts the

calibration procedure, and handles user feedback during the

calibration process. Refer to the manual calibration procedure

for details on the calibration process.

• Sending ‘Tc=s’ to the PAP starts the calibration pro-

cess.

• Sending ‘Tc’ without a modifi er requests the current

calibration values. A comma-separated list of all cal

values is returned.

Comma-separated response to ‘Tc’ with no modifi er:

llll,hhhh,mmmm< cr>

o llll is the pressure low cal (sensor offset). Convert

to voltage by dividing by 1024 and multiplying by 5.

o hhhh is the pressure high cal (sensor output at 20

cmH2O). Convert to VDC by dividing by 1024

and multiplying by 5.

o mmmm is the motor current calibration

(adc offset)

• Feedback is provided to the calibration task by sending

‘Tc=y’ when prompted.

7.

Page 16

16

LT-2 027

EN

Symptom Action (for symptoms listed at left, follow the steps listed below)

Blower does

not start when

powered up

1. Remove the cover. See Service Instructions.

2. Search for disconnected wire harnesses and reconnect, if

needed.

3. Determine if fuses are open.

Measures voltages on both sides of the F1 fuse. If 12 +/-.5 VDC

is not present on both sides of the fuse, the fuse is open and the

power supply board should be replaced. See Service Instructions.

Measure resistances, without AC power to unit, on the F2 and

F3 fuses with an ohmmeter. If either fuse is open, replace the PC

control board. See Service Instructions.

4. If all fuses are closed, install a blower known to operate properly,

see Service Instructions, and power up the unit.

If the new blower operates properly, replace the old blower.

If the new blower does not operate properly, replace the control

board. See Service Instructions.

5. Replace the cover. See Service Instructions.

E03, E04, or

E07 errors

display

OR display

is blank

E01 error code

displays

Replace the control board

Blower is loud 1. Remove the cover and control board. See Service Instructions.

2. Inspect the assembly of the foam, blower, and silicone isolator.

See Blower Replacement instructions for correct placement.

3. Inspect the blower for visible space between the blower halves

and press halves back together, if needed.

4. If the assembly is not correct, reassemble the components.

5. If assembly is correct, replace the blower. See Service Instructions.

6. Replace the control board and cover. See Service Instructions.

Blower does

not start when

powered up

and E06 error

displays

1. Remove the cover. See Service Instructions.

2. Search for disconnected, occluded, or kinked tubing on the pressure sensor, fl ow sensor, and chassis. Correct any issues.

3. Search for damage to the chassis, any foam pieces, and/or tubing

and replace the component, if damaged.

4. Remove the control board. See Service Instructions.

5. Search for signs of water damage to the blower assembly, pressure sensor, and/or fl ow sensor and replace, if damaged.

6. Inspect the blower. If a space is visible between the top and bottom sections, re-connect the halves to eliminate the space.

7. Re-calibrate the pressure and fl ow sensors.

8. If the above steps did not eliminate the error, replace the control

board. See Service Instructions.

9. Replace cover. See Service Instructions.

8. Troublesh ooting

Page 17

17

LT-2 0 27

Symptom Action (for symptoms listed at left, follow the steps listed below)

Pressure or

fl ow out of

tolerance

(Pressure ±

0.5 cmH2O of

setting)

(Flow ± 10

L/Min)

1. Remove the cover. See Service Instructions.

2. Search for disconnected, occluded, or kinked tubing on the pressure sensor or chassis. Correct any issues.

3. Search for damage to any foam pieces and/or tubing and replace

the component, if damaged.

4. Remove the control board. See Service Instructions.

5. Search for signs of water damage to the blower assembly, pressure sensor, and fl ow sensor and replace the component, if damaged.

6. Inspect the blower. If a space is visible between the top and bottom sections, press the halves together to eliminate the space.

7. Repeat the pressure and fl ow accuracy tests.

8. If the pressure or fl ow remains out of tolerance, re-calibrate the

unit. See Service Instructions.

9. If the pressure remains out of tolerance, replace the control

board. See Service Instructions.

10. Replace cover. See Service Instructions.

Calibration

failure–

Error codes

E95, E96, E97,

E98

Display on terminal program

during

calibration.

1. Remove the cover. See Service Instructions.

2. Search for damage, and/or loose connections, on the air intake

fi lter, intake foam components, and all internal tubing and replace

or reconnect components, if needed. Search for disconnected,

occluded, or kinked tubing on the pressure sensor, fl ow sensor,

or chassis and reconnect or replace tubing, if needed.

3. Remove the control board. See Service Instructions.

4. Search for signs of water damage to the blower assembly, pressure sensor, and fl ow sensor and replace, if damaged.

5. Inspect the blower. If a space is visible between the top and bottom sections, press the halves to eliminate the space.

6. Repeat Manual Calibration Procedure.

7. If the error codes are not resolved, replace the control board.

See Service Instructions.

8. Replace the cover. See Service Instructions.

8.

Page 18

18

LT-2 0 27

EN

NOTE– After performing any service on the DV54 PAP, please test the unit to ensure

proper operation and calibrate, if necessary.

A. COVER REMOVAL

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. If using a DV5HH, remove the heated humidifi er and unplug the tubing/humidifi er air supply port plug from the back of the cover and re-plug it in the outlet

on the bottom cover.

2. Position the PAP on a clean, fl at surface with the keypad facing down.

3. Remove four T-20 screws from the bottom cover.

4. Lift the bottom cover straight up off the top cover.

NOTE– Attempting to reorient the PAP in order to lift the top cover, instead of the bot-

tom cover, may damage this device.

5. Wearing an anti-static device, carefully lift the chassis off the top cover.

B. COVER REPLACEMENT

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. Wearing an anti-static device, search for and connect all loose wire harnesses.

2. Place the chassis into the top cover, with the keyboard facing the cover and fi tting the control board around the screw posts in the cover.

3. Connect all tubing, carefully creating the correct loops and eliminating any kinking. (Fig. 1)

4. With the 1/8 inch inside bottom cover foam oriented correctly and lying fl at,

place the bottom cover over the chassis and onto the top cover, fi tting the

screw posts into proper alignment with the chassis and moving any protruding

wire harnesses and tubing away from the edges of the cover.

5. Replace four T-20 screws.

C. CONTROL PC BOARD REMOVAL

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. Remove the cover. See instructions above.

2. Wearing an anti-static device, lift the cover off the chassis and place it, with the control board facing up and the blower facing down, onto a clean fl at surface.

3. Disconnect the three pieces of tubing from the outlet port side of the chassis.

4. Disconnect accessible wire harnesses: one behind and one to the left of the tubing in step 3, one at the right corner under the keypad, and one on the outside

of the power supply board.

5. Remove one T-15 screw, located near the middle of the board beside LCD

screen. Lift the board off the chassis slowly and disconnect any remaining wire

harnesses from the control board.

6. Place control board keypad facing down onto a clean, fl at, static-free surface, if

returning to the unit.

9. S er v i c e I ns t ru c t i o n s

1

Page 19

19

LT-2 0 27

D. CONTROL PC BOARD REPLACEMENT

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove the cover and the control PC board.

2. Wearing an anti-static device, verify that the silicone rattails holding the keyboard onto the control board are pulled through the appropriate holes in the

board. See Key Pad & LCD Display instructions.

3. Place the chassis on a clean fl at surface with the blower facing down. Orient the

replacement board so that the keypad is over the rounded end of the chassis.

4. Tilt the board and connect the two wire harnesses near the power supply board

and insert the brown and blue wires into the notch on the chassis. Tilt the board

and connect the two wire harnesses near the outlet port. Connect the wire harness near the right corner of the keypad. (Fig. 2)

5. Position the board (Fig. 3) so that: the hole on the board (A), located below the

ON/OFF key, is over the peg on the chassis; the small hole (B), located near

the LCD screen, is over the screw hole on the chassis; and the cut-out (C) on

the left rear corner fi ts around the protrusion above the air outlet port on the

chassis. Move any stray tubing from between the board and the chassis, verify

that all wire harnesses are properly routed, and replace the T-15 screw on the

board.

6. Replace the cover. See instructions above.

7. Connect the CPAP to a PC serial port with cable DV51D-615 and turn the

CPAP on.

8. Use a terminal program (such as Windows HyperTerminal, or equivalent) with

COM settings 9600 baud, no parity, 8 data bits, 1 stop bit, Flow Control set to

none.

9. When connection is established with the CPAP, the terminal program will show:

“RH;” every 1/2 seconds. This display indicates that the CPAP is waiting for a

handshake.

10. Type ‘rh’ and press ENTER. The CPAP should respond with the fi rmware version in the form “V0.XX dd/mm/yyyy.” Please note that all commands are

case sensitive. Repeat this step if necessary to complete the handshake.

11. Type ‘Mn<cr>’. The CPAP will report the model number saved in memory, it

should be “000000” if the PC board is new.

12. Read the model number from the CPAP label on the bottom of the unit (EX:

DV54SE).

13. Type ‘Mn=nnnnnn<cr>’ where nnnnnn is the 6 digit model number read in

the previous step (use a space for the last digit if necessary to make the string 6

digits). The CPAP should return the new six-digit model number.

14. Type ‘Sn<cr>’. The CPAP will report the serial number saved in memory, it

should be “00000000” if the PC board is new.

15. Read the serial number from the CPAP label on the bottom of the unit.

16. Type ‘Sn=nnnnnnnn<cr>’ where nnnnnnnn is the 8 digit serial number read in

the previous step. The CPAP should return the new eight-digit serial number.

17. Read the Hour Meter (“Uh<cr>”)– a new PC board should have 00000

hours. It is recommended that the original hour meter value be restored if the

original blower is used. Set the hour meter by sending ‘Uh=nnnn<cr>’ where

nnnn is the hour meter reading x 10 (Ex: 100.5 hours would be set by typing

‘Uh=1005<cr>’).

9.

2

3

A

B

C

Page 20

20

LT-2 0 27

18. Read the Compliance Meter (“Up<cr>”)– a new PC board should have 00000

hours. Clear the Compliance meter if it is not zero by typing ‘Up=c<cr>’. The

CPAP will return 000000.0 hours.

19. Check the fi rmware and hardware version information. Read and record the

following:

• BIOS rev “VB<cr>”

• Firmware rev “VF<cr>”

Check the present version of fi rmware to make sure the board is up to date.

Install new fi rmware if the board has an old version.

20. Check for last saved error, type ‘El<cr>’. The CPAP will respond with “Exx

dd/mm/yyyy” where xx is the last saved error code and dd/mm/yyyy is the

date that the error was detected. Clear the last error by typing ‘Ec<cr>’, the

CPAP will return “OK.” Verify that the error code is “00” by typing ‘El<cr>’.

21. Set all device settings to their default values by typing ‘TD<cr>’.

The CPAP should return “OK.”

22. Recalibrate the unit.

E. POWER SUPPLY BOARD REMOVAL

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove the cover and the control PC board.

2. Wearing an anti-static device and with the power supply board facing you, apply

thumb pressure to top left corner of the board while pulling the top right corner

up and out of the mount clip at its bottom.

3. Pulling the top left corner out of its mount clip, lift the board off the chassis.

4. If returning the power supply board to the unit, place the board onto a clean,

fl at, static-free surface with its large components facing up OR if discarding the

power supply board, remove the two wire harnesses for use with the replacement board or purchase a new wire harness kit.

F. POWER SUPPLY BOARD REPLACEMENT

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove the cover, the control PC board and the

power supply board.

2. Wearing an anti-static device, connect the wire harnesses from the old power

supply board to the new power supply board.

3. Position the chassis so that the blower faces down and the inlet and outlet ports

face you. Position the power supply board so that the components are facing

away from you with the large brown component in the bottom left corner and

the small blue component in the top right corner.

4. Place the board into the mount clips at the bottom of the power supply board cavity

and press down fi rmly on the top corners until the board is fully mounted.

5. See instructions above to replace the control PC board and the cover.

9.

Page 21

21

LT-2 0 27

G. BLOWER REMOVAL

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove the cover and control PC board

2. Carefully remove the silicone grommet holding the blower wire harness. (Fig. 4)

3. Holding the wire harness in your hand, turn the chassis over so that the blower

is facing up.

4. Remove the foam covering the blower and the foam around the blower.

5. Reach into the blower cavity and push the silicone isolator off the blower outlet. (Fig.

5)

6. Slowly lift blower out of the chassis and carefully pull the wire harness through the

hole in the chassis. If not returning blower to unit, remove foam from bottom of

blower and save for new blower. (Fig. 6)

H. BLOWER REPLACEMENT

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove the cover, control PC board and blower.

2. Insert the blower mount foam on the blower base so that the holes in the foam align

with the protrusions on the blower and the blower wire harness is through the center

hole in the foam. (Fig. 6)

3. Turn the blower over so that the motor is facing down. Guide the wire harness

through the hole in the bottom of the blower cavity portion of the chassis.

4. Lower the blower with its outlet port pointing at the silicone isolator. Position

the blower’s outlet port into the top edge of the silicone isolator then tilt the

outlet port into the isolator opening without folding the isolator. Push the outlet

port into the isolator until the port is evenly inserted into the isolator. See isolator image in Blower Removal instructions above.

5. Insert the blower wrap foam so that the single-notched end is beside the blower

outlet port. Wrap the remaining foam strip clockwise around the blower so

that the notched foam corresponds to the latches on the blower body. Wrap the

double-notched end around the blower and over the outlet port. The top edge

of the foam should be almost fl ush with the blower. (Fig. 7)

6. Insert the top blower foam so that it conforms to the edges of the blower cavity

portion of the chassis.

7. Turn the chassis over so that the blower is facing down. Gently pull any slack from the

wire harness. Insert the silicone grommet into the hole in the chassis so that the slit

in the grommet is toward the power supply board location, all the wires are in the

center hole of the grommet and the grommet fl ange is fully sealed. Route the wire

harness along the top of the chassis and down the front of the blower cavity portion of

the chassis. (Fig. 8)

8. See instructions above to replace the control PC board and the cover.

9.

4

5

6

7

8

Slit direction

harness direction

Page 22

22

LT-2 0 27

I. KEYPAD & LCD DISPLAY REMOVAL AND REPLACEMENT

CAUTION– Failure to wear anti-static equipment during service may damage

this device.

1. See instructions above to remove cover and control PC board.

2. Wearing an anti-static device, disconnect the two LCD display wire harnesses.

(Fig. 9)

NOTE– Do not touch the exposed contact area on the end of the ribbon cable. Dirt and

oils may damage it.

3. Gently roll the silicone frame away from the edges of the LCD display screen (Fig.

10), lift the display off the key pad and place it on a clean, fl at, anti-static surface, if

returning to the unit.

4. Lift the key pad off the board, gently pulling three silicone rattails through the

board.

NOTE– Do not touch the key pad contacts on the PC board. Dirt and oils may damage

them.

5. Replace the key pad by inserting the silicone rattails on the replacement key pad

through appropriate holes on the control board and gently pulling the rattails

through the holes.

6. Insert the LCD display into the silicone frame on the key pad and connect the

wire harnesses to the appropriate connectors on the board.

7. See instructions above to replace the control PC board and the cover.

J. FIRMWARE INSTALLATION

Go to http://www.devilbisshealthcare.com/Products to download the latest fi rmware update. Download and installation instructions are provided on the web site, if needed.

9.

10

9

Page 23

23

LT-2 027

EN

Unit Specifi cations

Size 4.2” H x 6.5” W x 6.9” D (10.7 cm x 16.5 cm x 17.5 cm)

Weight 2.7 lbs. (1.22 kg)

Electrical Requirements 100-240V~, 50/60 Hz

DC Operation 12 Volt, 5 Amps

Maximum Power Consumption 65 watts max from AC power source (PAP device only)

AutoAdjust CPAP Pressure Range 3-20 cmH2O

Operating Temperature Range 41°F to 104°F (5°C to 40°C)

Operating Humidity Range 0% to 95% RH non-condensing

Operating Atmospheric Conditions Sea level to 9,000 feet

Storage & Transportation Temperature Range -40°F to 158°F (-40°C to +70°C)

Storage & Transportation Humidity Range 0% to 95% RH non-condensing

Maximum Limited Pressure 20 cmH2O under normal use

Sound Level (tested per ISO 17510) 26 dBA

Filter Specifi cations

Standard Filter > 3.0 micron particles

Optional Fine Particle Filter > 0.3 micron particles

Max Flow Rates

83 L/m @ 6.5 cmH2O (1/3 max pressure)

134 L/m @ 13 cmH2O (2/3 max pressure)

163 L/m @ 20 cmH2O (max pressure)

Pressure Accuracy ± 1.0 cmH2O

Pressure Swings

(cmH2O peak to peak at 500mL tidal volume, sine wave profi le)

Breaths per

minute

10 15 20

@ 6.5 cmH2O 0.5 0.5 0.5

@ 13 cmH2O 1.0 1.0 1.0

@ 20 cmH2O 1.0 1.0 1.0

Other Specifi cations

Equipment classifi cation with respect to protection from electric

shock

Class II

Degree of protection from electric shock Type BF Applied Part

Degree of protection against ingress of liquids IPX1

Equipment not suitable for use in the presence of a fl ammable anesthetic mixture

with air or with oxygen or nitrous oxide.

Mode of operation Continuous

Clinical Specifi cations for Digital Outputs

Mask pressure 0 to 25.5 cmH2O ± 1.0

Patient Flow -127 to +127 L/min ± 10L/min

Leak Flow

0 to +127 L/min ± 10 L/min

Estimated Tidal Volume 0 to 1023 mL

Note– Tidal Volume is an estimate. It is provided for trending purposes only.

10. U nit Specific ations

Page 24

24

LT-2 0 27

EN

11 . Gen era l I nf orm at ion DV 5H H

A. SAFEGUARDS

When servicing electrical products, basic safety precautions

should always be followed. Important safety information in this

manual is highlighted by the following terms.

DANGER: Urgent safety information for hazards that

will cause serious injury or death.

WARNING: Important safety information for hazards

that might cause serious injury.

CAUTION: Information for preventing damage to the

product.

NOTE: Information to which you should pay

special attention.

PLEASE READ ALL INSTRUCTIONS BEFORE

SERVICING THIS DEVICE.

DANGER!

• Electric Shock Hazard – Do not use while bathing.

• Electric Shock Hazard – Do not immerse this

device into water or any other liquid.

• Electric Shock Hazard – Do not attempt to open or

remove the enclosure. There are no user-serviceable

internal components. If service is required, return

the product to your home care provider. Opening or

tampering with the product will void the warranty.

WARNING!

• Use the Heated Humidifi er system only for its

intended use as described in this manual.

• Be sure to read and understand all safety instructions supplied with your IntelliPAP or SleepCube fl ow

generator device.

• Use only accessories recommended by DeVilbiss.

• Always remove the water chamber from the humidifi er cradle for fi lling.

• Use only tubing recommended or supplied with the

fl ow generator.

• If water has been spilled onto the cradle or it has

been submerged into water, unplug the power cord

from the power source immediately. Allow the device to completely dry before use.

• If the device has been dropped, refer to the troubleshooting guide for instructions. Contact your homecare provider for evaluation of the device.

• Never block the air openings of the cradle or chamber.

Do not insert any objects into any openings or tubes.

• For proper operation of the humidifi er, the device

must be placed on a fl at, level surface.

• Never place the system on a soft surface such as a

bed or couch during operation.

• This heated humidifi er is intended for single-patient

use only.

B. TRAVEL

The DeVilbiss DV5HH humidifi er system

• Automatically accepts line voltages of 100-240 V, 50/60 Hz

• Needs power cord appropriate for area

o USA DV51D-606

o Europe, except UK DV51D-607

o UK DV51D-608

o Australia DV51D-609

o Set of 3 (UK, Europe, Australia) DV51D-611

C. DC POWER

The DeVilbiss DV5HH humidifi er system

• Will NOT operate, if the DC power is coming

directly from a 12V DC power source.

• Will operate, if the DC power coming to the PAP

passes through an inverter so that AC power is

delivered to the system.

• See DC Power information under the DV54 section

of this manual

D. PRODUCT DESCRIPTION

The DV5HH Standard Heated Humidifi er System is intended to

warm and add moisture to the pressurized air supplied to the patient during the treatment of Obstructive Sleep Apnea (OSA). The

addition of heated humidifi cation to the air relieves dryness and

irritation to the patient’s airway during OSA therapy. The heated

humidifi er is used in conjunction with the DV5X series PAP devices

and consists of a humidifi er chamber and humidifi er heater.

The humidifi er chamber holds enough water for a minimum

of 8 hours of operation, with the heating unit at the maximum

temperature setting at ambient conditions of 23°C and 25%

R.H. with a system fl ow rate of 60 L/Min. The chamber slides

out of the unit for cleaning and fi lling, without adjusting tubing

connections. The chamber’s halves separate for easy cleaning

but, when assembled, maintain a leak free seal to a maximum

operating pressure of 30 cmH2O.

Heat transferred from the humidifi er heater to the humidifi er

chamber raises the effi ciency of the DV5HH system. The patient controls the heater plate temperature using the up/down

arrow keypad keys on the attached PAP device to provide the

appropriate level of humidifi cation depending upon environmental conditions and individual preference.

Page 25

25

LT-2 027

EN

The heated humidifi er connects mechanically and electrically to a DV5X series PAP between the air stream going from the PAP to the patient. The keypad on the PAP controls

the heated humidifi er’s output and ON/OFF functions. Before operation, the humidifi er

chamber is fi lled with water to a predefi ned and visible water-fi ll level with the patient

tubing and patient interface attached to the outlet port on the heated humidifi er system.

During operation, the DV5X series PAP device routes AC electrical power (100 – 240

VAC 50/60 Hz) to the heated humidifi er’s drive circuitry, which is contained within the

PAP device. The drive circuitry directs the AC power to the heating element on the

heated humidifi er’s heater plate. A thermistor on the heater plate provides continuous

feedback back to the control circuitry so that the temperature of the heater plate is consistent with the setting selected via the PAP’s keyboard. The PAP’s internal switch-mode

power supply routes DC electrical power to the heater’s low-voltage circuitry.

The heated humidifi er’s heater plate transmits heat to the chamber, and then to the

water, through a heat transfer plate located on the bottom of the humidifi er chamber. As

the water is heated, its evaporation effi ciency increases. Air fl owing into the humidifi er

chamber from the PAP device is humidifi ed by the evaporation and is then transmitted to

the patient through the patient tubing and interface.

12. Descript ion of Normal Operat ion DV5HH

Page 26

26

LT-2 027

EN

A. CLEANING AND DISINFECTION

See the DV5HH Instruction Guide (A-DV5HH) for information on cleaning the humidifi er

chamber and heater base.

The DV5HH Standard Heated Humidifi er is single patient use only and therefore does

not require disinfection.

B. MAINTENANCE

The DV5HH Standard Heated Humidifi er System does not require regular maintenance.

C. TESTING

Since the DV5HH device is powered and controlled by the PAP, it is important to determine

which unit is at fault when there is an issue with humidity/heat. Use the following procedures

to determine whether the DV5HH device or the PAP device is faulty.

1. Connect the DV5HH device to a known good PAP device.

2. After turning the system on,

• if the LCD display does NOT show “Heat:XXX” on bottom line, proceed

to the troubleshooting section.

• if the DV5HH device does NOT produce heat, proceed to the troubleshooting section.

3. Connect the PAP to a known good DV5HH device and turn the PAP blower

ON, if the LCD display does NOT show ‘Heat:xxx’ on the bottom line, proceed to the troubleshooting section.

If you detect excessive air or water leaks in the DV5HH system, proceed to the troubleshooting section.

13. Maintenance and Testing DV5HH

Page 27

27

LT-2 027

EN

HEATER

Symptom Action

The PAP does not recognize the

heater. (With the PAP blower ON,

the PAP display does not indicate

Heat:xxx on the bottom line.)

Connect the heater to a known good PAP device, if one is available. If PAP display still does

not recognize the heater, replace the heater.

If a known good PAP device is not available, remove the PAP from the heater and check the

thermistor for resistance. The thermistor pins are located in the connector and are the ones

closest to each other. See image below. The resistance should be 10 K ohms +/- 1% at 25° C

(77°F). If open or shorted, replace the heater. See Service instructions. Alternatively: Replace

the heater plate assembly, DV5H-607. If the resistance is in the correct range, the issue is in

the PAP device. Troubleshoot as indicated below.

Heater plate does not respond to

the PAP heat setting.

(With the PAP blower ON and

the heat setting at 1 or above, the

heater plate does not get warm.)

Connect the heater to a known good PAP device, if one is available. If the heater still does not

respond to the heat setting, replace the heater.

If a known good PAP device is not available, connect the PAP, using the serial interface cable

DV51D-615, to a PC using a terminal program (such as Windows HyperTerminal, or equivalent)

with Com settings 9600 baud, no parity, 8 data stop bits, 1 stop bit, Flow Control set to none.

Turn the PAP blower ON and increase the heat setting to 10 using the PAP keypad (UP key). In

the terminal program, connect to the PAP device by typing ‘rh’ followed by ENTER; then type

‘Ht’ followed by ENTER. Repeat the ‘Ht’ – ENTER sequence every 2-3 minutes and verify that

the returned value increases. If the value increases, the system is operating normally. If the value

does not increase, remove the PAP device from heater and measure the heater resistance. The

heater terminals are the ones diagonal to each other on the connector.

heater terminals

t

hermistor terminals

The resistance should be between 180 to 220 ohms; if not replace the heater. See Service instructions. Alternatively: Replace the heater plate assembly, DV5H-607. If the resistance is in the

correct range, the issue is in the PAP device. Troubleshoot as indicated below.

PAP

Symptom Action

The PAP does not recognize a

known good DV5HH heater.

(With the PAP blower ON, the

PAP display does not indicate

Heat:xxx on the bottom line.)

Check the wire harness on the PAP / heater connector; repair or replace, if needed. If the wire

harness and connections are correct, replace the control PC board. See Service Instructions.

Heater plate on a known good

DV5HH heater does not respond

to the PAP heat setting.

(With the PAP blower ON and

the heat setting at 1 or above, the

heater plate does not get warm.)

Check the wire harness on the PAP / heater connector; repair or replace, if needed. If the wire

harness and connections are correct, replace the control PC board. See Service Instructions.

MANIFOLD and O-RING

Symptom Action

Excessive air leak Remove the humidifi er chamber. Inspect the manifold in the heater base and replace, if torn or

worn. Inspect the O-Ring in the humidifi er chamber and replace, if worn or missing.

Water leak from the humidifi er

chamber.

Remove the humidifi er chamber. Inspect the chamber for cracks in the plastic or water leaking from the heat transfer plate. If cracks or transfer plate leaks are found, replace the water

chamber. Inspect the O-Ring in the humidifi er chamber and replace, if worn or missing.

14. Troubleshoot ing DV5HH

Page 28

28

LT-2 0 27

EN

A. REMOVING THE DV5HH BASE COVER

1. Remove the humidifi er chamber from the DV5HH base.

2. Push the release button (Fig. 1) on the DV5HH base and lift the PAP device off

the heater base and set aside in a safe place.

3. Remove two T-10 screws from the top cover of the heater base.

4. Turn the base over so that the bottom of the unit faces up and remove four T-10

screws.

5. Lift the bottom cover off the unit

6. Remove the fi nal T-10 screw beside the wire harness clip. (Fig. 2)

7. Hold the heater plate onto the base and turn the unit over.

8. Gently pull the top of the unit off the chassis and carefully tilt the top without pull-

ing the wire harness out of the connector.

9. Carefully release the wire harness from the harness clip. Reposition the heater

plate so that the orange side is facing the harness clip and carefully push the

heater plate through the opening. (Fig. 3)

B. REPLACING THE DV5HH BASE COVER

1. Position the heater plate so that the orange side is facing the harness clip and

carefully push the heater plate through the opening in the base. See image

above.

2. Hold the heater plate onto the base and carefully insert the harness wires, two

at a time, into the harness clip. See image above.

3. Install the top of the base onto the heater chassis with the wire harness and

manifold clear of all edges and the latch working smooth and free. Fasten top to

chassis with two T-10 screws.

4. Holding the heater plate onto the base, turn the unit over and position heater

plate into the shallow opening with the metal side facing down and the orange

plastic side facing up. Move the harness wires between wire guides. (Fig. 4)

5. Replace the T-10 screw beside the wire harness clip.

6. Verify that the silicone spacer is in place on the inside of the bottom cover. (Fig.

5)

7. Install the cover onto the bottom of the unit matching the edges. Replace the 4

remaining T-10 screws in the bottom cover.

8. With the air supply support plug attached to the back of the PAP device, place

the front of the PAP onto the front of the heater base against the brackets and

push the back of the PAP down so that the latch closes and the electrical connector is tight.

9. Slide the humidifi er chamber into the heater base until it clicks into place.

15 . Ser v i ce I n st r uc t i o ns DV5 HH

1

2

harness

clip

T-10

screw

3

4

5

Page 29

29

LT-2 0 27

C. REMOVING AND REPLACING SILICONE MANIFOLD

1. Remove the cover as described above.

2. Squeeze the inlet port on the silicone manifold and push the port down into the

hole in the top cover, gently releasing the manifold from all other connections.

Discard the manifold or set aside in a safe place, if returning to the unit. (Fig. 6)

3. To replace, pinch the inlet port coupler on the replacement silicone manifold and

insert it, from the inside of the cover, through the cover hole so that the coupler

collar is fully and evenly positioned on the outside of the cover.

4. Press the manifold body into place and insert a fi nger into each of the rectangu-

lar openings, pressing the manifold’s rattails through the slots in the top cover

until they are fully seated. (Fig. 7)

5. Replace the cover as described above.

D. REMOVING AND REPLACING THE LATCH

1. Remove the cover and silicone manifold as described above.

2. Raise the latch control away from the top cover so that it lifts the attached spring.

Remove the spring from the latch and discard or set aside in a safe place, if returning it to the unit. (Fig. 8)

3. Still holding the latch control in a raised position, push it into the latch retainer and

rotate the latch so that the spring post faces up. Gently push the short leg of the

latch up and through the slot in the cover. Discard faulty latch.

4. Orient the replacement latch over the bottom side of the top cover so that

short leg of the latch is over the slot near the screw post and the spring post is

facing up.

5. Insert the latch into the slot by rotating the latch stem back toward the screw

post and gently applying pressure to the short leg until it fi ts through the slot.

6. Place one end of the spring over the spring post and insert the other end into

the channel on the cover by slightly compressing the spring. Push the latch control several times to ensure that the system is confi gured properly.

7. Replace the silicone manifold and cover as described above.

15 .

6

7

8

spring post

latch control

screw post

latch retainer

short leg

Page 30

30

LT-2 027

EN

Humidity Output

(in the operating fl ow range)

≥10 mgH2O/L air

Chamber/Cradle Dimensions

Size 2.6” H x 6.3” W x 8.4” D

(6.6 cm x16.0 cm x 21.3cm)

Weight 1.75 lbs. (0.794 Kg)

Electrical Rating:

Electrical Supply Frequency 50/60 Hz

Power Consumption 85 Watts

Voltage and Current:

DV5HH 100-240VAC, 0.95 A

Heater Plate Cutout 152°C (305°F)

Power/Temperature Control Setting of 1 (minimum) to

10 (maximum)

Heater Plate Temperature approx. 29°C to approx. 65°C

(84°F to 149°F)

Operating, Transport & Storage

Operating Temperature Range 41°F to 104°F (5°C to 40°C)

Operating Humidity Range 0 to 95% R.H. non-condensing

Operating Atmospheric Pressure Range 70.0 – 106.0 kPA

Transport & Storage Temperature Range -40°F to 158°F (-40°C to +70°C)

Transport & Storage Humidity Range 0 to 95% R.H. non-condensing

Transport & Storage Atmospheric Pressure Range

50.0 – 106.0 kPA

Class II Equipment; Type BF Applied Parts; Continuous Operation

IPX1, Drip-proof vertical

16. Unit Specifications DV5HH

Page 31

31

LT-2 027

EN

DV54 AND DV5HH

A. ORDERING NON-WARRANTY REPLACEMENT PARTS

Order non-warranty parts and literature from your distributor or, if you have a DeVilbiss

account, from DeVilbiss Customer Service. To expedite the process, be prepared to

provide the following information:

• Account and ship-to numbers

• Ship-to address

• Part numbers and/or

descriptions

• Quantity required

• Unit catalog number

• Unit serial number

B. ORDERING WARRANTY REPLACEMENT PARTS

Order warranty parts from your distributor or, if you have a DeVilbiss account, from

DeVilbiss Customer Service through the Return Material Authorization process. To expedite

the process, be prepared to provide the above information, along with the following:

• How and where the product was being used

• A detailed description of the problem associated with warranty replacement

item

All warranty replacement orders require the return of the defective part to DeVilbiss.

C. RETURNING WARRANTY DEFECTIVE PARTS

ALL DEFECTIVE PARTS, WHICH ARE STILL UNDER WARRANTY, MUST BE

RETURNED TO THE FACTORY IN SOMERSET, PA WITHIN 30 DAYS AFTER

SHIPMENT OF THE REPLACEMENT PARTS. AN INVOICE WILL BE ISSUED, IF

THE DEFECTIVE PARTS ARE NOT RECEIVED WITHIN THIS PERIOD.

D. PLACING ORDERS

Orders may be placed by calling

• Customer Service 800-338-1988

• Warranty Parts- USA 800-338-1988

• Canada 905-660-2459

• International Department 814-443-4881

Before returning parts or units to the factory, call the DeVilbiss Healthcare Customer

Service Department at 800-338-1988 or 814-443-4881 to obtain a return authorization

number. Include in the package a note indicating the return authorization number along

with your company name, address, phone number, and account number. The return

authorization number should also be written on the outside of the package.

17. Ordering and R eturning P arts

Page 32

32

LT-2 0 27

EN

18 . Pa r t s Li s t

DV54 PAP

Air-Inlet Filter (4/pk) DV51D-602

Optional Fine Particle Filter (4/pk) DV51D-603

Air supply tubing 7351D-616

Air supply support plug DV51D-604

Disinfection kit DV51D-682

Blower assembly, balanced DV51D-672

Blower isolator and grommet-silicone DV51D-676

Foam Repair Kit DV51D-678