Page 1

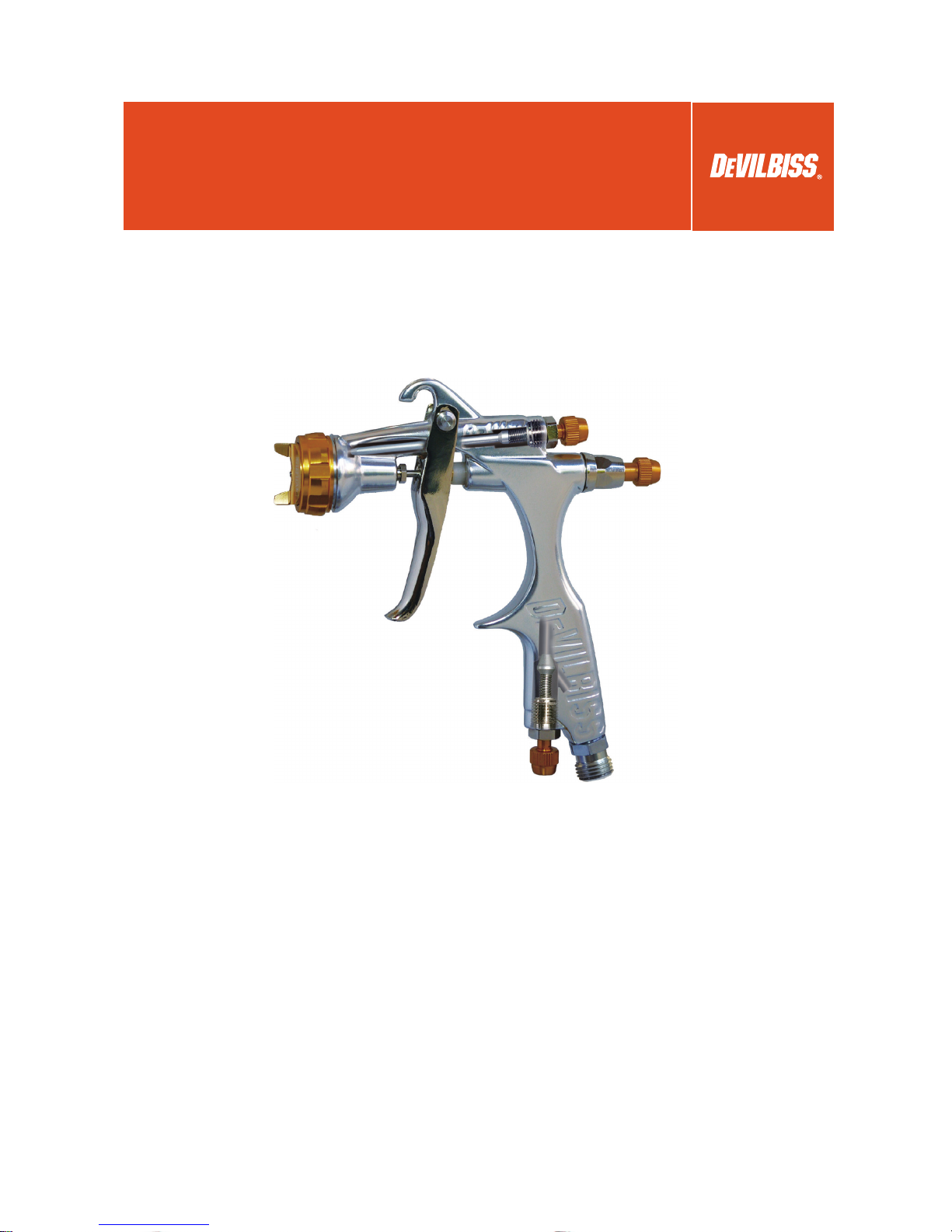

DEMI 2

Operation Manual

Read and follow all instructions and SAFETY PRECAUTIONS before

using this equipment.

Page 2

2

DEMI2

Table of Contents

MODELS ....................................................................................................... 3

SPECIFICATIONS ......................................................................................... 3

PARTS LIST .................................................................................................. 4

SAFETY PRECAUTIONS ............................................................................. 5

INSTALL ATI ON ............................................................................................. 6

OPER ATIO N ................................................................................................. 6

PREVENTIVE MAINTENANCE .................................................................... 6

REPLACEMENT OF PARTS ........................................................................ 7

SERVICE CHECKS ....................................................................................... 8

ACCESSORIES ............................................................................................. 9

Page 3

3

DEMI2

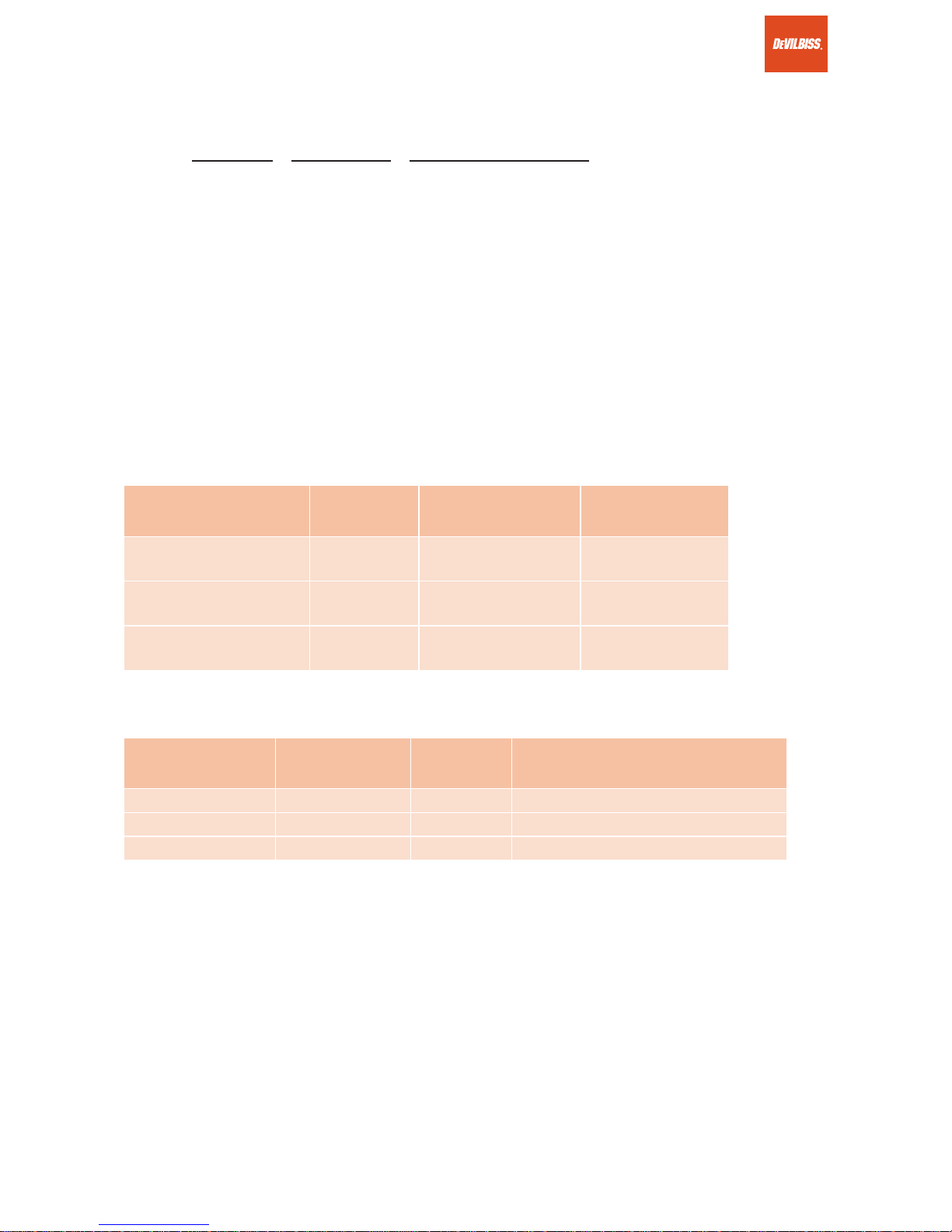

MODELS

DEMI2 – Air CapNo. – Fluid Tip Size – Type of Feed G : Gravity

(Ex.) : DEMI2-DL8-1.1-G ← (DL8 Air Cap - Size1.1mm - Gravity)

SPECIFICATIONS

Maximum Working Air Pressure: 0.69 MPa, Maximum Working Fluid Pressure: 0.69 MPa

Weight:190g

Fluid inlet : G1/4 Air inlet : G1/4

Chart. 1

Air Cap No.

Part Number

Type of Feed Air consumption Gun

inlet pressure

Pattern width (mm)

DL8

DM2-3-DL8

G

80

l

/

min

0.10 M Pa

140

DL6

DM2-3-DL6

G

60

l

/

min

0.10 M Pa

90

DR1

DM2-3- DR1

G

20

l

/

min

0.10 M Pa

Round

Chart. 2

Fluid Tip

Part Number

Needle

Part Number

Tip size

(mm)

Application

DM2- 4 -1.1 DM2- 41-1.1 1.1 Spot, Touch-up

DM2- 4-0.8 DM2- 41- 0.8 0.8 Spot, Touch-up

DM2-4-0.5 DM2-41-0.5 0.5 Deodorant, Hobby

Page 4

4

DEMI2

PARTS LIST

Chart 3

Ref.

No.

Part Number Description Qty

1 DM2-6 Retaining Ring Assy. 1

2 DM2-55-K5 Ring Seat Kit of 5 1

3 Refer to "Chart.1" Air Cap 1

4 Refer to "Chart.2" Fluid Tip 1

5 DM2-35 Paint Nipple(with Seat) 1

6 DM2- 44 Pattern Valve 1

7 DM2- 443 Air Seal Kit 1

8 DM2- 43 Air Valve 1

9 DM2-25-K5 Valve Spring Kit of 5 1

10 DM 2-12 Air Valve Bushing 1

11 Refer to "Chart.2" Needle 1

12 DM2-14-K5 Needle Spring Kit of 5 1

13 DM2-13 Needle Adjusting Knob 1

14 DM2-463 Needle Packing 1

15 DM2- 45 Bearing Stud Kit 1

16 DM 2-108 Trigger 1

17 DM2-42 Cheater Valve 1

18 DM2-30 Air Connector 1

Page 5

5

DEMI2

SAFETY PRECAUTIONS

This manual contains information that is important for you to know and understand. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. Read and

follow SAFETY PRECAUTIONS before using this equipment.

■FIRE OR EXPLOSION HAZARD

1. When spraying, adequate exhaust must be provided to keep air free of accumulations of

ammable vapors which may cause re or explosion.

2. Smoking must never be allowed in the spray area.

3. Static electricity is generated and a static spark could be produced in the spray area. To

prevent the risk of re or explosion, ground without fail all conductive objects in the spray

area.

4. Make it sure to use and ground hoses with static wire for spray gun operation. If

improperly grounded, a static spark possibly produced may cause re or explosion.

5. Fire extinguishing equipment must be provided in the spray area.

6. Solvents used for cleaning must have a flash point equal to or higher than that of the

coating. Those for general cleaning must have flash points above 37.8°C(100°F) to

prevent the risk of re.

■INHALING TOXIC SUBSTANCES

1. Toxic vapors and liquids are harmful to health. When spraying, adequate exhaust must be

provided to keep the air free of accumulations of toxic materials and the use at all times of

respiratory protective equipment must be set compulsory.

2. Always wear eye protection when spraying or cleaning the equipment.

3. Certain materials may be harmful if there is contact with the skin. Read carefully all the

labels and safety performance data of the materials and solvents to be used. Appropriate

clothes and gloves must be worn for spraying or cleaning the equipment.

■MISUSE

1. Operators should be given adequate and appropriate training in the safe use and

maintenance of this equipment.

2. Pressured liquids may injure eyes. Do not point the spray gun to any person.

3. Gravity or suction feed gun must not be used for pressure feed gun.

4. Parts with compressed air may damage the human body. Connect air hoses tightly by

using a spanner so that air never leaks. If tightened loosely, hoses can be removed which

may result in damaging the human body, objects to be coated and other equipment used

to gether.

5. Parts with compressed air or under spring pressure may injure the human body.When

replacing such parts, clean the spray gun by discharging the materials, discharge the air,

remove air hose and uid cup and then replace such parts by placing the gun at. Eye

protection must be worn when repairing the spray gun.

6. Do not use the gun at no more than maximum working pressure (0.69MPa).

Page 6

6

DEMI2

INSTALLATION

1. The air supplied to spray gun must be cleaned air which any water, oil and solid material

removed. To set up the Mist Separator and Air Transformer near the gun is recommended.

The use of air not cleaned may cause coating troubles.

2. Connect uid cup and air hoses tightly. If tightened loosely, hoses can be removed which

may result in damaging the human body, objects to be coated and other equipment used

to gether.

OPER ATION

1. The recommended pressure of air supplied to gun is in a range of 0.15MPa-0.20Mpa.

Do not supply to gun the air pressure in excess of the gun’s maximum working pressure

(0.69MPa).

2. Try with the pressure starting from 0.1MPa - 0.2Mpa or around as the spraying pressure

varies depending upon the inner diameter of gun, triggering distance, materials etc.

3. The recommended spray distance is 150mm. If the spray distance is too far, good result

does not appear.

4. In order to get uniform nishing the spray gun should be hold vertically toward the painting

surface.

PREVENTIVE MAINTENANCE

1. Daily lubrication and cleaning is necessary to maintain the best condition of the gun.

2. To clean the gun body, wipe exterior with solvent dampened cloth. Do not submerge the

gun body in solvent as any solids may get into the air passage and cause troubles.

3. Do not leave the gun with solvent in uid cup. Clean the spray gun after used with clean

solvent and empty the cup. To clean the uid cup, after removing extra paint, through the

appropriate solvent and ush down the residual paint.

4. The Air Cap can be immersed in solvent and brushed down for cleaning. If orices are

clogged, use a toothpick to remove obstruction. Never use a steel wire or hard instrument.

This will damage air cap and result in a distorted spray pattern.

5. Do not immerse any plastic parts in solvent for long time.

6. Certain portions of gun should be lubricated. Do not lubricate to any portion where

not instructed. For lubrication, SSL-10 Gun Lube* is recommended (*sold separately,

vegetable not repelling materials).

7. The following portions should be lubricated regularly; Trigger Stud (15), Pattern Valve

(6), threads of cheater Valve (17) and Adjusting Screw (13), Air Valve (8) stem, portion of

Packing Gland (14) here Needle (11) comes in and out.

8. When installing Air Cap (3), make sure no foreign materials adhered on Retaining Ring (1)

and thread of body and then oil one drop of Gun Lube SSL-10.

9. Apply non-silicone grease lightly on Needle Spring (12) and Air Valve Spring (9). Do not

apply too much grease as it may clog the air passage.

Page 7

7

DEMI2

REPLACEMENT OF PARTS

Before replacing gun parts, remove materials from the gun for cleaning. Then release the air

pressure in the gun and disconnect air hoses. All repairs should be made on a clean at surface.

Use only appropriate tools indicated for replacement of parts.

Fluid Tip (4) and Needle (11)

1. It is recommended to replace Fluid Tip (4) and Needle (11) as a set.

2. Loosen completely Pattern Valve (6) by turning the knob counterclockwise.

3. Remove Adjusting Screw (13) and Needle Spring (12) and then withdraw Needle (11) from

the gun body.

4. Remove Retaining Ring (1) and Air Cap (3).

5. Remove Fluid Tip (4) by using socket wrench, offset wrench or the spanner .

6. Recommended torque of Fluid tip is 8N·m when you re-assemble.

Fluid Inlet and Air Connector (18)

Fluid Inlet and Air Connector (18) are fixed together by sealing material. Do not disassemble

these connectors if it is not necessary. It may become a cause of problem.

Pattern Valve (6) and Cheater Valve (17)

When disassembling and reassembling Pattern Valve (6) and Cheater Valve (17), turn the knobs

completely counterclockwise and then disassemble or reassemble them.

Air Seal Kit (7)

1. Remove Needle Adjusting Screw (13) and Needle Spring (12) and then withdraw Needle

(11) from the Gun Body (8).

2. Remove Air Valve Bushing (10), Valve Spring(9), Air Valve (8).

3. From the back of the Trigger (16), push the front part of the Air Seal Kit toward the back of

the gun to remove it.

4. Hook the rear part of the Air Seal in the Air Valve Bushing (10) using a thin wire to remove it.

5. Do not reuse the removed Air Seal because usually it has been damaged.

6. Attach the new Air Seal, and then insert it into the body and Bushing. See the exploded

view and be careful of the installation direction when attaching.

Needle Packing (14)

1. Remove Bearing Stud kid (15) and Trigger (16) using at-blade screwdriver.

2. Remove Fluid Adjusting Knob (13) and Needle Spring (12) from gun, and then remove

Fluid Needle (11).

3. Loosen and remove the Packing (14) using wrench .

4. Re-assembling the Packing (14). Assemble into gun body by hand and then tighten using

the wrench.

5. Insert Fluid Needle (11), and then Needle Spring (12), and Needle Adjusting Knob (13).

6. Re-assembling Bearing Stud kid (15) and Trigger (16) using at-blade screwdriver.

7. Trigger the gun several times to verify correct operation and adjust the packing by using

the wrench.

Page 8

8

DEMI2

SERVICE CHECKS

Normal spray pattern

problem Cause Correction

Will not spray No pressure to gun.

Adjust ing Screw (13) not properly adjusted.

Check air and material lines.

Adjust.

Inproper spray pattern

A B C D

A,B : Material build up on the Air Cap or

Fluid Tip.

C,D : Incorrect uid delivery or viscosity.

A,B : Clean the Air Cap or Fluid

Tip.

C,D : Adjust.

Jerky or uttering

spray

Insufficient material in the cup or Loose

connector.

Gun material passage plugged.

Worn Needle Packing (14).

Loose or damaged Fluid Tip (4).

Fill cup or tighten the Connector.

Clean.

Replace.

Tighten or replace.

Fluid leaking from

needle packing nut

(14)

Loose of Needle Packing (14)

Worn or damaged Needle Packing (14).

Tighten Needle Packing (14).

Tighten or replace.

Dripping from uid

tip(4)

Worn or damaged Fluid Tip (4) or

Needle(11).

Stuck Needle Packing (14) or Needle(11).

Incorrect adjustment of Needle Packing (14)

Loose Adjusting Screw (12)

Replace.

Lubricate.

Hold the end of the Needle (11)

with your hand to adjust. Fix it but

leave some space so that it can

still move a little bit.

Adjust.

Page 9

9

DEMI2

ACCESSORIES

Part No. Description

KG-250-DEMI Stainless Steel Gravity Cup with Stand for DEMI gun (250cc) SUS

KG-250-FA-DEMI Gravity Cup with Stand for DEMI gun (250cc Free angle type) SUS

KG-150-FA-DEMI Gravity Cup with Stand for DEMI gun (150cc Free angle type) SUS

DAH-10 Air Hose Set (10m)

DAH-20 Air Hose Set (20m)

HAV-503-B Air Adjusting Valve with Gauge

HAF-507 Disposable Air Filter

SSL-10 Gun Lube (60ml)

42884-214-K5 Cleaning Brush (kit of 5)

SHIM-3 SHIM MASK

D803553-K12 Anti-Static Wiper (kit of 12)

Page 10

©2017 Carlisle Fluid Technologies.

15-5, Fukuura 1-chome, Kanazawa-ku, Yokohama, Kanagawa Japan 〒236-0004

TEL : +81-45-785-6434 / FAX : +81-45-785-6517

HP http://www.carlisleft.co.jp

DIVISION

®DEVILBISS is a registered trademark of Carlisle Fluid Technologies.

Ransburg Japan

KK

Loading...

Loading...