Page 1

OWNERS MANUAL FOR

PERMANENTLY LUBRICATED

AIR COMPRESSOR

MODEL NO. ,RlO2D-1

(For Home Use Only)

tl'r

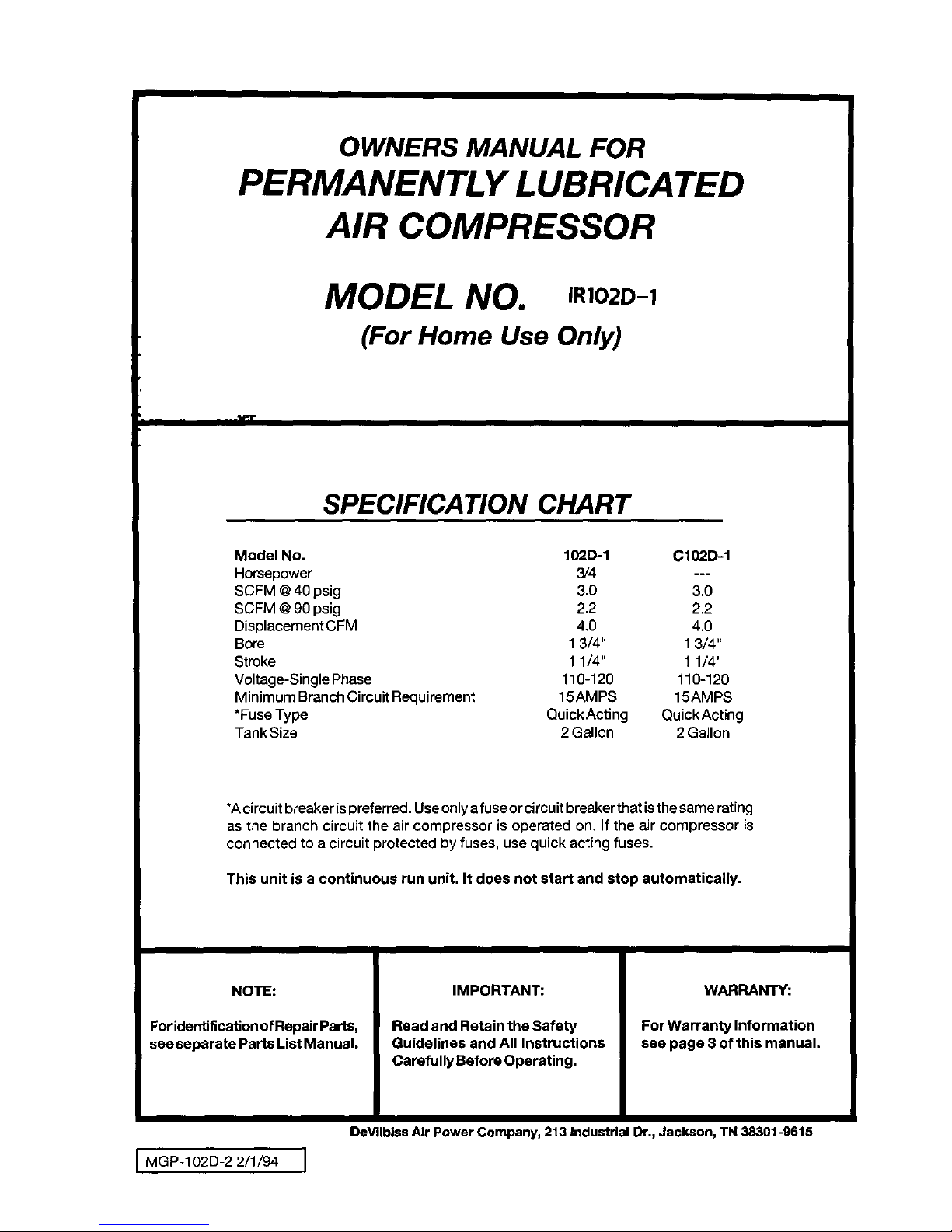

SPECIFICATION CHART

Model No. 102D-1 C10'2D-1

Horsepower 3/4 ---

SCFM @40 psig 3.0 3.0

SCFM @90 psig 2,2 2,2

Displacement CFM 4.0 4.0

Bore 1 3/4" 1 3/4"

Stroke 1 1/4" 1 1/4"

Voltage-Single Phase 110-120 110-120

Minimum Branch Circuit Requirement 15AMPS 15AMPS

*Fuse Type QuickActing QuickActing

Tank Size 2 Gallon 2 Gallon

*Acircuitbreaker ispreferred. Useonly afuse or circuit breaker that is the same rating

as the branch circuit the air compressor is operated on. If the air compressor is

connected to a circuit protected by fuses, use quick acting fuses.

This unit is a continuous run unit. It does not start and stop automatically.

NOTE:

ForidentificationofRepair Parts,

see separate Parts List Manual.

IMPORTANT:

Read and Retain the Safety

Guidelines and All Instructions

Carefully Before Operating.

WARRANTY:

For Warranty Information

see page 3 of this manual.

I MGP-102D-2 2/1/94 I

DeVilbiss Air Power Company, 213 Industrial Dr., Jackson, TN 38301-9615

Page 2

TABLE OF CONTENTS

I

Page

WARRANTY ........................................................ 3

SAFETYGUIDELINES .......................................... 4

WARNING CHART ............................................... 4-5

GLOSSARY......................................................... 5

UNPACKINGINSTRUCTIONS .............................. 5

STORAGE ........................................................... 5

DUTYCYCLE ...................................................... 5

DESCRIPTIONOFOPERATION ........................... 6

INSTALLATIONANDBREAK-IN

PROCEDURES.................................................... 6

Page

Locationof Air Compressor ........................... 6

ExtensionCords ........................................... 6

GroundingInstructions.................................. 6

AirHose ........................................................ 7

OPERATINGPROCEDURES ............................... 7

TROUBLESHOOTINGGUIDE .............................. 8

AIRCOMPRESSOR DIAGRAM

ANDPARTSLIST ................................................ 9-10

COMPRESSOR PUMP DIAGRAM

ANDPARTSLIST ............................................. 11-12

HOWTO ORDER REPAIR PARTS ..................... 13

In the unlikely event you should have a problem with this product or if you are

missing any parts, it is not necessary to return it to the store where you purchased

it. Simply call our toll free number and talk with our Service Representative.

OUR OFFICE HOURS ARE FROM

8 a.m. to 4:30 p.m. (CST)

MONDAY THROUGH FRIDAY

CALL TOLL FREE 1-800-888-2468, Ext. 2

2

Page 3

LIMITED WARRANTY

ONE YEAR FROM DATE OF PURCHASE

All merchandise manufactured by DeVilbissAir Power Company is warranted to be free ofdefects in workmanship

and material which occur during the first year from the date ofpurchase by the original purchaser (initialuser).

Products covered under this warranty include: air compressors, *airtools, accessories and serviceparts.

DeVilbiss Air Power willrepair or replace, at DeVilbiss 'soption, products or components which have failed within

the warranty period. Repair or replacement, and service calls on 60 and 80gallon air compressors, willbe handled

by Authorized Warranty Service Centers and will be scheduledand serviced according to the normal work flow at

the service center location, and depending on the availability of replacement parts.

All decisions of DeVilbiss Air Power Company with regard to this policy shall be final

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

i RESPONSIBILITYOFORIGINALPURCHASER(InitialUser):I

Q Retain original sales receipts as proof of purchase for warranty work.

[3 Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

{3 Deliver or ship the product to the nearest DeVilbiss Air Power Authorized Warranty Service

Center. Freight costs, if any, must be paid by the purchaser.

[3 Air compressors with 60 and 80 gallon tanks only will be inspected at the site of installation.

Contact the nearest Authorized Warranty Service Center, that provides on-site

service calls, for service call arrangement.

[3 If the purchaser does not receive satisfactory results from the Authorized Warranty Service

Center,

the

I I I I .... ; Air Power Company.

I THIS WARRANTYDOESNOTCOVER:

I

q

[3 Merchandise sold as, reconditioned, floor models and/or display models sold "as is", any damaged

or

incomplete equipment sold "as is".

[3 Merchandise used as "rental" equipment.

[3 Merchandise that has become inoperative because of ordinary wear, misuse, negligence,

accident,

improper and/or unauthorized repair or alterations including failure to operate the product in

accordance with the instructions provided in the Owners Manual (s) supplied

with the product.

[3 An air compressor that pumps air more than 50% during a one hour period is considered

misuse because the air compressor is undersized for the required air

demand. Maximum compressor pumping time per hour is 30 minutes.

[3 Merchandise sold by DeVilbiss Air Power which has been manufactured by and identified as the

product of another company. The product manufacturer's warranty will apply.

[3 Repair and transportation costs of merchandise determined not to be defective.

{3 Cost associated with assembly, required oil, adjustments or other installation and start-up cost.

{3 ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE

PRODUCT. Some states do not allow the ._xclusion or limitation of incidental

or con_e_lT._t_tiale_ien,_ve_bta'wsaJ_o_i|oldilati_tt_aqr_l_e, tbf_y are warranted for a period of 45 da_lp#or

WAR, MESSFORA

PA_'OI__ 213 IndustrialDrive • Jackson TN 38301-9615 • Telephone: 1o800_88-2468, Ext.2 • FAX: 1-800-888-

states do not

allow limitations on how long an implied warranty lasts, so the above limitations may not apply to

3

Page 4

I

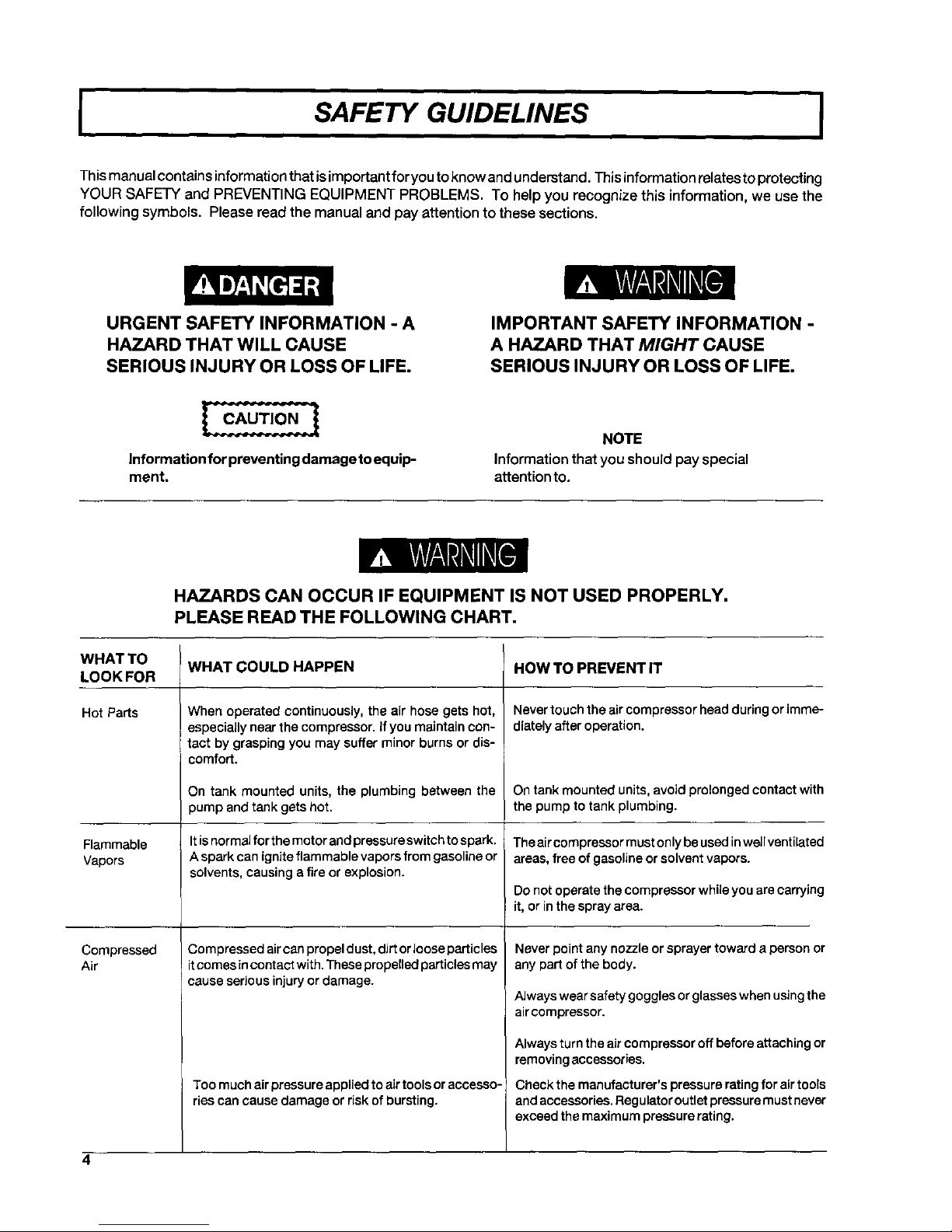

SAFETY GUIDELINES

I

Thismanual contain s information that is important foryou to know and understand. This information relatesto protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

following symbols. Please read the manual and pay attention to these sections.

URGENT SAFETY INFORMATION - A

HAZARD THAT WILL CAUSE

SERIOUS INJURY OR LOSS OF LIFE.

IMPORTANT SAFETY INFORMATION -

A HAZARD THAT MIGHT CAUSE

SERIOUS INJURY OR LOSS OF LIFE.

Information for preventingdamage toequip-

ment,

NOTE

informationthat you should payspecial

attentionto.

HAZARDS CAN OCCUR IF EQUIPMENT IS NOT USED PROPERLY.

PLEASE READ THE FOLLOWING CHART.

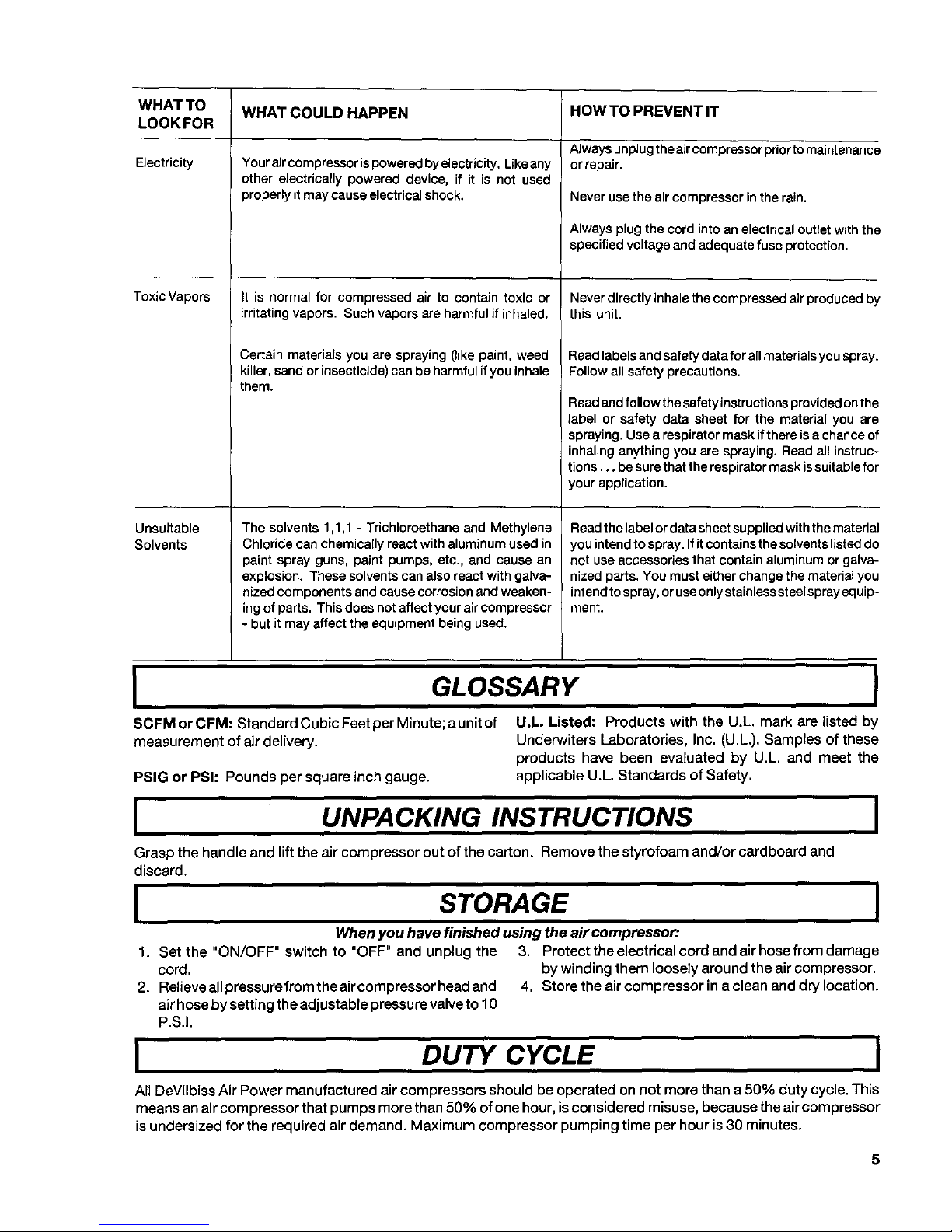

WHAT TO WHAT COULD HAPPEN HOW TO PREVENT IT

LOOK FOR

Hot Parts

Flammable

Vapors

Compressed

Air

When operated continuously, the air hose gets hot,

especially near the compressor. If you maintain con-

tact by grasping you may suffer minor burns or dis-

comfort.

On tank mounted units, the plumbing between the

pump and tank gets hot.

Itis normal for the motor and pressure switch to spark, i

A spark can ignite flammable vapors from gasoline or

solvents, causing afire or explosion.

Cornpressed air canpropel dust, dJrtorloose particles

it comes in contact with. These propelledparticles may

cause serious injury or damage.

Too much airpressure appliedto air toolsoraccesso-

ripscan cause damage or risk of bursting,

Never touch the air compressor head during or imme-

diately after operation.

On tank mounted units, avoid prolonged contact with

the pump to tank plumbing.

Theair compressormust onlybe usedin wellventilated

areas, free of gasoline or solvent vapors.

Donot operate the compressor whileyou are carrying

it, or in the spray area.

Never point any nozzle or sprayer toward a person or

any part of the body.

Always wear safety goggles or glasses when using the

air compressor.

Alwaysturn the air compressor off before attachingor

removingaccessories.

Check the manufacturer's pressure rating for air tools

and accessories. Regulatoroutlet pressuremust never

exceed the maximum pressure rating.

4

Page 5

WHAT TO WHAT COULD HAPPEN HOW TO PREVENT IT

LOOK FOR

EJectricity

Toxic Vapors

Unsuitable

Solvents

Your air compressor ispowered by electricity. Likeany

other electrically powered device, if it is not used

properly it may cause electrical shock.

It is normal for compressed air to contain toxic or

irritating vapors. Such vapors are harmful if inhaled.

Certain materials you are spraying (like paint, weed

killer, sand or insecticide) can be harmful if you inhale

them.

The solvents 1,1,1 - Trichloroethane and Methylene

Chloride can chemically react with aluminum used in

paint spray guns, paint pumps, etc., and cause an

explosion. These solvents can also react with galva-

nized components and cause corrosion and weaken-

ing of parts. This does not affect your air compressor

- but it may affect the equipment being used.

AJwaysunplug the aircompressor prior to maintenance

or repair.

Never use the air compressor in the rain.

Always plug the cord into an erectricaloutlet with the

specified voltage and adequate fuse protection.

Never directly inhale the compressed air produced by

this unit.

Read labels and safety data for all materials you spray.

Follow all safety precautions.

Read andfollowthe safetyinstructions provided onthe

label or safety data sheet for the material you are

spraying. Use a respirator mask if there is a chance of

inhaling anything you are spraying. Read all instruc-

tions.., be sure that the respirator mask issuitable for

your application.

Readthe label or data sheetsupplied with the material

you intend to spray. If it contains the solvents listed do

not use accessories that contain aluminum or galva-

nized parts. You must either change the material you

intend to spray, or use only stainless steel spray equip-

ment.

GLOSSARY I

SCFMorCFM: StandardCubicFeetperMinute;aunitof U.L. Listed: Products with the U.L mark are listed by

measurement of air delivery. Underwiters Laboratories, Inc. (U.L.). Samples of these

products have been evaluated by U.L. and meet the

PSIG or PSh Pounds per square inch gauge, applicable U.L. Standards of Safety.

I

UNPACKING INSTRUCTIONS

I

Grasp the handle and lift the air compressor out of the carton. Remove the styrofoam and/or cardboard and

discard.

I STORAGE I

When you have finished using the air compressor

1. Set the "ON/OFF" switch to "OFF" and unplug the 3. Protecttheelectricalcordandairhosefromdamage

cord, by winding them loosely around the air compressor,

2. Relieveallpressurefromtheaircompressorheadand 4. Storetheaircompressorinacleananddrylocation.

air hose by setting the adjustable pressure valve to 10

P.S.I.

DUTY CYCLE

All DeVilbiss Air Power manufactured air compressors should be operated on not more than a 50% duty cycle. This

means an air compressor that pumps more than 50% of onehour, isconsidered misuse, because the air compressor

is undersized for the required air demand. Maximum compressor pumping time per hour is 30 minutes.

5

Page 6

I

DESCRIPTION OF OPERATION

Air Compressor Pump: To compress air, the piston

moves up and down in the cylinder. On the downstroke,

air isdrawn inthroughthe air intake muffler (valves).The

exhaust valve remains closed. On the upstroke of the

piston, air is compressed. The intake valves close and

compressed air isforced out through the exhaust valve

and thenthrough the air hose.

Adjustable Pressure Valve: The pressurevalvecontrols

the amount of pressuregoing from the air compressorto

the accessory.The pressureadjustingvalve can be used

to set approximate pressure between 10 and 125 P.S.I.

(125 P.S.I. is the highest pressure this compressor will

deliver).Itisnormal for the adiustable oressure valve to

release air during ooeration.

I

Accumulator Tank: Your accumulator tank isequipped

with a relief (pop-off) valve to prevent an over pressure

conditioninthetank. This 2 gallontank isnotdesignedto

store air, but rather to provide the additional volume of

compressed airnecessaryto operate a wide varietyofair

tools. When startingyour compressor, attachthe toolto

the hose,set the pressureadjustingvalve at the required

pressure,wait a few moments untilthe tank fills withair.

You willknow thetankisfilledwhen youhear airbleeding

through the pressure adjusting valve. Depending onthe

type and size of tool being used, you will occasionally

need to wait for the tank to refill before continuing.When

you are finsihed or changing tools, turn the compressor

switch off and set the pressure adjusting valve to 10 PSI

and wait for the tank to discharge completely.

ALWAYS SET THE PRESSURE VALVE AT OR

BELOW THE REQUIRED PRESSURE FOR THE

ACCESSORY BEING USED BEFORE START-

ING YOUR COMPRESSOR. FOR INFLATION

OR OTHER USES REQUIRING ACCURATE

PRESSURE, USEA PRESSURE GAUGE.

I

INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Your compressor comes to you completely assembled

and ready for use. Operate the air compressor in a dry,

clean, cooland well ventilatedarea. The air compressor

pump and case aredesignedto allowfor propercooling.

Clean or blow off dust or dirt that collects on the air

compressor. A clean air compressor runs cooler and

providesIongerservice.The ventilationopeningsonyour

air compressor are necessaryto maintain properoperat-

ingtemperature. Do notplaceragsorother containerson

or nearthese openings.

Extension Cords

use extra air hose instead of an extensioncord to avoid

voltagedrop and power lossto the motor.

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding

plug, and a3-slot receptacle that will accept the plug on

the compressor

• in good condition

• nolonger than 50feet

• 14gauge (AWG)or larger. (Wiresize increases asgauge

number decreases.) 12AWG, 10AWG and8 AWG may

also be used. DONOT USE 16 OR 18AWG.

GROUNDING INSTRUCTIONS

RISK OF ELECTRICAL SHOCKI In the event of a

short circuit, grounding reduces the riskof shock by

providing an escape wire for the electdc current.

This air compressor must be properly grounded.

The aircompressor isequipped with a cord having a

grounding wire with an appropriate grounding plug.

The plug must be used with an outlet that has been

installed and grounded in accordance with all local

codes and ordinances. The outlet must have the same

configuration as the plug. See illustration. DO NOT

USE AN ADAPTER.

Inspectthe plug and cord before each use. Do notuse if

there are signs ofdamage.

IMPROPER GROUNDING CAN RESULT IN ELEC-

TRICAL SHOCK.

6

Page 7

I

INSTALLATION AND BREAK-IN PROCEDURES

I

Do not modify the plug that has been provided. Ifit

does not fit the available outlet, the correct outlet

should be installed by a qualified electrician.

If repairing or replacing cord or plug, the grounding

wire must be kept separate from the current-carrying

wires. Never connect the grounding wire to a flat blade

plug terminal. The grounding wire has insulation with

an outer surface that is green - with or without yellow

stripes.

If these grounding instructions arenotcompletely

understood, or if in doubt as to whether the compres-

sor is properly grounded, have the installation checked

by a qualified electrician.

Air Hose

The airhoseattached to you rcomporessor has an integral

pressure adjusting valve at the working end of the hose.

Should service or replacement be required, make sure that

the pressure adjusting valve is present inthe air hose line.

DONOTREPLACE THE HOSE WITH STANDARD HOSE

THAT IS NOT EQUIPPED WITH THE PRES-

SURE ADJUSTING VALVE.

120VoltModels

White

lS AMP PLUG OUTLET

_E_" _GROUNDED

GROUNDING .jI _

PIN

120 Volts, 15 Amps

Do notallow hose to become kinkedor pinched

at any time. This isimportantto avoid damage

to your compressor and to maintain pressure

adjusting valve control.

I

OPERATING PROCEDURES

1. Before plugging inthe aircompressor, set the adjust-

able pressure valve to "10" PSI. Make sure the "ON/

OFF" switch is in the "OFF" position.

2. Connect the air tool or accessory to the air hose.

Tighten securely.

3. Plug the power cord into the grounded outlet.

4. Start the compressor by setting the "ON/OFF" switch

to the "ON" position.

TOO M UCH AIR PRESSURE COULD CAUSE AN

AIR TOOL OR VEHICLE TIRE TO RUPTURE OR

EXPLODE. CAREFULLY FOLLOWSTEPS 5AND

6 EACH TIME YOU USE YOUR COMPRESSOR.

5,

Check the manufacturer's maximum pressure rating

for the air tool, accessory or vehicle tire being used.

Theaircompressoroutlet pressure must never exceed

the maximum pressure rating.

6. Slowly increasethe pressure settingof the adjustable

pressure valve. You should be ableto hear and feel air

pressure being relieved by the adjustable pressure

valve. If pressure is not being relieved, turn the air

compressor offimmediately. Thepressurevalvemust

be replaced.

Compressed air from the outfit may contain

water condensation. Do not spray unfiltered air

at an item that could be damaged by moisture,

Some air operated tools or devices may require

filtered air. Read the instructions for the air tool

ordevice.

7

Page 8

TROUBLESHOOTING GUIDE

I

VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR SOURCES ARE

EXPOSED WHEN REPAIRING THE COMPRESSOR. PERSONAL INJURY CAN

OCCUR. UNPLUG THE COMPRESSOR BEFORE AI-rEMPTING ANY REPAIRS.

PROBLEM CAUSE SOLUTION

Air Leaks Hose fitting loose. Tighten fitting.

Prolonged excessive use of air.Compressor isnot delivering

enough air.

Motor will not run.

High discharge pressure.

Cannot be adjusted lower.

Hole in hose.

Air leaks.

Fuse blown, circuit breaker tripped.

Extension cord is wrong length or

gauge.

Loose electrical connections.

Faultymotor.

Adjustable pressu revalve notfunc-

tioning.

Decrease the amount of air usage. Your com-

3ressor is not large enough for the air require-

meat.

Replace the hose.

Tighten fittings.

1,

Check fuse box for blown fuse andreplace as

necesssary. Reset circuit breaker. Do not

useafuse or circuit breaker with higher rating

than that specified for your particular branch

circuit.

2. Check for proper fuse. You should be using

a Quick Acting fuse.

3. Check for low voltage problem.

4. Check the extension cord.

5. Disconnect the other electrical appliances

from circuit or operate the compressor on its

own branch circuit.

Check the extension cord.

Check wiring connection inside terminal box

Have checked at a local Service Center.

RISK OF BURSTING. DO NOT OPER-

ATE THE COMPRESSOR IF THIS PROB-

LEM EXISTS. ADJUSTABLE PRESSURE

VALVE MUST BE REPLACED.

8

Page 9

I Air Compressor Diagram

I

1

2

4

5

7

6

TO TANK 9

21

/

10

18

17

*POWER CORD (GREEN)

GROUND WIRE

o

11

/

27

12

13

Y

15

14

Slide #19 over #7 as shown. Make sure that no part of #7 tube

touches #21 or #14 shroud when assembled.

9

Page 10

I

KEY

NO.

/ 1

2

* 3

* 4

5

* 6

7

+ 8

/ 9

+ 10

11

12

* 13

14

15

* 16

> 17

> 18

19

20

21

/ 22

PART NUMBER

CAC-1196

CAC-4323

CAC-1289

CAC-4111

CAC-1342

DAC-163

DAC-168

SSS-16

CAC-1285

CAC-4322-1

DAC-162

DAC-167

Parts List

DESCRIPTION

Screw #10-24 x 7/8 LG hex head thd. forming (4 required)

Cylinder Head

Tube Seal

Head Gasket

Valve PlateAssembly

"O" Ring

Outlet Tube

RodAssembly

Screw 3/8-16 x 1/25 LG hex socket flat head (torque to 350 in/Ib)

Cylinder Sleeve

EndbellAssembly

Timing Belt

Pump Isolator (5 required)

Shroud (right) for 102D-1

Shroud (right) for C102D-1

Switch

Tank Isolator (4 required)

Motor Baffle (right)

Motor Baffle (left)

Isolator (tube)

CordAssembly

Shroud (left) for 102D-1

Shroud (left) for C102D-1

Screws (5 used)

I

/

>

+

KK-4949

KK-4929

KK-4980

KK-4926

Isolator Kit includes Items 3, 4, 6, 13, 16, 34, 35, 27

Fastener Kit includes items 1,9, 22, 25.

Baffle Kit includes items 17,18.

Connecting Rod Kit includs items 8, 10.

10

Page 11

I

Compressor Pump Diagram

I

TO PUMP-,_---

I

t

\

11

Page 12

I

KEY

NO. PARTNUMBER

Parts List

DESCRIPTION

I

23

24

25

26

* 27

28

29

3O

31

33

* 34

* 35

CAC-1206

CAC-4324

CAC-4076

SSP-6102

SSP-3305-NI

TIA-4150

H-2105

SS-1286

SS-2707

Clamp(2 used)

Pressure Valve Assembly for 102D- 1

Pressure Valve Assembly for C102D-1

Ground Screw

Male Connector

Screw (tank retention) (as required)

Pipe Cross

SafetyValve

Hose Connection

Nipple

Drain Cock

Screw, self tapping

Recess Bumper

NOT ILLUSTRATED

SSH-8 Air Chuck

H-2099 Adapter

* KK_4949 Isolator Kit includes items 3, 4, 6, 13, 16, 34, 35, 27

12

Page 13

I

Service Notes

I

13

Page 14

I Service Notes I

14

Page 15

I

Service Notes

I

15

Page 16

OWNERS MANUAL FOR

PERMANENTLY

LUBRICATED

AIR COMPRESSOR

MODEL NOS,

102D-1

(For Home Use Only)

Attach Sales Receipt Here.

Retain Original Sales Receipt as

Proof of Purchase for Warranty

Repair Work.

WARRANTY

This product is covered by the

DeVilbiss one year limited

warranty (SP-100-C). The

warranty can be found in the

General Manual or is available

upon request.

An "Authorized Warranty Service Center Directory" is included with your

unit.

When ordering repair parts from your local Authorized Service Center,

always give the following information:

• Model number of your compressor

• Part number and description of the item

you wish to purchase

If you have any questions or need the location of the nearest Authorized

Service Center call our Customer Service Hotline (Toll Free) 1-800-888-

2468, Ext 2, Monday thru Friday 8:00 a.m. to 4:30 p.m. (CST) and talk with

our Trained Customer Service Representatives.

The Model number can be

found on the maintenance

label on the side of the tank.

Model

No.

The Date Code number can

be found on the foil label on

the air tank.

Date

Code

No.

The Manufactures

Number (ASME code

compressors only) is

located on the metal data

plate which is welded on

to the backside of the air

tank.

MFG

No.

DeVilbiss Air Power Company • 213 Industrial Drive • Jackson, TN 38301-9615

Loading...

Loading...