Page 1

Service Instruction

SI-6-18-12-C

Replaces SI-6-18-12-B

130526 THREE STAGE FILTER WITH REGULATORS

DESCRIPTION

The three stage filter unit, with two selfrelieving regulators, is designed to be a

point of use system. It is designed to

provide clean air for a paint spray gun,

breathable air unit and waterborne paint

dryers. It is capable of removing dirt,

water, oil, liquid aerosols, sub-micron

particles, oil vapors and odors.

SPECIFICATIONS

Air Flow: 65 SCFM @ 90 PSIG

Max. Pressure

: 150 PSIG

Max. Temperature: 150°F

Regulated Pressure Range: 2-125 psig

BREATHING AIR REQUIREMENTS

Supplied breathing air, as defined by

OSHA 29 CFR 1910.134(i), NIOSH 42 CFR

84.141, and CSA CAN 3-Z180.1-00 MUST

meet or exceed the following requirements

for Type 1-Grade D breathable air, as

defined in Compressed Gas Association

(CGA-G7-1-1997):

Contaminant

Oxygen

Carbon Monoxide

(ppm v/v)

Carbon Dioxide

(ppm v/v)

Oil (Condensed

Hydrocarbons)

3

mg/m

Odor

OSHA

19.5-23.5%

10

1,000

5

“lack of

noticable

odor”

CSA

20-22%

<5m L /m

500m L /m

1mg/m

“free of any

detectable

odor”

3

3

3

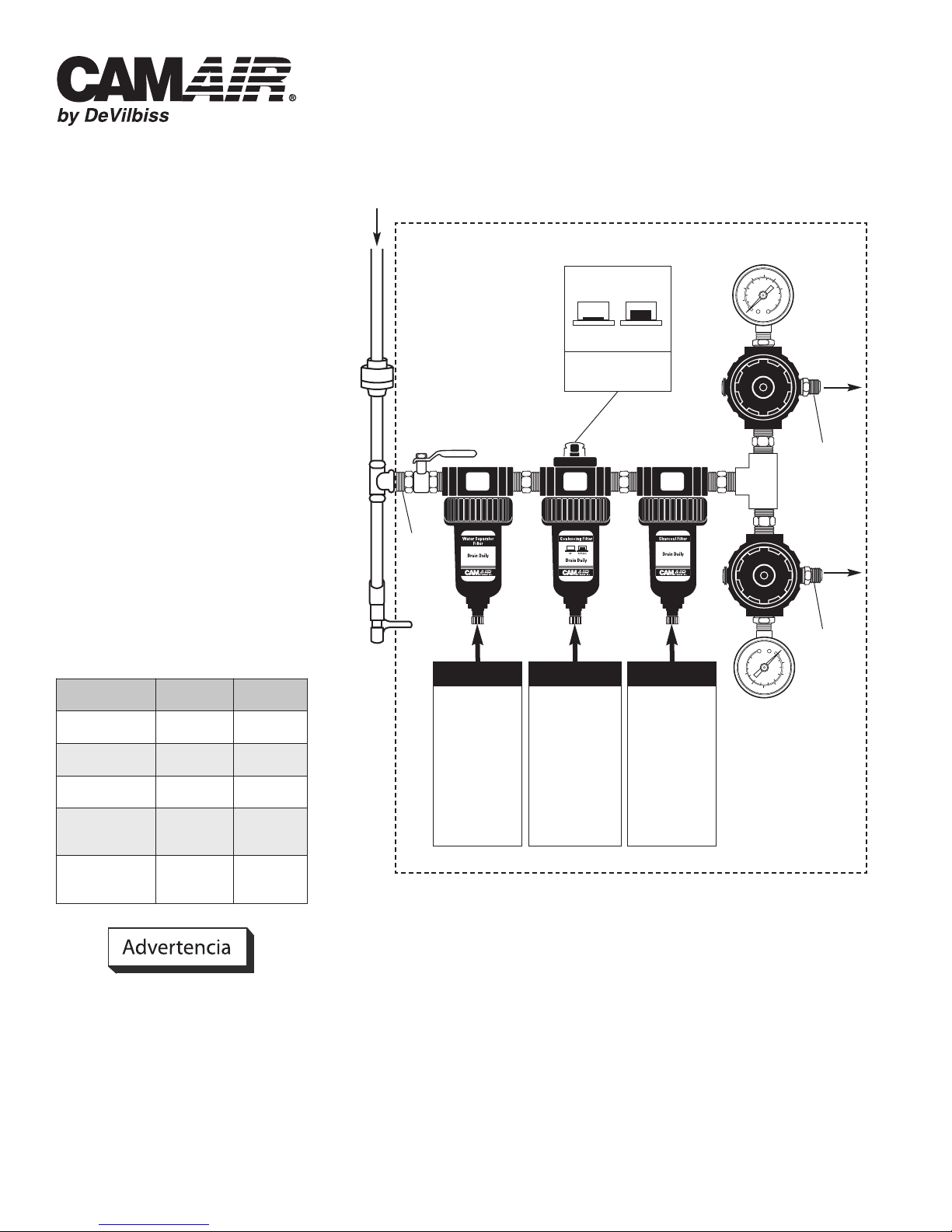

INLET AIR

DRAIN

UNION

1/2 NPT

1ST STAGE

Liquid & dirt

removal

40 microns

Replace

element

every

3 months

RECOMMENDED INSTALLATION

130526 ASSEMBLY

REPLACEMENT

INDICATOR

OK REPLACE

ELEMENT

CHECK WITH

AIR FLOWING

2ND STAGE

Liquid aerosol

& sub-micron

particle

removal

0.01 microns

Replace

element

when

indicator is

raised halfway

3RD STAGE

Charcoal

adsorber

Oil vapor &

odor removal

Replace

element every

six weeks

(or sooner

if odors

are present)

OUTLET

AIR

1/4 NPSM

OUTLET

OUTLET

AIR

1/4 NPSM

OUTLET

Risk of illness or death. Carbon monoxide

can cause nausea, fainting or death. Stop

using if carbon monoxide is present. This

unit does not remove carbon monoxide. A

carbon monoxide monitor should be incorporated into your air supply line to warn of

the presence of carbon monoxide.

It is up to the employer to assure that the

air compressor is properly maintained, that

the air compressor intake is located in a

clean contaminate free location and that

the air compressor is drawing in typical

atmospheric air, meeting all of the national

and local requirements for breathing air.

This filter unit does not remove or filter

Carbon Monoxide (CO). It is up to the

employer to ensure that the level of CO

does not exceed the maximum national or

local allowed level. The recommended

method to assure that the CO level is not

exceeded is to install a carbon monoxide

monitor and alarm.

This filter unit will only remove particulate

matter, water, oil and odor. This filter unit

will meet the particulate matter, oil and

odor requirements of Type 1-Grade D

Breathable Air and Compressed Breathing

Air, CSA-Z180.1 when:

• The filter unit is connected to a

compressed air source:

The compressor is properly main-

°

tained

The air compressor intake is located

°

in a clean contaminate free location

The air compressor is drawing in

°

typical atmospheric air, meeting all of

the national and local requirements

for breathing air

• The filters are properly maintained

• A properly operating CO monitor is

installed

Page 2

Page 2 SI-6-18-12-C

INSTALLATION

RISK OF PERSONAL INJURY

RISK OF PROPERTY DAMAGE

Except as otherwise specified by the

manufacturer, this product is specifically

designed for com pressed air service and

use with any other fluid (liquid or gas) is

a misapplication. For example, use with

or injection of certain hazardous gases in

the system (such as oxygen or liquid

petroleum gas) could be harmful to the

unit or result in a combustible condition

that may cause fire or explosion.

Manufacturer’s war ranties are void in the

event of misapplication and manufacturer assumes no responsibility for any

resulting loss.

1. Install as shown on page one.

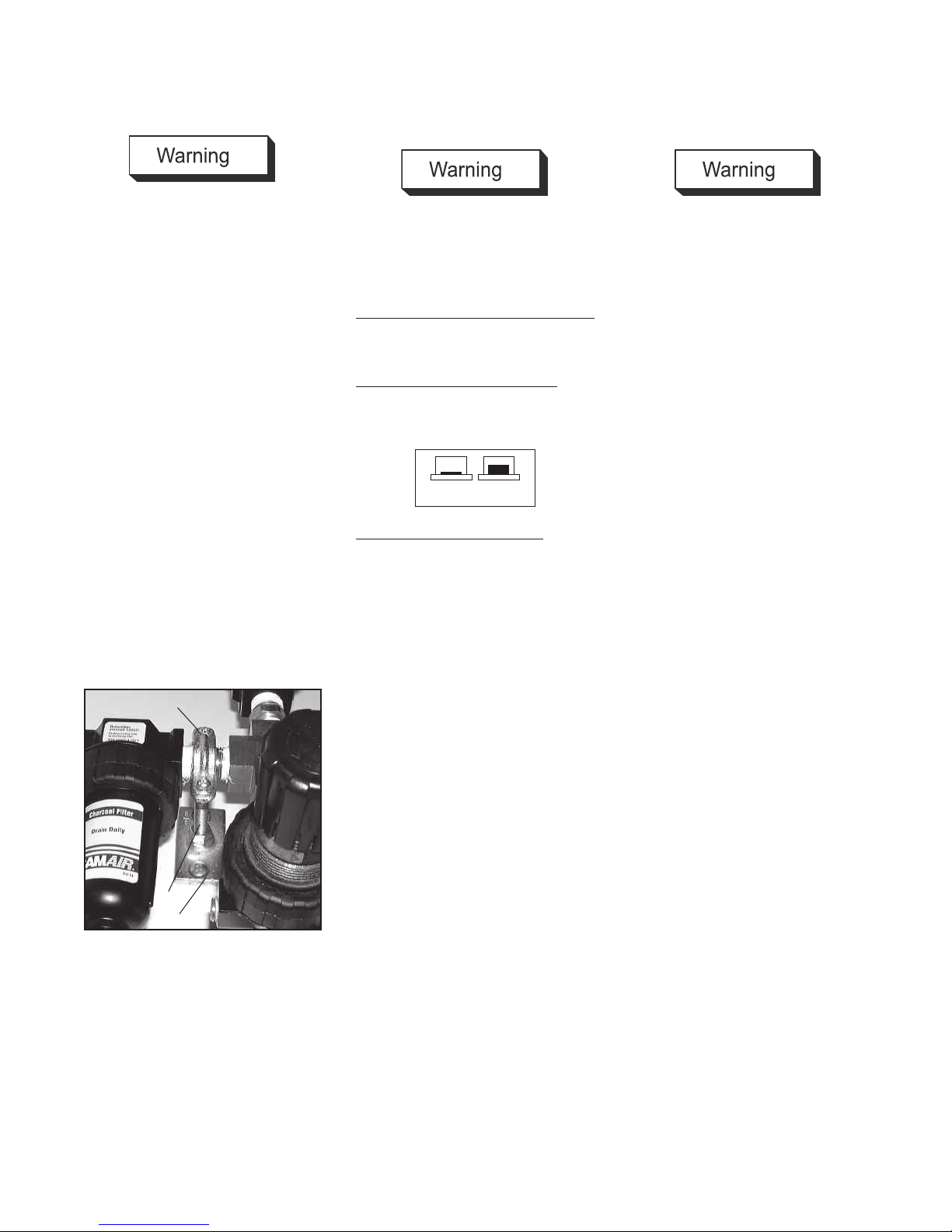

2. For an inexpensive wall bracket,

purchase the following parts at your

local hardware store:

A Split Ring Hanger, 3/4”

B Threaded Rod

C Ceiling Flange

(See Figure 1 below)

MAINTENANCE, FILTERS

(SEE PAGE 3)

RISK OF PERSONAL INJURY

Components are under pressure. Relieve

air pressure before performing any

maintenance.

1ST STAGE WATER SEPARATOR FILTER

1. Daily, twist drain to remove liquid.

2. Every 3 months, replace element.

2ND STAGE COALESCING FILTER

1. Daily, twist drain to remove liquid.

2. Daily, check replacement indicator

(with air flowing.)

OK REPLACE

ELEMENT

3RD STAGE ADSORBER FILTER

1. Daily, twist drain to remove liquid.

2. Replace charcoal element every six

weeks (or sooner if odors are

present.)

MAINTENANCE, REGULATOR

(SEE PAGE 3)

RISK OF PERSONAL INJURY

Components are under pressure. Relieve

air pressure before performing any

maintenance. Rotate regulator knob

fully counter-clockwise to relieve regulator spring pressure.

FIGURE 1

A

B

C

Page 3

Page 3SI-6-18-12-C

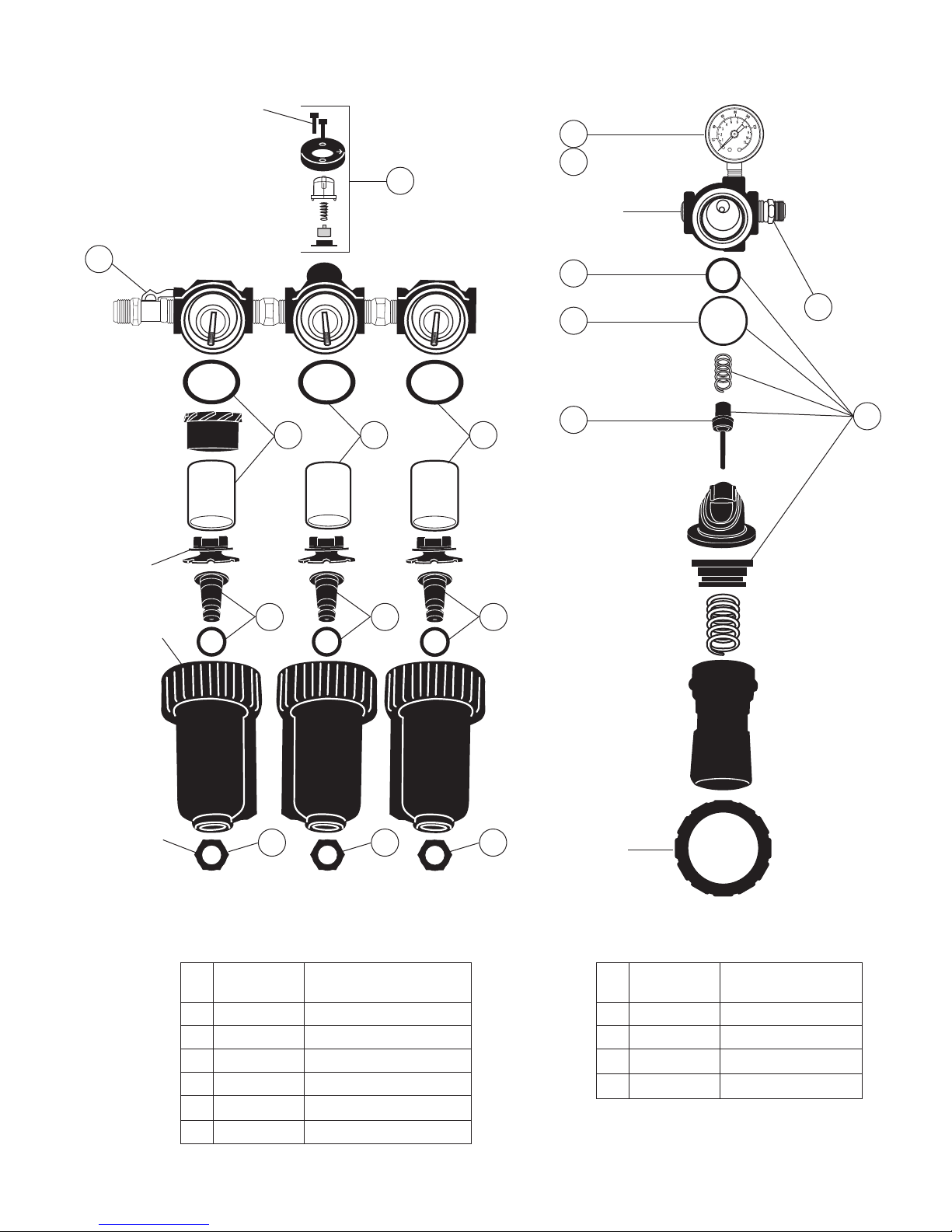

Snug tight

3

4

4

Note parts

orientation when

disassembling

Plug

5

*

2

*

Hand tight

Hand tight

plus 1/4 turn

Snug tight

2 3 6

1

1 1

1 1

1

*

*Lightly grease

with enclosed

lubricant

Handtight

plus 1/4 turn

1

PARTS LIST

Ref. Replacement

No. Part No. Description

1 130519 Drain Kit (one set)

2 130517 Filter Element, Water

3 130518 Filter Element, Coalescing

4 130520 Indicator Kit, Coalescing

5 VA-595 Shut-off Valve

6 130527 Filter Element, Charcoal

PARTS LIST

Ref. Replacement

No. Part No. Description

1 130521 Regulator Kit

2 H-2008 Adapter

3 GA-288 Gauge

4 GA-375 Gauge, Upside Down

Page 4

Instrucciones de servicio

SI-6-18-12-C

Substituye SI-6-18-12-B

130526 FILTRO DE TRES ETAPAS CON REGULADORES

DESCRIPCIÓN

La unidad del filtro de tres etapas, con dos

reguladores autodescargantes, está

diseñada para ser un sistema de punto de

uso. Está diseñada para proporcionar aire

limpio a una pistola pulverizadora de

pintura, unidad de aire respirable y

secadores de pintura transportada por

agua. Tiene capacidad para eliminar polvo,

agua, aceite, aerosoles líquidos, partículas

de submicro

nes, vapores de aceite y

olores.

ESPECIFICACIONES

Corriente de aire: 65 SCFM @ 90 PSIG

Presión máxima: 150 PSIG

Temperatura máxima: 150°F

Rango de presión regulada: De 2 a 125 psig

REQUISITOS DEL AIRE RESPIRABLE

El aire respirable suministrado, como lo

definen los estándares de la OSHA 29 CFR

1910.134(i), NIOSH 42 CFR 84.141 y CSA

CAN 3-Z180.1-00 DEBE satisfacer o exceder

los siguientes requisitos para el aire

pirable Tipo 1-Grado D, como lo define

res

la Asociación de Aire Comprimido (CGAG7-1-1997):

Contaminante

Oxígeno

Monóxido de

carbono (ppm v/v)

Anhídrido carbónico

(ppm v/v)

Aceite (hidrocarbonos condensados)

3

mg/m

Olor

OSHA

De 19.5 a 23.5%

10

1,000

5

“falta de olor

perceptible”

CSA

De 20 a 22%

3

<5m L /m

500m L /m

3

1mg/m

“libre de

cualquier olor

detectable”

3

Riesgo de enfermedad o muerte. El

monóxido de carbono puede producir

náusea, desmayo o la muerte. Deje de usar

la unidad si hubiese monóxido de carbono.

Esta unidad no elimina el monóxido de

carbono. Se debe incorporar a su línea de

suministro de aire un monitor de

monóxido de carbono para advertir sobre

la presencia de

monóxido de carbono.

Depende del empleador asegurar que el

compresor de aire reciba el debido

mantenimiento, que la entrada de aire del

compresor de aire se encuentre en un

lugar limpio y libre de contaminación y

AIRE DE ENTRADA

INSTALACIÓN RECOMENDADA

UNIÓN

1/2 NPT

DRENAJE

1aETAPA

Eliminación

de líquido

y polvo

40 micrones

Reemplace

el elemento

cada

2aETAPA

Eliminación de

aerosol líquido

y partículas de

submicrones

0.01 micrones

Reemplace

el elemento

3 meses

el indicador

haya subido

que el compresor de aire esté aspirando

aire atmosférico típico, cumpliendo con

todos los requisitos nacionales y locales

para el aire respirable.

Esta unidad de filtro no elimina ni filtra el

monóxido de carbono (CO). Depende del

empleador asegurar que el nivel de CO no

sobrepase el nivel máximo permitido a

escala nacional o local. El método

recomendado para asegurar que no se

sobrepase el nivel permitido d

e CO es

instalar un monitor y alarma de monóxido

de carbono.

Esta unidad de filtro sólo eliminará

macropartículas, agua, aceite y olor. Esta

unidad de filtro cumplirá con los requisitos

de macropartículas, aceite y olor del aire

respirable Tipo 1-Grado D y del aire

respirable comprimido, CSA-Z180.1

cuando:

130526 CONJUNTO

INDICADOR DE

REEMPLAZO

OK REEMPLACE

EL ELEMENTO

REVISE CON

EL AIRE

FLUYENDO

Reemplace el

cuando

elemento cada

seis semanas

a la mitad

hubiese olor)

• La unidad de filtro esté conectada en una

fuente de aire comprimido:

• Los filtros reciban el debido mantenimiento

Se instale un monitor de CO que opere

•

debidamente

AIRE DE

SALIDA

1/4 NPSM

SALIDA

AIRE DE

SALIDA

1/4 NPSM

SALIDA

3aETAPA

Adsorbedor

de carbón

Eliminación

del vapor de

aceite y los

olores

(o antes si

El compresor reciba el debido

°

mantenimiento

La entrada de aire del compresor de

°

aire se encuentre en un lugar limpio y

libre de contaminación

El compresor de aire esté aspirando

°

aire atmosférico típico, cumpliendo

con todos los requisitos nacionales y

locales para el aire respirable

Page 5

Página 5SI-6-18-12-C

INSTALACIÓN

RIESGO DE LESIÓN PERSONAL

RIESGO DE DAÑO A LA PROPIEDAD

Excepto lo especificado en contrario por

el fabricante, este producto está

diseñado específicamente para servicio

de aire comprimido y su uso con

cualquier otro fluido (líquido o gas) es

una aplicación indebida. Por ejemplo, su

uso con, o la inyección en el sistema de

ciertos gases peligrosos (como oxígeno o

gas de petróleo líquido), podría ser perjudicial para la unidad o producir una

condición combustible que podría causar

un incendio o explosión. Las garantías

del fabricante son nulas en caso de aplicación indebida y el fabricante no asume

ninguna responsabilidad por cualquier

pérdida que resulte de la misma.

1. Instalar como se muestra en la página

uno.

2. Para un soporte mural barato, compre

las siguientes piezas en la ferretería

de su localidad:

A Soporte colgante circular

hendido de 1.9 cm (3/4”)

B Varilla roscada

C Aleta de montaje en el cielorraso

(Ver figura 1 abajo)

MANTENIMIENTO, FILTROS

(VER PÁGINA 6)

RIESGO DE LESIÓN PERSONAL

Los componentes se encuentran bajo

presión. Reduzca la presión del aire

antes de realizar cualquier trabajo de

mantenimiento.

1a ETAPA FILTRO DEL SEPARADOR DE

AGUA

1. Diariamente, torsione el drenaje para

eliminar líquido.

2. Cada 3 meses, reemplace el

elemento.

2a ETAPA FILTRO COALESCENTE

1. Diariamente, torsione el drenaje para

eliminar líquido.

2. Diariamente, revise el indicador de

reemplazo (con el aire fluyendo).

OK REEMPLACE

EL ELEMENTO

3a ETAPA FILTRO COALESCENTE

1. Diariamente, torsione el drenaje para

eliminar líquido.

2. Cada seis semanas (o antes si

hubiese olor), reemplace el elemento

de carbón.

MANTENIMIENTO, REGULADOR

(VER PÁGINA 6)

RIESGO DE LESIÓN PERSONAL

Los componentes se encuentran bajo

presión. Reduzca la presión del aire

antes de realizar cualquier trabajo de

mantenimiento. Haga girar totalmente

la perilla del regulador en sentido antihorario para reducir la tensión de

resorte del regulador.

FIGURA 1

A

B

C

Page 6

Página 6 SI-6-18-12-C

Apriete para que

encaje bien

5

4

Anote la

orientación de

las piezas al

desensamblar

3

4

Tapón

*

2

*

Apriete a

mano

Apriete

a mano

dando

un 1/4

de vuelta

adicional

Apriete para

que encaje

bien

2 3 6

1

1 1

1 1

1

*

*Engrase ligeramente

con el lubricante

adjunto

Apriete

a mano

dando

un 1/4

de vuelta

adicional

1

LISTA DE PIEZAS

Ref. Refacción

No. No. Descripción

1 130519 Kit de drenaje (un juego)

2 130517 Elemento de filtro, agua

3 130518

4 130520

5 VA-595 Válvula de cierre

6 130527 Elemento de filtro, carbon

Elemento de filtro, coalescente

Kit del indicador, coalescente

LISTA DE PIEZAS

Ref. Refacción

No. No. Descripción

1 130521 Kit del regulador

2 H-2008 Adaptador

3 GA-288 Calibrador

4 GA-375 Calibrador, Invertido

Page 7

Directives d'entretien

SI-6-18-12-C

Remplace SI-6-18-12-B

130526 FILTRE TRIPHASÉ AVEC RÉGULATEURS

DESCRIPTION

L’unité de filtre triphasé, muni de deux

régulateurs à décharge automatique, est

conçu comme système de point d’utilisation. Il est conçu pour fournir de l'air

propre aux pistolets pulvérisateurs de

peinture, unités d’air respirable et séchoirs

de peinture à base d’eau. Il peut enlever la

saleté, l'eau, l'huile, les aérosols liquides,

les particules submicroniques, les

vapeurs

d'huile et les odeurs.

CARACTÉRISTIQUES

Pression d’air : 65 SCFM @ 90 PSIG

Pression maximale : 150 PSIG

Température maximale : 150°F (65,56°C)

Plage de pression régulée : 2 à 125 psig

EXIGENCES CONCERNANT L’AIR

RESPIRABLE

L’air respirable fourni, tel que défini par les

normes OSHA 29 CFR 1910.134(i), NIOSH

42 CFR 84.141, et CSA CAN 3-Z180.1-00

DOIT se conformer ou dépasser les

exigences suivantes pour l’air respirable

de Type 1-Grade D, tel que défini par la

Compressed Gas Association (CGA-G7-1-

1997).

Contaminant

Oxygène

Monoxyde de

carbone (ppm v/v)

Dioxyde de

carbone (ppm v/v)

Huile (hydrocarbures condensés)

3

mg/m

Odeur

OSHA

19.5-23.5%

10

1,000

5

« absence

d’odeur

prononcée »

CSA

20-22%

3

<5m L /m

3

500m L /m

3

1mg/m

« libre de toute

odeur

décelable »

Risque de maladie ou de mort. Le

monoxyde de carbone peut causer des

nausées, des évanouissements ou la mort.

Discontinuer l’usage en présence de

monoxyde de carbone. Cet unité n’enlève

pas le monoxyde de carbone. Un moniteur

de monoxyde de carbone doit être ajouté à

la conduite d’alimentation en air afin de

gnaler la présence de monoxyde de

si

carbone.

L’utilisateur doit s’assurer que le

compresseur d’air est entretenu correcte-

ENTRÉE D'AIR

INSTALLATION RECOMMANDÉE

130526 ASSEMBLY

REMPLACEMENT

RACCORD UNION

1/2 NPT

DRAIN

ÈRE

1

PHASE

Retire

les saletés

et liquides

40 microns

Remplacer l’élé-

ment tous les 3

mois

2EPHASE

Retire

les particules

microniques et

aérosols liquides

0,01 microns

Remplacer l’élé-

ment lorsque

l’indicateur

s’élève à la ligne

médiane

ment, que l’orifice d’aspiration du

compresseur d’air se trouve dans un

endroit propre et libre de contaminants et

que le compresseur d’air aspire de l’air

atmosphérique type qui répond à tous les

règlements nationaux et locaux concernant l’air respirable.

Cet unité de filtre n’enlève ni ne filtre le

monoxyde de carbone (CO). L’utilisateur

doit s’assurer que le niveau de CO ne

dépasse pas le niveau maximal

permis par

les réglementations locales et nationales.

La méthode recommandée pour vérifier

que le niveau de CO est admissible est d'in-

staller un analyseur de monoxyde de

carbone avec alarme.

Cet unité de filtre n’enlève que les particules, l’eau, l’huile et les odeurs. Cet unité

de filtre répondra aux exigences concernant les particules, l’huile et les odeurs de

TÉMOIN DE

OK

REMPLACER

L'ÉLÉMENT

VÉRIFIER

AVEC L’AIR

EN MARCHE

3EPHASE

Adsorbeur de

charbon de bois

Retire les

vapeurs d’huile

et les odeurs

Remplacer l’élé-

ment toutes les

six semaines (ou

plus souvent en

présence

d’odeurs)

la norme CSA-Z180.1, Air comprimé

respirable de Type 1-Grade D et systèmes

connexes, lorsque :

• l’unité de filtre est connecté à une source

d’air comprimé :

le compresseur est entretenu

°

correctement

l’orifice d'aspiration du compresseur

°

d'air se trouve dans un endroit propre

et libre de contaminants

le compresseur d’air aspire de l’air

°

atmosphérique type, répondant à

tous les règlements nationaux et

caux concernant l’air respirable

lo

• les filtres sont entretenus correctement

• un analyseur de CO en état de fonctionnement est installé

SORTIE

D'AIR

1/4 NPSM

SORTIE

SORTIE

D'AIR

1/4 NPSM

SORTIE

Page 8

Page 8 SI-6-18-12-C

INSTALLATION

RISQUE DE BLESSURES CORPORELLES

RISQUE DE DOMMAGES MATÉRIELS

Sauf indication contraire spécifiée par le

fabricant, ce produit est spécialement

conçu pour pour l’alimentation en air

comprimé et l’utilisation avec tout autre

fluide (liquide ou gaz) est interdite. Par

exemple, l’utilisation avec ou l’injection

dans le système de certains gaz nocifs

(tels que l’oxygène ou le gaz de pétrole

liquéfié) peut être nocif à l’unité ou

entraîner un état combustible qui pourrait cause un incendie ou une explosion.

Les garanties du fabricants seront

annulées en cas de mauvaise utilisation

et le fabricant n’accepte aucune responsabilité pour toute perte éventuelle.

1. Effectuer l’installation tel qu’illustré à

la première page.

2. Pour un support mural peu

dispendieux, acheter les pièces suivantes dans un magasin de quincaillerie :

A Support pour anneau brisé,

1,9 cm (3/4 po.)

B Tige filetée

C Bride de fixation au plafond

(Voir la figure 1 ci-dessous)

ENTRETIEN, FILTRES

(VOIR LA PAGE 6)

RISQUE DE BLESSURES CORPORELLES

Les composantes sont sous pression.

Décharger la pression d’air avant d’effectuer toute intervention.

ÈRE

1

PHASE FILTRE SÉPARATEUR D’EAU

1. Tous les jours, tourner le drain pour

vider le liquide.

2. Tous les 3 mois, remplacer l’élément.

2EPHASE FILTRE COALESCENT

1. Tous les jours, tourner le drain pour

vider le liquide.

2. Tous les jours, vérifier le témoin de

remplacement (avec l’air en marche)

OK

REMPLACER

L'ÉLÉMENT

3EPHASE FILTRE ADSORBANT

1. Tous les jours, tourner le drain pour

vider le liquide.

2. Remplacer l’élément de charbon de

bois toutes les six semaines (ou plus

souvent en présence d’odeurs).

ENTRETIEN, RÉGULATEUR

(VOIR LA PAGE 6)

RISQUE DE BLESSURES CORPORELLES

Les composantes sont sous pression.

Décharger la pression d’air avant d’effectuer toute intervention. Tourner le

bouton du régulateur à fond dans le

sens antihoraire pour décharger la pression du ressort du régulateur.

FIGURE 1

A

B

C

Page 9

Page 9SI-6-18-12-C

Bien resserrer.

3

4

4

Prendre note de

l'orientation des

pièces lors du

démontage.

Bouchon

5

*

2

*

Resserrer

à la main.

Resserrer à

la main plus

1/4 de tour.

Bien resserrer.

2 3 6

1

1 1

1 1

1

*

*Lubrifier légèrement

avec le lubrifiant

fourni

Resserrer à

la main plus

1/4 de tour.

1

LISTE DES PIÈCES

N° de

No de pièce

réf.

détachée Description

1 130519 Trousse de drain (une trousse)

2 130517 Élément du filtre, eau

3 130518 Élément du filtre, coalescent

4 130520 Trousse de témoin, coalescent

5 VA-595 Robinet d'arrêt

6 130527 Trousse de témoin, fusain

LISTE DES PIÈCES

Ref. Replacement

No. Part No. Description

1 130521 Trousse de régulateur

2 H-2008 Adaptateur

3 GA-288 Jauge

4 GA-375 Jauge, inversée

Page 10

Page 10 SI-6-18-12-C

NOTES / NOTAS

Page 11

NOTES / NOTAS

Page 11SI-6-18-12-C

Page 12

Page 12 SI-6-18-12-C

POLÍTICA DE GARANTÍAS

Los productos DeVilbiss están cubiertos por la garantía limitada de materiales y mano de obra por un año de Carlisle Fluid Technologies. El uso de cualquier

pieza o accesorio de una fuente que no sea Carlisle Fluid Technologies, anulará todas las garantías. Para obtener información especíca sobre la garantía,

favor ponerse en contacto con el local de Carlisle Fluid Technologies más cercano a usted entre los listados a continuación.

DeVilbiss Automotive Renishing es parte de Carlisle Fluid Technologies, un líder global en tecnologías

de acabados innovadores. Para asistencia técnica o para localizar un distribuidor autorizado, póngase en

contacto con uno de nuestros centros internacionales de ventas y apoyo al cliente listados.

EE.UU/Canadá

www.autorenishdevilbiss.com

askus@carlisleft.com

México

www.autorenishdevilbiss.com.mx

Tel gratuito: 1-888-835-6232 USA

Tel gratuito: 1-800-445-3988

Fax gratuito: 1-800-445-6643

Carlisle Fluid Technologies se reserva el derecho de modicar las especicaciones del equipo sin previo aviso. DeVilbiss®, Ransburg®, ms®, BGK®,

Binks®, TEKNA®, FinishLine®, StartingLine®, CamAir®, CVi®, PLUS®, GTi®, y PRi® son marcas registradas de Carlisle Fluid Technologies, Inc.

CONDITIONS DE GARANTIE

Les produits DeVilbiss sont couverts contre les vices de matériel et de fabrication par une garantie limitée d’un an de Carlisle Fluid Technologies.

L’utilisation de toutes pièces ou accessoires issus d’une source autre que Carlisle Fluid Technologies, annulera toutes les garanties. Pour des informations

précises sur la garantie, veuillez contacter le site de Carlisle Fluid Technologies le plus proche, que vous trouverez sur la liste ci-dessous.

DeVilbiss Automotive Renishing fait partie de Carlisle Fluid Technologies, un leader mondial dans le

domaine des technologies innovatrices de nition. Pour toute assistance technique ou pour localiser un

distributeur agréé, veuillez contacter l’un de nos bureaux de ventes internationaux et de soutien client.

USA/Canada

www.autorenishdevilbiss.com

askus@carlisleft.com

Mexique

www.autorenishdevilbiss.com.mx

Tél sans frais: 1-888-835-6232 USA

Tél sans frais: 1-800-445-3988

Fax sans frais: 1-800-445-6643

Carlisle Fluid Technologies se reserve le droit de modier sans préavis les spécications de l’équipement. DeVilbiss®, Ransburg®, ms®, BGK®, Binks®,

TEKNA®, FinishLine®, StartingLine®, CamAir®, CVi®, PLUS®, GTi®, et PRi® sont des marques de commerce déposées de Carlisle Fluid Technologies, Inc.

WARRANTY POLICY

DeVilbiss products are covered by Carlisle Fluid Technologies one year materials and workmanship limited warranty. The use of any parts or accessories,

from a source other than Carlisle Fluid Technologies, will void all warranties. For specic warranty information please contact the closest Carlisle Fluid

Technologies location listed below.

DeVilbiss Automotive Renishing is part of Carlisle Fluid Technologies, a global leader in innovative nishing

technologies. For technical assistance or to locate an authorized distributor, contact one of our international

sales and customer support locations.

USA/Canada

www.autorenishdevilbiss.com

askus@carlisleft.com

Toll Free Tel: 1-800-445-3988

Toll Free Fax: 1-800-445-6643

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice. DeVilbiss®, Ransburg®, ms®, BGK®, Binks®,

TEKNA®, FinishLine®, StartingLine®, CamAir®, CVi®, PLUS®, GTi®, and PRi® are registered trademarks of Carlisle Fluid Technologies, Inc.

Mexico

www.autorenishdevilbiss.com.mx

Toll Free Tel: 1-888-835-6232 USA

8/17 ©2017 Carlisle Fluid Technologies, Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...