Page 1

Service Bulletin

SB-2-658-D

Replaces SB-2-658-C

OPERATION MANUAL

CVi LIGHTWEIGHT GRAVITY FEED SPRAYGUN

English: Pages 3-10

MANUAL DE OPERACIÓN

CVi PISTOLA PULVERIZADORA LIGERO POR GRAVEDAD

Español: Páginas 11-18

GUIDE D’UTILISATION

PISTOLET PULVÉRISATEUR LÉGER À ALIMENTATION PAR GRAVITÉ CVi

Français: Pages 19-25

Page 2

Page 2 SB-2-658-D

In HVLP mandated areas, use only the #505 HVLP air cap.

Consult your local air quality management agency with any

questions regarding HVLP requirements in your area.

En las áreas donde se exige la indicación HVLP, use únicamente

NOTE:

NOTA:

el casquillo de aire #505 HVLP.

Consulte con la agencia de control de la calidad del aire

en su localidad, cualquier pregunta acerca de los requisitos

de HVLP en su área.

NOTE:

Dans les régions où la norme de grand débit à basse pression

(HVLP) s’applique, utiliser uniquement l'anneau déflecteur nº 505

à grand débit à basse pression.

Consulter l'agence locale de gestion de la qualité de l'air pour

toute question touchant les normes de grand débit à basse

pression (HVLP) en vigueur.

Page 3

IMPORTANT: Read and follow all instructions and SAFETY PRECAUTIONS before

using this equipment.

DESCRIPTION

The CVi Lightweight Gravity FeedSpraygun

Kit complies to ATEX regulations 94/9/EC,

protection level; II 2 G X, Suitable for use

in Zones 1 and 2.

When using the #505 air cap, this design

uses EPA compliant atomizing (HVLP)

technology to reduce overspray and

improve coating efficiency. This gun

produces approximately 10 psi air cap

pressure at 18 psi gun inlet pressure

(complies with rules issued by SCAQMD

and other air quality authorities.)

IMPORTANT: These Sprayguns are suitable for use with both waterbased and

solvent based coating materials. The

design uses HVLP atomizing technology

to reduce overspray and improve coating

efficiency. If there is any doubt regarding

the suitability of a specific material contact

your local Jobber or DeVilbiss direct.

Page 3SB-2-658-D

SAFETY WARNINGS

FIRE AND EXPLOSION

Solvents and coating materials can be highly flammable or

combustible when sprayed. ALWAYS refer to the coating material

suppliers instructions and COSHH sheets before using this equipment.

Users must comply with all local and national codes of practice and

insurance company requirements governing ventilation, fire precautions, operation and house-keeping of working areas.

This equipment, as supplied, is NOT

Hydrocarbons.

Static Electricity can be generated by fluid and/or air passing through

hoses, by the spraying process and by cleaning non- conductive parts

with cloths. To prevent ignition sources from static discharges, earth

continuity must be maintained to the spraygun and other metallic

equipment used. It is essential to use conductive air and/or fluid hoses.

PERSONAL PROTECTIVE EQUIPMENT

Toxic vapors – When sprayed, certain materials may be poisonous,

create irritation or be otherwise harmful to health. Always read all

labels and safety data sheets for the material before spraying and

follow any recommendations. If In Doubt, Contact Your Material

Supplier.

The use of respiratory protective equipment is recommended at all

times. The type of equipment must be compatible with the material

being sprayed.

Always wear eye protection when spraying or cleaning the spraygun

suitable for use with Halogenated

EC DECLARATION OF CONFORMITY

We: ITW Finishing UK, Ringwood Rd,

Bournemouth, Dorset, BH11 9LH, UK, as

the manufacturer of the Spraygun model

CVi, declare, under our sole responsi-

bility, that the equipment to which this

document relates is in conformity with

the following standards or other normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN

1953: 1999; and thereby conform to the

protection requirements of Council

Directive 98/37/EC relating to Machinery

Safety Directive, and; EN 13463-1:2001,

council Directive 94/9/EC relating to

Equipment and Protective Systems

intended for use in Potentially Explosive

Atmospheres protection level II 2 G X.

B. Holt, General Manager

30th June 2003

DeVilbiss Automotive Refinishing reserves

the right to modify equipment specification without prior notice.

Gloves must be worn when spraying or cleaning the equipment.

Training – Personnel should be given adequate training in the safe use

of spraying equipment.

MISUSE

Never aim a spraygun at any part of the body.

Never exceed the max. recommended safe working pressure for the

equipment.

The fitting of non-recommended or non-original spares may create

hazards.

Before cleaning or maintenance, all pressure must be isolated and

relieved from the equipment.

The product should be cleaned using a gun washing machine.

However, this equipment should not be left inside gun washing

machines for prolonged periods of time.

NOISE LEVELS

The A-weighted sound level of sprayguns may exceed 85 dB (A)

depending on the set-up being used. Details of actual noise levels are

available on request. It is recommended that ear protection is worn at

all times when spraying.

OPERATING

Spray Equipment using high pressures may be subject to recoil forces.

Under certain circumstances, such forces could result in repetitive

strain injury to the operator.

Page 4

Page 4 SB-2-658-D

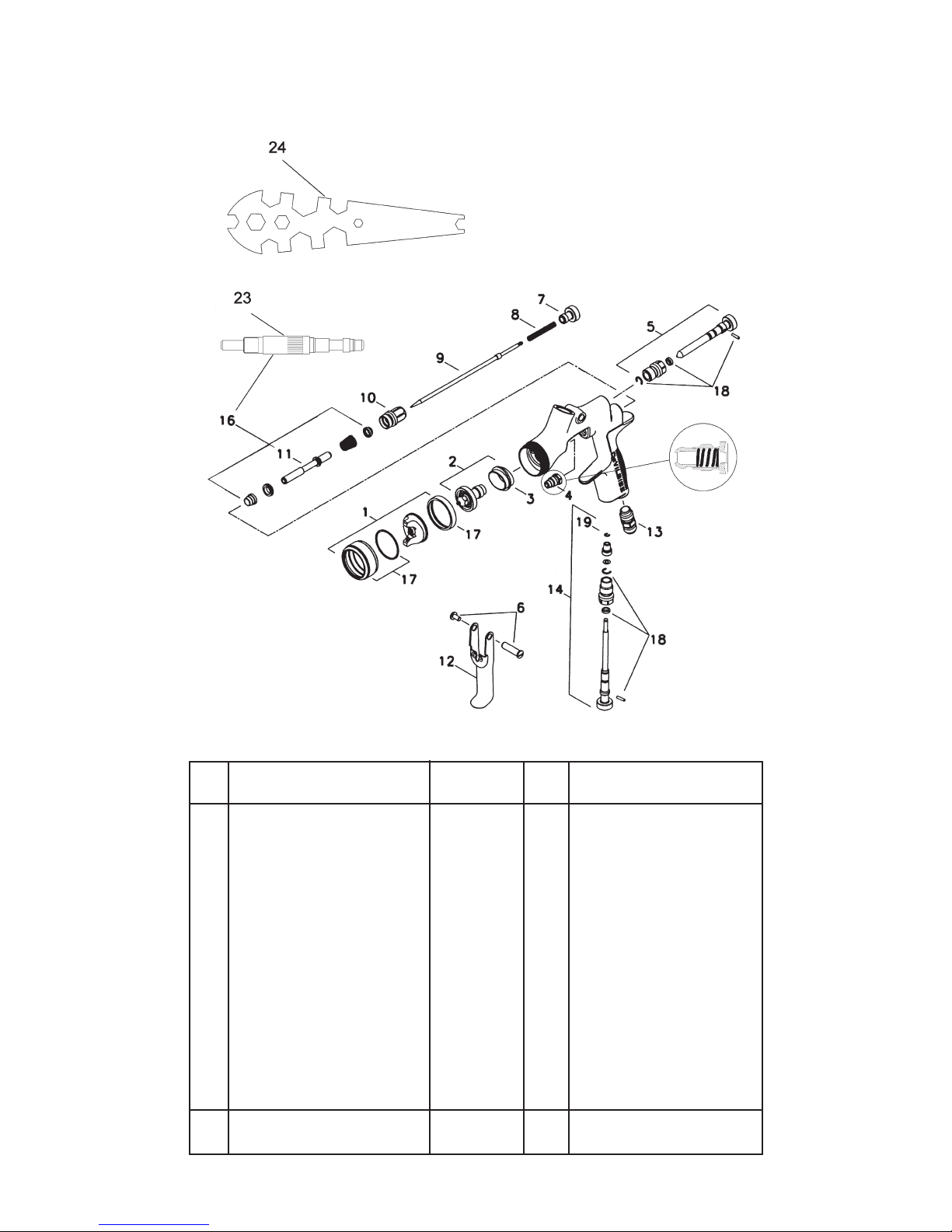

atent No. 2372465 (GB)

P

PARTS LIST

Ref.

No. Description Part Number Qty. Options

1 Air Cap/Retaining ring SP-100-***-K 1 505, 510 e.g *** = 510

2 Nozzle SP-200S-**-K 1 10, 12, 13, 14 e.g ** =13 =1.3 mm

+ 3 Separator SP-626-K5 5

+4 Packing GTI-445-K2 2

5 Spreader Valve SP-403-K 1

6 Stud and Screw GTI-408-K5 5

7 Needle Adjusting Screw SP-614-K 1

+8 Spring SP-622-K5 1

9 Needle SP-300S-**-K 1 10, 12, 13, 14 e.g ** =13 =1.3 mm

10 Airvalve housing & seal SP-612-K 1

11 Spindle 1

12 Trigger SP-617-K 1

13 Connector SP-611-K 1

14 Airflow Valve SP-402-K 1

16 Air Valve Service Kit SPK-101-K 1

17 Retaining Ring and Seals SPK-102-K 1

+18 Clip, Seal and Pin Kit GTI-428-K5 5

23 Air Valve assembly Tool 1

24 Spanner SPN-5-K 1

Spraygun Service Kit SPK-402-K 1

(parts included marked + )

Page 5

Page 5SB-2-658-D

SPECIFICATION

Air supply connection:

Universal 1/4" BSP and NPS

Maximum static Air inlet pressure:

P1= 12 bar (175 psi)

Nominal gun Air inlet pressure

with gun triggered:

1.2 bar (18 psi) 505 HVLP Air Cap

2 bar (29 psi) 510 Trans-Tech Air Cap

Maximum Service temperature: 40°C

Gun Weight: 412 g

MATERIALS OF CONSTRUCTION

Gun body: Anodized Aluminum

Nozzle: Stainless Steel

Needle: Stainless Steel

Fluid Inlet / Fluid Passages:

Anodized Aluminum & Stainless Steel

Trigger: Nickel Plated Steel

INSTALLATION

Important: To ensure that this

equipment reaches you in first

class condition, protective

coatings have been used. Flush

the equipment through with a

suitable solvent before use.

1. Attach air hose to connector (13).

Recommended hose size 8 mm

bore. The hose must be conductive

and electrical bond from the

spraygun to earth should be checked

with an ohmeter. A resistance of less

than 106Ohms is recommended.

2. Air supply should be filtered and

regulated.

3. Attach cup assembly by screwing

into the Fluid Inlet of the spraygun.

Tighten with a wrench.

OPERATION

1. Mix coating material to manufacturers instructions.

2. Fill the cup with the required amount

of material. Fill to no more than

25mm (1") from the top of the cup.

DO NOT OVERFILL.

3. Attach cup lid.

4. Turn needle adjusting screw (7)

clockwise to prevent movement.

5. Turn spreader valve (5) counterclockwise to fully open.

6. Adjust inlet air pressure (For recommended figures see Specifications)

at the gun inlet with the gun triggered. (pressure gauge attachment

shown under Accessories is recommended for this).

7. Turn needle adjusting screw counter

clockwise until first thread shows.

8. Test spray. If the finish is too dry

reduce airflow by reducing air inlet

pressure or by the Airflow Valve

(14). Screw the Adjusting Knob (14)

in to reduce pressure.

9. If finish is too wet reduce fluid flow

by turning needle adjusting screw

(7) clockwise. If atomization is too

coarse, increase inlet air pressure. If

too fine reduce inlet pressure.

10. The pattern size can be reduced by

turning spreader valve (5) clockwise.

11. Hold gun perpendicular to surface

being sprayed. Arcing or tilting may

result in uneven coating.

12. The recommended spray distance is

150-200 mm (6"-8").

13. Spray edges first. Overlap each

stroke a minimum of 50%. Move gun

at a constant speed.

14. Always turn off air supply and

relieve pressure when gun is not in

use.

PREVENTATIVE MAINTENANCE

1. Turn off air and relieve pressure in

the supply lines, or if using QD

system, disconnect from airline.

2. Remove cup lid and empty coating

material into a suitable container.

Clean the gun and cup, preferably in

a gun wash machine. Clean the cup.

3. Check the breather hole in the Lid

and the drip check lid is not blocked.

4. Remove air cap (1) and clean. If any

of the holes in the cap are blocked

with coating material use a toothpick

to clean. Never use metal wire which

could damage the cap and produce

distorted spray patterns

5. Ensure the tip of the nozzle (2) is

clean and free from damage. Build

up of dried paint can distort the

spray pattern.

6. Lubrication – stud/screw (6), needle

(9) and air valve (11) should be oiled

each day with gun oil.

REPLACEMENT OF PARTS

Nozzle (2) and Needle (9) – Remove parts

in the following order: 7, 8, 9, 1 and 2.

Replace any worn or damaged parts and

re-assemble in reverse order.

Recommended tightening torque for

nozzle (2) 9.5-12 Nm (80-100 lbf in).

Packing – Remove parts 7, 8, 9. Unscrew

cartridge (4). Fit new cartridge finger

tight. Re-assemble parts 9, 8, and 7 and

tighten cartridge (4) with spanner sufficient to seal but to allow free movement

of needle. Lubricate with gun oil.

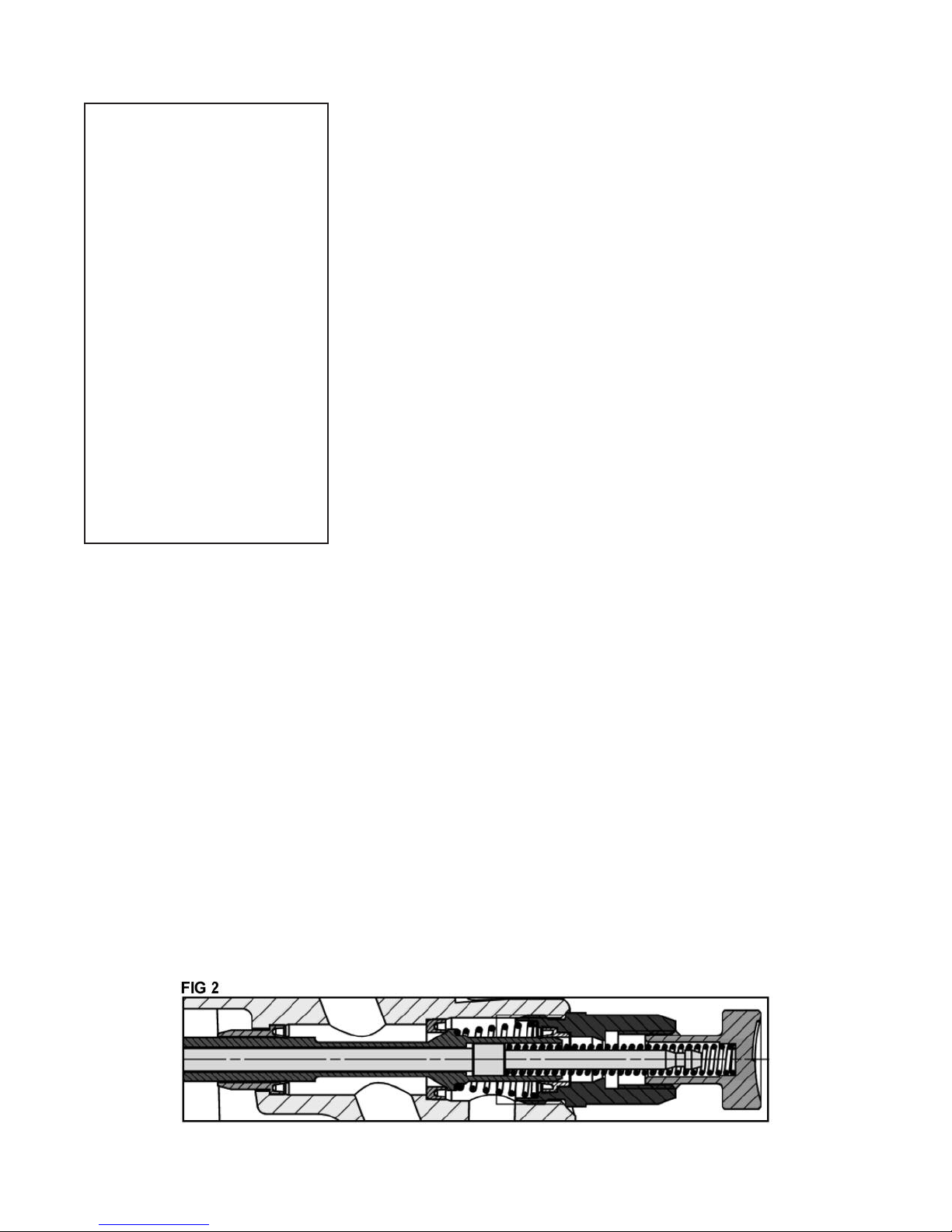

Air Valve Seal Kit (16) – (Refer to photos

1 to 21 and fig 2)

Spreader valve (5) – Caution: always

ensure that the valve is in the fully open

position by turning screw fully counterclockwise before fitting to body.

Page 6

Page 6 SB-2-658-D

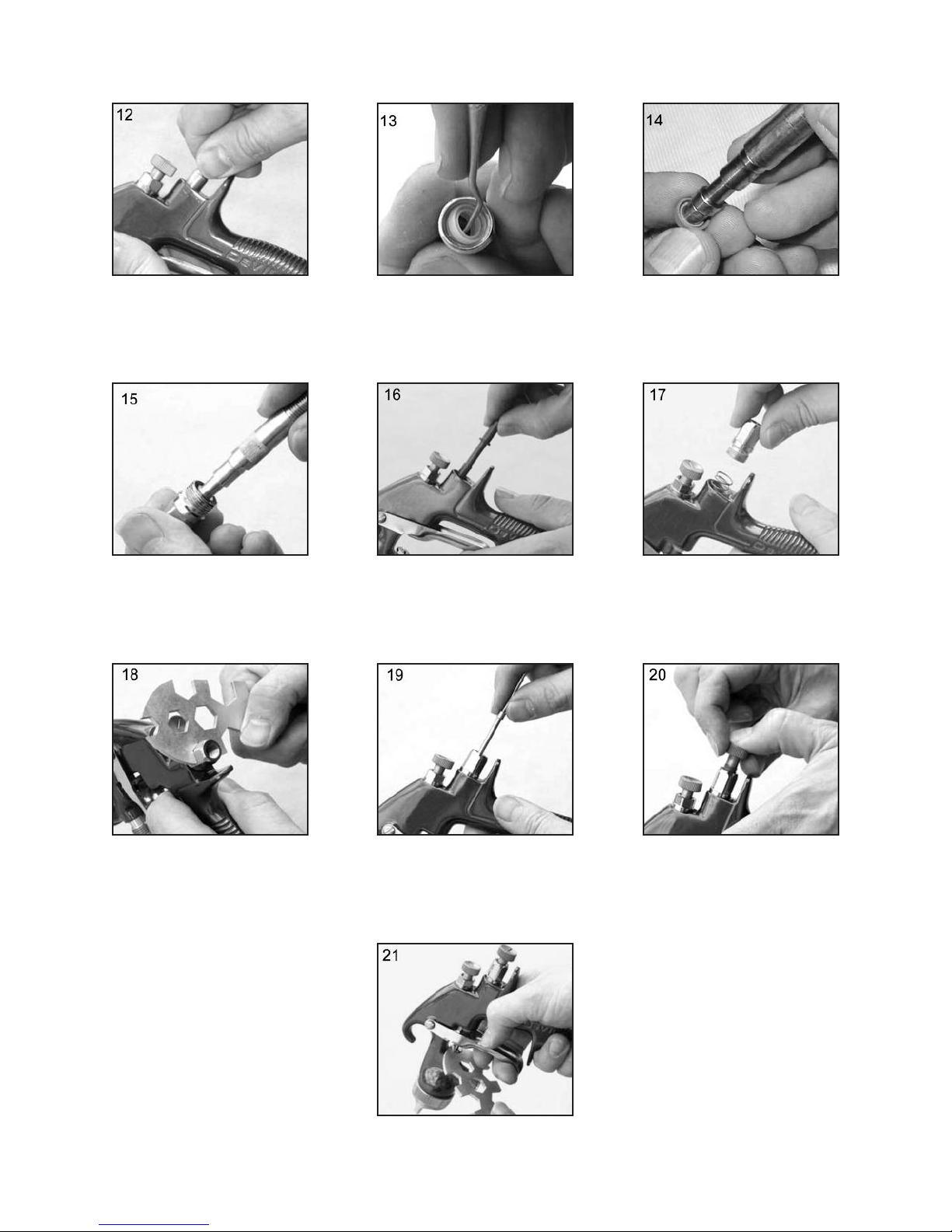

1. Remove Adjusting Knob (7),

Spring (8), and Needle (9).

4. Remove Valve (11). 5. Using Service Tool SPN-7,

2. Loosen Housing (10). 3. Remove Housing (10) and

engage groove behind the

Valve Seat.

Airvalve Spring.

6. Remove Valve Seat.

7. Push out the Front Airvalve

Seal with a finger.

10. Fit new Seal to gunbody and

press firmly to ensure Seal is

engaged.

8. Turn the Gun upside down

and let the Seal fall out.

11. Fit New Valve Seat to

Service Tool so that the

groove faces the handle end

of tool.

9. Fit New Front Seal to Service

Tool so that the groove faces

the handle end of tool.

Page 7

Page 7SB-2-658-D

12. Fit Valve Seat to Gunbody. 13. Remove Rear Airvalve Seal

from housing (10) with a

hooked instrument.

15. Fit Seal to Housing (10). 16. Replace Valve (11). 17. Replace Valve Spring by

14. Fit new Rear Seal to Service

Tool so that the groove faces

the handle end of tool.

inserting small end of spring

into gun, and screw in

Housing (10).

18. Tighten Housing. 19. Fit Needle (9). 20. Fit Spring (8) and Knob (7).

21. Adjust Needle Packing (4)

with Spanner sufficient to

seal but to allow free movement of needle. Lubricate

with gun oil.

Page 8

Page 8 SB-2-658-D

TROUBLESHOOTING

Heavy top or

bottom pattern

Heavy right or left

side pattern

Heavy center pattern

Split spray pattern

Jerky or fluttering spray

Unable to get round spray

Will not spray

Paint bubbles in cup

Fluid leaking or dripping from

cup lid

Starved spray pattern

Excessive overspray

Excessive fog

Dry spray

Fluid leaking from packing nut

Fluid leaking or dripping from

front of gun

*Most common problem.

Horn holes plugged.

Obstruction on top or bottom of fluid tip.

Cap and/or tip seat dirty.

Left or right side horn holes plugged.

Dirt on left or right side of fluid tip.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test

2. If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the

3. Check for dried paint just inside the opening; remove by washing with solvent.

Fluid flow too high for atomization air.

Material flow exceeds air cap's capacity.

Spreader adjustment valve set too low.

Atomizing pressure too low.

Material too thick.

Atomization air pressure too high.

Fluid flow too low.

Spreader adjusting valve set too high.

*Loose or damaged fluid tip/seat.

Baffle seal installed incorrectly.

Material level too low.

Container tipped too far.

Obstruction in fluid passage.

Dry or loose fluid needle packing nut.

Spreader adjustment screw not seating

properly.

Air cap retaining ring loose.

No air pressure at gun.

Fluid needle adjusting screw not open

enough.

Fluid too heavy for gravity feed.

Fluid tip not tight.

Cup lid loose.

Dirty threads on cup or lid.

Cracked cup or lid.

Inadequate material flow.

Low atomization air pressure.

Too much atomization air pressure.

Gun too far from work surface.

Improper stroking (arcing, gun motion too

fast).

Too much or too fast-drying thinner.

Too much atomization air pressure.

Air pressure too high.

Gun tip too far from work surface.

Gun motion too fast.

Gun out of adjustment.

Packing nut loose.

Packing worn or dry.

Packing nut too tight.

Dry packing.

Fluid tip or needle worn or damaged.

Foreign matter in tip.

Fluid needle spring broken.

Wrong size needle or tip.

Clean. Ream with non-metallic point.

Clean.

Clean.

Clean. Ream with non-metallic point.

Clean.

spray pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect

is inverted, obstruction is on the air cap. Clean the air cap as previously instructed.

fluid tip. Remove with #600 wet or dry sand paper.

Balance air pressure and fluid flow. Increase

spray pattern width with spreader adjustment

valve.

Thin or lower fluid flow.

Adjust.

Increase pressure.

Thin to proper consistency.

Reduce at transformer or gun.

Increase fluid flow (increases gun handling

speed).

Adjust.

Tighten or replace.

Install per directions.

Refill.

Hold more upright.

Backflush with solvent.

Lubricate or tighten.

Clean or replace.

Tighten.

Check air supply and air lines, blow out gun

air passages.

Open fluid needle adjusting screw.

Thin material and/or change to larger tip size.

Tighten tip to 9.5-12 Nm (80-100 lbf in.)

Push in or tighten lid.

Clean.

Replace cup and lid.

Back fluid adjusting screw out to first thread,

or change to larger tip size.

Increase air pressure and rebalance gun.

Reduce pressure.

Adjust to proper distance.

Move at moderate pace, parallel to work

surface.

Remix properly.

Reduce pressure.

Reduce air pressure.

Adjust to proper distance.

Slow down.

Adjust.

Tighten, do not bind needle.

Replace or lubricate.

Adjust.

Lubricate.

Replace tip and needle.

Clean.

Replace.

Replace.

Page 9

TROUBLESHOOTING (continued)

Page 9SB-2-658-D

Fluid dripping or leaking from

bottom of cup

Runs and sags

Thin, sandy coarse finish drying

before it flows out

Thick, dimpled finish "orange peel"

Cup loose on gun.

Cup gasket worn or missing below cup.

Cup threads dirty.

Too much material flow.

Material too thin.

Gun tilted on an angle, or gun

motion too slow.

Gun too far from surface.

Too much air pressure.

Improper thinner being used.

Gun too close to surface.

Air pressure too low.

Improper thinner being used.

Material not properly mixed.

Surface rough, oily, dirty.

Tighten.

Replace cup gasket.

Clean.

Adjust gun or reduce fluid flow.

Mix properly or apply light coats.

Hold gun at right angle to work and

adapt to proper gun technique.

Check distance. Normally approx. 8".

Reduce air pressure and check spray pattern.

Follow paint manufacturer's mixing instrs.

Check distance. Normally approx. 8".

Too much material coarsely atomized.

Increase air pressure or reduce fluid flow.

Follow paint manufacturer's mixing instrs.

Properly clean and prepare.

Page 10

Páge 10 SB-2-658-D

ACCESSORIES

GFC-501 (Acetal) 20 Oz. Cup

GFC-502 (Aluminum) 1-Liter Cup

Gravity Feed Cups

hese gravity feed cups

T

re designed to be used

a

with EXL, FLG, GFG,

GFHV, GTI or CVi gravity

eed spray guns.

f

KK-5033-505

Air Cap Test Kit

The purpose of this test

it is to measure air cap

k

atomizing air pressure at

he center air port of the

t

air cap. Used to confirm

code compliance and as

daily quality control

a

measure.

Spray Gun Lube

SSL-10-K12 (2 oz. bottle)

HAV-500 OR

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

AV-500 does not

H

have pressure gauge.

Use to control air

sage at gun.

u

192219

Gun Holder

Gun holder made

o hold guns with

t

gravity cups.

HAF-507

Whirlwind™

In-Line Air Filter

Removes water, oil,

nd debris from the

a

air line.

GI-501-PSI

D

Digital

Pressure Gauge

Digital pressure

gauge for precise

ressure control at

p

the gun.

GH-505

Gun Holder

92218 Scrubs

1

and Cleaner Towels

H

®

crubs

S

moistened hand cleaner

owel for painters, body

t

men and mechanics that

o where you go and no

g

water is needed.

®

re a pre-

a

GH-407

Gun Holder

Compatible with all paint materials;

ontains no silicone or petroleum

c

distillates to contaminate paint.

MSDS Sheetavailable uponrequest.

192212

Professional Spray Gun Cleaning Kit

Contains six precision tools designed

to effectively clean

all DeVilbiss, Binks,

Finishline and other

brand spray guns.

SPN-5 Wrench

ontains all neces-

C

sary tip, hose and

nut sizes used on or

with gun.

OMX-70-K48 Paint Cup Liner Kit

Allows quick & easy clean-up.

Consists of : 1 - Piercing Tool,

48 - Disposable Liners, 48 - Drain Bushings

Automotive Refinish Quick Connects

For HVLP Guns (Air)

HC-4419 Stem

1/4" NPT(F)

HC-4719 Coupler

1/4" NPT(M) /NPS(M)

1) Wall mount bracket

un holders are

G

made to hold

standard paint cups,

gravity feed guns and

cups, and paint filters.

(

included with GH-407.

Holds standard paint

cups,gravity feedgunsand

cups, and paint filters.

Paint Spray Respirators

MSP-523 (Sm) MSP-524 (Med) MSP-525 (Lg)

NIOSH-Certified for respiratory protection in

atmospheres not immediately dangerous to life.

High Flow Type.

HC-1166 Stem

1/4" NPT(M)

HC-4720 Coupler

1/4" NPT(F)

Page 11

IMPORTANTE: Lea y siga todas las

instrucciones y Precauciones de Seguridad

antes de utilizar este equipo.

DESCRIPCIÓN

El Kit de Pistola Pulverizadora Ligero por

Gravedad CVi cumple las normas ATEX

94/9/CE, nivel de protección; II 2 G X,

Adecuado para el uso en las Zonas 1 y 2.

Al usar el casquillo de aire #505, este

diseño utiliza tecnología (HVLP) de atomización que cumple con las especificaciones de EPA para reducir el exceso de

atomización y mejorar la eficacia del

recubrimiento. Esta pistola produce una

presión de casquillo de aire de aproximadamente 10 psi a una presión de

entrada de la pistola de 18 psi (cumple

con normas emitidas por SCAQMD y

otras autoridades de la calidad del aire).

IMPORTANTE: Estas Pistolas pulverizadoras son apropiadas para el uso con

materiales de recubrimiento a base de

agua o de disolventes. El diseño utiliza

tecnología de pulverización HVLP para

reducir la sobrepulverización y mejorar la

eficacia del recubrimiento. Si tiene

alguna duda respecto a la idoneidad de

un material específico, póngase en

contacto con su Distribuidor local o directamente con ITWIF.

DECLARACIÓN DE CONFORMIDAD CE

Nosotros: ITW Finishing UK, de

Ringwood Rd, Bournemouth, Dorset,

BH11 9LH, Reino Unido, como fabricantes

de la Pistola pulverizadora modelo CVi,

declaramos bajo nuestra exclusiva

responsabilidad que el equipo al que se

refiere este documento cumple los siguientes estándares o normas:

BS EN 292-1 PARTES 1 y 2: 1991, BS EN

1953:1999; y que por tanto cumple los

requisitos de protección de la Directiva del

Consejo 98/37/CE relativa a la Directiva

sobre Seguridad de las Máquinas y EN

13463-1:2001, Directiva del Consejo

94/9/CE relativa a Equipos y sistemas de

protección diseñados para ser utilizados

en atmósferas potencialmente explosivas

nivel de protección II 2 G X.

Página 11SB-2-658-D

ADVERTENCIAS DE SEGURIDAD

INCENDIO Y EXPLOSIÓN

Los disolventes y los materiales de recubrimiento pueden ser altamente inflamables o combustibles al pulverizarse. Consulte SIEMPRE

abricante del material de recubrimiento y las hojas COSHH antes de utilizar

f

ste equipo.

e

Los usuarios deben cumplir la normativa nacional y local y los requisitos de las

ompañías de seguros respecto a ventilación, precauciones contraincendios,

c

peración y mantenimiento de las zonas de trabajo.

o

Este equipo, tal y como se suministra, NO

idrocarburos Halogenados

H

a Electricidad Estática puede ser generada por el paso de fluido y/o aire por los

L

manguitos, por el proceso de pulverización y por la limpieza de piezas no

conductoras con paños. Para impedir que las descargas estáticas produzcan

uentes de ignición, debe mantenerse la continuidad de tierra a la pistola pulver-

f

izadora y a otros equipos metálicos utilizados. Es imprescindible utilizar

manguitos de aire y/o fluido que sean conductores de electricidad.

.

es adecuado para su uso con

EQUIPO DE PROTECCIÓN PERSONAL

Vapores tóxicos - Al pulverizarse, ciertos materiales pueden ser tóxicos, crear

rritación o ser dañinos para la salud de otra forma. Lea siempre todas las

i

etiquetas y hojas de datos de seguridad del material antes de pulverizar, y siga

cualquier recomendación. En caso de Duda, Póngase en Contacto con el

Proveedor del Material.

Se recomienda el uso de equipos de protección respiratoria en todo momento. El

tipo de equipo debe ser compatible con el material que se está pulverizando.

Lleve siempre protección ocular al pulverizar o al limpiar la pistola.

Deben llevarse guantes al pulverizar o al limpiar la pistola.

Formación - El personal debe recibir una formación adecuada en el uso seguro

de equipos de pulverización.

MAL USO

No apunte nunca con una pistola de pulverización a ninguna parte del cuerpo.

No supere nunca la presión máxima de operación segura recomendada del

equipo.

El acoplamiento de piezas de repuesto no recomendadas o no originales puede

crear riesgos.

Antes de realizar limpieza o mantenimiento, toda presión debe aislarse y aliviarse

en el equipo.

El producto debe ser limpiado usando una máquina para lavar pistolas. No

obstante, este equipo no debe dejarse dentro de una máquina de lavar pistolas

durante periodos de tiempo prolongados.

NIVELES SONOROS

El nivel sonoro con ponderación A de las pistolas de pulverización puede superar

los 85 dB(A) dependiendo de la configuración utilizada. Los detalles de niveles

sonoros reales están disponbles previa petición. Se recomienda llevar protección

acústica en todo momento durante la pulverización.

las instrucciones del

B. Holt, Director General

30/6/2003

DeVilbiss Automotive Refinishing se

reserva el derecho a modificar las especificaciones del equipo sin previo aviso.

OPERACIÓN

Los Equipos de Pulverización que funcionan a alta presión pueden verse

sometidos a fuerzas de retroceso. Bajo determinadas circunstancias, dichas

fuerzas podrían provocar al operador lesiones por esfuerzo repetitivo (RSI).

Page 12

Página 12 SB-2-658-D

Patente Nº 2372465 (GB)

LISTA DE PIEZAS

Nº Número

Ref. Descriptión de Pieza Cant Opciones

1 Casquillo de aire / Anillo de retención SP-100-***-K 1 505, 510 ej. *** = 510

2 Pico de fluido SP-200S-**-K 1 10, 12, 13, 14 ej. ** =13 =1.3 mm

+ 3 Separador SP-626-K5 5

+4 Empaquetadura GTI-445-K2 2

5 Válvula dispersora SP-403-K 1

6 Espiga y tornillo GTI-408-K5 5

7 Tornillo de ajuste de la aguja SP-614-K 1

+8 Muelle SP-622-K5 1

9 Aguja SP-300S-**-K 1 10, 12, 13, 14 ej. ** =13 =1.3 mm

10 Alojamiento de la válvula de aire SP-612-K 1

& junta

11 Vástago 1

12 Gatillo SP-617-K 1

13 Conector SP-611-K 1

14 Válvula de caudal de aire SP-402-K 1

16 Kit de mantenimiento de la SPK-101-K 1

válvula de aire

17 Retén y juntas SPK-102-K 1

+18 Kit de clip, junta y perno GTI-428-K5 5

23 Herramienta para el conjunto de

la válvula de aire 1

24 Llave SPN-5-K 1

Kit de Mantenimiento de SPK-402-K 1

la Pistola Pulverizadora

(piezas incluidas marcadas con + )

Page 13

Página 13SB-2-658-D

ESPECIFICACIÓN

Conexión del suministro de aire :

Universal 1/4" BSP and NPS

Presión nominal de entrada de aire

en la pistola – con el gatillo apretado:

1.2 bar (18 psi) casquillo de aire 505 HVLP

2 bar (29 psi) casquillo de aire 510 Trans-Tech

Temperatura Máxima de uso: 40°C

Peso de pistola: 412 g

MATERIALES DE CONSTRUCCIÓN

Cuerpo de la pistola: Aluminio

anodizado

Boquilla: Acero inoxidable

Aguja: Acero inoxidable

Entrada de fluido / Conductos de fluido:

Aluminio anodizado y acero inoxidable

Gatillo: Acero niquelado

INSTALACIÓN

Importante: Para asegurarse

de que este equipo llega a

usted en condiciones óptimas,

se han utilizado recubrimientos

protectores. Enjuague el

equipo con un disolvente

adecuado antes de su uso.

1. Acople el manguito de aire al

conector (13). Tamaño de manguito

recomendado: 8 mm diám. interior.

El manguito debe ser conductor de

electricidad y la conexión eléctrica

entre la pistola pulverizadora y tierra

debe verificarse con un ohmímetro.

Se recomienda una resistencia de

menos de 106Ω. El suministro de aire

debe estar filtrado y regulado.

2. El suministro de aire debe estar

filtrado y regulado.

3. Acople el conjunto de la cubeta

enroscándolo en la entrada de fluido

de la pistola pulverizadora. Apriete

cuando haya entrado del todo.

OPERACIÓN

1. Mezcle el material de recubrimiento

siguiendo las instrucciones del fabricante.

2. Llene la copa con la cantidad

requerida de material. No llene a

menos de 25 mm de la parte superior de la copa. NO LLENE

DEMASIADO.

3. Acople la tapa de la cubeta.

4. Gire el tornillo de ajuste de la aguja

(7) en el sentido de las agujas del

reloj para impedir que se mueva.

5. Gire la válvula de dispersión (5) en el

sentido contrario a las agujas del

reloj hasta que esté abierta del todo.

6. Ajuste la presión de aire de entrada

(ver valores recomendados en las

Especificaciones) en la entrada de la

pistola con el gatillo apretado. con el

gatillo apretado (se recomienda

utilizar para ello el manómetro

mostrado en Accesorios).

7. Gire el tornillo de ajuste de la aguja

en el sentido contrario a las agujas

del reloj hasta que se vea la primera

rosca.

8. Haga una prueba de pulverización.

Si el acabado es demasiado seco,

reduzca el caudal de aire reduciendo

la presión de entrada de aire o mediante la Válvula de Caudal de Aire

(14). Gire el Pomo de Ajuste (14)

hacia dentro para reducir la presión.

9. Si el acabado es demasiado

húmedo, reduzca el caudal de fluido

girando el tornillo de ajuste de la

aguja (7) en el sentido de las agujas

del reloj o reduciendo la presión del

fluido. Si la atomización es

demasiado gruesa, aumente la

presión de entrada de aire. Si es

demasiado fina, reduzca la presión

de entrada.

10. El tamaño del patrón puede

reducirse ajustando la válvula

dispersora (5) en el sentido de las

agujas del reloj.

11. Sujete la pistola perpendicular a la

superficie a pulverizar. Pulverizar en

arcos o con la pistola inclinada

puede producir un recubrimiento

desigual.

12. La distancia de pulverización

recomendada es de 150 - 200 mm.

13. Pulverice primero los bordes.

Solape cada pasada el 50% como

mínimo. Mueva la pistola a una

velocidad constante.

14. Cierre siempre el suministro de aire

y alivie la presión cuando la pistola

no se esté utilizando.

MANTENIMIENTO PREVENTIVO

1. Cierre el suministro de aire y alivie la

presión en los manguitos de suministro, o si utiliza el sistema QD,

desconéctelo del manguito de aire.

2. Retire la tapa de la cubeta y vacíe el

material de recubrimiento en un

recipiente apropiado. Limpie la

pistola y la cubeta, preferentemente

en una máquina de lavado de

pistolas. Limpie la cubeta.

3. Compruebe que el orificio de ventilación de la tapa y de la tapa antigoteo no está obstruido.

4. Retire el casquillo de aire (1) y

límpielo. Si alguno de los orificios

del casquillo está obstruido con

material de recubrimiento, utilice un

palillo de dientes para limpiarlo. No

utilice nunca un alambre metálico,

porque podría dañar el casquillo y

producir patrones de pulverización

distorsionados.

5. Asegúrese de que la punta de la

boquilla (2) está limpia y libre de

desperfectos. Una acumulación de

pintura seca puede distorsionar el

patrón de pulverización.

6. Lubricación – la espiga/tornillo (6), la

aguja (9) y la válvula de aire (11)

deben lubricarse con aceite cada dia

con aceite del pistola.

SUSTITUCIÓN DE PIEZAS

Boquilla (2) y Aguja (9) – Retire las piezas

en el siguiente orden: 7, 8, 9, 1 y 2.

Sustituya cualquier pieza desgastada o

dañada y vuelva a montar las piezas en

orden inverso. Par de apriete recomendado para la boquilla (2) 9,5-12 Nm (80100 pies-libra/pulgada).

Guarnición – Retire las piezas 7, 8, 9.

Desenrosque el cartucho (4). Coloque un

cartucho nuevo y apriete con los dedos

solamente. Vuelva a montar las piezas 9,

8 y 7 y apriete el cartucho (4) con una

llave, lo suficiente para hacer sello pero

dejando que la aguja se desplace libremente. Lubrique con aceite para pistolas.

Kit de Junta de la Válvula de Aire (16) –

(Ver FIG 2 y fotos 1 a 21).

Válvula Dispersora (5) – Precaución:

asegúrese siempre de que la válvula está

en posición completamente abierta

girando el tornillo en el sentido contrario

a las agujas del reloj hasta que haga tope

antes de instalarla en el cuerpo de la

pistola.

Page 14

Página 14 SB-2-658-D

1. Retire el pomo de ajuste (7),

el muelle (8), y la aguja (9).

4. Retire la válvula (11). 5. Usando la herramienta de

2. Afloje el alojamiento (10). 3. Retire el alojamiento (10) y

manteni-miento SPN-7,

enganche la muesca detrás

del asiento de la válvula.

el muelle de la válvula de

aire.

6. Retire el asiento de la

válvula.

7. Haga salir la junta delantera

de la válvula de aire empujando con el dedo.

10. Coloque la junta nueva sobre el

cuerpo de la pistola y empuje

firmemente para asegurarse de

que la junta quede correctamente colocada.

8. Ponga la pistola boca abajo

y deje que se caiga la junta.

11. Instale el asiento de la

válvula nuevo en la

herramienta de mantenimiento de manera que la

muesca quede orientada

hacia el extremo con mango

de la herramienta.

9. Instale una junta delantera

nueva en la herramienta de

mantenimiento de manera

que la muesca quede orientada hacia el extremo con

mango de la herramienta.

Page 15

Página 15SB-2-658-D

12. Coloque el asiento de

válvula en el cuerpo de la

pistola.

15. Coloque la junta en el

alojamiento (10).

13. Retire la junta de la válvula

de aire del alojamiento (10)

con un instrumento que

tenga gancho.

16. Vuelva a colocar el husillo

(11).

14. Instale una junta trasera

nueva en la herramienta de

mantenimiento de manera

que la muesca quede orientada hacia el extremo con

mango de la herramienta.

17. Vuelva a colocar el muelle

de la válvula insertando el

extremo pequeño del muelle

en la pistola, y el tornillo en

el alojamiento (10).

18. Apriete el alojamiento. 19. Coloque la aguja (9). 20. Instale el muelle (8) y el

pomo (7).

21. Ajuste la guarnición de la aguja (4) con

una llave lo suficiente para hacer sello

pero permitiendo que se desplace la

aguja. Lubrique con aceite para pistolas.

Page 16

Página 16 SB-2-658-D

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS

CONDICIÓN CAUSA CORRECCIÓN

Patrón pesado en

a parte superior

l

o inferior

atrón pesado en

P

el lado derecho

izquierdo

o

Patrón pesado

n el centro

e

atrón de pulverización

P

dividida

Pulverización entrecortada o

con vibraciones

Imposibilidad de obtener

pulverización redondeada

No pulveriza

Burbujas de pintura en la cubeta

El fluido se escapa o gotea de la tapa

de la cubeta

Patrón de pulverización subalimentada

Agujeros de la horquilla obstruidos.

bstrucción en la parte superior o inferior de la

O

punta de fluido.

asquillo y/o asiento de la punta está sucio.

C

gujeros en el lado izquierdo o derecho de la

A

orquilla obstruidos.

h

uciedad en el lado izquierdo o derecho de la

S

unta del líquido.

p

orrección de los patrones pesados en la parte superior, inferior, el lado derecho e izquierdo.

C

. Determine si la obstrucción está en el casquillo de aire o en la punta de fluido. Realice esto haciendo

1

na prueba del patrón de pulverización. Luego gire el casquillo media vuelta y pulverice con otro

u

atrón. Si se invierte el defecto, la obstrucción se encuentra en el casquillo de aire. Limpie el

p

asquillo de aire siguiendo las instrucciones previas.

c

i el defecto no se invierte, la obstrucción se encuentra en la punta de fluido. Verifique si hay una

S

.

2

equeña protuberancia en el borde de la punta de fluido. Quítela con papel de lija #600 húmedo o seco.

p

. Verifique si hay pintura seca dentro de la abertura; elimínela lavándola con disolvente.

3

El fluido fluye demasiado alto para el aire de

tomización.

a

l flujo del material sobrepasa la capacidad del

E

casquillo de aire.

l ajuste de la válvula dispersora es muy bajo.

E

La presión de atomización es muy baja.

l material es muy espeso.

E

a presión de aire de atomización es muy alta.

L

El fluido fluye muy bajo.

l ajuste de la válvula dispersora es muy alto.

E

La punta/el asiento del fluido está flojo o dañado.

*

La junta deflectora fue instalada incorrectamente.

El nivel del material es muy bajo.

El recipiente se inclinó mucho.

Obstrucción en el conducto del fluido.

La tuerca de la empaquetadura de la aguja de

fluido seca o floja.

El tornillo de ajuste del dispersador no está

alojado debidamente.

El anillo de retención del casquillo de aire está flojo.

No hay presión de aire en la pistola.

El tornillo de ajuste de la aguja de fluido no está

lo suficientemente abierto.

El fluido es muy pesado para la alimentación

por gravedad.

La punta de fluido no está apretada.

La tapa de la cubeta está floja.

Roscas sucias en la cubeta o tapa.

Cubeta o tapa agrietada.

Flujo inadecuado del material.

Presión de aire de atomización baja.

impie. Escariar con punta no metálica.

L

Limpie.

impie.

L

impie. Escariar con punta no metálica.

L

Limpie.

quilibre la presión de aire y el flujo de fluido.

E

Aumente el ancho del patrón de pulverización con la

válvula de ajuste del dispersador.

iluya o baje el flujo de fluido.

D

Ajuste.

umente la presión.

A

iluya hasta lograr la consistencia adecuada.

D

eduzca la presión en el transformador o en la pistola.

R

Aumente el flujo de líquido (aumente la velocidad de

anipulación de la pistola).

m

Ajuste.

Apriete o reemplace.

Instálelo de acuerdo con las instrucciones.

Vuelva a llenar.

Sosténgalo de forma más vertical.

Limpie con disolvente.

Lubrique o apriete.

Limpie o reemplace.

Apriete.

Verifique el suministro de aire y las líneas de aire,

limpie con aire comprimido los conductos de aire de

la pistola.

Abra el tornillo de ajuste de la aguja de fluido.

Diluya el material y/o cambie la punta por una más

grande.

Apriete la punta a 9.5-12 Nm (80-100 lbf in.)

Empuje o apriete la tapa.

Limpie.

Reemplace la cubeta o la tapa.

Retuerza el tornillo de ajuste de fluido hasta la

primera rosca o cambie la punta por una más grande.

Aumente la presión de aire y reequilibre la pistola.

Sobrepulverización excesiva

Nebulización excesiva

Pulverización seca

Escape de fluido por la tuerca de la

empaquetadura

Escape o goteo de fluido por la parte

delantera de la pistola

Demasiada presión de aire de atomización.

La pistola está muy alejada de la superficie de trabajo.

Carrera indebida (formación de arco, el desplazamiento de la pistola es muy rápido).

Demasiado diluyente o diluyente de secado

muy rápido.

Demasiada presión de aire de atomización.

Presión de aire muy alta.

Punta de pistola muy alejada de superficie de trabajo.

El desplazamiento de la pistola es muy rápido.

Pistola desajustada.

Tuerca de la empaquetadura floja.

Empaquetadura gastada o seca.

Tuerca de la empaquetadura muy apretada.

Empaquetadura seca.

Punta de fluido o aguja gastada o dañada.

Materias foráneas en la punta.

Muelle de la aguja del fluido roto.

Aguja o punta de tamaño inadecuado.

*Problemas más comunes.

Reduzca la presión.

Ajuste hasta la distancia adecuada.

Desplace la pistola a un ritmo moderado, paralelo a

la superficie de trabajo.

Vuelva a mezclar el diluyente debidamente.

Reduzca la presión.

Reduzca la presión de aire.

Ajuste hasta la distancia adecuada.

Reduzca la velocidad.

Ajuste.

Apriete, no bloquee la aguja.

Reemplace o lubrique.

Ajuste.

Lubrique.

Reemplace la punta y la aguja.

Limpie.

Reemplace.

Reemplace.

Page 17

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS (continuará)

CONDICIÓN CAUSA CORRECCIÓN

l fluido se escapa o gotea desde la parte

E

inferior de la cubeta.

e corre

S

Acabado rugoso arenoso, fino, que se

eca antes de fluir.

s

cabado grueso, no uniforme, como el de

A

una “cáscara de naranja”.

ubeta floja en la pistola.

C

uarnición de la cubeta gastada o falta

G

ebajo de la cubeta.

d

oscas de la cubeta sucias.

R

emasiado flujo de material.

D

Material demasiado diluido.

istola inclinada en ángulo o se desplaza

P

muy despacio.

Pistola muy lejos de la superficie.

emasiada presión de aire.

D

e está empleando un diluyendo inadecuado.

S

istola muy cerca de la superficie.

P

Presión de aire muy baja.

e está empleando un diluyente inadecuado.

S

No se ha mezclado debidamente el material.

uperficie áspera, aceitosa o sucia.

S

priete.

A

Reemplace la guarnición de la cubeta.

impie.

L

juste la pistola o reduzca el flujo de fluido.

A

ezcle debidamente o aplique capas livianas.

M

Sostenga la pistola en un ángulo correcto para

rabajar y adáptela a una técnica debida.

t

Verifique la distancia. Normalmente, aprox. 8 pulg.

Reduzca la presión de aire y verifique el patrón de

pulverización.

Siga las instrucciones de mezclado del fabricantede la pintura.

erifique la distancia. Normalmente, aprox. 8 pulg.

V

emasiado material áspero fue atomizado.

D

Aumente la presión de aire o reduzca el flujo de fluido.

Siga las instrucciones de mezclado del fabricante de

a pintura.

l

Limpie y prepare debidamente.

Página 17SB-2-658-D

Page 18

Página 18 SB-2-658-D

ACCESORIOS

ubeta GFC-501 (acetal)

C

ubeta de 1 litro GFC-502 (aluminio)

C

Cubetas alimentadas por gravedad

stas cubetas alimentadas por

E

ravedad son diseñadas para

g

ser usadas con pistolas

pulverizadoras EXL, FLG,

FG, GFHV, GTI o CVi.

G

K-5033-505

K

it de prueba

K

el casquillo de aire

d

El propósito de este kit de

prueba es medir la presión de

aire de atomización del

casquillo de aire en el puerto

central de aire del casquillo de

aire. Utilizado para confirmar

el cumplimiento con el código

y como una medida diaria de

control de calidad.

ubricante de pistola pulverizadora

L

SL-10-K12 (botella de 2 oz.)

S

ompatible con todos los materiales

C

de pintura; no contiene destilados de

ilicona ni petróleo que contaminen la

s

pintura.Hoja de Datos de Seguridadde

os Materiales (MSDS, por sus siglas

l

en inglés) disponible previa solicitud.

192212

Kit de limpieza de pistola

pulverizadora profesional

Contiene seis accesorios de precisión

diseñados para

limpiar eficazmente

todas las pistolas

p u l v e r i z a d o r a s

DeVilbiss, Binks,

Finishline y de otras

marcas.

AV-500 O

H

HAV-501

álvula reguladora

V

(HAV-501-MOSTRADA)

AV-500 no tiene

H

manómetro. Se utiliza

para controlar el uso

el aire en la pistola.

d

HAF-507

Filtro de aire en

línea Whirlwind™

Elimina el agua, el

ceite y la suciedad

a

de la línea de aire.

192219

Soporte de pistola

Soporte de pistola hecho

para sostener pistolas

on cubetas alimentadas

c

por gravedad.

lave SPN-5

ontiene todo los

C

tamaños necesarios

de punta, manguito

y tuerca utilizados

en o con la pistola.

Kit de forros de cubetas de pintura OMX-70-K48

Permite la limpieza rápida y fácil

Compuesto por: 1 herramienta perforadora,

48 – forros desechables, 48 – Boquillas

de descarga.

L

Dispositivos de conexión rápida para repintado automotriz

Para pistolas de HVLP (aire)

Tipo de alto flujo.

GI-501-PSI

D

Manómetro digital

Manómetro digital

para un control

reciso de la presión

p

en la pistola.

H-505

G

Soporte de pistola

os soportes de pistola se

L

fabrican para sostener cubetas

de pintura estándares, pistolas

alimentadas por gravedad

cubetas y filtros de pintura.

Respiradores para pulverizadores de pintura

MSP-523 (pequeño) MSP-524 (mediano)

Certificados por NIOSH para protección respiratoria en atmósferas que no implican riesgo

inmediato para la vida.

MSP-525 (grande)

92218 Scrubs

1

oallas para limpiarse las manos

T

®

crubs

S

rehumedecidas para que

p

intores, encargados de

p

arrocería y mecánicos se

c

impien las manos. Van

l

onde usted vaya y no se

d

ecesita agua.

n

GH-407

oporte de pistola

S

1) Soporte de montaje

(

mural incluido con GH-407.

ostiene cubetas de

S

pintura estándares, pistolas

alimentadas por gravedad y

cubetas y filtros de pintura.

®

on toallas

s

Vástago HC-4419

1/4 pulg. NPT(F)

Acoplador HC-4719

1/4 pulg. NPT(M) /NPS(M)

Vástago HC-1166

1/4 pulg. NPT(M)

Acoplador HC-4720

1/4 pulg. NPT(F)

Page 19

IMPORTANT : Lire et respecter toutes les direc-

ives et CONSIGNES DE SÉCURITÉ avant d’utiliser

t

cet appareil.

DESCRIPTION

Cette trousse de pistolet pulvérisateur léger à

alimentation par gravité CVi est conforme aux

ormes ATEX 94/9/EC, niveau de protection : II

n

2 G X, convenant à l’utilisation en zones 1 et 2.

orsqu’on emploie l’anneau déflecteur nº 505,

L

ce modèle utilise une technologie

’atomisation à grand débit à basse pression

d

conforme aux normes de l’EPA afin de réduire

es pertes de peinture et améliorer l’efficacité

l

de couverture. Ce pistolet génère une pression

de l’anneau déflecteur de 10 psi à une pression

’aspiration de 18 psi (conformément aux

d

normes émises par SCAQMD et d’autres organ-

smes de surveillance de la qualité de l’air).

i

IMPORTANT : Ces pistolets pulvérisateurs convi-

ennent à la pulvérisation de produits de revêtement à base d’eau ou de solvant. La conception

utilise une technologie d’atomisation à grand

débit à basse pression qui réduit les pertes de

peinture et améliore l’efficacité de couverture.

En cas de doute au sujet de la compatibilité d’un

matériau en particulier, communiquer avec le

représentant local ou directement avec

DeVilbiss.

Page 19SB-2-658-D

MISES EN GARDE

NCENDIE ET EXPLOSION

I

es solvants et les matériaux de revêtement peuvent être extrêmement inflam-

L

ables ou combustibles lorsqu’ils sont vaporisés. TOUJOURS consulter les

m

directives fournies par le fabricant des matériaux de revêtement et les fiches sur

la santé et sécurité au travail avant d’utiliser cet appareil.

es utilisateurs doivent se conformer à tous les codes de bonnes pratiques

L

ocaux et nationaux et aux exigences des assureurs concernant la ventilation, la

l

révention des incendies, le fonctionnement des appareils et la propreté des

p

espaces de travail.

Cet appareil, tel que fourni, ne convient PAS

hydrocarbure halogéné.

e passage des liquides ou de l’air dans les tuyaux, le processus de vaporisation

L

t le nettoyage des pièces non conductrices à l’aide de chiffons peuvent produire

e

de l’électricité statique. Afin de prévenir la formation de sources d’allumage en

aison de l’électricité statique, le pistolet pulvérisateur et les autres appareils en

r

étal utilisés doivent être reliés à la terre en permanence. Il est essentiel

m

d’utiliser des conduits en matériaux conducteurs pour l’air et les liquides.

MATÉRIEL DE PROTECTION DES EMPLOYÉS

apeurs toxiques : lorsqu’on les vaporise, certains matériaux peuvent être

V

toxiques, créer des irritations ou nuire d’une manière ou d’une autre à la santé.

Toujours lire toutes les étiquettes et fiches signalétiques des produits avant de

les vaporiser et suivre toutes les recommandations. En cas de doute, communi-

quer avec le fournisseur de matériaux.

Il est recommandé d’utiliser un dispositif de protection du système respiratoire

en tout temps. Le type de dispositif doit être compatible avec le produit vaporisé.

Toujours porter des lunettes de protection pour vaporiser ou nettoyer ce pistolet

pulvérisateur.

à l’utilisation avec des solvants de type

DÉCLARATION DE CONFORMITÉ EC

Nous : ITW Finishing UK, Ringwood Rd,

Bournemouth (Dorset) BH11 9LH, R.-U., en tant

que fabricant du pistolet pulvérisateur de

modèle CVi , déclare, en vertu de notre seule

responsabilité, que l’appareil au sujet duquel

porte ce document est conforme aux normes

suivantes et aux autres documents normatifs :

BS EN 292-1 PARTIES 1 et 2 : 1991, BS EN

1953 : 1999; et par conséquent est conforme

aux exigences de sécurité de la directive

98/37/EC du Conseil relative à la Directive sur

la sécurité des appareils et EN 13463-1 : 2001,

de la directive 94/9/EC du Conseil relative au

matériel et systèmes de protection destinés à

une utilisation dans des conditions

d’atmosphère potentiellement explosif,

niveau de protection II 2 G X.

B. Holt, directeur général,

30 juin 2003

DeVilbiss Automotive Refinishing se réserve

le droit de modifier les caractéristiques de

l’appareil sans préavis.

Porter des gants pour vaporiser ou nettoyer cet appareil.

Formation : le personnel doit recevoir une formation adéquate touchant

l’utilisation sécuritaire du matériel de pulvérisation.

MAUVAIS USAGE

Ne jamais diriger un pistolet pulvérisateur vers une partie du corps humain.

Ne jamais dépasser les pressions maximum recommandées pour un fonctionnement sécuritaire de l’appareil.

L’installation de pièces détachées non recommandées ou non originales peut être

dangereuse.

Avant de nettoyer ou d’entretenir l’appareil, toute portion sous pression doit être

isolée de l’appareil et purgée.

Ce produit doit être nettoyé à l’aide d’une laveuse à pistolet pulvérisateur.

Cependant, cet appareil ne doit pas être laissé dans la laveuse à pulvérisateur

pendant une période prolongée.

NIVEAU SONORE

Le niveau acoustique pondéré A des pistolets pulvérisateurs peut dépasser 85 dB

(A), en fonction de l’installation utilisée. Les détails du niveau sonore sont

disponibles sur demande. Il est recommandé de porter un dispositif de protection

de l’ouïe en tout temps lors de l’utilisation du pistolet pulvérisateur.

FONCTIONNEMENT

Le matériel de pulvérisation à haute pression peut produire un effet de recul.

Dans certaines circonstances, de telles forces peuvent occasionner des microtraumatismes répétés à l’opérateur.

Page 20

Page 20 SB-2-658-D

revet nº 2372465 (GB)

B

LISTE DE PIÈCES

Nº Numéro

de ref. Description de pièce Qté Options

1 Anneau déflecteur/anneau de retenue SP-100-***-K 1 505, 510 ex. *** = 510

2 Buse SP-200S-**-K 1 10, 12, 13, 14 ex. ** =13 =1,3 mm

+ 3 Séparateur SP-626-K5 5

+ 4 Garniture d’étanchéité GTI-445-K2 2

5 Soupape de diffusion SP-403-K 1

6 Pivot et vis GTI-408-K5 5

7 Vis de réglage du pointeau SP-614-K 1

+ 8 Ressort SP-622-K5 1

9 Pointeau SP-200S-**-K 1 10, 12, 13, 14 ex. ** =13 =1,3 mm

Boîtier et joint d’étanchéité de la soupape d’air

10

11 Arbre 1

12 Gâchette SP-617-K 1

13 Connecteur SP-611-K 1

14 Soupape de débit d’air SP-402-K 1

16 Trousse d’entretien de la soupape d’air SPK-101-K 1

17 Bague d’arrêt et joints SPK-102-K 1

+18 Ensemble d’agrafe, joint et goupille GTI-428-K5 5

23 Outils de montage de soupape d’air 1

24 Tricoise SPN-5-K 1

Trousse d’entretien de pistolet pulvérisateur

(les pièces incluses sont identifiés par un +)

SP-612-K 1

SPK-402-K 1

Page 21

Page 21SB-2-658-D

ARACTÉRISTIQUES

C

accord d’orifice d’admission :

R

niversel ⁄ po BSP et NPS

u

Pression d’aspiration statique maximum :

12 bars (175 psi)

=

P

1

ression d’aspiration nominale du pistolet

P

en appuyant sur la gâchette :

,2 bar (18 psi) Anneau déflecteur 505 à grand

1

débit à basse pression

bars (29 psi) 510 Anneau déflecteur

2

Trans-Tech

Température de fonctionnement maximum :

0°C

4

Poids du pistolet : 412 g

MATÉRIAUX DE FABRICATION

Corps du pistolet :Aluminium anodisé

Buse : Acier inoxydable

ointeau : Acier inoxydable

P

rifice d’alimentation/passages du liquide :

O

Aluminium anodisé et acier inoxydable

âchette : Acier nickelé

G

INSTALLATION

Important : Afin d’assurer que ce

matériel parvienne au consommateur en parfait état, on applique un

revêtement de protection. Rincer

abondamment l’appareil dans un

solvant adéquat avant de l’utiliser.

1. Fixer le tuyau d’alimentation en air au

raccord (13). On recommande d’utiliser

un tuyau de 8 mm d’alésage. Le tuyau

doit être conducteur et la mise à la terre

du pistolet pulvérisateur doit être vérifié à

l’aide d’un ohmmètre. Une résistance

inférieure à 10

6

ohms est recommandée.

2. Le débit d’air doit être régulé et filtré.

3. Fixer le module du réservoir en le vissant

à l’orifice d’alimentation en liquide du

pistolet pulvérisateur. Resserrer à l’aide

d’une clé.

FONCTIONNEMENT

1. Suivre les directives du fabricant du produit

e revêtement concernant la dilution.

d

. Remplir le réservoir avec la quantité de

2

produit requis. Ne pas remplir le réservoir

u vaporisateur à plus de 2,5 cm (1 po)

d

du sommet. NE PAS TROP REMPLIR.

3. Fixer le couvercle du réservoir.

4. Tourner la vis de réglage du pointeau (7)

ans le sens des aiguilles d’une montre

d

our prévenir les mouvements.

p

. Tourner la soupape de diffusion (5) dans

5

le sens contraire des aiguilles d’une

ontre pour l’ouvrir entièrement.

m

. Régler la pression d’aspiration (consulter

6

les caractéristiques pour connaître les

églages recommandés) à l’orifice

r

d’admission du pistolet, en appuyant sur

la détente (il est recommandé d’utiliser le

anomètre facultatif figurant dans les

m

accessoires).

. Tourner la vis de réglage du pointeau

7

dans le sens contraire des aiguilles d’une

ontre jusqu’à ce que le premier filet soit

m

visible.

8. Vérifier la pulvérisation. Si le fini est trop

sec, réduire le débit d’air en diminuant la

ression d’aspiration ou en réglant la

p

soupape de débit d’air (14). Visser le

bouton de réglage (14) pour reduire la

pression.

9. Si le fini est trop mouillé, refermer le

bouton de réglage du pointeau (7) en le

tournant en sens horaire. Si la pulvérisation est trop grossière, augmenter la pression d’aspiration. Si elle est trop fine,

réduire la pression d’aspiration.

10. On peut réduire la dimension du jet en

tournant la soupape de diffusion (5) dans

le sens contraire des aiguilles d’une

montre.

11. Tenir le pistolet perpendiculairement à la

surface de travail. Une position courbée

ou penchée peut produire une couverture

inégale.

12. La distance de pulvérisation recom-

mandée est de 150 à 200 mm (6 à 8

pouces).

13. Vaporiser d’abord les bordures.

Superposer chaque passage d’au moins

50 %. Déplacer le pistolet à vitesse

constante.

14. Toujours couper l’alimentation en air et

évacuer la pression lorsque le pistolet

n’est pas utilisé.

ENTRETIEN PRÉVENTIF

1. Toujours couper l’alimentation en air et

vacuer la pression des canalisations;

é

débrancher du système à raccord rapide, le

as échéant.

c

. Retirer le couvercle du réservoir à

2

matériau de revêtement et vider de son

ontenu dans un contenant adéquat.

c

ettoyé le pistolet et le réservoir, idéale-

N

ment à l’aide d’une laveuse à pistolet

ulvérisateur. Nettoyer le réservoir.

p

. Vérifier l’orifice d’aération du couvercle et

3

le dispositif de protection contre les fuites

our s’assurer qu’ils ne sont pas bloqués.

p

. Retirer l’anneau déflecteur (1) et nettoyer.

4

Nettoyer tout orifice du couvercle obstrué

par du matériau à revêtement à l’aide

’un cure-dent. Ne jamais utiliser de tige

d

de métal qui risquerait d’endommager le

ouvercle et produire un jet déformé.

c

. S’assurer que la pointe de la buse (2) est

5

propre est sans dommages. Les accumu-

ations de peinture séchée peuvent

l

déformer le jet.

6. Lubrification : le pivot/la vis (6), le

ointeau (9) et la soupape d’air (11)

p

doivent être graissés à tous les jours avec

u lubrifiant à pistolet pulvérisateur.

d

REMPLACEMENT DES PIÈCES

Buse (2) et pointeau (9) : Retirer les pièces dans

l’ordre suivant : 7, 8, 9, 1 et 2. Remplacer toute

pièce usée ou endommagée et remonter dans

l’ordre inverse. Serrage recommandé de la

buse (2) : 9,5 à 12 nm (80 à100 livres-force/po).

Garniture d’étanchéité : retirer les pièces 7, 8 et

9. Dévisser la cartouche (4). Installer une

nouvelle cartouche en la serrant à la main.

Remonter les pièces 9, 8 et 7, puis resserrer la

cartouche (4) à l’aide des tricoises suffisamment pour bien sceller, mais tout en permettant

le libre mouvement du pointeau. Lubrifier à

l’aide de lubrifiant à pistolet pulvérisateur.

Trousse d’étanchéité de la soupape d’air (16) :

(consulter les photos 1 à 21 et la fig. 2).

Soupape de diffusion (5) : mise en garde :

toujours assurer que la soupape est en position

entièrement ouverte en tournant la vis dans le

sens contraire des aiguilles d’une montre

jusqu’au bout avant de la fixer au corps du

pistolet.

Page 22

Page 22 SB-2-658-D

. Retirer le bouton de réglage (7),

1

le ressort (8) et le pointeau (9).

4. Retirer la soupape (11). 5. À l’aide de l’outil d’entretien

. Desserrer le boîtier (10). 3. Retirer le boîtier (10) et le ressort

2

SPN-7, saisir la rainure derrière

le support de la soupape.

de la soupape d’air.

6. Retirer le support de la soupape.

7. Pousser le joint avant de la

soupape d’air avec le doigt.

10. Installer le nouveau joint au

corps de la soupape et appuyer

fermement pour s’assurer que le

joint est bien en place.

8. Retourner le pistolet et laisser le

joint tomber.

11. Installer le nouveau siège de

soupape sur l’outil d’entretien de

façon à ce que la rainure soit

orientée vers la poignée de

l’outil.

9. Installer le nouveau joint avant

sur l’outil d’entretien de façon à

ce que la rainure soit orientée

vers la poignée de l’outil.

Page 23

Page 23SB-2-658-D

2. Installer le support au corps de la

1

soupape.

15. Installer le joint au boîtier (10). 16. Replacer la soupape (11). 17. Remplacer le ressort de soupape

3. Retirer le joint arrière de la

1

soupape d’air du boîtier (10) à

’aide d’un crochet.

l

4. Installer le nouveau joint arrière

1

sur l’outil d’entretien de façon à

e que la rainure soit orientée

c

vers la poignée de l’outil.

en introduisant la petite

extrémité du ressort dans le

pistolet, et le visser dans le

boîtier (10).

18. Resserrer le boîtier. 19. Installer le pointeau (9). 20. Installer le ressort (8) et le

bouton (7).

21. Resserrer la garniture d’étanchéité

du pointeau(4) à l’aide des

tricoises suffisamment pour bien

sceller, mais tout en permettant le

libre mouvement du pointeau.

Lubrifier à l’aide de lubrifiant à

pistolet pulvérisateur.

Page 24

Page 24 SB-2-658-D

DÉPANNAGE

PROBLÈME CAUSE MESURE CORRECTRICE

ettoyer. Évacuer les orifices à l’aide d’un objet

épartition du jet,

R

plus épais en haut

ou en bas

Les orifices des cornes sont obstrués.

Obstruction de l’entrée ou de la sortie de la buse.

ase de la buse ou de l’anneau déflecteur sale.

B

N

pointu non métallique.

ettoyer.

N

ettoyer.

N

épartition du jet,

R

lus épais à droite

p

u à gauche

o

épartition du jet, plus épais au centre

R

épartition du jet, divisé

R

Jet saccadé ou vacillant

Impossibilité d’obtenir un jet rond

Absence de jet

Bulles dans la peinture du réservoir

Liquide qui coule ou dégoutte par le

couvercle du réservoir

Jet étranglé

Perte de peinture excessive à la

pulvérisation

Orifice de la corne gauche ou droite obstrué.

Saleté du côté gauche ou droit de la buse.

olutions aux problèmes de mauvaise répartition du jet, trop épais en haut, en bas, à droite ou à gauche :

S

. Déterminer si l’obstruction se trouve sur l’anneau déflecteur ou sur la buse. Pour cela, faire un essai

1

e pulvérisation. Faire ensuite tourner l’anneau déflecteur un demi-tour et effectuer un autre essai.

d

Si le problème est inversé, alors c’est l’anneau déflecteur qui obstrué. Nettoyer l’anneau déflecteur

tel qu’expliqué précédemment.

2. Si le problème n’est pas inversé, alors c’est la buse qui est en cause. Vérifier s’il n’y a pas une petite

bavure à l’extrémité de la buse. Retirer avec du papier abrasif nº 600 humide ou sec.

. Vérifier s’il n’y a pas de peinture séchée à l’entrée de l’ouverture ; si oui, retirer avec du solvant.

3

ébit de liquide trop élevé pour la pression d’air

D

d’alimentation.

Le débit est supérieur à la capacité de l’anneau

déflecteur.

e réglage de la soupape de diffusion est trop

L

as.

b

a pression d’air d’alimentation est trop faible.

L

Le produit est trop épais.

La pression d’air d’alimentation est trop élevée.

Le débit du liquide est trop faible.

Le réglage de la soupape de diffusion est trop

élevé.

*La buse ou sa base sont mal fixées ou endommagées.

Joint du déflecteur mal installé.

Le niveau de produit est trop faible.

Le contenant est trop incliné.

Le passage du liquide est obstrué.

L’écrou d’étanchéité du pointeau est sec ou

relâché.

La soupape de réglage de diffusion est mal

posée.

La bague d’arrêt de l’anneau de déflection est

desserrée.

Il n’y a pas de pression dans le pistolet.

La vis de réglage du pointeau n’est pas assez

ouverte.

Le liquide est trop épais pour l’alimentation par

gravité.

La buse n’est pas bien serrée.

Le couvercle du réservoir est desserré.

Des traces de peinture sont présentes sur le

réservoir ou le couvercle.

Le réservoir ou le couvercle sont craqués.

Le débit du produit est insuffisant.

La pression d’air d’alimentation est faible.

La pression d’air d’alimentation est trop élevée.

Le pistolet est trop éloigné de la surface à recouvrir.

La technique d’application est mauvaise

(mouvement en arc, déplacement trop rapide du

pistolet).

Nettoyer. Évacuer les orifices à l’aide d’un objet

ointu non métallique.

p

ettoyer.

N

quilibrer la pression de l’air et le débit du liquide.

É

Augmenter la largeur de la surface de pulvérisation

à l’aide de la soupape de réglage de diffusion.

Diluer le produit ou réduire le débit.

juster

A

ugmenter la pression.

A

Diluer jusqu’à consistance adéquate.

Réduire au niveau du raccord ou du pistolet.

Augmenter le débit du liquide (ce qui augmente la

rapidité d’exécution du pistolet).

Ajuster

Resserrer ou remplacer.

Installer en suivant les directives.

Remplir.

Tenir plus droit.

Faire circuler du solvant en sens inverse.

Lubrifier ou resserrer.

Nettoyer ou remplacer.

Resserrer.

Vérifier la source d’alimentation en air et les

conduits, souffler dans les conduits d’air.

Ouvrir la vis de réglage du pointeau.

Diluer le produit et ou changer la buse pour le

modèle plus gros.

Resserrer la buse à 9,5 à 12 nm (80 à100 livresforce/po).

Repousser ou resserrer le couvercle.

Nettoyer.

Remplacer le réservoir ou le couvercle.

Desserrer la vis de réglage d’arrivée du liquide

jusqu’au premier filet ou changer la buse pour le

modèle plus gros.

Augmenter la pression de l’air et rééquilibrer le

pistolet.

Réduire la pression.

Régler la distance.

Se déplacer à un rythme modéré, parallèlement à

la surface de travail.

*Problème le plus fréquent.

Page 25

DÉPANNAGE (suite)

PROBLÈME CAUSE MESURE CORRECTRICE

uée excessive

B

ulvérisation sèche

P

iquide qui s’écoule de l’écrou

L

’étanchéité

d

iquide qui coule ou dégoutte par le

L

bout du pistolet

iquide qui coule ou dégoutte par le

L

ond du réservoir

f

Présence de coulisse ou d’accumulation

de peinture

Revêtement mince et granuleux qui

sèche avant d’avoir fini de s’écouler

Revêtement épais à texture de « peau

d’orange »

a peinture est trop diluée ou avec du

L

diluant séchant trop rapidement.

La pression d’air d’alimentation est trop

élevée.

a pression d’air est trop élevée.

L

a pointe du pistolet est trop éloignée de la

L

urface à recouvrir.

s

Le déplacement du pistolet est trop rapide.

Le pistolet est déréglé.

’écrou d’étanchéité est relâché.

L

e joint d’étanchéité est usé ou sec.

L

’écrou d’étanchéité est trop serré.

L

Le joint d’étanchéité est sec.

La buse ou le pointeau sont usés ou

endommagés.

Un corps étranger est logé dans la buse.

e ressort du pointeau est brisé.

L

e pointeau ou la buse sont de mauvaise

L

imension.

d

e réservoir est desserré d’après le pistolet.

L

’anneau d’étanchéité du réservoir est usé

L

ou manquant.

Les filets du réservoir sont sales.

Le débit du produit est trop fort.

Le produit est trop dilué.

Le pistolet est incliné, ou son déplacement

est trop lent.

Le pistolet est trop éloigné de la surface de

travail.

La pression d’air est trop élevée.

Le diluant utilisé ne convient pas.

Le pistolet est trop près de la surface de

travail.

La pression d’air est trop faible.

Le diluant utilisé ne convient pas.

La texture du produit n’est pas homogène.

La surface est rugueuse, huileuse ou sale.

efaire le mélange.

R

Réduire la pression.

éduire la pression d’air.

R

égler la distance.

R

Ralentir.

Ajuster

esserrer ; ne pas plier le pointeau.

R

emplacer ou lubrifier.

R

juster

A

Lubrifier.

Remplacer la buse et le pointeau.

Nettoyer.

emplacer.

R

emplacer.

R

esserrer.

R

emplacer l’anneau d’étanchéité du réservoir.

R

Nettoyer.

Régler le pistolet ou réduire le débit de liquide.

Mélanger convenablement ou appliquer de

minces couches.

Tenir le pistolet à angle droit pour appliquer la

peinture, et acquérir une technique adéquate et

acquérir une technique adéquate.

Faire attention à la distance qui doit normalement

être d’environ 20 cm (8 po).

Réduire la pression de l’air et vérifier si la forme

de la surface de pulvérisation est adéquate.

Suivre les directives du fabricant de peinture

concernant la dilution.

Faire attention à la distance qui doit normalement

être d’environ 20 cm (8 po).

Trop de produit tombant à grosses gouttes.

Augmenter la pression de l’air d’alimentation ou

réduire le débit de liquide.

Suivre les directives du fabricant de peinture

concernant la dilution.

Préparer et nettoyer adéquatement la surface.

Page 25SB-2-658-D

Page 26

Page 26 SB-2-658-D

ACCESSOIRES

Réservoir GFC-501 (Acetal) de 600 ml (20 oz)

éservoir GFC-502 (aluminium) de 1 litre

R

éservoirs à alimentation par gravité

R

Ces réservoirs à alimentation

par gravité sont conçus pour

tre utilisés avec les pistolets

ê

pulvérisateurs EXL, FLG,

GFG, GFHV, GTI ou CVi.

AV-500 OU

H

AV-501

H

oupape de réglage

S

(HAV-501 ILLUSTRÉE)

AF-507

H

M

hirlwind

W

Filtre à air pour

conduit

92218 Lingettes pour le

DGI-501-PSI

C

Manomètre

umérique

n

1

nettoyage des mains Scrubs

®

KK-5033-505

Trousse de vérification

de l’anneau déflecteur

ette trousse de vérification

C

permet de mesurer la pression d’air d’alimentation au

iveau du centre de l’arrivée

n

d’air de l’anneau déflecteur.

Sert à confirmer la conformité

u code et comme outil de

a

mesure permettant le contrôle

de la qualité.

ubrifiant à pistolet pulvérisateur

L

SL-10-K12 (bouteille de 60 ml/2 oz)

S

ompatible avec tous les produits de

C

peinture ; ne contient aucun silicone ni

distillat de pétrole susceptibles de conta-

iner la peinture. Une fiche signalétique

m

des matières dangereuses peut être obtenu

sur demande.

192212 192212Trousse de nettoyage

professionnel pour pistolet pulvérisateur

ontient six outils de

C

précision conçus pour

un nettoyage efficace

de tous les pistolets

p u l v é r i s a t e u r s

DeVilbiss, Binks,

Finishline et autres.

Le modèle HAV-500 n’a

pas de manomètre. Sert

régler la quantité d’air

à

utilisée par le pistolet.

upport à pistolet

S

Enlève l’eau, l’huile et les

débris des conduites

’air.

d

192219192219

Support à pistolet

conçu pour tenir des

istolets pulvéri-

p

sateurs avec réservoir

fonctionnant à gravité.

Clé SPN-5

Convient à toutes

tailles de buses,

tuyaux et écrous

nécessaires pour

l’entretien de votre

pistolet.

OMX-70-K48 Ensemble de doublure de réservoir

Permet un nettoyage rapide et facile.

Comprend : 1 poinçon,

48 doublures jetables, 48 douilles de drain

Dispositifs de raccord rapide automobiles

Pour les pistolets HVLP (à air)

Modèles à haut débit.

Les lingettes humides Scrubs

ettoient, sans nécessiter

Manomètre numérique

pour contrôler la pres-

ion du pistolet avec

s

précision.

upport à pistolet

S

GH-505

Les supports à pistolets

sont conçus pour porter

les réservoirs à peinture

standards, les pistolets à

alimentation par gravité

et leurs réservoirs, ainsi

que les filtres.

n

d’eau, les mains des peintres, carrossiers et mécani-

iens. Elles sont utiles

c

partout.

Support à pistolet

GH-407

(1) Un support mural à

pistolet est inclus avec le

modèle GH-407. Il est conçu

pour ranger les réservoirs à

peinture standards, les pistolets à alimentation pargravité et

leurs réservoirs, ainsi que les

filtres.

Respirateur pour pistolet pulvérisateur

MSP-523 (petit) MSP-524 (moyen) MSP-525 (grand)

Approuvé par NIOSH pour la protection du système respiratoire dans les milieux où les émanations ne mettent pas

immédiatement la vie en danger.

®

HC-4419 Raccord

⁄ po NPT(F)

HC-4719 Raccord

⁄ po NPT(M) /NPS(M)

HC-1166 Raccord

⁄ po NPT(M)

HC-4720 Raccord

⁄ po NPT(F)

Page 27

NOTES / NOTAS

Page 27SB-2-658-D

Page 28

Page 28 SB-2-658-D

GARANTIE

Ce produit est couvert par la garantie limitée d’un an de DeVilbiss. Voir SB-1-000 qu’on peut obtenir sur demande.

LISTE DES DISTRIBUTEURS ET RÉPARATEURS DeVILBISS À TRAVERS LE MONDE - www.devilbiss.com

REMISE À NEUF DE CARROSSERIES

On trouve des distributeurs autorisés DeVilbiss à travers le monde.

Pour vous procurer du matériel et des pièces, ou pour de l’entretien,

consultez la rubrique « Automobile – Réparation de carrosserie et peinture »

des Pages jaunes. Pour assistance technique, voir la liste ci-dessous.

Service à la clientèle, États-Unis:

1724 Indian Wood Circle, Suite J-K, Maumee, OH 43537

Numéro de téléphone sans frais

Numéro de télécopieur sans frais

: 1-800-445-3988 (U.S.A. et Canada exclusivement)

: 1-800-445-6643

GARANTIA

Este producto está cubierto por la garantía limitada de un año de DeVilbiss. Vea SB-1-000 disponible previa solicitud.

LISTADO MUNDIAL DE VENTAS Y SERVICIO DeVILBISS - www.devilbiss.com

ACABADO AUTOMOTRIZ

DeVilbiss tiene distribuidores autorizados por todo el mundo. Para equipo, piezas y

servicio compruebe las Páginas Amarillas bajo “Equipo y Suministros para el Taller de

Automóviles”. Para asistencia técnica, vea el listado a continuación.

Oficina de Servicio al cliente en EE.UU./Canadá:

1724 Indian Wood Circle, Suite J-K, Maumee, OH 43537

Número de teléfono gratis: 1-800-445-3988 (U.S.A. y Canadá exclusivamente)

Facsímile gratis: 1-800-445-6643

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

DeVilbiss Automotive Refinishing