Page 1

SERVICE MANUAL

EN

DAD-500 (130026)

DESICCANT AIR DRYING SYSTEM

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this manual.

Contact your local DeVilbiss representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS DEVILBISS PRODUCT.

SB-6-156-R1 (3/2018) 1 / 8 www.carlisleft.com

Page 2

EN

CA PROP

65

Air In

11

PROP 65 WARNING

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

15

8

14

10

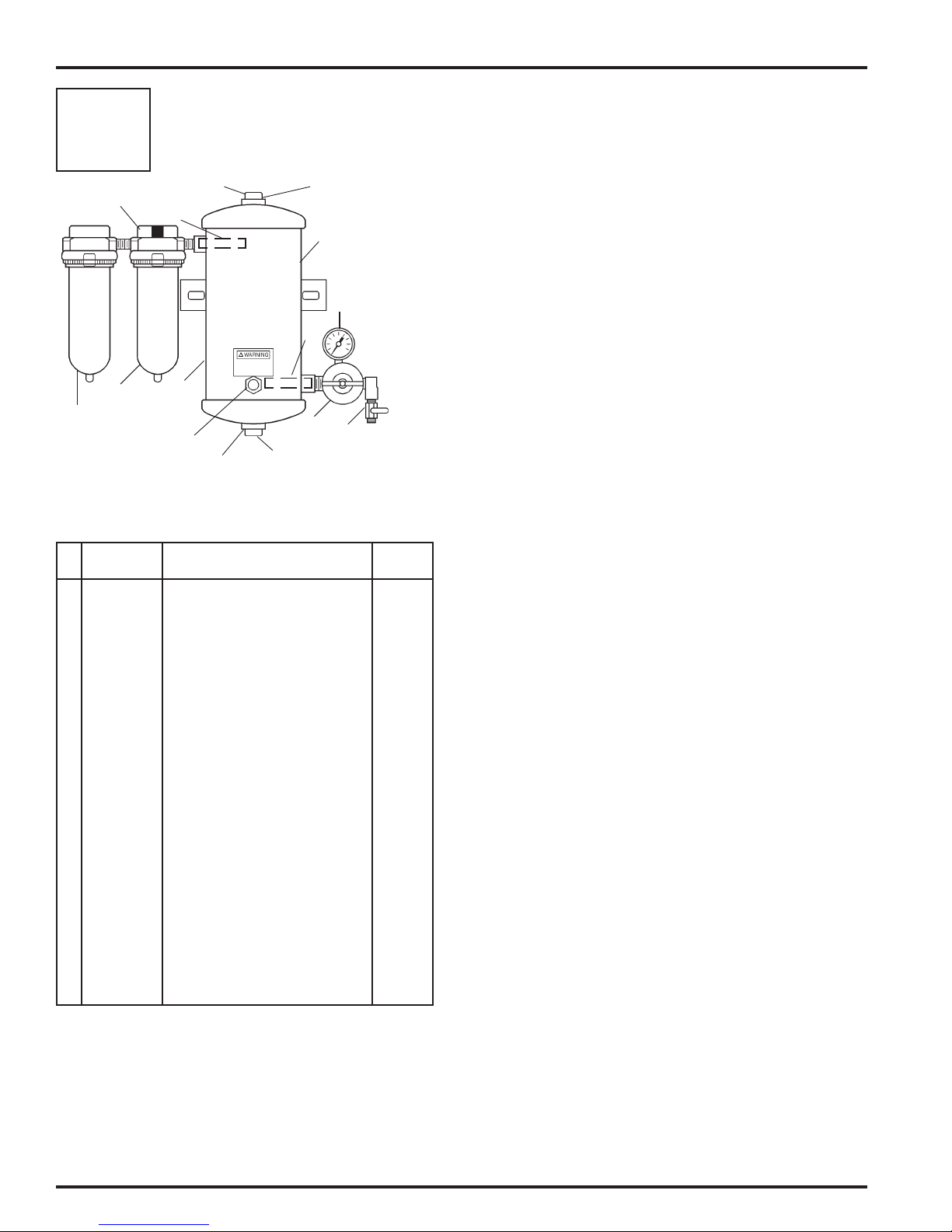

DESCRIPTION

The 25 CFM DAD-500 Desiccant Air Drying System

is designed to be a point of use system. It is capable

of removing dirt, water, oil and water vapor from

compresssed air. It consists of a filter separator,

coalescing filter, desiccant dryer, air regulator and main

air supply shut off valve.

SPECIFICATIONS

5

8

2

1

3

4

6

9

14

15

Air Out

Figure 1

DAD-500 25 CFM Desiccant Air Dryer

PARTS LIST

Ref. Replacement Individual

No. Part No. Description Parts Req.

1 13-0041 Water Separator Filter 1

(HAF-502)

2 HAF-505 Oil Coalescing Filter 1

3 --- Desiccant Dryer 1

4 HAR-507 Air Regulator 1

5 GA-288 Gauge 1

6 VA-542 Ball Valve 1

*7 DAD-1 Replacement Desiccant

(1 Humidity Indicator Paper

Included)

8 DAD-8 Air Filter, (inside of tank) 2

9 DAD-400 Humidity Indicator (1 Humidity 1

Indicator Paper Included)

10 PT-417 Desiccant Tank (without desiccant) 1

(Includes Ref. No. 8)

11 HAF-404 Filter Change Indicator 1

12 DAD-600 Dessicant Tune-Up Kit

Includes 1 each: DAD-1 and HAF-6.

13 DAD-600-1 Complete Tune-Up Kit

Includes 1 each: DAD-1, HAF-28,

and HAF-6.

14

SSG-8217-K2

15 PT-96 Pipe Plug, Special, 1-1/2 NPT 2

16 VA-595 Main Air Supply Shut Off Valve 1

O-Ring Kit (2) 1

(Not shown)

(Not shown)

(Not shown)

(Not shown)

1

1

1

13-0041 (HAF-502) Water Separator Filter - See page 4:

Air Inlet 1/2" NPT(F)

Air Outlet 1/2" NPT(F)

Air Flow Capacity 100 CFM

Maximum Operating Pressure 150 PSIG (10.3 Bar)

Maximum Temperature 150° F (65.6°C)

Automatic Drain Standard

Filter 5 micron

HAF-505 Oil Coalescing Filter - See page 5:

Air Inlet 1/2" NPT(F)

Air Outlet 1/2" NPT(F)

Air Flow Capacity 55 CFM

Maximum Operating Pressure 150 PSIG (10.3 Bar)

Maximum Temperature 150° F (65.6°C)

Automatic Mechanical Drain Standard

Pressure Differential Indicator Standard

Filter 0.01 Micron

Desiccant Dryer - See page 3:

Air Inlet 1/2" NPT(F)

Air Outlet 1/2" NPT(F)

Air Flow Capacity 25 CFM

Maximum Operating Pressure 150 PSIG (10.3 Bar)

Maximum Temperature 150° F (65.6°C)

Humidity Indicator Standard

Water Vapor Removal -40° F Dew Point

HAR-507 Air Regulator - See page 5:

Air Inlet 3/8" NPT(F)

Air Outlet 1/4" NPT(F) (3 ea.)

Air Flow 60 CFM

Maximum Operating Pressure 150 PSIG (10.3 Bar)

Maximum Temperature 120° F (65.6°C)

VA-595 Main Air Supply Shut Off Valve - Not Shown:

Air Inlet and Air Outlet 1/2" NPT(M)

Maximum Operating Pressure 175 PSIG (12.0 Bar)

*The Safety Data Sheet (SDS) is available upon request.

Shipping Weight: DAD-500 = 35 lbs.

SB-6-156-R1 (3/2018)2 / 8www.carlisleft.com

Page 3

EN

Risk of personal injury.

Risk of property damage.

Except as otherwise specified by

the manufacturer, this product

is specifically designed for compressed air service and use with

any other fluid (liquid or gas) is a

misapplication. For example, use

with or injection of certain hazardous gases in the system (such as

oxygen or liquid petroleum gas)

could be harmful to the unit or

result in a combustible condition

that may cause fire or explosion.

Manufacturer's warranties are

void in the event of misapplication

and manufacturer assumes no responsibility for any resulting loss.

INSTALLATION

Risk of injury. Release all air pressure from system before servicing system. Be sure to read and

understand all Service Bulletins on

the separate components before

using the system. Use only specified DeVilbiss parts.

Certain solvents, paints and

chemicals may attack plastic

filter bowl and can cause bowl

failure. Do not use near these

materials.

NOTE

Risk of equipment damage! Do

not install your DAD unit where

it is subjected to sudden depressurization cycles exceedling

20 PSIG. Quick relieving air

solenoid valves, typical in some

spray booths, will eventually fail

pressure gauges and filters, and

produce desiccant "dusting".

To minimize sudden depressurization effect, replace the

existing solenoid with a "slow

closing solenoid valve". (One

source: Automatic Switch Co.)

Or, install an air adjusting valve

at the existing solenoids outlet.

1. See Plumbing Guide on page 6.

Be sure to read all "Warnings" and

"Cautions" in this manual and component manuals on the unit before

installation or using this equipment.

2. Install air drying system as close as

possible to the point where the air is

being used. Use template to position

location of system.

3. Install main air supply shut off valve

and piping union fitting (supplied by

user) upstream of air drying system

to allow maintenance to the unit.

4. Install unit with air flow through filter

in direction of arrow on top of filters.

5. Minimum 1/2" NPT piping is recommended. Avoid using fittings, couplings, etc. that restrict air flow.

6. Maximum inlet pressure and operating

temperature is: 150 PSIG (10.3 bar) and

a150° F (65.6°C)

7. Fill tank with desiccant materials (see

paragraphs 4, 5, 6 under "MAINTENANCE".

8. Two 6' lengths of vinyl tubing are

shipped loose with the system. Slide

over automatic drains which protrude

from bottom of the water/separator

and the oil coalescing filters. Place the

other end of vinyl tubing into appropriate receptacle. Prevent vinyl tubing

from becoming kinked which would

prevent free movement of liquids

discharged from the automatic drain.

9. An optional manual drain (HAF-11) can

be installed in place of the automatic

drains.

OPERATION

After the system is installed and ready to use:

1. Attach air hose(s) to outlet valve.

2. Open main shut-off valve upstream of

system.

3. Adjust regulator to desired setting by

turning "T" handle in or out.

4. Open ball valve to supply air to spray

guns or tool being used. With air

flowing, readjust air pressure at regulator if necessary.

5. After use, shut off ball valve and bleed

off residual air in hose.

MAINTENANCE

Risk of injury. Components under

pressure. Relieve air pressure before

performing any maintenance.

Certain solvents, paints and chemicals may attack plastic bowl and

can cause bowl failure. Do not use

near these materials. When bowl

becomes dirty, wipe only with

a clean, dry cloth. Immediately

replace any crazed, cracked, damaged or deteriorated plastic bowl

with a new plastic bowl. Reinstall

metal bowl guard.

Risk of injury. Do not place unit

in service without metal bowl

guard installed.

1. Check system at least once per shift to

insure proper drainage. Look for water

in the drain tubing.

2. Before performing maintenance on

system, close main shut-off valve

located upstream. Bleed off residual

air in system.

MAINTENANCE - DESICCANT DAD-1

NOTE

The desiccant tank contains an internal filter (DAD-8) at the inlet and

outlet. Be careful not to damage

them when changing desiccant.

1. Replace the desiccant when the hu-

midity indicator changes to a pink or

white color. Remove the pipe plug at the

bottom of the tank. Allow the material

to drain into a two (2) gallon or larger

container.

2. Once all the material has been removed,

replace the pipe plug (see "Note" following) and tighten (do not over tighten)

securely (air tight).

NOTE

Use PTFE tape on pipe plug threads

and all threaded fittings to facilitate

removal in the future. Do not use

loctite or any material that may

bond and make removal difficult.

Risk of injury. Only use a socket

wrench to remove the DAD-400

humidity indicator from the desiccant tank. Immediately replace

the DAD-400 humidity indicator

if damaged.

3. Replace the humidity indicator paper

(supplied with DAD-1 Dessiccant) by

removing the DAD-400 humidity indicator. Pry out the old paper and push

in the new paper (printed side facing

away from the glass).

4. Remove the pipe plug on top of the

unit.

5. Replace desiccant material, DAD-1

(19-0831). Two bags are supplied.

Hold bag pointed upward and cut bag

on dotted line. Grasp and hold bag

where cut and rotate over opening on

top of tank. Empty both bags into tank.

("Note" tank must be filled completely

to prevent damage to desiccant.)

6. Wrap pipe plug with 2 wraps of PTFE

tape. Replace the pipe plug and tighten

until air tight (do not over tighten).

7. The humidity indicator will return to a

blue color within five minutes.

8. The desiccant material should be disposed of properly.

9. Refer to the appropriate service bulletin

for checking the filters and components.

NOTE

A desiccant Tune-Up Kit Part No.

DAD-600, is available. Contains the

following parts to completely recondition a desiccant air station:

SB-6-156-R1 (3/2018) 3 / 8 www.carlisleft.com

Page 4

EN

Part No. Description Qty. Supplied

DAD-1 Desiccant 1

HAF-6 Water Separater Filter

Element and O-Ring 1

DAD-8 In-Tank Filters Replacement Instructions (for filter between the coalescing filter

(stage 2) and the desiccant tank air inlet (stage

3). These filters keep the desiccant within the

tank: Replacing the air filter is not normally

needed. It is required only when the filter has

been damaged or plugged because the unit

was not properly maintained.

10. Be sure air supply to unit is shut off and

bleed off all air pressure from the DAD unit.

11. Make sure the desiccant material is drained

from unit per above instructions.

12. Remove the air supply line from the

water separator inlet (first stage).

13. Remove the filter bowls and filter elements

from both the first and second stage filters

of the unit.

14. Use an open end 7/8" wrench and remove

the hex nipple between the DAD tank and

the coalescing filter. The nipple should

unscrew out of the tank.

15. Using a large #3 Phillips screwdriver, unscrew the filter.

16. Use a large #3 Phillips screwdriver and

reverse the above procedures to install a

new DAD-8 filter. Install about halfway into

the tank fitting.

17. Reverse procedure to reassemble. Refill

with desiccant.

DAD-8 In-Tank Filter Replacement Instructions (for the filter between the air regulator

and the desiccant tank).

18. Be sure air supply to unit is off and

bleed all air from the DAD unit.

19. Be sure all desiccant material is

drained from the unit.

20. Remove air regulator from tank by

placing a 7/8" wrench on tank bushing and

a 1-1/8" wrench on regulator.

21. Remove the brass bushing from the tank

using a 7/8" wrench. Using a large #3 Phillips screwdriver, unscrew the filter.

22. Use a large #3 Phillips screwdriver and

reverse the above procedures to install a

new DAD-8. Install about halfway into the

tank fitting.

NOTE

The air regulator can be installed

back on the tank or additional piping can be installed to pipe the air

to a different location. Remember

that the volume of air flow can be

affected by the pipe and distance

to the new location. All fittings are

regular pipe fittings.

23. Reverse procedure to reassemble.

Refill with desiccant.

24. Before placing unit back into service,

make sure plastic bowl and metal

bowl guard are properly installed and

securely locked in place.

25. Confirm automatic drain operates

properly after unit is in operation. Replace

if necessary.

Figure 2 13-0041 (HAF-502) 100 CFM Water Separator Filter

*5 Automatic Drain

1

2

4

*10 Manual

Flexible Drain

6

3

7

8

*9 Used with automatic

drain only

PARTS LIST 13-0041

Ind.

Ref. Replacement Parts

No. Part No. Description Req.

1 --- Cover 1

2 --- O-Ring 1

3 HAF-26 Baffle Kit 1

4 HAF-6 Filter and O-Ring Kit 1

*5 HAF-18 Automatic Drain 1

6 HAF-8 Plastic Bowl 1

7 HAF-19 Metal Bowl Guard 1

8 HAF-409 Clamp Ring 1

*9 --- 1/2 x 3/8 Vinyl Tubing 1

6 ft.

*10 HAF-11 Manual Drain 1

*DAD-500 is supplied with an automatic

drain. If a 13-0041 (HAF-502) filter is ordered

separately, it will include a manual drain

(automatic drain must be ordered separately

if desired).

DESCRIPTION

This 100 CFM water separator (Model

13-0041) (HAF-502) is designed to remove

dirt, pipe scale and most liquid aerosol.

It includes a 5 micron filter element.

MAINTENANCE 13-0041 (HAF-502) WATER

SEPARATOR and HAF-505 OIL COALESCING

FILTER

1. Check for water in discharge tube and

bowl at least once per shift to insure

proper drainage.

2. Before performing maintenance on

unit, close main shut-off valve located

upstream of filter. Bleed off residual air

in unit.

3. To open filter, press button located

on clamp ring and rotate ring either

clockwise or counterclockwise while

pulling down on ring. The metal bowl

guard and plastic bowl can then be

removed from the filter head.

4. Remove the water separator filter element (HAF-6) by loosening the baffle

counterclockwise. Clean or replace

the filter element. The element can be

cleaned by blowing off with a duster

gun (clean from inside out). Frequency

of element cleaning/replacement will

depend upon air quality, air usage and

condition of the air piping. It is recommended to check and clean/replace the

filter element every 3-6 months.

5. Remove the coalescing element (HAF-

28) by loosening counterclockwise.

Change the element when the filter

change indicator turns red or every 12

to 18 months of service.

6. Inspect o-ring (2) for damage. Replace

if necessary.

7. Inspect plastic bowl for signs of

damage such as cracks, crazing or

deterioration. Replace if necessary. See

“Caution” on page 3.

Risk of injury. Do not place unit in

service without metal bowl guard

installed.

8. Before placing unit back into service,

make sure plastic bowl and metal

bowl guard are properly installed and

securely locked in place.

9. Confirm automatic drain operates properly after unit is in operation. Replace

if necessary.

SB-6-156-R1 (3/2018)4 / 8www.carlisleft.com

Page 5

EN

Figure 3 HAF-505 55 CFM Oil Coalescing Filter

9 (Optional)

1 (not shown)

1A

4

2

3

PARTS LIST HAF-505

Ind.

Ref Replacement Description Parts

No. Part No. Req.

1 HAF-404 Filter Change Indicator 1

(not shown)

1A --- Cover 1

2 --- O-Ring 1

3 HAF-28 Filter and O-Ring Kit 1

4 HAF-18 Automatic Drain 1

5 HAF-8 Plastic Bowl 1

6 HAF-19 Metal Bowl Guard 1

7 HAF-409 Clamp Ring 1

*8 --- 1/2 x 3/8 Vinyl Tubing 6' 1

5

6

7

9 HAF-11 Manual Drain 1

(available separately)

DESCRIPTION

The HAF-505, 55 CFM filter is designed to remove oil, dirt,

pipe scale and liquid aerosol. It includes a 0.01 micron filter

element and automatic mechanical drain.

*8 Used with automatic

drain only

HAR-507 Regulator

DESCRIPTION

This regulator has been designed to receive

air at main line pressure and to deliver it at

a desired lower regulated pressure.

See WARNINGS on Page 3.

REGULATOR MAINTENANCE

1. Occasionally remove bottom plug (7)

and clean valve seat (11) and body.

Clean parts with denatured alcohol,

wipe off seat and blow out body with

compressed air.

2. To disassemble regulator, remove

screws, bonnett, spring and spring

button. Diaphragm assembly can now

be removed.

3. Check all o-rings for signs of damage.

Replace if necessary.

4. Reassemble parts. Center stem of valve

in hole of regulator body. Screw bottom

plug into body.

NOTE

Erratic operation or loss of regulation is usually due to dirt in the

valve area and cleaning is necessary. If cleaning does not correct

the problem, replace the items

included in Repair Kit KK-4977.

If unit leaks air at A , install Repair

Kit KK-4977.

PARTS LIST - Model HAR-507 Regulator

Assembly

Ind.

Ref

Replacement

No.

Part No.

1 --- #10-32 x 9/16 Fillister 6

Hd. Screw

2 HAR-14 Cover 1

3 --- Spring Button 1

4 --- Diaphragm Spring 1

5 --- Body 1

6 --- Pipe Plug 1/4" NPT(M) 1

7 --- Bottom Plug 1

8 KK-4977 Repair Kit (includes 1

Items 9 thru 14)

9 --- Diaphragm Assembly 1

10 --- O-Ring 1

11 --- Valve 1

12 --- O-Ring 1

13 --- Spring 1

14 --- O-Ring 1

Parts

Description Req.

Figure 4

HAR-507 Air Regulator

1

2

3

4

5

6

7

A

9

10

8

11

12

13

14

SB-6-156-R1 (3/2018) 5 / 8 www.carlisleft.com

Page 6

EN

HAF-18 Automatic Drain

NOTE

The automatic drain includes a float. If water gets

into the float, the automatic drain may not function

properly. Under normal conditions, water will not enter

the float. However, water can get in the float if the filter

bowl is washed with the drain installed or if air line

contamination causes the drain mechanism to stick.

A Properly Piped Shop Of Prime Importance for a

Premium Finish.

The bottom line in finishing is a quality paint job. Though on the

surface it may not seem a significant factor in your being able to

turn out a quality paint job, the plumbing of your shop air lines

is very important. Correct installation is necessary for the proper

performance of your equipment - for an uncontaminated air

supply and for sufficient pressure to your spray gun.

Correct airline piping is so important that this one factor alone

can reduce contaminates in your air supply up to 75%*. Reducing contaminates to the filter also reduces the frequency of filter

replacement, maintenance, and of course, reduces the risk of

contaminates to the paint supply.

Even the size of the pipe is critical. Did you ever have only 60 or

70 pounds of pressure at your spray gun when your compressor

should deliver 100 pounds? Using pipe that is too small in diameter

can cause this pressure drop.

For example, if an air compressor delivers 100 psi through a 100 ft.

pipe, 1/2" in diameter, there’s greater pressure drop than if a 3/4"

diameter pipe were used.

The following chart will help reduce pipe pressure drop.

You can confirm the automatic drain is not operating if the water

level in the plastic bowl is higher than the top of the automatic drain.

If the drain does not work properly, replace. It is not repairable.

Body Shop Air Line Plumbing Guide:

1

After leaving the air compressor, air line pipe goes straight up

the shop wall as high as possible. This helps prevent any water

from leaving the compressor and traveling through the pipe.

2

Horizontal pipes should slope back towards the compressor at

least 4” per 50 ft. As warm air leaves the compressor, it cools

and thereby condenses as it travels through the pipe. This wa ter vapor, a problem in itself, also can cause scaling and rust

inside the piping. The backward sloping of the pipe helps push

these contaminates toward the compressor drain.

3

Take-off comes from the top of the main air supply line at each

air drop. This reduces the risk of water and other contaminates

from traveling down the drop into the water separator.

4

Pipe diameter must be of sufficient size for the volume of air

being passed as well as the length of pipe used. This will

minimize pressure drop.

5

First air drop should be at least 25 ft. from the compressor

although 50 ft. is optimum. This allows the compressed air to

cool to room temperature so any condensation can occur

before it gets to the water separator.

Minimum Pipe Size Recommendations

Compressor Compressor Main Min. Pipe

Size Capacity Air Line Diameter

1-1/2 and 2 HP 6 to 9 CFM Over 50 ft. 3/4"

3 and 5 HP 12 to 20 CFM Up to 200 ft. 3/4"

Over 200 ft. 1"

5 to 10 HP 20 to 40 CFM Up to 100 ft. 3/4"

100 to 200 ft. 1"

Over 200 ft. 1-1/4"

10 to 15 HP 40 to 60 CFM Up to 100 ft. 1"

100 to 200 ft. 1-1/4"

Over 200 ft. 1-1/2"

5

3

4

2

6

7

1

9

8

6

Shut-off valve is installed before the point of use filter. This

allows air to be shut off for filter maintenance.

7

Pipe union installed before DAD-500 allows easy installation

and removal of the air drying system.

8

Point-of use filter (not shown) attaches to spray gun, order

HAF-507. Strongly recommended for eliminating any remain ing contaminates.

9

Drain Valves - The daily draining of the system at each outlet

disposes of the contaminants that build up in the air supply.

10

Drain the compressor trap daily if equipped with a manual drain.

Proper maintenance of the air compressor can reduce airborne

contaminants such as particules and oils, and reduce heat and

|operating cost. Check air filters, oil level and perform regular

maintenance per operators manuals.

Guidelines To Piping Your Shop

• Pipe slopes upward - recommend 4” rise in 50 ft.

9

• Minimum 25 ft. to first outlet (50 ft. optimum)

• Pipe size (see chart)

• Shut off valve before filter

• Drain daily

10

SB-6-156-R1 (3/2018)6 / 8www.carlisleft.com

Page 7

NOTES

EN

SB-6-156-R1 (3/2018) 7 / 8 www.carlisleft.com

Page 8

EN

WARRANTY POLICY

This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Carlisle Fluid Technologies,

will void all warranties. Failure to reasonably follow any maintenance guidance provided

may invalidate any warranty.

For specic warranty information please contact Carlisle Fluid Technologies.

Carlisle Fluid Technologies is a global leader in innovative nishing technologies.

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, ms®, BGK®, and Binks®

are registered trademarks of Carlisle Fluid Technologies, Inc.

©2018 Carlisle Fluid Technologies, Inc.

All rights reserved.

For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations.

Region Industrial /Automotive Automotive Renishing

Americas

Europe, Africa,

Middle East, India

China

Japan

Australia

Tel: 1-800-992-4657 Tel: 1-800-445-3988

Fax: 1-888-246-5732 Fax: 1-800-445-6643

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Tel: +81 45 785 6421

Fax: +81 45 785 6517

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

For the latest information about our products, visit www.carlisleft.com

SB-6-156-R1 (3/2018)8 / 8www.carlisleft.com

Loading...

Loading...