DeVilbiss Compact COM-PS430-18-01, Compact COM-PS430-22-01, Compact COM-PS497-14-03, Compact COM-PS497-14-04 Operation Manual

Page 1

Service Bulletin

SB-2-548-B

Replaces SB-2-548-A

OperatiOn Manual

aDVanCeD-COnVentiOnal

preSSure FeeD / SuCtiOn FeeD Spraygun

English: Pages 2-9

Manual De OperaCión

piStOla pulVeriZaDOra COn aliMentaCión pOr preSión/pOr SuCCión

aVanZaDa-COnVenCiOnal

Español: Páginas 10-17

Page 2

Page 2 SB-2-548-B

IMPORTANT: Read and follow all instructions and SAFETY PRECAUTIONS before

using this equipment.

DESCRIPTION

The Compact Gravity feed Spraygun Kit

complies to ATEX regulations 94/9/EC,

protection level; II 2 G X, Suitable for use

in Zones 1 and 2.

IMPORTANT: These Sprayguns are suit-

able for use with solvent and water based

materials. If there is any doubt regarding

the suitability of a specific material

contact your local Distributor or ITWIF

direct.

EC DECLARATION OF CONFORMITY

We: ITW Finishing UK, Ringwood Rd,

Bournemouth, Dorset, BH11 9LH, UK, as

the manufacturer of the Spraygun model

Compact, declare, under our sole respon-

sibility, that the equipment to which this

document relates is in conformity with

the following standards or other normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN

1953: 1999; and thereby conform to the

protection requirements of Council

Directive 98/37/EC relating to Machinery

Safety Directive, and; EN 13463-1:2001,

council Directive 94/9/EC relating to

Equipment and Protective Systems

intended for use in Potentially Explosive

Atmospheres protection level II 2 G X.

SAFETY WARNINGS

FIRE AND EXPLOSION

Solvents and coating materials can be highly flammable or combustible when sprayed. ALWAYS refer to the coating material suppliers

instructions and COSHH sheets before using this equipment.

Users must comply with all local and national codes of practice and

insurance company requirements governing ventilation, fire precautions, operation and house-keeping of working areas.

This equipment, as supplied, is NOT suitable for use with Halogenated

Hydrocarbons.

Static Electricity can be generated by fluid and/or air passing through

hoses, by the spraying process and by cleaning non- conductive parts

with cloths. To prevent ignition sources from static discharges, earth

continuity must be maintained to the spraygun and other metallic

equipment used.

PERSONAL PROTECTIVE EQUIPMENT

Toxic vapors – When sprayed, certain materials may be poisonous,

create irritation or be otherwise harmful to health. Always read all

labels and safety data sheets for the material before spraying and

follow any recommendations. If In Doubt, Contact Your Material

Supplier.

The use of respiratory protective equipment is recommended at all

times. The type of equipment must be compatible with the material

being sprayed.

Always wear eye protection when spraying or cleaning the spraygun

Gloves must be worn when spraying or cleaning the equipment.

Training – Personnel should be given adequate training in the safe use

of spraying equipment.

MISUSE

Never aim a spraygun at any part of the body.

ITWIF reserve the right to modify equipment specification without prior notice.

B. Holt, General Manager

30th June 2003

Never exceed the max. recommended safe working pressure for the

equipment.

The fitting of non-recommended or non-original spares may create

hazards.

Before cleaning or maintenance, all pressure must be isolated and

relieved from the equipment.

The product should be cleaned using a gun washing machine.

However, this equipment should not be left inside gun washing

machines for prolonged periods of time.

NOISE LEVELS

The A-weighted sound level of sprayguns may exceed 85 dB (A)

depending on the set-up being used. It is recommended that ear

protection is worn at all times when spraying.

OPERATING

Spray Equipment using high pressures may be subject to recoil forces.

Under certain circumstances, such forces could result in repetitive

strain injury to the operator.

Page 3

Patent No. 2372465 (GB)

Page 3SB-2-548-B

MODEL PART NUMBER

Example: COM-PS430-14-00

Stainless Steel

Fluid Passage

Aircap

Fluid nozzle size

(14 = 1.4 mm)

00 = No cup

01 = Siphon cup

03 = TSC-591 1 qt. SS cup

with KK-4980 regulator

04 = TLC-576 1 qt. aluminum cup

with KK-4980 regulator

PARTS LIST

Ref.

No. Description Part Number Qty. Options

1 Air Cap/Retaining ring SP-100-***-K 1 430, 443, 497 e.g *** = 430

COM-430, COM-443 or COM-497

2 Nozzle SP-200S-**-K 1 10, 14, 18, 22 e.g ** =14 =1.4 mm

+3 Separator (Pack of 5) SP-623-K5 1

+4 Packing (Pack of 2) GTI-445-K2 1

5 Spreader Valve SP-401-K 1

6 Stud and Screw (Pack of 5) GTI-408-K5 1

7 Needle Adjusting Screw SP-614-K 1

+8 Spring SP-622-K5 1

9 Needle SP-300S-**-K 1 10, 14, 18, 22 e.g ** =14 =1.4 mm

10 Airvalve housing & seal SP-612-K 1

11 Spindle 1

12 Trigger SP-617-K 1

13 Connector Air SP-611-K 1

14 Plug SP-637 1

15 Fluid Inlet Connector and seal SP-636-K 1

17 Retaining Ring and Seals SPK-102-K 1

+18 Clip, Seal and Pin Kit (Pack of 5) GTI-428-K5 1

20 Air Valve Assembly Tool 1

21 Wrench SPN-5 1

Spraygun Service Kit SPK-402 1

(parts included marked + )

16 Air Valve Service Kit SPK-101-K 1

Page 4

Page 4 SB-2-548-B

SPECIFICATION

Air supply connection:

Universal 1/4" BSP and NPS

Fluid supply connection:

Universal 3/8" BSP and NPS

Maximum static Air inlet pressure:

P1 = 12 bar (175 psi)

Maximum static Fluid inlet pressure:

P2 = 15 bar (218 psi)

Nominal gun Air inlet pressure

with gun triggered:

3.5 bar (50 psi)

Maximum Service temperature: 104°F

Gun Weight: 14.5 oz.

MATERIALS OF CONSTRUCTION

Gun body: Anodized Aluminum

Nozzle: Stainless Steel

Needle: Stainless Steel

Fluid Inlet / Fluid Passages:

Stainless Steel / PTFE

Trigger: Nickel Plated Steel

INSTALLATION

Important: To ensure that this

equipment reaches you in first

class condition, protective

coatings have been used. Flush

the equipment through with a

suitable solvent before use.

1. Attach air hose to connector (13).

Recommended hose size 5/16" ID.

2. Attach fluid supply hose to Fluid

Inlet (15).

OPERATION

1. Mix coating material to manufacturers instructions

2. Turn needle adjusting screw (7)

clockwise to prevent movement.

3. Turn spreader valve (5) counterclockwise to fully open.

4. Adjust inlet air pressure (For recommended figures see Specifications)

at the gun inlet with the gun triggered. (pressure gauge attachment

shown under Accessories is recommended for this).

5. Turn needle adjusting screw counter

clockwise until first thread shows or

full needle travel is achieved.

6. Test spray. If the finish is too dry

reduce airflow by reducing air inlet

pressure or by the Airflow Valve (14).

Screw the Adjusting Knob (14) in to

reduce pressure.

7. If finish is too wet reduce fluid flow

by turning needle screw (7) clockwise or reducing the fluid pressure.

If atomization is too coarse, increase

inlet air pressure. If too fine reduce

inlet pressure.

8. The pattern size can be reduced by

turning spreader valve (5) clockwise.

9. Hold gun perpendicular to surface

being sprayed. Arcing or tilting may

result in uneven coating.

10. The recommended spray distance is

150-200 mm (6"-8").

11. Spray edges first. Overlap each

stroke a minimum of 50%. Move gun

at a constant speed.

12. Always turn off air and fluid supply

and relieve pressure when gun is

not in use.

PREVENTATIVE MAINTENANCE

1. Turn off air and coating supply and

relieve pressure in the supply lines,

or if using QD system, disconnect

from airline and fluid line.

2. Remove air cap (1) and clean. If any

of the holes in the cap are blocked

with coating material use a toothpick

to clean. Never use metal wire which

could damage the cap and produce

distorted spray patterns

3. Ensure the tip of the nozzle (2) is

clean and free from damage. Build

up of dried paint can distort the

spray pattern.

4. Lubrication – stud/screw (6), packing

(4) and air valve (11) should be oiled

each day.

REPLACEMENT OF PARTS

Nozzle (2) and Needle (9) – Remove parts

in the following order: 7, 8, 9, 1 and 2.

Replace any worn or damaged parts and

re-assembl e i n reverse o rder.

Recommended tightening torque for

nozzle (2) 9.5-12 Nm (80-100 lbf in).

Packing – Remove parts 7, 8, 9. Unscrew

cartridge (4). Fit new cartridge finger

tight. Re-assemble parts 9, 8, and 7 and

tighten cartridge (4) with spanner sufficient to seal but to allow free movement

of needle. Lubricate with gun oil.

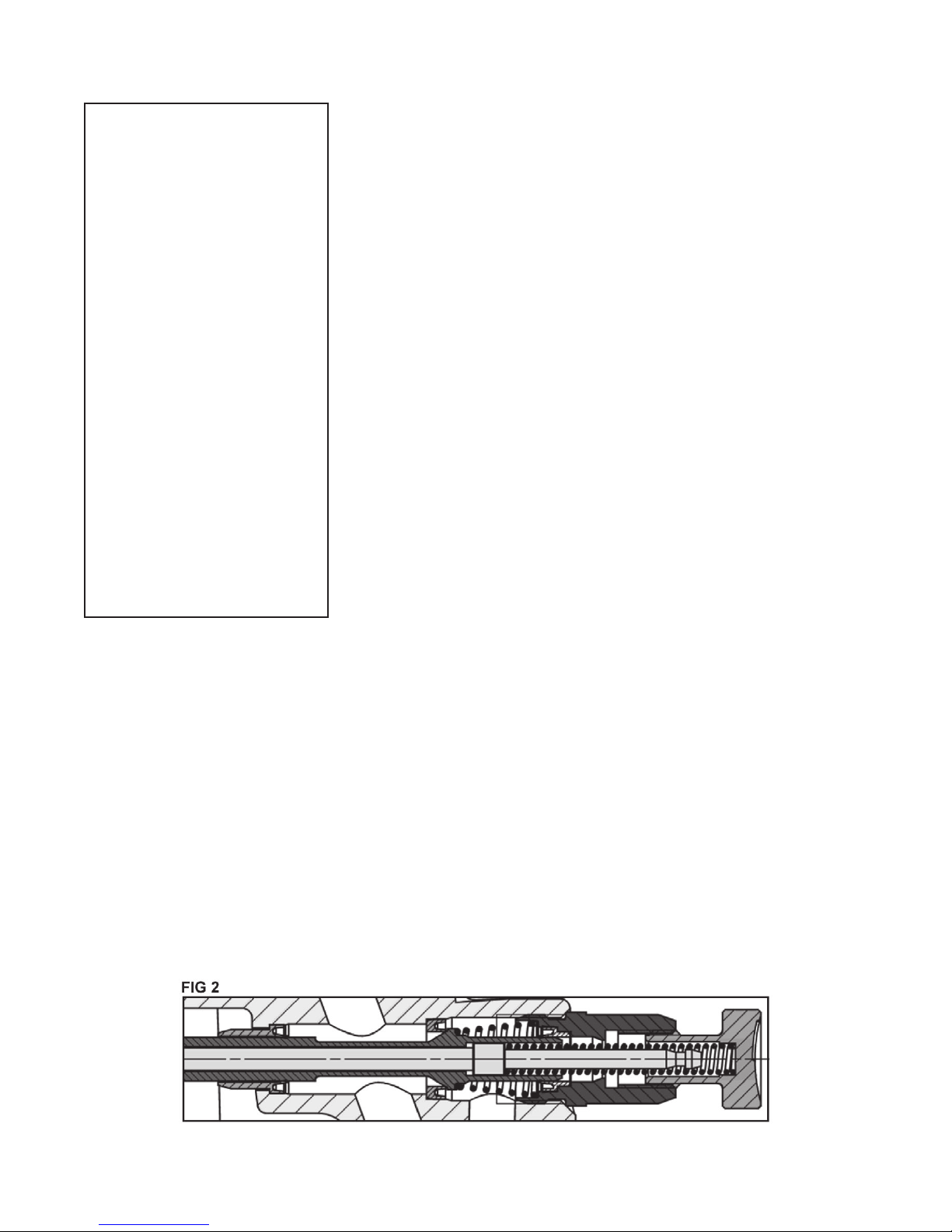

Air Valve Seal Kit (16) – (Refer to photos

1 to 28 and fig 2)

Spreader valve (5) – Caution: always

ensure that the valve is in the fully open

position by turning screw fully counterclockwise before fitting to body.

Page 5

Page 5SB-2-548-B

1. Remove Adjusting Knob (7),

Spring (8), and Needle (9).

4. Remove Valve (11). 5. Using Service Tool SPN-7,

2. Loosen Housing (10). 3. Remove Housing (10) and

engage groove behind the

Valve Seat.

Airvalve Spring.

6. Remove Valve Seat.

7. Push out the Front Airvalve

Seal with a finger.

10. Fit new Seal to gunbody and

press firmly to ensure Seal is

engaged.

8. Turn the Gun upside down

and let the Seal fall out.

11. Fit New Valve Seat to Service

Tool. Groove must face

outwards.

9. Fit New Front Seal to Service

Tool.

Page 6

Page 6 SB-2-548-B

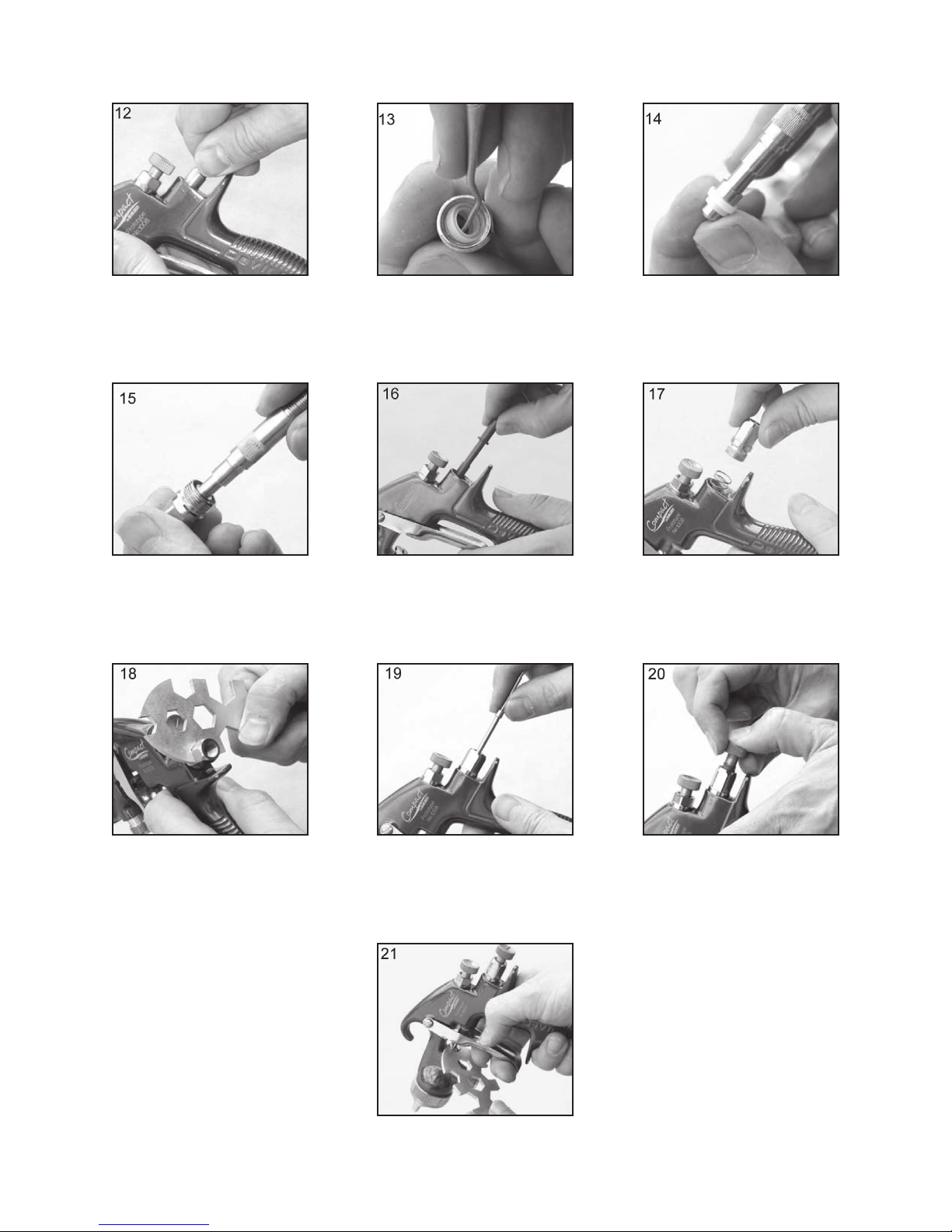

12. Fit Valve Seat to Gunbody. 13. Remove Rear Airvalve Seal

from housing (10) with a

hooked instrument.

15. Fit Seal to Housing (10). 16. Replace Valve (11). 17. Replace Valve Spring and

14. Fit new Seal to Service Tool.

screw in Housing (10).

18. Tighten Housing. 19. Fit Needle (9). 20. Fit Spring (8) and Knob (7).

21. Adjust Needle Packing (4)

with wrench sufficient to

seal but to allow free movement of needle. Lubricate

with gun oil.

Page 7

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy top or Horn holes plugged. Clean. Ream with non-metallic point.

bottom pattern Obstruction on top or bottom of fluid tip. Clean.

Cap and/or tip seat dirty. Clean.

Heavy right or left side pattern Left or right side horn holes plugged. Clean. Ream with non-metallic point.

Dirt on left or right side of fluid tip. Clean.

Remedies for the top-heavy, bottom-heavy, right-heavy and left-heavy patterns:

1) Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap. Clean the air cap as previously instructed.

2) If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the fluid tip.

Remove with #600 wet or dry sand paper.

3) Check for dried paint just inside the opening. Remove paint by washing with solvent.

Heavy center pattern Fluid pressure too high for atomization Balance air and fluid pressure.

air (pressure feed). Increase spray pattern width with

spreader adjustment valve.

Material flow exceeds air cap's capacity. Thin or lower fluid flow.

Spreader adjustment valve set too low. Adjust.

Atomizing pressure too low. Increase pressure.

Material too thick. Thin to proper consistency.

Split spray pattern Atomization air pressure too high. Reduce at transformer or gun.

Fluid pressure too low (pressure feed only). Increase fluid pressure (increases gun

handling speed).

Spreader adjusting valve set too high. Adjust.

Jerky or fluttering spray *Loose or damaged fluid tip/seat. Tighten or replace.

Material level too low. Refill.

Container tipped too far. Hold more upright.

Obstruction in fluid passage. Backflush with solvent.

Loose or broken fluid tube or fluid inlet nipple. Tighten or replace.

Dry or loose fluid needle packing nut. Lubricate or tighten.

Unable to get round spray Spreader adjustment screw not seating properly. Clean or replace.

Air cap retaining ring loose. Tighten.

Will not spray No air pressure at gun. Check air supply and air lines.

Internal mix or pressure feed air cap and tip Change to proper suction feed air cap and tip.

used with suction feed.

Fluid pressure too low with internal mix cap and Increase fluid pressure at tank.

pressure tank.

Fluid needle adjusting screw not open enough. Open fluid needle adjusting screw.

Fluid too heavy for suction feed. Thin material or change to pressure feed.

Excessive overspray Too much atomization air pressure Reduce pressure.

Gun too far from work surface. Adjust to proper distance.

Improper stroking (arcing, gun motion too fast). Move at moderate pace, parallel towork surface.

Excessive fog Too much, or too fast-drying thinner. Remix properly.

Too much atomization air pressure. Reduce pressure.

Dry Spray Air pressure too high. Reduce air pressure.

Gun tip too far from work surface. Adjust to proper distance.

Gun motion too fast. Slow down.

Gun out of adjustment Adjust.

Fluid leaking from packing nut Packing nut loose. Tighten, do not bind needle.

Packing worn or dry Replace or lubricate.

Fluid leaking or dripping from Packing nut too tight. Adjust.

front of pressure feed gun Dry packing. Lubricate.

Fluid tip or needle worn or damaged. Replace tip & needle with lapped sets.

Foreign matter in tip. Clean.

Fluid needle spring broken. Replace.

Wrong size needle or tip. Replace.

Page 7SB-2-548-B

Runs and sags Too much material flow. Adjust gun or reduce fluid pressure.

Material too thin. Mix properly or apply light coats.

Gun tilted on an angle, or gun motion too slow. Hold gun at right angle to work and adapt to

proper gun technique

Thin, sandy coarse finish Gun too far from surface. Check distance. Normally approx. 8".

drying before it flows out

Too much air pressure. Reduce air pressure and check spray pattern.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

*Most common problem.

Page 8

Page 8 SB-2-548-B

TROUBLESHOOTING (continued)

CONDITION CAUSE CORRECTION

Thick, dimpled finish "orange Gun too close to surface. Check distance. Normally approx. 8".

peel". Too much material coarsely atomized. Increase air pressure or decrease fluid pressure.

Air pressure too low. Increase air pressure or reduce fluid pressure.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

Material not properly mixed. Follow paint manufacturer's mixing instructions.

Surface rough, oily, dirty. Properly clean and prepare.

AVAILABLE OUTFITS

COM-PS430-18-01 ............... Siphon Feed Gun with TGC-545 1 qt Aluminum Cup

COM-PS430-22-01 ............... Siphon Feed Gun with TGC-545 1 qt Aluminum Cup

COM-PS497-14-03 ............... Pressure Assist Outfit with TSC-591 1 qt SS Cup with KK-4980 Regulator and

COM-PS497-14-04 ............... Pressure Outfit with 1 qt Aluminum Cup and KK-4980 Regulator

98-3151 ................................ 1/2" Diaphragm Pump Outfit / 5 gal Pail Mount with Advanced Conventional Compact Gun

Advanced Conventional Compact Gun

Page 9

ACCESSORIES

P-H-5516 Air

Adjusting Valve

HAV-500 or

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

HD-503

SolventSaver™

Hose/Gun Cleaner

HARG-510 Air

Regulator

29-3100 Scrubs®

Hand Cleaner

Towels

Page 9SB-2-548-B

SPN-5

Wrench

Enables user to control

and reduce air usage

at the gun. Ideal for

low pressure spraying.

42884-214-K5 3/8"

42884-215-K10 5/8"

Cleaning Brushes

These brush es are

helpf ul in cleaning

threads and recesses

of gun body.

Millennium 3000

Twin Cartridge Paint Spray Respirator

HAV-500 does not have

pressure gage. Use to

control air us age at

gun.

PLH-MF-6-100

Mini-Strainer

(100 mesh)

For trapping fo reign

particles in the paint

supply.

40-141 Small

40-128 Medium

40-143 Large

NIOSH-Certified, for respiratory protection in atmospheres not immediately dangerous to life.

TLC-576 Aluminum Cup

(Teflon Lined) &

TSC-591Stainless Steel Cup

1 Qt. pressure feed cups.

3/8" NPS (F), cam lock lid.

Requires KK-4980 air regulator kit.

83C-220

2 Gallon Tank

80-600

SG2 Plus Cup

2 Qt Hose/Gun Cleaner

used to clean the

inside of ho se, fluid

passageways of gun &

other paint equipment.

83GZ-5200

SolventSaver™

Use to maintain nearly

constant outlet pressure despite changes

in inlet pressure and

downstream flow.

SP-402-K Air

Adjusting Valve

Hose/Gun Cleaner

2 Gallon galvanized

tank used to clean the

inside of hose and

material passages of

the gun.

Quick Disconnect Approved for

HVLP Guns (Air)

High Flow Ball and Ring Type

HC-4419 1/4"

NPS(F)

HC-4700

1/4" NPT(F)

Installs into gun to

enable user to control

and reduce air usage

at the gun. Replaces

SP-637 plug.

HC-4699

1/4" NPT(M)

HC-1166

1/4" NPT(M)

MPV-60-K3

Air Inlet Swivel

(Pack of 3)

Fits Compact gun only.

Compatible with DeVilbiss high

flow quick disconnects.

80-295 Cup

Scrubs® are a premoistened hand cleaner

towel for painters. No

water is needed.

Spray Gun Lube

SSL-10 (2 oz.

bottle)

Compatible with all

pa in t mat eri al s:

contains no silicone or

petroleum distillates to

contami nat e pai nt.

MSDS sheet available

upon request.

KB-555 (Aluminum) &

KB-545-SS (S/S) 2 qt. Pressure

Feed Cup With Regulator

Pro vi des gre at er

degre e of control

over cup fluid pressure.

Plastic Tipped Fluid Needle

SP-300P-10-K

Compatible with SP-200S-08-K (0.55 mm) and

SP-200S-10-K (1.0 mm) fluid tips

SP-300P-14-K

Compatible with SP-200S-14-K fluid tips

Contains all necessary

tip, hose and nut sizes

used on or with gun.

TGC-545 Aluminum

TGC-555 Teflon Lined

TGC-595 Stainless Steel

Siphon Cups

HAF-507

Whirlwind™

In-Line Air Filter

Removes wat er, oil,

and debris from the air

line.

Zinc plated tank. 2 qt . cup.

Waterborne compatible when 80-35 6

liner is used.

2 qt. aluminum cup

with regulator.

Page 10

Página 10 SB-2-548-B

IMPORTANTE: Lea y siga todas las

instrucciones y Precauciones de Seguridad

antes de utilizar este equipo.

DESCRIPCIÓN

El Kit de Pistola Pulverizadora por

Gravedad Compact cumple las normas

ATEX 94/9/CE, nivel de protección; II 2 G X,

Adecuado para el uso en las Zonas 1 y 2.

IMPORTANTE: Estas pistolas pulveriza-

doras son apropiadas para el uso con

materiales al agua y a base de disolventes. Si tiene alguna duda respecto a la

idoneidad de un material específico,

póngase en contacto con su Distribuidor

local o directamente con ITWIF.

DECLARACIÓN DE CONFORMIDAD CE

Nosotros: ITW Finishing UK, de Ringwood

Rd, Bournemouth, Dorset, BH11 9LH,

Reino Unido, como fabricantes de la

Pistola pulverizadora modelo Compact,

declaramos bajo nuestra exclusiva

responsabilidad que el equipo al que se

refiere este documento cumple los

siguientes estándares o normas:

BS EN 292-1 PARTES 1 y 2: 1991, BS EN

1953:1999; y que por tanto cumple los

requisitos de protección de la Directiva del

Consejo 98/37/CE relativa a la Directiva

sobre Seguridad de las Máquinas y EN

13463-1:2001, Directiva del Consejo 94/9/

CE relativa a Equipos y sistemas de

protección diseñados para ser utilizados

en atmósferas potencialmente explosivas

nivel de protección II 2 G X.

ITW Finishing Systems and Products se

reserva el derecho a modificar las especificaciones del equipo sin previo aviso.

B. Holt, Director General

30/6/2003

ADVERTENCIAS DE SEGURIDAD

INCENDIO Y EXPLOSIÓN

Los disolventes y los materiales de recubrimiento pueden ser altamente inflamables o combustibles al pulverizarse. Consulte SIEMPRE las instrucciones del

fabricante del material de recubrimiento y las hojas COSHH antes de utilizar

este equipo.

Los usuarios deben cumplir la normativa nacional y local y los requisitos de las

compañías de seguros respecto a ventilación, precauciones contraincendios,

operación y mantenimiento de las zonas de trabajo.

Este equipo, tal y como se suministra, NO es adecuado para su uso con

Hidrocarburos Halogenados.

La Electricidad Estática puede ser generada por el paso de fluido y/o aire por los

manguitos, por el proceso de pulverización y por la limpieza de piezas no

conductoras con paños. Para impedir que las descargas estáticas produzcan

fuentes de ignición, debe mantenerse la continuidad de tierra a la pistola pulverizadora y a otros equipos metálicos utilizados.

EQUIPO DE PROTECCIÓN PERSONAL

Vapores tóxicos - Al pulverizarse, ciertos materiales pueden ser tóxicos, crear irri-

tación o ser dañinos para la salud de otra forma. Lea siempre todas las etiquetas

y hojas de datos de seguridad del material antes de pulverizar, y siga cualquier

recomendación. En caso de Duda, Póngase en Contacto con el Proveedor del

Material.

Se recomienda el uso de equipos de protección respiratoria en todo momento. El

tipo de equipo debe ser compatible con el material que se está pulverizando.

Lleve siempre protección ocular al pulverizar o al limpiar la pistola.

Deben llevarse guantes al pulverizar o al limpiar la pistola.

Formación - El personal debe recibir una formación adecuada en el uso seguro

de equipos de pulverización.

MAL USO

No apunte nunca con una pistola de pulverización a ninguna parte del cuerpo.

No supere nunca la presión máxima de operación segura recomendada del

equipo.

El acoplamiento de piezas de repuesto no recomendadas o no originales puede

crear riesgos.

Antes de realizar limpieza o mantenimiento, toda presión debe aislarse y aliviarse

en el equipo.

El producto debe ser limpiado usando una máquina para lavar pistolas. No

obstante, este equipo no debe dejarse dentro de una máquina de lavar pistolas

durante periodos de tiempo prolongados.

NIVELES SONOROS

El nivel sonoro con ponderación A de las pistolas de pulverización puede superar

los 85 dB(A) dependiendo de la configuración utilizada. Se recomienda llevar

protección acústica en todo momento durante la pulverización.

OPERACIÓN

Los Equipos de Pulverización que funcionan a alta presión pueden verse

sometidos a fuerzas de retroceso. Bajo determinadas circunstancias, dichas

fuerzas podrían provocar al operador lesiones por esfuerzo repetitivo (RSI).

Page 11

Patente Nº 2372465 (GB)

Página 11SB-2-548-B

MODELO-NÚMERO PIEZA

Ejemplo: COM-PS430-14-00

Conducto de

fluido en acero

inoxidable

Casquillo de aire

Diámetro del pico

de fluido

(14 = 1.4 mm)

00 = Sin cubeta

01 = Cubeta de sifón

03 = Cubeta SS TSC-591

de 1 cuarto de galón

con regulador KK-4980

04 = Cubeta de aluminio TLC-576

de 1 cuarto de galón

con regulador KK-4980

LISTA DE PIEZAS

Nº Número

Ref. Descriptión de Pieza Cant Opciones

1

2 Pico de fluido SP-200S-**-K 1 10, 14, 18, 22 ej. ** =14 =1.4 mm

+3 Separador (paquete de 5) SP-623-K5 1

+4 Empaquetadura (paquete de 2) GTI-445-K2 1

5 Válvula dispersora SP-401-K 1

6 Espiga y tornillo (paquete de 5) GTI-408-K5 1

7 Tornillo de ajuste de la aguja SP-614-K 1

+8 Muelle SP-622-K5 1

9 Aguja SP-300S-**-K 1 10, 14, 18, 22 ej. ** =14 =1.4 mm

10 Alojamiento de la válvula de aire SP-612-K 1

11 Vástago 1

12 Gatillo SP-617-K 1

13 Conector de aire SP-611-K 1

14 Tapón SP-637 1

15 Entrada de fluido – Conector y junta SP-636-K 1

17 Retén y juntas SPK-102-K 1

+18

20 Herramienta para el conjunto de

21 Llave SPN-5 1

Kit de Mantenimiento de SPK-402 1

Casquillo de aire / Anillo de retención

COM-430, COM-443 o COM-497

& junta

Kit de clip, junta y perno (paquete de 5)

la válvula de aire 1

la Pistola Pulverizadora

(piezas incluidas marcadas con + )

SP-100-***-K 1 430, 443, 497 ej. *** = 430

GTI-428-K5 1

16 Kit de mantenimiento de la SPK-101-K 1

válvula de aire

Page 12

Página 12 SB-2-548-B

ESPECIFICACIÓN

Conexión del suministro de aire:

Universal 1/4" BSP y NPS

Conexión del suministro de fluido:

Universal 3/8" BSP y NPS

Presión estática máxima de entrada

de aire: P1 = 12 bar (175 psi)

Presión estática máxima de entrada

de fluido: P2 = 15 bar (218 psi)

Presión nominal de entrada de aire

en la pistola – con el gatillo apretado:

3.5 bar (50 psi)

Temperatura Máxima de uso: 104°F

Peso de pistola: 14.5 oz

MATERIALES DE CONSTRUCCIÓN

Cuerpo de la pistola: Aluminio anod-

izado

Boquilla: Acero inoxidable

Aguja: Acero inoxidable

Entrada de fluido / Conductos de fluido:

Acero inoxidable / PTFE

Gatillo: Acero niquelado

INSTALACIÓN

Importante: Para asegurarse

de que este equipo llega a

usted en condiciones óptimas,

se han utilizado recubrimientos

protect ores. Enjuague el equipo

con un disolvente adecuado

antes de su uso.

1. Acople el manguito de aire al

conector (13). Tamaño de manguito

recomendado: 5/16" diám. interior.

2. Acople el manguito de suministro de

fluido a la Entrada de Fluido (15).

OPERACIÓN

1. Mezcle el material de recubrimiento

siguiendo las instrucciones del fabricante.

2. Gire el tornillo de ajuste de la aguja

(7) en el sentido de las agujas del

reloj para impedir que se mueva.

3. Gire la válvula de dispersión (5) en el

sentido contrario a las agujas del

reloj hasta que esté abierta del todo.

4. Ajuste la presión de aire de entrada

(ver valores recomendados en las

Especificaciones) en la entrada de

la pistola con el gatillo apretado.

(se recomienda utilizar para ello el

ma nó met ro mo str ad o e n

Accesorios).

5. Gire el tornillo de ajuste de la aguja

en el sentido contrario a las agujas

del reloj hasta que se vea la primera

rosca o un viaje completo se logra.

6. Haga una prueba de pulverización.

Si el acabado es demasiado seco,

reduzca el caudal de aire reduciendo

la presión de entrada de aire o mediante la Válvula de Caudal de Aire

(14). Gire el Pomo de Ajuste (14)

hacia dentro para reducir la presión.

7. Si el acabado es demasiado húmedo,

reduzca el caudal de fluido girando

el tornillo de la aguja (7) en el

sentido de las agujas del reloj o

reduciendo la presión del fluido.

Si la atomización es demasiado

gruesa, aumente la presión de

entrada de aire. Si es demasiado

fina, reduzca la presión de entrada.

8. El tamaño del patrón puede

reducirse ajustando la válvula (5) en

el sentido de las agujas del reloj.

9. Sujete la pistola perpendicular a la

superficie a pulverizar. Pulverizar en

arcos o con la pistola inclinada

puede producir un recubrimiento

desigual.

10. La distancia de pulverización recomendada es de 150 - 200 mm.

11. Pulverice primero los bordes. Solape

cada pasada el 50% como mínimo.

Mueva la pistola a una velocidad

constante.

12. Cierre siempre el suministro de aire

y fluido y alivie la presión cuando la

pistola no se esté utilizando.

MANTENIMIENTO PREVENTIVO

1. Cierre el suministro de aire y recubrimiento, y alivie la presión en los

manguitos, o si utiliza el sistema QD,

desconéctelo del manguito de aire y

de fluido.

2. Retire el casquillo de aire (1) y límpielo. Si alguno de los orificios del

casquillo está obstruido con material de recubrimiento, utilice un

palillo para limpiarlo. No utilice

nunca un alambre metálico, porque

podría dañar el casquillo y producir

patrones de pulverización distorsionados.

3. Asegúrese de que la punta de la

boquilla (2) está limpia y libre de

desperfectos. Una acumulación de

pintura seca puede distorsionar el

patrón de pulverización.

4. Lubricación – la espiga/tornillo (6), la

empaquetadura (4) y la válvula de

aire (11) deben lubricarse con aceite

cada día.

SUSTITUCIÓN DE PIEZAS

Boquilla (2) y Aguja (9) – Retire las piezas

en el siguiente orden: 7, 8, 9, 1 y 2.

Sustituya cualquier pieza desgastada o

dañada y vuelva a montar las piezas en

orden inverso. Par de apriete recomendado para la boquilla (2) 9,5-12 Nm

(80-100 pies-libra/pulgada).

Guarnición – Retire las piezas 7, 8, 9.

Desenrosque el cartucho (4). Coloque un

cartucho nuevo y apriete con los dedos

solamente. Vuelva a montar las piezas 9,

8 y 7 y apriete el cartucho (4) con una

llave, lo suficiente para hacer sello pero

dejando que la aguja se desplace libremente. Lubrique con aceite para pistolas.

Kit de Junta de la Válvula de Aire (16) –

(Ver FIG 2 y fotos 1 a 28).

Válvula Dispersora (5) – Precaución:

asegúrese siempre de que la válvula está

en posición completamente abierta

girando el tornillo en el sentido contrario

a las agujas del reloj hasta que haga tope

antes de instalarla en el cuerpo de la

pistola.

Page 13

Página 13SB-2-548-B

1. Retire el pomo de ajuste (7),

el muelle (8), y la aguja (9).

4. Retire la válvula (11). 5. Usando la herramienta de

2. Afloje el alojamiento (10). 3. Retire el alojamiento (10) y

mante ni-miento SP N-7,

enganche la muesca detrás

del asiento de la válvula.

el muelle de la válvula de

aire.

6. Retire el asiento de la

válvula.

7. Haga salir la junta delantera

de la válvula de aire empujando con el dedo.

10. Coloque la junta nueva sobre

el cuerpo de la pistola y empuje

firmemente para asegurarse

de que la junta quede correctamente colocada.

8. Ponga la pistola boca abajo

y deje que se caiga la junta.

11. Coloque un asiento de

válvula nuevo en la herramienta de mantenimiento.

9. Instale una junta delantera

nueva en la herramienta de

mantenimiento.

Page 14

Página 14 SB-2-548-B

12. Coloque el asiento de

válvula en el cuerpo de la

pistola.

15. Coloque la junta en el alojamiento (10).

13. Retire la junta de la válvula

de aire del alojamiento (10)

con un instrumento que

tenga gancho.

16. Vuelva a colocar el husillo

(11).

14. Instale una junta nueva en la

herramienta de mantenimiento.

17. Vuelva a colocar el muelle

de la válvula y el tornillo en

el alojamiento (10).

18. Apriete el alojamiento. 19. Coloque la aguja (9). 20. Instale el muelle (8) y el

pomo (7).

21. Ajuste la guarnición de la aguja (4) con

una llave lo suficiente para hacer sello

pero permitiendo que se desplace la

aguja. Lubrique con aceite para pistolas.

Page 15

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS

CONDICIÓN CAUSE CORRECCIÓN

Patrón pesado en

la parte superior

o inferior

Agujeros de la horquilla obstruidos.

Obstrucción en la parte superior o inferior de la punta de fluido.

Casquillo y/o asiento de la punta está sucio.

Limpie. Escariar con punta no metálica.

Limpie.

Limpie.

Página 15SB-2-548-B

Patrón pesado en el lado

derecho o izquierdo

Patrón pesado en

el centro

Patrón de

pulverización

dividida

Pulverización entrecortada o con vibraciones

Imposibilidad de obtener pulverización

redondeada

No pulveriza

Sobrepulverización excesiva

Nebulización excesiva

Agujeros en el lado izquierdo o derecho de la horquilla obstruidos.

Suciedad en el lado izquierdo o derecho de la punta del líquido.

Corrección de los patrones pesados en la parte superior, inferior, el lado derecho e izquierdo.

1. Determine si la obstrucción está en el casquillo de aire o en la punta de fluido. Realice esto haciendo una prueba del

patrón de pulverización. Luego gire el casquillo media vuelta y pulverice con otro patrón. Si se invierte el defecto, la

obstrucción se encuentra en el casquillo de aire. Limpie el casquillo de aire siguiendo las instrucciones previas.

2. Si el defecto no se invierte, la obstrucción se encuentra en la punta de fluido. Verifique si hay una pequeña protuberancia

en el borde de la punta de fluido. Quítela con papel de lija #600 húmedo o seco.

3. Verifique si hay pintura seca dentro de la abertura; elimínela lavándola con disolvente.

La presión del fluido es demasiado alta para el aire de atom-

ización (alimentado por presión).

El flujo del material sobrepasa la capacidad del casquillo de aire.

El ajuste de la válvula dispersora es muy bajo.

La presión de atomización es muy baja.

El material es muy espeso.

La presión de aire de atomización es muy alta.

La presión del fluido es muy baja (únicamente alimentada por presión).

El ajuste de la válvula dispersora es muy alto.

*La punta/el asiento del fluido está flojo o dañado.

El nivel del material es muy bajo.

El recipiente se inclinó mucho.

Obstrucción en el conducto del fluido.

El tubo del fluido o la boquilla de entrada del fluido está flojo o roto.

La tuerca de la empaquetadura de la aguja de fluido seca o floja.

El tornillo de ajuste del dispersador no está alojado debidamente.

El anillo de retención del casquillo de aire está flojo.

No hay presión de aire en la pistola.

La mezcla interna o el casquillo de aire alimentado por presión

y la punta utilizados con alimentación por succión.

La presión del fluido es muy baja con el casquillo de la mezcla

interna y el tanque de presión.

El tornillo de ajuste de la aguja de fluido no está lo suficientemente abierto.

El fluido es muy pesado para la alimentación por succión.

Demasiada presión de aire de atomización.

La pistola está muy alejada de la superficie de trabajo.

Carrera indebida (formación de arco, el desplazamiento de la pistola es muy rápido).

Demasiado diluyente o diluyente de secado muy rápido.

Demasiada presión de aire de atomización.

Limpie. Escariar con punta no metálica.

Limpie.

Equilibre la presión de aire y flujo de fluido.

Au mente el ancho del patrón de pulverización con la válvula

de ajuste del dispersador.

Diluya o baje el flujo de fluido.

Ajuste.

Aumente la presión.

Diluya hasta lograr la consistencia adecuada.

Reduzca la presión en el transformador o en la pistola.

Au mente la presión del fluido (aumente la velocidad de

manipulación de la pistola).

Ajuste.

Apriete o reemplace.

Vuelva a llenar.

Sosténgalo de forma más vertical.

Limpie con disolvente.

Apriete o reemplace.

Lubrique o apriete.

Limpie o reemplace.

Apriete.

Verifique el suministro de aire y las líneas de aire.

Ca mbie el casquillo de aire y la punta a la alimentación por

succión adecuada.

Aumente la presión del fluido en el tanque.

Abra el tornillo de ajuste de la aguja de fluido.

Diluya el material o cambie a alimentación por presión.

Reduzca la presión.

Ajuste hasta la distancia debida.

Desplácese a ritmo moderado, paralelo a la superficie de trabajo.

Vuelva a mezclar adecuadamente.

Reduzca la presión.

Pulverización seca

Escape de fluido por la tuerca de la

empaquetadura

Escape o goteo de fluido por la parte

delantera de la pistola alimentada

por presión

Se corre

Acabado rugoso arenoso, fino,

que se seca antes de fluir.

*Problemas más comunes

Presión de aire muy alta.

Punta de pistola muy alejada de superficie de trabajo.

El desplazamiento de la pistola es muy rápido.

Pistola desajustada.

Tuerca de la empaquetadura floja.

Empaquetadura gastada o seca.

Tuerca de la empaquetadura muy apretada.

Empaquetadura seca.

Punta de fluido o aguja gastada o dañada.

Materias foráneas en la punta.

Muelle de la aguja del fluido roto.

Aguja o punta de tamaño inadecuado.

Demasiado flujo de material.

El material es muy delgado.

Pi stola inclinada en un ángulo o el desplazamiento de la

pistola es muy despacio.

La pistola está muy alejada de la superficie.

Demasiada presión de aire.

Se está utilizando un diluyente inadecuado.

Reduzca la presión de aire.

Ajuste hasta la distancia debida.

Desacelere.

Ajuste.

Apriete, no bloquee la aguja.

Reemplace o lubrique.

Ajuste.

Lubrique.

Reemplace la punta y la aguja con instrumentos solapados.

Limpie.

Reemplace.

Reemplace.

Ajuste la pistola o reduzca la presión de fluido.

Mezcle debidamente o aplique capas livianas.

So stenga la pistola en un ángulo correcto para trabajar y

adáptela a una técnica debida.

Verifique la distancia. Normalmente, aprox. 8 pulg.

Reduzca la presión de aire y verifique el patrón de pulverización.

Siga las instrucciones de mezclado del fabricante de la pintura.

Page 16

Página 16 SB-2-548-B

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS (continuación)

CONDICIÓN CAUSE CORRECCIÓN

Acabado grueso, no uniforme, como

el de una “cáscara de naranja”.

EQUIPOS DISPONIBLES

COM-PS430-18-01 ............... Pistola alimentada por sifón con cubeta de aluminio TGC-545 de 1 cuarto de galón

COM-PS430-22-01 ............... Pistola alimentada por sifón con cubeta de aluminio TGC-545 de 1 cuarto de galón

Verifique la distancia. Normalmente, aprox. 8 pulg.

Aumente la presión de aire o disminuya la presión del fluido.

Aumente la presión de aire o reduzca la presión del fluido.

Siga las instrucciones de mezclado del fabricante de la pintura.

Siga las instrucciones de mezclado del fabricante de la pintura.

Limpie y prepare debidamente.

Pistola muy cerca de la superficie.

Demasiado material áspero fue atomizado.

Presión de aire muy baja.

Se está empleando un diluyente inadecuado.

No se ha mezclado debidamente el material.

Superficie áspera, aceitosa o sucia.

COM-PS497-14-03 ............... Equipo asistido por presión con cubeta SS TSC-591 de 1 cuarto de galón con regulador KK-4980 y

COM-PS497-14-04 ............... Equipo a presión con cubeta de aluminio de 1 cuarto de galón y regulador KK-4980

98-3151 ................................ Equipo de bomba con diafragma de 1/2" pulg. / montura en bidón cilíndrico de 5 galones con

pistola compacta convencional avanzada

pistola compacta convencional avanzada

Page 17

ACCESORIOS

P-H-5516 Válvula

reguladora de aire

HAV-500 o

HAV-501

Válvula reguladora

(HAV-501 MOSTRADA)

HD-503

SolventSaver™

Limpiador de

manguito/pistola

HARG-510

Regulador de aire

29-3100 Scrubs®

Toallas para limpi-

arse las manos

Página 17SB-2-548-B

SPN-5

Llave

Permite al usuario controlar y

reducir el uso del aire en la

pistola. Ideal para pulverización con presión baja.

42884-214-K5 3/8 de pulg.

42884-215-K10 5/8 de pulg.

Cepillos de limpieza

Estos cepillos ayudan a limpiar

las roscas y los lugares ocultos

del cuerpo de la pistola.

Respirador para pulverizador de pintura

Millennium 3000

con cartucho doble

HAV-500 no tiene manómetro.

Utilizada para controlar el uso

del aire en la pistola.

PLH-MF-6-100

Mini-colador

(malla 100)

Para atrapar partículas

foráneas en el suministro de pintura.

40-141 Pequeñas

40-128 Medianas

40-143 Grandes

Certificado por NIOSH, para protección de la respiración en

atmósferas que no implican riesgo inmediato para la vida.

Cubeta de aluminio

TLC-576 (forrada con Teflón)

y Cubeta de acero inoxid-

able TSC-591

Cubetas alimentadas por presión de

1 cuarto de galón. 3/8 de pulg. NPS (F),

tapa con cerrojo de leva. Requiere del

kit del regulador de aire KK-4980.

83C-220

Tanque de 2 galones

80-600

Cubeta SG2 Plus

Limpiador de manguito/pistola de

2 cuartos de galón, utilizado para

limpiar el interior del manguito, los

conductos de fluido de la pistola y

otros equipos de pintura.

83GZ-5200

SolventSaver™

Limpiador de

manguito/pistola

Tanque galvanizado de 2 galones

utilizado para limpiar el interior

del manguito y los conductos de

materiales de la pistola.

Dispositivo de desconexión

rápida aprobado para

pistolas HVLP (aire)

Tipo de bola y anillo de alto flujo

HC-4419 de 1/4 de pulg.

NPS(F)

HC-4700

de 1/4 de pulg. NPT(F)

Utilizado para mantener una

pres ión d e sal ida c asi

constant e a pesar de los

cambios en la presión de

entrada y el flujo descendente.

SP-402-K Válvula

reguladora de aire

Se instala en la pistola para

permitir al usuario controlar y

reducir el uso de aire en la

pistola. Reemplaza el tapón

SP-637.

HC-4699

1/4 de pulg.

NPT(M)

HC-1166

1/4 de pulg. NPT(M)

MPV-60-K3

Eslabón giratorio de

entrada de aire

(paquete de 3)

Para pistola Compact únicamente.

Compatible con el dispositivo de descon-

exión rápida de alto

flujo DeVilbiss.

80-295 Cubeta

Las Scrubs® son toallas prehumedecidas para limpiarse las

manos los pintores. No se

necesita agua.

Lubricante de

pistola pulverizadora

SSL-10-K12 (botella de 2 oz.)

Compatible con todos los materiales de pintura; no contiene destilados de silicona ni petróleo que

contaminen la pintura. Hoja de

Datos de Seguridad de los

Materiales (MSDS, por sus siglas en

inglés) disponible previa solicitud.

KB-555 (aluminio) y KB-545-SS

(S/S) Cubeta de 2 cuartos de

galón alimentada por presión

con regulador

Proporciona un mayor grado

de control sobre la presión

del fluido de la cubeta.

Aguja de fluido con punta plástica

SP-300P-10-K

Compatible con puntas de fluido

SP-200S-08-K (0.55 mm) y

SP-200S-10-K (1.0 mm)

SP-300P-14-K

Compatible con puntas de fluido

SP-200S-14-K

Contiene to dos los t amaños

necesarios de punta, manguito y

tuerca utilizados en o con la

pistola.

Cubeta de succión

de aluminio

TGC-545 aluminio

TGC-555 con

revestimiento de Teflon

TGC-595 de acero

inoxidable

HAF-507

Filtro de aire en

línea Whirlwind

Elimina el agua, el aceite y la

basura de la línea de aire

TM

Zincado tanque. 2 cuarto. A base de

ag ua, ma terial

compatible cuando

se utiliza de forros

80-356.

2 cuarto. Cubeta de

aluminio con regulador.

Page 18

Page 18 SB-2-548-B

NOTES

Page 19

NOTAS

Página 19SB-2-548-B

Page 20

Page 20 SB-2-548-B

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

ITW Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

2/10 ©2010 Illinois Tool Works Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...