Page 1

1

Product Guide – ineo 361/421/501

ineo 361/421/501

Product Guide

10.03.09

Page 2

2

Product Guide ineo 361/421/501

Table of contents

Product Basic........................................................................................................................3

Product Configuration .........................................................................................................4

System Specifications ...........................................................................................................8

Copier Specifications ..........................................................................................................17

Printer Specifications .........................................................................................................20

Scanner Specifications........................................................................................................26

Fax Specifications...............................................................................................................28

Consumables.......................................................................................................................34

Article Numbers and Compatibility ..................................................................................35

Service Part.........................................................................................................................37

Appendix.............................................................................................................................39

10.08.07

Page 3

3

Product Guide – ineo 361/421/501

PPrroodduuccttBBaassiic

c

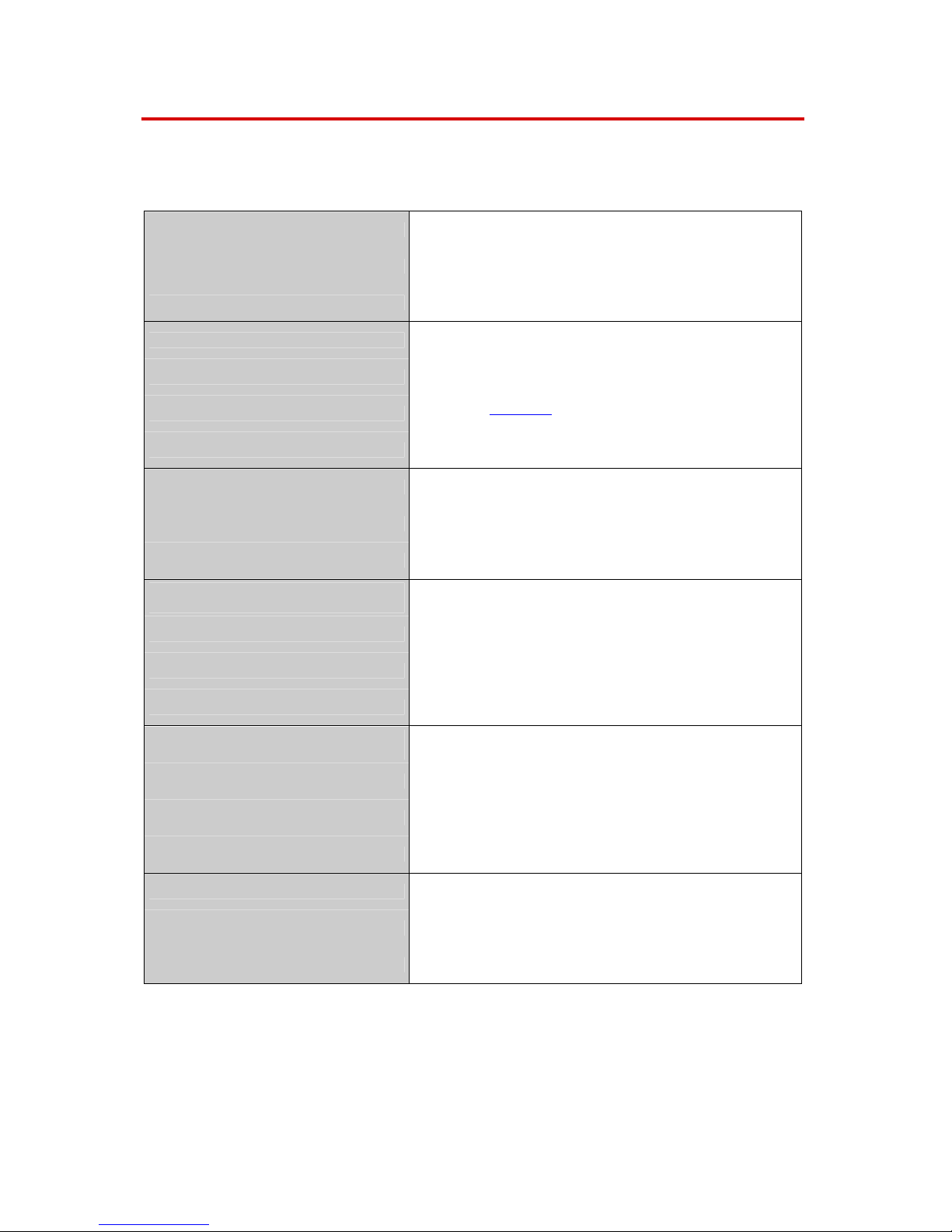

MODEL DEVELOPMENT CODE Ganges M1 Ganges M2 Ganges M3

PROPOSED MODEL NAME

ineo 501 ineo 421 ineo 361

SUCCESSOR MODEL FOR

ineo 500 ineo 420 ineo 360

ESTIMATED SALES START

08/08 08/08 08/08

DATAQUEST SEGMENT

III III VI

ALSO AVAILABLE AS

KM bizhub 501 KM bizhub 421 KM bizhub 361

TYPE

Console / Stationary Platen

MAX. (PEAK) MO NTHLY COPY VOLUME

175 k prints 150 k prints 125 k prints

MAX AVERAGE/PERMANENT MONTHLY

COPY VOLUME

41.6 k prints 30 k prints 30 k prints

MACHINE LIFE

2.5 Mill. prints 1.8 Mill. prints 1.8 Mill. prints

MCBF Body

(Mean Copies Between Failure)

? ? ?

MCBF System

(Mean Copies Between Failure)

70 k prints 50 k prints 50 k prints

MCBJ (Mean Copies Between Jam)

15 k prints 10 k prints 10 k prints

MCBV (Mean Copies between Visit)

? ? ?

MTTR (Mean Time To Repair)

30 min. 30 min. 30 min.

SAFETY & ENVIRONMENT

English Data Sheets dBox / Marketing / Safety and Envir onment

German Data Sheets dBox / Marketing / Safety and Environment

PLEASE NOTICE

Standard paper wei ght for s ystems is 8 0 g/m2 for mono chrome machines a nd 90 g/m2 for full colour one s. Since usin g these standards

result in optimum s ystem performance, all spe cificati ons on pe rformance, reliability, mainten ance and re placeme nt based on those st andard pape rs. Using thick p apers, labels, transfer a nd polyester film s continu ously c an increase the wea r and tear o n replacement pa rts

and consu mables – meaning your servi cing cost s will go u p.

Use the byp ass or the lo wer tra y from the paper feed u nit when working wit h materials having such characteri stics as pol yester films,

textile t ransfer fi lms and labels. Otherwise, you may be faced with doub le feedi ng or a highe r number of feedi ng jams.

If possible use subtray when working with materials having such characteristics as polyester films, textile t ransfer films and labels. Rollermarks on t he copy or p rint may a ppear o r increased jams can occur. St andard p aper wei ghts yie ld the best possible copy an d print results.

Using hi gher grammage ma y influence the quality of the output. U sing standard pape r weights also guarantees t hat double sided copies

and prints are made reliably. Different characters of films as well as thick, thin and coat ed papers may incre ase the jam rate for double

sided copies and prints.

Page 4

4

Product Guide ineo 361/421/501

PPrroodduuccttCCoonnffiigguurraattiioon

n

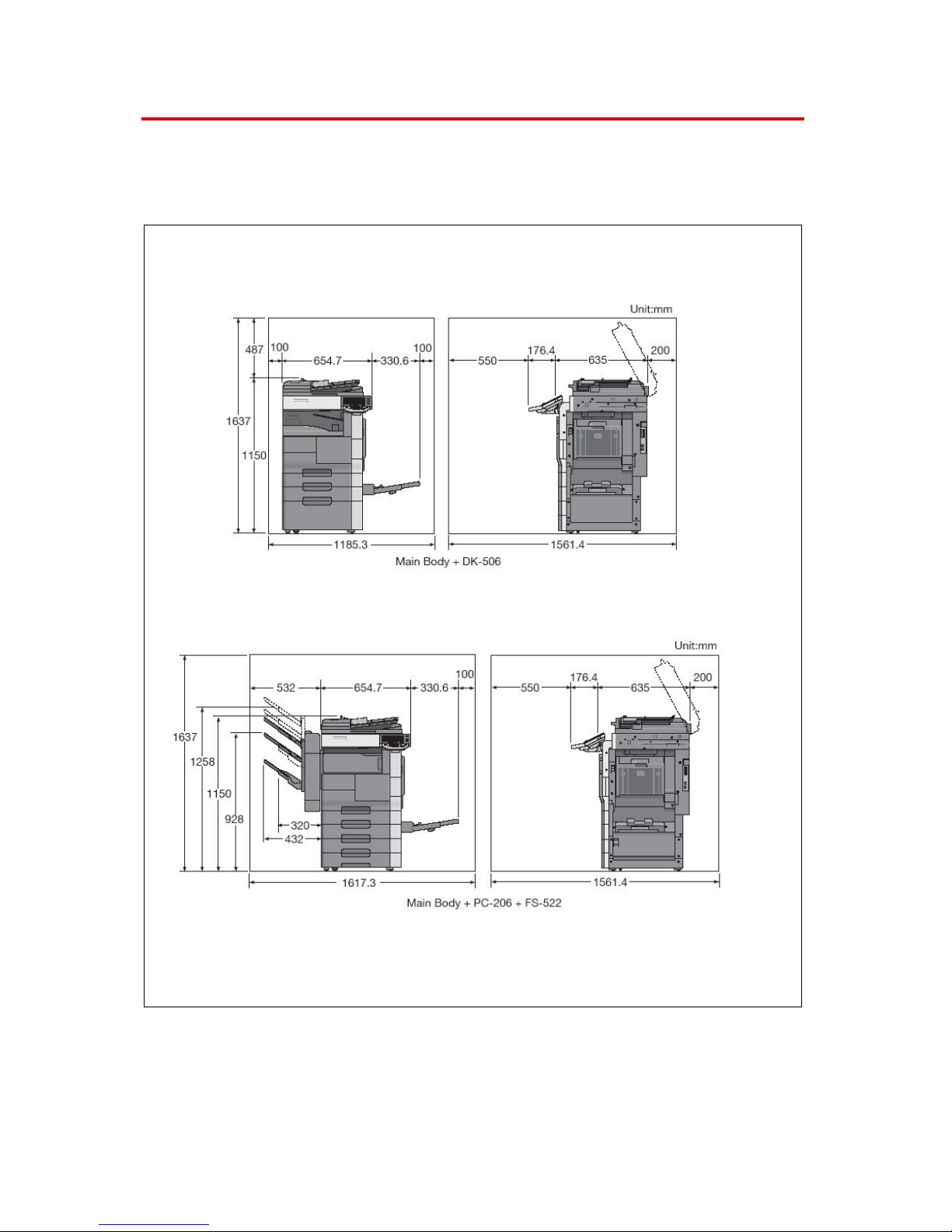

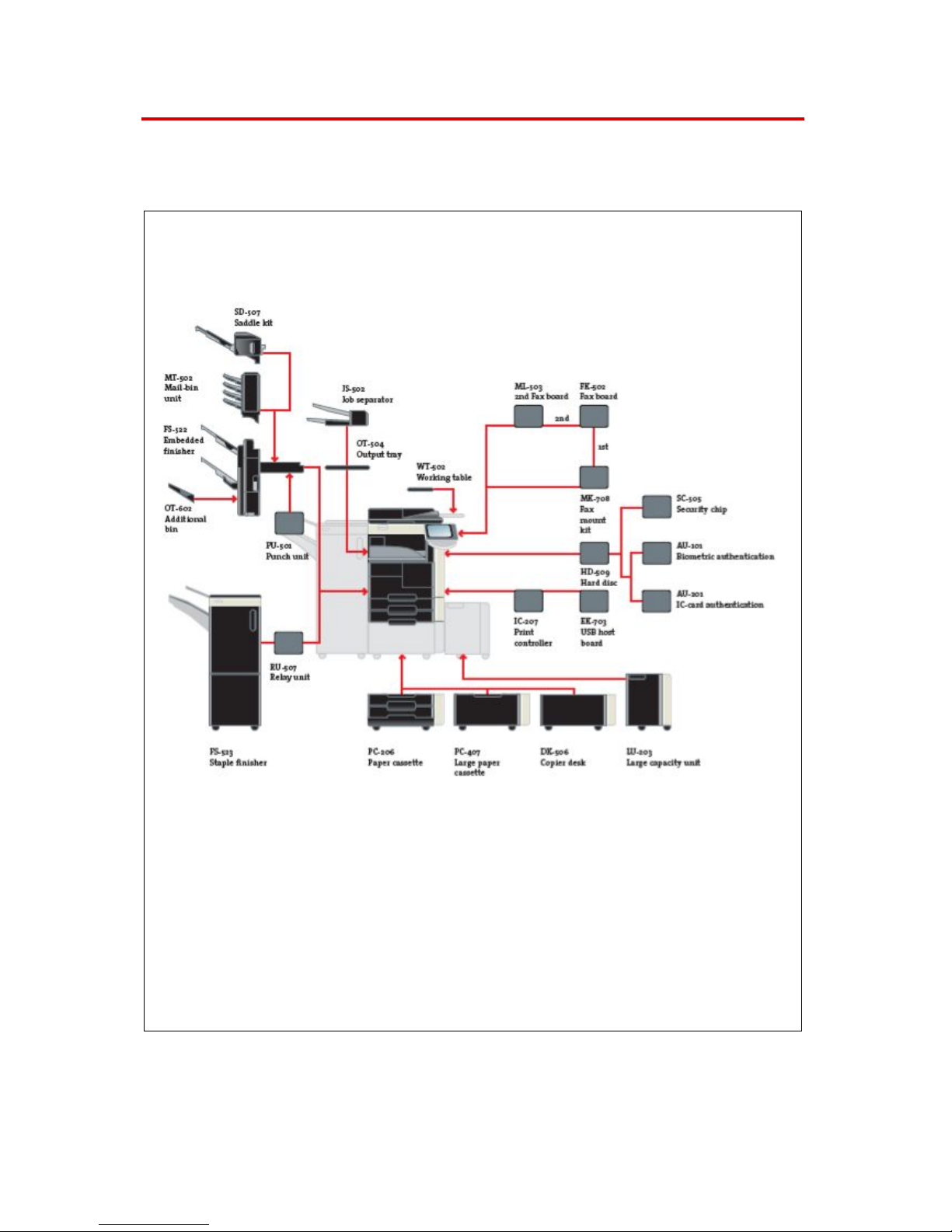

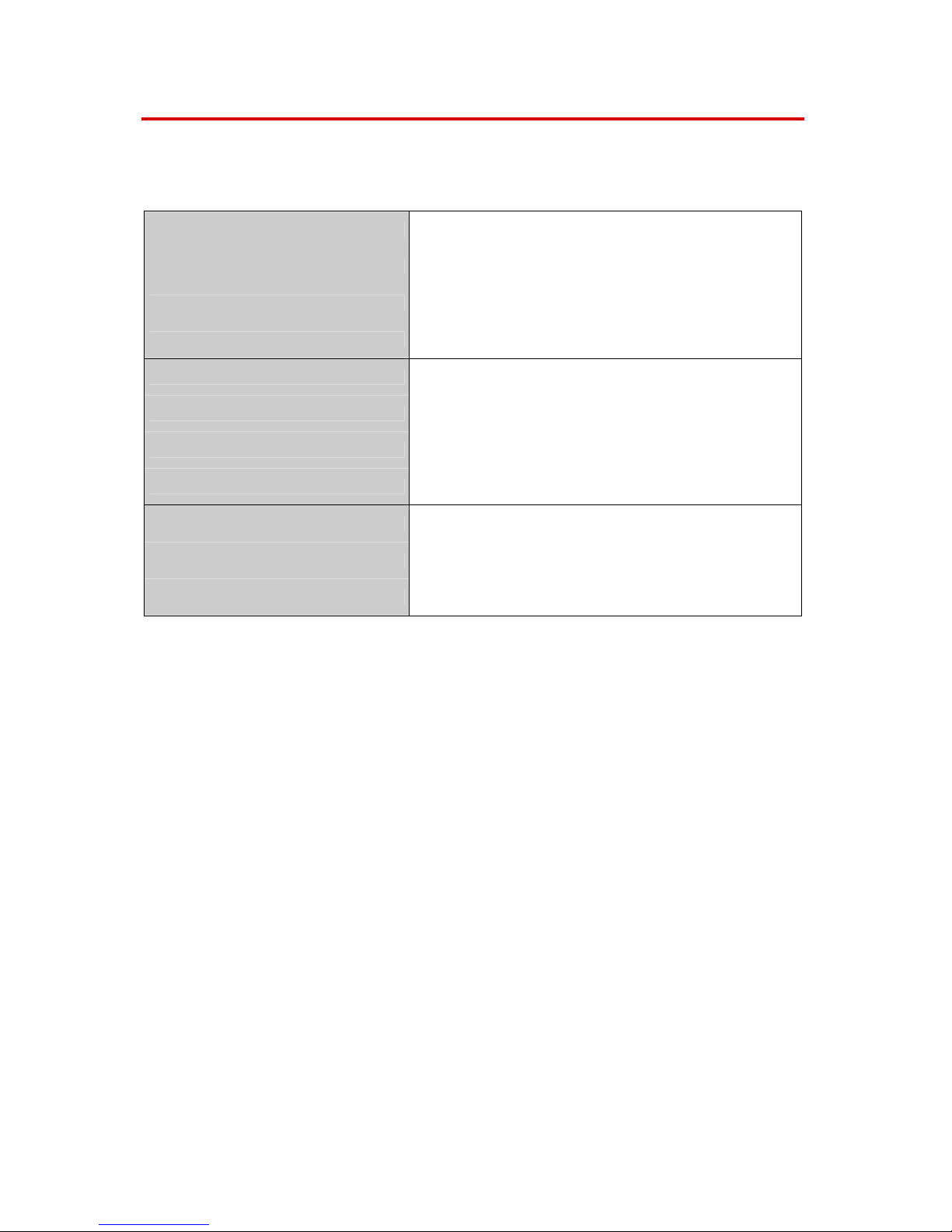

SYSTEM DIMENSIONS

Page 5

5

Product Guide ineo 361/421/501

SYSTEM DIMENSIONS

Page 6

6

Product Guide ineo 361/421/501

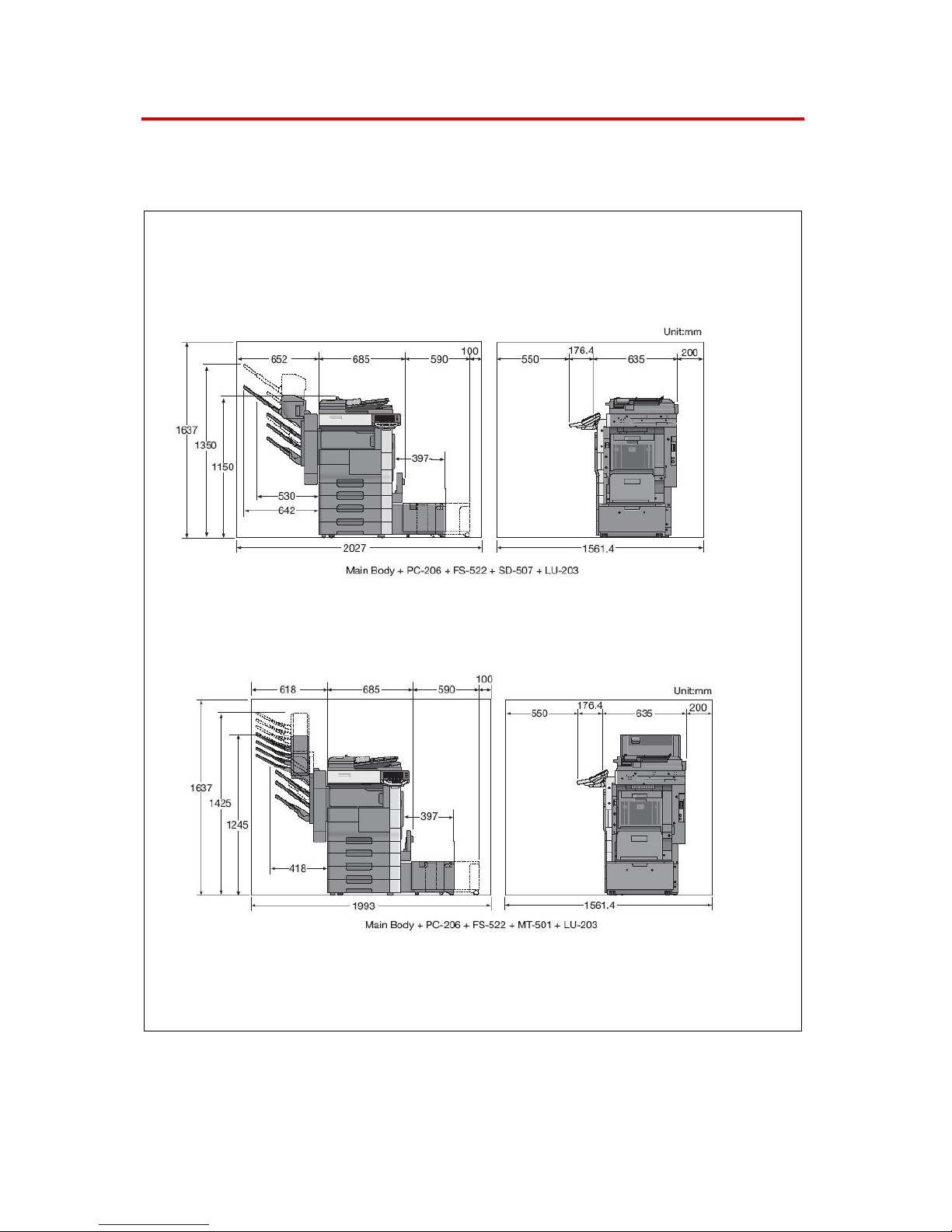

SYSTEM DIMENSIONS

Page 7

7

Product Guide ineo 361/421/501

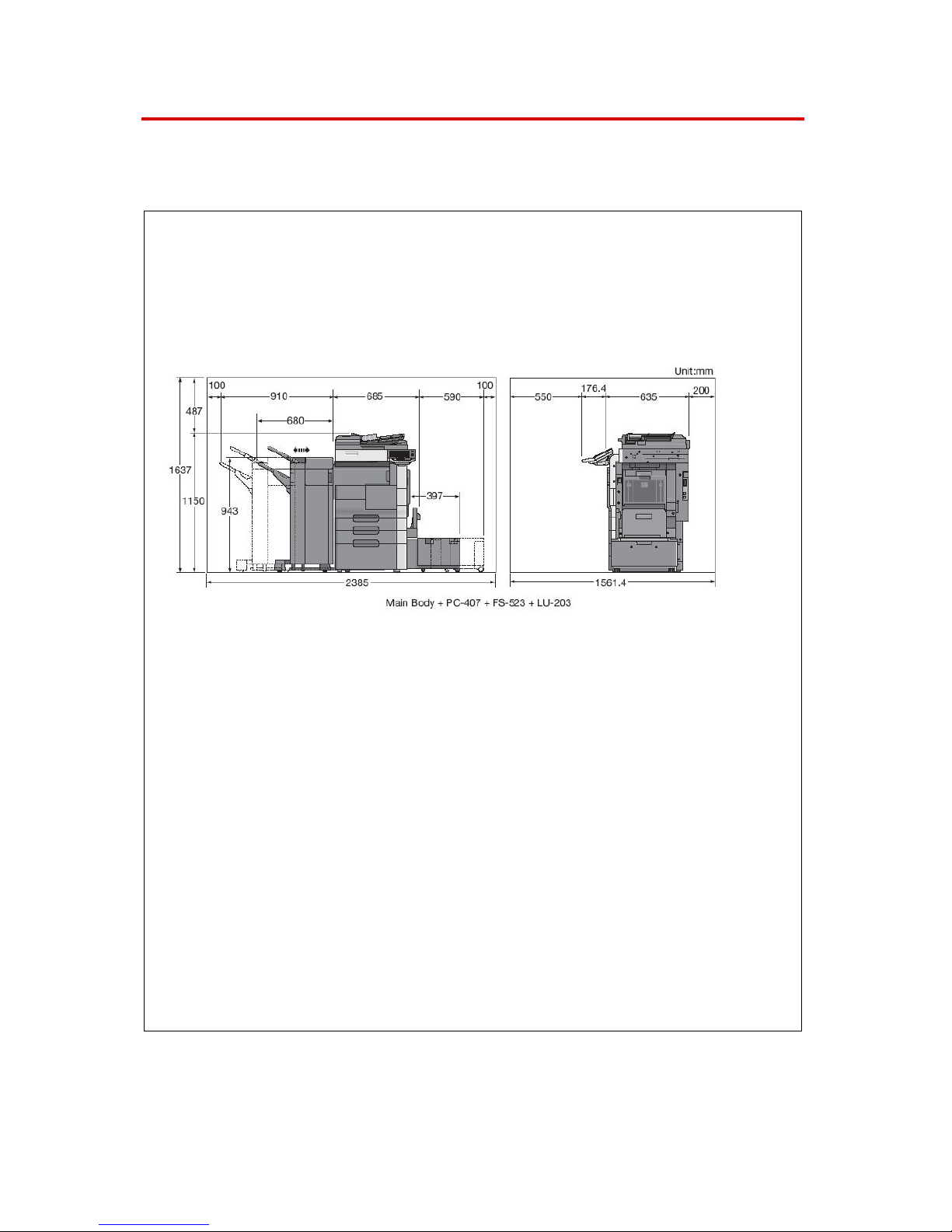

SYSTEM CONFIGURATION

Page 8

8

Product Guide ineo 361/421/501

SSyysstteemmSSppeecciiffiiccaattiioonns

s

DOCUMENT FEEDER (DF-613)

Availability Status Standard

Original Size A5 – A3

Original Weight

Simplex: 35 ~ 128 g/m

2

Duplex: 50 ~ 128g/m

2

Tray Capacity 80 originals (80 g/m2)

Feeding Type Face up, upper sheet

Feeding Speed

50 opm/A4 size simplex (600 x 600 dpi)

70 opm/A4 size simplex (300 x 300 dpi)

Dimensions (WxDxH) mm 582 x 558 x 145

Weight (kg) Approx. 10

Remark The DF-613 is already mounted to the machine from factory side.

PAPER CASSETTES

Availability Status Standard

Capacity 2 x 500 sheets universal (80 g/m2)

Paper Format A5 – A3

Paper Weight 60 – 105 g/m

2

Max. Paper Capacity 1150 sheets standard, max. 5650 sheets

TWO WAY PAPER CABINET (PC-206)

Availability Status Option

Capacity 2 x 500 sheets universal (80 g/m2)

Paper Format A5 – A3

Paper Weight 60 – 105 g/m

2

Dimensions (WxDxH) (mm) 570 x 577 x 300

Page 9

9

Product Guide ineo 361/421/501

TWO WAY PAPER CABINET (PC-206)

cont..

Weight (kg) ?

Remark To connect LU-203 either the PC-206 or the PC-407 is required.

LARGE CAPACITY CABINET (PC-407)

Availability Status Option

Capacity 2,500 sheets (80 g/m2)

Paper Format A4 crosswise

Paper Weight

60 – 105 g/m

2

Dimensions (WxDxH) (mm) 570 x 577 x 300

Weight (kg) ?

Remark To connect LU-203 either the PC-206 or the PC-407 is required.

2000 SHEET TRAY (LU-203)

Availability Status Option

Capacity 2000 sheets A4 crosswise (80 g/m2)

Paper Size A4 crosswise

Paper Weight 60 – 105 g/m

2

Dimension (WxDxH) (mm) 424 x 515 x 295

Weight (kg) 16

Remark To connect LU-203 either the PC-206 or the PC-407 is required.

COPY DESK (DK-506)

Availability Status Option

Remark

Used if no other cassette is connected. For storing paper and

consumables.

Page 10

10

Product Guide ineo 361/421/501

DUPLEX UNIT

Availability Status Standard

Capacity one sheet duplex

Paper Format A5 lengt hwise – A3

Paper Weight 60 – 105 g/m

2

BYPASS

Availability Status Standard

Capacity 150 sheets (80 g/m2)

Paper Format

A6 – A3 (min.: 92 x 148 mm, max.: 297 x 431.8 mm) with automatic

size detection

Paper Weight 50 to 210 g/m

2

Copy Media Envelopes (refer to recommended media), OHP, thick paper

EMBEDDED FINISHER (FS-522)

Availability Status Option

Finishing Modes Non-sort, sort, group, staple

Tray Capacity

Upper tray: 200 sheets (A4 / 80 g/m2)

Lower tray: 1000 sheets (A4 / 80 g/m2)

Stapling Modes Corner stapling, two position stapling

Stapling Capacity 50 sheets

Stapling Format Corner(far side, near side), Parallel binding(far side, near side, 2 points)

Dimensions (WxDxH) (mm) 319 x 558 x 573

Weight (kg)

21.4

Remark 1 staple cartridge MS – 5D is included

Page 11

11

Product Guide – ineo 361/421/501

ADDITIONAL FINISHER TRAY (OT-602)

Availability Status Option for FS-522

Paper Format

Bin Capacity 200 sheets

Remark

Used for FS-522. For more d etails in regard to the capacity refer to the

chapter “Appendix”

MAIL BIN TRAY (MT-502)

Availability Status Option for FS-522

Paper Format

Number of Bins 4

Bin Capacity 125 sheets each

Dimensions (WxDxH) (mm) 624 x 503 x 390

Weight (kg) 8

Remarks Either Mail Bin Tray or Saddle Stitch Unit can be installed to FS-522

SADDLE STITCH UNIT (SD-507)

Availability Status Option for FS-522

Folding Crease fold

Paper Size A4 lengthwise / A3

Paper Weight 60 – 90 g/m

2

Tray Capacity 200 sheets or 20 sets

Stapling Modes Centre parallel 2 points

Stapling Capacity 2 – 15 sheets

Dimensions (WxDxH) (mm)

Inside the transport section: 48 x 399 x 146

Staple Unit and Output Tray: 576 x 281 x 478

Page 12

12

Product Guide ineo 361/421/501

SADDLE STITCH UNIT (SD-507)

cont…

Weight (kg) 9.3

Remark 1 staple cartridge MS – 2C is included in the kit

Either Saddle Stitch Unit or Mail Bin Tray can be installed to FS-522

PUNCH UNIT (P U-501)

Availability Status Option for FS-522

Number of Holes 4

Paper Size A4 – A3

Paper Weight 60 – 160 g/m

2

Dimensions (WxDxH) (mm) 114 x 461 x 136

JOB SEPARATOR (JS-502)

Availability Status Option

Number of Trays 2

Tray Capacity

Tray 1: 250 sheets (60 – 90 g/m2), 20 sh. (90 – 210 g/m2)

Tray 2: 100 sheets (60 – 90 g/m2)

Paper Size

Tray 1: A5 lengthwise – A3

Tray 2: A5 – A3

Paper Weight

Tray 1: 60 – 210 g/m

2

Tray 2: 60 – 90 g/m

2

Dimensions (WxDxH) (mm) 450 x 443 x 75

Weight (kg) 1.7

Remark OT-504 is required in addition if the Job Separator should be connected

STAPLE FINISHER (FS-523)

(Floor Type)

Availability Status Option

Finishing Modes Non-Sort, Sort (30 mm shift), Staple Sort, Staple Group, Punch

Tray Capacity

Non-Sort Tray: 250 sheets

Elevator Tray: 3000 sheets A4 or 1500 sheets B4 and bigger or 100

stapled sets with two A4 sheets

Page 13

13

Product Guide ineo 361/421/501

STAPLE FINISHER (FS-523)

(Floor Type) cont…

Stapling Modes

Corner upper or lower – 1-point (45 degree diagonal)

Corner upper or lower – 1 point (parallel)

Centre – 2 point

Stapling Format

Corner upper or lower – 1 point (parallel)

A4S / B5S

Corner upper or lower – 1-point (45 degree diagonal)

A4L / A3S / B5L / B4S

Centre – 2 point

A4S7L / A3S / B4S / B5S/L

Stapling Capacity 50 sheets

Punching Mode

4 hole punch (standard European for mat, Swedish Punch unit available

as option)

Paper Size A4 (crosswise / lengthwise) / B4 / A3

Paper Weight 60 – 90 g/m

2

Dimensions (WxDxH) (mm) 538 x 637 x 978

Weight (kg) 39.2

Remark

To connect the FS-523 either PC-206, PC-407 or the Copy Desk are

required in order to get the height for the paper exit/entrance. To install

finisher FS-523, RU-507 is required.

RELAY UNIT (RU-507)

Availability Status Bundled with FS-523

Dimensions (WxDxH) (mm) 430 x 445 x 445

Weight (kg) 4.9

Remark To install finisher FS-523, RU-507 is required.

OUTPUT TRAY (OT-504)

Availability Status Option

Capacity 100 sheets

Remark

OT-504 is always required if no finisher is connected to the machine.

The Job Separator needs also the OT-504.

Page 14

14

Product Guide ineo 361/421/501

IMAGE CONTROLLER (IC-207)

Availability Status Option

Remark For details please refer to the chapter “Printer Specifications”

FAX KIT (FK-502)

Availability Status Option

Remarks MK-708 is required to connect FK-502 to the machine.

MULTI-LINE FAX KIT (ML-503)

Availability Status Option

Remarks Together with ML-503 and MK-708 a second FK-502 can be connected.

FAX CONNECTION KIT (MK-708)

Availability Status Option

Remark Required if FK-502 should be connected.

STAMP UNIT FAX (SP-501)

Availability Status Option for DF-613

Remark Fax originals for outgoing faxes are marked

REPLACEMENT STAMP for SP-501

Availability Status Option for SP-501

Remark Spare stamp

DATA DRIVE (HD-509)

Availability Status Option

Memory Capacity 60 GB

Remark

Large data handling, numbering, Box functionality, multi jobs, address

management for fax, etc. please refer to “Appendix”

Page 15

15

Product Guide ineo 361/421/501

SECURITY CHIP (SC-505)

Availability Status Option

Remark For HDD data encryption

i-Option Upgrade Kit (UK-202)

Availability Status Option

Articles included 1 GB memory, Stylus pen and function labels for the panel

Remark UK-202 is required if i-Option (LK-xxx) is used

LOCAL INTERFACE KIT (EK-703)

Availability Status Option

Remark USB 2.0 Interface for local USB printing if IC-207 is installed

BIOMETRIC AUTHENTICATION UNIT

(AU-101)

Availability Status Option

Function Authentication by finger vein scanner

Remark

HD-509 is required. It is recommended to use the WT-502 in addition to

place AU-101.

IC CARD AUTHENTICATION UNIT (AU-

201)

Availability Status Option

Function Authentication by contact less IC cards

Remark

HD-509 is required. It is recommended to use the WT-502 in addition to

place AU-201

WORKING TABLE (WT-502)

Availability Status Option

Function To place eg. originals or an Authentication Unit

Page 16

16

Product Guide ineo 361/421/501

LICENSE KEY (LK-101) Available for ineo 361/421/501 end of 2008

Availability Status Option

Function Web Browser Function

Remark EM-312 is required in addition. Planned to be be part of an UK?

LICENSE KEY (LK-102) Available for ineo 361/421/501 end of 2008

Availability Status Option

Function PDF Encryption Function

Remark EM-312 is required in addition. Planned to be be part of an UK?

KEY COUNTER Kit 4

Availability Status Option

Remark The kit includes a counter, a socket, a bracket, a cover and a cable.

Page 17

17

Product Guide ineo 361/421/501

CCooppiieerrSSppeecciiffiiccaattiioonns

s

ineo 501 ineo 421 ineo 361

WARM-UP TIME Main Power

ON

60 sec. 30 sec. 30 sec.

FIRST COPY

3.2 sec. 3.6 sec. 3.6 sec.

COPY SPEED

50 cpm A4 crosswise

(simplex & duplex)

42 cpm A4 crosswise

(simplex & duplex)

36 cpm A4 crosswise

(simplex & duplex)

35 cpm A4 lengthwise 30 cpm A4 lengthwise 30 cpm A4 lengthwise

31 cpm B4 26 cpm B4 26 cpm B4

27 cpm A3 23 cpm A3 23 cpm A3

COPY RESOLUTION

Read: 600 x 600 dpi

Write: 2400 (equivalent) x 600 dpi

COPY RAM Standard Memory: 1 GB Image memory & system memory

ZOOM

25 % - 400 % adjustable in 0.1 % steps

MULTI COPY

1 – 999

EXPOSURE CONTROL

Auto/Manual (9 steps), Text, Text/Photo, Photo, Dot Matrix

VOID AREA

Single Sided Copies

Left/right/leading edge: within 3 mm

Tailing edge: within 6 mm

INNER OUTPUT TRAY CAPACITY

100 sheets (w. OT-504)

POWER REQUIREMENT

220 – 240 V : 7 A + 10 % 50 Hz

POWER CONSUMPTION

max.: Less than 1560 W

Low Power Mode: 95 W

Sleep Mode: 2.8 W

Plug-in: 0.2 W

COPIER DIMENSIONS (W x D x H)

mm

677 x 708 x 895 (Main Body incl. DF-613)

COPIER WEIGHT (kg)

97.0 (Main Body incl. DF-613)

Page 18

18

Product Guide ineo 361/421/501

FEATURE LIST

AMS/APS Yes / Yes

2 in 1 Original Separation Yes

N in 1 Yes, 2, 4, 8 in 1 also duplex

Book Copy Yes

Booklet Creation Yes, also in combination with cover selection

Page Insertion Yes, up to 30 inserts

Continuous Page Numbering Yes

Cover Mode Yes

Date / Time Stamp Yes

Built-in Stamp Yes

Set Numbering (Distribution Numbering) Yes

Watermark Yes

Image Overlay Yes

Registration Overlay Yes HDD required

Department Control Yes

Edge / Frame Erase Yes / Yes

Image Insertion Yes

Chapter Insertion Yes

Image Repeat Yes

Image Shift Yes

Image Rotation Yes, criss/cross possible

Job / Memory Recall Yes

Page 19

19

Product Guide ineo 361/421/501

FEATURE LIST cont.

Non-Image Area Erase Yes

OHP Interleaving Yes

Positive-Negative-Mode Yes

X/Y Independent Zoom Yes

Program Memor y Yes (30)

Proof Copy Yes

Separate Scanning Yes

Skip Job Yes

Program Job Yes

Enlarge Rotation Yes

Mixplex Setting Yes

Page 20

20

Product Guide ineo 361/421/501

PPrriinntteerrSSppeecciiffiiccaattiioonns

s

TYPE / Version

Embedded ineo Controller as option

CPU

Celeron 600 MHz

PRINT SPEED

36 / 42 / 50 ppm A4 (crosswise)

23 / 23 / 27 ppm A3

PRINT RESOLUTION

600 x 600dpi,

2400 / 1200 x 600 dpi (Smoothing Technology)

MAX PRINTABLE AREA

Front: max. 293 x 426 mm

Back: max. 293 x 424 mm

PDL

PCL5e/XL (PCL6) emulation

PostScript 3 emulation

PRINT RAM

Standard 1 GB memory shared

PRINT HDD

60 GB (option) for common use, copy, print, scan

FONTS

PCL: 80 fonts

PS: 136 fonts

INTERFACE

USB Yes , option (EK-703)

10BaseT / 100 / 1000BaseTX Yes, standard

ETHERNET PORT

Port 9100 bi-direction (status Read back OK)

DIRECT PRINT

PDF / TIFF / XPS (HDD required)

PROTOCOLS

Nibble/ECP Yes/Yes

EtherTalk Yes (PAP)

IPX/SPX Yes with support of NDS (Novell Directly Service)

Page 21

21

Product Guide ineo 361/421/501

PROTOCOLS… cont…

TCP/IP Yes (LPR, RAW Socket)

SNMP Yes.

SMTP/POP3 Yes.

HTTP Yes.

Netware Yes

NDPS Yes

Ipd Yes

IPP Yes

Apple Talk Yes

PRINTER DRIVER

Windows 2000 Yes, for both PCL6, PCL5e, PS (native).

Windows XP Yes, for both PCL6, PCL5e, PS (native).

Windows Server 2003 Yes, for both PCL6, PCL5e, PS (native)

Vista Yes

Mac 9.0 or later Yes

Mac OS X (10.2, 10.3 & 10.4)

Yes

NETWORK

Frame Type IEEE802.2 / 802.3 / Ethernet II / IEEE802.3SNAP

Interface Ethernet 10/100/1000Base-T

Connector RJ-45

Network Management Protocol

TCP/IP: BOOTP, ARP, ICMP, DHCP, SNMP, HTTP, IPP

IPX/SPX: SNMP, AppleTalk (EtherTalk): PAP

Dynamic DNS, NTLM (vers. 2.0), NTTP

Page 22

22

Product Guide ineo 361/421/501

NETWORK

cont…

Support NOS

Windows2000/XP/Server2003/Vista 32/64 Bit

Mac 9.2 or later, Mac OS 10.2, 10.3, 10.4

Novel Netware (3.x, 4.x, 5.x, 6.x

Multi Protocol Automatic

UTILITIES

Net Care Yes (bundled with the ineo system)

Network Setup Yes (bundled wit h the i neo system)

NDPS Gateway Yes (bundled with the ineo system)

PEMS Plug-ins Yes (bundle d with the ineo system)

Workware Yes

ineo Remote Care Yes

Data Administrator Yes (bundled with the ineo system)

Print Utility for Unix Yes

Page 23

23

Product Guide ineo 361/421/501

PRINTER DRIVER SPECIFICATIONS

Copies 1 - 999

Printing Direction Portrait / Landscape

Specify Original Size Yes

Specify Print Size

Yes, with PCL / PS Visual driver

No, with PS (PPD) driver

Zoom 25 % - 400 %

Specify Paper Take up Tray Yes

Specify Kinds of Paper Yes

N - up 2 / 4 / / 6 / 9 / 16 up

Poster Mode 2x2, 3x3, 4x4

Stitch Positioning Left / Top / Right

Duplex Print Yes

Book Print Yes (Left / Right)

After Copy Treatment

Selection of Exit Tray (Main Tray, Sub Tray, Booklet Tray)

Sort (On / Off)

Staple (1 or 2 Position)

Half Fold & Centre Stapling

Punch (Specify 2 or 4 holes)

Sort Yes

Mixmedia Yes

OHP Interleaving Yes

Stamp Yes

Date / Time Stamp No

Overlay Create / Use Yes / Yes

Distribution Numbering Yes

Proof & Print Yes

Page 24

24

Product Guide ineo 361/421/501

PRINTER DRIVER SPECIFICATIONS

CONT..

Secure Job Yes

Store Job to HDD Yes

User Authentication Yes

Section Management Print Yes

MixPlex Yes

Image Shift Yes

Smoothing Yes

Specify Print Density Yes

User Authentication Yes

Specify Toner Save Yes

OHP Overlay Non–Print Overlay / Print Overlay

Cover Page, Rear Cover Page

Cover Page: Non–Print / Print

Rear Cover Page: Non – Print / Print

Mixed Media Yes

Chapter Yes

Non Print Paper Restraint Yes

AMS Yes

Watermark Yes

Form Overlay Yes

PC - Fax Yes, separate PC fax driver

Transmit Once Print Many Yes

RIP Once Print Many Yes

Page 25

25

Product Guide ineo 361/421/501

FINISHING

Sorting Yes

Stapling Yes

Punching Yes

Folding Yes

Cover Insert ion No

Trimming No

Page 26

26

Product Guide ineo 361/421/501

SSccaannnneerrSSppeecciiffiiccaattiioonns

s

SCAN FUNCTIONS

Network Twain Scan Yes (with HD-509)

Scan to FTP Yes

Scan to HDD (Scan to Mailbox) Yes (with HD-509)

Scan to E-mail Yes

Scan to PC (SMB) Yes

Scan to USB Yes

Scan to iFAX Yes (with HD-509 and IC-207)

SCAN BASICS

Scan Speed (with EDH)

70 scans per minute with 200 x 200 dpi, 300 x 300 dpi, 400 x 400 dpi

or 50 scans per minute with 600 x 600 dpi for all models with

Document Feeder

Paper Size A5 – A3

Colour Scanning Capability No

Separate Scan Counter Yes

Scan Format TIFF, PDF, XPS (with HD-509)

Coding (Compression) MH, MR, MMR

NETWORK TWAIN

Client OS Win98SE/Me/NT4.0, SP6/2000/XP/2003/Vista

SCAN TO EMAIL

Protocol SMTP

Resolution 200x200 (default), 400x400, 600x600 dpi.

Max. destinations

2100 (2000 single + 100 groups)

300 scan programs = Destination + Scan Setting

Image divisi on Yes ( Off / On by Page or Size )

Page 27

27

Product Guide ineo 361/421/501

SCAN TO FTP

Protocol FTP

Resolution 200x200 (default), 400x400, 600x600 dpi.

Max. destinations

2100 (2000 single + 100 groups)

300 scan programs = Destination + Scan Setting

SCAN TO HDD (box)

(HD-509 required )

Resolution 200x200 (default), 400x400, 600x600 dpi.

Max. Boxes (Scan to HDD) 1000

Password protection Yes (except Public mailbox).

Notes

Stored scanned image can be retri eved fr om both

Web Connection and Twain driver.

LAN-FAX

Protocol e-mail : SMTP, POP3 ; LAN-FAX : TCP/IP

Paper Size

E-mail : Only A4, B4, A3 (depends on the ability of receiver) ; LANFAX : Same with FAX

Resolution

200 x 100, 200 x 200, 400 x 400, 600 x 600 dpi

( e-mail : depends on the ability of receiver )

ENHANCED FEATURES

Address Setting LDAP, Import/Export address from Web Connection

Authentication Yes, Authentication in sending E-Mail, Network User Authentication

UTILITIES

Workware Yes , (Workware Trial/Demo)

Data Administrator Yes (EFGIS. FGIS comes later on)

Page 28

28

Product Guide ineo 361/421/501

FFaaxxSSppeecciiffiiccaattiioonns

s

GENERAL DATA

Protocol

Group 3 (compliant to ITU-T T.30)

F-Code communication

Min Transmission Time (seconds) < 3 Sec. ITU-T V.34,JBIG (ITU No. 1)

Max. Modem Speed / Compatibility 33,6 kbps / ECM, Super G3

Coding / Error Correction (ECM) MH, MR, MMR, JBIG

Modulation Method V27ter, V29, (V33), V17, V8 and V34

Document Memory 32 MB (shared with scanner).

Memory Battery Buffered

60 hrs. (after 28 hrs. full charge)

Life: charging and discharging 5.000 times

Dual Access (2 channels) Yes

Dual Line Ye s (two FK-502 are required)

Remote Diagnostic CS Remote Care (via fax-line)

Display / Error Indicator Yes

DIALING

Max. Numbers Stored (Scanner & Fax)

Abbreviated dial: 2000 w HDD, 1000 w/o HDD

One-touch dial: 400 (with HDD)

Max. Phone Digits 38 digits

Program Keys (Scanner & Fax) Yes, 400 w HDD, 200 w/o HDD

Group Setti ng (max.) Yes, 100 (max. 500 destinations)

Tone / Pulse Select Yes / No

PSTN-access by No / Earth Key / Flash Yes / No / Yes (default: off, service function)

Sub addressing Yes

Auto Redial / Last Number Redial Yes / Yes (possible to select from five latest histories)

Electronic Telephone Book Function Yes

Monitor Speaker Yes

Page 29

29

Product Guide ineo 361/421/501

TRANSMISSION / INPUT

Transmission Resolution 200 x 100 dpi, 200 x 200 dpi, 400 x 400 dpi, 600 x 600 dpi

Effective Scanning Width Max A3

Max. Size FBS (W x L) 216 x 356 mm

Halftones Yes, 256

Number of Timers max. 20

Storable TX Jobs max. 99

ADF/Memory Transmission Yes / Yes

Book Transmission Yes

Header Line (TTI) Yes

Department Management Yes

Closed Network TX / Protected TX Yes / Yes

Quick Memory Transmission Yes

Batch Transmission Yes

2-to-1 Transmission No

2-Sided Transmission No

Cover Page Function Yes

Max. Broadcasting Locations 230

Relay Broadcasting Yes (using ITU subaddress function)

Relay Broadcast Command Yes (using ITU subaddress function)

Page 30

30

Product Guide ineo 361/421/501

RECEIVING / OUTPUT

Recei ving Resolution 203 x 98 dpi, 203 x 196 dpi, 406 x 392 dpi

Effective Print Wi dth (fax mode) A4 (3±2 mm margin)

Smoothing Yes, for 203 x 98 dpi only

Auto / Manual Reception Yes / Yes

Storable RX Jobs Max. 250

Reduction in Fax Mode Yes

Paper source selection Yes

Receiving / Output Tray Selection No

Memory Receiving Yes

Footer Print Yes

Closed Network RX / Protected RX No / Yes (block Junk Fax)

2 to 1 Receiving Yes (A5/2 pages => A4/1 page)

Duplex Reception Yes

RX-Memory Print by Password Yes (Security reception)

Forward Function [Fax Gateway] Yes [fax number, Box and to-eMail]

Max. Polling Locations max. 230

Selective / Protected Polling Yes (ITU subaddress) / yes (ITU subaddress)

Memory Polling (Database Polling) Yes

Page 31

31

Product Guide ineo 361/421/501

REPORTS AND LISTS

Telephone List Yes

Key Setting List Yes (Soft key: Included in Machine Setting List)

Transmission Report Yes

Reception Result Report Yes

Reser vation Report Yes (Command List)

Broadcast Report Yes (Transmission Confirmation Report)

Error Report Yes (Transmission Confirmation Report)

Machine Status List Yes (Machine Setting List)

Journal Yes

Consumable Order Report Yes ( default: off, service function)

Memory Data List / Print Yes (Stored Document List)

User/Department Management List Yes

UTILITIES

Data Administrator Yes [for programming fax recipi ent]

Page 32

32

Product Guide – ineo 361/421/501

INTERNET FAX

Communication Protocol

Transmission: SMTP

Reception: POP3, TCP/IP

Communication Mode Full mode

Encoding System MH/MR/MMR

Original Size A3, B4, A4

Recording Size Max. A3 (Max. A3 long size original: 1000 mm with document feeder)

Interface Ethernet 10/100/1000Base-T

Resolution 200 x 100 dpi, 200 x 200 dpi, 400 x 400 dpi, 600 x 600 dpi

Format

Transmission: TIFF-S

Reception: TIFF-F

Server Software Send mail, Postfix, Qmail t

Remark HD-509, IC-207 required

IP ADDRESS FAX

Communication Protocol Transmission & Reception: SMTP

Colour Mode Monochrome

Encoding System MH/MR/MMR

Original Size A3, B4, A4

Recording Size Max. A3 (Max. A3 long size original: 1000 mm with document feeder)

Interface Ethernet 10/100/1000Base-T

Resolution 200 x 100 dpi, 200 x 200 dpi, 400 x 400 dpi, 600 x 600 dpi

Format TIFF-F

Remark HD-509, FK-502, IC-207 required

Page 33

33

Product Guide – ineo 361/421/501

SIP FAX

Encoding System MH/MR/MMR

Original Size A3, B4, A4

Recording Size Max. A3 (Max. A3 long size original: 1000 mm with document feeder)

Interface Ethernet 10/100/1000Base-T

Resolution 200 x 100 dpi, 200 x 200 dpi, 400 x 400 dpi, 600 x 600 dpi

Format TIFF-F

Remark HD-509, FK-502, IC-207, SIP FAX adapter required

Note: Specification may vary due to national PTT regulations

Page 34

34

Product Guide ineo 361/421/501

CCoonnssuummaabbllees

s

TONER for ineo 501/421/361

Name TN-511

Concept Cartridge system

Weight 676 g

Yield 32.2 k copies / prints (6% coverage)

Units per carton 1 cartridge

Remark With Toner Recycling

DEVELOPER for ineo 501/421/361

Name DV-511

Weight 625 g

Yield

225 k copies prints ineo 361

250 k copies / prints ineo 421/501

Units per carton 1

PC-DRUM for ineo 501/421/361

Name DR-510

Yield

225 k copies prints ineo 361

250 k copies / prints ineo 421 / 501

Units per carton 1

STAPLE CARTRIDGE FOR FS-522/523

Name MS – 5D (MAXX)

Quantity per Sales Unit 3 x 5000 staples

STAPLE CARTRIDGES FOR SD-507

Name MS – 2C (MAXX)

Quantity per Sales Unit 4 x 2000 staples

Page 35

35

Product Guide ineo 361/421/501

AArrttiicclleeNNuummbbeerrssaannddCCoommppaattiibbiilliitty

y

MACHINE Article Number

ineo 361

A0R7121

ineo 421

A0R6121

ineo 501

A0R5121

Accessories Article Number Compatibiliy

Document Feeder DF-613 --- --- (Standard)

Paper Cabinet PC-206 A0RCW21 ---

Large Capacity Tray PC-407 A0RCW22 ---

2000 Sheet Tray LU-203 A0R9W21 ---

Copy Desk DK-506 9960780000 ---

Embedded Finisher FS-522 A0HNW21 ---

Additional Finisher Tray OT-602 4625246 FS-519

Mail Bin Tray MT-502 4510761 FS-519

Saddle Stitch Unit SD-507 A0PGW21 ---

Punch Unit European Version PU-501 4512814 FS-508, FS-510

Punch Unit Swedish Version PU-501 4512817 FS-508, FS-510

Floor Type Finisher FS-523 A0PH W21 ---

Relay Unit RU-507 A0RDWY1 ---

Swedish Punch Kit G (for FS-523) 4623 421 FS-511

Job Separator JS-502 4347 711 ineo 200/250/350/360/420/500

Output Tray OT-504 A0RAWY1 ---

Image Controller IC-207 A0P8W21 ---

Local Interface Kit EK-703 A0P4WY1 ---

Page 36

36

Product Guide ineo 361/421/501

Accessories cont. Article Number Compatibiliy

Hard Disk Drive HD-509 9967000675 ---

Security Chip SC-505 A0PAWY1 ---

Working Table WT-502 A07EWW0 ineo+ 203/253/353/451/550/650

Biometric Authentication Unit AU-101 A09MWY1 ineo+ 203/253/353/451/550/650

IC Card Authentication Unit AU-201 A09NWY1 ineo+ 203/253/353/451/550/650

MIFARE IC Cards for AU-201

(100 cards)

9967000175 ineo+ 203/253/353/451/550/650

Fax Kit FK-502 15PP

ineo 360/420/500/600/750

ineo+ 250/ 251/300/351/450/451/

550/650/203/253/353

Fax Connecting Kit MK-708 16LA ineo 360/420/500

Fax Multiline Kit ML-503 16PA New version (yellow label)

Stamp Unit Fax SP-501 4614506

AFR-19, DF-601, DF-605, DF607, DF-608, DF-610, DF-611,

Replacement Stamp 4614511

AFR-19, DF-601, DF-605, DF607, DF-608, DF-610, DF-611,

Key Counter Kit 4 4599211

ineo200/250/350/360/420/

500/600/750

i-Option Upgrade Kit UK-202

999966770000000077552

2 (04/09) ineo+ 552/652

License Kit LK-101 A0PDW21 ineo+ 203/253/353/451/550/650

License Kit LK-102 A0PDW22 ineo+ 203/253/353/451/550/650

Consumables

Toner TN-511 024F ineo 360/420/500

Developer DV-511 024H ineo 360/420/500

Drum Unit DR-510 024L ineo 360/420/500

Staples

MS-5D for FS-522 / FS-523 4623 361

FN-8/105/107/109/113/117

FS-508/510/511

MS-2C for SD-507 4599161 SK-1, SD-502/503/505

Page 37

37

Product Guide ineo 361/421/501

SSeerrvviicceePPaarrt

t

Installation

Installation Time

Installation time is based on the following definition.

Ø Place: At the environment with sufficient space to keep the package and packaging materials

Ø Start of measurement: All packed products are prepared on the floor

Ø End of measurement: All products work normally after all adjustment defined on installation manual.

Item

Approx. Time

(Min.)

Main body ineo 501/421/361 20 min.

Simple Copy Desk DK-506 10 min.

Two way paper cabinet PC-206 17 min.

Large capacity cabinet PC-407 13 min.

2000 sheet tray LU-203 13 min.

Relay unit + floor type finisher RU-507+FS-523 13 min.

Inner type finisher FS-522 22 min.

Mail-bin kit MT-502 16 min.

Saddle stitch unit SD-507 25 min.

Punch kit PU-501 22 min.

Additional finisher tray OT-602 5 min.

Output tray kit OT-504 5 min.

FAX connecting kit / FAX kit

FAX multiline/ FAX kit

MK-708/FK-502

ML-503/FK-502

10 min.

Hard disk (for main body) HD-509 5 min.

Security chip SC-505 5 min.

Image controller IC-207 5 min.

Page 38

38

Product Guide ineo 361/421/501

Maintenance

Maintenance Parts 250 k copies for ineo 421/501 and 225 k copies for ineo 361

Part No. Part Name Qty.

1

50GA-209 Drum Cleaning Blade Assy 1

2

50GA-336 Filter Mounting Plate Assy 1

3

50GA1031 Ozone Filter 1

4

40LAR70500 Suction Filter Assy 1

5

A0R5R70100 Filter Cover Assy 1

6

50GA-311 Suction Cover 2 Assy 2

7

50GA5303 Fusing Roller 1

8

50GA5304 Fusing Pressure Roller 1

9

50GA540 Fusing Web 1

10

26NA5372 Heat Insulating Sleeve A 2

11

26NA5371 Fusing Bearing Upper 2

12

50GA5359 Fusing Bearing Lower 2

13

4040R70600 Exit Roll Holder 1 Assy 2

14

4040R70700 Exit Roll Holder 2 Assy 2

15

50GA4406 Paper Exit Suction Filter 1

Notebook recommendation for Service support (minimum configuration)

Hardware:

Notebook, 512MB RAM, 80GB HDD (at least 30 GBs free HDD space when fully configured),

Optical Drive (CD/DVD Read & Write), PCMCIA Slot, 10/100Mbit Ethernet, USB 2.0

Software:

WinXP (rather than Vista), MS-Office, Acrobat Reader, Burning Software (Nero Suite, IBM Record Now etc.), FTP Client

(Filezilla etc.)

Page 39

39

Product Guide ineo 361/421/501

AAppppeennddiix

x

Compatibility between ineo 361/421/501 vs. ineo 360/420/500

Accessories/Consumables Compatibility Remarks

Document Feeder DF-613 no

Document Feeder DF-607 no

colour

Paper Cabinet PC-206 no

Paper Cabinet PC-202 no

colour, size

Paper Cabinet PC-407 no

Paper Cabinet PC-402 no

colour, size

2000 sheet Tray LU-203 no

2000 sheet Tray LU-201 no

colour

Copy Desk DK-506 no

Copy Desk no

colour, size

Embedded Finisher FS-522 no

Embedded Finisher FS-510 no

colour

Additional Finisher Tray OT-602 no

Additional Finisher Tray OT-601 no

colour

Mail Bin Tray MT-502 no

Mail Bin Tray MT-501 no

colour

Saddle Stitch Unit SD-507 no

Saddle Stitch Unit SD-507 no

colour

Punch Unit PU-501 (EU/S) yes ---

Floor Type Finisher FS-523 no

Floor Type Finisher FS-511 no

colour

Relay Unit RU-507 no

Relay Unit RU-502 no

colour

Page 40

40

Product Guide ineo 361/421/501

Compatibility between ineo 361/421/501 vs. ineo 360/420/500

Accessories/Consumables Compatibility Remarks

Job Separator JS-502 yes

Output Tray OT-504 no

Output Tray OT-501 no

colour

Image Controller IC-207 no

Image Controller IC-204 no

Local Interface Kit EK-703 --- Not available for ineo 360/420/500

Hard Disk Drive HD-509 no

Hard Disk Drive HD-505 no

Security Chip SC-505 no

Security Chip SC-502 no

Working Table WT-502 --- Not avail able for ineo 360/420/500

Biometric Authentication Unit AU-101 --- Not avail able for ineo 360/420/500

IC Card Authentication Unit AU-201 --- Not available for ineo 360/420/500

Fax Kit FK-502 yes

Fax Connecting Kit MK-708 yes

Fax Multiline Kit ML-503 yes New F/W (marked with yellow label)

Stamp Unit Fax SP-501 yes

Expanded Memory EM-312 --- Not available for ineo 360/420/500

License Key LK-101/102 --- Not available for ineo 360/420/500

Toner TN-511 yes

Used for ineo 361/421/501 and

ineo 360/420/500

Developer DV-511 yes

Used for ineo 361/421/501 and

ineo 360/420/500

Drum Unit DR-510 yes

Used for ineo 361/421/501 and

ineo 360/420/500

Page 41

41

Product Guide ineo 361/421/501

Maximum paper capacity of FS-522 with different configurations

Total Capacity

Non-Sort /

Sort / Group

Sort Staple Saddle Staple

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

1200 sheets A4

1000 sheets

500 / 250 sheets or 50

/ 25 sets

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

500 / 250 sheets

500 / 250 sheets or 50

/ 25 sets

Additional Finisher

Tray

900 sheets A4

200 sheets

200 sheets or

20 sets

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

500 / 250 sheets

500 / 250 sheets or 50

/ 25 sets

Saddle Stitch Unit

900 sheets A4

200 sheets or

20 sets

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

200 / 100 sheets

200 / 100 or

20 / 10 sets

Additional Finisher

Tray

200 sheets

200 sheets or

20 sets

Saddle Stitch Unit

800 sheets A4

200 sheets or

20 sets

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

500 / 250 sheets

500 / 250 sheets or 50

/ 25 sets

Mail Bin Tray

1200 sheets A4

500 sheets

1st Tray

200 sheets

200 sheets or

20 sets

2nd Tray

(A4 / B4 or A3)

200 / 100 sheets

200 / 100 sheets or 20

/ 10 sets

Additional Finisher

Tray

200 sheets

200 sheets or

20 sets

Mail Bin Tray

1100 sheets A4

500 sheets

Page 42

42

Product Guide ineo 361/421/501

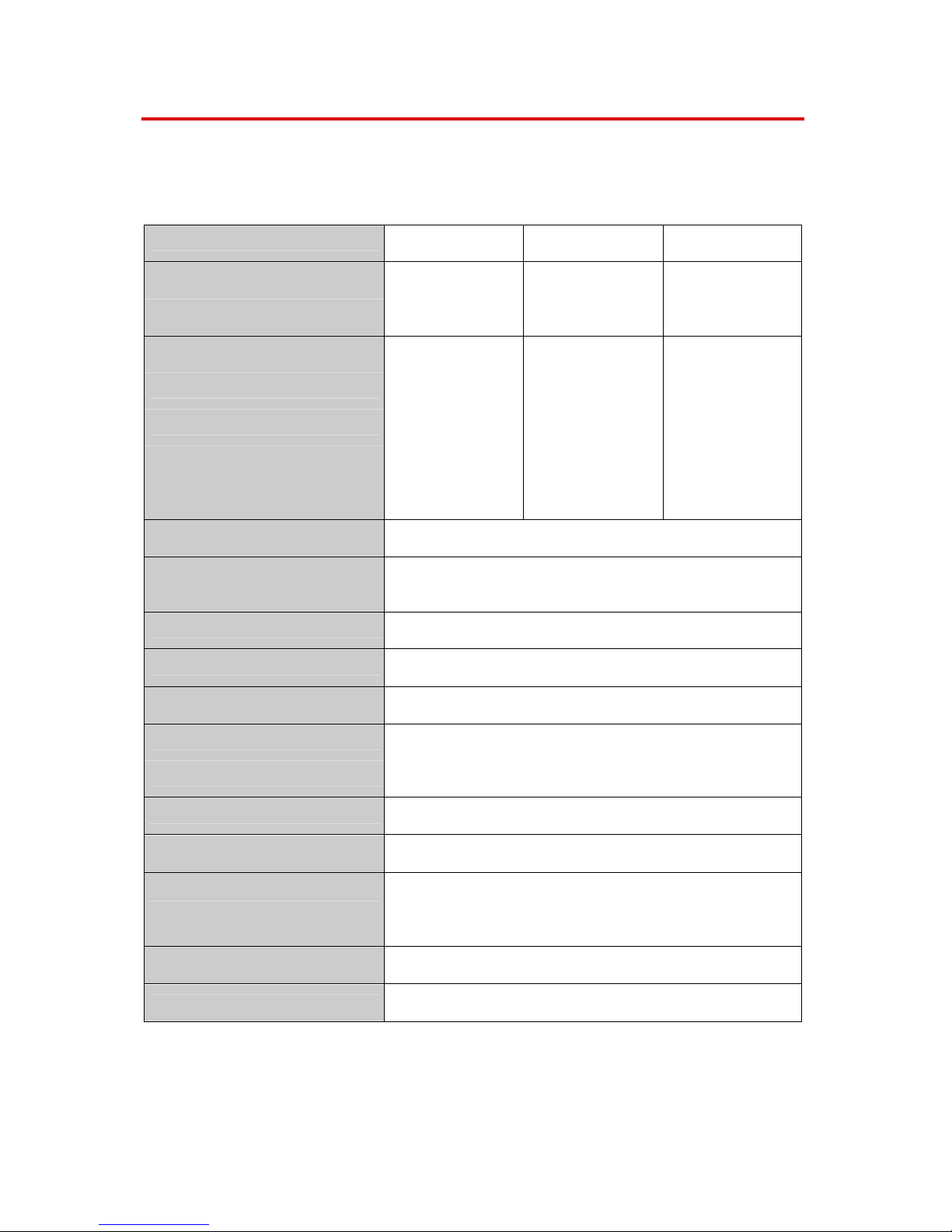

Combination of Finishing Accessories

FS-522 OT-602 MT-502 SD-507 PU-501 FS-523 JS-502

FS-522

yes yes1) yes1) yes no no

OT-602

yes yes yes yes no no

MT-502

yes yes no yes no no

SD-507

yes yes no yes no no

PU-501

yes yes yes yes no no

FS-523

no no no no no no

JS-502

no no no no no no

Either MT-502 or SD-507 can be used with FS-522

Finishing M atrix for FS-522

FS-522

Mail Bin Tray

Punching Stapling

Fold / Saddle

Stitch

FS-522

Yes Yes Yes Yes

Mail Bin Tray

Yes Yes No No

Punching

Yes Yes Yes Yes

Stapling

Yes No Yes Yes

Fold / Saddle

Stitch

Yes No Yes Yes

Page 43

43

Product Guide – ineo 361/421/501

Stacking Capacity of FS-523

Sheets stapled Sets Sheets

2 100 200

3 - 5 80 400

6 - 10 60 600

11 - 20 60 1200

21 - 30 60 1800

31 - 40 60 2400

41 - 50 60 3000

Page 44

44

Product Guide – ineo 361/421/501

Paper Weights

Option / Feature 60 ~ 105 g/m

2

105 ~ 210 g/m

2

Machine Yes No

PC-206 Yes No

PC-407 Yes No

LU-203 Yes No

Manual Feed Yes Yes

ineo 361

ineo 421

ineo 501

Duplex Yes No

1st Tray Yes Yes

2nd Tray Yes Yes

Additional Tray Yes Yes

FS-522

Mail Bin Yes (up to 90 g/m2) No

Stapling Yes (up to 90 g/m2) No

Punching Yes Yes (up to 160 g/m2)Finishing Functionality

Folding Yes No

FS-523

Non-Sort Tray Yes Yes

1st Tray Yes Yes

JS-502

2nd Tray Yes (up to 90 g/m2) No

Page 45

45

Product Guide – ineo 361/421/501

Option Matrix

Paper Exit Options

JS-502 OT-504 FS-522 MT-502 SD-507 PU-501 OT-602 FS-523 RU-507

JS-502

must no no no no no no no

OT-504

must no no no no no no no

FS-522

no no OK OK OK OK no no

MT-502

no no OK no OK OK no no

SD-507

no no OK no OK OK no no

PU-501

no no OK OK OK OK no no

OT-602

no no OK OK OK OK

no no

FS-523

no no no no no no no must

RU-507

no no no no no no no must

Inner Options

IC-207

FK-502

(1)

FK-502

(2)

MK-708 ML-503 HD-509 SC-505

EM-312

(pend.)

LK

Kits

IC-207

OK OK OK OK OK OK OK OK

FK-502

(1)

OK

OK must OK OK OK OK OK

FK-502

(2)

OK must

must must OK OK OK OK

MK-708

OK must OK OK OK OK OK OK

ML-503

OK must must must OK OK OK OK

HD-509

OK OK OK OK OK

OK OK OK

SC-505

OK OK OK OK OK OK OK OK

EM-312

OK OK OK OK OK OK

must

Licen.

Kits

OK OK OK OK OK OK OK OK

Page 46

46

Product Guide ineo 361/421/501

Option Matrix continued

Paper Feed Options

PC-206 PC-407 Copy Desk LU-203

PC-206

No no OK

PC-407

no no OK

Copy Desk

no no no

LU-203

must (either) no

Remark: The Finisher FS-523 has always to be combined with PC-206, PC-407 or with the

Copy Desk in order to get the correct height for the paper entrance into the finisher.

The Large Capacity Tray LU-203 has always to be combined with either PC-206 or

PC-407 as the paper path of those cassettes is used to transport the paper into the

machine.

The Output Tray OT-504 is always required if either no

Finisher is used or JS-502

should be connected. It covers the output section in the machine.

Page 47

47

Product Guide – ineo 361/421/501

Function Matrix

Function IC-207 HD-509

FK-502 +

MK-708

ML-503 SC-502

AU-101/

AU-201

WT-502

Copy

--- --- --- --- --- --- ---

PCL/PS Print

Yes --- --- ---

Fax

--- --- Yes --- --- --- ---

Dual line fax

--- ---

Yes (2 x

FK-502)

Yes --- --- ---

Scan-to-eMail/FTP/SMB

--- --- --- --- --- --- ---

Scan-to-Box/HDD/Twain

--- Yes --- --- --- --- ---

Data encryption

--- Yes --- --- Yes

iFax

Yes Yes --- --- --- --- ---

IP-Address Fax

Yes Yes Yes --- --- --- ---

SIP-Fax ٭

Yes Yes Yes --- --- --- ---

Authentication

--- Yes --- --- --- Yes Yes

XPS scan/XPS prin t

--- Yes --- --- --- --- ---

٭ SIP Adapter also required!

Function HD-509 EK-703 UK-202 LK-101/102 I-Enabler

Pull Scan

Yes --- --- --- ---

i-option

Yes --- Yes Yes ---

Local print through USB if IC-

207 is installed

---

Yes --- --- ---

Right Fax

Yes ٭

--- --- --- ---

٭ Setup Utility for Right Fax is required in addition. If FK-502 is connected, Right Fax is not

possible!

Page 48

48

Product Guide – ineo 361/421/501

Function Enhancement with HD-509

ð Handling of larger data

ð Account Control w & w/o HDD 1000 accounts, w/o HDD 100 accountsCopying / Printing Features

ð Account Track by Password with 8 Characters

One touch: 400 w HDD

200 w/o HDD

Program: 400 w HDD

200 w/o HDD

Fax Features

ð Increased addresses

Shortcut: 2,000 w HDD

1,000 w/o HDD

Scanning Features

ð Increased addresses for

Scan to HDD (Box) and

Push Scan

Program: 400 w HDD

200 w/o HDD

Address Book: 2,000 w HDD

1,000 w/o HDD

ð Volume

Saving copies / prints in Boxes:

10,000 sheets ( total: copy, print,

scan, fax)

HDD / Box

ð Volume, when an output is

overdue

Saving copies / prints in Boxes: 2,000

sheets ( total: copy, print, scan, fax,

while operating)

Page 49

49

Product Guide ineo 361/421/501

Functions, which require HD-509

Function Item Detail

ð Saving copies, prints and scans in Boxes

ð Saving Fax–TXs in Boxes:

Bulletin Setting

Polling

Remark: When there is no HDD, data will be saved in

memory

ð Saving Fax-RX in Boxes:

Memory RX

Confidential RX

Remark: When there is no HDD, data will be saved in

memory

Saving

ð Saving Internet Fax-RX in Boxes

ð Copies, prints and scans are treated similarly

in Boxes.

ð Grouping by folder

Common Management

ð Distributing RX to Boxes

ð Number of boxes: 1000

ð Box Name:

20 characters for name

9 characters for numbers

Box

ð Box Password:

max. 8 characters

ð Naming documents:

Auto or User settings

Document Information

ð User Name

By personal User Box

HDD / Box

Auto Delete Document ð Setting time for Auto Delete Document

Page 50

50

Product Guide – ineo 361/421/501

Functions, which require HD-509… cont..

Function Item Detail

ð TX

Network TX: Scans, faxes, copies, prints

Fax TX: Faxes

ð Print

ð Printing scanning image ( Printing Proof Copy)

Remark: Only the first page is printed

Using Data in Boxes

ð Print by Mode Setting

Number of sets, finishing, etc.

ð Multiple documents can be bound together and

printed.

Using Data in Boxes

ð Copy, Print job memory and Print

ð Back Up, Restore by PC Utility Soft Ware

(Phase 2, TBD)

Registering Boxes

ð Change Owner

ð Delete

Editing Document Data

ð Edit Name

HDD / Box

Managing Images

ð Managing list of images on the computer

Remark: Function of PC Software

ð Secure Printing

User Name and Password: max. 64

characters each

Print

Mode, et c.

ð Saving and Printing

User Authentication

Default Function Permission

ð User Box

Including Secure Print Permission

ð HDD Lock Password

Security

ISO 15408

ð To delete confidential documents on the HDD

(0 clear)

Page 51

51

Product Guide ineo 361/421/501

Productivity in accordance to BLI testing

Job

No. of

copies

ineo 361

(%)

ineo 421

(%)

ineo 501

(%)

1 61.8 58.2 54.3

3 83.2 81.2 78.8

5 89.5 87.8 86.1

1 to 1

10 94.8 93.9 92.8

1 49.3 44.1 41.5

3 74.5 70.5 67.9

5 83.3 80.0 77.9

1 to 2

10 90.8 88.8 87.5

1 55.7 48.3 41.9

3 79.4 74.2 68.6

5 86.7 82.9 78.6

2 to 1

10 93.2 91.0 88.3

1 52.7 45.4 39.6

3 76.9 71.5 66.2

5 84.7 80.6 76.3

Mode

· A4 crosswise

· Upper cassette

· DF

· Sort on finisher

· No rotation

2 to 2

10 91.9 89.1 86.5

Page 52

52

Product Guide – ineo 361/421/501

Utilities

Data Administrator

Application to control and enter the user’s

information in the device

(user list/account authentication information,

address book, [mail address, fax number

program registration])

Box Operator

S/W which can take image out of Box

Device Manger

Client/Server style network device

management S/W, formerly ‘NMU’

Direct Print

Instant direct printing of PDF, TIFF, PCL/PS

files without print commands or opening

source applications

Font Management

Provides fast and straightforward access to

the resident fonts on any output device,

flexible uploading of new fonts and forms

Network Setup

S/W for initial configuration, management

and status monitoring of Develop

MFP/Printer.

NDPS Gateway

Plug-in for NDPS object management of

Develop devices on NetWare-standard

management S/W (NWAdmin) in Novell

NetWare environment and also for the

information provision.

Utility CD

(bundled with main body)

EMS Plug-in

System, that enables linkage using Plug-in,

the printer-supporting expanded module,

while EMS integrates and manages network

in companies where large scale network is

operated.

Page 53

53

Product Guide – ineo 361/421/501

Utilities… cont..

ineo Remote Care

System to collect various management

information such as counter or maintenance

information of former Develop MIF, former

Develop MIF and integrated models using

modem, fax or e-mail and controls it

centrally at a sales company’s service centre.

Print Utility for Unix

Unix Filter

TWAIN Driver

HDD TWAIN

eCopy TWAIN Driver

TWAIN driver dedicated to grant

connectivity to the eCopy Scanstation

Print Status Notifier

A small utility operating in the Windows

Task Tray which automatically informs users

about the status of their print jobs

Driver Packaging Utility

A tool helping to create driver packages

ready for company-wide distribution and

installation. Supports customized driver

settings.

Log Management Utility

Utility to extract security log information

devices, search for information and store

them externally.

Copy Protection Utility

Utility to create customized patterns (text or

images) for the copy protection functionality.

(FE2 December 08)

Set-up Utility for Right FAX

Utility to setup the MFP with a Captaris

RightFax server for panel integrated faxserver connectivity

i Enabler

To enable i-option functionality (available

for ineo 361/421/501 end

of 2008)

Page 54

54

Product Guide – ineo 361/421/501

Utilities… cont..

Utility for Download from Web

(FOC)

Device Manager

By using the Device Manager in a Web

browser, you can check the usage status of

multiple MFPs and printers in real time. Also

various settings can be specified collectively

and automatic notification can be specified

for status information and counter data for

the MFP, formerly ‘NMU’

Workware

Document management S/W for personal use

for scan data and digital files

Account Manager

By using Account Manager in a Web

browser, the usage and costs for each

account or each user of the network devices

can be totalled and analyzed.

MyPanel Manager

By using MyPanel Manager you can create

personalized Panel contents for all users

individually. This includes individual

address books, shortcuts, language and start

screens.

Software to be charged

Authentication Manager

By using Authentication Manager in a Web

browser you can manage accounts, users and

external servers used by the network devices,

total copies and prints and apply specified

function limitations.

Page 55

55

Product Guide ineo 361/421/501

What is delivered with the machine?

Parts Packed in Japan Added in Europe

PC-Drum yes ---

Developer yes ---

DF Yes (mounted at factory side) ---

Original Cover N / A N / A

Copy Tray --- ---

Operator Manual --- yes

Face Sheets --- yes

Labels --- yes

Page 56

56

Note!

Since changes in technical features ar e

the order of the day in the world of

digital copiers and printing technology,

please note that the technical data

provided in this material was issued in

May 2008. We reserve the right to

make changes to the technical design.

Specifications refer to maximum

performance under standard conditions.

No guarantee is provided in

relation to any of the data supplied.

Your Develop Marketing

www.develop.eu

Develop GmbH

Hessenstr. 1

30855 Langenhagen

Germany

Phone +49 (0)511 5334-50

Loading...

Loading...