Page 1

Service Bulletin

SB-2-055-F

by

AIRBRUSH INSTRUCTIONS AND MAINTENANCE

Replaces SB-2-055-E

Thank you for purchasing your DeVilbiss

®

airbrush! You will find that this high

DAGR

quality, versatile airbrush gives the

demanding professional artist the full range

of performance—from spraying fine lines to

wide backgrounds—with a wide range of

materials—from solvent-based automotive

paints to waterbase inks.

DAGR airbrushes are precision made with

micro machining and high quality

materials. Each airbrush is spray tested

before being packaged in its collector’s tin,

assuring that it meets the tough quality

standards you have come to expect from

DeVilbiss. With proper care, your DAGR

airbrush will provide you with excellent

performance to express your creativity.

SPECIFICATIONS

Operating Pressures:

20 to 50 psi

Maximum Inlet Pressure:

175 psi

Airbrush Plating:

Nickel, copper, chrome

Needle Packing:

PTFE (solvent-proof)

GET READY TO SPRAY

SAFETY FIRST

Please read all safety information on pages

8 and 9.

Connect to Compressed Air

Connect your DAGR airbrush to a

regulated air line or select an appropriate

compressor. The DeVilbiss Airblade

single piston compressor is a compact,

economical choice for the beginner and

will provide approximately 25-30 psi of air

pressure to the DAGR airbrush. At 35-40

psi, the DAGR will produce a high paint

flow for shadow, fade, and background

spray, as well as for detail work and fine

lines.

®

Page 2

Page 2 SB-2-055-F

Assemble Airbrush to Compressor

Connect the air hose to the compressor

and airbrush, then turn on the compressor.

If using an Airblade

the pressure to between 20 and 30 psi.

®

compressor, adjust

Listen for any air leaks in the compressor

or air hose fittings. Point the airbrush away

from you and press down on the trigger

(#13) to start the flow of air through the

airbrush. Place a small amount of solvent

or cleaner into the cup and pull back on the

trigger. This will clean out any residual

factory testing material that may still be in

the airbrush.

Mix Paint and Fill the Removable Cup

Follow the paint manufacturer’s

instructions and thin the paint with its

proper solvent. Filter it through a nylon

mesh strainer. It is best to "over-reduce" or

prepare the paint relatively thin and make

continuous passes across your work to

achieve the desired shade. This will also

decrease paint buildup on the needle and

cleaning time. The DAGR features a

removable cup. Depending on the amount

of paint you wish to spray, use the

standard 1/3 oz. (9 cc) cup or select an

optional 1/4 oz. (7 cc) or 1/2 oz. (14 cc) cup.

For small amounts of material, simply

remove the cup and fill the cup socket,

which will give you best visibility for closeup work.

GENERAL OPERATION

The DAGR is a double action airbrush for

fine control. Push the trigger down for air

flow and pull the trigger back for paint

flow. For best results during spraying, keep

air flow even when you have stopped paint

flow.

Air Pressure Range

Working pressures vary between 20 and 50

psi, depending on what type of work is

being done, what spray characteristics are

desired, and paint viscosity. Generally,

thicker paints or higher paint flow will

require higher pressures.

Spraying Fine Lines and Detail

To spray a fine line or detail, press the

trigger down for air flow and pull it back

slightly for paint flow while moving the

airbrush very close to the surface. Control

the thickness of the line by adjusting the

distance between the airbrush and the

surface and by adjusting the amount of

paint flow with the trigger. An even finer

line can be achieved by carefully removing

the crown cap (#1) and moving the

airbrush closer to the surface.

NOTE: The needle and nozzle are very

finely machined. A slight bend on the tip

of the needle can result in an uneven

pattern. The crown cap protects the

needle yet still allows fine lines to be

sprayed.

Wide Lines, Fades, and

Background Spraying

For wider lines, fades, and background

spraying, pull the trigger further back for

more paint flow. Increase the distance

between the airbrush and artwork up to six

inches to control the line width. Increasing

the air pressure will also affect the spray

width. The DAGR will spray a background

width of approximately two inches. Speed

of movement controls the density of the

color and fading effects.

Spraying Lines Without Heavy Ends

To spray a fine or wide line without heavy

ends, start moving the airbrush with the

trigger pushed down for air. Then pull the

trigger back for paint flow at the beginning

of the line and stop paint flow at the end,

but continue the motion of the airbrush.

Page 3

Page 3SB-2-055-F

Stippling (Dots)

Stippling (coarse or fine dots) can add

special textured effects to artwork. Simply

remove the crown cap (#1) and air cap (#2)

and adjust the air pressure between 5 and

50 psi. Lower air pressure will produce

coarse dots; higher pressure will produce

fine dots. Paint viscosity affects stippling,

as well.

Removing Clogs

The cutaway handle (#21) allows the artist

to remove paint buildup from the tip of the

airbrush without removing the handle and

needle. Just grip the exposed needle

locknut (#19) and pull back while pushing

down on the trigger (#13). More paint will

flow past the needle and tip, clearing the

clog.

Another method is to keep a second

airbrush nearby that has solvent in the cup

and use it to spray the nozzle/needle tip.

A third method is to increase the air

pressure and spray solvent through the

airbrush for a short period.

Crown Cap

The crown cap (#1) is used to protect the

needle when spraying a fine line and to

prevent paint build-up and spitting when

spraying large backgrounds.

Pre-Set Handle

The pre-set handle (#21) has a threaded

adjusting knob (#23) on the back that limits

the amount of the trigger pull back and

needle movement. This controls the

amount of paint being sprayed. Reference

markers are on the knob.

CLEANING AND LUBRICATION

Before Each Spray Session

Spray the appropriate solvent or cleaner

through the airbrush to make sure it is

working properly.

To Clean Between Color Changes

Empty the excess paint left in the cup.

Rinse the cup with solvent and use a paper

towel to wipe out any left over paint.

Fill the bottom of the cup with solvent and

spray it through until the spray is clear.

Fill with the next color.

After Each Spray Session

Increase the air pressure and spray

cleaning solution through the airbrush.

This will help thoroughly clean the paint

passages, nozzle, and needle. Remove the

needle and wipe it clean (see below).

Wipe down the outside of the airbrush

with a solvent-dampened cloth, and soak

the crown cap, if needed.

Do not soak the airbrush body in solvent

unless the air valve has been

disassembled and removed. The air valve

o-ring could swell and cause air flow

problems.

To Clean the Needle

Remove the back handle, loosen the

needle locknut (#19), and remove the

needle (#20). Using a soft cloth folded over

the needle, wipe the residue off the needle

by rotating it. Inspect the needle. If it is

bent or mis-shapen, replace it.

Holding the trigger down, carefully reinsert the needle into the airbrush near the

back and push gently until it seats against

the nozzle and is visible through the tip.

You should feel a slight resistance as the

needle passes through the packing (#6).

Page 4

Page 4 SB-2-055-F

If the needle stops suddenly, pull it out and

check the trigger for proper positioning,

then re-insert the needle. Release the

trigger and tighten the needle locknut.

Lubrication

To insure smooth trigger action, periodically

remove the needle and coat it with a highquality lubricant (like DeVilbiss SSL-10

Spray Lube). Wipe the needle with a soft

cloth, leaving it lightly coated. Re-insert the

needle and re-tighten the needle locknut.

Place a few drops of lube in the trigger slot

in the airbrush body.

®

NOTE: Do not use WD-40

oil for lubrication, which will cause the

or light machine

needle to bind as it moves through the PTFE

packing. Do not over-lubricate the needle or

the trigger. The excess lube could be

pushed into the nozzle, causing paint flow

problems.

REPLACEMENT PARTS AND

ACCESSORIES

NOTE: If you must disassemble the

airbrush, please do not use pliers. Tools

are rarely needed. If needed, however, use

a small wrench to unscrew and lightly re-

tighten the head cap (#3), which seats the

nozzle on to the airbrush body. Do not

overtighten!

Nozzle (#4)

If the nozzle becomes worn or damaged, it

must be replaced. Before replacing the

nozzle, protect the needle by pulling it back

slightly. To do this, remove the handle

(#21), loosen the needle locknut (#19), and

carefully pull the needle back through the

nozzle. Remove the head cap (#3) and pull

out the nozzle. If it is stuck, loosen it by

gently pushing the side of it with your

thumb. Pull the nozzle off and replace it

with the new one. Re-assemble the head

cap and tighten it by hand or lightly with a

wrench. Do not over tighten. Re-seat the

needle into the nozzle by gently pushing it

forward until it seats with the fluid nozzle.

Tighten the needle locknut and continue

reassembly.

NOTE: To insure even wear, change the

needle at the same time as the nozzle.

Needle (#20)

DeVilbiss needles are made of precision

machined stainless steel and are designed

for long-term use. However, because of

their long tapers and very fine tips they

can be easily damaged. If the needle point

becomes bent or hooked, it should be

straightened before being pulled back

through the nozzle or the nozzle could

become damaged. If the needle is not bent

too badly, roll it between your finger and a

smooth flat surface to straighten the point.

Quick Disconnect

(Optional Accessory)

A quick disconnect stem is screwed on to

each airbrush and a quick disconnect

adapter is screwed on to the air hose. This

allows for quick changes between

airbrushes using one hose.

Hose

Use high quality, flexible DeVilbiss braided

nylon air hose. Order DGR-123 (802769)

10’ air hose assembly or DGR-124 (802770)

10’ air hose assembly with quick disconnect.

Page 5

TROUBLESHOOTING

CAUSE CORRECTION

Skipping:

1. Air pressure too high 1. Reduce pressure

2. Paint too thick 2. Reduce with solvent

3. Airbrush is dirty 3. Refer to Cleaning in Maintenance

Section

4. Nozzle not seated on body 4. Tighten head cap (by hand or lightly

with wrench)

5. Nozzle damaged or cracked 5. Replace nozzle

6. Dried paint on tip of needle 6. Refer to "To Clean the Needle"

7. Nozzle not centered in air cap 7. Clean nozzle & airbrush seats

Spitting:

1. Dried paint on tip of needle 1. Refer to "To Clean the Needle"

2. Airbrush is dirty 2. Refer to "Cleaning and Lubrication"

3. Paint too thick 3. Reduce with solvent

4. Air pressure too low 4. Increase air pressure

Bubbling in cup

1. Loose head cap or nozzle not 1. Tighten head cap (by hand or lightly

seated on body with wrench)

2. Nozzle damaged or cracked 2. Replace nozzle

Page 5SB-2-055-F

CAUSE CORRECTION

Will Not Spray:

1. Clogged nozzle 1. Refer to "Cleaning and Lubrication"

2. Loose head cap 2. Tighten (by hand or lightly with

wrench)

3. Loose needle locknut 3. Tighten

4. Improper air pressure 4. Adjust

5. Paint too thick 5. Reduce with solvent

6. Nozzle damaged or cracked 6. Replace nozzle

7. Vent hole in cup lid is plugged 7. Unplug with toothpick or brush

Sprays Double Line:

1. Airbrush is dirty 1. Refer to "Cleaning and Lubrication"

2. Bent needle 2. Replace or straighten needle

3. Dirt on tip of nozzle or in air cap 3. Flush with solvent or remove and

soak parts

4. Nozzle damaged or cracked 4. Replace nozzle

5. Dried paint on tip of needle 5. Refer to "To Clean the Needle"

Trigger sticks or does not move smoothly

1. Needs lubrication 1. Refer to "Lubrication"

2. Material leaked past packing 2. Thoroughly clean airbrush (including

trigger) and tighten packing (#6) by

inserting small slotted screwdriver

into airbrush body until it contacts

packing nut. Turn slightly clockwise.

Page 6

Page 6 SB-2-055-F

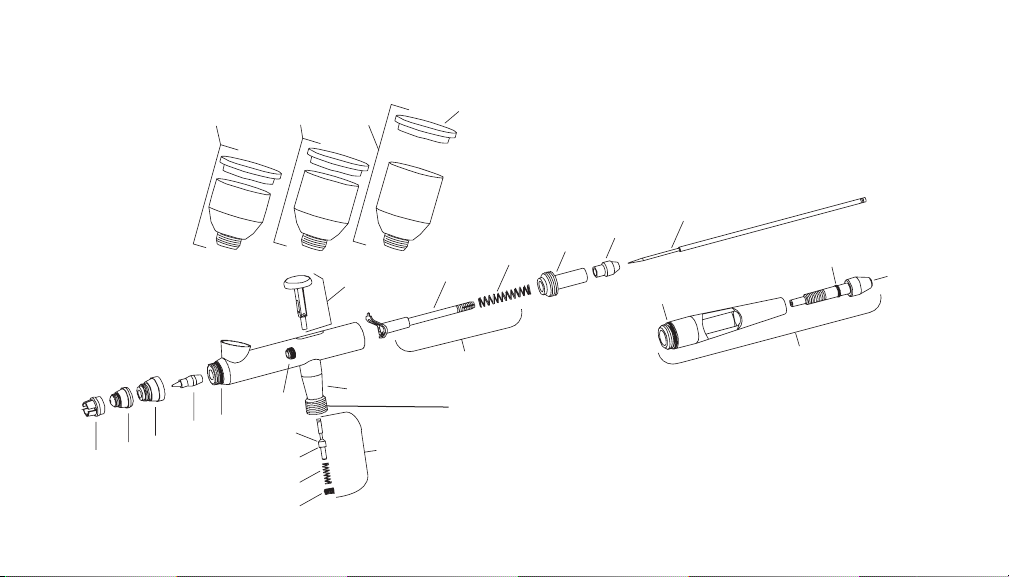

27

13

15

16

17

18

19

5

22

21

20

2524

26

1

2

3

4

5

7

8

6

9

10

11

12

23

Air Inlet 1/8” BPT

Page 7

Page 7SB-2-055-F

Ref.

No. Order No. Model No. Description

1 802613 DGR-101 Crown cap

2 802615 DGR-103-35 Air cap (for .35mm nozzle)

3 802616 DGR-104 Head cap

4 802618 DGR-105-35 Nozzle (.35mm)

• 5 –– O-ring (head cap & handle)

6 802619 DGR-106K Packing and nut assembly (PTFE)

7 802620 DGR-107 Air valve casing

8 803644 DGR-308K Air valve kit

• 9 –– Air valve o-ring

10 –– Air valve plunger

11 –– Air valve spring

12 –– Air valve nut

13 803645 DGR-323 Trigger

Ref.

No. Order No. Model No. Description

15 802623 DGR-110K Needle guide, rocker, & spring

16 –– Needle guide and rocker

• 17 –– Needle spring

18 802624 DGR-111 Spring guide

19 802625 DGR-112 Needle locknut

20 802627 DGR-113-35 Needle (for .35mm nozzle)

21 802628 DGR-114 Cutaway handle w/pre-set

• 22 –– O-ring (pre-set needle knob)

23 802630 DGR-116 Pre-set needle knob

24 802631 DGR-117 1/4 oz.(7 cc) cup and lid

25 802632 DGR-118 1/3 oz.(9 cc) cup and lid (standard)

26 802633 DGR-119 1/2 oz.(14 cc) cup and lid

27 802634 DGR-120 Cup lid

28 802635 DGR-121K DAGR repair kit

30 802975 DGR-18-K5 O-ring (head cap & handle) kit (5)

• DAGR Repair Kit 802635 (DGR-121K) includes:

Ref. Description Qty.

5 O-ring (head cap & handle) 3

9 Air valve o-ring 2

17 Needle spring 1

22 O-ring (pre-set needle knob) 1

Page 8

Page 8 SB-2-055-F

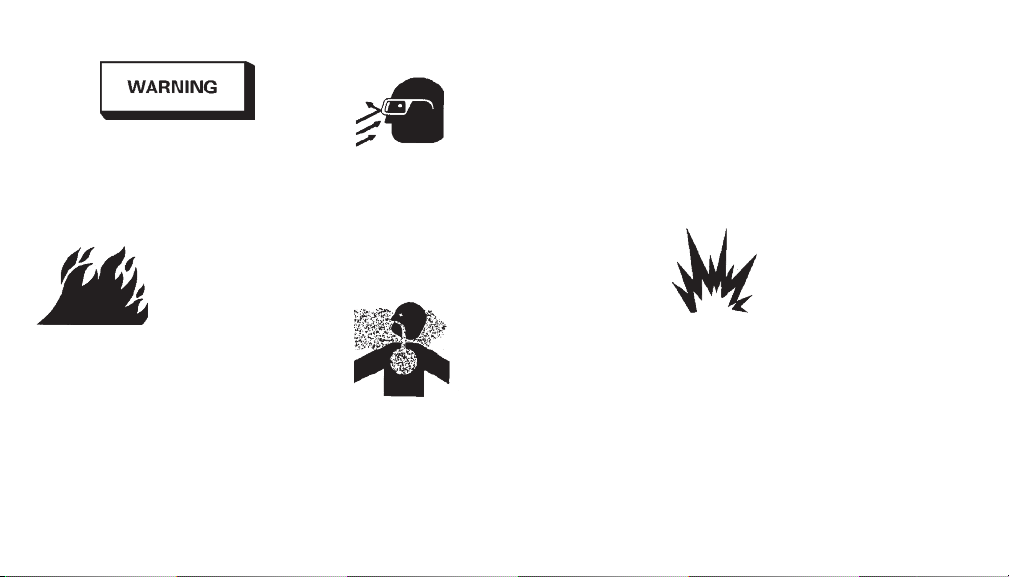

The following hazards may occur

during the normal use of this

equipment. Please read the following

warnings before using this

equipment.

HAZARD: SOLVENT SPRAY

CAUSE: During use and while cleaning and

flushing, solvents can be forcefully

expelled from fluid and air passages.

Some solvents can cause eye injury.

SAFEGUARDS: Wear eye protection.

keep the air free of accumulations of toxic

materials.

Use a mask or respirator whenever there is

a chance of inhaling sprayed materials.

The mask must be compatible with the

material being sprayed and its

concentration. Equipment must be as

prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

HAZARD: FIRE

CAUSE: Solvent and coatings can be

highly flammable or combustible

especially when sprayed.

SAFEGUARDS: Adequate exhaust must be

provided to keep air free of accumulations

of flammable vapors.

Smoking must never be allowed in the

spray area.

Fire extinguishing equipment must be

present in the spray area.

HAZARD: INHALING TOXIC SUBSTANCES

CAUSE: Certain materials may be harmful

if inhaled, or if there is contact with the

skin.

SAFEGUARDS: Follow the requirements of

the Material Safety Data Sheet supplied by

your coating material manufacturer.

Adequate exhaust must be provided to

HAZARD: EXPLOSION HAZARD –

INCOMPATIBLE MATERIALS

CAUSE: Halogenated hydrocarbon solvents

– for example; methylene chloride and

1,1,1, – Trichloroethane are not chemically

compatible with the aluminum that might

be used in many system components. The

chemical reaction caused by these

solvents reacting with aluminum can

become violent and lead to an equipment

explosion.

SAFEGUARDS: Guns with stainless steel

internal passageways may be used with

Page 9

Page 9SB-2-055-F

these solvents. However, aluminum is

widely used in other spray application

equipment – such as material pumps,

regulators, valves, and this gun and cup.

Check all equipment items before use and

make sure they can also be used safely

with these solvents. Read the label or data

sheet for the material you intend to spray.

If in doubt as to whether or not a coating or

cleaning material is compatible, contact

your material supplier.

HAZARD: GENERAL SAFETY

CAUSE: Improper operation or

maintenance of equipment.

SAFEGUARDS: Operators should be given

adequate training in the safe use and

maintenance of the equipment (in

accordance with the requirements of

NFPA-33, Chapter 15). Users must comply

with all local and national codes of practice

and insurance company requirements

governing ventilation, fire precautions,

operation, maintenance, and house keeping. These are OSHA Sections 1910.94

and 1910.107 and NFPA-33.

HAZARD: CUMULATIVE TRAUMA

DISORDERS ("CTD'S")

CTD's, or musculoskeletal disorders,

involve damage to the hands, wrists,

elbows, shoulders, neck, and back. Carpal

tunnel syndrome and tendonitis (such as

tennis elbow or rotator cuff syndrome) are

examples of CTD's.

CAUSE: Use of hand tools may cause

cumulative trauma disorders ("CTD's").

CTD's, when using hand tools, tend to

affect the upper extremities. Factors which

may increase the risk of developing a CTD

include:

1. High frequency of the activity.

2. Excessive force, such as gripping,

pinching, or pressing with the hands

and fingers.

3. Extreme or awkward finger, wrist, or

arm positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD's can also be caused by such activities

as sewing, golf, tennis, and bowling, to

name a few.

SAFEGUARDS: Pain, tingling, or numb ness in the shoulder, forearm, wrist,

hands, or fingers, especially during the

night, may be early symptoms of a CTD.

Do not ignore them. Should you exper ience

any such symptoms, see a physician

immediately. Other early symptoms may

include vague discomfort in the hand, loss

of manual dexterity, and nonspecific pain

in the arm. Ignoring early symptoms and

continued repetitive use of the arm, wrist,

and hand can lead to serious disability.

Risk is reduced by avoiding or lessening

factors 1-7.

Page 10

Page 10 SB-2-055-F

NOTES

Page 11

Boletín de mantenimiento

SB-2-055-F

por

INSTRUCCIONES Y MANTENIMIENTO DEL AERÓGRAFO

Substituye SB-2-055-E

¡Gracias por su compra del aerógrafo

DAGR®de DeVilbiss! Usted encontrará que

este aerógrafo versátil y de alta calidad

proporciona al artista profesional exigente

una gama completa—de rendimiento para

atomizar desde líneas finas hasta fondos

amplios—con una gama amplia de

materiales—desde pinturas a base de

solventes para automotores hasta tintas a

base de agua.

Los aerógrafos DAGR son instrumentos de

precisión hechos con micromaquinado y

materiales de alta calidad. Cada aerógrafo

se prueba atomizando antes de empacarlo

en su lata de colección, asegurando que

cumpla con los estándares de calidad

estrictos que usted ha llegado a esperar de

DeVilbiss. Con el debido cuidado, su

aerógrafo DAGR le ofrecerá un

rendimiento excelente para expresar su

creatividad.

ESPECIFICACIONES

Presiones operativas:

de 20 a 50 psi

Presión de admisión máxima:

175 psi

Enchapado del aerógrafo:

Níquel, cobre, cromo

Empaquetamiento de la aguja:

PTFE (a prueba de solvente)

PREPÁRESE PARA ATOMIZAR

SEGURIDAD ANTE TODO

Sírvase leer toda la información de

seguridad en las páginas 18 y 19.

Conexión al aire comprimido

Conecte su aerógrafo DAGR a una línea

neumática regulada o seleccione un

compresor apropiado. El compresor

®

Airblade

es una opción compacta y económica para

el principiante y le dará aproximadamente

de 25 a 30 psi de presión neumática al

aerógrafo DAGR. Operando de 35 a 40 psi,

el aerógrafo DAGR producirá un alto flujo

de pintura para sombrear, difuminar y

crear fondos, así como para trabajos

detallados y líneas finas.

de DeVilbiss con un solo pistón

Page 12

Página 12 SB-2-055-F

Ensamblaje del aerógrafo al compresor

Conecte la manguera neumática al

compresor y aerógrafo, luego active el

compresor. Si está usando el compresor

®

Airblade

psi. Escuche cualquier filtración de aire en

el compresor o los accesorios de la

manguera neumática. Oriente el aerógrafo

lejos de usted y pulse el disparador (#13)

para empezar el flujo de aire a través del

aerógrafo. Ponga una pequeña cantidad

de solvente o limpiador en la taza y tire el

disparador hacia atrás. Esto limpiará

cualquier material remanente de la prueba

en fábrica que pudiera haber en el

aerógrafo.

Mezcla de pintura y relleno de la taza

desmontable

Siga las instrucciones del fabricante de la

pintura y diluya la pintura con el solvente

apropiado. Fíltrela usando un tamizador de

malla de nylon. Es mejor “sobrerreducir” o

preparar la pintura relativamente diluida y

hacer pases continuos en su trabajo para

lograr el matiz deseado. Esto también

disminuirá la acumulación de pintura en la

aguja y el tiempo de limpieza. El aerógrafo

DAGR cuenta con una taza desmontable.

Dependiendo de la cantidad de pintura que

desea atomizar, utilice la taza estándar de

9 cc (1/3 oz.) o seleccione la taza opcional

de 7 cc (1/4 oz.) ó 14 cc (1/2 oz.). Para

pequeñas cantidades de material, no tiene

, ajuste la presión entre 20 y 30

más que sacar la taza y llenar el encaje de

la taza, lo cual le dará mejor visibilidad

para trabajos detallados de cerca.

FUNCIONAMIENTO GENERAL

El aerógrafo DAGR es un instrumento de

doble acción para control fino. Pulse el

disparador para que fluya el aire y tire del

disparador hacia atrás para que fluya la

pintura. Para mejores resultados durante

la atomización, mantenga el flujo de aire

uniforme aún cuando haya detenido el

flujo de pintura.

Autonomía de la presión neumática

Las presiones de trabajo varían entre 20 y

50 psi, dependiendo del tipo de trabajo

que se está haciendo, las características

deseadas al atomizar y la viscosidad de la

pintura. Generalmente, las pinturas más

espesas o el flujo de pintura más alto

requerirá presiones mayores.

Atomización de líneas finas y detalles

Para atomizar una línea fina o detalle,

pulse el disparador para que fluya el aire y

tírelo ligeramente hacia atrás para que

fluya la pintura al tiempo que mueve el

aerógrafo muy cerca de la superficie.

Controle el espesor de la línea ajustando la

distancia entre el aerógrafo y la superficie,

y ajustando la cantidad de flujo de pintura

con el disparador. Puede lograrse una

línea aún más fina quitando

cuidadosamente el sombrerete superior

(#1) y moviendo el aerógrafo más cerca de

la superficie.

NOTA: La aguja y la boquilla están están

maquinadas con mucha precisión. Una

leve curvatura en la punta de la aguja

puede producir un patrón disparejo. El

sombrerete superior protege la aguja y aún

así permite que se atomicen líneas finas.

Atomización de líneas anchas,

difuminaciones y fondos

Para atomizar líneas más anchas,

difuminaciones y fondos, tire del

disparador más hacia atrás para que fluya

más pintura. Aumente la distancia entre el

aerógrafo y el material gráfico hasta 15,24

cm (6 pulg.) para controlar el ancho de la

línea. Aumentar la presión neumática

también afectará el ancho de lo atomizado.

El aerógrafo DAGR atomizará un ancho de

fondo de aproximadamente 5 cm (2 pulg.).

La velocidad del movimiento controla la

densidad del color y los efectos de

difuminación.

Atomización de líneas sin terminaciones

gruesas

Para atomizar una línea fina o ancha sin

terminación gruesa, comience moviendo

el aerógrafo manteniendo el disparador

pulsado para que fluya el aire. A

continuación, tire del disparador hacia

Page 13

Página 13SB-2-055-F

atrás para que fluya la pintura al comienzo

de la línea y detenga el flujo de pintura al

final, pero continúe el movimiento del

aerógrafo.

Moteado (lunares)

El moteado (lunares finos o gruesos)

pueden añadir efectos especiales de

textura al material gráfico. Nada más retire

el sombrerete superior (#1) y el

sombrerete de aire (#2) y ajuste la presión

del aire entre 5 y 50 psi. Reducir la presión

del aire producirá lunares gruesos; las

presiones mayores producirán lunares

finos. De igual manera, la viscosidad de la

pintura afecta el moteado.

Eliminación de obstrucciones

El asa de corte (#21) permite al artista

eliminar la acumulación de pintura de la

punta del aerógrafo sin quitar el asa ni la

aguja. Sólo agarre la contratuerca de la

aguja (#19) expuesta y tire hacia atrás

mientras mantiene el disparador (#13)

pulsado. Más pintura fluirá por la aguja y

punta, destapando la obstrucción.

Otro método es mantener un segundo

aerógrafo cerca que contenga solvente en

la taza y usarlo para atomizar la punta de

la boquilla/aguja.

Un tercer método es aumentar la presión

del aire y atomizar solvente por el

aerógrafo por un período breve.

Sombrerete superior

El sombrerete superior (#1) se usa para

proteger la aguja al atomizar una línea fina

y para prevenir la acumulación y escurrido

de la pintura al atomizar fondos grandes.

Asa preprogramada

El asa preprogramada (#21) tiene un botón

de ajuste roscado (#23) en la parte

posterior que limita cuanto puede tirarse

del disparador hacia atrás y el movimiento

de la aguja. Esto controla la cantidad de

pintura que se atomiza. El botón tiene

marcas de referencia.

LIMPIEZA Y LUBRICACIÓN

Antes de cada sesión de atomización

Atomice el solvente o limpiador apropiado

por el aerógrafo para asegurarse de que

esté funcionando como es debido.

Limpieza entre cambios de colores

Vacíe la pintura sobrante en la taza. Aclare

la taza con solvente y use un papel toalla

para limpiar cualquier remanente de

pintura. Llene el fondo de la taza con

solvente y atomícelo totalmente hasta que

el espray esté claro. Llene con el siguiente

color.

Después de cada sesión de atomización

Aumente la presión del aire y atomice el

aerógrafo con una solución limpiadora.

Esto ayudará a limpiar a fondo los pasajes

de pintura, la boquilla y la aguja. Saque la

aguja y límpiela con un paño (ver abajo).

Limpie la parte externa del aerógrafo con

un paño humedecido con solvente y

ponga en remojo el sombrerete superior,

si es necesario.

No ponga en remojo el cuerpo del

aerógrafo en solvente a menos que se

haya desarmado y sacado la válvula de

aire. La junta tórica de la válvula de aire

puede hincharse y causar problemas de

flujo de aire.

Limpieza de la aguja

Quite el asa posterior, afloje la

contratuerca de la aguja (#19) y saque la

aguja (#20). Usando un paño suave

doblado sobre la aguja, limpie cualquier

residuo en la aguja haciéndola girar.

Inspeccione la aguja. Si está curvada o

deformada, reemplácela.

Manteniendo el disparador oprimido,

reinserte con cuidado la aguja en el

aerógrafo cerca de la parte posterior y

empújela suavemente hasta que quede

asentada en la boquilla y sea visible a

través de la punta. Debe sentir una

resistencia leve cuando la aguja pasa por

Page 14

Página 14 SB-2-055-F

el empaquetamiento (#6). Si la aguja se

detiene de repente, sáquela y verifique el

debido posicionamiento del disparador,

luego reinserte la aguja. Deje de oprimir el

disparador y ajuste la contratuerca de la

aguja.

Lubricación

Para asegurar que el disparador se accione

sin problemas, saque periódicamente la

aguja y cúbrala con un lubricante de alta

calidad (como el lubricante en atomizador

SSL-10 de DeVilbiss). Limpie la aguja con un

paño suave dejándola ligeramente

recubierta. Reinserte la aguja y reajuste la

contratuerca de la aguja. Ponga unas

cuantas gotas del lubricante en la ranura del

disparador en el cuerpo del aerógrafo.

NOTA: Para lubricación, no utilice WD-40

aceite liviano para máquinas porque esto

hará que la aguja ponga cierta resistencia a

medida que se mueva por el

empaquetamiento de PTFE. No lubrique

demasiado la aguja ni el disparador. El

lubricante excedente podría ser empujado a

la boquilla, lo que causaría problemas de

flujo de pintura.

®

REPUESTOS Y ACCESORIOS

NOTA: Si debe desarmar el aerógrafo, por

favor no utilice alicates. Rara vez se

necesita usar herramientas. Sin embargo,

si lo necesita utilice una llave inglesa

pequeña para destornillar y reajuste

suavemente el sombrerete cabecero (#3),

que sirve para asentar la boquilla en el

cuerpo del aerógrafo. ¡No ajuste

demasiado!

Boquilla (#4)

Si la boquilla se desgasta o daña, debe

reemplazarse. Antes de reemplazar la

boquilla, proteja la aguja tirándola un poco

hacia atrás. Para hacer esto, quite el asa

(#21), afloje la contratuerca de la aguja

(#19) y tire con cuidado de la aguja hacia

atrás a través de la boquilla. Quite el

sombrerete cabecero (#3) y saque la

boquilla. Si está atascada, aflójela

empujando suavemente su costado con el

dedo pulgar. Saque la boquilla y

reemplácela con una nueva. Reensamble

o

el sombrerete cabecero y ajústelo a mano

o suavemente con una llave inglesa. No lo

ajuste demasiado. Vuelva a asentar la

aguja en la boquilla empujándola con

cuidado hacia adelante hasta que quede

asentada con la boquilla de fluido. Ajuste

la contratuerca de la aguja y continúe

reensamblando.

NOTA: Para asegurar un uso parejo,

cambie la aguja al mismo tiempo que la

boquilla.

Aguja (#20)

Las agujas DeVilbiss están hechas de

acero inoxidable maquinado con precisión

y están diseñadas para uso por largo

tiempo. Sin embargo, debido a sus puntas

muy finas y su longitud ahusada pueden

dañarse fácilmente. Si la punta de la aguja

se pone curva o ganchuda, debe

enderezarse antes de sacarla por la

boquilla o la boquilla podría resultar

dañada. Si la aguja no está muy curvada,

hágala rodar entre su dedo y una

superficie lisa y plana para enderezar la

punta.

Dispositivo de desconexión rápida

(accesorio opcional)

Un vástago de desconexión rápida está

atornillado en cada aerógrafo y un

adaptador de desconexión rápida está

atornillado en la manguera neumática.

Esto permite hacer cambios rápidos entre

aerógrafos usando una manguera.

Manguera

Use la manguera neumática flexible, de alta

calidad y de nylon trenzado de DeVilbiss.

Pida la unidad de manguera neumática de

3 metros (10 pies) (3 DGR-123 (802769) o la

unidad de manguera neumática de 3 metros

(10 pies) con dispositivo de desconexión

rápida DGR-124 (802770).

Page 15

LOCALIZACIÓN Y SOLUCIÓN DE PROBLEMAS

CAUSA CORRECCIÓN

Pintura irregular:

1. Presión del aire demasiado alta 1. Reduzca la presión

2. Pintura demasiado espesa 2. Reducir con solvente

3. Aerógrafo sucio 3. Remítase a Limpieza en la sección

4. Boquilla no asentada en el cuerpo 4. Ajuste el sombrerete cabecero (a

5. Boquilla dañada o rajada 5. Reemplace la boquilla

6. Pintura seca en la punta de 6. Remítase a “Limpieza de la aguja”

la aguja

7. Boquila descentrada en el 7. Limpie la boquilla y los asientos

sombrerete de aire del aerógrafo

Pintura escurrida:

1. Pintura seca en la punta de 1. Remítase a “Limpieza de la aguja”

la aguja

2. Aerógrafo sucio 2. Remítase a “Limpieza y lubricación”

3. Pintura demasiado espesa 3. Reducir con solvente

4. Presión del aire demasiado baja 4. Aumentar la presión del aire

Formación de burbujas en

la taza

1. Afloje el sombrerete cabecero o 1. Ajuste el sombrerete cabecero

boquilla no asentada en (a mano o suavemente con

el cuerpo llave inglesa)

2. Boquilla dañada o rajada 2. Reemplace la boquilla

de Mantenimiento

mano o suavemente con llave

inglesa)

Página 15SB-2-055-F

CAUSA CORRECCIÓN

No atomiza:

1. Boquilla obstruida 1. Remítase a “Limpieza y lubricación”

2. Sombrerete cabecero flojo 2. Ajústelo (a mano o suavemente con

3. Contratuerca de la aguja floja 3. Ajústela

4. Presión del aire indebida 4. Ajústela

5. Pintura demasiado espesa 5. Reducir con solvente

6. Boquilla dañada o rajada 6. Reemplace la boquilla

7. Agujero de ventilación en la tapa 7. Desatasque con un mondadientes

de la taza bloqueado o cepillo

Atomiza líneas dobles:

1. Aerógrafo sucio 1. Remítase a “Limpieza y lubricación”

2. Aguja curvada 2. Reemplace o enderece la aguja

3. Suciedad en la punta de la 3. Purgue con solvente o quite las

boquilla o en el sombrerete de aire piezas y remójelas

4. Boquilla dañada o rajada 4. Reemplace la boquilla

5. Pintura seca en la punta de 5. Remítase a “Limpieza de la aguja”

la aguja

Disparador atascado o no se mueve sin problemas

1. Necesita lubricación 1. Remítase a “Lubricación”

2. Material filtrado más allá 2. Limpie el aerógrafo a fondo

del empaquetamiento

llave inglesa)

(incluyendo el disparador) y ajuste el

empaquetamiento (#6) insertando un

destornillador pequeño ranurado en el

cuerpo del aerógrafo hasta que haga

contacto con la tuerca del empaquetamiento. Haga girar un poco en sentido horario.

Page 16

Página 16 SB-2-055-F

27

13

15

16

17

18

19

5

22

21

20

2524

26

1

2

3

4

5

7

8

6

9

10

11

12

23

Entrada de aire 1/8” BPT

Page 17

Página 17SB-2-055-F

No. de

Ref. Pida el No. No. de modelo Descripción

1 802613 DGR-101 Sombrerete superior

2 802615 DGR-103-35

3 802616 DGR-104 Sombrerete cabecero

4 802618 DGR-105-35 Boquilla (0,35 mm)

• 5 –– Junta tórica (sombrerete cabecero y asa)

6 802619 DGR-106K

7 802620 DGR-107 Cubierta de la válvula de aire

8 803644 DGR-308K Kit de válvula de aire

• 9 –– Junta tórica de la válvula de aire

10 –– Émbolo de la válvula de aire

11 –– Resorte de la válvula de aire

12 –– Tuerca de la válvula de aire

13 803645 DGR-323 Disparador

Sombrerete de aire (para boquilla de 0,35 mm)

Unidad de empaquetamiento y tuerca (PTFE)

No. de

Ref. Pida el No. No. de modelo Descripción

15 802623 DGR-110K Guía de la aguja, balancín y resorte

16 –– Guía de la aguja y balancín

• 17 –– Resorte de la aguja

18 802624 DGR-111 Guía de resorte

19 802625 DGR-112 Contratuerca de la aguja

20 802627 DGR-113-35 Aguja (para boquilla de 0,35 mm)

21 802628 DGR-114 Asa de corte preprogramada

• 22 ––

23 802630 DGR-116 Botón preprogramado de aguja

24 802631 DGR-117 Taza de 7 cc (1/4 oz.) y tapa

25 802632 DGR-118 Taza de 9 cc (1/3 oz.) y tapa (estándar)

26 802633 DGR-119 Taza de 14 cc (1/2 oz.) y tapa

27 802634 DGR-120 Tapa de taza

28 802635 DGR-121K Kit de reparación para el aerógrafo DAGR

30 802975 DGR-18-K5

• El kit de reparación 802635 para el aerógrafo DAGR (DGR-121K) incluye:

Ref. Descripción Cantidad

5 Junta tórica (sombrerete cabecero y asa) 3

Junta tórica

9

17 Resorte de la aguja 1

22 Junta tórica (botón preprogramado de aguja) 1

de la válvula de aire 2

Junta tórica (botón preprogramado de aguja)

Kit de junta tórica (sombrerete cabecero y asa) (5)

Page 18

Página 18 SB-2-055-F

ADVERTENCIA

Durante el uso normal de este

equipo pueden ocurrir las siguientes

situaciones de peligro. Sírvanse leer

las siguientes advertencias antes de

usar este equipo.

PELIGRO: ATOMIZACIÓN DE SOLVENTE

CAUSA: Durante el uso y mientras se

limpia y purga, los solventes pueden

expulsarse con fuerza de los pasajes de

fluido y aire. Algunos solventes pueden

causar lesiones en los ojos.

MEDIDAS PREVENTIVAS: Use gafas de

protección.

Debe proveerse de un escape adecuado

para mantener el aire libre de

acumulaciones de vapores tóxicos.

Use una máscara o respirador siempre que

haya riesgo de inhalar materiales

atomizados. La máscara debe ser

compatible con el material que se atomiza

y su concentración. El equipo debe ser

como el recomendado por un higienista

industrial o experto en seguridad y

aprobado por NIOSH.

PELIGRO: INCENDIO

CAUSA: El solvente y los recubrimientos

pueden ser altamente inflamables o

combustibles especialmente cuando se

atomizan.

MEDIDAS PREVENTIVAS: Debe proveerse

de un escape adecuado para mantener el

aire libre de acumulaciones de vapores

inflamables.

Nunca debe permitirse fumar en el área

donde se atomiza.

En el área donde se atomiza debe haber

equipo extintor de incendios.

PELIGRO: INHALACIÓN DE SUSTANCIAS

TÓXICAS

CAUSA: Ciertos materiales pueden ser

dañinos si se inhalan o si tienen contacto

con la piel.

MEDIDAS PREVENTIVAS: Siga los

requisitos de la Hoja de datos de

seguridad (MSDS) suministrada por el

fabricante del material de recubrimiento.

PELIGRO: PELIGRO DE EXPLOSIÓN –

MATERIALES INCOMPATIBLES

CAUSA: Solventes de hidrocarburos

halogenados – por ejemplo; cloruro de

metileno y tricloretano-1,1,1 no son

compatibles químicamente con el

aluminio que pudiera ser usado en

muchos componentes del sistema. La

reacción química causada por estos

solventes reaccionando con el aluminio

puede tornarse violenta y producir una

explosión del equipo.

MEDIDAS PREVENTIVAS: Las pistolas con

pasajes internos de acero inoxidable

Page 19

Página 19SB-2-055-F

pueden usarse con estos solventes. Sin

embargo, en otros equipos de

atomizadores suele utilizarse el aluminio –

como bombas de material, reguladores,

válvulas y esta pistola y taza. Revise todos

los componentes del equipo antes de

usarlos y asegúrese de que puedan usarse

sin peligro con estos solventes. Lea la

etiqueta u hoja de seguridad para el

material que piensa atomizar. Si tiene

dudas sobre si un recubrimiento o material

de limpieza es compatible o no, póngase

en contacto con el proveedor del material.

PELIGRO: SEGURIDAD EN GENERAL

CAUSA: Operación o mantenimiento

indebidos del equipo.

MEDIDAS PREVENTIVAS: Los usuarios

deben recibir una capacitación adecuada

en el uso y mantenimiento seguro del

equipo (de acuerdo con los requisitos de

NFPA-33, Capítulo 15). Los usuarios deben

cumplir con todos los códigos locales y

nacionales de práctica y los requisitos de

las compañías de seguro sobre

ventilación, precauciones de incendio,

operación, mantenimiento y limpieza del

lugar de trabajo. Estas son las Secciones

1910.94 y 1910.107 de OSHA y NFPA-33.

PELIGRO: TRASTORNOS TRAUMÁTICOS

ACUMULATIVOS (“CTD”)

Los CTD, o trastornos musculoesqueléticos,

implican daño a las manos, las muñecas, los

codos, los hombros, el cuello y la espalda.

Ejemplos de los CTD son el síndrome de

túnel carpiano y la tendonitis (como el codo

de tenista o el síndrome del manguito

rotador).

CAUSA: El uso de herramientas manuales

puede causar trastornos traumáticos

acumulativos (“CTD”).

Cuando se usan herramientas manuales,

los CTD tienden a afectar las extremidades

superiores. Los factores que pueden

aumentar el riesgo de desarrollar un CTD

incluyen:

1. Alta frecuencia de la actividad.

2. Fuerza excesiva, p. ej. al agarrar, apretar

u oprimir con las manos y dedos.

3. Posiciones extremas o forzadas de los

dedos, la muñeca o los brazos.

4. Duración excesiva de la actividad.

5. Vibración de la herramienta.

6. Presión repetida en una parte del cuerpo.

7. Trabajar en temperaturas frías.

Los CTD también pueden ser causados por

actividades como coser, jugar golf, tenis y

bolos por mencionar algunas.

MEDIDAS PREVENTIVAS: Un dolor,

hormigueo o entumecimiento en el

hombro, el antebrazo, las muñecas, las

manos o los dedos, especialmente durante

la noche, pueden ser síntomas tempranos

de un CTD. No los ignore. Si experimenta

cualquiera de dichos síntomas, vea de

inmediato a un médico. Otros síntomas

tempranos pueden incluir molestias en las

manos, pérdida de dexteridad manual y un

dolor no específico en el brazo. Ignorar los

síntomas tempranos y continuar usando

repetitivamente los brazos, las muñecas y

las manos puede conducir a una

discapacidad grave. El riesgo se disminuye

evitando o reduciendo los factores listados

del 1 al 7.

Page 20

Página 20 SB-2-055-F

NOTAS

Page 21

Bulletin de service

SB-2-055-F

par

MODE D’EMPLOI ET ENTRETIEN DE L’AÉROGRAPHE

Remplace SB-2-055-E

Merci d’avoir acheté l’aérographe DeVilbiss

®

! Vous trouverez que cet aérographe

DAGR

polylvalent de haute qualité offre à l’artiste

professionnel et exigeant la gamme

complète de performance—de la

pulvérisation de lignes minces aux arrièreplans larges—avec une gamme généreuse

de matériaux—allant des peintures

automobile à base de diluants jusqu’aux

encres à base d’eau.

Les aérographes DAGR de précision sont

micro-usinés et fabriqués de matériaux de

qualité supérieure. Le pulvérisateur de

chaque aérographe est testé avant d’être

emballé dans sa boîte de collection, ce qui

assure qu’il répond aux normes de qualité

exigeantes de DeVilbiss. Entretenu

correctement, votre aérographe DAGR

vous offrira une performance excellente

pour exprimer votre créativité.

CARACTÉRISTIQUES

Pressions de fonctionnement :

20 à 50 psi

Pression d’entrée maximum :

175 psi

Revêtement de l’aérographe :

Nickel, cuivre, chrome

Emballage de l’aiguille :

PTFE (à l’épreuve des solvents)

PRÉPAREZ-VOUS À PULVÉRISER

LA SÉCURITÉ D’ABORD

Veuillez lire toutes les informations sur la

sécurité sur les pages 28 et 29.

Connexion à l’air comprimé

Connectez votre aérographe DAGR à la

conduite d’air régulée ou choisissez un

compresseur approprié. Le compresseur à

piston simple Airblade

choix du débutant compact et économique

qui fournit à l’aérographe DAGR environ

25 à 30 psi de pression d’air. Avec 35 à 40

psi, le DAGR produira un débit élevé pour

l’effet d’ombrage, de fond et de dégradé

de teintes, ainsi que pour le travail détaillé

et les lignes fines.

®

de DeVilbiss est le

Page 22

Page 22 SB-2-055-F

Montage de l’aérographe sur le compresseur

Branchez le conduit d’air sur le compresseur

et sur l’aérographe et mettez le compresseur

sous tension. Si vous utilisez un

compresseur Airblade

entre 20 et 30 psi. Écoutez attentivement

pour toute fuite d’air dans le compresseur

ou dans les raccords du conduit d’air.

Pointez l’aérographe loin de vous et

appuyez sur la gâchette (#13) pour amorcer

le débit d’air dans l’aérographe. Placez une

petite quantité de diluant ou de produit

nettoyant dans le godet et tirez sur la

gâchette. Cette action nettoiera tout résidu

de matériau d’épreuve en usine qui pourrait

se trouver dans l’aérographe.

Mélanger la peinture et remplir le godet

amovible

Suivez les instructions du fabricant de

peinture et éclaircissez la peinture au

moyen du diluant approprié. Filtrez-la dans

une passoire en nylon. Il est mieux de “surréduire”, ou de péparer une peinture

relativement claire et d’effectuer des

passes en continu sur le travail pour

obtenir la teinte désirée. Cela réduira

également l’accumulation de peinture sur

l’aiguille ainsi que le temps de nettoyage.

Le DAGR est doté d’un godet amovible.

Selon la quantité de peinture que vous

désirez pulvériser, utilisez le godet

standard 9cc (1/3 oz) ou choisissez un

®

, réglez la pression

godet facultatif de 7cc (1/4 oz) ou 14cc (1/2

oz). Pour de petites quantités de peinture,

retirez simplement le godet et remplissez la

douille du godet, ce qui vous donnera une

meilleure visibilité pour le travail de près.

FONCTIONNEMENT GÉNÉRAL

Le DAGR est un aérographe à double

action pour le contrôle raffiné. Tirez la

gâchette vers le bas pour le débit d’air et

tirez la gâchette vers l’arrière pour le débit

de peinture. Pour les meilleurs résultats

lors de la pulvérisation, maintenez un débit

d’air régulier même lorsque vous arrêtez le

débit de peinture.

Plage de pression d’air

Les pressions de fonctionnement varient

entre 20 et 50 psi en fonction du genre de

travail effectué, des caractéristiques de

pulvérisation désirés, et de la viscosité de

la peinture. En général, les peintures plus

épaisses ou le débit de peinture élevé

exigent des pressions plus élevées.

Pulvérisation de lignes fines et détaillées

Pour pulvériser une ligne fine ou détaillée,

tirez la gâchette vers le bas pour le débit

d’air et tirez-la légèrement vers l’arrière

pour le débit de peinture tout en déplaçant

le pistolet très près de la surface. Contrôlez

l’épaisseur de la ligne en ajustant la

distance entre le pistolet et la surface et en

ajustant le débit de peinture au moyen de

la gâchette. Vous pouvez obtenir une ligne

encore plus fine si vous enlevez le

capuchon (#1) et placez le pistolet plus

près de la surface.

REMARQUE : L’aiguille et la buse sont

finement usinées. Une courbe, même

légère, du bout de l’aiguille peut causer

une pulvérisation inégale. Le capuchon

protège l’aiguille tout en permettant la

pulvérisation de lignes fines.

Pulvérisation de lignes larges, de fonds et

de dégradés de teintes

Pour des lignes larges, des fonds et des

dégradés de teintes, tirez la gâchette plus

loin pour un débit de peinture plus élevé.

Augmentez d’environ six pouces la

distance entre l’aérographe et le travail

afin de contrôler la largeur de la ligne.

Augmenter la pression d’air affectera

également la largeur de la pulvérisation.

Le DAGR pulvérisera un fond d’une largeur

d’environ deux pouces. La vitesse de

mouvement contrôle l’intensité de la

couleur et des dégradés de teintes.

Tracer des lignes sans dégâts

Pour tracer une ligne fine ou large sans

dégâts, commencez par déplacer

Page 23

Page 23SB-2-055-F

l’aérographe avec la gâchette enfoncée

pour l’air. Ensuite tirez sur la gâchette pour

le débit de peinture au début de la ligne et

arrêtez le débit de peinture à la fin mais

continuez le mouvement de l’aérographe.

Pointillage

Le pointillage (gros ou petits pois) peut

ajouter un effect texturisé à l’oeuvre.

Retirez simplement le capuchon (#1) et le

chapeau d’air (#2) et réglez la pression d’air

entre 5 et 50 psi. Une pression faible

produira de gros pois ; une pression élevée

produira de petits pois. La viscosité de la

peinture affecte également le pointillage.

Décrassage

Le levier (#21) permet à l’artiste de retirer

l’accumulation de peinture de l’embout de

l’aérographe sans enlever la poignée et

l’aiguille. Grippez le contre-écrou exposé

de l’aiguille (#19) et tirez dessus tout en

appuyant sur la gâchette (#13). Une plus

grande quantité de peinture s’écoulera de

l’aiguille et de l’embout et débouchera

ainsi l’accumulation de peinture.

Une autre méthode serait d’avoir à portée

de la main un deuxième aérographe

comportant du diluant dans son godet que

vous pourrez utiliser pour vaporiser

l’embout de la buse / de l’aiguille.

Une troisième méthode est d’augmenter la

pression d’air et de vaporiser du diluant dans

l’aérographe pendant une courte durée.

Capuchon

Le capuchon (#1) sert à protéger l’aiguille

lorsque vous vaporisez une ligne fine ainsi

qu’à prévenir l’accumulation et les crachotis

lorsque vous réalisez de grands fonds.

Levier de préréglage

Le levier de préréglage (#21) est doté à

l’arrière d’un bouton de réglage fileté (#23)

qui limite les mouvements de la gâchette

et de l’aiguille. Ceci contrôle la quantité de

peinture vaporisée. Le bouton est doté de

marques de référence.

NETTOYAGE ET LUBRIFICATION

Avant chaque session de vaporisation

Vaporisez du diluant ou du produit

nettoyant approprié dans l’aérographe afin

d’assurer son bon fonctionnement.

Nettoyer à chaque changement de couleur

Videz l’excédent de peinture dans le godet.

Rincez le godet au diluant et employez un

essuie-tout pour récupérer tou te la

peinture restante. Remplissez le fond du

godet de diluant et vaporisez jusqu’à ce

que la brume soit claire. Remplissez

maintenant de la couleur désirée.

Après chaque session de vaporisation

Augmentez la pression d’air et vaporisez

du diluant dans l’aérographe. Cela aidera à

nettoyer à fond les conduits de peinture, la

buse et l’aiguille. Retirez l’aiguille et

essuyez-la à fond (voir ci-dessous).

Essuyez l’extérieur de l’aérographe avec

un linge imprégné de diluant, et laissez

tremper le capuchon au besoin.

Démontez et retirez la soupape d’air avant

de laisser tremper le corps de l’aérographe

dans le diluant. Le joint torique de la

soupape d’air pourrait gonfler et entraver

le débit d’air.

Nettoyage de l’aiguille

Retirez la poignée arrière, desserrez le

contre-écrou de l’aiguille (#19) et retirez

l’aiguille (#20). Enlevez le résidu de

l’aiguille en la faisant rouler à plat sur un

linge doux. Inspectez l’aiguille. Si elle est

tordue ou courbée, remplacez-la.

Appuyez sur la gâchette et introduisez

l’aiguille soigneusement dans l’aérographe

près de l’arrière et appuyez doucement

jusqu’à ce qu’elle siège contre la buse. Elle

Page 24

Page 24 SB-2-055-F

sera alors visible dans l’embout. Vous

sentirez une légère résistance au moment

où l’aiguille pénètre l’étoffage (#6). Si

l’aiguille s’arrête tout à coup, retirez-la et

vérifiez que la gâchette est dans la bonne

position, puis réintroduisez l’aiguille.

Relâchez la gâchette et serrez le contreécrou de l’aiguille.

Lubrification

Afin d’assurer l’action souple de la gâchette,

retirez l’aiguille de temps à autre et

enduisez-la d’un lubrifiant de haute qualité

(par exemple le lubrifiant à vaporiser

DeVilbiss SSL-10). Essuyez l’aiguille avec un

linge doux en laissant une pellicule de

lubrifiant. Réintroduisez l’aiguille et serrez le

contre-écrou de l’aiguille. Mettez quelques

gouttes de lubrifiant dans la fente de la

gâchette dans le corps de l’aérographe.

REMARQUE : N’utilisez pas de WD-40

d’huile à machine légère pour lubrifier, car

celles-ci causeront le blocage de l’aiguille à

mesure qu’elle pénètre l’étoffage PTFE. Ne

pas trop lubrifier l’aiguille ni la gâchette.

L’excédent de lubrifiant pourrait s’introduire

dans la buse, causant ainsi des problèmes

de débit de la peinture.

®

ou

ACCESSOIRES ET PIÈCES DE

RECHANGE

REMARQUE : Si vous devez démonter

l’aérographe, n’utilisez pas de pinces. Les

outils sont rarement nécessaires.

Toutefois se cela s’avère nécessaire,

utilisez une petite clé pour desserrer et

resserrer légèrement le chapeau (#3) qui

siège la buse contre le corps de

l’aérographe. Ne pas trop serrer !

Buse (#4)

Si la buse s’use ou s’endommage, vous

devez la remplacer. Avant de remplacer la

buse, protégez l’aiguille en la tirant

doucement. Pour ce faire, retirez la

poignée (#21), desserrez le contre-écrou de

l’aiguille (#19) et tirez soigneusement

l’aiguille à travers la buse. Retirez le

chapeau (#3) et sortez la buse. Si celle-ci

est coincée, décoincez-la en la poussant

doucement sur le côté avec votre pouce.

Retirez la buse et remplacez-la par une

neuve. Remontez le chapeau et serrez-le à

la main ou légèrement à l’aide d’une clé.

Ne le serrez pas trop. Replacez l’aiguille

dans la buse en la poussant légèrement

vers l’avant jusqu’à ce qu’elle siège sur la

buse de liquide. Serrez le contre-écrou de

l’aiguille et finissez le remontage.

REMARQUE : Afin d’assurer l’usure

uniforme, remplacez l’aiguille en même

temps que la buse.

Aiguille (#20)

Les aiguilles DeVilbiss sont fabriquées en

acier inoxydable usiné en précision et

conçues pour une longue vie de service.

Cela dit, elles sont facilement endommagées

en raison de leurs longues mèches fines et

leurs embouts très fins. Si la pointe de

l’aiguille se courbe ou se plie, vous devez

la redresser avant de la retirer à travers la

buse, sinon la buse pourrait s’endommager.

Si l’aiguille n’est pas trop courbée, roulezla sur une surface plate avec votre doigt

pour la redresser.

Déconnexion rapide (accessoire en option)

Une tige de déconnexion rapide est vissée

sur l’aérographe et un adaptateur de

déconnexion rapide est vissé sur le

conduit d’air. Cela permet les

changements rapides entre aérographes

employant un seul conduit.

Conduit

Utilisez un conduit d’air souple de haute

qualité DeVilbiss tressé en nylon.

Commandez l’ensemble de conduit d’air

de 10 pieds DGR-123 (802769) ou l’ensemble

de conduit d’air de 10 pieds à déconnexion

rapide DGR-124 (802770).

Page 25

DÉPANNAGE

CAUSE CORRECTION

Lacunes :

1. Pression d’air trop élevée 1. Réduire la pression

2. Peinture trop épaisse 2. Réduire avec du diluant

3. Aérographe sale 3. Consulter la section Nettoyage et

4. Buse mal assise sur le corps 4. Serrer le chapeau (à la main ou

5. Buse endommagée ou craquée 5. Remplacer la buse

6. Peinture séchée sur le bout de 6. Consulter la section Nettoyage

l’aiguille de l’aiguille

7. Buse non centrée dans le chapeau 7. Nettoyer les sièges de la buse et

d’air de l’aérographe

Crachotis :

1. Peinture séchée sur le bout de 1. Consulter la section Nettoyage de

l’aiguille l’aiguille

2. Aérographe sale 2. Consulter la section Nettoyage et

3. Peinture trop épaisse 3. Réduire avec du diluant

4. Pression d’air trop basse 4. Augmenter la pression d’air

Bouillonnements dans

le godet

1. Buse ou chapeau desserré ou 1. Serrer le chapeau (à la main ou

mal légèrement assis sur le corps au moyen d’une clé)

2. Buse endommagée ou craquée 2. Remplacer la buse

entretien

légèrement au moyen d’une clé)

lubrification

Page 25SB-2-055-F

CAUSE CORRECTION

Ne vaporise pas :

1. Buse colmatée 1. Consulter la section Nettoyage

2. Desserrer le chapeau 2. Serrer (à la main ou légèrement au

3. Contre-écrou d’aiguille desserré 3. Serrer

4. Mauvaise pression d’air 4. Ajuster

5. Peinture trop épaisse 5. Réduire avec du diluant

6. Buse endommagée ou craquée 6. Remplacer la buse

7. Trou d’évent du couvercle du 7. Débloquer à l’aide d’un cure-dent

godet colmaté ou d’une brosse

Vaporise en ligne double :

1. Aérographe sale 1. Consulter la section Nettoyage

2. Aiguille tordue 2. Remplacer ou redresser l’aiguille

3. Saleté sur l’extrémité de la buse 3. Rincer au diluant ou démonter et

ou dans le chapeau d’air laisser tremper les pièces

4. Buse endommagée ou craquée 4. Remplacer la buse

5. Peinture séchée sur le bout de 5. Consulter la section Nettoyage

l’aiguille de l’aiguille

La gâchette résiste ou ne se déplace pas sans à-coups

1. Lubrification nécessaire 1. Consulter la section Lubrification

2. La peinture a coulé au-delà de 2. Nettoyer à fond l’aérographe

l’étoffage (y compris la gâchette) et serrer

et lubrification

moyen d’une clé)

et lubrification

l’étoffage (#6) en introduisant un

petit tournevis pour écrous à fente

dans le corps de l’aérographe

jusqu’à ce qu’il rejoigne l’écrou

d’étoffage. Tourner légèrement dans

le sens des aiguilles d’une montre.

Page 26

Page 26 SB-2-055-F

27

13

15

16

17

18

19

5

22

21

20

2524

26

1

2

3

4

5

7

8

6

9

10

11

12

23

Entrée d'air 1/8” BPT

Page 27

Page 27SB-2-055-F

Numéro de Numéro de Numéro de

référence commande modèle Description

1 802613 DGR-101 Capuchon

2 802615 DGR-103-35 Chapeau d’air (pour buse 0,35 mm)

3 802616 DGR-104 Chapeau

4 802618 DGR-105-35 Buse (0,35 mm)

• 5 –– Joint torique (chapeau et poignée)

6 802619 DGR-106K Ensemble écrou et étoffage (PTFE)

7 802620 DGR-107 Boîtier de la soupape d’air

8 803644 DGR-308K Ensemble de soupape d’air

• 9 –– Joint torique de soupape d’air

10 –– Piston de soupape d’air

11 –– Ressort de soupape d’air

12 –– Écrou de soupape d’air

13 803645 DGR-323 Gâchette

Numéro de Numéro de Numéro de

référence commande modèle Description

15 802623 DGR-110K Guide-aiguille, bascule et ressort

16 –– Guide-aiguille et bascule

• 17 –– Ressort de l’aiguille

18 802624 DGR-111 Guide du ressort

19 802625 DGR-112 Contre-écrou de l’aiguille

20 802627 DGR-113-35 Aiguille (pour buse 0,35 mm)

21 802628 DGR-114 Levier avec préréglage

• 23 ––

23 802630 DGR-116 Bouton de préréglage de l’aiguille

24 802631 DGR-117 Godet 7 cc (1/4 oz) et couvercle

25 802632 DGR-118

26 802633 DGR-119 Godet 14 cc (1/2 oz) et couvercle

27 802634 DGR-120 Couvercle de godet

28 802635 DGR-121K Trousse de réparation DAGR

30 802975 DGR-18-K5

• La trousse de réparation DAGR 802635 (DGR-121K) comprend :

Numéro Description Qté.

5 Joint torique (chapeau et poignée) 3

9 Joint torique de soupape d’air 2

17 Ressort de l’aiguille 1

22 Joint torique (bouton de préréglage de l’aiguille) 1

Joint torique (bouton de préréglage de l’aiguille)

Godet 9 cc (1/3 oz) et couvercle (standard)

Trousse de joint torique (chapeau et poignée) (5)

Page 28

Page 28 SB-2-055-F

MISE EN GARDE

Les dangers suivants peuvent

survenir lors de l’utilisation normale

de cet équipement. Veuillez lire les

mises en garde suivantes avant

d’utiliser cet équipement.

DANGER : INCENDIE

CAUSE : Les diluants et revêtements

peuvent être extrêmement inflammables

ou combustibles, surtout une fois

vaporisés.

MESURES DE PROTECTION : La

ventilation est indispensable afin d’éviter

l’accumulation de vapeurs inflammables.

Il est interdit de fumer dans la zone de

pulvérisation.

L’équipement d’extinction d’incendie est

indispensable dans la zone de

pulvérisation.

DANGER : VAPORISATION DE DILUANT

CAUSE : Lors de l’utilisation et pendant le

nettoyage et le rinçage, les diluants

peuvent être exprimés des conduits d’air

et de liquide. Certain diluants causent des

blessures aux yeux.

MESURES DE PROTECTION : Lunettes de

protection obligatoires.

DANGER : INHALATION DE SUBSTANCES

TOXIQUES

CAUSE : Certaines matières peuvent être

nocives si inhalées, ou si elles entrent en

contact avec la peau.

MESURES DE PROTECTION : Suivez les

consignes de la fiche signalétique fournie

par le fabricant de revêtement.

Une ventilation adéquate est

indispensable afin d’éviter l’accumulation

de matières toxiques dans l’air.

Utilisez un masque ou un appareil

respiratoire lorsqu’il y a un risque d’inhaler

des matières vaporisées. Le masque doit

être compatible avec la matière vaporisée

ainsi que sa concentration. L’équipement

doit être tel que prescrit par un hygiéniste

industriel ou un professionnel de la

sécurité et approuvé par NIOSH.

DANGER : RISQUE D’EXPLOSION –

MATÉRIAUX INCOMPATIBLES

CAUSE : Diluants d’hydrocarbure halogéné –

par exemple : chlorure de méthylène et

1,1,1, – Trichloroéthane ne sont pas

chimiquement compatibles avec

l’aluminium qui pourrait être utilisé dans

différents composants du système. La

réaction chimique causée par ces diluants

réagissant avec l’aluminium peut devenir

violente et mener à une explosion de

l’équipement.

Page 29

Page 29SB-2-055-F

MESURES DE PROTECTION : Les pistolets

comportant des conduits internes en acier

inoxydable peuvent être utilisés avec ces

diluants. Toutefois l’aluminium s’utilise

généralement avec d’autres équipements

de vaporisation, tels que les pompes,

régulateurs, soupapes, ce pistolet et ce

godet. Vérifiez tous les articles de

l’équipement avant l’utilisation pour vous

assurer qu’ils s’utilisent sans danger avec

ces diluants. Lisez l’étiquette ou la fiche

signalétique de la matière que vous désirez

vaporiser. Si vous avez des doutes

concernant la compatibilité d’un revêtement

ou d’un diluant, contactez votre fournisseur.

DANGER : SÉCURITÉ GÉNÉRALE

CAUSE : Fonctionnement ou entretien

inadéquat de l’équipement.

MESURES DE PROTECTION : Les opérateurs

doivent recevoir une formation adéquate

dans l’utilisation et l’entretien sécuritaires de

l’équipement (conforme aux exigeances de

la NFPA-33, chapitre 15). Les utilisateurs

doivent se conformer aux codes de bonne

pratique locaux et nationaux ainsi qu’aux

exigeances des sociétés d’assurances

concernant la ventilation, les précautions à

prendre contre l’incendie, le fonctionnement

et l’entretien de l’équipement et des locaux.

Ceux-ci se trouvent dans les sections 1910.94

et 1910.107 de l’OSHA et dans la NFPA-33.

DANGER : TROUBLES CONSÉCUTIFS

AUX TRAUMAS CUMULATIFS

Les troubles consécutifs aux traumas

cumulatifs, ou traumatismes musculosquelettiques, impliquent des lésions aux

mains, poignets, coudes, épaules, cou et

dos. Le syndrome du canal carpien et la

tendinite (comme l’épicondylite ou le

syndrome de la coiffe des rotateurs) sont

des exemples de troubles consécutifs aux

traumas cumulatifs.

CAUSE : L’utilisation d’outils à main peut

causer des troubles consécutifs aux

traumas cumulatifs.

Les troubles consécutifs aux traumas

cumulatifs causés par l’utilisation d’outils à

main ont tendance à affecter les membres

supérieurs. Les facteurs pouvant

augmenter le risque de développer des

troubles consécutifs aux traumas

cumulatifs comprennent :

1. Fréquence élevée de l’activité.

2. Force excessive, telle que le grippage, le

pinçage ou la pression avec les mains et

les doigts.

3. Les positions de doigt, de poignet ou de

main extrêmes ou maladroites.

4. Durée excessive de l’activité.

5. Vibration de l’outil.

6. Pression répétée sur une partie du corps.

7. Travailler au froid.

Les troubles consécutifs aux traumas

cumulatifs sont aussi causés par des

activités telles que la couture, le golf, le

tennis et les quilles, entre autres.

MESURES DE PROTECTION : Les douleurs,

fourmillements, ou engourdissements

dans l’épaule, l’avant-bras, le poignet, la

main ou les doigts, surtout la nuit, peuvent

être des symptômes précoces d’un trouble

consécutif aux traumas cumulatifs. Ne les

négligez pas. Si jamais vous ressentez

l’un de ces symptômes, consultez

immédiatement votre médecin. D’autres

symptômes précoces peuvent inclure un

vague malaise dans la main, la perte de la

dextérité, et des douleurs non spécifiques

dans le bras. Le fait de négliger les

symptômes précoces et de continuer

l’usage répétitif du bras, du poignet et de la

main peut entraîner une invalidité sérieuse.

Les risques sont réduits en évitant ou en

réduisant les facteurs 1 à 7.

Page 30

Page 30 SB-2-055-F

GARANTÍA DE CINCO AÑOS DISPONIBLE

Este producto es cubierto por DeVilbiss' garantía limitada 1 año. Una garantía limitada 4 años adicional está disponible colocán-

dose en www.autorefinishdevilbiss.com.

Centros de venta y servicios de DeVilbiss a escala mundial: www.devilbiss.com

Repintado automotriz de DeVilbiss

DeVilbiss tiene distribuidores autorizados en todo el mundo.

Para equipos, repuestos y servicio, consulte las Páginas amarillas

bajo “Equipos y suministros para talleres de repintado automotriz.” Para asistencia técnica, consulte la lista abajo.

Oficina de servicio al cliente en EE.UU./Canadá:

11360 S. Airfield Road, Swanton, OH 43558

Teléfono gratuito: 1-800-445-3988 (sólo en EE.UU. y Canadá)

Fax gratuito: 1-800-445-6643

3/14 ©2014 DeVilbiss Automotive Refinishing Todos los derechos reservados. Impreso en EE.UU.

Page 31

Page 31SB-2-055-F

GARANTIE DE CINQ ANS DISPONIBLE

Ce produit est couvert garantie limitée d'une année par DeVilbiss. Une garantie limitée de quatre ans additionnelle est

disponible par l'enregistrement à www.autorefinishdevilbiss.com.

Informations sur les ventes et le service DeVilbiss dans le monde entier : www.devilbiss.com

Repeinturage automobile DeVilbiss

DeVilbiss a des concessionnaires agréés partout au monde.

Pour l’équipement, les pièces et le service, vérifiez les pages

jaunes sous “Automobile - Équipement et fournitures de réparation de carosserie.” Pour de l’aide technique, consultez les informations ci-dessous.

Bureau du service à la clientèle au Canada / aux É.-U. :

11360 S. Airfield Road, Swanton, OH 43558

Téléphone sans frais : 1-800-445-3988 (Canada et É.-U. seulement)

Télécopieur sans frais : 1-800-445-6643

3/14 ©2014 DeVilbiss Automotive Refinishing Tous droits réservés. Imprimé aux É.-U.

Page 32

Page 32 SB-2-055-F

FIVE-YEAR WARRANTY AVAILABLE

This product is covered by DeVilbiss’ 1-year Limited Warranty. An additional 4-year limited warranty is available by registering

at www.autorefinishdevilbiss.com.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

DeVilbiss Automotive Refinishing

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S./Canada Customer Service Office:

11360 S. Airfield Road, Swanton, OH 43558

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

3/14 ©2014 DeVilbiss Automotive Refinishing All rights reserved. Printed in U.S.A.

Loading...

Loading...