Page 1

DEVELOP

SERVICE MANUAL

THEORY OF OPERATION

QC 2235plus

Page 2

Page 3

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand

them before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this product as well as

the risk of damage to the product, Develop GmbH. (hereafter called the Develop) strongly

recommends that all servicing be performed only by Develop-trained service technicians.

Changes may have been made to this product to improve its performance after this Service

Manual was printed. Accordingly, Develop does not warrant, either explicitly or implicitly,

that the information contained in this Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to

the product while servicing the product for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the

course of technical training and even after that, for performing maintenance and control of

the product properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION

In this Service Manual, each of three expressions " DANGER", " WARNING", and

" CAUTION" is defined as follows together with a symbol mark to be used in a limited

meaning.

When servicing the product, the relevant works (disassembling, reassembling, adjustment,

repair, maintenance, etc.) need to be conducted with utmost care.

DANGER: Action having a high possibility of suffering death or serious injury

WARNING: Action having a possibility of suffering death or serious injury

CAUTION: Action having a possibility of suffering a slight wound, medium

Symbols used for safety and important warning items are defined as follows:

:Precaution when servicing the

product.

:Prohibition when servicing the

product.

:Direction when servicing the

product.

trouble, and property damage

General

precaution

General

prohibition

General

instruction

S-1

Electric hazard High temperature

Do not touch

with wet hand

Unplug Ground/Earth

Do not

disassemble

Page 4

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

SAFETY WARNINGS

[1] MODIFICATIONS NOT AUTHORIZED BY DEVELOP GMBH

Develop brand products are renowned for their high reliability. This reliability is achieved

through high-quality design and a solid service network.

Product design is a highly complicated and delicate process where numerous mechanical,

physical, and electrical aspects have to be taken into consideration, with the aim of arriving

at proper tolerances and safety factors. For this reason, unauthorized modifications involve

a high risk of degradation in performance and safety. Such modifications are therefore

strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

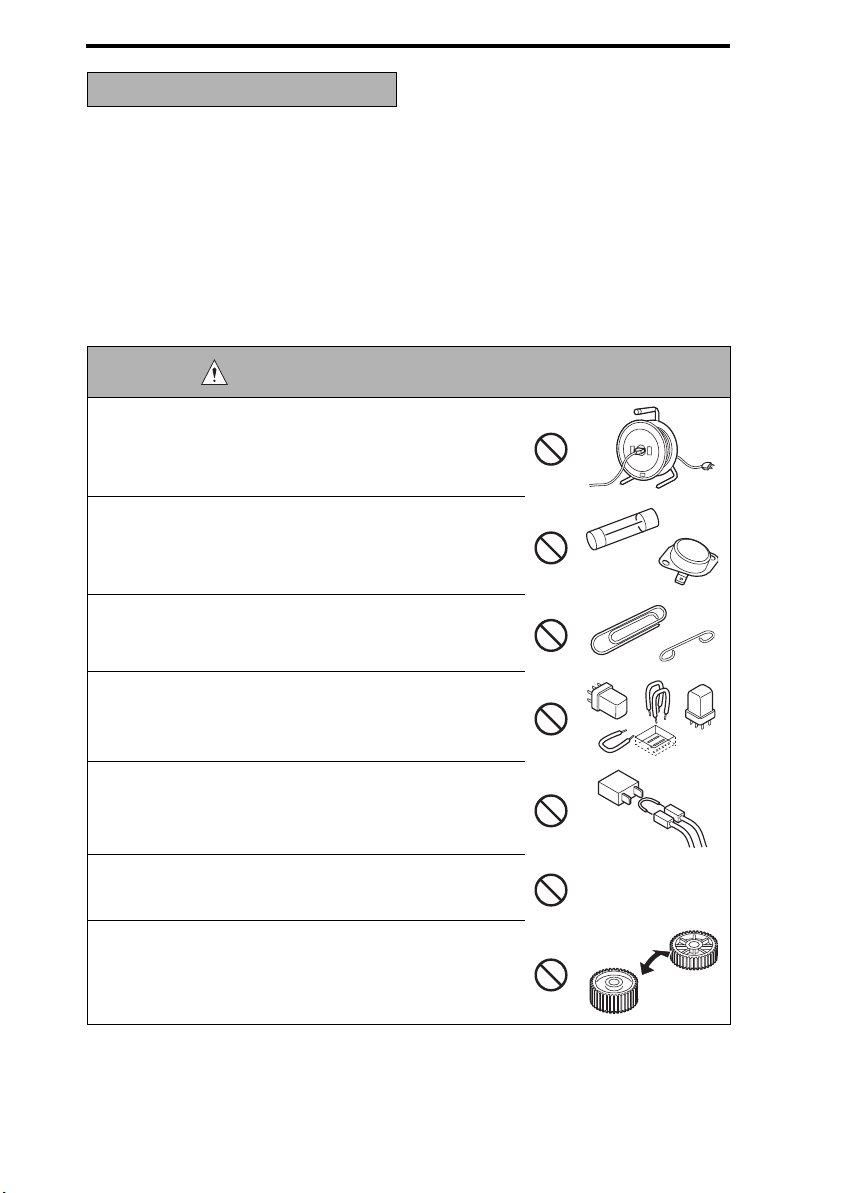

DANGER : PROHIBITED ACTIONS

• Using any cables or power cord not specified by Develop.

• Using any fuse or thermostat not specified by Develop.

Safety will not be assured, leading to a risk of fire and

injury.

• Disabling fuse functions or bridging fuse terminals with

wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between

relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.)

Safety will not be assured, leading to a risk of fire and

injury.

• Making any modification to the product unless instructed

by Develop

• Using parts not specified by Develop

S-2

Page 5

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

[2] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Develop brand products are extensively tested before shipping, to ensure that all applicable

safety standards are met, in order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical equipment

may be subject to parts wear and eventual failure. In order to maintain safety and reliability,

the CE must perform regular safety checks.

1. Power Supply

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power

cord into the dedicated wall outlet with a capacity greater

than the maximum power consumption.

If excessive current flows in the wall outlet, fire may

result.

• If two or more power cords can be plugged into the wall

outlet, the total load must not exceed the rating of the wall

outlet.

If excessive current flows in the wall outlet, fire may

result.

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet

securely.

Contact problems may lead to increased resistance,

overheating, and the risk of fire.

• Check whether the power cord is damaged. Check

whether the sheath is damaged.

If the power plug, cord, or sheath is damaged, replace

with a new power cord (with plug and connector on each

end) specified by Develop. Using the damaged power

cord may result in fire or electric shock.

S-3

Page 6

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

WARNING: Power Plug and Cord

• When using the power cord (inlet type) that came with this

product, be sure to observe the following precautions:

a. Make sure the connector is securely inserted in the inlet

on the rear panel of the product.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a

new power cord (with plugs on both ends) specified by

Develop.

If the power cord (inlet type) is not connected to the

product securely, a contact problem may lead to

increased resistance, overheating, and risk of fire.

• Check whether the power cord is not stepped on or

pinched by a table and so on.

Overheating may occur there, leading to a risk of fire.

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug

and wall outlet.

Using the power plug and wall outlet without removing

dust may result in fire.

• Do not insert the power plug into the wall outlet with a wet

hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the

cable.

The cable may be broken, leading to a risk of fire and

electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords

in the same outlet.

If used, the risk of fire exists.

S-4

Page 7

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

WARNING: Wiring

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so

using a too long extension cord may result in fire.

Do not use an extension cable reel with the cable taken

up. Fire may result.

WARNING: Ground connection

• Check whether the product is grounded properly.

If current leakage occurs in an ungrounded product, you

may suffer electric shock while operating the product.

Connect power plug to grounded wall outlet.

2. Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the product near flammable materials or volatile materials that may catch fire.

A risk of fire exists.

• Do not place the product in a place exposed to water such

as rain.

A risk of fire and electric shock exists.

WARNING: When not using product for a long time

• When the product is not used over an extended period of

time (holidays, etc.), switch it off and unplug the power

cord.

Dust collected around the power plug and outlet may

cause fire.

S-5

Page 8

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

CAUTION: Ventilation

• The product generates ozone gas during operation, but it

will not be harmful to the human body.

If a bad smell of ozone is present in the following cases,

ventilate the room.

a. When the product is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple products at the same time

CAUTION: Fixing

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the product may

slide, leading to a injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (service manual, technical notices, etc.) and

proceed with the inspection following the prescribed procedure, using only the prescribed tools. Do not make any

adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the product may break and a risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect

the power plugs from the product and options.

When the power plug is inserted in the wall outlet, some

units are still powered even if the POWER switch is

turned OFF. A risk of electric shock exists.

• The area around the fixing unit is hot.

You may get burnt.

S-6

Page 9

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

WARNING: Work Performed with the product Powered

• Take every care when making adjustments or performing

an operation check with the product powered.

If you make adjustments or perform an operation check

with the external cover detached, you may touch live or

high-voltage parts or you may be caught in moving gears

or the timing belt, leading to a risk of injury.

• Take every care when servicing with the external cover

detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other

damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and

screws to fall into the product.

They can short internal circuits and cause electric shock

or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or

fire.

• Carefully remove all toner remnants and dust from electrical parts and electrode units such as a charging corona

unit.

Current can leak, leading to a risk of product trouble or

fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or

fire.

• Check electrode units such as a charging corona unit for

deterioration and sign of leakage.

Current can leak, leading to a risk of trouble or fire.

S-7

Page 10

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

WARNING: Safety Checkpoints

• Before disassembling or adjusting the write unit (P/H unit)

incorporating a laser, make sure that the power cord has

been disconnected.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• Do not remove the cover of the write unit. Do not supply

power with the write unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery specified in the Parts Guide Manual. Dispose

of the used lithium battery using the method specified by

local authority.

Improper replacement can cause explosion.

• After replacing a part to which AC voltage is applied (e.g.,

optical lamp and fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and

check whether the interlock functions properly.

If the interlock does not function, you may receive an

electric shock or be injured when you insert your hand in

the product (e.g., for clearing paper jam).

• Make sure the wiring cannot come into contact with sharp

edges, burrs, or other pointed parts.

Current can leak, leading to a risk of electric shock or

fire.

• Make sure that all screws, components, wiring, connectors, etc. that were removed for safety check and maintenance have been reinstalled in the original location. (Pay

special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of product trouble, electric shock, and fire exists.

S-8

Page 11

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

WARNING: HANDLING OF CONSUMABLE

• Toner and developer are not harmful substances, but care

must be taken not to breathe excessive amounts or let the

substances come into contact with eyes, etc. It may be

stimulative.

If the substances get in the eye, rinse with plenty of water

immediately. When symptoms are noticeable, consult a

physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

CAUTION: HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are highly flammable and must be handled

with care. A risk of fire exists.

• Do not replace the cover or turn the product ON before

any solvent remnants on the cleaned parts have fully

evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take

care not to spill any liquid. If this happens, immediately

wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to

discomfort.

S-9

Page 12

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

[3] MEASURES TO TAKE IN CASE OF AN ACCIDENT

1. If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to provide relief to affected persons and to prevent

further damage.

2. If a report of a serious accident has been received from a customer, an on-site evaluation must be carried out quickly and Develop must be notified.

3. To determine the cause of the accident, conditions and materials must be recorded

through direct on-site checks, in accordance with instructions issued by Develop.

[4] CONCLUSION

1. Safety of users and customer engineers depends highly on accurate maintenance and

administration. Therefore, safety can be maintained by the appropriate daily service

work conducted by the customer engineer.

2. When performing service, each product on the site must be tested for safety. The customer engineer must verify the safety of parts and ensure appropriate management of

the equipment.

[5] FUSE

CAUTION

Double pole / neutral fusing

ATTENTION

Double pôle / fusible sur le neutre.

[6] LED Radiation Safety

• This product is a copier which operates by means of a LED (light emitting diodes) expo-

sure system. There is no possibility of danger from the LED optical radiation, because

the LED optical radiation level dose not exceed the accessible radiation limit of class 1

under all conditions of operation, maintenance, service and failure.

S-10

Page 13

QC 2235plus Field Service Ver1.0 Mar. 2004 SAFETY AND IMPORTANT WARNING

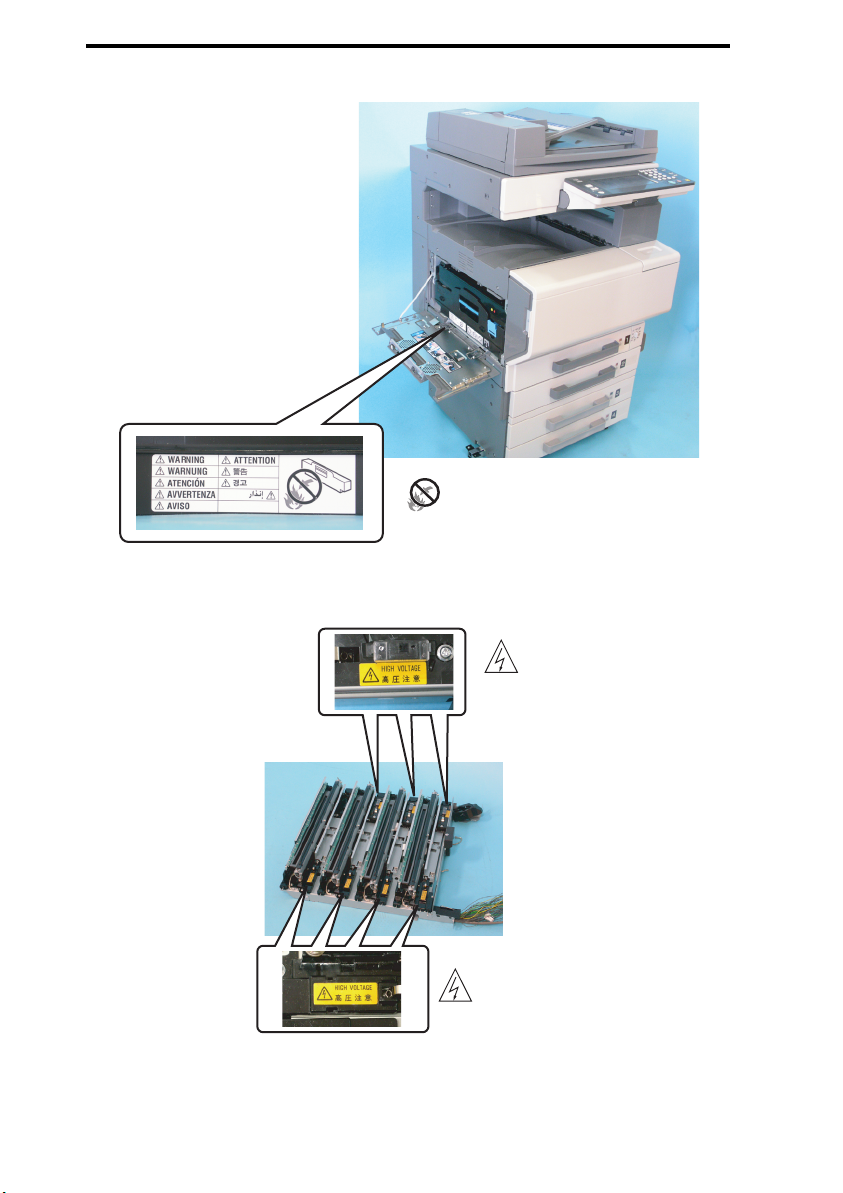

INDICATION OF WARNING ON THE MACHINE

Caution labels shown are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should

be taken to avoid burns and electric shock.

High voltage

High temperature

S-11

High voltage

High temperature

4036fsS001c0

Page 14

SAFETY AND IMPORTANT WARNING ITEMS QC 2235plus Field Service Ver1.0 Mar.

Do not throw into a fire

4036fsS002c0

S-12

High voltage

High voltage

4036fsS003c0

Page 15

DEVELOP

SERVICE MANUAL

THEORY OF OPERATION

QC 2235plus

Main Unit

Page 16

Page 17

QC 2235plus Theory of Operation Ver1.0 Mar. 2004

CONTENTS

IOutline

1. System configuration............................................................................................1-1

2. Product specifications ..........................................................................................1-3

2.1 Type ...................................................................................................................1-3

2.2 Functions...........................................................................................................1-3

2.3 Types of paper ...................................................................................................1-4

2.4 Maintenance......................................................................................................1-4

2.5 Machine specifications.......................................................................................1-4

2.6 Operating environment ......................................................................................1-4

2.7 Built-in controllers..............................................................................................1-5

3. Center cross section ............................................................................................1-6

4. Paper path............................................................................................................1-7

5. Image creation process........................................................................................1-8

I Outline

II Composition/Operation

1. Overall composition..............................................................................................2-1

1.1 Timing chart at machine power up ....................................................................2-1

1.2 Control block diagram........................................................................................2-2

2. Scanner section (IR section) ................................................................................2-3

2.1 Composition.......................................................................................................2-3

2.2 Drive ..................................................................................................................2-5

2.3 Operation...........................................................................................................2-5

2.3.1 Scan and Exposure Lamp control ................................................................2-5

2.3.2 Original Size Detection control .....................................................................2-6

3. Write section (PH section)....................................................................................2-9

3.1 Composition.......................................................................................................2-9

3.2 Operation.........................................................................................................2-10

3.2.1 Outline ........................................................................................................2-10

3.2.2 Color Shift Correction System ....................................................................2-11

4. Imaging Unit section (IU section).......................................................................2-12

4.1 Composition.....................................................................................................2-12

4.2 Drive ................................................................................................................2-13

4.3 Operation.........................................................................................................2-14

4.3.1 IU Life control..............................................................................................2-14

5. Photo Conductor section....................................................................................2-15

5.1 Composition.....................................................................................................2-15

5.2 Drive ................................................................................................................2-15

II Composition/Operation

i

Page 18

QC 2235plus Theory of Operation Ver1.0 Mar. 2004

5.3 Operation......................................................................................................... 2-16

5.3.1 PC Drum Drive mechanism........................................................................ 2-16

5.3.2 PC Drum Phase control ............................................................................. 2-16

5.3.3 PC Drum small amount rotation control ..................................................... 2-17

6. Charge Corona section ...................................................................................... 2-18

6.1 Operation......................................................................................................... 2-19

6.1.1 PC Drum Charge Corona ON/OFF control.................................................2-19

I Outline

6.1.2 Cleaning/Main Erase mechanism............................................................... 2-19

7. Developing section............................................................................................. 2-20

7.1 Composition .................................................................................................... 2-20

7.2 Drive................................................................................................................ 2-21

7.3 Operation......................................................................................................... 2-22

7.3.1 Developing Drive control ............................................................................2-22

7.3.2 Developer flow............................................................................................2-22

7.3.3 Developing bias.......................................................................................... 2-23

7.3.4 HMT (High grade Micro Toning) development............................................ 2-23

II Composition/Operation

7.3.5 Developer scattering prevention mechanism.............................................. 2-23

7.3.6 ATDC Sensor control.................................................................................. 2-24

8. Toner Supply section..........................................................................................2-26

8.1 Composition .................................................................................................... 2-26

8.2 Drive................................................................................................................ 2-27

8.3 Operation......................................................................................................... 2-28

8.3.1 Toner Replenishing mechanism/control ..................................................... 2-28

8.3.2 Toner Near-Empty and Toner Empty detection control............................... 2-29

8.3.3 Shutter mechanism .................................................................................... 2-30

9. Transfer Corona section..................................................................................... 2-31

9.1 Composition .................................................................................................... 2-31

9.1.1 1st Image Transfer section ......................................................................... 2-31

9.1.2 2nd Image Transfer section ........................................................................ 2-33

9.2 Drive................................................................................................................ 2-34

9.2.1 1st Image Transfer section ......................................................................... 2-34

9.2.2 2nd Image Transfer section ........................................................................ 2-35

9.3 Operation......................................................................................................... 2-35

9.3.1 Transfer Belt speed control.........................................................................2-35

9.3.2 1st Image Transfer Roller mechanism........................................................2-36

9.3.3 2nd Image Transfer Roller pressure mechanism........................................ 2-39

9.3.4 AIDC Sensor Shutter mechanism ..............................................................2-40

9.3.5 ATVC (Auto Transfer Voltage Control)........................................................2-41

ii

Page 19

QC 2235plus Theory of Operation Ver1.0 Mar. 2004

9.3.6 Transfer Belt cleaning .................................................................................2-42

9.3.7 2nd Image Transfer Roller cleaning............................................................2-43

9.3.8 Charge neutralization and separation of paper ..........................................2-44

9.3.9 Detection of New Transfer Belt Unit............................................................2-45

9.3.10 ACS control.................................................................................................2-46

10. Toner Collecting section .....................................................................................2-47

10.1 Composition.....................................................................................................2-47

10.2 Drive ................................................................................................................2-48

10.3 Operation.........................................................................................................2-49

10.3.1 Toner collecting mechanism .......................................................................2-49

10.3.2 Waste Toner Bottle-in-position detection ....................................................2-49

10.3.3 Waste Toner Near-Full/Full detection control..............................................2-50

11. Paper feed section..............................................................................................2-51

11.1 Composition.....................................................................................................2-51

11.1.1 Tray1 ...........................................................................................................2-51

11.1.2 Tray2 ...........................................................................................................2-52

11.2 Drive ................................................................................................................2-54

11.2.1 Tray1 ...........................................................................................................2-54

11.2.2 Tray2 ...........................................................................................................2-54

11.3 Operation.........................................................................................................2-55

11.3.1 Paper Take-up control (Tray1).....................................................................2-55

11.3.2 Tray1 double feed control............................................................................2-55

11.3.3 Deceleration control....................................................................................2-55

11.3.4 Paper supply level detection control...........................................................2-56

11.3.5 Paper Near-Empty/Paper Empty detection.................................................2-56

11.3.6 Tray1 paper type detting .............................................................................2-57

11.3.7 Paper size detection control .......................................................................2-58

11.3.8 Tray2 paper lifting motion control................................................................2-61

12. Bypass section...................................................................................................2-62

12.1 Composition.....................................................................................................2-62

12.2 Drive ................................................................................................................2-63

12.3 Operation.........................................................................................................2-64

12.3.1 Bypass Paper Take-up control....................................................................2-64

12.3.2 Paper Empty detection ...............................................................................2-64

12.3.3 Bypass Paper Lifting Motion Control ..........................................................2-64

12.3.4 Paper size detection ...................................................................................2-66

13. Conveyance section...........................................................................................2-68

13.1 Composition.....................................................................................................2-68

I Outline

II Composition/Operation

iii

Page 20

QC 2235plus Theory of Operation Ver1.0 Mar. 2004

14. Synchronizing Roller section..............................................................................2-69

14.1 Composition .................................................................................................... 2-69

14.2 Drive................................................................................................................2-69

14.3 Operation.........................................................................................................2-70

14.3.1 Synchronizing Roller control.......................................................................2-70

14.3.2 OHP detection............................................................................................2-71

15. Fusing section....................................................................................................2-72

I Outline

15.1 Composition .................................................................................................... 2-72

15.2 Drive................................................................................................................2-73

15.3 Operation.........................................................................................................2-74

15.3.1 Fusing Roller drive control..........................................................................2-74

15.3.2 Fusing Roller pressure/retraction mechanism............................................2-76

15.3.3 Fusing temperature control ........................................................................ 2-77

15.3.4 Protection against abnormal conditions ..................................................... 2-79

15.3.5 Detection of a New Fusing Unit.................................................................. 2-81

15.3.6 PPM control................................................................................................2-81

II Composition/Operation

16. Paper exit section............................................................................................... 2-82

16.1 Composition .................................................................................................... 2-82

16.2 Drive................................................................................................................2-83

17. Image stabilization control ................................................................................. 2-84

17.1 Overview .........................................................................................................2-84

17.2 Operation.........................................................................................................2-85

17.2.1 Background margin control ........................................................................2-85

17.2.2 AIDC Sensor LED intensity control ............................................................ 2-85

17.2.3 Max. density control ................................................................................... 2-85

17.2.4 g correction control.....................................................................................2-85

17.3 Operation timing.............................................................................................. 2-85

17.4 Operation flow ................................................................................................. 2-86

18. Image processing............................................................................................... 2-87

18.1 Scanner section image processing block diagram .......................................... 2-87

18.2 Write section image processing block diagram ............................................... 2-89

19. Other control ......................................................................................................2-91

19.1 Fan control....................................................................................................... 2-91

19.1.1 Construction............................................................................................... 2-91

19.1.2 Operation.................................................................................................... 2-92

19.2 Power distribution control at machine power up.............................................. 2-93

19.2.1 Parts operated when the Power Switch is turned ON ................................ 2-93

19.3 Counter control................................................................................................2-94

19.3.1 Construction............................................................................................... 2-94

iv

Page 21

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 System configuration

I Outline

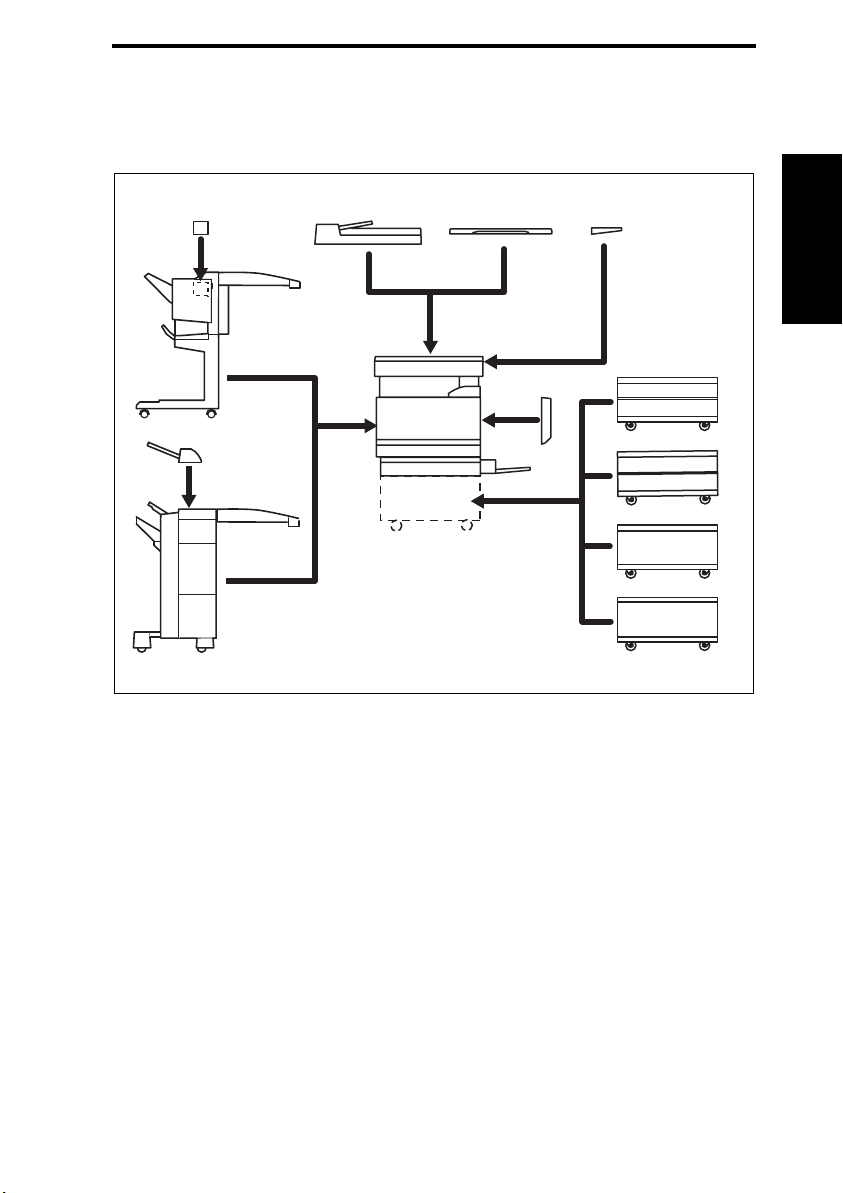

1. System configuration

1/2 System front view

[10]

[9]

[8]

[7]

[1] Machine [8] Job Separator JS-601

[2] Automatic Duplex Unit AD-501 [9] Finisher FS-601

[3] Paper Feed Cabinet PC-201 [10] Punch Kit PK-4 for FS-601

[4] Paper Feed Cabinet PC-101 [11] Reverse Automatic Document Feeder DF-601

[5] Desk DK-501 [12] Original Cover OC-501

[6] Paper Feed Cabinet PC-401 [13] Working Table WT-501

[7] Finisher FS-501

[11]

[1]

[12] [13]

[2]

[3]

[4]

[5]

[6]

4036fs1001j0

I Outline

1-1

Page 22

System configuration QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

2/2 System rear view

[10]

[11]

[9]

I Outline

[8]

[7]

[1]

[5]

[6]

PC-101

PC-201

PC-401

[4]

[1] Machine [7] Local Interface Kit EK-501

[2] Vender Kit VK-501

(South Central America, North America,

Europe Only)

[3] Data Terminal DT-105

(South Central America, North America

Only)

[4] Dehumidifier Heater 1C [10] Hard Disk HD-501

[5] Video Interface Kit VI-501 [11] Expanded Memory Unit EM-301

[6] Image Controller X3e 22C-KM

[8] Mechanical Counter

[9] Key Counter Kit KIT-1

[2]

[3]

Dk-501

4036fs1002e0

1-2

Page 23

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Product specifications

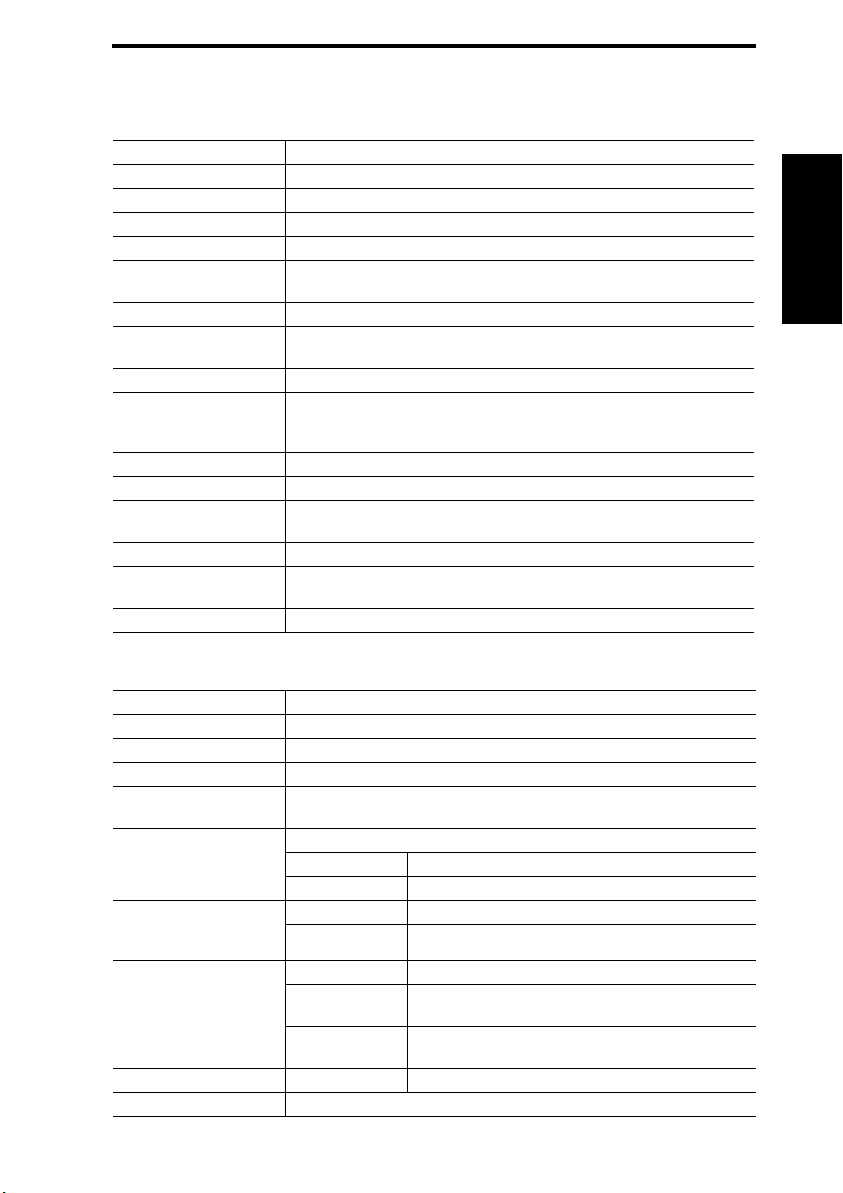

2. Product specifications

2.1 Type

Type Desktop-type printer integrated with scanner

Copying System Electrostatic dry-powdered image transfer to plain paper

Printing Process Tandem-type indirect electrostatic recording system

PC Drum Type OPC (organic photo conductor)

Scanning Density Equivalent to 600 dpi

Print Density Equivalent to 600 dpi in main scanning direction × 1800 dpi in sub scanning

Platen Stationary (mirror scan)

Original Scanning Scanning in main scanning direction with a CCD

Registration Rear left edge

Paper Feeding System

(Standard)

Three-way system

Exposure System Four-LED exposure

Developing System HMT developing system

Charging System DC comb electrode Scorotron system with electrode cleaning function

Image Transfer System Intermediate transfer belt system

Paper Separating System Selecting either application of nonwoven fabric bias + low-pressure paper

Fusing System Belt fusing

direction

(one-shot reading system)

Multiple Bypass: 150 sheets

Tray1: 250 sheets

Tray2: 500 sheets

(manual)

separator claws

I Outline

2.2 Functions

Types of Original Sheets, books, and three-dimensional objects

Max. Original Size A3 or 11 × 17

Multiple Copies 1 to 999

Warming-up Time 99 sec. or less (at ambient temperature of 23 °C and rated source voltage)

Image Loss

First Copy Time (Tray1, A4, full size)

Copying Speed for Multicopy Cycle

(A4, 8-1/2 × 11)

Fixed Zoom Ratios Full size ×1.000

Variable Zoom Ratios ×0.250 to ×4.000 in 0.001 increments

Exposure Lamp White rare-gas fluorescent lamp 30 W

Leading edge: 5 mm, Trailing edge: 3 mm,

Rear edge: 3 mm, Front edge: 3 mm

Monochrome print 6.8 sec. or less

Color print 12.8 sec. or less

Monochrome print 1-sided: 35 copies/min; 2-sided: 31 copies/min

Color print 1-sided: 22 copies/min; 2-sided: 22 copies/min

Reduction

Enlargement

Metric Area: ×0.500, ×0.707, ×0.816, ×0.866

Inch Area: ×0.500, ×0.647, ×0.733, ×0.785

Metric Area: ×1.154, ×1.224, ×1.414, ×2.000

Inch Area: ×1.214, ×1.294, ×1.547, ×2.000

1-3

Page 24

Product specifications QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

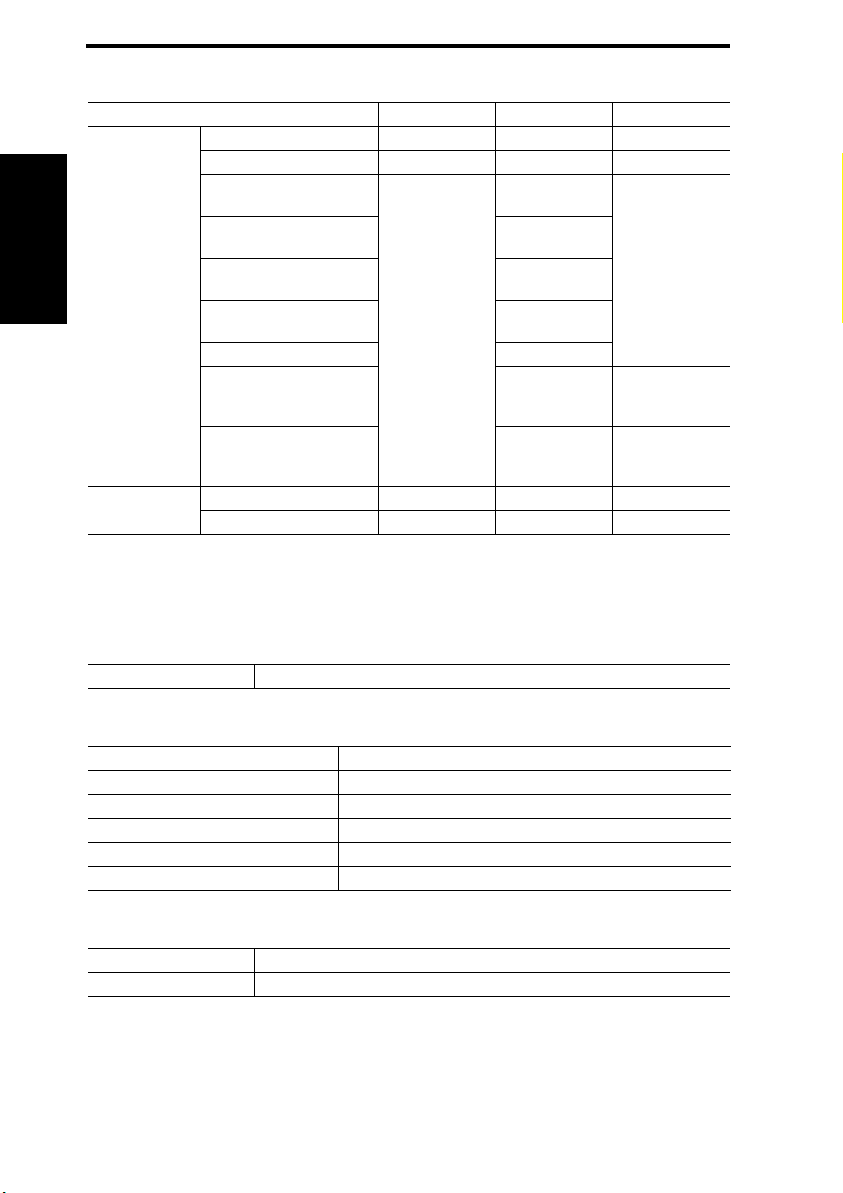

2.3 Types of paper

I Outline

Copy paper type

Copy paper

dimensions

Paper Source Tray1 Tray2 Multiple Bypass

Plain paper (60 to 90 g/m

Translucent paper – – –

OHP transparencies

(crosswise feeding only)

Thick paper 1

(91 to 150 g/m

Thick paper 2

(151 to 209 g/m

Thick paper 3

(210 to 256 g/m

Postcards –

Envelopes –

Labels –

Max (width × length) 311 × 457 mm 297 × 432 mm 311 × 457 mm

Min (width × length) 90 × 140 mm 140 × 182 mm 90 × 140 mm

2

2

)

2

) *1

)

2

)

(20 sheets or

❍❍❍

❍

less)

*1: Image is not guaranteed when thick paper 3 is used.

Optional Paper Feed Cabinet: Only the plain paper weighing 60 to 90 g/m

Automatic Duplex Unit: Only the plain paper weighing 64 to 90 g/m

2.4 Maintenance

Machine Durability 800,000 prints or 5 years, whichever is earlier

–

–

–

–

2

is reliably fed.

2

is reliably fed.

❍

(20 sheets or

less)

❍

(10 sheets or

less)

❍

(20 sheets or

less)

2.5 Machine specifications

Power Requirements Voltage: AC100 V ±10 %

Frequency: 50/60 Hz ±0.3 Hz

Max Power Consumption 15 kW (100 V, 15 A)

Dimensions 903 (W) × 730 (D) × 770 (H) mm

Space Requirements 1014 (W) × 1151 (D) mm

Mass Approx. 100 kg (without IU)

2.6 Operating environment

Temperature 10 to 30 °C (with a fluctuation of 10 °C/h)

Humidity 15 to 85 % (with a fluctuation of 20 %/h)

1-4

Page 25

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Product specifications

2.7 Built-in controllers

Printer Driver PCL5c printer driver

Scan Driver TWAIN driver

OS Compatibility Windows 98/Me, Windows NT/2000/XP, Windows Server 2003

Interface Ethernet 10/100BaseTX

NOTE

• These specifications are subject to change without notice.

I Outline

1-5

Page 26

Center cross section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

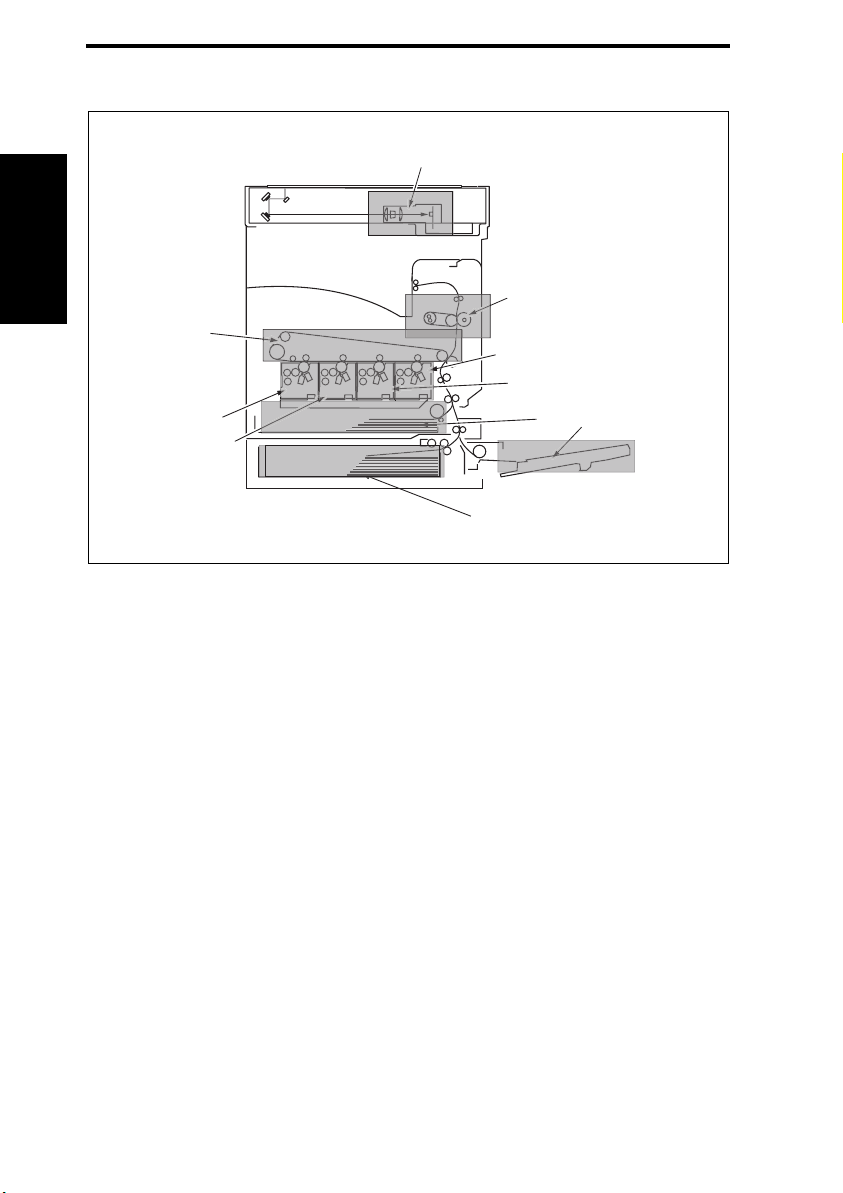

3. Center cross section

[1]

I Outline

[2]

[10]

[9]

[8]

[1] CCD Unit [6] Multiple Bypass

[2] Fusing Unit [7] Tray2

[3] Imaging Unit/Bk [8] Imaging Unit/M

[4] Imaging Unit/C [9] Imaging Unit/Y

[5] Tray1 [10] Transfer Belt Unit

[7]

[3]

[4]

[5]

4036ma101c0

[6]

1-6

Page 27

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Paper path

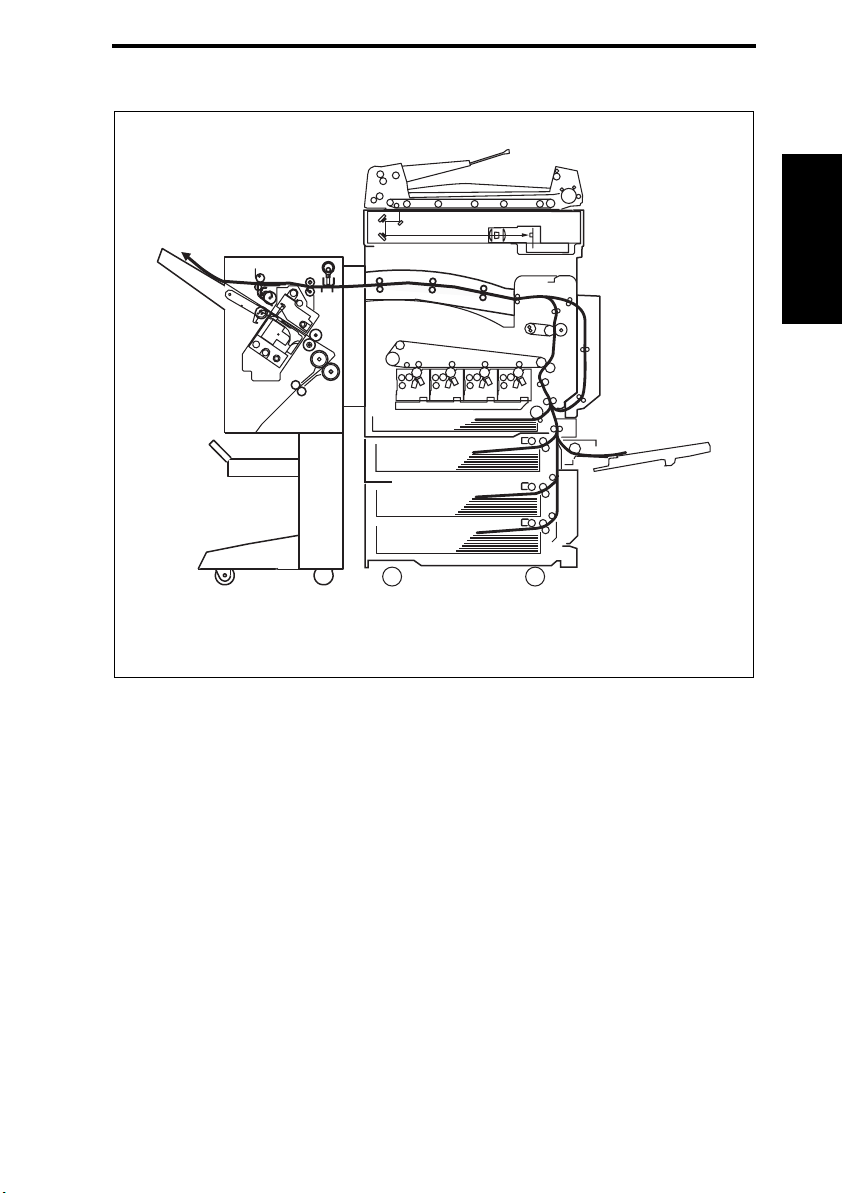

4. Paper path

I Outline

1-7

4036ma102c0

Page 28

Image creation process QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

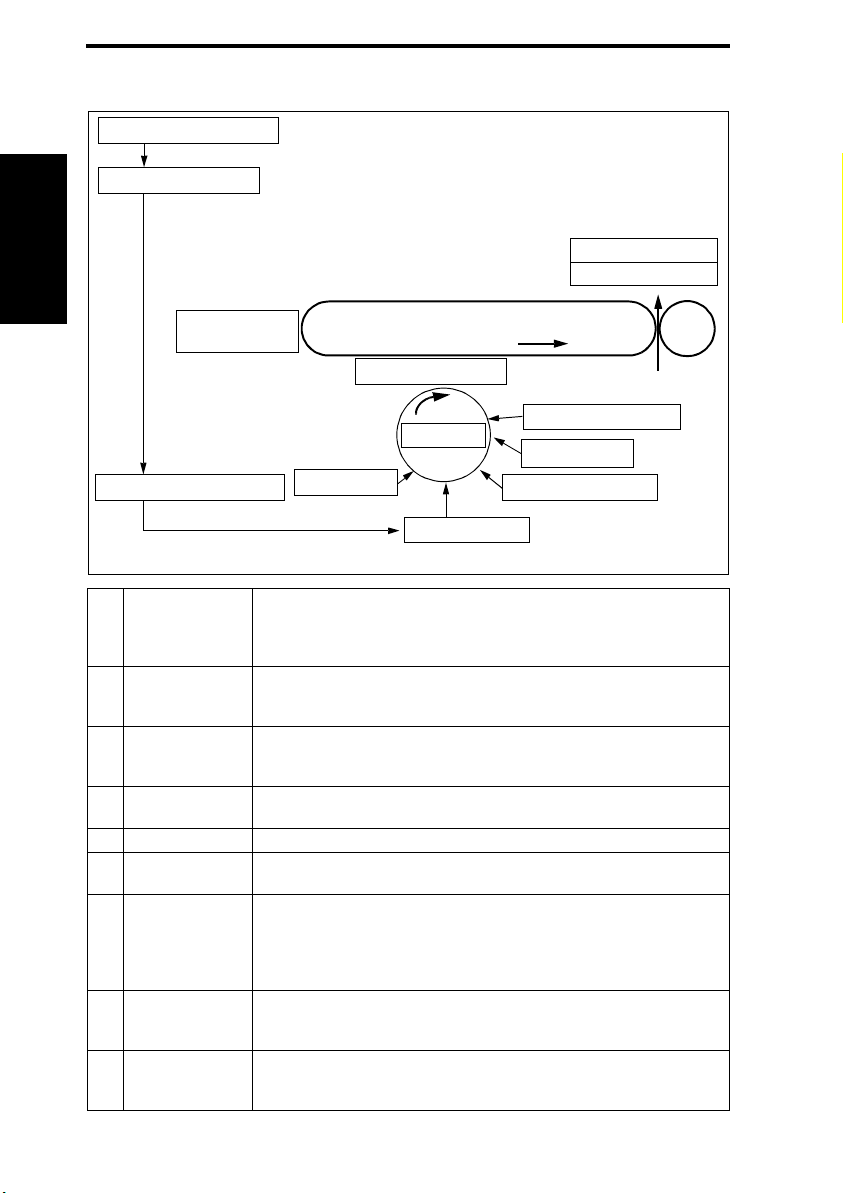

5. Image creation process

[1] Photoelectric Conversion

[2] IR Image Processing

I Outline

[11] Transfer

Belt Cleaning

[8] 1st Image Transfer

[4] PC Drum

[3] Printer Image Processing

Photoelectric

[1]

Conversion

IR Image

[2]

Processing

Printer Image

[3]

Processing

[4] PC Drum

[5] PC Drum Charging • A negative DC charge layer is formed on the surface of the PC Drum.

[6] LED Exposure

[7] Developing

[8] 1st Image Transfer

[9] 2nd Image Transfer

[7] Developing

[6] LED Exposure

• The light reflected off the surface of the original is separated into different

colors using the color filters (R, G, and B); CCD then converts it into a corresponding electric signal and outputs the signal to the IR Imaging Processing Section.

• The electric signal is converted to 8-bit digital image signals. After going

through some corrections, video signals (C, M, Y, and Bk) are output to

the Printer Image Processing Section.

• The video signals (C, M, Y, and Bk) go through some corrections. Following digital-to-analog conversion, these signals are used for the control of

the intensity level of the LED.

• The image of the original projected onto the surface of the PC Drum is

changed to a corresponding electrostatic latent image.

• The surface of the PC Drum is irradiated with LED light and an electrostatic latent image is thereby formed.

• The toner, agitated and negatively charged in the Developer Mixing Chamber, is attracted onto the electrostatic latent image formed on the surface of

the PC Drum. It is thereby changed to a visible, developed image.

• AC and DC negative bias voltages are applied to the Developing Roller,

thereby preventing toner from sticking to the background image portion.

• A DC positive voltage is applied to the backside of the Transfer Belt,

thereby allowing the visible, developed image on the surface of each of

the PC Drums (Y, M, C, and Bk) to be transferred onto the Transfer Belt.

• A DC positive voltage is applied to the backside of the paper, thereby

allowing the visible, developed image on the surface of the Transfer Belt to

be transferred onto the paper.

[5] PC Drum Charging

[10] Paper Separation

[9] 2nd Image Transfer

[12] PC Drum Cleaning

[13] Main Erase

1-8

Page 29

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Image creation process

[10] Paper Separation

Transfer Belt

[11]

Cleaning

[12] PC Drum Cleaning • The residual toner left on the surface of the PC Drum is scraped off.

[13] Main Erase

• The paper, which has undergone the 2nd image transfer process, is neutralized so that it can be properly separated from the Transfer Belt by the

Paper Separator Claws.

• A charge is applied to the Transfer Belt. By potential difference, residual

toner on the surface of the Transfer Belt is collected for cleaning.

• The surface of the PC Drum is irradiated with light, which neutralizes any

surface potential remaining on the surface of the PC Drum.

I Outline

1-9

Page 30

Page 31

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Overall composition

II Composition/Operation

2. Overall composition

2.1 Timing chart at machine power up

Power Switch ON

Fusing Pressure Roller Heater

Lamp (H3)

Heating Roller Heater Lamp/1

(H1)

Fusing Pressure Roller Pressure/

Retraction Motor (M19)

Fusing Drive Motor (M2)

Exposure Lamp (FL201)

Scanner Motor (M201)

Main Motor (M1)

1st Image Transfer Pressure/

Retraction Motor (M11)

1st Image Transfer Retraction

Position Sensor (PC12)

Transfer Belt Cleaning Bias

Cleaning Brush Motor (M22)

2nd Image Transfer Pressure/

Retraction Motor (M13)

2nd Image Transfer Pressure/

Retraction Position Sensor (PC29)

2nd Image Transfer Bias

Retraction

Bk Pressure

Retraction

Pressure/Retraction

Pressure

Retraction

100°C

Temperature Control

Pressure

Retraction

II Composition/Operationn

2-1

4036ma2052e0

Page 32

Overall composition QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

2.2 Control block diagram

Scanner Section

CCD Sensor

Board (PWB-A)

Inverter Board

Exposure Lamp

(FL201)

Scanner Motor Drive

Board (PWB-IC)

II Composition/Operationn

Image Processing Board (PWB-C)

MFP Control Board (PWB-MFP)

Standard

Controller

LPH/Y

IC-401

Image

Processing

LED Drive Board

(PWB-LED)

LPH/M

LPH/C

Scanner Motor (M201)

Control Board (PWB-MC)

LPH/Bk

Finishing

Option

CPU

Panel

Paper

Source

Option

DF-601

Printer Section

Paper Takeup/Transport

Process

Fusing

AD-501

Control System Line

Image Bus Line

4036ma2053e0

2-2

Page 33

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Scanner section (IR section)

3. Scanner section (IR section)

3.1 Composition

[1]

[2]

4036ma2110c0

[3]

[13]

[4]

[5]

[12]

[11]

[6]

4036ma2501c0

II Composition/Operationn

[7]

[8]

[9]

[10]

4036ma2001c1

2-3

Page 34

Scanner section (IR section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

Key Name Function/System

[1] Original Cover Angle Sensor (PC202) • Validates or resets the size of the original.

[2] Original Size Sensor FD1 (PC203) • Detects the original of a small size in the FD direction.

[3] Scanner Motor Drive Board (PWB-IC) • Drives the Scanner Motor.

[4] Original Size Sensor FD2 (PC204) • Detects the original of a large size in the FD direction.

• Drives the Scanner Drive Cables for moving the Expo-

[5] Scanner Motor (M201)

sure Lamp and Scanner.

• Drives the Scanner Motor Drive Board (PWB-IC).

•

Three-phase stepping motor

[6] Lens • F5.0, focal length 71.2 mm

• Changes optical image data to a corresponding electric

[7] CCD Unit *1

signal (600 dpi).

• Three-line (RGB) linear image sensor

• Detects the position of the Original Cover or ADF,

[8] Size Reset Switch (SW201)

whether it is raised or lowered.

• Resets the size of the original when the ADF is raised.

• Magnetic sensor type

[9] Image Processing Board (PWB-C) • Processes image data that has been scanned.

[10] Exposure Unit • Slit exposure

[11] Mirror Unit • Reflects the light reflected off the original.

II Composition/Operationn

[12] Original Size Sensor CD1 (PC206) • Detects the original of a large size in the CD direction.

[13] Scanner Home Sensor (PC201) • Detects the Scanner at its home position.

∗1: CCD Unit

R

G

B

Sub Scanning

Direction

Main Scanning

Direction

Scanning Direction

2-4

CCD Sensor

37.3 µm

37.3 µm

9.325 µm

9.325 µm

4036ma2602c0

Page 35

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Scanner section (IR section)

3.2 Drive

[4]

[3]

[2]

[5]

[1]

[6]

[1] Scanner Drive Cable/R [4] Scanner Motor

[2] Mirror Unit [5] Scanner Drive Cable/F

[3] Exposure Unit [6] Scanner Home Sensor

4036ma2002c1

3.3 Operation

3.3.1 Scan and Exposure Lamp control A. When the Power Switch is turned ON

1. The Exposure Unit moves in the return direction until the Scanner Home Sensor is activated. It does not move if the Scanner Home Sensor is already activated.

2. The Exposure Unit moves in the scan direction and stops at a position under the shading correction sheet.

3. The gain value of the CCD Sensor output voltage is adjusted for R, G, and B.

4. A shading correction is made.

5. After the adjustment has been made, the Exposure Unit moves in the return direction

and stops at the Scanner Home Sensor. This position serves as the home position.

* The same operation is performed for the auto and manual exposure control.

Home Position

Gain Adjustment and Shading Correction

II Composition/Operationn

2-5

Exposure Lamp (FL201) ON

Scanner Movement

4036ma2190c0

Page 36

Scanner section (IR section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

B. When the Start key is pressed

1. The Exposure Lamp turns ON when the Start key is pressed.

2. The gain adjustment is made when the Exposure Unit moves past the point under the

shading sheet. Thereafter, a shading correction is made.

3. The Exposure Unit starts a scan motion with the original position.

4. After completing the scan motion for the original, the Exposure Unit temporarily stops

and the Exposure Lamp goes out.

5. The Exposure Unit makes a return motion and stops at the home position. Each of the

R, G, and B data is stored in memory during a single scan motion. The Exposure Unit

therefore makes only a single scan motion even for a multi-copy cycle.

Home Position

Original Position

Exposure Lamp (FL201) ON

Gain Adjustment and Shading Correction

Scan

II Composition/Operationn

3.3.2 Original Size Detection control

A. Detection Method

• Reflective size sensors are used for detection of the size of the original.

• Mounting the optional size sensors permits detection of originals of inch size.

Original Size Sensor FD1

(PC203)

Metric area: Standard

Inch area: Option

A5R

B5R

A4R

B4,

B5

A3,

A4

Original Size Sensor

CD1 (PC206)

Original Size Sensor

FD2 (PC204)

7

6

8

Original Size Sensor

CD2 (PC207): Option

1

B5

8.5 X 11

A4,

A5R

234

Original Size Sensor

FD3 (PC205): Option

8.5 X 11 R 8.5 X 14 11 X 17

5

A4R

B5R

B4

4036ma2191c0

8.5 X 14

8.5 X 11 R

11 X 17

8.5 X 11

A3

4036ma2003c0

2-6

Page 37

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Scanner section (IR section)

• The Image Processing Board determines the size of the original based on the combination of detection made by each of the Original Size Sensors, whether or not there is an

original loaded.

• An original of an irregular size is rounded to the nearest standard size.

Metric Area

Original Size

Determined

A3 ●●●●●

B4 ●●●●–

A4R ●●● ––

A4 ● ––●●

B5 – – – ● –

A5R ● ––––

8.5 × 11R ●● –––

: Original Loaded –: Original Not Loaded

●

FD1 FD2 CD1

12367

• When the optional sensors are mounted

Original Size

Determined

A3 ●●●●●●●●

B4 ●●●●●● ––

A4R ●●●●––––

A4 ● ––––●●●

B5R ●●––––––

B5 –––––● ––

A5R ● –––––––

11 × 17 ●●●●●●● –

8.5 × 14 ●●●●● –––

8.5 × 11R ●●● –––––

8.5 × 11 ● ––––●● –

: Original Loaded –: Original Not Loaded

●

FD1 FD2

12345678

FD3

(option)

CD1

CD2

(option)

II Composition/Operationn

2-7

Page 38

Scanner section (IR section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

Inch Area - Standard

Original Size

Determined

11 × 17 ●●●●

B4 ●●● –

8.5 × 14 ●● ––

8.5 × 11R ● –––

8.5 × 11 – – ●●

B5 – – ● –

: Original Loaded –: Original Not Loaded

●

FD2 CD1

2367

• When the optional sensors are mounted

Original Size

Determined

11 × 17 ●●●●●●● –

8.5 × 14 ●●●●●–––

FLS ●●●●––––

II Composition/Operationn

8.5 × 11R ●● –––––

8.5 × 11 ● ––––●● –

5.5 × 8.5R ● –––––––

A3 ●●●●●●●●

B4 ●●●●●●––

A4R ●●● ––––

A4 ● ––––●●●

B5 –––––● ––

: Original Loaded –: Original Not Loaded

●

FD1

(option)

12345678

FD2

FD3

(option)

CD1

CD2

(option)

B. Detection Timing (When the ADF is Used)

Original Size Sensors FD1 (PC203),

FD2 (PC204), and FD3 (PC205)

Original Size Sensors CD1 (PC206)

and CD2 (PC207)

Original Cover Angle Sensor (PC202)

Size Reset Switch (SW201)

Validates the original size

when the ADF is lowered

Resets the original size

when the ADF is raised

4036ma2007c0

• The original size is validated if the Start key is pressed with the ADF in the raised position.

2-8

Page 39

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Write section (PH section)

4. Write section (PH section)

4.1 Composition

[1]

4036ma2218c0

4036ma2502c0

[2]

[5]

[3]

[4]

4036ma2219c0

Key Name Function/System

[1] LED Unit • Four LED assemblies are integrated into a single unit.

[2] SELFOC Lens

[3] LED Chips

• The rays of light emitted by the LED chips are brought to a focus

on the surface of the PC Drum to form a full-size image.

• Approximately 7,700 LED chips (600 dpi) arranged in the main

scanning direction

[4] LED Assy/Y, M, C, Bk • LED Assy for each color of Y, M, C, and Bk

[5] PC Drum/Y, M, C, Bk • Irradiated with LED light to form an electrostatic latent image.

II Composition/Operationn

2-9

Page 40

Write section (PH section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

4.2 Operation

4.2.1 Outline

• Each of the PC Drums is irradiated with LED light and an electrostatic latent image is

thereby formed.

• The LED print head is a fixed scanning type exposure system that includes approx.

7,700 LED chips (600 dpi) arranged in the main scanning direction and a SELFOC lens

array, or SLA that brings rays of light emitted by the LED chips to a focus on the surface

of the PC Drum to form a full-size image.

• The special service jig for cleaning the surface of the LED print head should be used,

since a special coating is applied to the surface of the SLA to prevent ozone from sticking

to it.

II Composition/Operationn

PC Drum Y

Tran sfer Bel t

Y Bk

LED/Y LED/M

M

SELFOC Lens

2nd Image Transfer Roller

C

LED/C LED/Bk

4036ma2004c1

Approx. 7,700

LED chips

4036ma2222c0

2-10

Page 41

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Write section (PH section)

4.2.2 Color Shift Correction System

• In a tandem engine, in which an independent image reproduction process is provided for

each of the four different colors of toner. Incorrect color registration, or color shift, is

therefore more likely to occur due to each of the LED assemblies being out of correct

position. The color shift correction system automatically detects any misalignment

among the different colors, correcting it both in the main scanning and sub scanning

directions.

• The color shift detection sequence proceeds as follows. A detection pattern each in the

sub scanning direction is produced at the front and rear on the Transfer Belt. Each of

AIDC/Registration Sensor/1 and /2 at the front and rear reads the corresponding pattern.

The amount of color shift in the sub scanning direction is then calculated and stored in

memory. A detection pattern each in the main scanning direction is next produced at the

front and rear on the Transfer Belt. Each of AIDC/Registration Sensor/1 and /2 at the

front and rear reads the corresponding pattern. The amount of color shift in the main

scanning direction is then calculated and stored in memory. Based on the data representing the amounts of color shift, the machine calculates how much each of the different

colors should be corrected. The correction data is further stored in memory. Based on

the data stored in memory, the machine controls each dot during production of image

outputs, thereby correcting the color shift (varying the timing at which the LED is turned

ON).

• The color shift correction is made when the Left Door is opened and closed, the IU is

removed and reinstalled, or an image stabilization sequence is carried out from the control panel.

II Composition/Operationn

Detection Pattern for Sub

Scanning Direction

Transfer Belt

Detection Pattern for Main

Scanning Direction

AIDC/Registration Sensor/1

and /2 (PC8 and PC9)

2-11

4036ma2226c0

4036ma2227c0

Page 42

Imaging Unit section (IU section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

5. Imaging Unit section (IU section)

5.1 Composition

[1]

4036ma2130c0

[6]

II Composition/Operationn

4036ma2239c0

Key Name Function/System

[1] PC Drum/Y, M, C, Bk

[2] Cleaning Blade • Scrapes toner off the surface of the PC Drum.

[3] Toner Collecting Screw

[4] PC Drum Charge Corona/Y, M, C, Bk

Main Erase Lamp/Y, M, C, Bk

[5]

(LA1 to LA4)

[6] Developing Unit/Y, M, C, Bk

• Forms an image of each of different colors.

•OPC drum (φ30 mm)

• Conveys waste toner from the IU to the Toner Collecting Section.

• Screw type

• Deposits a charge across the entire surface of the

PC Drum.

• DC comb electrode Scorotron system

• Neutralizes any charge left on the surface of the PC

Drum.

•LED type

• Developer capacity 400 g (C, M, Y, Bk)

• T/C ratio 8% (C, M, Y, Bk)

4036ma2503c0

[1]

[2]

[3]

[4]

[5]

2-12

Page 43

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Imaging Unit section (IU section)

5.2 Drive

[2]

[1]

[4]

[3]

4036ma2008c1

II Composition/Operationn

4036ma2007c1

[1] Developing Clutch/Bk (CL2) [3] Color Developing Motor (M6)

[2] Bk PC Motor (M7) [4] Color PC Drum Motor (M5)

2-13

Page 44

Imaging Unit section (IU section) QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

5.3 Operation

5.3.1 IU Life control

• Each IU has EEPROM that detects a new IU and keeps track of the service life of the IU.

A. New IU detection

• new IU is detected when 24 V is turned ON as the Power Switch is turned OFF and ON

or the Front Door is opened and closed. If a new IU is not detected the machine does not

execute image stabilization sequence.

• When a new IU is detected, an ATDC adjustment sequence is carried out.

Operation when a new IU is detected

Transfer Belt

is retracted

ATDC

automatic

adjustment

Transfer Belt

cleaning

1st image

transfer/ATVC

adjustment

Image stabilization

Operation when a new IU is not detected

II Composition/Operationn

Transfer Belt

is retracted

Transfer Belt

cleaning

1st image

transfer/ATVC

adjustment

Image stabilization

B. When life is reached

• The IU Life Counter is used to keep track of IU life.

• When the life value is reached, a warning message is given on the screen. When a predetermined number of printed pages are produced after the life value has been reached,

the machine inhibits the initiation of a new print cycle with a message prompting the user

to replace the IU given on the screen.

At print stop When a life value is reached

4036ma2058e0

4036ma2133c0

4036ma2059e0

• The warning screen and IU replacement screen change when the settings are changed

for “Display PM Parts Lifetime” and “Unit Change” available from the Tech. Rep. mode

and “IU Life Stop Setting” available from the Security mode.

2-14

Page 45

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Photo Conductor section

6. Photo Conductor section

6.1 Composition

Charge Generating

Charge Transport

Layer (CTL)

Layer (CGL)

Aluminum

Cylinder

4036ma2338c0

[1]

Key Name Function/System

[1] PC Drum/Y, M, C, Bk

4036ma2543c0

• Forms an image of each of different colors.

•OPC drum (φ30 mm)

6.2 Drive

[2]

[1]

[6]

[1] Color PC Drum Motor (M5) [4] PC Drum/C

[2] Bk PC Motor (M7) [5] PC Drum/M

[3] PC Drum/Bk [6] PC Drum/Y

[3]

[5]

[4]

4036ma2551c0

II Composition/Operationn

2-15

Page 46

Photo Conductor section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

6.3 Operation

6.3.1 PC Drum Drive mechanism

• Two independent PC Drum motors are used for the drive mechanism to suppress incorrect color registration and uneven pitch.

• The Color PC Drum Motor drives the PC Drums/Y, M, and C, while the Bk PC Motor

drives the PC Drum/Bk.

• Gears having a large diameter are used to enhance rotating accuracy of the PC Drums.

• The use of gears having a large diameter provides a large number of gear teeth, which

suppresses uneven pitch and eccentricity.

• Drive is transmitted to each of the PC Drums when the triangular coupling is engaged

with the mating part that also has a triangular shape.

Color PC Drum Motor (M5)

Bk PC Motor (M7)

Large-diameter Gear

Shaft

II Composition/Operationn

Coupling

4036ma2051c0

Coupling

4036ma2552c0

4036ma2544c0

6.3.2 PC Drum Phase control

• To enhance image quality, sensors are used to detect operating conditions while the PC

Drum turns, thereby providing drum drive control.

2-16

Page 47

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Photo Conductor section

6.3.3 PC Drum small amount rotation control

• Humidity around the IU can produce a difference in sensitivity among different PC

Drums. This could lead to drum memory, allowing black bands to occur in the image. In

addition, ozone stagnant in areas near the PC Drum Charge Corona reduces sensitivity

of the PC Drums, causing white bands to occur in the image.

• To prevent these image problems, it should be ensured that the same face of the PC

Drum is left exposed to the same condition for an extended period of time. The PC Drum

is therefore turned at regular intervals to keep the surface sensitivity uniform.

A. PC Drum small amount rotation timing

• The PC Drum is turned the small amount when a predetermined threshold value of the

cumulative PC Drum driven distance is exceeded during a multi-print cycle or when intermittent print cycles are consecutively run with an intermission of less than a predetermined period of time between them.

PC Drum

4036ma2549c0

II Composition/Operationn

2-17

Page 48

Charge Corona section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

7. Charge Corona section

[1]

[3]

4036ma2130c0

4036ma2506c0

[4]

[3]

[1]

II Composition/Operationn

[5]

4036ma2138c0

Key Name Function/System

[1] Corona Wire • Comb electrode type

[2] Corona Wire Cleaning Lever

• For cleaning the corona wire

• Slide out to clean the corona wire.

[3] Grid Mesh • Applies the grid voltage

[4] Cleaning Blade • Scrapes residual toner off the surface of the PC Drum

• Illuminates the surface of the PC Drum to neutralize

[5] Main Erase Lamp

any surface potential remaining on the surface of the

PC Drum

•LED type

[2]

4036ma2009c1

2-18

Page 49

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Charge Corona section

7.1 Operation

7.1.1 PC Drum Charge Corona ON/OFF control

• The grid voltage (VG) applied to the Grid Mesh is controlled through the image stabilization control.

Color PC Drum Motor Energized

Bk PC Motor Energized

Drum Charge Corona Bias Y, M, C

Drum Charge Corona Bias Bk

Color Developing Motor (M6)

Developing Clutch/Bk (CL2)

4036ma2251c0

7.1.2 Cleaning/Main Erase mechanism

A. Cleaning/main erase operation

1. The Cleaning Blade is pressed up against the surface of the PC Drum, scraping resid-

ual toner off the surface (forward blade system).

2. Toner, which has been scraped off the surface of the PC Drum, is fed by the Toner Col-

lecting Screw back toward to the Conveying Screw in the rear of the machine. It is then

collected in the Waste Toner Collecting Box.

3. The surface of the PC Drum after the image transfer process is irradiated with light from

the Main Erase Lamp. This neutralizes any potential left on the surface of the PC Drum.

II Composition/Operationn

4036ma2539c0

Toner Collecting

Screw

Cleaning

Blade

Main Erase

Lamp

2-19

Cleaning Blade

4036ma2505c0

Page 50

Developing section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

8. Developing section

8.1 Composition

[3]

[2]

[7]

4036ma2130c0

[4]

[9]

[5]

II Composition/Operationn

[8]

[6]

[2]

4036ma2010c1

Key Name Function/System

[1] Doctor Blade • Controls the height of the developer brush on the Developing Roller

Supply/Agitating/Convey-

[2]

ing Screws

[3] Developing Roller

• Vertical two-shaft circulating system that employs screws having a

small diameter arranged in the vertical direction

• Conveys developer through magnetism to the point of development

• Two-component developing system

• Drives the PC Drum of the IU/Bk

[4] Bk PC Motor (M7)

• Energized by the Control Board (PWB-MC)

• Brushless DC motor

[5] PC Drum/Bk

Developing Clutch/Bk

[6]

(CL2)

Color PC Drum Motor

[7]

(M5)

[8] PC Drum/Y

• Forms an image

•OPC drum (φ30 mm)

• Transmits drive to the Developing Roller, Supply/Agitating/Conveying Screws, and Toner Collecting Screw of the IU/Bk.

• Drives the PC Drums of the IU/Y, IU/M, and IU/C

• Energized by the Control Board (PWB-MC)

• Brushless DC motor

• Forms an image of each of different colors

•OPC drum (φ30 mm)

• Drives the Developing Rollers, Supply/Agitating/Conveying Screws,

Color Developing Motor

[9]

(M6)

and Toner Collecting Screws of the IU/Y, IU/M, and IU/C

• Energized by the Control Board (PWB-MC)

• Brushless DC motor

[1]

4036ma2139c0

[3]

4036ma2011c1

2-20

Page 51

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Developing section

8.2 Drive

[9]

[6]

[8]

[7]

[5]

[1]

[2]

[4]

4036ma2603c0

[1] PC Drum/Bk [6] Bk PC Motor (M7)

[2] Developing Roller [7] PC Drum/Y

[3] Toner Collecting Screw [8] Color Developing Motor (M6)

[4] Supply/Agitating/Conveying Screws [9] Color PC Drum Motor (M5)

[5] Developing Clutch/Bk (CL2)

[3]

4036ma2604c0

II Composition/Operationn

2-21

Page 52

Developing section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

Retraction Signal

8.3 Operation

8.3.1 Developing Drive control

Main Motor ON Signal

DCDCPrinting DC

DC

Printing DC

II Composition/Operationn

Developing Bias/Y, M, C

Main Motor (M1)

Color PC Drum Motor (M5)

Bk PC Motor (M7)

Developing Bias/Bk

Drum Charge Corona Bias Y, M, C

Drum Charge Corona Bias Bk

Color Developing Motor (M6)

Developing Clutch/Bk (CL2)

1st Image Transfer Pressure/

Retraction Motor (M11)

2nd Image Transfer Pressure/

Retraction Motor (M13)

*1: Actual YMC timing depends on the position of each PC Drum.

8.3.2 Developer flow

1. Toner supplied from the front end of the Developing Unit is fed to the lower screw. It is

then fed to the rear of the unit, while being mixed with developer and electrically

charged by the Supply/Agitating/Conveying Screws.

2. The ATDC Sensor installed on the underside of the Developing Unit detects toner-tocarrier ratio during this time.

3. The developer, fed to the rear of the Developing Unit, is conveyed further to the upper

screw.

4. Because of the magnetic pole positioning of the Developing Roller, the developer is

conveyed onto the upper part of the Developing Roller. The Doctor Blade then controls

the height of the developer brush to ensure that the developer on the Developing Roller

levels out.

5. The Toner sticks to the electrostatic latent image on the surface of the PC Drum. The

developer that is left on the Sleeve is returned to the upper screw by the magnetic pole

positioning of the Developing Roller. It is then conveyed to the front side of the Developing Unit.

For IU/Y

PC Drum/Y

AC *1

AC *1

Developing Roller

Doctor Blade

DC

4036ma2152c0

Toner Supplied

from Hopper

Supply/Agitating/Conveying Screws

2-22

4036ma2605c0

Page 53

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Developing section

8.3.3 Developing bias

• The developing bias voltage (Vb) is applied to the Developing Roller so that an adequate

amount of toner is attracted onto the surface of the PC Drum.

• In addition to the negative DC component, AC voltage is applied during development to

help toner to be attracted more easily to the surface of the PC Drum. This AC component

is applied only while development is taking place.

• The developing bias (Vb) is supplied from High Voltage Unit/2.

Developing Roller

Developing Bias

4036ma2507c0

8.3.4 HMT (High grade Micro Toning) development

• The machine employs the two-component non-contact development system.

• With the HMT method, the magnetic developer brush does not rub against the surface of

the PC Drum (the images). Accordingly, sharper line images can be reproduced, involving no uneven image density at the trailing edge or thin lines and achieving even finer

reproduction of the solid image areas.

II Composition/Operationn

Developing Roller

PC Drum

4036ma2013c1

8.3.5 Developer scattering prevention mechanism

• To prevent the image and machine interior from being dirtied, a filter installed in the rear

of the IU and the Toner Suction Fan Motor work to trap toner particles rising up during

development.

IU

Holder

Filter

Holder

4036ma2247c0

2-23

Page 54

Developing section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

8.3.6 ATDC Sensor control

• The ATDC Sensor is mounted on the underside of each of the Developing Sections. The

sensor for C, M, and Y is an optical type, while that for Bk is a magnetic type. Each of

these sensors detects toner-to-carrier ratio (T/C) of the developer. The reading is used

for determining the amount of toner supplied.

• Only when a new Imaging Unit is installed in the machine, an automatic adjustment is

made of each of these ATDC Sensors. The sensors cannot be adjusted manually.

• The target T/C is 8 % both for color and Bk. This T/C can, however, be changed using

“ATDC Level” of “Image Adjust” available from the Tech. Rep. mode.

A. Optical ATDC sensor

• A bias is applied to the ATDC Sensor window to prevent toner from sticking to it. There is

a magnetic brush provided for the Conveying Screw portion to clean the surface of the

window.

• The sensor portion is separated from the Developing Section (Imaging Unit). When the

ATDC Sensor is replaced, it is necessary to replace the Imaging Unit with a new one.

• This represents the fact that the ATDC Sensor is adjusted only when a new Imaging Unit

is installed. In addition, if the LPH Unit is to be replaced, it is necessary to remove the

ATDC Sensor from the old LPH Unit and mounted it in the new LPH Unit.

B. Magnetic ATDC Sensor

• The magnetic permeability (powder density) of the carrier in the developer is measured

II Composition/Operationn

to determine the T/C.

• A mylar is provided for the Conveying Screw portion to scrape toner off the surface of the

ATDC Sensor.

• The ATDC Sensor is integrated with the Imaging Unit. When the ATDC Sensor is to be

replaced with a new one, the entire Imaging Unit must be replaced.

Magnetic

Brush

ATDC

Sensor

Window

ATDC Sensor/Y, M, C ATDC Sensor/Bk

Optical ATDC Sensor

ATDC Sensor/C, M, Y

(PWB-N1, N2, N3)

4036ma2187c0

4036ma2508c0

Magnetic ATDC Sensor

Mylar

2-24

4036ma2504c0

ATDC Sensor/Bk

4036ma2188c0

Page 55

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Developing section

C. ATDC window bias

• Since the optical ATDC Sensor is used for C, M, and Y, a bias is applied to the ATDC window to prevent toner from sticking to it. No bias is applied to the ATDC Sensor for Bk,

which is the magnetic type.

• The bias is applied from the bias terminal of the LED Unit by way of the mounting screw

of the ATDC window to the ATDC window.

ATDC Bias

ScrewATDC Window

4036ma2509c0

II Composition/Operationn

2-25

Page 56

Toner Supply section QC 2235plus Theory of Operation Ver.1.0 Feb. 2004

9. Toner Supply section

9.1 Composition

[1] [4][2] [3]

4036ma2143c0

II Composition/Operationn

[13]

[11]

[12]

[6][5]

[7] [8]

4036ma2510c0

[9]

[10]

[14]

4036ma2512c1

4036ma2511c0

Key Name Function/System

[1] Cartridge/Y • Replenishes the supply of Y toner

[2] Cartridge/M • Replenishes the supply of M toner

[3] Cartridge/C • Replenishes the supply of C toner

[4] Cartridge/Bk • Replenishes the supply of Bk toner

[5] Toner Set Sensor/Bk • Detects Cartridge/Bk as it is loaded in position

[6] Toner Set Sensor/C • Detects Cartridge/C as it is loaded in position

2-26

Page 57

QC 2235plus Theory of Operation Ver.1.0 Mar. 2004 Toner Supply section

Key Name Function/System

[7] Toner Set Sensor/M • Detects Cartridge/M as it is loaded in position

[8] Toner Set Sensor/Y • Detects Cartridge/Y as it is loaded in position

• Drives the Agitating Blades and Metering Rollers of

[9] Toner Supply Motor Y/M (M4)

Cartridges/Y and M

• Energized by the Control Board (PWB-MC)

• Two-phase stepping motor

• Drives the Agitating Blades and Metering Rollers of

[10] Toner Supply Motor C/Bk (M3)

Cartridges/C and Bk

• Energized by the Control Board (PWB-MC)

• Two-phase stepping motor

[11] Agitating Blade/Y, M, C, Bk • Agitates each of different colors of toner

Toner Near-Empty Sensor PQ/Y, M, C,

[12]

Bk (PC15, PC16, PC17, PC18)

Toner Near-Empty Sensor LED/Y, M, C,

[13]

Bk (PC21, PC22, PC23, PC24)