Page 1

SB-E-2-534 ISS.06

Operation Manual

Advanced - Conventional Gravity

Feed Spraygun

E

P 1 – 12

Page 2

E

Operation Manual

COMPACT – Gravity Feed S p r aygun

Important

Read and follow all instructions and Safety Precautions before using this equipment

Description

The Compact Gravity feed Spraygun Kit complies to ATEX regulations 94/9/EC, protection level;

II 2 G X, Suitable for use in Zones 1 and 2

Important: : These Sprayguns are suitable for use with solvent based materials. These guns are not

designed for use with highly corrosive and/or abrasive materials and if used with such materials it must

be expected that the need for cleaning and/or replacement of parts will be increased. If there is any

doubt regarding the suitability of a specific material contact your local Distributor or ITW Finishing direct.

.

COM-G430-16

Model Part Number

Example:

Aircap

Fluid Nozzle size

(14 = 1.4 mm)

EC Declaration of Conformity

We, ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the

manufacturer of the Spray gun model Compact, declare, under our sole responsibility, that the

equipment to which this document relates is in conformity with the following standards or other

normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the

protection requirements of Council Directive 98/37/EEC relating to Machinery Safety Directive,

and: EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and Protective

Systems intended for use in Potentially Explosive Atmospheres protection level II 2 G X.

For HVLP and Trans-Tech Aircaps these products comply with the requirements of the EPA

guidelines, PG6/34,PG6/20 and PG6/23 achieving transfer efficiency in excess of 65%.

B. Holt, General Manager

30th June 2003

ITW Finishing Systems and Products reserve the right to modify equipment specification without prior

notice.

2 © 2003 ITW Finishing Systems and Products

Page 3

E

SAFETY WARNINGS

Fire and explosion

Solvents and coating materials can be highly flammable or combustible when sprayed.

ALWAYS

before using this equipment.

Users must comply with all local and national codes of practice and insurance company

requirements governing ventilation, fire precautions, operation and house-keeping of

working areas.

This equipment, as supplied, is NOT

Hydrocarbons.

Static electricity can be generated by fluid and/or air passing through hoses, by the

spraying process and by cleaning non-conductive parts with cloths. To prevent ignition

sources from static discharges, earth continuity must be maintained to the spray gun

and other metallic equipment used. It is essential to use conductive air and/or fluid

hoses.

Toxic vapours – When sprayed, certain materials may be poisonous, create irritation or

be otherwise harmful to health. Always read all labels, safety data sheets and follow any

recommendations for the material before spraying. If in doubt, contact your material

supplier.

The use of respiratory protective equipment is recommended at all times. The type of

equipment must be compatible with the material being sprayed.

Always wear eye protection when spraying or cleaning the spray gun.

Gloves must be worn when spraying or cleaning the equipment.

Training – Personnel should be given adequate training in the safe use of spraying equipment.

refer to the coating material suppliers instructions and COSHH sheets

suitable for use with Halogenated

Personal Protective Equipment

Misuse

Never aim a spray gun at any part of the body.

Never exceed the max. recommended safe working pressure for th e equipment.

The fitting of non-recommended or non-original spares may create hazards.

Before cleaning or maintenance, all pressure must be isolated and relieved from the equip ment.

The product should be cleaned using a gun-washing machine. However, this equipment should

not be left inside gun-washing machines for prolonged periods of time.

Noise Levels

The A-weighted sound level of spray guns may exceed 85 dB (A) depending on the setup being used. Details of actual noise levels are available on request. It is

recommended that ear protection is worn at all times when spraying.

Operating

Spray equipment using high pressures may be subject to recoil forces. Under certain

circumstances, such forces could result in repetitive strain injury to the operator.

© 2003 ITW Finishing Systems and Products 3

Page 4

E

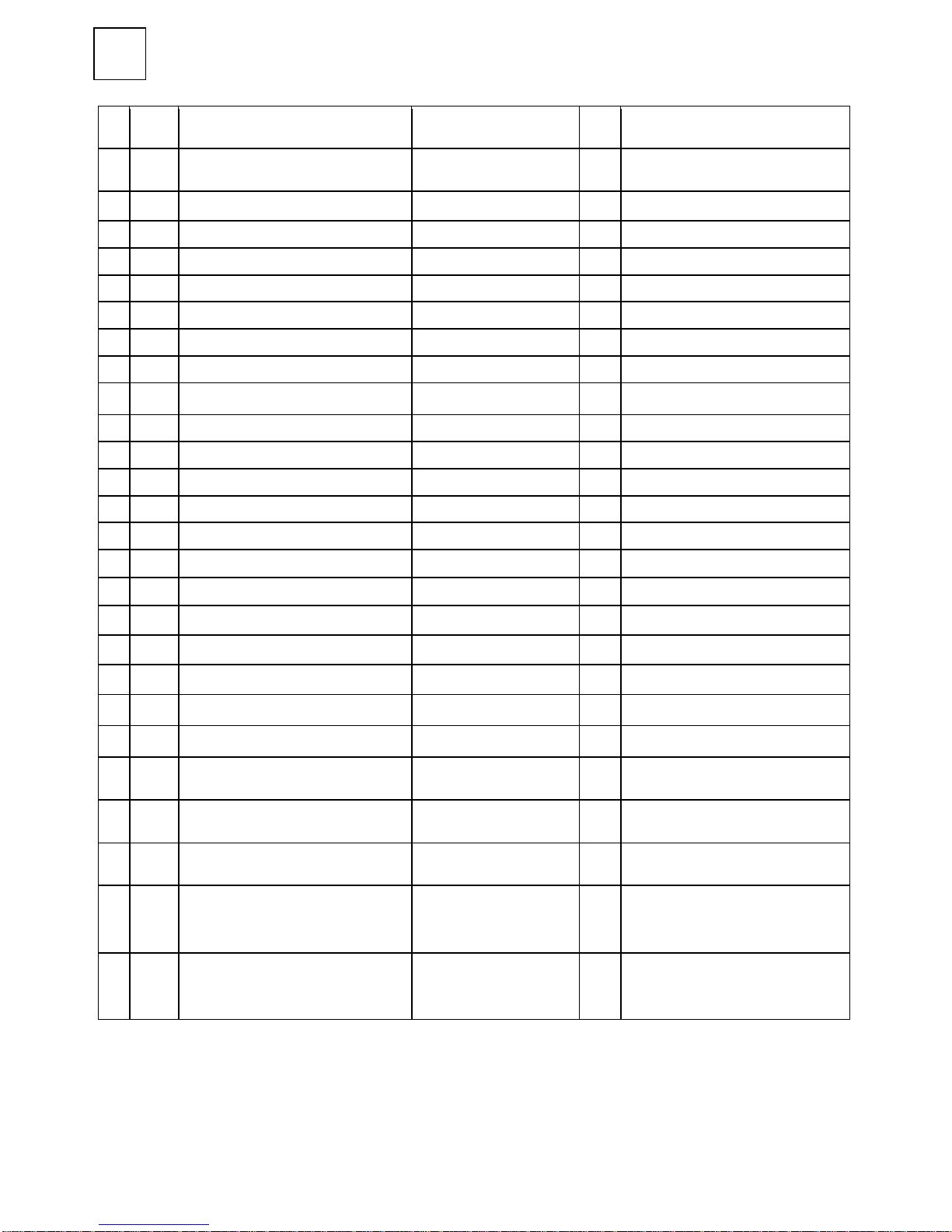

Parts List

Ref.

No

1 Air Cap/Retaining ring

2 Nozzle See Selection Chart

*+ 3 Separator SP-626-K5 5

*+ 4 Packing GTI-445-K2 2

5 Spreader Valve SP-403-K 1

6 Stud and Screw GTI-408-K5 5

7 Needle Adjusting Screw SP-614-K 1

*+ 8 Spring SP-622-K5 1

+ 9 Needle See Selection Chart

10 Airvalve housing + seal SP-612-K 1

*+ 11 Spindle 1

12 Trigger SP-617-K 1

13 Connector SP-611-K 1

Description Part Number Qty Options

See Selection Chart

14 Airflow Valve SP-402-K 1

15 Drip Check Lid kit of 5 GFC-2-K5 1

+ 16 Air Valve Service Kit SPK-101-K 1

17 Retaining Ring and Seals SPK-102-K 1

*+ 18 Spreader/ Cheater Service Kit GTI-428-K5 5

19 Circlip 25746-007-K5 5

+ 20 Cup Lid GFC-501 1

21 Filter KGP-5 1

22 1/2 Ltr Gravity Cup Kit GFC-501

* 23 Air Valve assembly Tool

24 Spanner SPN-5

Spraygun Service Kit

(parts included marked + )

Spraygun Service Kit

(parts included marked * )

SPK-401-** 1 ,13,14, 16,18,20,22

SPK-402-** 1 ,13,14, 16,18,20,22

e.g ** =14 =1.4 mm

e.g ** =14 =1.4 mm

4 © 2003 ITW Finishing Systems and Products

Page 5

CHART : AIR CAPS / NOZZLES AND NEEDLE COMBINATIONS

AIR CAP/ RETAINING RING SP-100-***- K e.g *** = 430

CONVENTIONAL HVLP TRANS -TECH

430,497,443,

470 505 510,522,523,513, 590

Nozzle SP-200S-**-K

e.g ** =14 =1.4mm

085,10,12,13,14,

16,18,20,22

085,10,12,13,14,

16,18,20,22

085,10,12,13,

14,16,18,20,22

Needle SP-300S-**-K

e.g ** =14 =1.4mm

085,10,12,13,14,16,

18,20,22,28

085,10,12,13,

14,16,18,20,22

085,10,12,13,

14,16,18,20,22

05,07,10

Needle

Plastic tipped

SP-300P-**-K

e.g ** =14 =1.4mm

10, 12, 14

10, 12, 14

10, 12, 14

10

Nozzle Hardened SP-200N-**-K

e.g ** =14 =1.4mm

14,18, 22

14,18, 22 14,18, 22

Nozzle Hardened

( Air Cap 470 only)

SP-247N-**-K

e.g ** =22 =2.2mm

22,28

Needle Hardened SP-300N-**-K

e.g ** =14 =1.4mm

14,18,22

22,28 14, 18, 22

14, 18, 22

Nozzle

(Air Cap 590 only)

SP-259S-**-K

e.g **=10=1.0mm

05,07,10

Nozzle

( Air Cap 470 only)

SP-247S-**-K

e.g ** =22 =2.2mm

22,28

Page 6

Specification

Air supply connection - Universal 1/4“ BSP and NPS

Maximum static Air inlet pressure - P1 = 12 bar (175 psi)

Nominal gun Air inlet pressure -

with gun triggered

Maximum Service temperature 40°C

Gun Weight - 583 g

Gun body Aluminium

Nozzle Stainless Steel

Needle Stainless Steel

Fluid Inlet / Fluid Passages Stainless Steel / PTFE

Trigger Nickel Plated Steel

Cup Acetal (Anti-static)

Cup Lid Acetal (Anti-static)

3 bar (44 psi)

Materials of Construction

Page 7

E

Installation

Important: To ensure that this equipment reaches you in first class condition, protective coatings have

been used. Flush the equipment through with a suitable solvent before use.

1. Attach air hose to connector (13). Recommended hose size 8 mm bore. The hose must be

conductive and electrical bond from the spraygun to earth should be checked with an ohmeter. A

resistance of less than 10

2. Air supply should be filtered and regulated.

3. Attach Cup assembly (22) by screwing into the Fluid Inlet of the spraygun. Tighen when fully

home.

6

Ohms is recommended.

Operation

1. Mix coating material to manufacturers instructions.

2. Fill the cup with the required amount of material. Fill to no more than 25mm (1“) from the top of

the cup. DO NOT OVERFILL.

3. Attach Cup Lid.

4. Turn needle adjusting screw (7) clockwise to prevent movement.

5. Turn spreader valve (5) counter-clockwise to fully open.

6. Adjust inlet air pressure to give 3 bar (44 psi) at the gun inlet with the gun triggered. (pressure

gauge attachment shown under Accessories is recommended for this).

7. Turn needle adjusting screw counter clockwise until first thread shows.

8. Test spray. If the finish is too dry reduce airflow by reducing air inlet pressure or by the Airflow

Valve (14). Screw the Adjusting Knob (14) in to reduce pressure.

9. If finish is too wet reduce fluid flow by turning needle screw (7) clockwise. If atomisation is too

coarse, increase inlet air pressure. If too fine reduce inlet pressure.

10. The pattern size can be reduced by turning adjusting valve (5) clockwise.

11. Hold gun perpendicular to surface being sprayed. Arcing or tilting may result in uneven coating.

12. The recommended spray distance is 150-200 mm (6”-8”).

13. Spray edges first. Overlap each stroke a minimum of 50%. Move gun at a constant speed.

14. Always turn off air supply and relieve pressure when gun is not in use.

1. Turn off air and relieve pressure in the supply lines, or if using QD system, disconnect from

airline.

2. Remove Cup Lid (20 )and empty coating material into a suitable container. Clean the gun and

cup, preferably in a gun wash machine. Clean the cup.

3. Check the breather hole in the Lid and the Drip Check Lid is not blocked.

4. Remove air cap (1) and clean. If any of the holes in the cap are blocked with coating material use

a toothpick to clean. Never use metal wire which could damage the cap and produce distorted

spray patterns

5. Ensure the tip of the nozzle (2) is clean and free from damage. Build up of dried paint can distort

the spray pattern.

6. Lubrication – stud/screw (6), needle (9) and air valve (11) should be oiled each day.

© 2003 ITW Finishing Systems and Products 7

Preventative Maintenance

Page 8

E

Replacement of Parts

Nozzle (2) and Needle (9) – Remove parts in the following order: 7, 8, 9, 1 and 2. Replace any worn or

damaged parts and re-assemble in reverse order. Recommended tightening torque for nozzle (2) 9.5-12

Nm (80-100 lbf in).

Packing – Remove parts 7, 8, 9. Unscrew cartridge (4). Fit new cartridge finger tight. Re-assemble

parts 9, 8, and 7 and tighten cartridge (4) with spanner sufficient to seal but to allow free movement of

needle. Lubricate with gun oil.

Air Valve Seal Kit (16) - (Refer to photos 1 to 28 and fig 2)

1. Remove Adjusting Knob (7), Spring (8), and Needle (9).

2. Loosen Housing (10).

3. Remove Housing (10) and Airvalve Spring.

4. Remove Valve (11).

5. Using Service Tool SPN-7, engage groove behind the Valve Seat.

6. Remove Valve Seat.

7. Push out the Front Airvalve Seal with a finger.

8. Turn the Gun upside down and let the Seal fall out.

9. Fit New Front Seal to Service Tool.

10. Fit new Seal to gunbody and press firmly to ensure Seal is engaged.

11. Fit New Valve Seat to Service Tool. Groove must face outwards.

12. Fit Valve Seat to Gunbody.

13. Remove Rear Airvalve Seal from housing (10) with a hooked instrument.

14. Fit new Seal to Service Tool.

15. Fit Seal to Housing (10).

16. Replace Valve (11).

17. Replace Valve Spring and screw in Housing (10).

18. Tighten Housing.

19. Fit Needle (9).

20. Fit Spring (8) and Knob (7).

21. Adjust Needle Packing (4) with Spanner sufficient to seal but to allow free movement of needle.

Lubricate with gun oil.

Spreader valve (5) – Caution: always ensure that the valve is in the fully open position by turning screw

fully counter-clockwise before fitting to body.

Refer to coating material manufacturers recommendations or ITW Finishing UK Website:

www.itweuropeanfinishing.com

FIG 2

Air cap / Nozzle Selection

8 © 2003 ITW Finishing Systems and Products

Page 9

1 2

3 4

E

5 6

7 8

© 2003 ITW Finishing Systems and Products 9

Page 10

E

9 10

11 11a

12 13

14

10 © 2003 ITW Finishing Systems and Products

15

Page 11

16

18

20 21

17

19

© 2003 ITW Finishing Systems and Products 11

E

Page 12

E

Accessories

Spanner – order SPN-5

Cleaning Brush – order 4900-5-1-K3

Regulator/Gauge Attachment - order HAV-501-B or DGI-501-BAR

Pressure gauge Attachment – order GA-515

Gun Mounted Regulator – order DVR-501

Spraygun Lubricant - order GL-1-K10

ITW Finishing Systems and Products

Ringwood Road,

Bournemouth,

BH11 9LH,

Angleterre

Tél. : +44 (0)1202 571111

Fax : +44 (0)1202 581940

Site web : http://www.itweuropeanfinishing.com

ITW Finishing Systems and Products is a Division of ITW Ltd. Reg. Office:

Admiral House,

St Leonard’s Road,

Windsor,

Berkshire,

SL4 3BL,

UK

Registered in England: No 559693 Vat No 619 5461 24

ITW Automotive Finishing UK

Anchorbrook Industrial Estate

Lockside

Aldridge,

Walsall,

Royaume-Uni

Tél. : +44 (0)1922 423700

Fax : +44 (0)1922 423705

Site web :

http://www.itweuropeanfinishing.com

12 © 2003 ITW Finishing Systems and Products

Loading...

Loading...