DeVilbiss AGX-552, AGX-553 Operation Manual

1

Important:Read and follow all instructions and SAFETY PRECAUTIONS before using this equipment.

Retain for future reference.

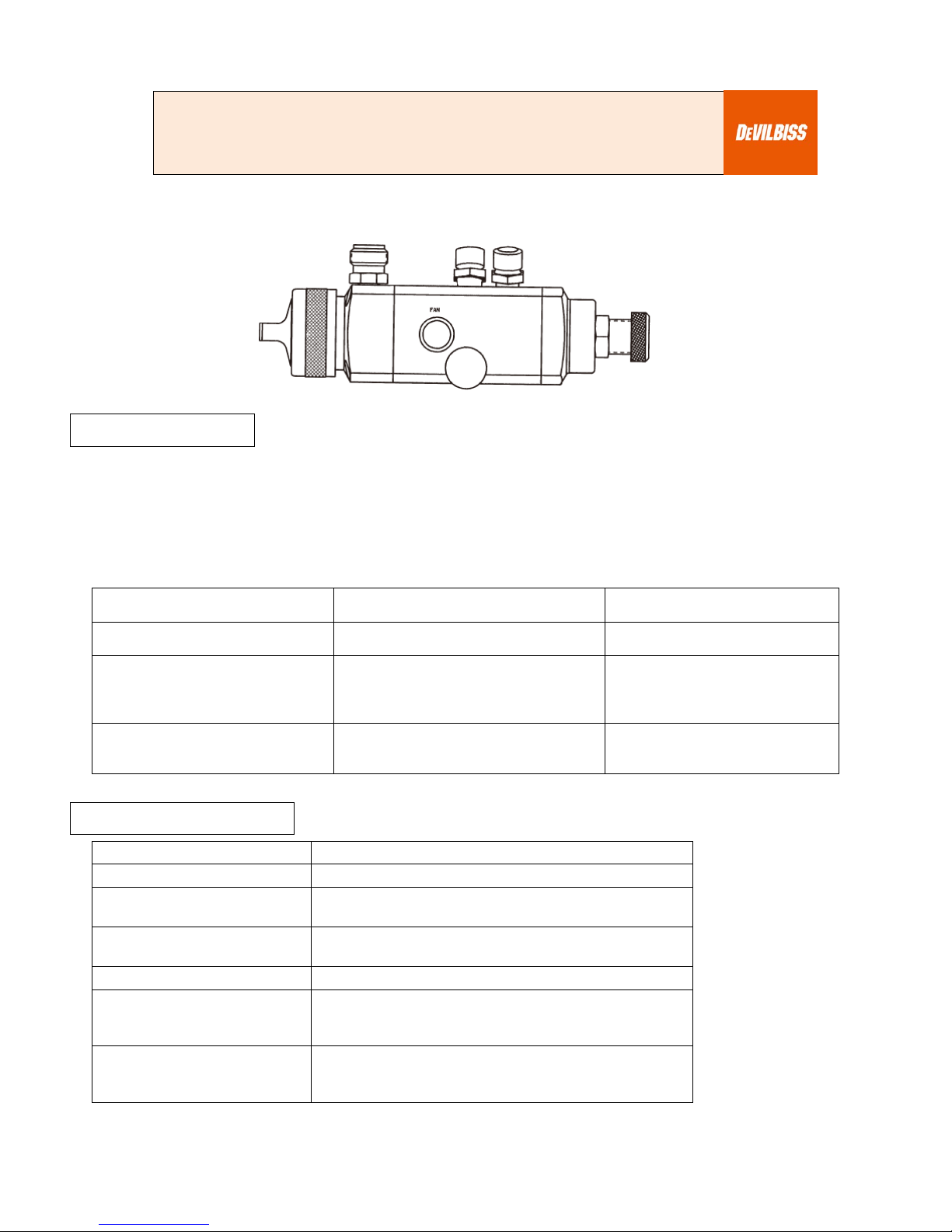

DESCRIPTION

The AGX spray gun is used on automatic and semi-automatic machines where mass production spraying of articles is

necessary or hand spraying is not accurate enough. Models and application information follows.

NOTE:

This gun may be used with chlorinated solvents. Aluminum is not used in fluid passages. If using chlorinated

solvents, make sure all other fluid handling components are also compatible.

Chart 1 MODELS

Model No.

(Available Tip Sizes)

Typical Applications Fluid Tip/Needle Construction

AGX-550 (AC, D, E, FF, FX, G)

Most conventional materials and most

waterbornes and chlorinated solvents.

400 Gr. Stainless

303 Gr. Stainless

AGX-552 (D, EE, FF)

Abrasive materials (i.e. porcelain

enamel, ceramic glazes, buffing

compounds) and/or water mix materials.

Includes abrasive fluid seal.

Carboloy, 400 Gr.

Stainless

AGX-553 (E, FF, FX)

Waterbornes and more corrosive

materials (below 7 pH)

303 Gr.Stainless

w/U.H.M.W.poly.

insert

SPECIFICATIONS

Max. Air Pressure

0.69MPa (100 psi)

Max. Fluid Pressure

0.69MPa (100 psi)

Cylinder Air Pressure

Min. 0.35MPa (*50 psi)

Max. 0.69MPa (100 psi)

Weight

without mounting stud 737g

with mounting stud 865g

Mounting Stud Diameter

3/4" (see Accessories for Optional 1/2" mounting)

Wetted Parts

AGX-550 300 & 400 Gr.Stainless, PTFE

AGX-552 300 & 400 Gr. S.S., carboloy, PTFE

AGX-553 300 Gr. S.S., PTFE, U.H.M.W. Poly.

Hose Connections

- Fluid Inlet 3/8" NPS(M)

- Cylinder Air 1/4" NPS(M)

- Atomization Air 1/4" NPS(M)

* For installations where 50 psi cylinder air is not available, the inner (red) piston spring can be removed which lowers the

minimum cylinder air to approximately 37 psi. Refer to Operations, page 5, paragraph 2.

AGX-550, AGX-552 & AGX-553

AUTOMATIC SPRAY GUNS OPERATION MANUAL

2

FLUID TIP ORIFICE SIZES

Letters on Tip

Inch

mm

AC

.110"

2.8

D

.086"

2.2 E .070"

1.8

EE

.070"

1.8

FF

.055"

1.4

FX

.042"

1.1 G .028"

0.7

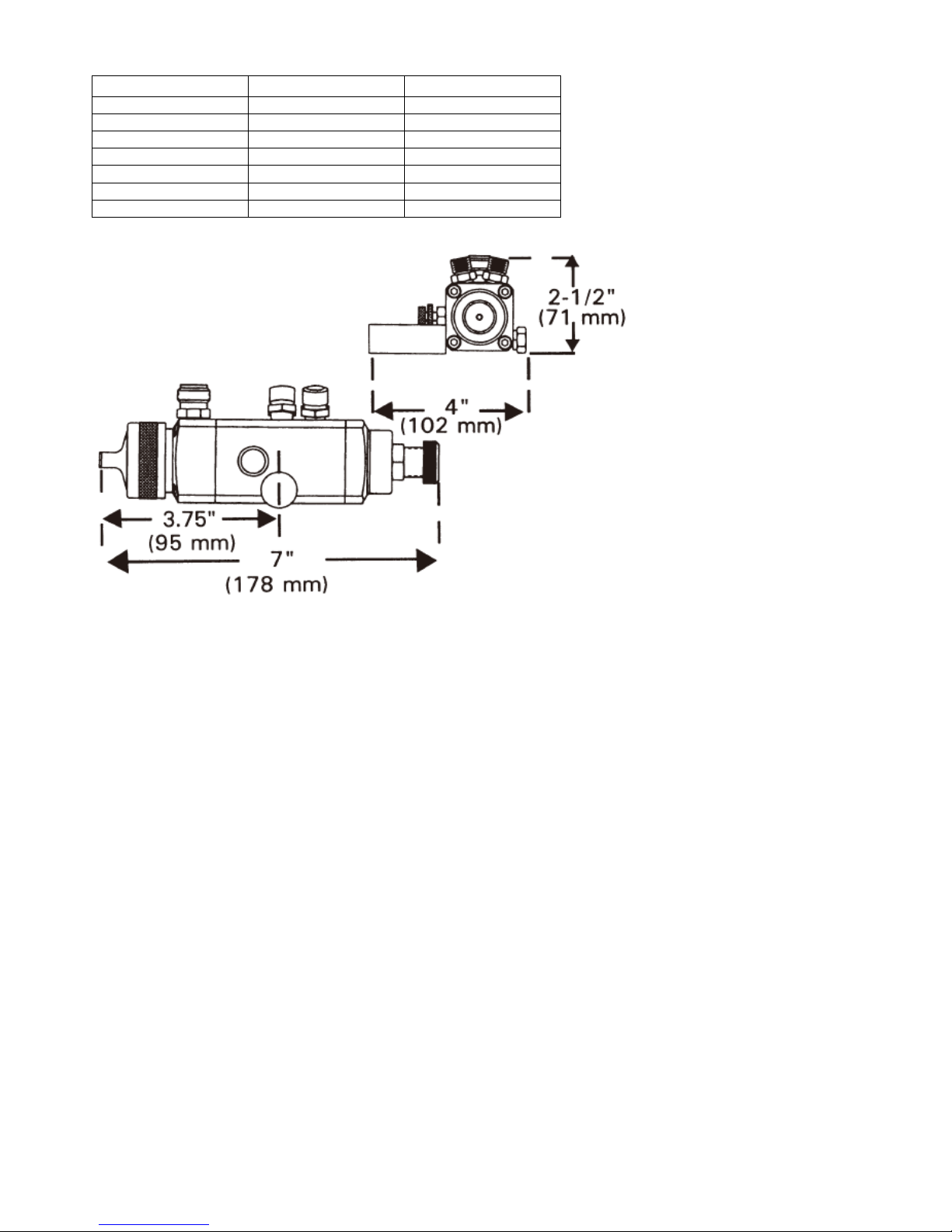

FIGURE 1 DIMENSIONS

Tools Required:

Adjustable wrench for hose connections

1/2" six point box wrench for Ref. (3)

9/16" open wrench for Ref. (9)

3/16" hex wrench for Ref. (6)

Long neck pliers for Ref. (19)

1/8" hex key for Ref. (24)

1/2" and 9/16" socket wrench for Ref. (3) (9)

3

SAFETY PRECAUTIONS

This manual contains important information that ALL users should know and understand BEFORE using this equipment. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the following terms to draw your attention to certain equipment labels and

portions of this manual. Pay special attention to any label or information that is highlighted by one of these terms:

PROP 65 WARNING

WARNING: This product contains chemicals known to the State of

California to cause

cancer and birth defects or other reproductive harm.

WARNING

Important information to alert you to a situation that might cause serious injury or loss of life if

instructions are not followed.

CAUTION

Important information that tells how to prevent damage to equipment.

NOTE

Information that you should pay special attention to.

WARNING

The following hazards may occur during the normal use of this equipment. Please read the following chart.

HAZARD

CAUSE

SAFEGUARDS

Fire Solvents and coatings can be highly

flammable or combustible, especially

when sprayed.

1. Adequate exhaust must be provided to keep

the air free of accumulations of flammable

vapors.

2. Smoking must never be allowed in the spray

area.

3. Fire extinguishing equipment must be

present in the spray area.

4. Static discharges must be prevented. Ground

(earth) all conductive objects in the spray

area, such as a cleaning solvent bucket, fire

extinguisher, etc.

5. When using solvents for cleaning:

• Those used for equipment flushing must

have a flash point equal to or greater than

that of the coating.

•

Those used for general cleaning must

have flash points above 100°F (37.8°C).

Inhaling Toxic Substances

Certain materials may be harmful if

inhaled or if there is contact with the

skin.

1. Follow the requirements of the Material

Safety Data Sheet supplied by coating

material manufacturer.

2. Adequate exhaust must be provided to keep

the air free of accumulations of toxic

materials.

3. Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The

mask must be compatible with the material

being sprayed and its concentration.

Equipment must be as prescribed by an

industrial hygienist or safety expert, and be

NIOSH approved.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon Solvents-

for example:

methylene chloride and

1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum can

become violent and lead to an

equipment explosion.

The AGXV spray gun can be used with these

solvents.

However, aluminum is widely used in other

spray application equipment – such as material

pumps, cups, regulators, valves, etc. Check all

other equipment items before use of these

solvents. Read the label or data sheet for the

material you intend to spray. If in doubt as to

where or not a coating or cleaning material is

compatible, contact your material supplier.

4

HAZARD

CAUSE

SAFEGUARDS

General Safety

Improper operation or maintenance

may create a hazard.

Operators should be given adequate training in

the safe use and maintenance of the equipment

(in accordance with the requirements of

NFPA-33, Chapter 15 in U.S.). Users must

comply with all local and national codes of

practice and insurance company requirements

governing ventilation, fire precautions, operation,

maintenance and housekeeping (in the U.S.,

these are OSHA Sections 1910.94 and

1910.107 and NFPA-33).

Noise Levels

The continuous A-weighted sound

pressure level of this spray gun may

exceed 85dB(A) depending on the

air cap/nozzle set-up being used.

Sound levels are measured using an

impulse sound level meter and

analyzer, when the gun is being used

in a normal spraying application.

Details of actual noise levels

produced by the various air

cap/nozzle set-ups are available on

request.

Wear earplugs when using the spray gun.

Spraying solvent

Pressured air/fluid passage may be

broken when cleaning or flashing

with solvent.

The solvent may be harmful if

contacted with eyes.

Always wear eye protection when spraying or

cleaning the equipment.

Misuse:

• All spray guns project particles at high velocity and must never be aimed t any part of body.

• Never exceed the recommended safe working pressure for any of the equipment used.

• The fitting of non-recommended or non-original accessories or spare parts may create hazardous conditions.

• Before dismantling the equipment for cleaning or maintenance, all pressures, air and material, must be isolated and

released.

Disposal of non-metallic materials must be carried out in an approved manner. Burning may generate toxic fumes.

The removal of waste solvents and coating materials should be carried out by an authorized local waste disposal service.

INSTALLATION

Mount the gun with the stud (13) or on a 5/16" dia. rod tightening adequately with the 1/4-28 X 1/4" set screws (Ref. No. 24).

See "ACCESSORIES" for mounting clamps.

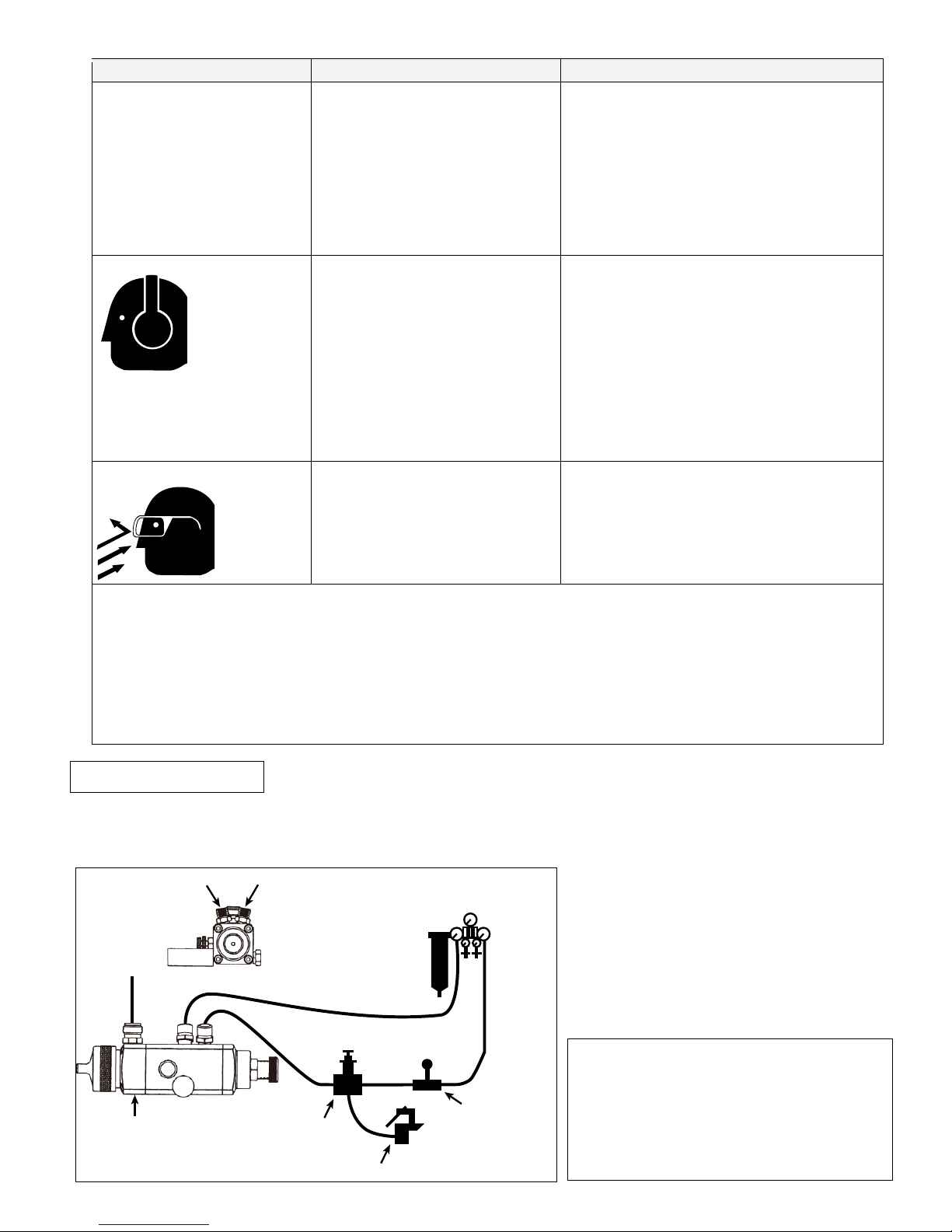

Figure 2. TYPICAL INSTALLATION

Trigger/

Cylinder Air

Atomization Air

Atomization Air

Trigger/

Cylinder Air

HFRL-511

Filter-Regulator

Fluid

Reciculating Port

Automatic Valve

Skip Spray Valve

3 Way Hand Valve

Attach trigger/cylinder air hose and atomization

air hose to connections as indicated by

markings on gun body. The air supply should be

filtered and regulated. Attach material hose to

fluid inlet on the body. Fluid can be recirculated

by installing a fluid fitting (AGX-415) (order

separately) at recirculating port. See Caution

below.

Loading...

Loading...