DeVilbiss HD-503 Service Manual

SERVICE MANUAL

HD-503

HOSE/GUN CLEANER

EN

Important: Before using this equipment, read all safety precautions and

instructions. Keep for future use.

DESCRIPTION

Halogenated Hydrocarbon solvents - for example; 1, 1, 1 - Trichloroethane and Methylene Chloride

- can chemically react with the

aluminum in this hose/gun cleaner

and cause an explosion hazard.

Read the label or data sheet for

the material you intend to spray.

Do not use materials containing

these solvents with the hose/gun

cleaner listed above.

This hose/gun cleaner provides a means

of cleaning the inside of material hose,

fluid passageways of spray guns and

other paint equipment. It is designed

to mix solvents and compressed air to

pressure flush paint lines and passages

quickly and thoroughly, eliminating color

contamination and saving time. This results in clean and dry paint passageways

using less than 25% of cleaning solvents

required in wet flush systems.

SPECIFICATIONS

Fluid Capacity: 2 quarts

Dry Weight: 5 lbs.

Maximum Working Pressure: 50 PSI

Air Inlet Size Ball Valve: 1/4” NPS(M)

Fluid Outlet Size: Ball Valve 3/8” NPS(M)

WETTED PARTS

Wetted parts are aluminum, nickle plated

brass, PTFE and santoprene gasket.

INSTALLATION

Static electricity is produced

when using this hose/gun cleaner.

Static electricity sparks may be

created during the cleaning operation. A spark from static electricity may cause fire or explosion.

If the gun or tool attached to the

fluid hose line is not grounded, it

will build a static charge. To prevent sparks from static electricity,

you must ground:

1. The hose/gun cleaner

2. The gun or tool attached to

the fluid hose line from the

equipment cleaner.

3. The waste container.

To ground equipment:

1. Use air hose containing a

static electricity grounding

wire.

2. Attach one end of a ground

wire to each item listed

above.

3. Attach the other end of the

wire to a water pipe, metal

electrical conduit or any

pipe or structural member

known to be grounded.

Overpressurized equipment and

hoses may be damaged or subject

to hazardous bursting. Your hose/

gun cleaner is designed to have

a maximum working pressure

(MWP) of 50 psi. Always use hose

and accessories designed for this

maximum fluid pressure.

Air pressure loads that are higher

than design loads, or changes to

the hose/gun cleaner can cause it

to rupture or explode.

A safety valve protects the cleaner

from overpressurization. During

each use, pull the ring on the safety valve to make sure it operates

freely and relieves air pressure. If

the valve is stuck, does not operate freely or does not relieve air

pressure, it must be replaced. Do

not eliminate, make adjustments

or substitutions to this valve.

Changes to the hose/gun cleaner

will weaken it. Never drill into,

weld, or change the hose/gun

cleaner in any way.

The maximum working pressure

of the cleaner is 50 psi.

OPERATION

When spraying is complete, back flush

remaining material in spray gun and hose

as follows:

1. Turn off air to material tank and bleed

air out of the material tank.

2. Loosen clamps on tank lid. Tip lid so

material will run out of fluid tube into

material tank.

3. Loosen air cap on gun several turns

and hold rag over cap. Pull trigger

and force material from gun and

hose back into tank.

To clean hose and gun passages:

1.

Fill hose/gun cleaner with suitable

cleaning solvent (see “Warning” in

Column 1 on Halogenated Hydrocarbon solvents). Close lid on cleaner.

2. Connect air hose to 1/4” NPS(M) ball

valve on gun/hose cleaner. Close ball

valve. Regulate air pressure (must be

remotely regulated) to a maximum

of 50 psig.

3. Disconnect material hose from

material supply tank and connect to

3/8” NPS(M) ball valve on hose/gun

cleaner.

4. When ready to clean, open both ball

valves on hose/gun cleaner.

5. Turn metering valve on top of hose/

gun cleaner to adjust amount of

solvent - air ratio. Turn counterclockwise to increase, clockwise to

decrease. Fully clockwise shuts off

solvent completely. To begin, open

counterclockwise at least 2 turns for

sufficient solvent for cleaning.

6. Trigger gun with solvent going into

spray booth or properly grounded

container. Continue spraying until

solvent is clear with no traces of

paint.

7. Turn metering valve on hose/gun

cleaner fully clockwise shutting off

solvent flow, while allowing air to

continue to flow. Continue until

solvent residue is removed.

8. Turn off air at source. Trigger gun to

remove residual air pressure. Close

both ball valves on hose/gun cleaner.

PREVENTIVE MAINTENANCE

Check lid gasket (7) and needle valve

gasket (2) for signs of wear or damage.

Replace as needed.

SB-14-052-K (11/2015) 1 / 4

EN

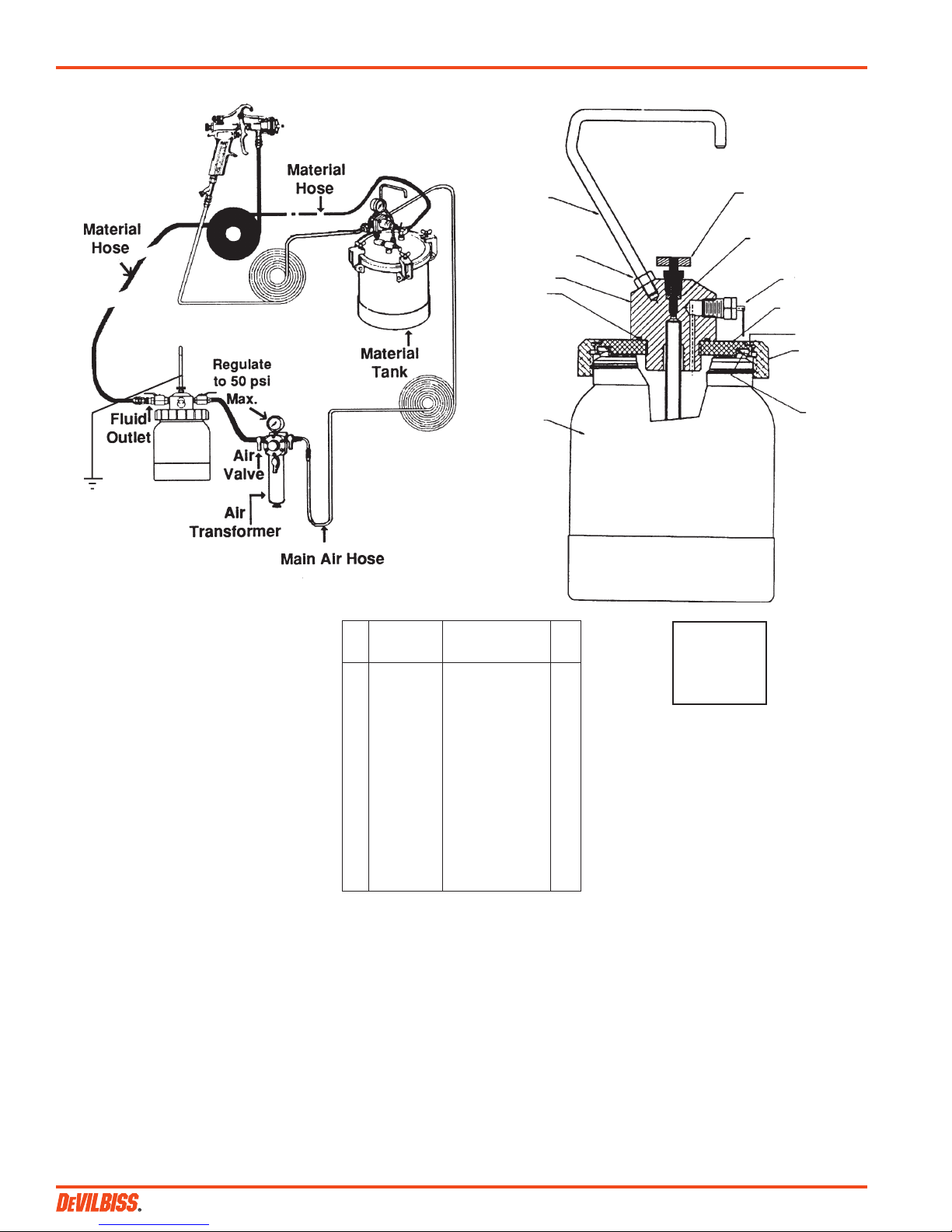

FIGURE 1 - TYPICAL INSTALLATION

HD-503

Earth

Ground

FIGURE 2 - HD-503 HOSE/GUN CLEANER CROSS SECTION VIEW

12

11

10

9

8

8

1

2

3

4

5

6

7

ACCESSORIES

Air Supply Hose:

H-1921 or 71-20000 Air Hose - with static

ground wire braid, 5/16” ID. Also need two

3-piece reuseable P-HC-4527 or 72-1317

connectors.

or

H-1958 or 71-21000 Air Hose - with static

ground wire braid, 3/8 ID. Also need two

3-piece reuseable P-HC-4528 or 72-1325

connectors.

Fluid Delivery Hose:

H-1973-1 or 71-282 Nyliner II fluid hose -

3/8” ID. Also need two 3-piece reuseable

P-HC-4548 or 72-1328 connectors.

PARTS LIST

Ind.

Ref. Replacement Parts

No Part Number Description Req.

1 HD-409 Needle Valve Assy. 1

2 HD-39-K2 Needle Valve Gasket 1

(Kit of 2)

3 TIA-4355 Safety Valve 1

4 HD-42 Lid 1

5 KB-81-K5 Ring Gasket (Kit of 5) 1

6 KB-64 Retaining Ring 1

7 KB-80-K5 Gasket Kit (Kit of 5) 1

8 KB-422 Cup (2 quart) 1

9 SSG-8184-K2 O-Ring Kit (Kit of 2) 1

10 HD-408 Hub Assembly 1

• 11 --- Nut (5/16-18) 1

12 KB-74 Handle 1

13 VA-542 Ball Valve, 1/4 NPS 1

(air) (not shown)

14 VA-540 Ball Valve, 3/8 NPS 1

(fluid) (not shown)

• Purchase locally.

CA PROP

65

PROP 65 WARNING

WARNING: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

IT IS THE RESPONSIBILITY OF THE

EMPLOYER TO PROVIDE THIS INFORMATION

TO THE OPERATOR OF THE EQUIPMENT.

FOR FURTHER SAFETY INFORMATION

REGARDING BINKS AND DEVILBISS

EQUIPMENT, SEE THE GENERAL

EQUIPMENT SAFETY BOOKLET (77-5300).

SB-14-052-K (11/2015)2 / 4

Loading...

Loading...