DeVilbiss Cobra 2 Operation Manual

EN

SB-E-2-CBA2

Operation Manual

Cobra 2 – Automatic Spray Gun

ISS.09

1

Operation Manual

Cobra 2 Automatic Spraygun

Important

Read and follow all instructions and Safety Precautions before using this

equipment

CHARACTERISTICS

This automatic spray gun complies to ATEX regulations 94/9/EC, protection level II 2 G X, suitable to

use in Zones 1 & 2.

This Cobra 2 is a production spray gun suitable for use with automatic and semi-automatic machines

in conventional, HVLP or Trans-Tech applications.

Cobra 2 has a ¼ turn Quick detachable device, so to reduce maintenance & set up time (SMED).

To handle a wide range of coating materials the fluid passages are manufactured from high grade

stainless steel.

This spray gun is supplied with an indexed air cap. You can leave your air cap capable of free

rotation by removing the indexed plastic ring which is located by 2 pins on the air cap.

Pressure feed material supply can be re-circulating or direct.

The needle adjustment knob has 18 ratchet positions, allows fine and accurate fluid flow control.

SPECIFICATIONS & MATERIALS OF CONSTRUCTION

Thread Pressure

Fluid inlet & recirculation “P”

Air inlet (Atom+Fan) “A” “F”

Cylinder/trigger “C”

Maximum temperature in use

Spray gun weight

Gun body

Tip / Needle / Spray head/ Base plate

1/8 BSP

1/8 BSP

1/8 BSP

40° C

950 g

Aluminium hard anodized

Stainless steel 303

Max 7 Bar

Max 7 Bar

4 to 7 bar

EC Declaration of Conformity

We, ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the

manufacturer of the Spray gun model COBRA , declare, under our sole responsibility that the

equipment to which this document relates is in conformity with the following standards or other

normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the protection

requirements of Council Directive 98/37/EEC relating to Machinery Safety Directive, and;

EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and Protective Systems

intended for use in Potentially Explosive Atmospheres protection level II 2 G X.

B. Holt, General Manager 24th April 2007

ITW Finishing Systems and Products reserve the right to modify equipment specification without prior notice.

2

SAFETY WARNINGS

Fire and explosion

Solvents and coating materials can be highly flammable or combustible when sprayed.

ALWAYS refer to the coating material supplier’s instructions and COSHH sheets

before using this equipment.

Users must comply with all local and national codes of practice and insurance company

requirements governing ventilation, fire precautions, operation and house-keeping of

working areas.

This equipment, as supplied, is NOT suitable for use with Halogenated

Hydrocarbons.

Static electricity can be generated by fluid and/or air passing through hoses, by the

spraying process and by cleaning non- conductive parts with cloths. To prevent ignition

sources from static discharges, earth continuity must be maintained to the spray gun and

other metallic equipment used. It is essential to use conductive air and/or fluid hoses.

Personal Protective Equipment

Toxic vapours – When sprayed, certain materials may be poisonous, create irritation or

are otherwise harmful to health. Always read all labels, safety data sheets and follow any

recommendations for the material before spraying. If in doubt, contact your material

supplier.

The use of respiratory protective equipment is recommended at all times. The type of

equipment must be compatible with the material being sprayed.

Always wear eye protection when spraying or cleaning the spray gun.

Gloves must be worn when spraying or cleaning the equipment.

Training – Personnel should be given adequate training in the safe use of spraying equipment.

Misuse

Never aim a spray gun at any part of the body.

Never exceed the max. Recommended safe working pressure for the equipment.

The fitting of non-recommended or non-original spares may create hazards.

Before cleaning or maintenance, all pressure must be isolated and relieved from the equipment.

The product should be cleaned using a gun-washing machine. However, this equipment should

not be left inside gun-washing machines for prolonged periods of time.

Noise Levels

The A-weighted sound level of spray guns may exceed 85 dB (A) depending on the setup being used. Details of actual noise levels are available on request. It is recommended

that ear protection is worn at all times when spraying.

Operating

Spray equipment using high pressures may be subject to recoil forces. Under certain

circumstances, such forces could result in repetitive strain injury to the operator.

3

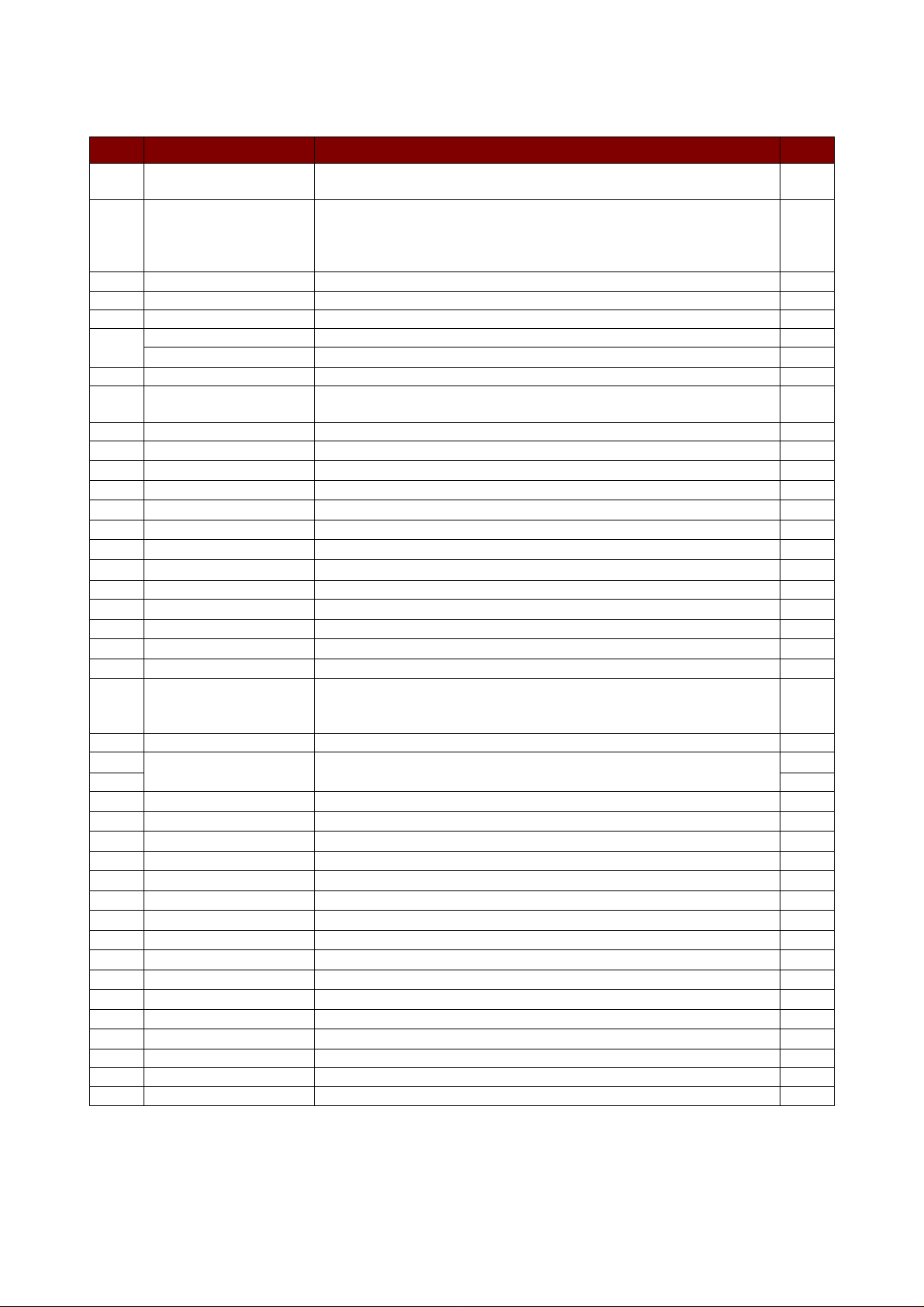

LIST OF SPARE PARTS

Rep Ref Description Qty

1 SP-100-xxx-K

SP-247S-xx-K

2

SP-200S-xx-K

SP-259S-xx-K

4 SPA-112

5 SPA-27-K5

6 S-14192-K4

SPA-50

8

SPA-50U

8a SPA-51

SPA-86-K

9

SPA-86-K10

10 SPA-29X-K4

11 SPA-53-K10

12 SPA-1-CBA2

12a SPA-52

12b S-28223X-K4

13 AGG-403

14 S-28220X-K2

15 SPA-60X-K

15b SPA-62-K2

15c S-28224X-K4

15d S-28225X-K2

16 S-28219X-K4

17 SPA-13

SPA-320-xx-K

18

SPA-320P-xx-K

SPA-320N-xx-K

19 SPA-3

20

SPA-KK-1

21

22 SPA-31

23 SPA-37

24 SPA-49

25 SPA-4

26* SPA-7-K

27 SPA-55-K

28 SPA-56-K

28a SPA-59

29* SS-659-CD

30* AGGS-33

31 S-14193

32* SPA-111-K2

33 ADV-403-K

36 JGA-156-K5

37 SPK-109

38 SPK-118

For the arrangement of the parts, refer to the exploded view on p3.5

See chart and reference above.

Air cap with retaining ring, seals.

Fluid tip with air separator seal

Ø 2,2 / 2,8 for Air cap 470

Ø 0,6 / 0,85 / 1,0 / 1,2 / 1,4 / 1,6 /1,8 / 2,2 / 2,8

Ø 0,5 / 0,7 / 1,0 for Air cap 590 & 591

Index ring (Air cap) 1

Separator Kit of 5 1

Screw M4 x 25 Kit of 4 (Torx 20) 4

Spray head 1

Spray head - recirculation 1

Quick Release Pin 1

Packing Kit of 1

Packing Kit of 10

O ring Kit of 4 4

Gasket Kit of 10 2

Gun body 1

Location Pin 1

O ring Kit of 4 1

Air valve (Fan & Atomising) 2

O Ring Kit of 2 1

Piston Assembly & seals (16,15b,15c & 15d) 1

Small Piston. 2

O ring Kit of 4 2

O Ring Kit of 2 1

O ring Kit of 4 1

Piston Spring 1

Stainless steel needle 0,5/0,7/0,85/1,0/1,2/1,4/1,6/1,8/2,2/2,8

Acetal Tipped Stainless Steel Needle 085-10 & 1,4

Hardened Needle 1,4

Housing 1

Ring and ball for ratchet

Spring 1

Collar 1

Button 1

Adjusting knob 1

Kit rear housing without adjustment (option F) 1

Base plate (no baseplate option G) 1

Quick Release Cam (28,28a & 8a) 1

Retaining screw 1

Nut 1

Mounting bar 1

M6 Set Screw 5,5 long 1

Kit of 2 plugs which replace manual air valve (13) (option P) 1

Kit of retaining ring with seals 1

Spring Clip Kit of 5 1

Manifold Seal Kit 10 (x4), 12b (x1) 1

Seal kit - 9, 11( x2), 14, 15c( x2), 15d 1

1

1

2

1

1

3

4

Loading...

Loading...