SB-E-2-792

ISS.01

OPERATION MANUAL

FLG-P5-14

Transtech Pressure-feed Spray Gun

E

E

D

D

1 – 8

16 – 22

F

F

NL

NL

9 – 15

23 – 30

EE

Operation Manual

FLG5 – Pressure-Feed Spray Gun

Important

Read and follow all instructions and Safety warnings before using this

equipment

Description

The FLG5 pressure feed Spraygun is fitted with a 1.4mm Nozzle for use with common

coating materials. A 1.1mm Nozzle and Needle is available as an alternative. The

FLG5 Spraygun is approved to ATEX regulations 94/9/EC, protection level;

II 2 G X. Suitable for use in Zones 1 and 2

Important: These spray guns are suitable for use with both water-based and solvent-

based coating materials. The design uses EPA compliant atomising (Devilbiss TransTech®) technology to reduce overspray and improve coating efficiency. Nozzles and

needles are manufactured in stainless steel. These guns are not designed for use with

highly corrosive and/or abrasive materials and if used with such materials it must be

expected that the need for cleaning and/or replacement of parts will be increased. If

there is any doubt regarding the suitability of a specific material contact your local

Distributor or ITW Finishing direct.

SPECIFICATION

Air supply connection – Universal 1/4 BSP and NPS

Maximum static air inlet pressure – P

Nominal gun inlet pressure with gun triggered – 2.4 bar (35 psi)

Maximum Service temperature – 40°C

Gun Weight – 930g

Airflow – 277 l/min (9.8 cfm)

Materials of Construction

Gun body – Aluminium. Stainless steel fluid passages

Nozzle – Stainless steel

Needle – Stainless Steel

ITW Finishing Systems and Products reserve the right to modify equipment specification without prior notice.

© 2005 ITW Finishing Systems and Products

2

= 12 bar (175 psi)

1

SAFETY WARNINGS

EE

Fire and explosion

Solvents and coating materials

can be highly flammable or

combustible when sprayed. ALWAYS

refer to the coating material suppliers

instructions and COSHH sheets

before using this equipment

Users must comply with all local

and national codes of practice

and insurance company

requirements governing

ventilation, fire precautions, operation

and house-keeping of working areas

This equipment, as supplied,

is NOT

Halogenated Hydrocarbons

cleaning non- conductive parts with

cloths. To prevent ignition sources from

static discharges, earth continuity must

be maintained to the spraygun and other

metallic equipment used. It is essential to

use conductive air and/or fluid hoses.

suitable for use with

Static Electricity can be

generated by fluid and/or air

passing through hoses, by the

spraying process and by

.

Personal Protective

Equipment

Toxic vapours – When sprayed,

certain materials may be

poisonous, create irritation or be

otherwise harmful to health.

Always read all labels and safety data

sheets for the material before spraying

and follow any recommendations. If In

Doubt, Contact Your Material Supplier

The use of respiratory protective

equipment is recommended at all

times. The type of equipment

must be compatible with the

material being sprayed.

Always wear eye protection

when spraying or cleaning the

spraygun

Gloves must be worn when

spraying or cleaning the

equipment

Training – Personnel should be given

adequate training in the safe use of

spraying equipment.

Misuse

Never aim a spraygun at any part of the

body

Never exceed the max. recommended

safe working pressure for the equipment

The fitting of non-recommended or nonoriginal spares may create hazards

Before cleaning or maintenance, all

pressure must be isolated and relieved

from the equipment

The product should be cleaned using a

gun washing machine. However, this

equipment should not be left inside gun

washing machines for prolonged periods

of time.

Noise Levels

The A-weighted sound level of

sprayguns may exceed 85 dB (A)

depending on the set-up being

used. Details of actual noise

levels are available on request. It is

recommended that ear protection is worn

at all times when spraying.

Operating

Spray Equipment using high pressures

may be subject to recoil forces. Under

certain circumstances, such forces could

result in repetitive strain injury to the

operator.

3

© 2005 ITW Finishing Systems and Products

EE

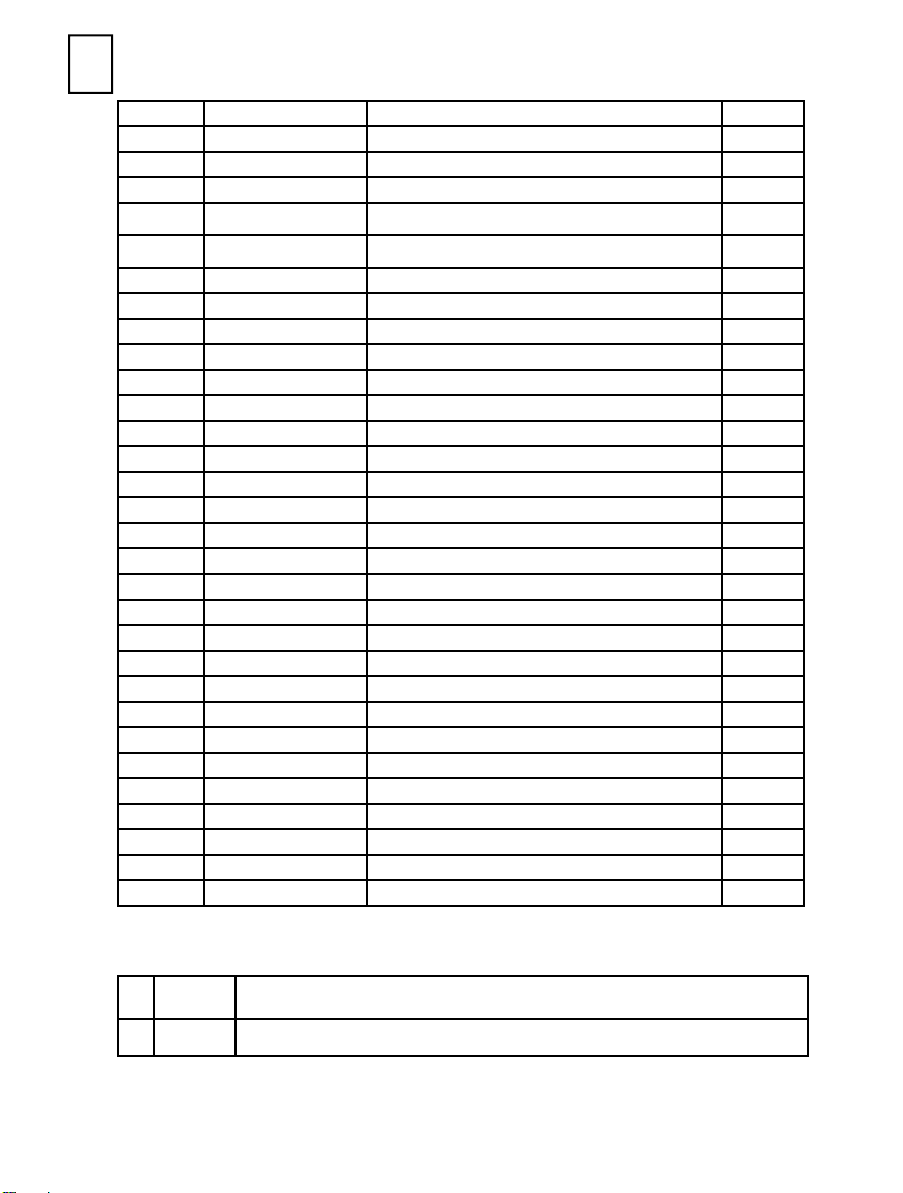

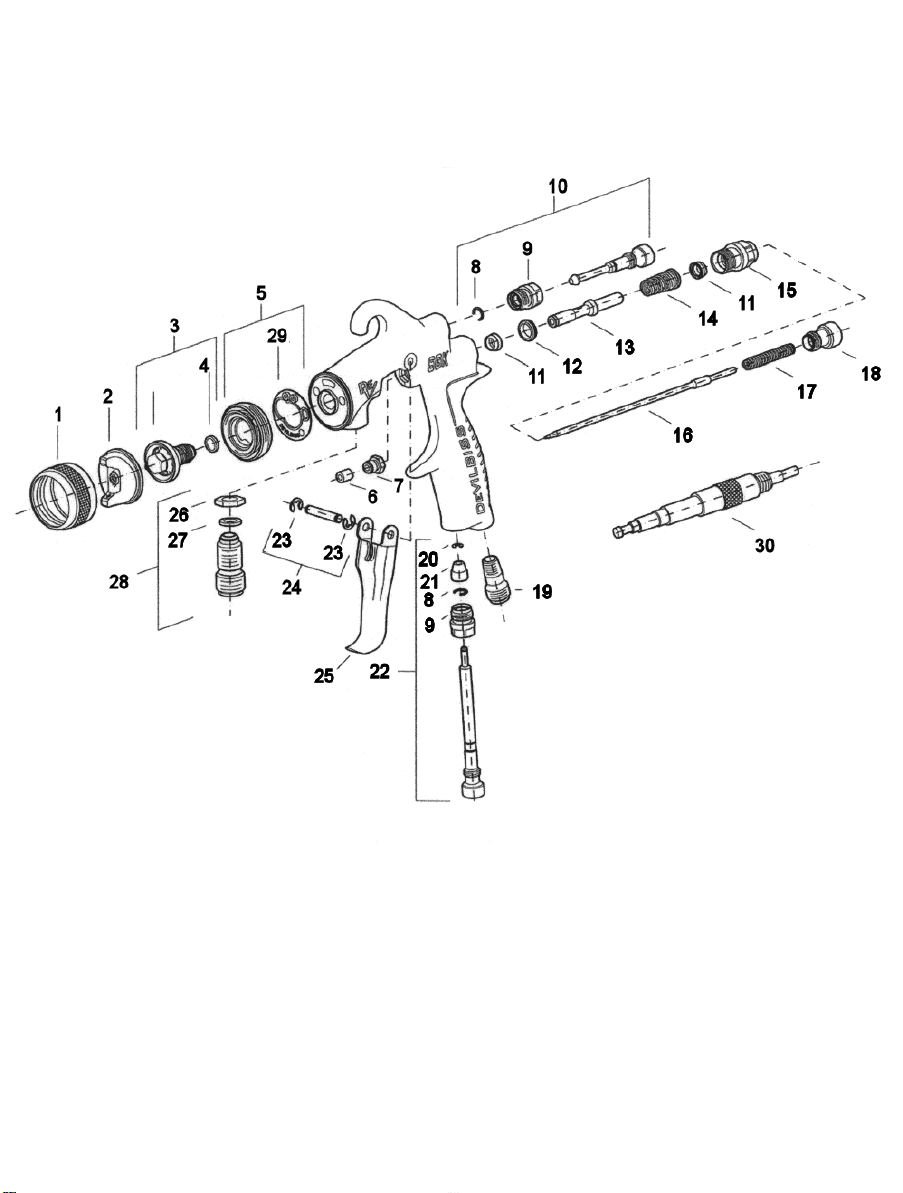

Ref. No Part Number Description

1 SGK-0023 Retaining ring 1

2 FLG-1-5 Air cap 1

3 SGK-0014-14 Fluid tip 1.8mm 1

● 4 - Gasket 1

● 5 K-5032- Sprayhead Kit 1

6 - Packing 1

7 - Packing gland nut 1

8 - Circlip 1

9 - Spray pattern adjustment valve bushing 1

10 - Spray pattern valve 1

11 - U-cup seal 2

12 - Air-valve seat 1

13 - Air-valve stem 1

14 - Air-valve spring 1

15 - Air-valve bushing 1

16 SGK-430-14 Fluid needle 1.8mm 1

17 - Fluid needle spring 1

18 - Fluid adjustment knob 1

19 - Nipple 1

20 - Circlip 1

21 - Air adjusting valve head 1

22 - Air adjusting valve assembly 1

23 - Circlip 1

24 - Trigger pin assembly 1

25 - Trigger 1

26 - Nut 1

27 - Washer 1

28 - Nipple assembly fluid 1

● 29 - Gasket 1

30 - Assembly Tool 1

K-5044

● K-5030: Baffle replacement kit, items 4 and 5.

© 2005 ITW Finishing Systems and Products

Seal, baffle and gasket replacement kit, items 4, 5, 6, 11, 12, 13, 14,

and 30

4

5

© 2005 ITW Finishing Systems and Products

EE

Installation

Important: To ensure that this equipment

reaches you in first class condition,

protective coatings have been used. Flush

the equipment through with a suitable

solvent before use.

1. Attach air hose to connector (19).

Recommended hose size 8 mm bore.

Operation

1. Mix coating material to manufacturers

instructions.

2. Turn needle adjusting screw (18)

clockwise to prevent movement.

3. Turn spreader valve (10) counterclockwise to fully open.

4. Adjust inlet air pressure (For

recommended figures see

Specifications) at the gun inlet with the

gun triggered. (pressure gauge

attachment shown under Accessories is

recommended for this).

5. Turn needle adjusting screw counter

clockwise until first thread shows.

6. Test spray. If the finish is too dry reduce

airflow by reducing air inlet pressure or

by the Airflow Valve (22). Screw the

Adjusting Knob in to reduce pressure.

The hose must be conductive and

electrical bond from the spraygun to

earth should be checked with an

ohmeter. A resistance of less than 10

Ohms is recommended.

2. Attach fluid supply hose to Fluid Inlet

(28).

7. If finish is too wet reduce fluid flow by

turning needle screw (18) clockwise or

reducing the fluid pressure. If

atomisation is too coarse, increase inlet

air pressure. If too fine reduce inlet

pressure.

8. The pattern size can be reduced by

turning adjusting valve (10) clockwise.

9. Hold gun perpendicular to surface being

sprayed. Arcing or tilting may result in

uneven coating.

10. The recommended spray distance is

150-200 mm (6”-8”).

11. Spray edges first. Overlap each stroke a

minimum of 50%. Move gun at a

constant speed.

12. Always turn off air and fluid supply and

relieve pressure when gun is not in use.

6

Preventative Maintenance

1. Turn off air and coating supply and

relieve pressure in the supply lines, or

if using QD system, disconnect from

airline and fluid line.

2. Remove air cap (1) & (2) and clean. If

any of the holes in the cap are blocked

with coating material use a toothpick to

clean. Never use metal wire which

© 2005 ITW Finishing Systems and Products

could damage the cap and produce

distorted spray patterns.

3. Ensure the tip of the nozzle (3) is clean

and free from damage. Build up of

dried paint can distort the spray

pattern.

4. Lubrication – stud (24), needle (16) and

air valve (13) should be oiled each day.

6

Replacement of Parts

Nozzle (3) and Needle (16) – Remove

parts in the following order: 18, 17, 16, 1,

2 and 3. Check condition of Nozzle Seal

(4) and replace if necessary. Replace any

worn or damaged parts and re-assemble

in reverse order. Recommended

tightening torque for nozzle (3) 16-20 Nm

(150-180 lbf in).

Packing – Remove parts 18, 17, 16.

Unscrew Packing Nut (7). Remove

packing (6). Fit new packing (6) and Nut

(7). Re-assemble parts 16, 17, and 18

and tighten Packing Nut (7) with spanner

sufficient to seal but to allow free

movement of needle. Lubricate with gun

oil.

Air Valve Seal Kit K-5040

1. Remove Adjusting Knob (18), Spring

(17), and Needle (16).

2. Loosen Housing (15).

3. Remove Housing (15) and Airvalve

Spring (14).

4. Remove Spindle (13).

5. Using Service Tool (40), engage

groove behind the Valve Seat (12)

and remove Valve Seat.

6. Push out the Front Airvalve Seal (11).

7. Turn the Gun upside down and let the

Seal fall out.

8. Fit New Front Seal (11) to Service

Tool.

9. Fit new Seal to gunbody and press

firmly to ensure Seal is engaged.

10. Fit New Valve Seat (12) to Service

Tool and fit Valve Seat into Gunbody.

11. Remove Rear Airvalve Seal (11) from

housing (15) with a hooked

instrument.

12. Fit new Seal to Service Tool and Fit

Seal to Housing (15).

13. Replace Spindle (13).

14. Replace Valve Spring (14), screw in

Housing (15) and tighten.

15. Screw reverse end of Service tool

into housing until fully engaged.

Tighten by hand to seat the Valve

Seat. Remove tool.

16. Fit Needle (16), Spring (17) and Knob

(18).

17. Adjust Needle Packing (7) with

Spanner sufficient to seal but to allow

free movement of needle. Lubricate

with gun oil.

Spreader valve (10) – Caution: always

ensure that the valve is in the fully open

position by turning screw fully counterclockwise before fitting to body.

Air cap / Nozzle Selection

Refer to coating material manufacturers

recommendations or ITW Finishing UK

Website:

www.itweuropeanfinishing.com

EE

Accessories

Cleaning Brush – order 4900-5-1-K3

Air adjusting valve and gauge – order HAV-501

Digital Pressure Gauge – DGI-501-BAR

Lubricant – order GL-1-K10

Drip free diaphragm – order KR-115-K5

Spraygun cleaning Kit – KK-4584

7

© 2005 ITW Finishing Systems and Products

EE

EC Declaration of Conformity

We: ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the

Authorised Representative of the manufacturer of the Spraygun model FLG5, declare, under our

sole responsibility, that the equipment to which this document relates is in conformity with the

following standards or other normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the

protection requirements of Council Directive 98/37/EC relating to Machinery Safety Directive,

and;

EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and Protective

Systems intended for use in Potentially Explosive Atmospheres protection level II 2 GX.

This product also complies with the requirements of the EPA guidelines, PG6/34. Transfer

efficiency certificates are available on request.

B. Holt, General Manager

1st January 2006

© 2005 ITW Finishing Systems and Products

8

FF

Manuel d’utilisation

FLG5 – Pistolet à peinture sous pression

Important

Lire attentivement toutes les instructions et les Consignes de sécurité

avant d’utiliser ce matériel

Description

Le pistolet sous pression FLG5 est équipé d'une buse de 1,4 mm permettant

l'application des produits de revêtement courants. Une buse de 1,1 mm et une aiguille

sont disponibles en remplacement. Le pistolet FLG5 est conforme à la réglementation

ATEX 94/9/CE, niveau de protection :

II 2 G X, et convient à l’utilisation dans les Zones 1 et 2

Important : Ces pistolets peuvent être utilisés avec des produits à la fois à base

aqueuse et à base de solvant. La conception fait appel à une technologie de

pulvérisation (Devilbiss Trans-Tech®), conforme aux règles EPA, qui réduit les

retombées de pistolage et améliore le rendement en application. Les buses et les

aiguilles sont en acier inoxydable. Ces pistolets ne sont pas conçus pour l’utilisation

avec des produits fortement corrosifs et/ou abrasifs. S’ils sont utilisés avec de tels

produits, ils devront être nettoyés et/ou les pièces devront être remplacées plus

souvent. S’il y a le moindre doute en ce qui concerne le caractère approprié d’un

produit spécifique, contactez votre distributeur local ou ITW Finishing directement.

SPECIFICATIONS

Raccord d’alimentation d’air - Universel 1/4" BSP et NPS

Pression d’entrée d’air statique maximale - P

Pression d’entrée nominale du pistolet

quand la gâchette est actionnée - 2,4 bar (35 psi)

Température de service maximale - 40°C

Poids du pistolet - 930 g

Débit d’air - 277 l/min

Matières de construction

Corps du pistolet - Aluminium. Passages de liquide en acier inoxydable

Buse - Acier inoxydable

Aiguille - Acier inoxydable

ITW Finishing Systems and Products se réserve le droit de modifier les spécifications de ses produits sans préavis.

9

= 12 bar (175 psi)

1

© 2005 ITW Finishing Systems and Products

FF

CONSIGNES DE SECURITE

Incendie et explosion

Les solvants et produits de

revêtement peuvent être

extrêmement inflammables ou combustibles

lorsqu’ils sont pulvérisés. Se reporter

TOUJOURS

fournisseurs de produits et aux fiches

COSHH avant d’utiliser ce matériel.

ventilation, les précautions à prendre contre

l’incendie, le fonctionnement et la surveillance

des lieux de travail.

Ce pistolet, tel qu’il est fourni, n’est PAS

prévu pour l’utilisation avec des hydrocarbures halogénés.

avec des chiffons. Pour éviter de créer des

sources d’inflammation avec des décharges

statiques, la continuité à la terre doit être

maintenue avec le pistolet et tout autre

materiel métallique utilisé. Il est essentiel

d’utiliser des flexibles d’air et/ou de liquide

conducteurs.

aux instructions des

Les utilisateurs doivent se conformer à

tous les codes de pratique locaux et

nationaux et aux exigences des

compagnies d’assurance régissant la

De l’électricité statique peut être

produite par le liquide et/ou l’air qui

circule dans les flexibles, par le

processus de pulvérisation et par le

nettoyage de pièces non-conductrices

Équipement de protection

individuelle

Vapeurs toxiques – Lorsqu’ils sont

pulvérisés, certains produits peuvent

être toxiques, irritants ou

les étiquettes et les fiches signalétiques des

produits avant de les pulvériser, et respecter

les consignes de sécurité. En cas de doute,

contacter le fournisseur du produit.

être compatible avec le produit pulvérisé

généralement nocifs. Toujours lire

Il est recommandé d’utiliser un

appareil de protection respiratoire à

tout moment. Le type d’appareil doit

.

Toujours porter une protection

oculaire pour pulvériser ou nettoyer le

pistolet.

Porter des gants pour pulvériser ou

nettoyer le pistolet.

Formation – Le personnel doit être

correctement formé à l’utilisation sans risque

du pistolet.

Mauvaise utilisation

Ne jamais diriger le pistolet vers une

quelconque partie du corps.

Ne jamais excéder la pression de service

maximale recommandée pour le pistolet.

La pose de pièces détachées nonrecommandées ou qui ne sont pas d’origine

peut engendrer des risques.

Avant le nettoyage ou l’entretien, isoler et

évacuer la pression du pistolet.

Nettoyer le pistolet avec une machine

spécialement conçue à cet effet. Toutefois, ne

pas laisser le pistolet à l’intérieur de la

machine pendant une période prolongée.

Niveaux sonores

Le niveau sonore pondéré A des

pistolets de pulvérisation peut

dépasser 85 dB (A) selon la

configuration utilisée. Le détail des niveaux

sonores actuels est disponible sur demande.

Le port de protecteurs d’oreilles est

recommandé à tout moment pendant la

pulvérisation.

Utilisation

Le pistolet fonctionne sous hautes pressions

susceptibles de provoquer un effort de recul.

Dans certains cas, ces forces peuvent infliger

des microtraumatismes répétés à l’utilisateur.

© 2005 ITW Finishing Systems and Products

10

Loading...

Loading...