DeVilbiss EGA-503 Service Manual

SERVICE MANUAL

*Repair Kit No. KK-5044

(190681)

EGA-503 SPRAY GUN

(SPRAY PISTOL)

Important: Before using this equipment,

read all safety precautions and instructions.

Keep for future use.

DESCRIPTION

The EGA-503 is an external mix, touch-up

gun. The gun has a long needle taper making detail work easy. The forefinger trigger

gives added control for delicate application. Can be used for touch-up, shading,

edging or any type of precision painting.

Use as either suction or pressure feed

application.

Note

Wetted surfaces are stainless steel

and aluminum. Please see Warning on Page 2 regarding explosion

hazard.

SPECIFICATIONS

Air Inlet: 1/4" NPS (M)

Fluid Inlet: 1/4" NPS (M)

Type Feed: Suction or Pressure

Wetted Parts: Aluminum & Stainless Steel

P1 = Maximum Air Pressure 100 PSI (7 bar)

P2 = Maximum Fluid Pressure 10 PSI (.68 bar)

OPERATION

Prepare and strain material according to the

paint manufacturer's instructions. Attach

container to fluid inlet and tighten. Adjust

incoming air pressure to gun to achieve

desired spray results.

Note

To minimize overspray, only use as

much pressure as required to atomize material.

PREVENTIVE MAINTENANCE

To clean fluid passages, remove excess

material at source, then flush with a suitable solvent.

To clean air cap and fluid tip, brush with a

stiff bristle brush. If necessary, use a broom

straw or toothpick. Never use a wire or hard

instrument. This may scratch or burr holes

causing a distorted spray pattern.

Note

Worn parts can cause fluid leakage.

When replacing fluid tip or fluid

needle, replace both at the same

time. Lapped sets are available.

Also replace the fluid tip gasket and

needle packing at this time.

To prevent damage to the fluid tip or

fluid needle, be sure to either 1) push

the trigger and hold while tightening

the fluid tip or 2) remove the fluid

needle adjusting screw to relieve

spring pressure.

*Government NSN No. 4940-01-182-6975

= KK-5044

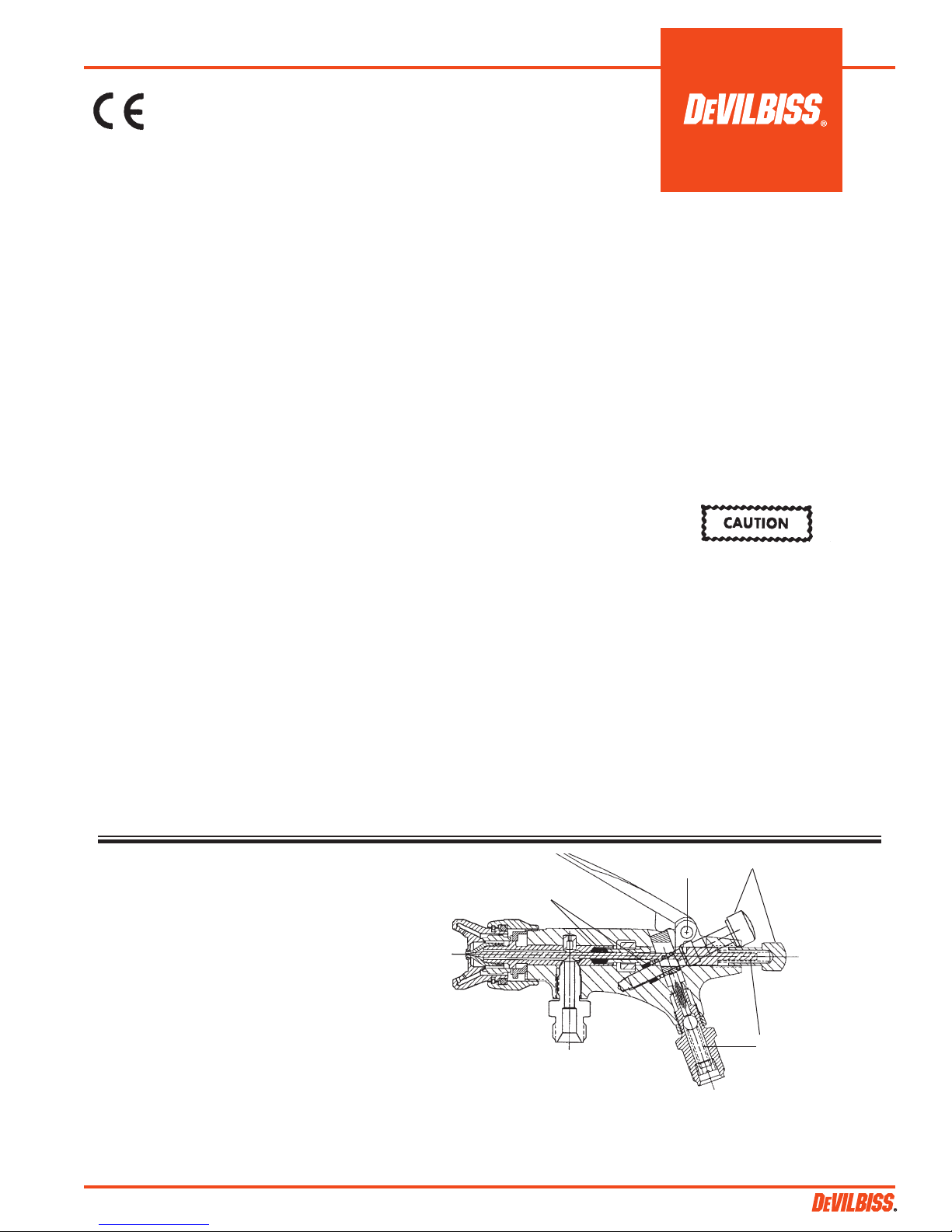

LUBRICATION

For best results, lubricate the points indicated in Figure 1 daily using Gun Lube

SSL-10.

A. Trigger points

B. Packings

C. Adjusting valves

D. Needle/Air valve springs

(occasionally)

SB-2-163-M (11/2014) 1 / 8

Figure 1

A

B

C

D

SAFETY PRECAUTIONS

This manual contains information that is important for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

NOTE

Important safety information – a hazard

that may cause serious injury or loss of

life.

Important information that tells how to prevent damage to equipment, or how to avoid

a situation that may cause minor injury.

CA PROP

Information that you should pay special

attention to.

65

PROP 65 WARNING

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

The following hazards may occur during the normal use of this equipment. Please read the following chart.

CAUSE SAFEGUARDSHAZARD

Fire

Solvents and coatings can be highly

flammable or combustible, especially

when sprayed.

1. Adequate exhaust must be provided to keep the

air free of accumulations of flammable vapors.

2. Smoking must never be allowed in the spray area.

3. Fire extinguishing equipment must be present in

the spray area.

4. Static discharges must be prevented. Ground

(earth) all conductive objects in the spray

area, such as a cleaning solvent bucket, fire

extinguisher, etc.

5. When using solvents for cleaning:

• Those used for equipment flushing must have

a flash point equal to or higher than that of the

coating.

• Those used for general cleaning must

have flash points above 100°F (37.8°C).

Inhaling Toxic Substances

Explosion Hazard –

Incompatible Materials

Certain materials may be harmful if

inhaled or if there is contact with the

skin.

Halogenated hydrocarbon solvents,

for example" methylene chloride and

1, 1, 1, - Trichloroethane, are not

chemically compatible with the

aluminum that might be used in many

system components. The chemical

reaction caused by these solvents

reacting with aluminum can become

violent and lead to an equipment

explosion.

1. Follow the requirements of the Material

Safety Data Sheet supplied by your coating

manufacturer.

2. Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

3. Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration.

This spray gun (spray pistol) has aluminum

passages and cannot be used with these solvents.

Aluminum is also widely used in other spray

application equipment – such as material pumps,

regulators, valves, etc. Check all other equipment

items before use. Read the label or data sheet for

the material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is

compatible, contact your material supplier.

SB-2-163-M (11/2014)2 / 8

SAFETY PRECAUTIONS (Continued)

CAUSE SAFEGUARDSHAZARD

General Safety

Solvent Spray

Misuse:

• All spray guns (spray pistols) project particles at high velocity and must never be aimed at any part of the body.

• Never exceed the recommended safe working pressures for any of the equipment used.

• The use of non-recommended or non-original accessories or spare parts may create hazardous conditions.

• Before dismantling the equipment for cleaning or maintenance, all pressures, air and fluid, must be isolated and released.

The disposal of waste materials must be carried out in an approved manner. Burning may generate toxic fumes. The removal or

waste solvents and coating materials should be carried out by an authorized local waste disposal service.

Improper operation or maintenance of

equipment.

During cleaning and flushing, solvents

can be forcefully expelled from fluid

and air passages. Some solvents can

cause eye injury.

Operators should be given adequate training in

the safe use and maintenance of the equipment

(in accordance with the requirements of NFPA-33,

Chapter 15 in U.S.). Users must comply with all

local and national codes of practice and insurance

company requirements governing ventilation,

fire precautions, operation, maintenance and

housekeeping (in the U.S., these are OSHA Sections

1910.94 and 1910.107 and NFPA-33).

Wear eye protection.

SB-2-163-M (11/2014) 3 / 8

Loading...

Loading...