Page 1

SERVICE BULLETIN

SB-2-601-C

Replaces SB-2-601-B

Gun Repair Kit FLG-480

FLG-513, FLG-606 AND FLG-626 SPRAY GUN

IMPORTANT: Before using this equipment, read all safety

precautions on page 2 and instructions. Keep for future use.

DESCRIPTION - MODEL FLG-606 & FLG-626 SPRAY GUNS

The FLG-606 and FLG-626 are light weight, general purpose suction

feed spray guns for both conventional and HVLP spraying applications suitable for use with a wide variety of common coating

materials. These models include the TGC-545 suction cup. The FLG513 is a pressure feed HVLP spray gun.

Halogenated hydrocarbon solvents - for example; 1, 1, 1trichloroethane and methylene chloride - can chemically

react with the aluminum in this gun and cause an explosion hazard. Read the label or data sheet for the material

you intend to spray. Do not use spray materials containing these solvents with this spray gun.

IMPORTANT: This gun may be used with most common coating

and finishing materials. It is designed for use with mildly corrosive

and non-abrasive materials. If used with other high corrosive or

abrasive materials, it must be expected that frequent and thorough cleaning will be required and the necessity for replacement

of parts will be increased.

OPERATION

Strain material thru 60 or 90 mesh screen.

Model FLG-606:

The No. 1 (conventional) air cap requires an air supply at the gun

inlet of approximately 45 psi, measured with the trigger pulled

and can be operated from a 3 H.P. compressor.

HVLP Models FLG-513 and FLG-626:

The No. 3 (HVLP) air cap requires an air supply at the gun inlet of

23 psi max., measured with the trigger pulled.

This gun was manufactured to provide maximum transfer efficiency

by limiting air cap pressure to 10 psi (complies with rules issued by

SCAQMD and other air quality authorities).

possible. If a wire or hard instrument is used, extreme care must

be used to prevent scratching or burring of the holes which will

cause a distorted spray pattern.

To clean fluid passages, remove excess material at source, then

flush with a suitable solvent. Wipe gun exterior with a solvent

dampened cloth. Never completely immerse in solvent as this

is detrimental to the lubricants and packings.

When replacing the fluid tip or fluid needle, replace both

at the same time. Using worn parts can cause fluid leakage. Using the supplied fluid tip tool (16), tighten fluid tip

hand tight.

To prevent damage to the fluid tip (3) or fluid needle (6),

be sure to either 1) pull the trigger and hold while tightening or loosening the fluid tip or 2) remove fluid needle

adjusting screw (15) to relieve spring pressure against

needle collar.

Spray Gun Lubrication

Daily, apply a drop of SSL-10 spray gun lube at trigger bearing stud

(11) and the stem of the air valve (17) where it enters the air valve

assembly (21). The shank of the fluid needle (6) where it enters the

packing nut (8) should also be oiled. The fluid needle packing (9)

should be kept soft and pliable by periodic lubrication. Make sure

the baffle (5) and retaining ring (1) threads are clean and free of

foreign matter. Before assembling retaining ring to baffle, clean

the threads thoroughly, then add two drops of SSL-10 spray gun

lube to threads. The fluid needle spring (14) and air valve spring (18)

should be coated with a very light grease, making sure that any

excess grease will not clog the air passages. For best results,

lubricate the points indicated, daily.

A. Trigger Points

B. Packing

C. Adjusting Valves

D. Baffle Threads

Note

A

C

This gun will produce approximately 10 psi cap pressure at 23 psi

inlet pressure, as measured at the gun inlet. An air cap test kit (see

ACCESSORIES) should be used to insure 10 psi cap pressure is not

exceeded.

Adjust fluid pressure to deliver the desired paint volume. Adjust air

pressure and fluid flow to provide a uniform dispersion of atomized

paint throughout the pattern. Keep air pressure as low as possible

to minimize bounce - back and overspray. Excessive air pressure

will result in split patterns. Low air pressure will result in heavy

centered patterns and poor atomization. Excessive fluid flow will

result in heavy center spray patterns. Inadequate fluid flows may

cause the pattern to split. See Spray Gun Guide, SB-2-001, which is

available upon request, for details concerning set up of spray guns.

PREVENTIVE MAINTENANCE

To clean air cap and fluid tip, brush exterior with a stiff bristle brush.

If necessary to clean cap holes, use a broom straw or toothpick if

D

B

Figure 1

DESCRIPTION - MODEL TGC-545 CUP

This one quart capacity drip free suction cup has a unique, two

position valve which permits selection of either a drip free spraying

mode or a conventional open vent mode.

In the drip free position, air is directed through the vent in the lid to

a channel beneath the lid gasket before entering the cup at the valve.

This allows the cup to be tilted when full without dripping paint

through the vent. The cup can also be inverted while spraying

without leaking.

The open position isolates the channel and opens a direct vent into

the cup.

(Continued on page 3)

Page 2

Page 2 SB-2-601-C

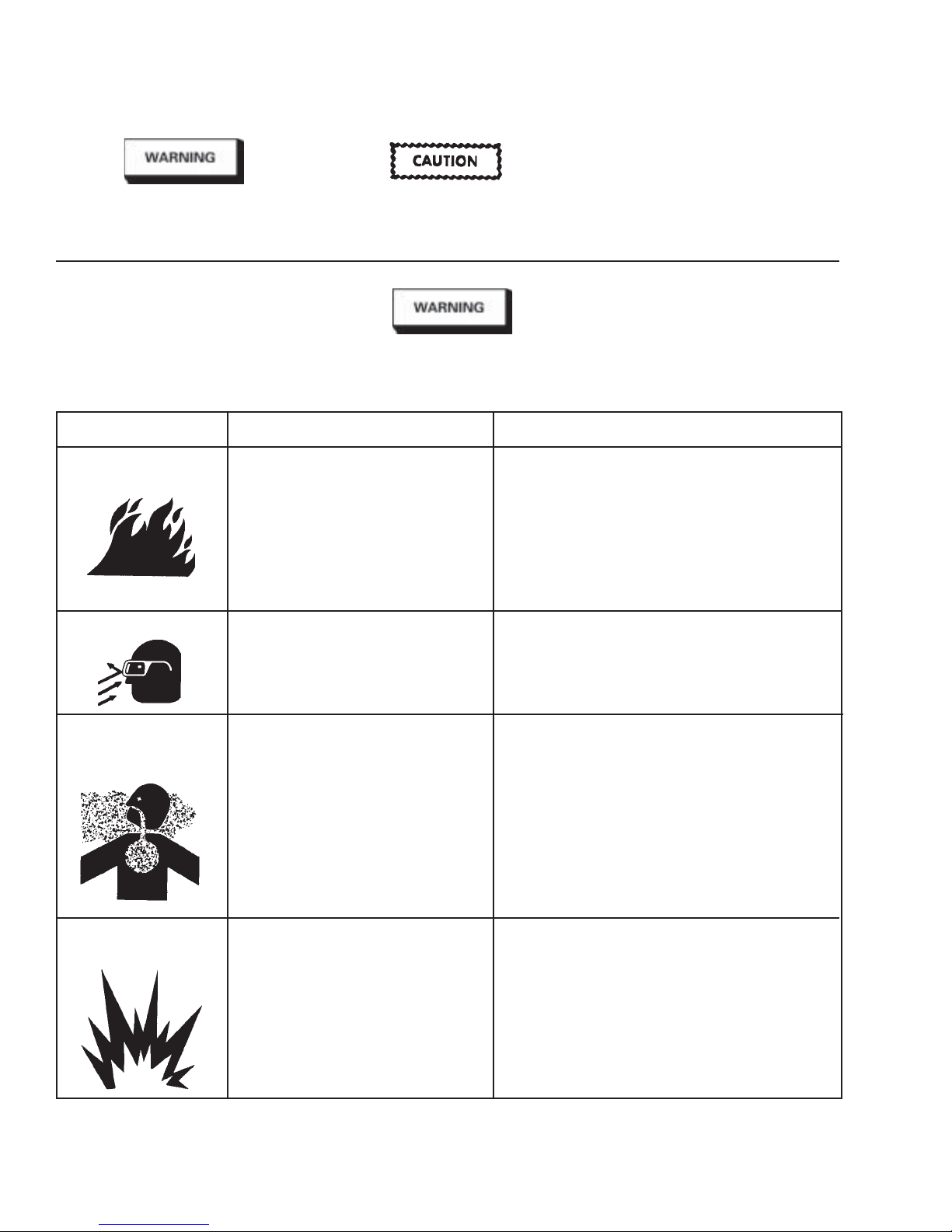

SAFETY PRECAUTIONS

This manual contains information that is improtant for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention

to these sections.

Note

Important safety information - A hazard

that may cause serious injury or loss of

life.

The following hazards may occur during the normal use of this equipment.

HAZARD CAUSE SAFEGUARDS

Fire

Solvent Spray

Please read the following chart before using this equipment.

Solvent and coatings can be highly flam- Adequate exhaust must be provided to keep air free of

mable or combustible especially when accumulations of flammable vapors.

sprayed.

During cleaning and flushing, solvents can Wear eye protection.

be forcefully expelled from fluid and air

passages. Some solvents can cause eye

injury.

Important information that tells how to

prevent damage to equipment, or how

to avoid a situation that may cause

minor inury.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present

in the spray area.

Information that you should pay

special attention to.

Inhaling Toxic

Substances

Explosion Hazard Incompatible Materials

Certain materials may be harmful if Follow the requirements of the Material Safety Data

inhaled, or if there is contact with the skin. Sheet supplied by your coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compatible

with the material being sprayed and its concentration.

Equipment must be as prescribed by an industrial

hygienist or safety expert, and be NIOSH approved.

Halogenated hydrocarbon solvents - for Guns with stainless steel internal passageways may be

example; methylene chloride and 1, 1, 1 - used with these solvents. However, aluminum is widely

Trichlorethylene are not chemically com- used in other spray application equipment - such as

patible with the aluminum that might be material pumps, regulators, valves, and this gun and cup.

used in many system components. The Check all equipment items before use and make sure they

chemical reaction caused by these solvents can also be used safely with these solvents. Read the

reacting with aluminum can become violent label or data sheet for the material you intend to spray.

and lead to an equipment explosion. If in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Page 3

The position of the valve is indicated by alignment of the hole in the

valve slot with the marks cast on the lid. These positions are

identified as on the lid as "O" for vent open and "D/F" for drip free.

OPERATION

Open Vent Mode "O" - To operate in the open vent mode, rotate the

valve with a screwdriver or coin so that the hole in the valve slot is

aligned with the "O" on the lid. See Figure 2.

If the valve slot hole should plug while operating in the "O" vent

mode, use a pointed tool such as a nail or drill bit to probe through

the valve slot hole to clear away the obstruction.

Figure 2 - Open Vent Mode

Lid UndersideLid Top

Gasket

Channel

Channel

Vent

Hole

Gasket shown

partially removed

Channel

Vent Hole

(Do Not Probe)

O

D/F

Valve in Open Position

Valve slot

hole can be

probed to

clean.

Drip Free Mode "D/F" - To operate in the drip free mode, rotate the

valve with a screwdriver or coin so that the hole in the valve slot is

aligned with the "D/F" on the lid. See Figure 3.

Do not probe through the valve slot hole while the valve

is in D/F position. These holes are sealed by lid gasket and

damage could result. See Figs. 2 & 3.

Valve Movement

Do not forcibly rotate the valve. If it will not move freely, soak in

solvent or remove the lid assembly from the cup and press down on

the top of the valve until it breaks free. The valve has free travel

vertically of about 1/8". This can be used to push out the lid gasket.

Figure 3 - Drip Free Mode

Lid Top

Valve slot

hole sealed (Do Not Probe)

Channel

Vent Hole

(Do Not Probe)

D/F

O

Valve in Drip Free Position

INSTALLATION

1. Position yoke at right angle to gun body with vent hole in lid

toward rear and lever of cam (26) toward front of gun.

2. Fasten cup lid assembly to gun by attaching nut (25), see

Figure 5, to fluid inlet nipple on gun. Tighten nut with wrench

only until snug.

3. Strain material to be sprayed through a 60-90 mesh screen

before pouring into cup.

4. Engage pins on cup into yoke and tighten yoke by moving

lever of cam clockwise.

MAINTENANCE

Lid Repair/Replacement:

1. To replace a damaged part, use a 5/16" Allen wrench to loosen

and remove adapter (24), nut (25)and yoke and cam (26). Lid

and tube assembly are now loose for replacement.

2. Replace damaged parts on the lid and tube assembly. The cam

lever should be located on opposite side of lid from valve (27).

Lid Underside

Gasket shown

partially removed

SB-2-601-C Page 3

3. Apply sealant (Loctite #262) to the first two full threads of

adapter. Insert threaded end of adapter (24) into open end of

nut (25).

4. Install adapter (24) and nut (25) in top of lid and tube assembly.

Use a 5/16" Allen wrench to tighten firmly (10-12 foot pounds).

Valve and Lid Gasket Replacement:

1. To remove a damaged valve (27) or lid gasket (28), press down

on top of valve until it breaks free.The valve pushes the lid

gasket from the seat. The lid gasket may now be removed from

the lid. Continue pressing hard on the valve to remove it from

the lid.

2. Install replacement valve (27) through bottom of lid so that the

valve tab is toward center of lid. Snap in place. If necessary,

use a plastic mallet or screwdriver handle to tap the valve in

place. Press the lid gasket (28) firmly in the lid using the end of

a crescent wrench handle. Insert the side with the black marks

first.

CLEANING

General: For routine cleaning, it is not necessary to remove the lid

gasket. It is not necessary or desirable to remove the valve for any

cleaning procedure. The valve can be depressed from the outside

to assist in removal of the gasket for gasket replacement or when

cleaning dried paint from the channel. The valve should not be

forced past the shoulder which retains it in the lid except for

replacement.

The cam and mating surfaces on the lid and yoke normally don't

require removal for cleaning. Spraying some materials containing

PTFE® or similar materials can necessitate more frequent cleaning

and possible disassembly of the cam. The ovespray containing

PTFE® can build up on the cam and mating surfaces causing a

condition where the cam may loosen during use.

Note

Clean cam and mating surface on lid with a solvent soaked

Scotch™ pad and blow dry. If cam loosening persists,

removal of the yoke and cam will be required for more

thorough cleaning of these parts. Again, use a solvent

soaked Scotch™ pad for this purpose. Reassemble lid.

Air Pressure: Always clean with reduced air pressure. An air

pressure no greater than 15 to 20 psi will allow quick and thorough

cleaning of the cup and gun and at the same time will:

1. Minimize the amount of solvent atomized into the air.

2. Prevent possibility of damage to cup from excessive back

pressure.

3. Reduce the force with which solvent is expelled from the vent.

Cleaning Procedures:

1. Empty paint from cup and add small amount of clean solvent.

The amount required will vary with different coatings and

solvents.

2. Shake cup to wash down inside surfaces. Then spray solvent

at low air pressure (15-20 psi) to flush out fluid passages.

3. Pour out solvent and add same amount of clean solvent.

4a. Again, shake cup. Loosen air cap. Hold a folded cloth over

front of gun and invert cup over solvent receptacle. Trigger

with short bursts to back flush vent channel. With valve in the

D/F position, solvent will be expelled with force from the

channel vent hole in lid.

Alternative to Step 4a.

4b. Shut off air to gun. With valve in the D/F position, invert cup

over solvent receptacle. Trigger gun. Allow solvent to drip out

channel vent hole in lid for several seconds, or until clean

solvent is seen.

IMMERSION

Since all materials in the cup are highly solvent resistant, the cup

assembly may be immersed for cleaning. Immersion should not

exceed 24 hours. The use of paint strippers should be avoided

because strippers will affect the aluminum as well as other nonmetallic components. If the lid gasket has become swollen from

prolonged exposure to solvents, it will return to its original size

without loss of properties when allowed to dry.

Page 4

Page 4 SB-2-601-C

Figure 4 Gun Drawing

21

13

15

14

6

16

11

18

17

12

3

1

2

Use Fluid Tip Tool, hand tight.

• 9

4

5

22

8

7

10

PARTS LIST

Ref. Computer Replacement Ind. Parts

No. Part No. Part No. Description Required

1 690002 FLG-101-K2 Retaining Ring (Kit of 2) 1

2 --- See Chart 1 Air Cap 1

3 --- See Chart 1 Fluid Tip, Seal and Tip Tool 1

*4 690015 FLG-4-1-K5 Fluid Tip Seal (Kit of 5) 1

5 690007 FLG-105 Baffle 1

6 690011 FLG-431 Fluid Needle 1

*7 690012 FLG-440-K5 Packing Kit (includes 1 packing nut 1

*8 --- --- Packing Nut 1

9 192109 JGA-4035-K5 Packing Kit (Kit of 15) 1

10 519132 FLG-412 Trigger 1

*11 519029 FLG-8-K2 Trigger Stud Kit (Kit of 2) 1

*12 --- --- C-clip 2

13 690010 FLG-416 Spreader Adjustment Valve 1

*14 --- --- Spring 1

15 690008 FLG-109-K2 Needle Adjusting Screw (Kit of 2) 1

*16 690009 FLG-111-K2 Fluid Tip Tool (Kit of 2) 1

*17 --- --- Air Valve Stem and Seal 1

*18 --- --- Air Valve Spring 1

*19 --- --- Air Valve Cap Body 1

*20 --- --- Air Valve Cap 1

21 --- --- Gun Hook 1

22 519054 FLG-40 Air Inlet Adapter 1

23 519134 FLG-414 Air Valve Service Kit 1

+24 --- --- Adapter, 1/2" NPS (M) 1

+25 --- --- Nut, 3/8" NPS (F) 1

+26 --- --- Cam 1

+27 190924 TGC-407-1-K3 Drip Free Valve & Gasket (Kit of 3) 1

+28 190391 TGC-9-K5 **Tri Seal® Lid Gasket (Kit of 5) 1

29 190381 TGC-404 Lid Assembly (Quart) 1

30 190221 KR-428-2 Suction Cup Assembly (Quart) 1

31 120011 TGC-545 Suction Cup Assembly (includes

and 5 packing sets)

Ref. Nos. 24-30)

20

19

23

Apply sealant to

first two threads

Yoke

(Loctite #262).

Figure 5 - Cup Drawing

• (Ref. No. 9) Neede Packing Assembly. Detailed 3-piece drawing.

24

27

28

26

25

29

31

30

* A quantity of necessary parts is included in Repair Kit FLG-480 (Computer No. 690013)

for complete gun repair and should be kept on hand for service convenience.

+ KK-5007 Repair Kit includes Ref. Nos. 24-28. Repair kit contains enough parts to repair

one complete assembly.

Page 5

SB-2-601-C Page 5

Chart 1 For Model Numbers FLG-513, FLG-606 and FLG-626 Spray Guns

Spray Gun Spray Gun No. on Ref. No. 2 Ref. No. 3 Fluid

Model Computer Air Air Cap Fluid Tip Tip

Number Number Cap Part No. Computer No. Part No. Computer No. Size

FLG-513-316 611104 3 FLG-1-3 690001 FLG-102-16K 690004 1.6 (Std.)

FLG-606-116 611100 1 FLG-1-1 690000 FLG-102-16K 690004 1.6 (Std.)

FLG-626-322 611102 3 FLG-1-3 690001 FLG-102-22K 690006 2.2 (Std.)

Optional tips for FLG guns available as service parts only.

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy top or

bottom pattern

Heavy right or left

side pattern

Horn holes plugged.

Obstruction on top or bottom of fluid tip.

Cap and/or tip seat dirty.

Left or right side horn holes plugged.

Dirt on left or right side of fluid tip.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap. Clean the air cap as previously instructed.

2. If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the fluid

tip. Remove with #600 wet or dry sand paper.

3. Check for dried paint just inside the opening; remove by washing with solvent.

FLG-102-18K 690005 1.8 (Std.)

FLG-102-14K 690003 1.4 (Opt.)

Clean. Ream with non-metallic point.

Clean.

Clean.

Clean. Ream with non-metallic point.

Clean.

Heavy center pattern

Split spray pattern

Jerky or fluttering spray

Unable to get round spray

Will not spray

Starved spray pattern

Excessive overspray

Excessive fog

Dry spray

*Most common problem.

Fluid flow too high for atomization air

(pressure feed).

Material flow exceeds air cap's capacity.

Spreader adjustment valve set too low.

Atomizing pressure too low.

Material too thick.

Fluid adjusting knob turned in too far.

Atomization air pressure too high.

Fluid pressure too low (pressure feed only).

Spreader adjusting valve set too high.

*Loose or damaged fluid tip/seat.

Material level too low.

Container tipped too far.

Obstruction in fluid passage.

Loose or broken fluid tube or fluid inlet nipple.

Dry or loose fluid needle packing nut.

Fan adjustment screw not seating properly.

Air cap retaining ring loose.

No air pressure at gun.

Internal mix or pressure feed air cap and tip

used with suction feed.

Fluid pressure too low.

Fluid needle adjusting screw not open enough.

Fluid too heavy for gravity feed.

Inadequate material flow.

Low atomization air pressure.

Too much atomization air pressure.

Gun too far from work surface.

Improper stroking (arcing, gun motion too

fast).

Too much or too fast-drying thinner.

Too much atomization air pressure.

Air pressure too high.

Gun tip too far from work surface.

Gun motion too fast.

Gun out of adjustment.

Balance air pressure and fluid pressure.

Increase spray pattern width with spreader

adjustment valve.

Thin or lower fluid flow.

Adjust.

Increase pressure.

Thin to proper consistency.

Back out counterclockwise to achieve

proper flow.

Reduce at transformer or gun.

Increase fluid pressure (increases gun

handling speed).

Adjust.

Tighten or replace.

Refill.

Hold more upright.

Backflush with solvent.

Tighten or replace

Lubricate or tighten.

Clean or replace.

Tighten.

Check air supply and air lines.

Change to proper suction feed air cap and tip.

Increase fluid presssure at tank.

Open fluid needle adjusting screw.

Thin material and/or change to larger tip size.

Back fluid adjusting screw out to first thread, or

increase fluid pressure at tank, or change to

larger tip size.

Increase air pressure and rebalance gun.

Reduce pressure.

Adjust to proper distance.

Move at moderate pace, parallel to work surface.

Remix properly.

Reduce pressure.

Decrease air pressure.

Adjust to proper distance.

Slow down.

Adjust.

Page 6

Page 6 SB-2-601-C

TROUBLESHOOTING (continued)

CONDITION CAUSE CORRECTION

Fluid leaking from packing nut Packing nut loose. Tighten, do not bind needle.

Fluid leaking or dripping from Packing nut too tight. Adjust

front of gun

Runs and sags Too much material flow. Adjust gun or reduce fluid pressure.

Thin, sandy coarse finish Gun too far from surface. Check distance. Normally 6-8".

drying before it flows out

Thick, dimpled finish "orange Gun too close to surface. Check distance. Normally 6-8".

peel". Too much material coarsely atomized. Turn in fluid adjusting screw or reduce fluid

Packing worn or dry. Replace or lubricate.

Dry packing. Lubricate.

Fluid tip or needle worn or damaged. Replace tip & needle.

Foreign matter in tip. Clean.

Fluid needle spring broken. Replace.

Wrong size needle or tip. Replace.

Material to thin. Mix properly or apply light coats.

Gun tilted on an angle or gun motion too slow. Hold gun at right angle to work and adapt to

proper gun technique

Too much air pressure. Reduce air pressure and check spray pattern.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

pressure or change to a smaller tip size.

Air pressure too low. Increase air pressure or reduce fluid pressure.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

Material not properly mixed. Follow paint manufacturer's mixing instructions.

Surface rough, oily, dirty. Properly clean and prepare.

ACCESSORIES

TGC-545 Aluminum

TLC-555 (PTFE Lined)

Drip Free Suction Cups

Cups have a unique, two

position valve which permits

selection of either a drip free or

conventional open vent mode.

®

Scrubs

Hand Cleaner Towels

192218 ( Automotive Refinish)

29-3100 ( Industrial Finishing)

Scrubs® are a pre-moistened

hand cleaner towel for painters. No water is needed.

MSP-524 Twin Cartridge,

Paint Spray Respirator

192212

Professional Spray

Gun Cleaning Kit

Contains 6 precision

tools to effectively

clean DeVilbiss, Binks,

Finishline and other

brand spray guns

WR-103 Wrench

Contains all necessary tip,

hose and nut sizes used on or

with gun.

HAF-507 Whirlwind™

In-Line Air Filter

Removes water, oil, and

debris from the air line.

NIOSH-Certified

(TC-84A-1623) for respiratory protection in atmospheres not immediately

dangerous to life.

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

HAV-500 OR

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

HAV-500 does not have

pressure gauge. Use to

control air usage at gun.

FLG-463

Air Cap Test Kit

(#3 Air Cap)

The purpose of this

test kit is to measure

air cap atomizing air

pressure at the

center air port of the

air cap. Used to

confirm code

compliance and as a

daily quality control

measure.

Spray Gun Lube

SSL-10

(2 oz. bottle)

Compatible with all

paint materials; contains no silicone or

petroleum distillates

to contaminate paint.

MSDS available upon

request.

Automotive Quick Connects

For HVLP Guns (Air)

High Flow Type.

HC-4719

HC-4419 Stem

1/4" NPT(F)

HC-1166 Stem

1/4" NPT(M)

Industrial Quick Connects

Approved for HVLP Guns (Air)

High Flow Ball and Ring Type

HC-4419 1/4"

NPS(F)

HC-4700

1/4" NPT(F)

Coupler

1/4" NPT(M) /

NPS(M)

HC-4720 Coupler

1/4" NPT(F)

HC-4699

1/4" NPT(M)

HC-1166

1/4" NPT(M)

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

Automotive Refinishing

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S./Canada Customer Service Office:

1724 Indian Wood Circle, Suite J-K, Maumee, OH 43537

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

5/04 ©2004 Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...