DeVilbiss FA153, FAC153 Owner's Manual

OWNERS MANUAL FOR

PERMANENTLY LUBRICATED AIR COMPRESSOR

(For Home Use Only)

MODEL NO.

FA153

FAC153

SPECIFICATION CHART

MODEL NO.

Horsepower

SCFM @ 40 psig

SCFM @ 90 psig

Cut-In

Cut-Out

Bore

Stroke

Voltage/Hertz/ Phase

Minimum Branch Circuit

Requirement

*Fuse Type

Amperage at Max. Load

Tank Size

*A circuit breaker is preferred. Use only a fuse or

circuit breaker that is the same rating as the branch

circuit the air compressor is operated on. If the air

compressor is connected to a circuit protected by

fuses, use quick acting fuses.

FA153

1.5

4.0

2.9

100 PSI

125 PSI

1 7/8"

1 1/4"

120/60/1

15 AMPS

Quick Acting

10 AMPS

3 Gallon

FAC153

100 PSI

125 PSI

1 7/8"

1 1/4"

120/60/1

15 AMPS

Quick Acting

10 AMPS

3 Gallon

-----

4.0

2.9

TABLE OF CONTENTS

SAFETY GUIDELINES ....................................................... 1

WARRANTY ....................................................................... 2

WARNING CHART ......................................................... 3-4

GLOSSARY ........................................................................ 5

DUTY CYCLE ..................................................................... 5

STORAGE ...........................................................................5

DESCRIPTION OF OPERATION .......................................6

INSTALLATION AND BREAK-IN

PROCEDURES .............................................................. 6-7

Location of Air Compressor ........................................ 6

Extension Cords .......................................................... 6

Voltage and Circuit Protection ..................................... 6

Grounding Instructions ............................................... 7

Additional Regulators and Controls ............................ 7

Break-In Procedures .................................................... 7

OPERATING PROCEDURES ............................................ 8

TROUBLESHOOTING GUIDE ..................................... 9-10

COMPRESSOR PARTS LIST .......................................... 11

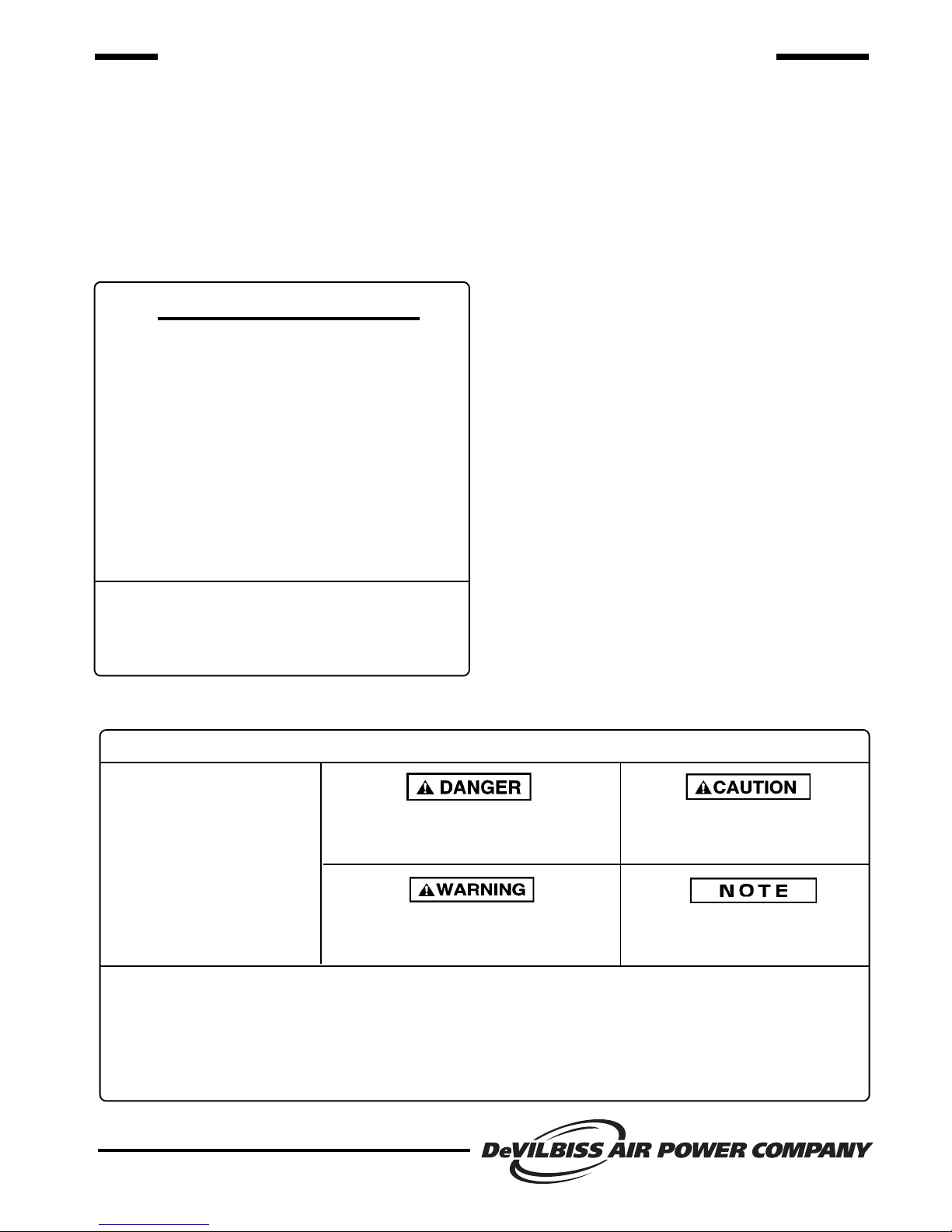

SAFETY GUIDELINES - DEFINITIONS

This manual contains information

that is important for you to know

and understand. This information

relates to protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this information, we use the symbols to the

right. Please read the manual and

pay attention to these sections.

Call our Toll Free Number 1-800-888-2468, Ext 2, then 1, to obtain the location of the nearest Authorized Service

Center for ordering repair parts and for warranty repairs.

When ordering repair parts from your local Authorized Service Center, always give the following information:

• Model number of your compressor

• Part number and description of the item you wish to purchase

MGP-FA153A 10/1/97

URGENT SAFETY INFORMATION - A HAZARD

THAT WILL CAUSE SERIOUS INJURY OR LOSS

OF LIFE.

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

Information for preventing damage to

equipment.

Information that you should pay

special attention to.

LIMITED WARRANTY

ONE YEAR FROM DATE OF PURCHASE

All merchandise manufactured by DeVilbiss Air Power Company is warranted to be free of defects in workmanship

and material which occur during the first year from the date of purchase by the original purchaser (initial user). Products

covered under this warranty include: air compressors, *air tools, accessories, service parts, pressure washers, and

generators used in consumer applications (i.e., personal residential household usage only).

Air compressors, *air tools, accessories, service parts, pressure washers, and generators used in commercial

applications (income producing) are covered by a 90 day warranty.

DeVilbiss Air Power will repair or replace, at DeVilbiss's option, products or components which have failed within the

warranty period. Repair or replacement, and service calls on 60 and 80 gallon air compressors, will be handled by

Authorized Warranty Service Centers and will be scheduled and serviced according to the normal work flow and

business hours at the service center location, and depending on the availability of replacement parts.

All decisions of DeVilbiss Air Power Company with regard to this policy shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (Initial User):

❏ Retain original cash register sales receipt as proof of purchase for warranty work.

❏ Use reasonable care in the operation and maintenance of the product as described in the Owners Manual(s).

❏ Deliver or ship the product to the nearest DeVilbiss Air Power Authorized Warranty Service Center.

Freight costs, if any, must be paid by the purchaser.

❏ Air compressors with 60 and 80 gallon tanks only will be inspected at the site of installation. Contact the nearest

Authorized Warranty Service Center, that provides on-site service calls, for service call arrangement.

❏ If the purchaser does not receive satisfactory results from the Authorized Warranty Service Center, the purchaser

should contact DeVilbiss Air Power Company.

THIS WARRANTY DOES NOT COVER:

❏ Merchandise sold as reconditioned, floor models and/or display models. Any damaged or incomplete equipment

sold "as is".

❏ Merchandise used as "rental" equipment.

❏ Merchandise that has become inoperative because of ordinary wear, misuse, freeze damage, use of improper

chemicals, negligence, accident, improper and/or unauthorized repair or alterations including failure to operate

the product in accordance with the instructions provided in the Owners Manual (s) supplied with the product.

*Air Tools: O-Rings and driver blades are considered ordinary wear parts, therefore, they are warranted for a

period of 45 days from the date of purchase.

❏ An air compressor that pumps air more than 50% during a one hour period is considered misuse because

the air compressor is undersized for the required air demand. Maximum compressor pumping time per hour is

30 minutes.

❏ Merchandise sold by DeVilbiss Air Power which has been manufactured by and identified as the product of

another company. The product manufacturer's warranty will apply.

❏ Repair and transportation costs of merchandise determined not to be defective.

❏ Cost associated with assembly, required oil, adjustments or other installation and start-up cost.

❏ ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM

ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT. Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

❏ IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615 • Telephone: 1-800-888-2468 , Ext. 2 • FAX: 1-800-888-9036

DeVilbiss Air Power Company

Form: SP-100-E - 4/25/96

2 - ENG

IMPORTANT SAFETY INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS

INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING

INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

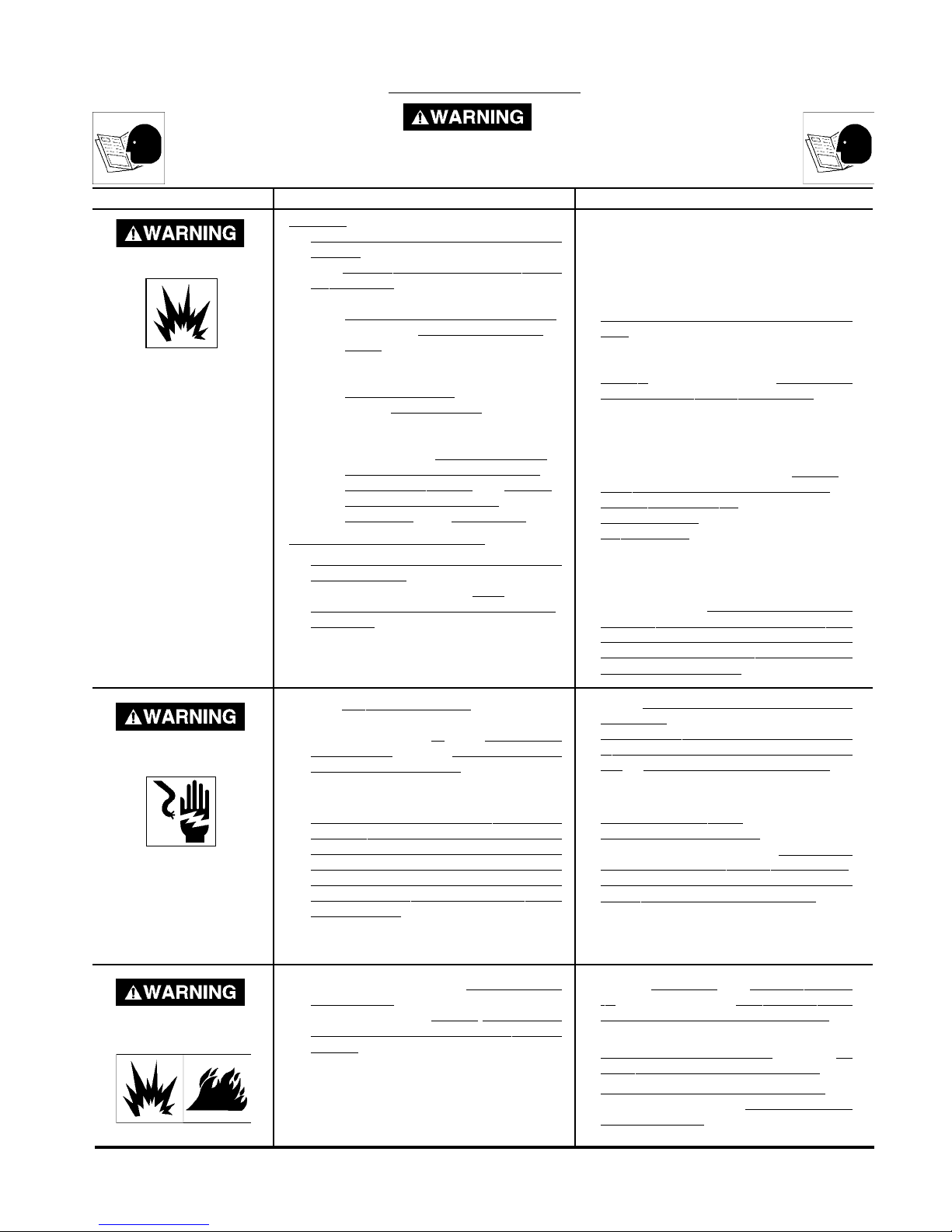

HAZARD

RISK OF BURSTING

• SAVE THESE INSTRUCTIONS •

WHAT CAN HAPPEN HOW TO PREVENT IT

Air Tank

•

THE FOLLOWING CONDITIONS

COULD lead to a weakening of the tank,

and

RESULT IN A VIOLENT TANK

EXPLOSION:

FAILURE TO PROPERLY DRAIN

1.

condensed

TANK, causing rust and thinning of

the tank steel.

MODIFICATIONS or attempted

2.

repairs

3. Unauthorized

TO THE PRESSURE SWITCH,

SAFETY VALVE, OR any OTHER

COMPONENTS WHICH

CONTROL tank PRESSURE.

Attachments and Accessories

•

EXCEEDING THE PRESSURE RATING

OF AIR TOOLS, spray guns, air operated

accessories, tires

INFLATABLES CAN CAUSE THEM TO

EXPLODE or fly apart, and could result in

serious injury.

WATER FROM THE

TO THE TANK.

MODIFICATIONS

AND other

•

DRAIN TANK DAILY OR AFTER EACH

USE. If tank develops a leak, replace it

immediately with a new tank or new

compressor outfit.

•

NEVER drill into, weld, or MAKE ANY

MODIFICATIONS TO THE TANK or its

attachments. Never attempt to repair a

damaged or leaking tank. Replace with

a new tank.

• The tank is designed to withstand

specific operating pressures.

MAKE ADJUSTMENTS OR PARTS

SUBSTITUTIONS TO alter the

FACTORY SET operating

PRESSURES.

• Follow the equipment manufacturers

recommendation and never exceed the

maximum allowable pressure rating of

attachments.

COMPRESSOR TO INFLATE SMALL

LOW -PRESSURE OBJECTS SUC H

AS CHILDREN’S TOYS, FOOTBALLS,

BASKETBALLS, ETC.

NEVER USE THE

NEVER

RISK OF ELECTRIC

SHOCK

RISK OF EXPLOSION OR

FIRE

•Your

•

•It is normal for

AIR COMPRESSOR is powered by

electricity. Like any other electrically

powered device,

PROPERLY it MAY CAU SE

ELECTRICAL SHOCK.

ELECTRICAL GROUNDING: FAILURE

TO PROVIDE ADEQUATE GROUNDING TO THIS PRODUCT COULD

RESULT IN SERIOUS IN JURY OR

DEATH FROM ELECTROCUTION.

SEE GROUNDING INSTRUCTIONS IF

APPLICABLE.

CON TACTS within the motor and

pressure switch to

THE COMPRESSOR STARTS OR

STOPS.

IF it is NOT USED

ELECTRICAL

SPARK WHENEVER

•Any

•

• Never operate the compressor outdoors

•Always

• If spraying flammable materials,

•

ELECTRICAL WIRING OR

REPAIRS required to this product

SHOULD BE PERFORMED BY

QUALIFIED SE RVICE PERSONNEL

OR a LICENSED ELECTRICIAN, in

accordance with national and local

electrical codes.

MAKE CERTA IN that the

ELECTRICAL CIRCUIT to which the

compressor is connected

PROPER ELECTRICAL GROUNDING,

CORRECT VOLTAGE , AND

ADEQUATE FUSE PROTECTION.

when it is raining.

OPERATE the COMPRESSOR

IN a well ventilated AREA FREE OF

GASOLINE OR SOLVENT VAPORS.

LOCATE COMPRESSOR at least 20

FEET AWAY FROM SPRAY AREA.

STORE FLAMMABLE MATERIALS in a

secure location

COMPRESSOR.

PROVIDES

AWAY FROM

3 - ENG

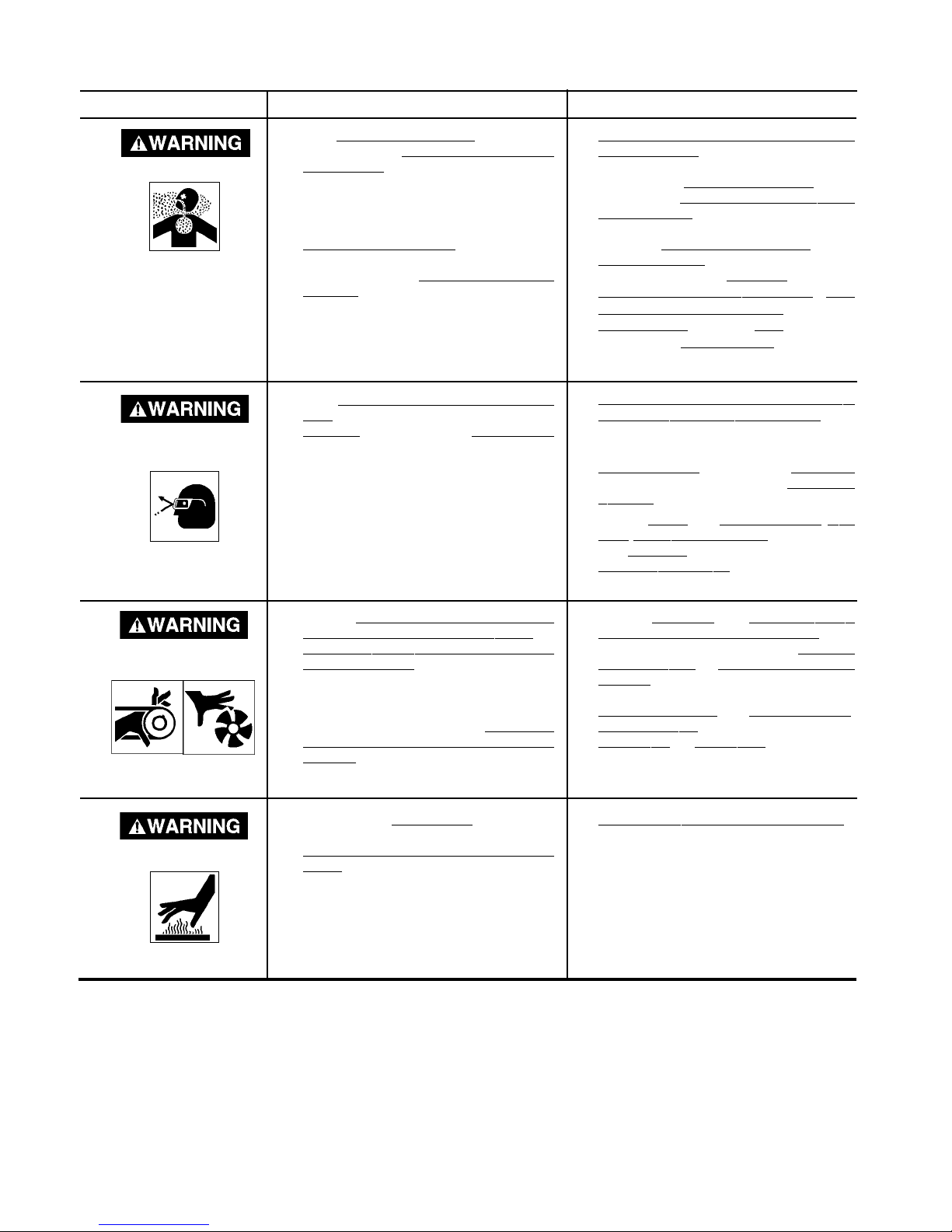

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

HAZARD

RISK TO BREATHING

RISK FROM FLYING

OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• The COMPRESSED AIR from your

compressor

BREATHING! The air stream may contain

carbon monoxide or other toxic vapors,

or particles from the tank or other

components.

•

SPRAYED MATERIALS such as paint,

paint solvents, paint remover, insecticides,

weed killers, etc.,

VAPORS and poisons.

•The

COMPRESSED AIR STREAM

CAN cause soft tissue damage, and can

PROPEL dirt, chips, loose PARTICLES

and small objects at high speed,

resulting in property damage or

personal injury.

IS NOT SAFE FOR

CONTAIN HARMFUL

•

NEVER INHALE AIR FROM THE

COMPRESSOR, either directly or from a

breathing device connected to the

compressor.

equipped

VENTILATION.

• Read and

INSTRUCTIONS provided on the label

or safety data sheet

MATERIAL YOU ARE SPRAYING. USE

WORK IN AN AREA

WITH GOO D CROSS-

FOLLOW THE SAFETY

FOR THE

A NIOSH/MSHA APPROVED

RESPIRATOR designed FOR use with

your specific APPLICATION.

• ALWAYS WEAR ANSI Z87.1

APPROVED SAFETY GLA SSES with

side shields when using the

compressor.

•

NEVER POINT any nozzle or SPRAYER

toward any part of the body or

PEOPLE or animals.

•Always

AND BLEED PRESSURE from the air

line

ATTACHING TOOLS or accessories.

TURN the COMPRESSOR OFF

BEFORE attempting maintenance,

AT OTHER

RISK FROM MOVING

PARTS

RISK OF BURN

PCOM1096

•The

AUT OMATIC ALLY WHEN the

PRESSURE SWITCH IS IN THE ON/

AUTO POSITION! If you attempt repair

or maintenance while the compressor is

operating, or with the switch in the ON/

AUTO position, you can expose yourself

to moving parts. These

PARTS CAN C AUSE SERIOUS

INJURY or damage if they come into

contact with you or your clothing.

•Contact with

compressor head or outlet tubes

COULD RESULT IN A SERIOUS SKIN

BURN.

COMPRESSOR CYCLES

M OVING

HOT PARTS such as the

•Always

AND RELEASE AIR PRESSURE from

the tank and any attachments

ATTEMPTING any MAINTENANCE OR

REPAIR.

NEVER OPERATE the COMPRESSOR

•

WITH GUARDS or covers which are

DAMAGED or REMOVED.

•

NEVER TOUCH HOT COMPONENTS

during or immediately after operation of

the compressor. Do not reach around

protective shrouds or attempt

maintenance until unit has been allowed

to cool.

UNPLUG the COMPRE SSOR

BEFORE

4 - ENG

Loading...

Loading...