DeVilbiss CMAX-B14-M, CMAX-B10-M, CMAX-B85PM, CMAX-B10-M-507, CMAX-B14PM Service Manual

...Page 1

SERVICE MANUAL

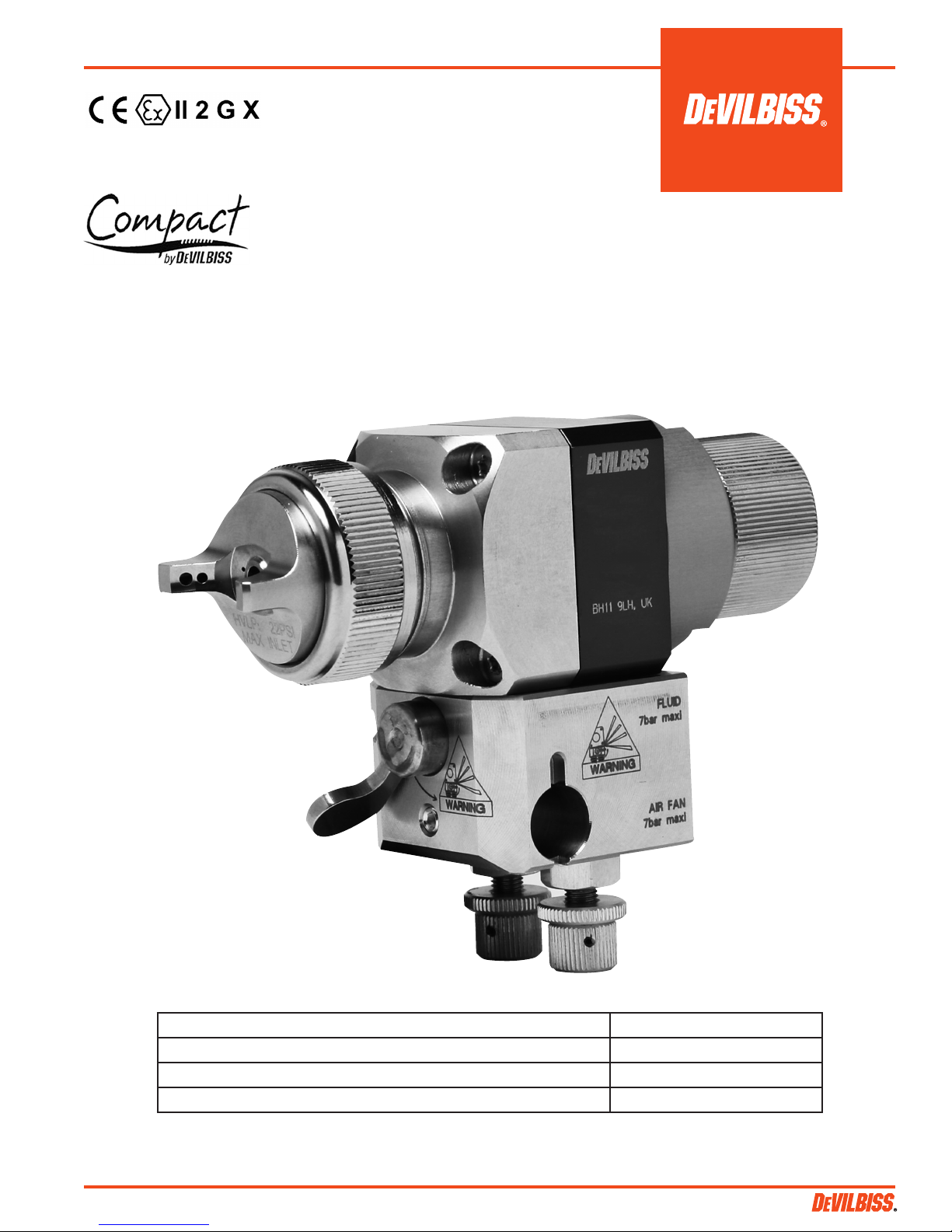

COMPACT-X — AUTOMATIC SPRAY GUN

CONVENTIONAL (SILVER), TRANS-TECH (GREEN) & HVLP (BLUE)

EN

OPERATION MANUAL

Replacement Parts Ordering Information SEE PAGE 4

Explanation of Conventional, Trans-Tech and HVLP SEE PAGE 9

Complete Spray Gun Assembly Ordering Information SEE PAGE 10

Installation Details SEE PAGES 11, 13, 14, 15

SB-2-584-H (4/2016) 1 / 16

Page 2

EN

Operation Manual

Compact-X Automatic Spraygun

Important

Read and follow all instructions and Safety Precautions before using

this equipment

CHARACTERISTICS

This automatic spray gun complies to ATEX regulations

94/9/EC, protection level II 2 G X, suitable to use in Zones

1 & 2.

This Compact-X spray gun is a production spray gun

suitable for use with automatic and semi-automatic

machines in conventional, HVLP or Trans-Tech

applications. (See page 9 for application details.)

manufactured from high grade stainless steel. Several

needles are available with plastic tips.

This spray gun can be provided with an indexed air cap

(order separately.) You can leave your air cap capable

of free rotation by removing the indexed plastic ring

which is located by 2 pins on the air cap. Pressure feed

material supply can be re-circulating or direct.

Compact-X has a ¼ turn Quick detachable manifold,

so to reduce maintenance & set up time. To handle a

wide range of coating materials the fluid passages are

The needle adjustment knob has 18 ratchet positions

(per one revolution of the knob) which allows fine and

accurate fluid flow control.

SPECIFICATIONS & MATERIALS OF CONSTRUCTION

Thread Pressure

Fluid inlet & recirculation “P” & "R"

Air inlet (Atom+Fan) “A” & “F”

Cylinder/trigger “Cyl”

Maximum temperature in use

Spray gun weight

Gun body

Tip / Needle / Spray head/ Base plate

EC Declaration of Conformity

We, Finishing Brands UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the manufacturer of

the Spray gun model COMPACT-X, declare, under our sole responsibility that the equipment to which

this document relates is in conformity with the following standards or other normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the protection requirements

of Council Directive 98/37/EEC relating to Machinery Safety Directive, and; EN 13463-1:2001, council

Directive 94/9/EC relating to Equipment and Protective Systems intended for use in Potentially

Explosive Atmospheres protection level II 2 G X.

1/8" BSPP(F) Max 7 Bars (100 psi)

1/8" BSPP(F) Max 7 Bars (100 psi)

1/8" BSPP(F) 4 to 7 Bars (60-100 psi)

40° C (104° F)

950 gms (2 lbs)

Aluminium hard anodized

Stainless steel 303

DeVilbiss reserves the right to modify equipment specification without prior notice.

D. Smith, General Manager

12th February 2014

SB-2-584-H (4/2016)2 / 16

Page 3

EN

SAFETY WARNINGS

FIRE AND EXPLOSION

Solvents and coating materials can be highly flammable or combustible when sprayed. ALWAYS refer

to the coating material supplier's instructions and MSDS sheets before using this equipment.

Users must comply with all local and national codes of practice and insurance company requirements

governing ventilation, fire precautions, operation and house-keeping of working areas.

This equipment, as supplied, is NOT suitable for use with Halogenated Hydrocarbons.

Static Electricity can be generated by fluid and/or air passing through hoses, by the spraying process

and by cleaning non- conductive parts with cloths. To prevent ignition sources from static discharges,

earth continuity must be maintained to the spraygun and other metallic equipment used. It is essential

to use conductive air and/or fluid hoses.

PERSONAL PROTECTIVE EQUIPMENT

Toxic vapors – When sprayed, certain materials may be poisonous, create irritation or be otherwise

harmful to health. Always read all labels, safety data sheets and follow any recommendations for the

material before spraying. If In doubt, contact your material supplier.

The use of respiratory protective equipment is recommended at all times. The type of equipment must

be compatible with the material being sprayed.

Always wear eye protection when spraying or cleaning the spray gun

Gloves must be worn when spraying or cleaning the equipment.

TRAINING

Personnel should be given adequate training in the safe use of spraying equipment.

MISUSE

Never aim a spray gun at any part of the body.

Never exceed the max. recommended safe working pressure for the equipment.

The fitting of non-recommended or non-original spares may create hazards.

Before cleaning or maintenance, all pressure must be isolated and relieved from the equipment.

The product's metal parts can be cleaned using a gun-washing machine. However, this equipment

should not be left inside gun-washing machines for prolonged periods of time. Certain selas and

o-rings may not be solvent compatible.

NOISE LEVELS

The A-weighted sound level of spray guns may exceed 85 dB (A) depending on the set-up being used.

Details of actual noise levels are available on request. It is recommended that ear protection is worn at

all times when spraying.

OPERATING

Spray Equipment using high pressures may be subject to recoil forces. Under certain circumstances,

such forces could result in repetitive strain injury to the operator.

SB-2-584-H (4/2016) 3 / 16

Page 4

EN

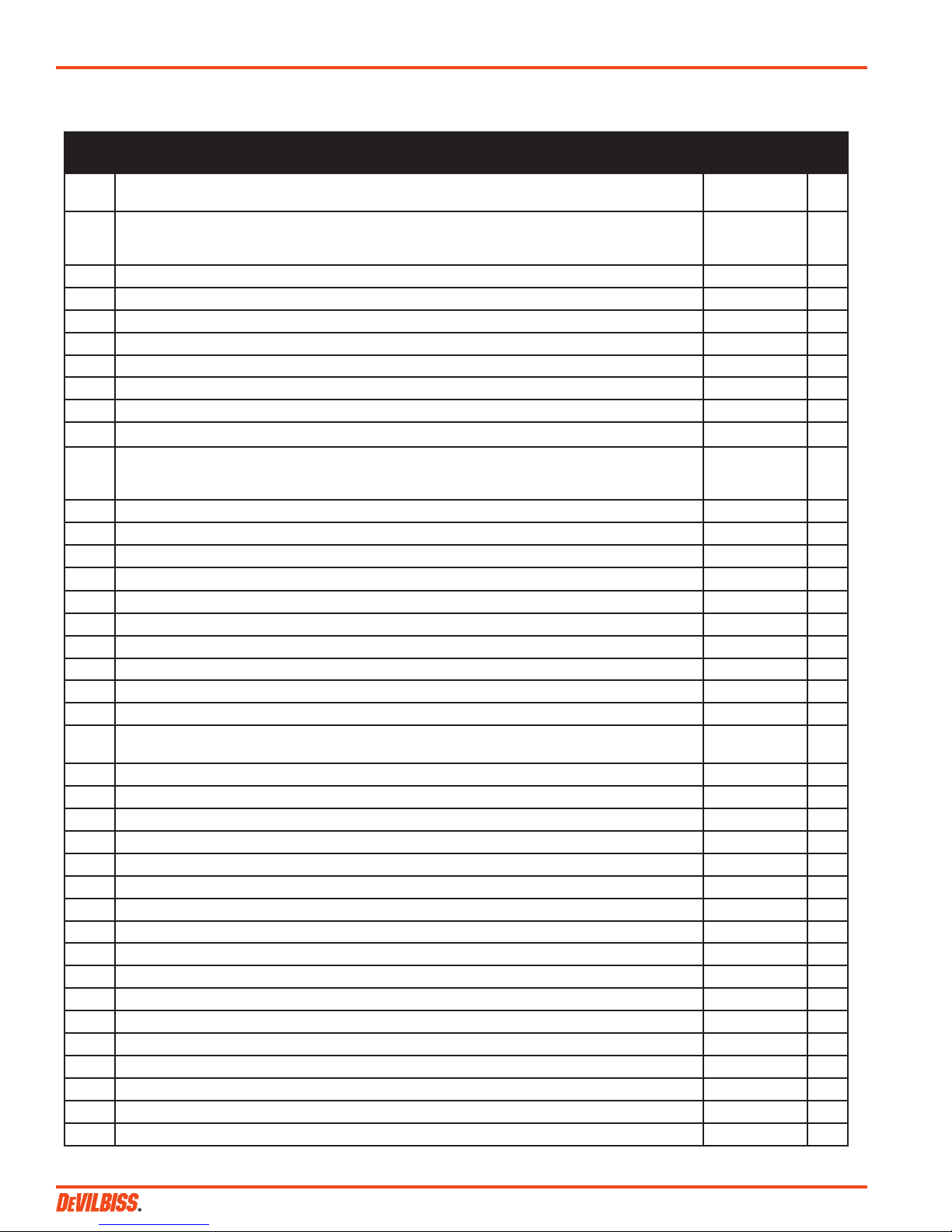

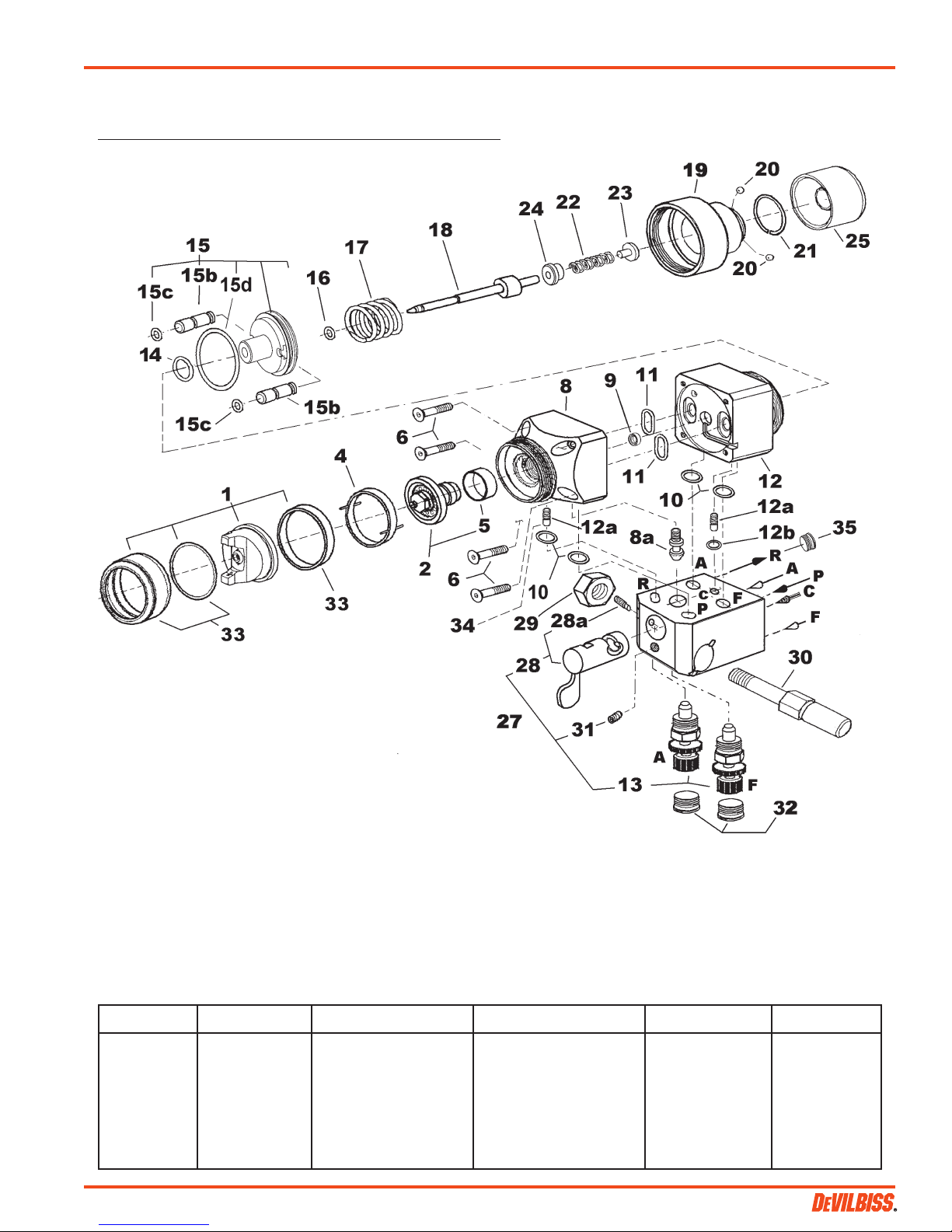

PARTS LIST

For the arrangement of the parts, refer to the exploded view on page 5.

Item Description

See chart and reference on page 6.

1

Air cap with retaining ring, seals and no indexing ring.

Fluid tip with air separator seal SPA-27-K5

2

Ø 0.85 / 1.0 / 1.4 / 1.8 / 2.2 mm

Ø 0.5 for Air cap 590 Ø 0.7 mm for Air cap 591

4 Locator ring for indexed air cap (optional item) SPA-112 1

5 Air separator seal (kit of 5 rings) SPA-27-K5* 1

6 Screw M4 x 25 kit of 4 (Torx 20) — (kit includes items 6, 8a, 12a) SPK-108* 4

8 Spray head – Compact-X SPA-50P 1

8a Fixing rod on base plate (kit includes items 6, 8a, 12a) SPK-108* 1

9 Packing seal for needle (kit includes items 9, 11) SPK-107* 1

10 O-ring (kit includes items 10, 12b) SPK-109* 4

11

O-ring gasket (kit includes items 9, 11n)

12 Gun body for Compact-X ( -S = Silver / -G = Green / -B = Blue )

12a Locating air tube (kit includes items 6, 8a, 12a) SPK-108* 1

12b O-ring (kit includes items 10, 12b) SPK-109* 1

13 Air valve (Fan & Atomising air) AGG-403 2

14 O-ring (kit includes items 14, 15c, 15d, 16) SPK-104* 1

15 Piston assembly (includes items 14, 15b, 15c, 15d, 16) SPA-60X-K 1

15b Piston for air valve (kit includes qty. 2) SPA-60X-K 1

15c O-ring for small piston (kit includes items 14, 15c, 15d, 16) SPK-104* 2

15d O-ring for large piston (kit includes items 14, 15c, 15d, 16) SPK-104* 1

16 O-ring piston to needle (kit includes items 14, 15c, 15d, 16) SPK-104* 1

17 Piston Spring (kit includes items 17, 22, 23, 24) SPK-105* 1

Stainless steel needle 0.5 / 0.7 / 0.85 / 1.0 / 1.4 / 1.8 / 2.2

18

Plastic tip 1.0 / 1.4

19 Housing SPA-3 1

20 Ring and ball (2) — (kit includes items 20, 21, 25) SPK-106* 1

21 Ring (kit includes items 20, 21, 25) SPK-106* 1

22 Needle Spring (kit includes items 22, 23, 24) SPK-105* 1

23 Spring cap (kit includes items 22, 23, 24) SPK-105* 1

24 Spring washer (kit includes items 22, 23, 24) SPK-105* 1

25 Adjusting knob (kit includes items 20, 21, 25) SPK-106* 1

27 Manifold assembly – complete with lever and air valves SPA-55-K 1

28 Locking lever (kit includes items 28, 28a & 8a) SPA-56-K* 1

28a Retaining screw of locking device (kit includes items 28, 28a & 8a) SPA-56-K* 1

29 Gun mounting bar nut (kit includes items 29, 30 & 31) SPK-110* 1

30 Gun mounting bar (kit includes items 29, 30 & 31) SPK-110* 1

31 M6 hexagon socket head cap screw, length 5.5 (kit includes items 29, 30 & 31) SPK-110* 2

32 Kit of 2 plugs which replace manual air valve (13) — for remote fan/atom SPA-111-K2* 1

33 Kit of retaining ring with gasket (kit includes air cap ring and gaskets) SPK-102-K* 1

34 Recirculation Port Plug (kit includes hex wrench SPA-30) SPK-116* 1

35 Manifold Plug, 1/8" BSPP (not sold as a spare part) REF. 1

* Spare parts must be ordered as part of replacement kits listed above.

See page 10 for additional adapter and fitting kits.

Item 9: Fluid packings only (10 pack) SPA-86-K10.

Optional: Fluid packings (2 pack) SPA-20-K2

n Item 11: Air gaskets only (10 pack) SPA-53-K10.

Order

Part Number

SP-100-xxx-K 1

SP-200S-xx-K

SP-259S-xx-K

SPK-107* 2

SPA-1-CMAX-S

SPA-1-CMAX-G

SPA-1-CMAX-B

SPA-320-xx

SPA-320P-xx

Qty

1

1

1

SB-2-584-H (4/2016)4 / 16

Page 5

COMPACT-X AUTOMATIC SPRAY GUN

REF. ONLY:

• SPA-60X-K (includes items 14, 15b, 15c, 15d, 16)

• SPK-104 (includes items 15c–qty.10, 15d–qty.5, 16–qty.10, 14–qty.5)

• SPK-105 (includes items 17, 22, 23, 24)

• SPK-107 (includes items 9, 11)

EN

NOTE: SPN-8 Torx Wrench for item 6 shipped with gun.

SPA-30 Hex Wrench for item 34 shipped with gun.

SPN-8 and SPN-30 not shown on exploded view above.

COMPACT-X AUTOMATIC GUN

EXAMPLE OF PART NUMBERING SYSTEM

CMAX–B85PM–507

CMAX– B 85 P M 507

Compact-X

Automatic

Manifold Type

Spray Gun

SB-2-584-H (4/2016) 5 / 16

B = Blue (HVLP)

G = Green

(Trans-Tech)

No Letter =

Conventional

85 = .85 mm Fluid Nozzle

00 = No Fluid Nozzle,

and Needle

No Needle

See page 10 for standard set-ups.

See page 11 for hook-up schematic.

P = Plastic Needle

– or no letter = Stainless

Steel

Needle

M = With Manifold

O = No Manifold

507 = Air Cap

Page 6

EN

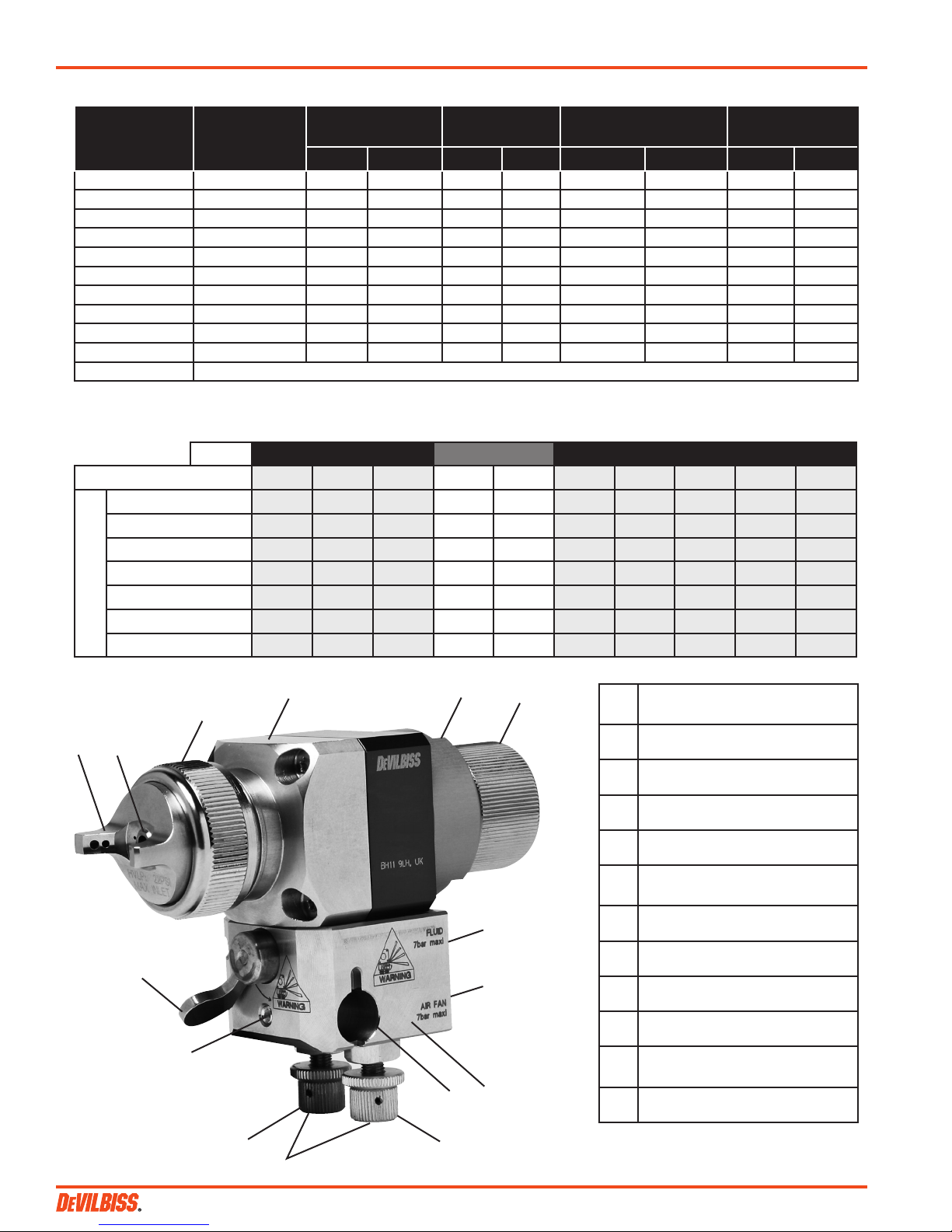

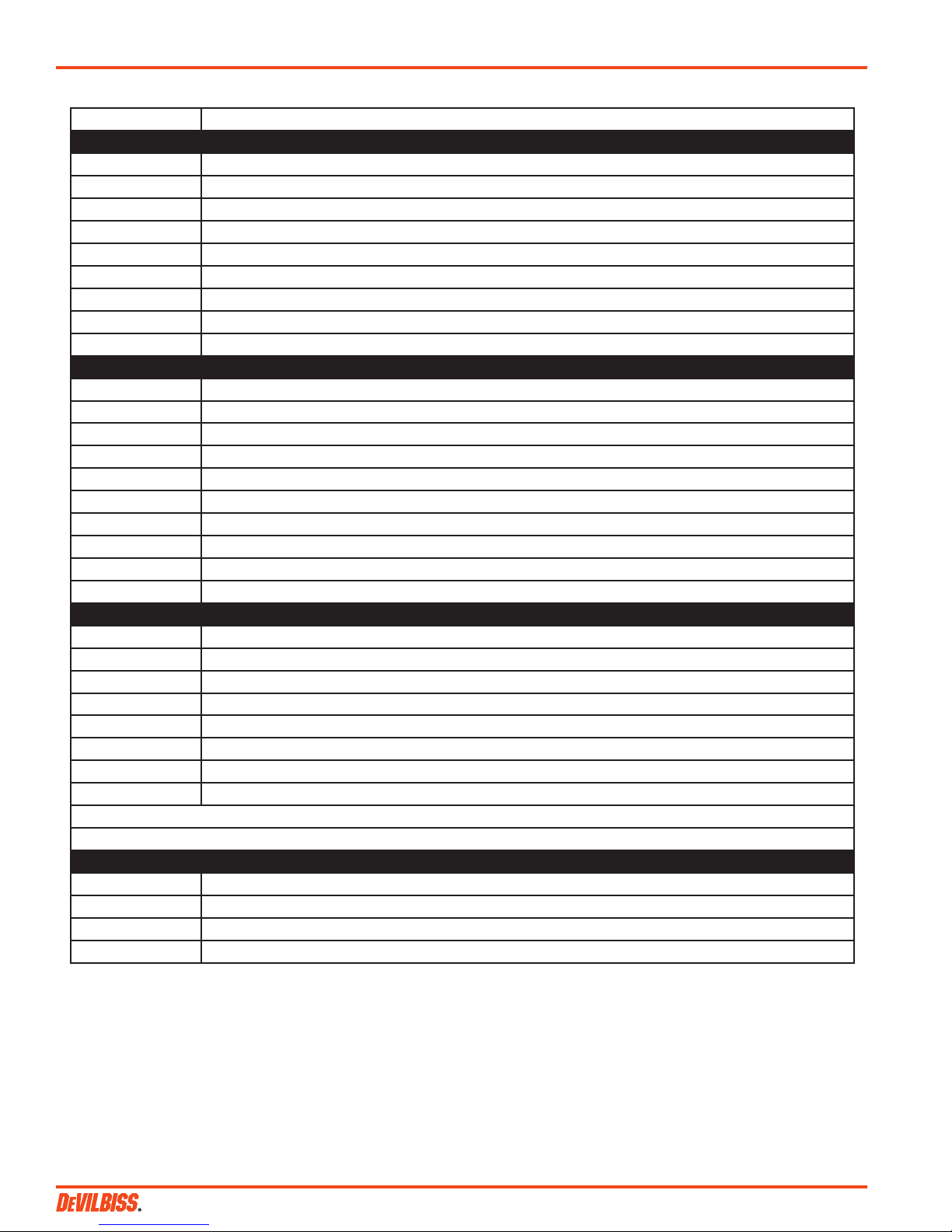

COMPACT-X AUTOMATIC GUN — AVAILABLE AIR CAPS

Air cap Type

SP-100-430-K Conventional 12 340 50.7 3.5 6.7 - 9.5 200 - 280 7.9 200

SP-100-443-K Conventional 12.2 345 43.5 3.0 6.7 - 10.1 200 - 300 11.8 300

SP-100-497-K Conventional 18 510 50.7 3.5 6.7 - 20.2 200 - 600 15.0 380

SP-100-500R-K

SP-100-507-K H V L P 19 385 40 1.4 4.4 - 6.5 130 – 190 10.6 270

SP-100-510-K Trans-Tech 10 283 29 2.0 5.4 - 7.5 160 - 220 10.6 270

SP-100-513-K Trans-Tech 18.8 531 43.5 3.0 6.7 - 20.2 200 - 600 13.8 350

SP-100-522-K Trans-Tech 14.5 410 29 2.0 6.7 - 20.2 200 - 600 13.8 350

SP-100-590-K Trans-Tech 7.7 218 29 2.0 1.6 - 5.0 50 -150 6.0 150

SP-100-591-K Trans-Tech 12.3 350 29 2.0 1.7 - 5.1 50 -150 4.5 115

KK-5090-507 HVLP Test Kit – includes cap, gauge & tube

Other test kits available: KK-5090-430, KK-5090-443, KK-5090-497, KK-5090-506, KK-5090-510, KK-5090-513, KK-5090-522, KK-5009-590

COMPACT-X AUTOMATIC GUN — AIR CAP / FLUID TIP COMBINATIONS

AIR CAP MODEL NO. 430 443 497 500R 507 510 513 522 590 591

.020" (0.5 mm) X X

.028" (0.7 mm) X

.033" (0.85 mm) X X X X X X

.039" (1.0 mm) X X X X X X X X

.055" (1.4 mm) X X X X X X X X

.070" (1.8 mm) X X X X X X X X

FLUID TIP SIZES

.086" (2.2 mm) X X X X X

HVLP Round Spray

TYPE

CONVENTIONAL HVLP TRANS-TECH

Air Flow

SCFM l/min psi bar oz/min ml/min in mm

6.8 200 16.0 1.1 .6 - 5.0 20-150 1.6 40

Pressure

at Inlet

Fluid Flow

Pattern size

@ 8" distance

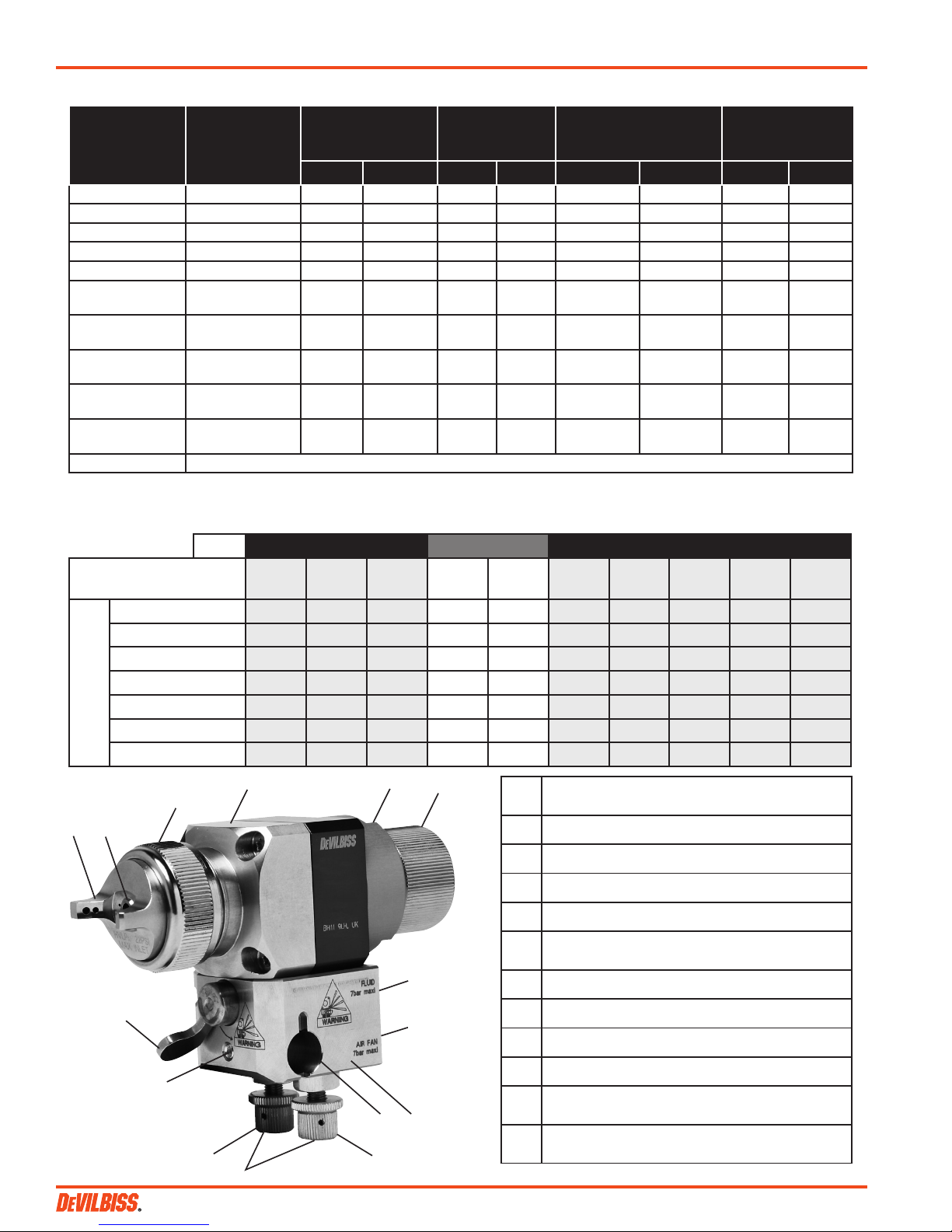

B

C

D

G

I

J

ATOM FAN

E

F

FLUID INLET

P/R

AIR INLET

ATOM,

CYL FAN

H

K

A

Needle travel adjusting knob –

A

18 positions per 1 turn

B Gun head – stainless steel

C Air cap ring

D Air cap

E Air valve (fan / atom)

Spray gun body – anodized

F

aluminum

G Fluid tip – stainless steel

H Manifold – stainless steel

I Manifold locking lever

J Support tightening screw

Spray gun mounting hole –

K

1/2" diameter

P/R Fluid inlet, fluid return

SB-2-584-H (4/2016)6 / 16

Page 7

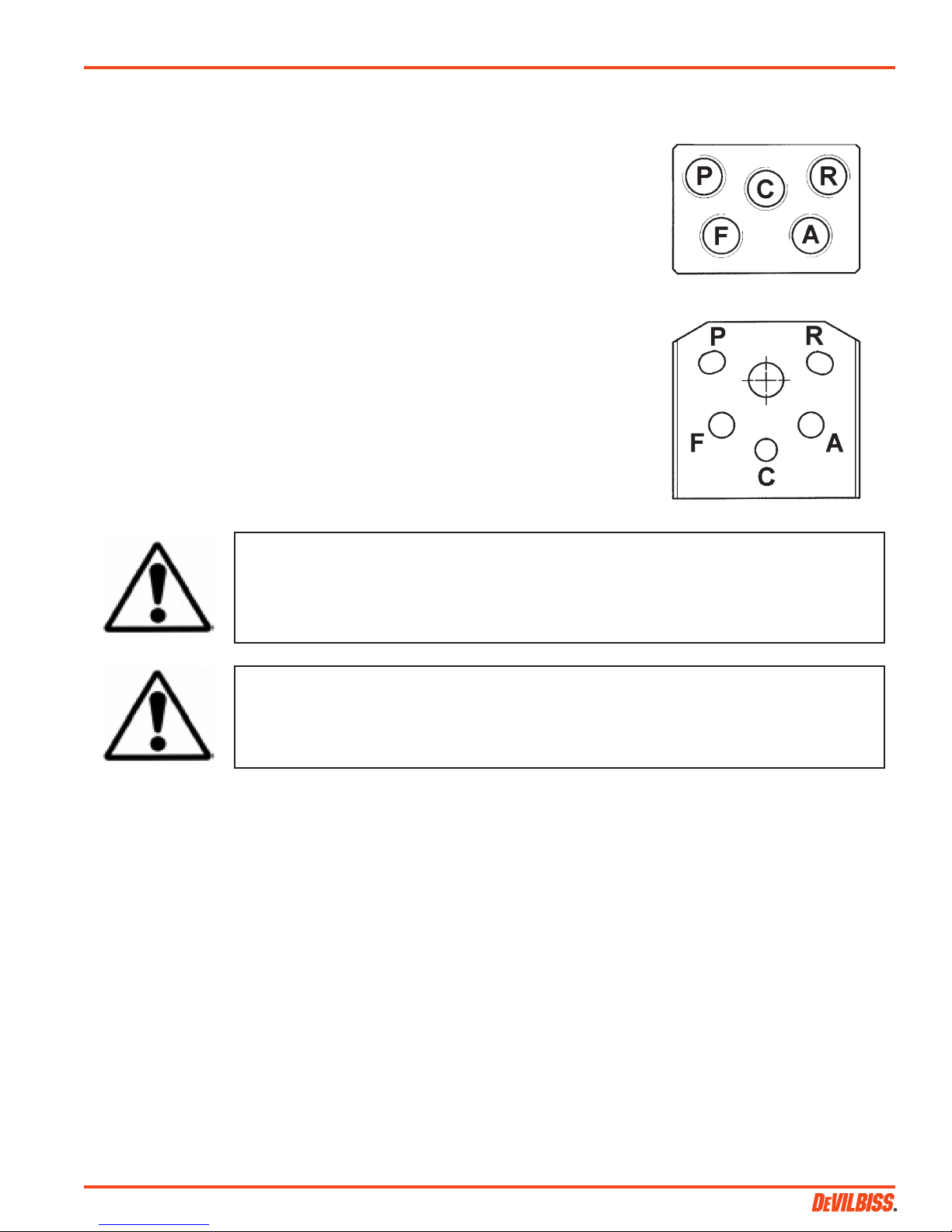

INSTALLATION

EN

AIR AND FLUID HOSES

See pages 11, 13, 14 and 15 for installation details.

Use separate filtered regulated air supplies for atomizing and cylinder

air. Connect all the air and fluid hoses at the back of the manifold (1/8”

BSP): (See figure)

• Cylinder air ‘C = Cyl’ via a control valve. For fast cylinder operation

the control valve should be fitted as close to the gun as possible or

an additional quick exhaust valve installed in the line.

• Separated atomizing and fan “F” & “A” air supply.

• Material hose ‘P’. If material re-circulation is required, remove the

plug from port ‘R’ (35) and plug from spray head (34).

Recommended hose size up to 34 ft. (10 m) long:

Atomization Air = 0.315 in. (8 mm)

Cylinder Air = 0.236 in. (6 mm)

Material = 0.315 in. (8 mm)

Important: The Spray gun must be grounded to dissipate any electrostatic charges

which may be created by fluid or air flows. This can be achieved through the Spray

gun mounting, or conductive air/fluid hoses. Electrical bond from the spray gun to

earth should be checked with an ohmmeter. A resistance of less than 106 Ohms is

recommended.

BACK Face of Manifold

TOP Face of Manifold

Important: To ensure that this equipment reaches you in first class condition,

protective coatings have been used. Flush the equipment through with appropriate

solvent before use. Fix the spray gun base plate using mounting stem ref.30 and

secure it with nut ref.29.

SETTING

Check that the gun has all of the O-rings installed

on the sealing surface and check that the locking

device (28) is in the correct position to lock the

spray gun on to the connecting plate.

1. The ATOM ‘A’ air valve controls the atomizing air

pressure.

2. The FAN ‘F’ valve controls the spray pattern size.

3. Fluid flow is adjusted with the rear ratchet knob

(25).

For the arrangement of the parts, refer to the

exploded view on page 5.

START UP

1. Turn the needle adjusting knob (25) clockwise

until the needle is fully closed.

2. Turn the FAN ‘F’ and ATOM ‘A’ air valves (13)

counter-clockwise to be full open.

3. Use the air cap chart to set the air pressure at the

air regulator to achieve recommended pressures.

4. Turn the adjusting knob (25) counter clockwise to

obtain the desired fluid flow.

5. Test spray. If the finish is too dry or fine, reduce

the airflow by reducing the air inlet pressure or

by screwing the valve ATOM ‘A’ (13) in clockwise,

or increase the fluid flow using ratchet knob,

rotating counter clockwise.

SB-2-584-H (4/2016) 7 / 16

Page 8

EN

INSTALLATION (CONTINUED)

START UP (continued)

6. If the finish is too wet, turn the ratchet knob (25)

in clockwise to reduce the fluid flow, or reduce

the fluid pressure. If the atomization is too

coarse, increase inlet air pressure, or reduce fluid

flow.

7. The pattern size can be reduced by turning

adjusting valve FAN ‘F’ (13) clockwise.

8. The spray pattern will give the best results when

perpendicular to the target.

MAINTENANCE

PREVENTIVE MAINTENANCE

Turn off air and coating supply and

relieve pressure in the supply lines, or

disconnect from airline and fluid line.

1. Unlock the spray gun from the base plate, remove

it, and if available re-attach an alternative gun.

Now the spray gun maintenance can be done

outside the spray booth while production is still

continuing.

9. The recommended spray distance is 6’’ to 8’’

(150-220 mm).

10. Spray edges first. Overlap each stroke a

minimum of 50%. Move gun at a constant

speed.

11. Always turn off air and fluid supply and relieve

pressure and clean down when gun is not in

use.

Remove the tip (2) and its air separator ring (3) by

unscrewing counter- clockwise with 10mm

hexagonal spanner.

Unscrew the adjusting needle knob (25) fully in

counter-clockwise rotation, push the needle from

the front of the spay gun, carefully so to avoid

damage the needle end, then pull out the needle

(18) from the back.

If necessary, replace the needle and the tip, first

refitting the tip with its air separator ring

(recommended torque between 9,5 to 12 Nm).

2. Remove air cap (1) and clean. If any of the holes

in the cap are blocked with coating material use

a toothpick to clean. Never use metal wire which

could damage the cap and produce distorted

spray patterns

3. Ensure the nozzle of the fluid tip (2) is clean and

free from damage. Any build up of dried paint

can distort the spray pattern.

REPLACEMENT OF PARTS

Turn off air and coating supply and

relieve pressure in the supply lines,

before any maintenance operation.

TIP (2) & NEEDLE (18)

Remove the air cap (1) by unscrewing its retaining

ring counter- clockwise, remove the index ring if it

remains on the gun head (if fitted and used).

Lubricate all the surface of the needle which will be

in contact with the packing and o ring. Slide the

needle into the spray gun from the back. Fit the

needle springs with its plastic pad (22,23,24) and

replace the needle adjusting knob (25).

PACKING SEAL (9)

Unscrew the air cap (1), tip (2) and its air separator

ring (3).

Unscrew the 4 screws (6) to disassemble the gun

head (8). Push back the packing seal (9) using a

5,5mm diameter rod from the front of the gun head.

Clean the packing location hole carefully with

adequate solvent.

Fit a new packing seal (9) U face towards the fluid

passage.

SB-2-584-H (4/2016)8 / 16

Page 9

REPLACEMENT OF PARTS (CONTINUED)

EN

FAN & ATOM AIR VALVE (13)

Before assembling, check the air valve

is in fully open position by unscrewing

it counter-clockwise.

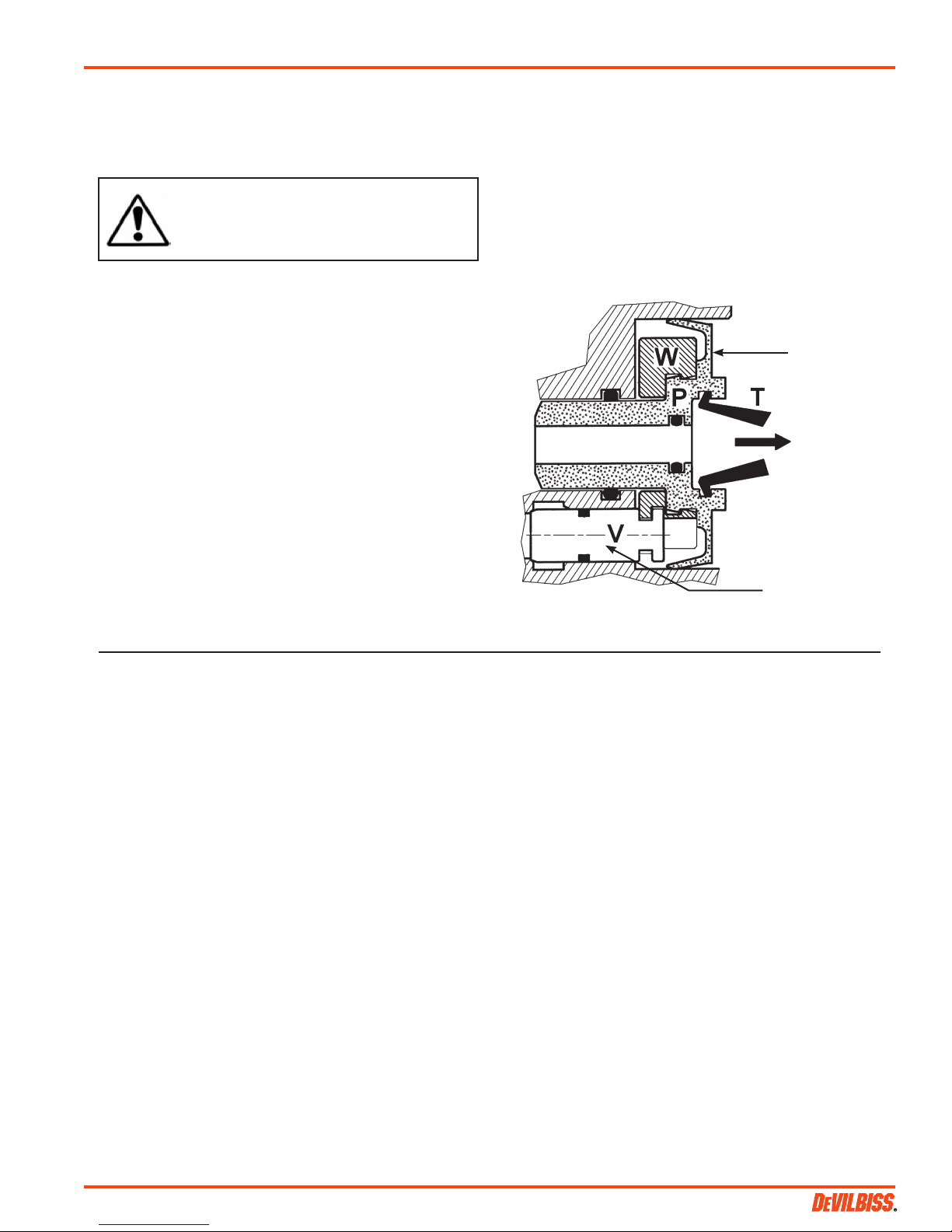

PISTON (15), O RING (16, 14 & 15C)

Unscrew the rear housing (19) at the back of the

gun body counter clockwise, pull out the needle

(18).

Use bent nose pliers “T” so to pull out the piston

which has a 12mm internal groove for this purpose.

Piston “P+W” and two valve “V” will pull out at

the same time. The ring “W” is located by pressing

it onto the piston body and can not be removed

from it.

The valve “V” can be removed easily from the

piston ring. We recommend to replace the full

piston at the same time (Item number SPA-60x-K).

It’s recommended to replace all the O-rings (14, 16

& 15c) in the gun body as soon you disassemble the

Piston from the gun.

Slightly lubricate the piston lip before fitting again

into the gun body. Use petroleum jelly to lubricate

the piston parts and o-rings.

Piston

Assembly

(ref.)

Air Valve (ref.)

DEVILBISS SPRAY GUN TECHNOLOGY—APPLICATION DETAILS

HVLP (BLUE)

Maintains Regulatory

Compliance

The DeVilbiss "Blue" Compact

gun allows you to maintain EPA

compliance and produce a

superb finish.

Built to provide outstanding

coating atomization, the "Blue"

Compact can handle all types of

solvent and waterborne

materials.

High performance is coupled

with a gun body light in weight

and designed for operator

comfort to increase productivity.

TRANS-TECH (GREEN)

Maximum Efficiency with

Environmental Responsibility

The DeVilbiss "Green" Compact

gun utilizes the very latest

advances in computational fluid

dynamics. This results in

superior atomization with the

new DeVilbiss TRANSFERTECHNOLOGY.

Exceptionally efficient material

transfer for optimum coverage

and paint usage is achieved with

reduced air consumption,

lowering your electrical needs

and energy costs.

Exceed your production

requirements with the highest

atomization levels at an

accelerated application rate of up

to 600cc/min.

CONVENTIONAL (SILVER)

Outperforms the Competition

The DeVilbiss "Silver" Compact

is our Advanced Conventional

gun and has a unique high

capacity airflow with outstanding

atomization to produce a superior

result.

Compact's Advanced Conventional Air Caps make this gun the

ideal performer in both small

operations or high volume

facilities, with the added bonus

of instantly improved finishing

productivity.

SB-2-584-H (4/2016) 9 / 16

Page 10

EN

STANDARD SET-UPS AVAILABLE FOR COMPACT-X AUTOMATIC SPRAY GUN

PART NUMBER DESCRIPTION

HVLP GUNS

CMAX-B85-M COMPACT AUTO-X HVLP .85 MM W/ MANIFOLD NO CAP

CMAX-B10-M COMPACT AUTO-X HVLP 1.0 MM W/ MANIFOLD, NO AIR CAP

CMAX-B14-M COMPACT AUTO-X HVLP 1.4 MM W/ MANIFOLD, NO AIR CAP

CMAX-B18-M COMPACT AUTO-X HVLP 1.8 MM W/ MANIFOLD, NO AIR CAP

CMAX-B85PM COMPACT AUTO-X HVLP .85 MM PLASTIC NEEDLE W/ MANIFOLD, NO AIR CAP

CMAX-B14PM COMPACT AUTO-X HVLP 1.4 MM PLASTIC NEEDLE W/ MANIFOLD, NO AIR CAP

CMAX-B10-M-507 COMPACT AUTO-X HVLP 1.0 MM WITH MANIFOLD, 507 AIR CAP INCLUDED

CMAX-B14-M-507 COMPACT AUTO-X HVLP 1.4 MM WITH MANIFOLD, 507 AIR CAP INCLUDED

CMAX-B00-0 COMPACT AUTO-X HVLP NO MANIFOLD , LESS-- NOZZLE, NEEDLE, CAP

TRANS-TECH GUNS

CMAX-G05-M-590 COMPACT AUTO-X TRANS .5 MM W/ MANIFOLD, 590 AIR CAP INCLUDED

CMAX-G85-M COMPACT AUTO-X TRANS .85 MM W/ MANIFOLD, NO AIR CAP

CMAX-G10-M COMPACT AUTO-X TRANS 1.0 MM W/ MANIFOLD, NO AIR CAP

CMAX-G-14-M COMPACT AUTO-X TRANS 1.4 MM W/ MANIFOLD, NO AIR CAP

CMAX-G18-M COMPACT AUTO-X TRANS 1.8 MM W/ MANIFOLD, NO AIR CAP

CMAX-G85PM COMPACT AUTO-X TRANS .85 MM PLASTIC NEEDLE W/ MANIFOLD, NO AIR CAP

CMAX-G14PM COMPACT AUTO-X TRANS 1.4 MM PLASTIC NEEDLE W/ MANIFOLD, NO AIR CAP

CMAX-G10-M-513 COMPACT AUTO-X TRANS 1.0 MM W/ MANIFOLD, 513 AIR CAP INCLUDED

CMAX-G-14-M-513 COMPACT AUTO-X TRANS 1.4 MM W/ MANIFOLD, 513 AIR CAP INCLUDED

CMAX-G00-0 COMPACT AUTO-X TRANS NO MANIFOLD, LESS-- NOZZLE, NEEDLE, CAP

CONVENTIONAL GUNS

CMAX-10-M COMPACT AUTO-X CONV. 1.0 MM W/ MANIFOLD, NO AIR CAP

CMAX-14-M COMPACT AUTO-X CONV. 1.4 MM W/ MANIFOLD, NO AIR CAP

CMAX-18-M COMPACT AUTO-X CONV. 1.8 MM W/ MANIFOLD, NO AIR CAP

CMAX-22-M COMPACT AUTO-X CONV. 2.2 MM W/MANIFOLD, NO AIR CAP

CMAX-10-M-497 COMPACT AUTO-X CONV. 1.0 MM W/ MANIFOLD, 497 AIR CAP INCLUDED

CMAX-14-M-497 COMPACT AUTO-X CONV. 1.4 MM W/ MANIFOLD, 497 AIR CAP INCLUDED

CMAX-14PM COMPACT AUTO-X CONV. 1.4 MM PLASTIC NEEDLE W/ MANIFOLD, NO AIR CAP

CMAX-00-0 COMPACT AUTO-X CONV. NO MANIFOLD, LESS-- NOZZLE, NEEDLE, CAP

NOTE: Air caps can be ordered separately. Refer to page 8 for air cap ordering information.

COMPACT AUTOMATIC - X GUN MOUNTING ADAPTERS AND HOSE FITTING KITS:

SPK-111 CEFLA MACHINES - MOUNTING ADAPTER KIT (PAGE 14)

6-531 CEFLA MACHINES - FITTING KIT FOR AIR AND FLUID (PAGE 14)

6-534 SUPERFICII MACHINES - FITTINGS FOR AIR AND FLUID (PAGE 13)

6-533 FLUID/AIR FITTING KIT FOR NPS CONNECTIONS (PAGE 15)

SB-2-584-H (4/2016)10 / 16

Page 11

COMPACT-X AUTOMATIC GUN — TYPICAL AIR & FLUID DIAGRAMS

COMBINED FAN & ATOMIZING AIR

(STANDARD GUN HOOK-UP)

FLUID RETURN (IF USED)

CYLINDER AIR SUPPLY

(COMBINED)

FAN & ATOMIZING AIR SUPPLY

EN

BACK PRESSURE

VALVE

CYLINDER AIR

VALVE (3 WAY)

AIR REGULATOR

(FAN & ATOMIZING

AIR COMBINED)

REAR

VIEW

REAR

VIEW

ATOMIZING ADJUSTMENT VALVE

FAN ADJUSTMENT VALVE

SEPARATE FAN & ATOMIZING AIR

(OPTIONAL GUN HOOK-UP)

ATOMIZING ADJUSTMENT VALVE

FAN ADJUSTMENT VALVE

FLUID SUPPLY

FLUID RETURN (IF USED)

CYLINDER AIR SUPPLY

ATOMIZING AIR SUPPLY

FLUID

REGULATOR

BACK PRESSURE

VALVE

CYLINDER AIR VALVE

(3 WAY)

ATOMIZING AIR

REGULATOR

ATOMIZING ADJUSTMENT VALVE

FAN ADJUSTMENT VALVE

SB-2-584-H (4/2016) 11 / 16

FAN AIR SUPPLY

FAN AIR

REGULATOR

FLUID SUPPLY

FLUID

REGULATOR

Page 12

EN

INSTALLATION DIMENSIONS for COMPACT AUTOMATIC "X" GUN

For mounting to machine plate/bracket

(MULTIPLY BY .03937 TO OBTAIN INCHES)

BSPP = BRITISH STRAIGHT PIPE PARALLEL

DIMENSIONS IN MM

SB-2-584-H (4/2016)12 / 16

Page 13

6-534 SUPERFICI MACHINE FITTING KIT for COMPACT AUTOMATIC "X" GUN

EN

8 MM O.D. TUBE (2) FLUID

CONNECTION

6 MM O.D. TUBE CONNECTION

FOR CYLINDER AIR

8 MM O.D. TUBE 2" LONG QTY. 4

(FOR ATOM / FAN / FLUID)

SUPPLIED BY CUSTOMER

1/4" BSPP (M)

CONNECTION (2)

FOR FLUID SUPPLY

AND RETURN

REF. 8 MM SCREW THREAD FOR

MOUNTING TO PLATE

ATTACHMENT OF THE MACHINE

REF. SPA-111-K2 PLUG (M12-1.0)

VALVES (PURCHASE SEPARATE)

REMOVED FROM THE EDGE OF

NOTE: USE 1/8" BSPP PLUG (1) FOR FLUID RETURN PORT

WHEN CIRCULATING IS NOT REQUIRED.

(PLUG SUPPLIED WITH THIS KIT)

NOTE: ALL MANIFOLD AIR AND FLUID PORTS ARE 1/8" BSPP (m)

8 MM O.D. TUBING

CONNECTION (2) ATOM / FAN

KIT TO REPLACE MANUAL

FOR MOUNTING THE SPRAY

GUN USING THE 8 MM

THREADED HOLE, SOME

MATERIAL MAY NEED TO BE

THE SPA-111 PLUGS, AS

SHOWN.

8 MM O.D. TUBE "Y"

CONNECTION FOR COMBINED

ATOM / FAN CONNECTION

SB-2-584-H (4/2016) 13 / 16

BSPP = BRITISH STRAIGHT PIPE PARALLEL

Page 14

EN

6-531 CEFLA MACHINE FITTING KIT for COMPACT AUTOMATIC "X" GUN

6 MM O.D. TUBE CONNECTION

FOR CYLINDER AIR (CEFLA)

OR

4 MM O.D. TUBE CONNECTION

FOR CYLINDER AIR (FALCONI)

8 MM O.D.

TUBE

CONNECTION (2)

FLUID

8 MM O.D. TUBE 2" LONG QTY. 4

FOR ATOM / FAN / FLUID

(PURCHASE SEPARATELY)

1/4" BSPP (M)

CONNECTION (2)

FOR FLUID SUPPLY

AND RETURN

REF: SPK-111 CEFLA MACHINE MOUNTING ADAPTER

NOTE: ALL MANIFOLD AIR AND FLUID PORTS ARE 1/8" BSPP (m)

8 MM TUBE O.D. (2)

ATOM / FAN

(PURCHASE SEPARATELY)

BSPP = BRITISH STRAIGHT PIPE PARALLEL

8 MM O.D.

TUBE CONNECTOR (1)

FOR COMBINED

ATOM / FAN

CONNECTION

SB-2-584-H (4/2016)14 / 16

Page 15

6-533 FITTING KIT WITH 1/4" NPS (m) for COMPACT AUTOMATIC "X" GUN

6 MM O.D. TUBE CONNECTION

FOR CYLINDER AIR

EN

1/4" NPS (M)

CONNECTION (2)

FOR FLUID SUPPLY

AND RETURN

NOTE: ALL MANIFOLD AIR AND FLUID PORTS ARE 1/8" BSPP (m)

SB-2-584-H (4/2016) 15 / 16

1/4" NPS (M) CONNECTION

(1) FOR ATOMIZING AIR

(1) FOR FAN AIR

BSPP = BRITISH STRAIGHT PIPE PARALLEL

Page 16

EN

SB-2-584-H (4/2016)16 / 16

Page 17

MANUAL DE SERVICIO

MANUAL DE OPERACIONES

PISTOLA PULVERIZADORA AUTOMÁTICA COMPACT-X

CONVENCIONAL (PLATEADA), TEC-TRANS (VERDE) Y HVIP (AZUL)

ES

Información para pedir piezas de reemplazo VER PÁGINA 4

Explicación de Convencional, Tec-Trans y HVLP VER PÁGINA 9

Información completa para pedir el conjunto de la pistola pulverizadora VER PÁGINA 10

Detalles de la instalación VER PÁGINAS 11, 13, 14, 15

SB-2-584-H (4/2016) ES-1 / 16

Page 18

ES

Manual de Operaciones

Pistola pulverizadora automática Compact-X

Importante

Lea y siga todas las instrucciones y precauciones

de seguridad antes de usar este equipo

CARACTERÍSTICAS

Esta pistola pulverizadora automática cumple con las

regulaciones 94/9/CE de ATEX, nivel de protección II 2 G X,

adecuada para uso en Zonas 1 y 2.

Esta pistola modelo Compact-X es una pistola pulverizadora

de producción adecuada para uso con máquinas automáticas

y semiautomáticas en aplicaciones convencionales, HVLP o

de tecnología de transferencia. (Para detalles de aplicaciones

ver página 9).

fabricados de acero inoxidable de alta calidad. Varias agujas

están disponibles con puntas de plástico.

Esta pistola pulverizadora puede ser provista con un casquillo

de aire indexado (se pide por separado). Usted puede

capacitar su casquillo de aire con rotación libre quitando el

anillo plástico indexado fijado con 2 clavijas en el casquillo de

aire. El suministro de materiales alimentado a presión puede

ser recirculatorio o directo.

La pistola Compact-X tiene un colector de desprendimiento

rápido de ¼ de vuelta, para reducir el tiempo de mantenimiento

y configuración. Para funcionar con una amplia gama

de materiales de recubrimiento los pasajes de fluido son

La perilla de ajuste de la aguja tiene 18 posiciones de trinquete

(por una revolución de la perilla) permite el control fino y

preciso del caudal de flujo.

ESPECIFICACIONES Y MATERIALES DE CONSTRUCCIÓN

Rosca Presión

Entrada de fluido y recirculación “P” y "R"

Entrada de aire (atomizador + ventilador)

“A” y “F”

Cilindro/disparador “Cyl”

Temperatura máxima en uso

Peso de la pistola pulverizadora

Cuerpo de la pistola

Punta / aguja / boquilla pulverizadora /

placa de asiento

Declaración de conformidad de CE

Nosotros, Finishing Brands UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, como los fabricantes de

la Pistola pulverizadora modelo COMPACT-X, declaramos, bajo nuestra sola responsabilidad que el equipo al

que se relaciona este documento cumple con las siguientes normas u otros documentos normativos:

1/8" BSPP(F) Máx. 7 Bars (100 psi)

1/8" BSPP(F) Máx. 7 Bars (100 psi)

1/8" BSPP(F) de 4 a 7 Bars (60-100 psi)

40° C (104° F)

950 g (2 lbs)

Aluminio duro anodizado

Acero inoxidable 303

BS EN 292-1 PARTES 1 y 2: 1991, BS EN 1953: 1999; y por consiguiente cumple con los requisitos de

protección de la Directiva del Consejo 98/37/CEE relacionada con la Directiva de Seguridad de Maquinarias,

y; EN 13463-1:2001, la Directiva del Consejo 94/9/CE relacionada con Equipos y Sistemas Protectores

destinados para uso en Atmósferas Potencialmente Explosivas nivel de protección II 2 G X.

DeVilbiss se reserva el derecho de modificar la especificación del equipo sin previo aviso.

D. Smith, Gerente General

12 de febrero de 2014

SB-2-584-H (4/2016)ES-2 / 16

Page 19

ADVERTENCIAS DE SEGURIDAD

INCENDIO Y EXPLOSIÓN

Los disolventes y los materiales de recubrimiento pueden ser altamente inflamables o combustibles al

ser rociados. Consulte SIEMPRE las instrucciones del proveedor del material de recubrimiento y la

hoja de datos de seguridad de los materiales (MSDS) antes de usar este equipo.

Los usuarios deben cumplir con todos los códigos locales y nacionales de práctica y los requisitos de

la compañía aseguradora que rigen la ventilación, precauciones para casos de incendio, operación y

limpieza de las áreas de trabajo.

Este equipo, como se provee, NO es adecuado para uso con Hidrocarburos Halogenados.

La electricidad estática puede ser generada por el fluido y/o el aire que pasa por las mangueras, por el

proceso de rociado y limpiando con paños las partes no conductoras. Para prevenir la ignición por

descargas estáticas, se debe mantener la continuidad de la conexión a tierra hacia la pistola

pulverizadora y otros equipos metálicos utilizados. Es esencial utilizar aire conductor y/o mangueras

de fluidos.

EQUIPO DE PROTECCIÓN PERSONAL

Vapores tóxicos – Al ser rociados, ciertos materiales pueden ser tóxicos, producir irritación o

perjudicar la salud. Lea siempre todas las etiquetas, hojas de datos de seguridad y siga todas las

recomendaciones para los materiales antes de rociar. Si tiene duda, póngase en contacto con su

proveedor de materiales.

ES

Se recomienda usar todo el tiempo equipo de protección para la respiración. El tipo de equipo tiene

que ser compatible con el material que está siendo rociado.

Use siempre protección para los ojos al rociar o limpiar la pistola pulverizadora.

Se deben usar guantes al rociar o limpiar el equipo.

CAPACITACIÓN

El personal tiene que recibir la capacitación adecuada en el uso sin riesgos del equipo pulverizador.

USO INDEBIDO

Nunca apunte la pistola pulverizadora a una parte del cuerpo.

Nunca sobrepase la presión de trabajo segura máxima recomendada para el equipo.

El uso de piezas de reemplazo no recomendadas o no originales puede resultar peligroso.

Antes de limpiar o dar mantenimiento, se debe eliminar toda la presión del equipo.

Las partes metálicas del producto se pueden limpiar usando una máquina para limpiar pistolas. Sin

embargo, no se debe dejar este equipo dentro de máquinas para limpiar pistolas por períodos

prolongados. Ciertos sellos y las juntas tóricas podrían no ser compatibles con el disolvente.

NIVELES DE RUIDO

El nivel de ruido con ponderación A de las pistolas pulverizadoras puede sobrepasar los 85 dB (A)

dependiendo de la configuración que se esté usando. Los detalles de los niveles de ruido reales están

disponibles previa solicitud. Se recomienda el uso de protección para los oídos siempre que se rocíe.

OPERACIÓN

Los equipos pulverizadores que usan presiones altas pueden generar fuerzas de reacción. Bajo ciertas

circunstancias, tales fuerzas pueden producir lesiones repetitivas por tensión en el operador.

SB-2-584-H (4/2016) ES-3 / 16

Page 20

ES

LISTA DE PIEZAS

Para la disposición de las piezas, consulte la vista de componentes en la página 5.

Artículo Descripción

1

2

4 Anillo posicionador para el casquillo de aire indexado (artículo opcional) SPA-112 1

5 Sello del separador de aire (kit de 5 anillos) SPA-27-K5* 1

6 Tornillo M4 x 25 kit de 4 (Torx 20) — (kit incluye los artículos 6, 8a, 12a) SPK-108* 4

8 Boquilla pulverizadora – Compact-X SPA-50P 1

8a Varilla de sujeción en la placa de asiento (kit incluye los artículos 6, 8a, 12a) SPK-108* 1

9 Sello empaquetador para aguja (kit incluye los artículos 9, 11) SPK-107* 1

10 Junta tórica (kit incluye los artículos 10, 12b) SPK-109* 4

11

12 Cuerpo de la pistola para el modelo Compact-X (-S = Plateado / -G = Verde / -B = Azul)

12a Tubo de aire localizador (kit incluye los artículos 6, 8a, 12a) SPK-108* 1

12b Junta tórica (kit incluye los artículos 10, 12b) SPK-109* 1

13 Válvula de aire (ventilador / atomizador) AGG-403 2

14 Junta tórica (kit incluye los artículos 14, 15c, 15d, 16) SPK-104* 1

15 Émbolo montaje (incluye los artículos 14, 15b, 15c, 15d, 16) SPA-60X-K 1

15b Émbolo para válvula de aire (kit incluye cant. 2) SPA-60X-K 1

15c Junta tórica para émbolo pequeño (kit incluye los artículos 14, 15c, 15d, 16) SPK-104* 2

15d Junta tórica para émbolo grande (kit incluye los artículos 14, 15c, 15d, 16) SPK-104* 1

16 Junta tórica para émbolo para aguja (kit incluye los artículos 14, 15c, 15d, 16) SPK-104* 1

17 Resorte del émbolo (kit incluye los artículos 17, 22, 23, 24) SPK-105* 1

18

19 Alojamiento SPA-3 1

20 Anillo y bola (2) (kit incluye los artículos 20, 21, 25) SPK-106* 1

21 Anillo (kit incluye los artículos 20, 21, 25) SPK-106* 1

22 Resorte de la aguja (kit incluye los artículos 22, 23, 24) SPK-105* 1

23 Tapa de resorte (kit incluye los artículos 22, 23, 24) SPK-105* 1

24 Arandela de resorte (kit incluye los artículos 22, 23, 24) SPK-105* 1

25 Perilla de ajuste (kit incluye los artículos 20, 21, 25) SPK-106* 1

27 Manifold asamblea — completa con palanca y válvulas de aire SPA-55-K 1

28 Palanca inmovilizadora (kit incluye los artículos 28, 28a, 8a) SPA-56-K* 1

28a Tornillo sujetador del dispositivo de seguridad (kit incluye los artículos 28, 28a, 8a) SPA-56-K* 1

29 Tuerca de la barra de montaje de la pistola (kit incluye los artículos 29, 30, 31) SPK-110* 1

30 Barra de montaje de la pistola (kit incluye los artículos 29, 30, 31) SPK-110* 1

31

32 Kit de 2 tapones que reemplazan la válvula de aire manual (13) — para ven/atom remoto SPA-111-K2* 1

33

34 Tapón para puerto de recirculación (kit incluye una llave hexagonal SPA-30) SPK-116* 1

35 Tapón para manifold, 1/8" BSPP (no se vende como una pieza de reemplazo) REF. 1

* Piezas de reemplazo — Se deben pedir como parte de los kits de

reemplazo listados anteriormente.

Ver kits de adaptadores y accesorios adicionales en la página 10.

Ver tabla y referencia en la página 6.

Casquillo de aire con anillo de retención, sellos y sin anillo indexado.

Punta hidráulica con sello del separador de aire SPA-27-K5

Ø 0.85 / 1.0 / 1.4 / 1.8 / 2.2 mm

Ø 0.5 para casquillo de aire 590 Ø 0.7 para casquillo de aire 591

Empaque para junta tórica (kit incluye los artículos 9, 11n)

Aguja de acero inoxidable 0.5 / 0.7 / 0.85 / 1.0 / 1.4 / 1.8 / 2.2

Punta de plástico 1.0 / 1.4

M6 tornillo con cabeza encastrada hexagonal, longitud 5.5 (kit incluye los artículos 29, 30, 31)

Kit de anillo de retención con empaque (kit incluye anillo para el casquillo de aire y las empaques)

Artículo 9: Sello empaquetador sólo (paquete de 10) SPA-86-K10.

Opcional: Sello empaquetador sólo (paquete de 2) SPA-20-K2.

n Artículo 11: Empaque para junta tórica

Número

de pieza

SP-100-xxx-K 1

SP-200S-xx-K

SP-259S-xx-K

SPK-107* 2

SPA-1-CMAX-S

SPA-1-CMAX-G

SPA-1-CMAX-B

SPA-320-xx

SPA-320P-xx

SPK-110* 2

SPK-102-K* 1

sólo (paquete de 10) SPA-53-K10.

Cant.

1

1

1

SB-2-584-H (4/2016)ES-4 / 16

Page 21

PISTOLA PULVERIZADORA AUTOMÁTICA COMPACT-X

SÓLO COMO REFERENCIA:

• SPA-60X-K (incluye los artículos 14, 15b, 15c, 15d, 16)

• SPK-104 (incluye los artículos 15c–qty.10, 15d–qty.5, 16–qty.10, 14–qty.5)

• SPK-105 (incluye los artículos 17, 22, 23, 24)

• SPK-107 (incluye los artículos 9, 11)

ES

NOTA: La llave Torx SPN-8 para el artículo 6 se envía con la pistola.

La llave hexagonal SPN-30 para el artículo 34 se envía con la pistola.

SPN-8 y SPN-30 no ilustrados en la vista de componentes anteriores.

PISTOLA AUTOMÁTICA COMPACT-X

EJEMPLO DE SISTEMA DE NUMERACIÓN DE PIEZAS

CMAX–B85PM–507

CMAX– B 85 P M 507

Pistola

pulverizadora

automática

Compact-X

tipo colector

SB-2-584-H (4/2016) ES-5 / 16

B = Azul (HVLP)

G = Verde

(Tec-Trans)

Ninguna letra =

Convencional

85 = 0.85 mm

00 = Sin boquilla

boquilla de

fluido y aguja

hidráulica,

Sin aguja

Ver la página 10 para configuraciones estándares.

Ver página 11 para esquema de enganche.

P = Aguja plástica

– o ninguna letra = Aguja de

acero

inoxidable

M = Con colector

O = Sin colector

507 = Casquillo

de aire

Page 22

ES

PISTOLA AUTOMÁTICA Compact-X — CASQUILLOS DE AIRE DISPONIBLES

Tamaño del

patrón @ 8"

de distancia

Casquillo de

aire

Tipo

Flujo de aire

Presión

en la entrada

Caudal de fluido

SCFM l/min psi bar oz/min ml/min pulg. mm

SP-100-430-K Convencional 12 340 50.7 3.5 6.7 - 9.5 200 - 280 7.9 200

SP-100-443-K Convencional 12.2 345 43.5 3.0 6.7 - 10.1 200 - 300 11.8 300

SP-100-497-K Convencional 18 510 50.7 3.5 6.7 - 20.2 200 - 600 15.0 380

SP-100-500R-K

Aerosol Ronda HVLP

6.8 200 16.0 1.1 .6 - 5.0 20-150 1.6 40

SP-100-507-K H V L P 19 385 40 1.4 4.4 - 6.5 130 – 190 10.6 270

SP-100-510-K

SP-100-513-K

SP-100-522-K

SP-100-590-K

SP-100-591-K

Tecnología de

transferencia

Tecnología de

transferencia

Tecnología de

transferencia

Tecnología de

transferencia

Tecnología de

transferencia

10 283 29 2.0 5.4 - 7.5 160 - 220 10.6 270

18.8 531 43.5 3.0 6.7 - 20.2 200 - 600 13.8 350

14.5 410 29 2.0 6.7 - 20.2 200 - 600 13.8 350

7.7 218 29 2.0 1.6 - 5.0 50 -150 6.0 150

12.3 350 29 2.0 1.7 - 5.1 50 -150 4.5 115

KK-5090-507 Kit de prueba para HVLP – incluye tapa, calibrador y tubo

Other test kits available: KK-5090-430, KK-5090-443, KK-5090-497, KK-5090-506, KK-5090-510, KK-5090-513, KK-5090-522, KK-5009-590

PISTOLA AUTOMÁTICA Compact-X — COMBINACIONES DEL CASQUILLO DE AIRE

TIPO

CASQUILLO DE AIRE

MODELO NO.

CONVENCIONAL HVLP TECNOLOGÍA DE TRANSFERENCIA

430 443 497 500R 507 510 513 522 590 591

.020" (0.5 mm) X X

.028" (0.7 mm) X

.033" (0.85 mm) X X X X X X

.039" (1.0 mm) X X X X X X X X

.055" (1.4 mm) X X X X X X X X

HIDRÁULICA

.070" (1.8 mm) X X X X X X X X

TAMAÑOS DE PUNTA

.086" (2.2 mm) X X X X X

B

C

D

G

I

J

ATOM VEN

E

F

ENTRADA DE

FLUIDO

P/R

ENTRADA DE

AIRE

ATOM,

CYL VEN

K

H

A

Perilla de ajuste del desplazamiento de la

A

aguja – 18 posiciones por una vez

B Cabeza de la pistola – acero inoxidable

C Anillo del casquillo de aire

D Casquillo de aire

E Válvula de aire (ventilador / atomizador)

Cuerpo de la pistola pulverizadora –

F

aluminio anodizado

G Punta hidráulica – acero inoxidable

H Manifold – acero inoxidable

I Palanca inmovilizadora de la manifold

J Tornillo de apoyo/apriete

Orificio de montaje de la pistola

K

pulverizadora – 1/2" de diámetro

Entrada de fluido, retorno

P/R

de fluido

SB-2-584-H (4/2016)ES-6 / 16

Page 23

INSTALACIÓN

ES

MANGUERAS DE AIRE Y LÍQUIDO

Ver las páginas 11, 13, 14 y 15 para los detalles de instalación.

Utilice suministros de aire regulados y filtrados separados para el atomizador

y el cilindro neumáticos. Conecte todas las mangueras de aire y fluido en la

parte trasera del colector (1/8” BSP): (Ver figura)

• Cilindro neumático ‘C = Cyl’ mediante una válvula de control. Para la

operación rápida del cilindro, la válvula de control se debe colocar lo más

cerca de la pistola posible o instalar en la línea una válvula de exhaustación

rápida.

• Suministro de aire del atomizador y del ventilador “F” y “A” separados.

• Manguera del material ‘P’. Si se necesita la recirculación del material, quitar

el tapón del ventilador ‘R’ (35) y retirar el tapón de boquilla pulverizadora

(34).

Tamaño de la manguera recomendado hasta 34 pies (10 m) de longitud:

Atomización neumática = 0.315 pulg. (8 mm)

Cilindro neumático = 0.236 pulg. (6 mm)

Material = 0.315 pulg. (8 mm)

Importante: La pistola pulverizadora debe conectarse a tierra para disipar cualquier carga

electrostática que pueda ser creada por caudales de fluido o flujos de aire. Esto se puede

lograr mediante la montura de la pistola pulverizadora o las mangueras conductoras de

aire/fluido. Se debe chequear la conexión eléctrica de la pistola pulverizadora a tierra con

un ohmiómetro. Se recomienda una resistencia de menos de 106.

Superficie TRASERA del colector

Superficie SUPERIOR del colector

Importante: Para asegurar que usted reciba este equipo en condiciones óptimas, se han

usado recubrimientos protectores. Antes de usarlo, lave bien el equipo con el disolvente

apropiado. Instale la placa de asiento de la pistola pulverizadora usando un vástago de

montaje (ref. 30) y ajústela con la tuerca (ref. 29).

MONTAJE

Verifique que la pistola tenga instaladas todas las

juntas tóricas en la superficie selladora y verifique

que el dispositivo de seguridad (28) se encuentre en

la posición correcta para asegurar la pistola

pulverizadora en la placa de conexión.

1. La válvula de aire del ATOMIZADOR ‘A’ controla

la presión del atomizador neumático.

2. La válvula del VENTILADOR ‘F’ controla el

tamaño del patrón de pulverización.

3. El caudal de fluido se puede ajustar con la perilla

trasera del trinquete (25).

Para la disposición de las piezas, consulte la vista

de componentes en la página 5.

INICIO

1. Gire la perilla de ajuste de la aguja (25) en sentido

horario hasta que la aguja se cierre completamente.

2. Gire las válvulas de aire (13) del VENTILADOR ‘F’

y del ATOMIZADOR ‘A’ en sentido antihorario

para que se abran completamente.

3. Utilice la tabla del casquillo de aire para fijar la

presión de aire en el regulador de aire para lograr

la presión recomendada.

4. Gire la perilla de ajuste (25) en sentido antihorario

para obtener el caudal de fluido que desee.

5. Pruebe el pulverizador. Si el acabado es muy

seco o fino, reduzca el flujo de aire reduciendo la

presión de entrada de aire o atornillando la

válvula del ATOMIZADOR ‘A’ (13) en sentido

horario o aumente el caudal de fluido utilizando

la perilla del trinquete, haciéndola girar en

sentido antihorario.

SB-2-584-H (4/2016) ES-7 / 16

Page 24

ES

INSTALACIÓN (CONTINÚA)

INICIO (continúa)

6. Si el acabado es muy húmedo, gire la perilla del

trinquete (25) en sentido horario para reducir el

caudal de fluido o reducir la presión del fluido. Si

la atomización es muy gruesa, aumente la presión

de aire de entrada o reduzca el caudal de fluido.

7. El tamaño del patrón se puede reducir girando la

válvula de ajuste del VENTILADOR ‘F’ (13) en

sentido horario.

8. El patrón de pulverización produce mejores

resultados cuando es perpendicular al blanco.

MANTENIMIENTO

MANTENIMIENTO PREVENTIVO

Apague el suministro de aire y

recubrimiento y reduzca la presión en las

líneas de suministro o desconéctelo de la

línea de aire o de la línea de fluido.

1. Desenganche la pistola pulverizadora de la placa

de asiento, quítela y, si hubiese una disponible,

reacople una pistola alternativa. Ahora el

mantenimiento de la pistola pulverizadora se

puede hacer desde el exterior del recinto de

pulverización sin interrumpir la producción.

2. Quite el casquillo de aire (1) y limpie. Si cualquiera

de los orificios en el casquillo está bloqueado

con material de recubrimiento use un palillo de

dientes para limpiarlo. Nunca use alambre

metálico que pueda dañar el casquillo y

distorsionar los patrones de pulverización

3. Asegúrese de que la boquilla de la punta

hidráulica (2) esté limpia y sin daños. Cualquier

acumulación de pintura seca puede distorsionar

el patrón de pulverización.

REEMPLAZO DE PIEZAS

PUNTA (2) Y AGUJA (18)

Apague el suministro de aire y

recubrimiento y reduzca la presión en

las líneas de suministro antes de iniciar

cualquier operación de mantenimiento.

Quite el casquillo de aire (1) destornillando su anillo

de retención en sentido antihorario, quite el anillo

indexado si permanece en la cabeza de la pistola (si

está colocado y ha sido usado).

9. La distancia de rociado recomendada es de 6’’ a

8’’ (150-220 mm).

10. Rocíe los bordes primero. Superponga cada

golpe de rociado al menos un 50%. Mueva la

pistola a velocidad constante.

11. Apague siempre el suministro de aire y fluido y

reduzca la presión y limpie cuando la pistola no

esté en uso.

Quite la punta (2) y su anillo separador de aire (3)

destornillándolos en sentido antihorario con una

llave hexagonal de 10 mm.

Destornille la perilla de ajuste de la aguja (25)

girándola completamente en sentido antihorario,

empuje la aguja desde la parte delantera de la

pistola pulverizadora, con cuidado para no dañar el

extremo de la aguja, luego saque la aguja (18)

desde la parte trasera.

Si fuese necesario, vuelva a colocar la aguja y la

punta, primero reajustando la punta con su anillo

separador de aire (par de torsión recomendado

entre 9,5 y 12 Nm).

Lubrique todas las superficies de la aguja que

estarán en contacto con el empaque y la junta

tórica. Deslice la aguja en la pistola pulverizadora

desde la parte trasera. Fije los resortes de la aguja

en su atenuador plástico correspondiente (22, 23,

24) y vuelva a colocar la perilla de ajuste de la

aguja (25).

SELLO EMPAQUETADOR (9)

Destornille el casquillo de aire (1), la punta (2) y su

anillo separador de aire (3).

Destornille los 4 tornillos (6) para desmontar la

cabeza de la pistola (8). Empuje hacia atrás el sello

empaquetador (9) utilizando una varilla de 5,5 mm

de diámetro desde la parte delantera de la cabeza

de la pistola. Limpie el orificio de localización del

empaque cuidadosamente con el disolvente

adecuado.

Instale un nuevo sello empaquetador (9) con su

lado en "U" orientado hacia el pasaje del fluido.

SB-2-584-H (4/2016)ES-8 / 16

Page 25

REEMPLAZO DE PIEZAS (CONTINÚA)

ES

VÁLVULA DE AIRE DEL VENTILADOR Y

ATOMIZADOR (13)

Antes de ensamblar, revise si la válvula de aire se

encuentra completamente abierta destornillándola

en sentido antihorario.

ÉMBOLO (15), JUNTA TÓRICA (16, 14 Y 15C)

Destornille el alojamiento trasero (19) en la parte

trasera del cuerpo de la pistola en sentido

antihorario, saque la aguja (18).

Utilice pinzas de nariz doblada en “T” para extraer

el émbolo que tiene una muesca interna de 12 mm

para este fin.

El émbolo “P+W” y dos válvulas “V” serán

eyectadas al mismo tiempo. El anillo “W” se

coloca oprimiéndolo dentro del émbolo y no se

pude separar del mismo.

La válvula “V” se puede sacar con facilidad del

anillo del émbolo. Recomendamos volver a colocar

la pistola completa al mismo tiempo (artículo

número SPA-60x-K).

Se recomienda volver a instalar todas las juntas

tóricas (14, 16 y 15c) en el cuerpo de la pistola tan

pronto usted desmonte el émbolo de la pistola.

Lubrique ligeramente el borde del émbolo antes de

instalarlo en el cuerpo de la pistola. Use vaselina

para lubricar las piezas del émbolo y juntas tóricas.

Conjunto

del émbolo

(ref.)

Válvula de

aire (ref.)

TECNOLOGÍA DE LA PISTOLA PULVERIZADORA DE DEVILBISS—DETALLES DE APLICACIÓN

HVLP (AZUL)

Mantiene el cumplimiento

reglamentario

La pistola Compact “azul” de

DeVilbiss le permite mantener el

cumplimiento con las normas de

EPA y producir un acabado

soberbio.

Diseñada para proporcionar una

atomización de recubrimiento

excepcional, la pistola Compact

"azul" puede usarse con todos

los tipos de disolventes y

materiales hidrotransportados.

El rendimiento superior de la

pistola se combina con un cuerpo

liviano, diseñado para dar

comodidad al operador y

aumentar la productividad.

TECNOLOGÍA DE

TRANSFERENCIA (VERDE)

Máxima eficiencia con

responsabilidad ambiental

La pistola Compact “verde” de

DeVilbiss utiliza los avances más

recientes en dinámica computacional de fluidos. El resultado es

una automatización superior con

la nueva TECNOLOGÍA DE

TRANSFERENCIA de DeVilbiss.

Transferencia de material

excepcionalmente eficiente para

cobertura y uso de pintura

óptimos se logra con un consumo

de aire reducido, reduciendo sus

necesidades de electricidad y

costos de energía eléctrica.

Supera sus requisitos de

producción con los niveles más

altos de atomización a un ritmo

acelerado de aplicación de hasta

de 600cc/min.

CONVENCIONAL (PLATEADA)

Supera en rendimiento a la

competencia

La pistola Compact “plateada”

de DeVilbiss es nuestra pistola

convencional avanzada y tiene

un flujo de aire único de alta

capacidad con atomización

excepcional para producir

resultados superiores.

Los casquillos de aire

convencionales avanzados de la

pistola Compact permiten un

rendimiento ideal de esta pistola

en operaciones tanto pequeñas

como en instalaciones de gran

volumen, con la bonificación

adicional de una mejora

instantánea de la productividad

de los acabados.

SB-2-584-H (4/2016) ES-9 / 16

Page 26

ES

CONFIGURACIONES ESTÁNDARES DISPONIBLES PARA LA PISTOLA PULVERIZADORA

AUTOMÁTICA COMPACT-X

NÚMERO DE PIEZA DESCRIPCIÓN

PISTOLAS HVLP

CMAX-B85-M PISTOLA AUTOMÁTICA COMPACT-X HVLP 0.85 MM CON COLECTOR, SIN CASQUILLO

CMAX-B10-M PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.0 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-B14-M PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.4 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-B18-M PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.8 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-B85PM PISTOLA AUTOMÁTICA COMPACT-X HVLP 0.85 MM AGUJA PLÁSTICA C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-B14PM PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.4 MM AGUJA PLÁSTICA C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-B10-M-507 PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.0 MM C/COLECTOR, 507 CASQUILLO DE AIRE INCLUIDO

CMAX-B14-M-507 PISTOLA AUTOMÁTICA COMPACT-X HVLP 1.4 MM C/COLECTOR, 507 CASQUILLO DE AIRE INCLUIDO

CMAX-B00-0 PISTOLA AUTOMÁTICA COMPACT-X HVLP SIN COLECTOR, MENOS BOQUILLA, AGUJA, CASQUILLO

PISTOLAS TEC-TRANS

CMAX-G05-M-590 PISTOLA AUTOMÁTICA COMPACT-X TRANS 0.5 MM C/COLECTOR, 590 CASQUILLO DE AIRE INCLUIDO

CMAX-G85-M PISTOLA AUTOMÁTICA COMPACT-X TRANS 0.85 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G10-M PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.0 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G-14-M PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.4 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G18-M PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.8 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G85PM PISTOLA AUTOMÁTICA COMPACT-X TRANS 0.85 MM AGUJA PLÁSTICA C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G14PM PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.4 MM AGUJA PLÁSTICA C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-G10-M-513 PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.0 MM C/COLECTOR, 513 CASQUILLO DE AIRE INCLUIDO

CMAX-G-14-M-513 PISTOLA AUTOMÁTICA COMPACT-X TRANS 1.4 MM C/COLECTOR, 513 CASQUILLO DE AIRE INCLUIDO

CMAX-G00-0 PISTOLA AUTOMÁTICA COMPACT-X TRANS SIN COLECTOR, MENOS BOQUILLA, AGUJA, CASQUILLO

PISTOLAS CONVENCIONALES

CMAX-10-M PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.0 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-14-M PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.4 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-18-M PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.8 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-22-M PISTOLA AUTOMÁTICA COMPACT-X CONV. 2.2 MM C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-10-M-497 PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.0 MM C/COLECTOR, 497 CASQUILLO DE AIRE INCLUIDO

CMAX-14-M-497 PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.4 MM C/COLECTOR, 497 CASQUILLO DE AIRE INCLUIDO

CMAX-14PM PISTOLA AUTOMÁTICA COMPACT-X CONV. 1.4 MM AGUJA PLÁSTICA C/COLECTOR, SIN CASQUILLO DE AIRE

CMAX-00-0 PISTOLA AUTOMÁTICA COMPACT-X CONV. SIN COLECTOR, MENOS BOQUILLA, AGUJA, CASQUILLO

NOTA: El casquillo de aire se puede pedir por separado. Información para pedir el casquillo de aire en la página 6.

PISTOLA AUTOMÁTICA COMPACT-X – KITS DE ADAPTADORES PARA MONTAJE Y ACCESORIOS DE MANGUERA:

SPK-111 MÁQUINAS CEFLA – KIT DE ADAPTADORES DE MONTAJE

6-531 MÁQUINAS CEFLA – KIT DE ACCESORIOS PARA AIRE Y FLUIDO

6-534 MÁQUINAS SUPERFICII – ACCESORIOS PARA AIRE Y FLUIDO

6-533 KIT DE ACCESORIOS DE FLUIDO/AIRE PARA CONEXIONES NPS (PÁGINA 15)

(PÁGINA 14)

(PÁGINA 14)

(PÁGINA 13)

SB-2-584-H (4/2016)ES-10 / 16

Page 27

PISTOLA AUTOMÁTICA COMPACT-X —

DIAGRAMAS TÍPICOS DE AIRE Y FLUIDO

VENTILADOR Y ATOMIZADOR NEUMÁTICO COMBINADOS

(ENGANCHE ESTÁNDAR DE LA PISTOLA)

RETORNO DE FLUIDO (SI SE UTILIZA)

SUMINISTRO DEL CILINDRO NEUMÁTICO

SUMINISTRO DEL VENTILADOR Y

(COMBINADOS)

ATOMIZADOR NEUMÁTICOS

ES

VÁLVULA DE

CONTRAPRESIÓN

VÁLVULA DEL

CILINDRO

NEUMÁTICO

(3 VÍAS)

REGULADOR

DE AIRE

(VENTILADOR Y

ATOMIZADOR

NEUMÁTICOS

COMBINADOS)

VISTA

TRASERA

VISTA

TRASERA

SUMINISTRO DE FLUIDO

VÁLVULA DE AJUSTE DEL ATOMIZADOR

VÁLVULA DE AJUSTE DEL VENTILADOR

VENTILADOR Y ATOMIZADOR NEUMÁTICOS SEPARADOS

(ENGANCHE OPCIONAL)

VÁLVULA DE AJUSTE DEL ATOMIZADOR

VÁLVULA DE AJUSTE DEL VENTILADOR

RETORNO DE FLUIDO (SI SE UTILIZA)

SUMINISTRO DEL CILINDRO NEUMÁTICO

SUMINISTRO DEL ATOMIZADOR NEUMÁTICO

REGULADOR

DE FLUIDO

VÁLVULA DE

CONTRAPRESIÓN

VÁLVULA DEL CILINDRO

NEUMÁTICO (3 VÍAS)

REGULADOR DEL

ATOMIZADOR

NEUMÁTICO

VÁLVULA DE AJUSTE DEL ATOMIZADOR

VÁLVULA DE AJUSTE DEL VENTILADOR

SB-2-584-H (4/2016) ES-11 / 16

SUMINISTRO DEL VENTILADOR NEUMÁTICO

REGULADOR DEL

VENTILADOR

NEUMÁTICO

SUMINISTRO DE FLUIDO

REGULADOR DE

FLUIDO

Page 28

ES

DIMENSIONES DE INSTALACIÓN para PISTOLA AUTOMÁTICA COMPACT “X”

320 de ancho x

3.5 de profundidad

05 Orificio de Localización

M8 X 1.25P X 7.5 de profundidad

Para el montaje de la placa de la máquina / soporte

DIMENSIONES EN MM.

(MULTIPLICAR POR .03937 PARA OBTENER PULGADAS)

BSPP = BRITISH STRAIGHT PIPE PARALLEL (TUBO RECTO BRITÁNICO PARALELO)

SB-2-584-H (4/2016)ES-12 / 16

Page 29

6-534 KIT DE ACCESORIOS DE MÁQUINA SUPERFICI para PISTOLA AUTOMÁTICA COMPACT “X”

CONEXIÓN DE TUBO CON O.D.

TUBO CON O.D. DE 8 MM. (2)

CONEXIÓN DE FLUIDO

DE 6 MM. PARA CILINDRO

NEUMÁTICO

TUBO CON O.D. DE 8 MM. 2 PULG.

DE LONGITUD- CANTIDAD 4 (PARA

ATOMIZADOR / VENTILADOR /

FLUIDO) PROVISTO POR EL CLIENTE

CONEXIÓN DE 1/4”

BSPP (M) (2) PARA

SUMINISTRO DE

FLUIDO Y RETORNO

ES

REF. ROSCA DE TORNILLO DE

8 MM PARA MONTAJE EN EL

ACCESORIO DE LA PLACA DE

LA MÁQUINA

REF. SPA-111-K2 KIT DE TAPÓN

(M12-1.0) PARA REEMPLAZAR

VÁLVULAS MANUALES+

(COMPRAR POR SEPARADO)

CUANDO SE UTILIZA EL 8MM

AGUJERO PARA MONTAR LA

PISTOLA DE PULVERIZACIÓN,

PARTE DEL MATERIAL PODRÍA

NECESITAN SER REMOVIDOS

DESDE EL BORDE DEL SPA-111

TAPONES, COMO SE MUESTRA.

NOTAS:

O.D. = Diámetro exterior (m) = conexión macho (h) = conexión hembra

USE TAPÓN DE 1/8” BSPP (1) PARA PUERTO DE RETORNO DE FLUIDO CUANDO NO SE

REQUIERA CIRCULACIÓN. (TAPÓN PROVISTO EN ESTE KIT)

CONEXIÓN DE TUBERÍA CON

O.D. DE 8 MM (2) ATOMIZADOR /

VENTILADOR

CONEXIÓN EN “Y” DE

TUBO CON O.D. DE 8 MM.

PARA CONEXIÓN

COMBINADA DE

ATOMIZADOR /

VENTILADOR

NOTA: TODOS LOS PUERTOS DE AIRE Y PUERTOS DE FLUIDO PARA SON DE 1/8" BSPP (m)

BSPP = BRITISH STRAIGHT PIPE PARALLEL (TUBO RECTO BRITÁNICO PARALELO)

SB-2-584-H (4/2016) ES-13 / 16

EN EL MANIFOLD

Page 30

ES

6-531 KIT DE ACCESORIOS DE MÁQUINA CEFLA para PISTOLA AUTOMÁTICA COMPACT “X”

CONEXIÓN DE TUBO CON O.D.

DE 6 MM. PARA CILINDRO

NEUMÁTICO (CEFLA)

O

CONEXIÓN DE TUBO CON O.D.

DE 4 MM PARA CILINDRO

NEUMÁTICO (FALCONI)

TUBO CON O.D. DE 8 MM. 2 PULG. DE

LONGITUD- CANTIDAD 4

PARA ATOMIZADOR / VENTILADOR / FLUIDO

(COMPRAR POR SEPARADO)

CONEXIÓN DE 1/4”

BSPP (M) (2) PARA

SUMINISTRO DE

FLUIDO Y

RETORNO

CONEXIÓN DE

TUBO CON O.D.

DE 8 MM (2)

FLUIDO

CONECTOR DE TUBO

CON O.D. DE 8 MM (1)

TUBO CON O.D. DE 8

MM (2)

ATOMIZADOR /

VENTILADOR

REF: SPK-111 ADAPTADOR DE MONTAJE DE MÁQUINA CEFLA

(COMPRAR POR SEPARADO)

PARA CONEXIÓN

COMBINADA DE

ATOMIZADOR /

VENTILADOR

O.D. = Diámetro exterior (m) = conexión macho (h) = conexión hembra

NOTA: TODOS LOS PUERTOS DE AIRE Y PUERTOS DE FLUIDO PARA SON DE 1/8" BSPP (m)

BSPP = BRITISH STRAIGHT PIPE PARALLEL (TUBO RECTO BRITÁNICO PARALELO)

NOTAS:

EN EL MANIFOLD

SB-2-584-H (4/2016)ES-14 / 16

Page 31

6-533 KIT DE ACCESORIOS CON 1/4" NPS (m) para PISTOLA AUTOMÁTICA COMPACT “X”

CONEXIÓN DE TUBO CON O.D. DE

6 MM. PARA CILINDRO

NEUMÁTICO

CONEXIÓN DE 1/4”

NPS (M) (2) PARA

SUMINISTRO DE

FLUIDO Y

RETORNO

ES

O.D. = Diámetro exterior (m) = conexión macho (h) = conexión hembra

NOTA: TODOS LOS PUERTOS DE AIRE Y PUERTOS DE FLUIDO PARA SON DE 1/8" BSPP (m)

BSPP = BRITISH STRAIGHT PIPE PARALLEL (TUBO RECTO BRITÁNICO PARALELO)

SB-2-584-H (4/2016) ES-15 / 16

CONEXIÓN DE 1/4” NPS (M)

(1) PARA ATOMIZADOR

NEUMÁTICO (1) PARA

VENTILADOR NEUMÁTICO

NOTAS:

EN EL MANIFOLD

Page 32

ES

WARRANTY POLICY

DeVilbiss products are covered by Finishing Brands one year materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Finishing Brands, will void all warranties.

For specic warranty information please contact the closest Finishing Brands location listed below.

Finishing Brands reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, BGK®, and Binks® are registered trademarks of Carlisle Fluid Technologies, Inc.,

dba Finishing Brands. ©2016 Carlisle Fluid Technologies, Inc., dba Finishing Brands. All rights reserved.

DeVilbiss is part of Finishing Brands, a global leader in innovative spray nishing

technologies. For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations below.

USA/Canada

www.devilbiss.com

info@carlisleft.com

Tel: 1-800-992-4657

Fax: 1-888-246-5732

United Kingdom

www.nishingbrands.eu

info@carlisleft.eu

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

www.nishingbrands.com.cn

mkt@carlisleft.com.cn

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Mexico

www.carlisleft.com.mx

ventas@carlisleft.com.mx

Tel: 011 52 55 5321 2300

Fax: 011 52 55 5310 4790

France

www.nishingbrands.eu

info@carlisleft.eu

Tel: +33(0)475 75 27 00

Fax: +33(0)475 75 27 59

Japan

www.ransburg.co.jp

overseas-sales@carlisleft.co.jp

Tel: 081 45 785 6421

Fax: 081 45 785 6517

Brazil

www.devilbiss.com.br

vendas@carlisleft.com.br

Tel: +55 11 5641 2776

Fax: 55 11 5641 1256

Germany

www.nishingbrands.eu

info@carlisleft.eu

Tel: +49 (0) 6074 403 1

Fax: +49 (0) 6074 403 281

Australia

www.nishingbrands.com.au

sales@carlisleft.com.au

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

SB-2-584-H (4/2016)ES-16 / 16

Loading...

Loading...