Page 1

SB-E-3-150 iss. 5

Operation Manual

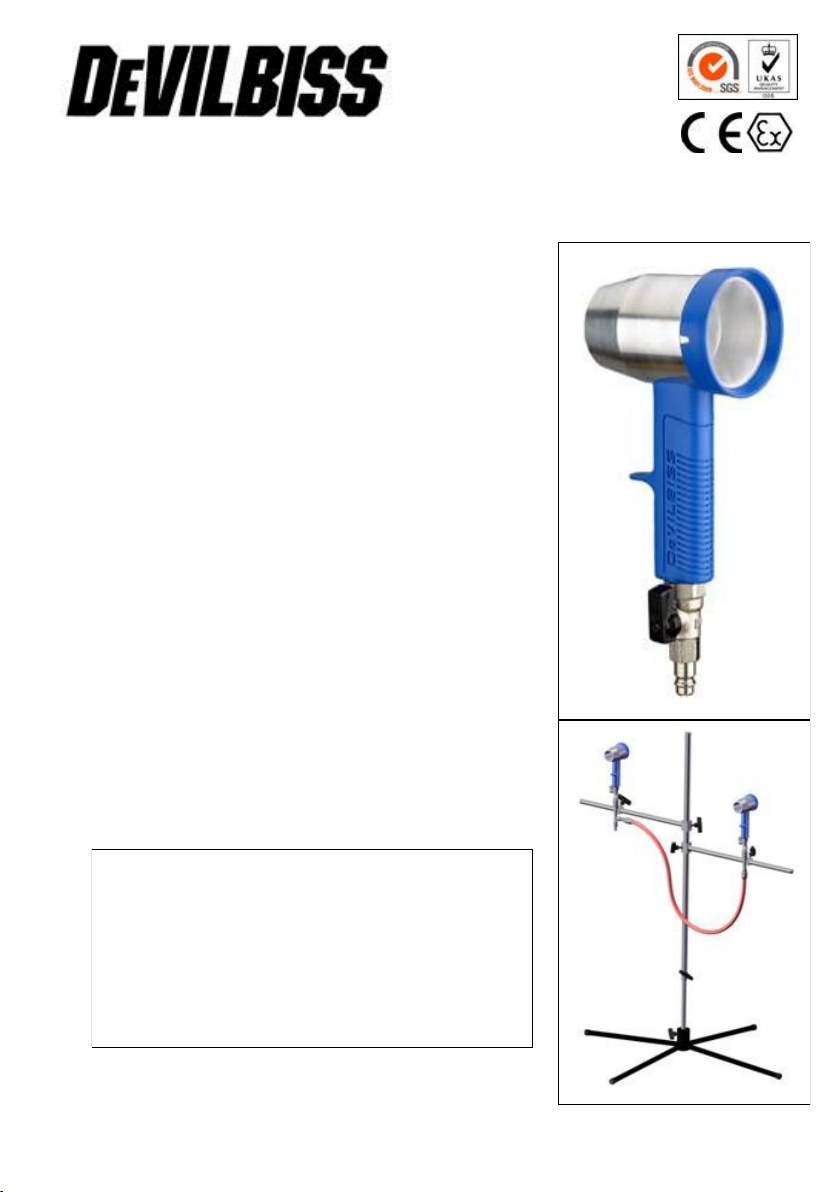

DMG-501 & 620– Waterbased Paint Dryer System

Important

Read and follow all instructions and Safety

Precautions before using this equipment

Description

The DMG-620 Dryer System consists of a stand

and 2 DMG-501 Dryer Guns (also available

separately). These products have been developed

for accelerated drying of waterbased paints, to

reduce drying times and increase productivity.

The Dryer uses the Coanda principle, amplifying

the airflow though the device from a low input of air

into the Handle. A replaceable filter is included to

trap any airborne debris from contaminating the

paint finish.

The DMG Air Dyer System complies to ATEX

regulations 94/9/EC, protection level; II 2 G X,

Suitable for use in Zones 1 and 2.

Product Specification

DMG-501 Dryer

Max inlet pressure 7 bar

Typical Air consumption 325 litre/min @

3.5 bar

DMG-520 Stand

Max inlet pressure 7 bar

Hose attachment by QD

1

© 2012 Finishing Brands UK Ltd.

Page 2

Static Electricity can be generated by air passing though hoses. To prevent such a

risk, earth continuity to the equipment and the object being sprayed should be

maintained. Use conductive hoses and recommended to attach an earth clamp to the

stand upright. Check earth continuity with an ohmmeter, Should be less than 1 MΩ.

Never exceed the max. recommended safe working pressure for the equipment.

Never aim the Dryer at anybody. It is recommended that eye protection is worn when

using this equipment.

The A-weighted sound level of this product may exceed 85 dB (A) depending on the

pressure/airflow being used. Details of actual noise levels are available on request. It

is recommended that ear protection is worn at all times when using this equipment.

Safety Warnings

Installation and Operation

Assembly

1. Fit 4 legs to base (3). Fit lower

stand upright into base and

tighten with thumbscrew. Fit

upper stand upright and tighten

with thumbscrew.

2. Fit thumbscrews to arms (6) and

slide both arms over upright.

Secure with thumbscrew to

required height.

3. Assemble clamp assembly 5A

and 5B as per the diagrams on

P3.

4. Slide clamp assemblies over the

arms (6) and secure with

thumbscrew.

5. Attach hose (7) to the 2 clamp

assemblies.

6. Insert the 2 dryers into the 2

QD’s.

7. Make sure the dryer ball valves

are turned off, then attach the air

supply hose to clamp 5A

8. The Air supply should be filtered,

dry and free from oil (as you

would supply to the spraygun).

The DeVilbiss range of DVFR

Filter/Regulators are

recommended for this.

Operation

1. Turn the Dryer Ball Valves to the

off position.

2. Turn on air supply. Turn on the

Dryer Ball Valves until the

required airflow is achieved. If

more air is required, increase the

pressure at the regulator.

Moving the stand

Grasp the stand and not the dryer

gun handles. This will prevent

accidentally disengaging the quickdisconnect if the system is

pressurised.

© 2012 Finishing Brands UK Ltd.

2

Page 3

Clamp Assemblies

Stand Assembly

Maintenance

The only maintenance required is to ensure the equipment is kept clean and free

from paint contamination.

Regularly check the filter. If the filter is blocked it will restrict the airflow and

reduce the drying effect. When contaminated, dispose of the filter and use a

new replacement. Filters are available in packs of 3, (Part No. DMG-5-K3).

3

© 2012 Finishing Brands UK Ltd.

Page 4

Spare Parts DMG-501-K Air Dryer

1 Filter pack of 3 DMG-5-K3 1

2 Male QD MPV-5 1

Spare Parts DMG-520-K Stand Assembly

3 Stand Base - 1

4 Stand upright 1

5 Clamp Assembly - 2

6 Extension Arm - 2

7 Hose assembly H-7501HA-1.2 1

8 Thumbscrew - 5

9 Female QD MPV-424 2

EC Declaration of Conformity

We: Finishing Brands UK Limited., Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as

the manufacturer of the DMG Air Dryer System, declare, under our sole responsibility, that the

equipment to which this document relates is in conformity with the following standards or other

normative documents:

EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and

Protective Systems intended for use in Potentially Explosive Atmospheres protection level II

2 G X.

D, Smith. General Manager

23rd April 2012

Finishing Brands UK Limited.

Ringwood Road,

Bournemouth,

BH11 9LH,

England.

Tel. No. (01202) 571111

Telefax No. (01202) 581940,

Website address http://www.finishingbrands.eu

Finishing Brands UK Limited., Reg. 400, Capability Green, Luton, Bedfordshire, LU1 3AE. UK

Registered in England: No 07656273 Vat No GB 113 5531 50

© 2012 Finishing Brands UK Ltd.

4

Loading...

Loading...