Page 1

SERVICE BULLETIN

SB-2-179-F

Replaces SB-2-179-E

Repair Kit KK-5025

GFGTM GRAVITY PROTM MODEL GFG-517

CONVENTIONAL SPRAY GUN

IMPORTANT: Before using this

equipment, read all safety precautions

and instructions. Keep for future use.

DESCRIPTION

The GFG-517 is a general purpose, heavy

duty, high production spray gun suitable for

use with most types of materials. The fluid

tip and needle and internal fluid passages

are stainless steel.

Note

This gun includes 300 series stainless steel fluid passages and 400/

300 S.S. series tip and needle.

Guns may be used with chlorinated

solvent materials. The gravity cup

must also be compatible for use

with chlorinated solvent materials

(GFC-501 Acetal).

IMPORTANT: This gun is designed for use

with mildly corrosive and non-abrasive materials. If used with other high corrosive or

abrasive materials, it must be expected

that frequent and thorough cleaning will

be required and the necessity for replacement of parts will be increased.

Note

The GFC gravity feed cups are included with the gun as part of the

GFG-618 gun and cup kits. See

Accessories

information.

on page 6 for more

2. Attach the gravity feed cup to the

material inlet.

Note

Protective coating and rust inhibitors have been used to keep the

gun in good condition prior to shipment. Before using the gun, flush it

with solvents so that these materials will be removed from fluid passages.

OPERATION

Mix, prepare and strain the material to be

sprayed according to the paint

manufacturer's instructions.

Strain material through a 60 or 90 mesh

screen.

1. Fill the gravity feed cup with the material. Do not overfill. Make sure that

the cup lid vent hole is clear.

2. Turn on the air at the source of supply.

Adjust the atomization air pressure to

35 psi.

3. Open the spreader adjustment valve

(19) (Fan) by turning the valve stem

counter-clockwise.

4. Close the fluid needle adjusting screw

(25) by turning clockwise.

5. Spray a test area by turning the fluid

needle adjusting screw (25) counterclockwise until a full coat is obtained.

PREVENTIVE MAINTENANCE

To clean air cap and fluid tip, brush exterior

with a stiff bristle brush. If necessary to

clean cap holes, use a broom straw or

toothpick. Never use a wire or hard instru-

ment. This may scratch or burr holes causing a distorted spray pattern.

To clean fluid passages, remove excess

material from cup, then flush with a suitable

solvent. Wipe gun exterior with a solvent

dampened cloth. Never completely immerse

in solvent as this is detrimental to the

lubricants and packings.

Note

When replacing the fluid tip or fluid

needle, replace both at the same

time. Using worn parts can cause

fluid leakage. Tip and needle sets

are available. See Chart 2. Also,

replace the needle packing at this

time. Lightly lubricate the threads

of the fluid tip before reassembling.

Torque to 12-15 ft. lbs. Do not overtighten the fluid tip.

To prevent damage to the fluid tip (2)

or fluid needle (2), be sure to either 1)

pull the trigger and hold while tightening or loosening the fluid tip or 2)

remove fluid needle adjusting screw

(25) to relieve spring pressure against

needle collar.

INSTALLATION

1. Attach the air supply line to the air inlet

(18). An air transformer installed as

close as possible to the gun will provide

filtered and regulated air.

Note

When larger diameter air hoses are

used, it is advisable to use an 8' or

10' "whip end" or a smaller diameter hose at the gun for greater

flexibility or movement.

If the finish is too sandy and dry, the

material flow may be too low for the atomization air pressure being used.

If the finish sags, there is too much material

flowing for the atomization air pressure

being used.

Both of the above can be corrected by

increasing or decreasing the atomization air

pressure or the material flow. Pattern width

can be altered by turning the spreader

adjustment valve (19), either clockwise to

decrease the width or counter-clockwise to

increase the width.

SPRAY GUN LUBRICATION

Daily, apply a drop of SSL-10* spray gun

lube at trigger bearing stud (15) and the

stem of the air valve (10) where it enters the

air valve assembly (13). The shank of the

fluid needle (2) where it enters the packing

nut (6) should also be oiled. The fluid needle

packing (5) should be lubricated periodically. Make sure the baffle (4) and retaining

ring (1) threads are clean and free of foreign matter. Before assembling retaining

ring to baffle, clean the threads thoroughly,

then add two drops of SSL-10 spray gun

lube to threads. The fluid needle spring (22)

and air valve spring (11) should be coated

(Continued on page 3)

Page 2

Page 2 SB-2-179-F

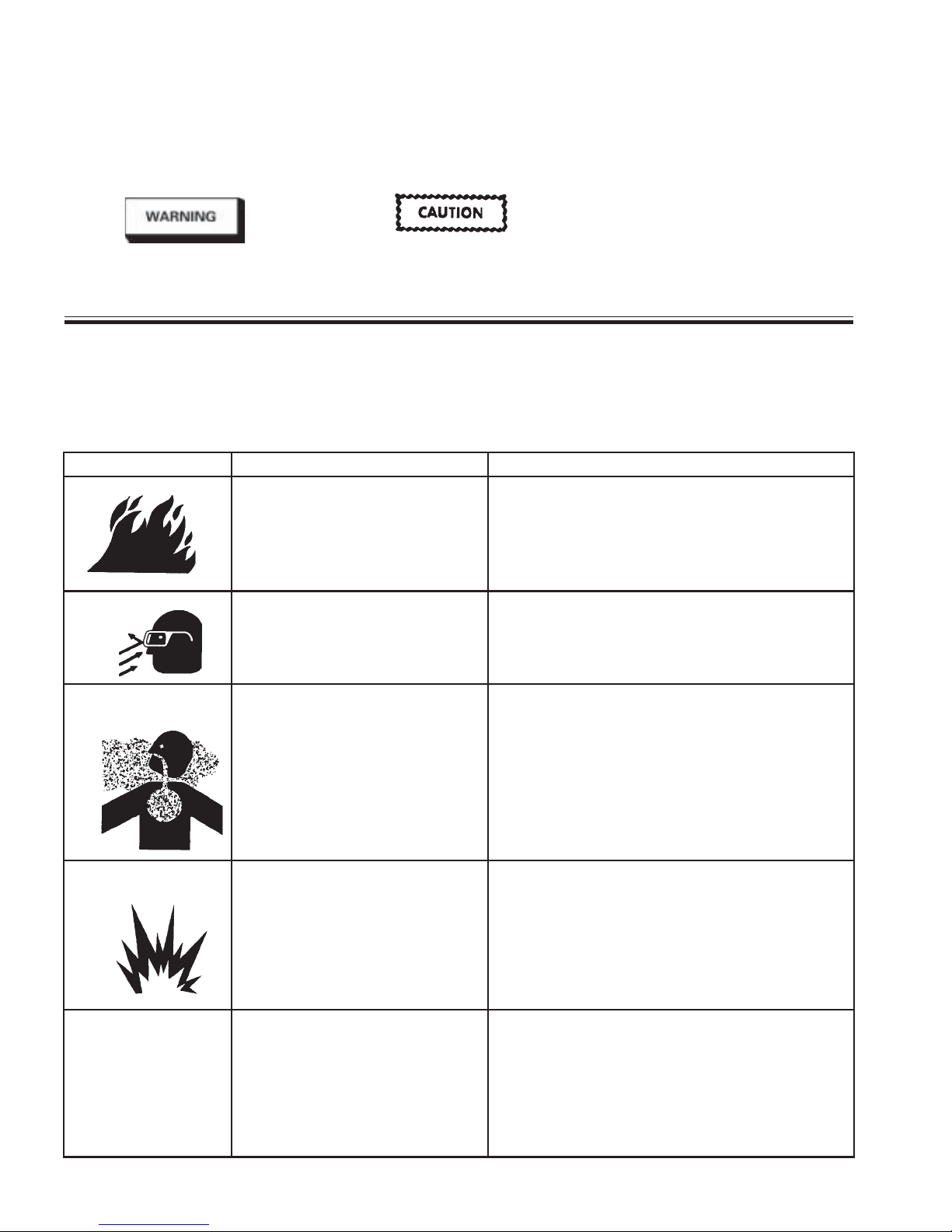

SAFETY PRECAUTIONS

This manual contains information that is important for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention

to these sections.

NOTE

Important information that tells how to

Important safety information - A hazard

that may cause serious injury or loss of

life.

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire

Solvent Spray

Inhaling Toxic Substances

Solvent and coatings can be highly

flammable or combustible especially when

sprayed.

During use and while cleaning and flushing,

solvents can be forcefully expelled from

fluid and air passages. Some solvents

can cause eye injury.

Certain materials may be harmful if inhaled,

or if there is contact with the skin.

prevent damage to equipment, or how

to avoid a situation that may cause minor injury.

Adequate exhaust must be provided to keep air free of

accumulations of flammable vapors.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray

area.

Wear eye protection.

Follow the requirements of the Material Safety Data Sheet

supplied by your coating material manufacturer.

Information that you should pay

special attention to.

Explosion Hazard Incompatible Materials

General Safety

Halogenated hydrocarbon solvents - for

example; methylene chloride and 1,1,1,

- Trichloroethane are not chemically

compatible with the aluminum that might

be used in many system components.

The chemical reaction caused by these

solvents reacting with aluminum can

become violent and lead to an equipment

explosion.

Improper operation or maintenance of

equipment.

Adequate exhaust must be provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compatible

with the material being sprayed and its concentration. Equipment must be as prescribed by an industrial hygienst or

safety expert, and be NIOSH approved.

Guns with stainless steel internal passageways may be used

with these solvents. However, aluminum is widely used in

other spray application equipment - such as material pumps,

regulators, valves, and cups. Check all equipment items

before use and make sure they can also be used safely with

these solvents. Read the label or data sheet for the material

you intend to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your material

supplier.

Operators should be given adequate training in the safe use

and maintenance of the equipment (in accordance with the

requirements of NFPA-33, Chapter 15). Users must comply

with all local and national codes of practice and insurance

company requirements governing ventilation, fire

precautions, operation, maintenance, and housekeeping.

These are OSHA Sections 1910.94 and 1910.107 and NFPA-

33. Risk is reduced by avoiding or lessening factors 1-7.

Page 3

HAZARD CAUSE SAFEGUARDS

SB-2-179-F Page 3

Cumulative Trauma

Disorders ("CTD's")

CTD's, or musculoskeletal

disorders, involve damage

to the hands, wrists,

elbows, shoulders, neck,

and back. Carpal tunnel

syndrome and tendonitis

(such as tennis elbow or

rotator cuff syndrome) are

examples of CTD's.

with a very light grease, making sure that

any excess grease will not clog the air passages. For best results, lubricate the points

indicated, daily.

*Not for air tools or high RPM equipment.

A. Trigger Points

B. Packing

C. Adjusting Valves

D. Baffle Threads

E. Air Valve Cartridge

Use of hand tools may casue cumulative

trauma disorders ("CTD's").

CTD's, when using hand tools, tend to

affect the upper extremities. Factors which

may increase the risk of developing a CTD

include:

1. High frequency of the activity.

2. Excessive force, such as gripping,

pinching, or pressing with the hands

and fingers.

3. Extreme or awkward finger, wrist, or

arm positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD's can also be caused by such activities

as sewing, golf, tennis, and bowling, to

name a few.

Pain, tingling, or numbness in the shoulder, forearm, wrist,

hands, or fingers, especially during the night, may be early

symptoms of a CTD. Do not ignore them. Should you

experience any such symptoms, see a physician

immediately. Other early symptoms may include vague

discomfort in the hand, loss of manual dexterity, and

nonspecific pain in the arm. Ignoring early symptoms and

continued repetitive use of the arm, wrist, and hand can

lead to serious disability.

PARTS REPLACEMENT

Replacement Instructions for O-ring on

Spreader Adjustment Valve

1. Remove retaining ring (20) on spreader

adjustment.

2. Remove valve stem and PTFE® O-ring

(21) from valve body.

3. Insert new PTFE® O-ring (21) in valve

body. Make sure it is pushed past the

threads.

4. Insert valve stem.

5. Reinstall retaining ring (20).

CHART 1

Air Caps

If This No. On Ref. No. 1 Air Cap

Cap, Order with Retaining Ring

No. 9000 AV-440-9000

No. 80 MB-4039-80

GTI-33 Baffle Seal Replacement (3)

1. Remove fluid tip (2).

2. Remove baffle (4).

3. Remove seal (3) from baffle.

4. Assemble seal to baffle with angled

side up as shown at right.

NOTE

The seal should be a tight fit

on the baffle. If it is a loose fit

on the baffle, assure that it is

assembled with the angled

side up.

5. Install baffle on gun.

6. Install fluid tip (2) and tighten to 12-15

ft-lbs.

The seal is designed to be a tight fit

on the baffle. The seal should be

able to be removed using your

fingers. If you are unable to remove the seal using your fingers,

insert a small screwdriver between the outer lip and the back of

the baffle and pry the seal off.

CHART 2

Fluid Tips and Needles

GFG-517 Ref. #2

Tip Fluid Tip Size If This No. On Tip and

Size I.D. Dimensions Tip, Order Needle Sets

EX 0.070" 1.75 mm AV-2115-EX JGA-4040-EX

FW 0.063" 1.6 mm AV-2115-FW JGA-4040-FW

FF 0.055" 1.4 mm AV-2115-FF JGA-4040-FF

ANGLED SIDE

SEAL

NOTE

Pry here if

necessary

THICK SIDE

BAFFLE

Page 4

Page 4 SB-2-179-F

See GTI-33 Baffle Seal

Replacement instructions

on page 3.

4

27

20

21

19

(Accessory)

2

25

24

12

23

22

26

2

3

Torque to

12-15 ft. lbs.

1

6

5

12

11

10

9

8

7

13

PARTS LIST

Ref. Individual

No. Part No. Description Parts Req.

1 See Chart 1 Air Cap & Retaining Ring 1

2 See Chart 2 Lapped Fluid Tip and Needle 1

• 3 GTI-33-K5 Seal Kit (Kit of 5) 1

4 GTI-425 Baffle Assembly 1

•+ 5 JGV-463-K3 Fluid Needle Packing (Kit of 3) 1

6 34411-122-K10 Fluid Needle Packing Gland 1

(Kit of 10)

• 7 —— Snap Ring 1

• 8 —— Washer 1

•+ 9 —— U Cup 1

• 10 —— Air Valve 1

• 11 —— Spring 1

•+12 JGS-72-K10 Gasket (Kit of 10) (PTFE®) 2

13 JGS-449-1 Air Valve Assembly 1

• 14 —— Screw 1

15 —— Trigger Bearing Stud 1

16 JGS-478 Stud and Screw Kit 1

(Kit includes 3 studs & 5 screws)

19 (Spreader

20

Adjustment)

21

28

*Apply Loctite #242

(Blue) to threads and

torque to 15 ft. lbs.

18 (1/4 NPS(M)

Detail Ref. No. 5 - Two piece packing

15

16

14

Ref. Individual

No. Part No. Description Parts Req.

17 JGS-477-1 Trigger, Stud and Screw Kit 1

18 P-MB-51 Air Inlet Connector 1/4" NPS(M) 1

19 GFG-413-2 Spreader Adjustment Valve 1

• 20 —— Retaining Ring 1

•+21 —— O-ring (PTFE®) 1

• 22 MBD-19-K10 Fluid Needle Spring (Kit of 10) 1

• 23 —— Spring Pad (Included with #22) 1

24 —— Gun Body Bushing 1

25 GTI-414 Fluid Needle Adjusting Screw 1

26 JGA-4041 Bushing, Spring & Knob Kit 1

27 6000-12 Plug 1

28 GFG-6 Gun Hook 1

• KK-5025 Gun Repair Kit includes a quantity of necessary parts

and should be kept on hand for service convenience.

+ KK-5036 Soft Gun Repair Kit includes a quantity of necessary

parts.

Suffixes - K5, K10 designate kits of multiple parts.

(Example) GTI-33-K5 is a kit of 5 seals.

covered by U.S. Patent No. 5,209,501.

+ Tapered edge faces out towards packing

nut.

Fluid Packing Nut

+Inner PTFE

17

Piece

Outer

U.H.M.W.

Poly. Piece

(Kit includes 1 each)

Fluid Needle

Page 5

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy top or

bottom pattern

Horn holes plugged.

Obstruction on top or bottom of fluid tip.

Cap and/or tip seat dirty.

Clean. Ream with non-metallic point.

Clean.

Clean.

SB-2-179-F Page 5

Heavy right or left

side pattern

Heavy center pattern

Split spray pattern

Jerky or fluttering spray

Unable to get round spray

Will not spray

Paint bubbles in cup

Fluid leaking or dripping from

cup lid

Starved spray pattern

Excessive overspray

Excessive fog

Dry spray

Fluid leaking from packing nut

Fluid leaking or dripping from

front of gun

*Most common problem.

Left or right side horn holes plugged.

Dirt on left or right side of fluid tip.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap. Clean the air cap as previously instructed.

2. If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the fluid

tip. Remove with #600 wet or dry sand paper.

3. Check for dried paint just inside the opening; remove by washing with solvent.

Fluid flow too high for atomization air.

Material flow exceeds air cap's capacity.

Spreader adjustment valve set too low.

Atomizing pressure too low.

Material too thick.

Atomization air pressure too high.

Fluid flow too low.

Spreader adjusting valve set too high.

*Loose or damaged fluid tip/seat.

Material level too low.

Container tipped too far.

Obstruction in fluid passage.

Dry or loose fluid needle packing nut.

Spreader adjustment screw not seating

properly.

Air cap retaining ring loose.

No air pressure at gun.

Fluid needle adjusting screw not open enough.

Fluid too heavy for gravity feed.

Fluid tip not tight.

Cup lid loose.

Dirty threads on cup or lid.

Cracked cup or lid.

Inadequate material flow.

Low atomization air pressure.

Too much atomization air pressure.

Gun too far from work surface.

Improper stroking (arcing, gun motion too

fast).

Too much or too fast-drying thinner.

Too much atomization air pressure.

Air pressure too high.

Gun tip too far from work surface.

Gun motion too fast.

Gun out of adjustment.

Packing nut loose.

Packing worn or dry.

Packing nut too tight.

Dry packing.

Fluid tip or needle worn or damaged.

Foreign matter in tip.

Fluid needle spring broken.

Wrong size needle or tip.

Clean. Ream with non-metallic point.

Clean.

Balance air pressure and fluid flow. Increase

spray pattern width with spreader adjustment

valve.

Thin or lower fluid flow.

Adjust.

Increase pressure.

Thin to proper consistency.

Reduce at transformer or gun.

Increase fluid flow (increases gun handling speed).

Adjust.

Tighten or replace.

Refill.

Hold more upright.

Backflush with solvent.

Lubricate or tighten.

Clean or replace.

Tighten.

Check air supply and air lines, blow out gun air

passages.

Open fluid needle adjusting screw.

Thin material and/or change to larger tip size.

Tighten tip to 20-25 ft-lbs.

Tight lid.

Clean.

Replace cup and lid.

Back fluid adjusting screw out to first thread,

or change to larger tip size.

Increase air pressure and rebalance gun.

Reduce pressure.

Adjust to proper distance.

Move at moderate pace, parallel to work

surface.

Remix properly.

Reduce pressure.

Reduce air pressure.

Adjust to proper distance.

Slow down.

Adjust.

Tighten, do not bind needle.

Replace or lubricate.

Adjust.

Lubricate.

Replace tip and needle with lapped sets.

Clean.

Replace.

Replace.

Page 6

Page 6 SB-2-179-F

TROUBLESHOOTING (Continued)

CONDITION CAUSE CORRECTION

Fluid dripping or leaking from

bottom of cup

Runs and sags

Thin, sandy coarse finish drying

before it flows out

Thick, dimpled finish "orange

peel"

ACCESSORIES

GFC-501 (Acetal) 20 Oz. Cup

GFC-502 (Aluminum) 32 Oz. Cup

Gravity Feed Cups

These gravity feed cups are designed

to be used with GFG gravity feed spray

guns.

Cup loose on gun.

Washer worn or missing below cup.

Cup threads dirty.

Too much material flow.

Material too thin.

Gun tilted on an angle, or gun motion too

slow.

Gun too far from surface.

Too much air pressure.

Improper thinner being used.

Gun too close to surface.

Air pressure too low.

Improper thinner being used.

Material not properly mixed.

Surface rough, oily, dirty.

WR-103 Wrench

HAV-500 OR

Adjusting Valve

(HAV-501 SHOWN)

Tighten.

Replace washer.

Clean.

Adjust gun or reduce fluid flow.

Mix properly or apply light coats.

Hold gun at right angle to work and adapt to

proper gun technique.

Check distance. Normally approx. 8".

Reduce air pressure and check spray pattern.

Follow paint manufacturer's mixing instrs.

Check distance. Normally approx. 8".

Too much material coarsely atomized.

Increase air pressure or reduce fluid flow.

Follow paint manufacturer's mixing instrs.

Follow paint manufacturer's mixing instrs.

Properly clean and prepare.

HAV-501

HARG-510

Air Regulator

42884-214-K5 3/8"

42884-215-K10 5/8"

Cleaning Brushes

Spray Gun and Cup Kits

GFG-517 Spray Gun is also sold in the following Kits: Each Kits includes (1) GFG-517

Spray Gun and (1) GFG-502 Cup:

GFG-618-80FW GFG-618-90FF

GFG-618-90FW

Quick Disconnect Approved For

HVLP Guns (Air)

High Flow Ball and Ring Type.

HC-4419

1/4" NPS(F)

HC-4700

1/4" NPT(F)

JGA-156-K10 Spring Clips

Joins any single piece Devilbiss air cap

with latest version MBC-368 or MSA-1

retaining ring,. Helps prevent parts loss

and provides easier assembly.

1/4" NPT(M)

1/4" NPT(M)

HC-1166

HC-4699

Contains all necessary tip, hose, and

nut sizes used on or

with gun.

GH-505 Gun Holder

Gun holders are

made to hold standard paint cups,

gravity feed guns

and cups, and paint

filters.

HAV-500 does not

have pressure gage.

Use to control air

pessure at gun.

GH-407 Gun Holder

(1) Wall mount

bracket included

with GH-407.

OMX-70-K48 PAINT CUP LINER KIT

Allows quick and easy clean-up.

Consists of : 1 - Piercing Tool,

48 - Disposable Liners,

48 - Drain Bushings

Use to maintain

nearly constant outlet pressure despite

changes in inlet

pressure and downstream flow.

Spray Gun Lube

SSL-10-K12

(2 oz. bottle)

Compatible with all

paint materials; contains no silicone or

petroleum distillates to contaminate

paint.

HAF-507 Whirlwind™

In-Line Air Filter

Removes water, oil, and

debris from the air line.

29-3100 Scrubs® Hand

Cleaner Towels

These brushes are

helpful in cleaning

threads and

recesses of gun

body.

GFG-413-2 Air

Adjustment Valve

Installs into gun

to enable user to

control and

reduce air

pressure at the

gun. Replaces

6000-12 plug.

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

Scrubs® are a pre-moistened

hand cleaner towel for painters.

No water is needed.

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing:

www.devilbiss.com

6/04 ©2004 Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...