Page 1

Service Manual

Digital Copier

DEVELOP

D 2500iD

Page 2

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the following precautions to

prevent accidents and ensure utmost safety.

✽

Depending on the model, some of the precautions given in the following do not apply.

Different markings are used to denote specific meanings as detailed below.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

The following graphic symbols are used to giv e instructions that need to be observed.

Used to call the service technician’s attention to what is graphically represented

inside the marking (including a warning).

Used to prohibit the service technician’s from doing what is graphically represented inside the marking.

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Used to instruct the service technician’s to do what is graphically represented

inside the marking.

WARNING

1. Always observe precautions.

•

Parts requiring special attention in this product will include a label containing the

mark shown on the left plus precautionary notes. Be sure to observe the precautions.

•

Be sure to observe the “Safety Information” given in the Operator’s Manual.

2. Before starting the procedures, be sure to unplug the power cord.

•

This product contains a high-voltage unit and a circuit with a large current

capacity that may cause an electric shock or burn.

•

The product also contains parts that can jerk suddenly and cause injury.

•

If this product uses a laser, laser beam leakage may cause eye damage or

blindness.

3. Use the specified parts.

•

For replacement parts, always use the genuine parts specified in the manufacturer’s parts manual. Installing a wrong or unauthorized part could cause

dielectric breakdown, overload, or undermine safety devices resulting in possible electric shock or fire.

•

Replace a blown electrical fuse or thermal fuse with its corresponding genuine

part specified in the manufacturer’s parts manual. Installing a fuse of a diff erent

make or rating could lead to a possible fire. If a thermal fuse blows frequently,

the temperature control system may have a problem and action must be taken

to eliminate the cause of the problem.

P-1

Page 3

4. Handle the power cord with care and never use a multiple outlet.

•

Do not break, crush or otherwise damage the power cord. Placing a heavy

object on the power cord, or pulling or bending it may damage it, resulting in a

possible fire or electric shock.

•

Do not use a multiple outlet to which any other appliance or machine is connected.

•

Be sure the power outlet meets or exceeds the specified capacity.

5. Be careful with the high-voltage parts.

•

A part mar ked with the symbol shown on the left carries a high voltage. Touching it could result in an electric shock or burn. Be sure to unplug the power cord

before servicing this part or the parts near it.

6. Do not work with wet hands.

•

Do not unplug or plug in the power cord, or perform any kind of service or

inspection with wet hands. Doing so could result in an electric shock.

7. Do not touch a high-temperature part.

•

A part mar ked with the symbol shown on the left and other parts such as the

exposure lamp and fusing roller can be very hot while the machine is energiz ed.

Touching them may result in a burn.

•

Wait until these parts have cooled down before replacing them or any surrounding parts.

8. Maintain a grounded connection at all times. (This item may not apply in the USA.)

•

Be sure to connect the ground wire to the ground terminal even when performing an inspection or repair. Without proper grounding, electrical leakage could

result in an electric shock or fire.

•

Nev er connect the ground wire to a gas pipe, water pipe, telephone ground wire,

or a lightning conductor.

9. Do not remodel the product.

•

Modifying this product in a manner not authorized by the manuf acturer may

result in a fire or electric shock. If this product uses a laser, laser beam leakage

may cause eye damage or blindness.

10. Restore all parts and harnesses to their original positions.

•

To promote safety and prevent product damage, make sure the harnesses are

returned to their original positions and properly secured in their clamps and saddles in order to avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

•

To promote safety, make sure that all tubing and other insulating materials are

returned to their original positions. Make sure that fl oating components mounted

on the circuit boards are at their correct distance and position off the boards.

P-2

Page 4

CAUTION

1. Precautions for Service Jobs

•

A toothed washer and spring washer, if used originally, must be reinstalled.

Omitting them may result in contact failure which could cause an electric shock

or fire.

•

When reassembling parts, make sure that the correct screws (size, type) are

used in the correct places. Using the wrong screw could lead to stripped

threads, poorly secured parts, poor insulating or grounding, and result in a malfunction, electric shock or injury .

•

Take great care to avoid personal injury from possible burrs and sharp edges on

the parts, frames and chassis of the product.

•

When moving the product or removing an option, use care not to injure your

back or allow your hands to be caught in mechanisms.

2. Precautions for Servicing with Covers and Parts Removed

•

Wherever f easible, keep all parts and covers mounted when energizing the

product.

•

If energizing the product with a cover removed is absolutely unav oidable, do not

touch any exposed live parts and use care not to allow your clothing to be

caught in the moving parts. Never leave a product in this condition unattended.

•

Nev er place disassembled parts or a container of liquid on the product. Parts

falling into, or the liquid spilling inside, the mechanism could result in an electric

shock or fire.

•

Nev er use a flammable spray near the product. This could result in a fire.

•

Make sure the power cord is unplugged before removing or installing circuit

boards or plugging in or unplugging connectors.

•

Always use the int erlock switch actuating jig to actuate an interlock swit ch when

a cover is opened or removed. The use of folded paper or some other object

may damage the interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

3. Precautions for the Working Environment

•

The product must be placed on a flat, level surface that is stable and secure.

•

Never place this product or its parts on an unsteady or tilting workbench when

servicing.

•

Provide good ventilation at regular intervals if a service job must be done in a

confined space for a long period of time.

•

Avoid dusty locations and places exposed to oil or steam.

•

Avoid working positions that may block the ventilation ports of the product.

4. Precautions for Handling Batteries

•

Replace a rundown battery with the same type as specified in the manufacturer’s parts manual.

•

Before installing a new battery, make sure of the correct polarity of the installation or the battery could burst.

•

Dispose of used batteries according to the local regulations. Never dispose of

them at the user’s premises or attempt to try to discharge one.

P-3

Page 5

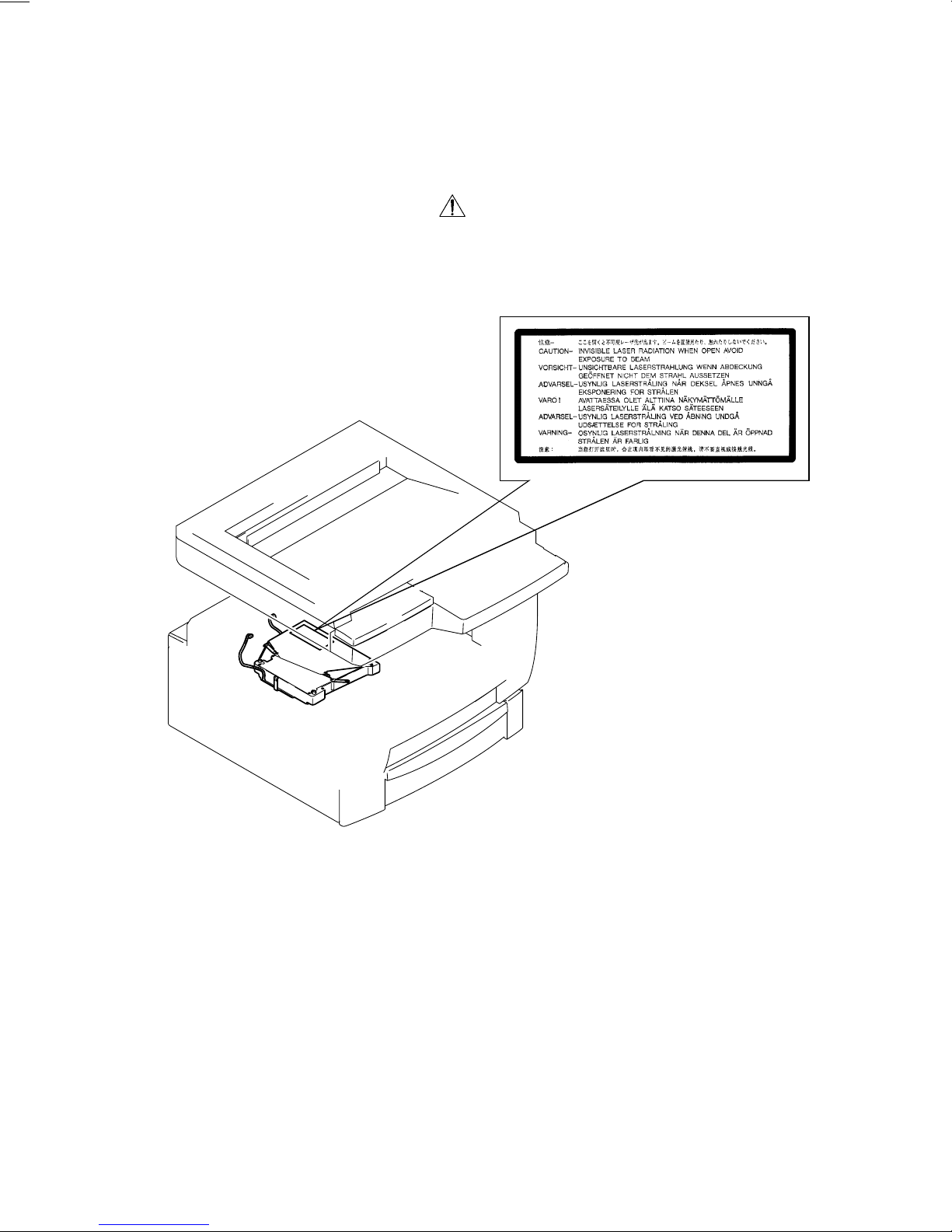

5. Precautions for the Laser Beam (Only for Products Employing a Laser)

•

Removing the cover marked with the following caution label could lead to possible exposure to the laser beam, resulting in eye damage or blindness. Be sure

to unplug the power cord before removing this cover.

•

If removing this cover while the pow er is ON is una v oidab le , be sure to wear protective laser goggles that meet specifications.

•

Make sure that no one enters the room when the machine is in this condition.

•

When handling the laser unit, observe the “Precautions for Handling Laser

Equipment.”

.

DANGER

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE

TO BEAM

0947-7127-01

1144D270AA

1167P001AA

P-4

Page 6

Other Precautions

•

To reassemble the product, reverse the order of disassembly unless otherwise specified.

•

While the product is energized, do not unplug or plug connectors into the circuit boards

or harnesses.

•

The magnet roller generates a strong magnetic field. Do not bring it near a watch, floppy

disk, magnetic card, or CRT tube.

•

An air gun and vacuum cleaner generates a strong electrostatic charge that can destroy

the ATDC sensor and other sensors. Before cleaning a component with one of these

devices, be sure to remove all the sensors. Otherwise, use a blower brush and cloth

when cleaning parts.

•

When handling circuit boards with MOS ICs, observe the “INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs” (applicable only to the products using MOS ICs).

•

The PC Drum is a very delicate component. Observe the precautions given in “HANDLING OF THE PC DRUM” because mishandling may result in serious image problems.

•

Note that replacement of a circuit board may call for readjustments or resetting of particular items, or software installation.

•

After completing a service job, perform a safety check. Make sure that all parts, wiring

and screws are returned to their original positions.

•

Check the area surrounding the service site for any signs of damage, wear or need of

repair.

•

Do not pull out the toner hopper while the toner bottle is turning. This could result in a

damaged hopper motor or locking mechanism.

•

If the product is to be run with the front door open, make sure that the toner hopper is in

the locked position.

P-5

Page 7

Used Batteries Precautions

ALL Areas

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Germany

VORSICHT!

Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Ersatz nur durch denselben oder einen vom Hersteller empfohlenen ähnlichen Typ.

Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

France

ATTENTION

Ily a danger d’explosion s’ily a remplacement incorrec de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un type équivalent recommande par le constructueur.

Mettre au rebut les batteries usageés conformément aux instructions du fabricant.

Denmark

AD VARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Norway

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

Sweden

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

Finland

VAROlTUS

Paristo voi räjähtää, los se on virheellisesti asennettu.

V aihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä Käytetty paristo

valmistajan ohjeiden mukaisesti.

P-6

Page 8

D 2500iD

GENERAL

Page 9

CONTENTS

1. SAFETY INFORMATION .......................................... .................................. .....G-1

2. SPECIFICATIONS ........................................................................................... G-8

3. PRECAUTIONS FOR INSTALLATION ......... ....................... ............................G-10

4. PRECAUTIONS FOR USE .......... .................................. ................................. .G-11

5. HANDLING OF THE CONSUMABLES .................. ............. ............................G-12

6. OTHER PRECAUTIONS .................................. .................................. .............G-12

7. SYSTEM OPTIONS ......................................................................................... G-13

i

Page 10

1170SBG0100A

1 SAFETY INFORMATION

Laser Safety

This is a digital machine which prints by means of a laser. There is no possibility of danger

from the laser, provided the machine is operated according to the instructions in this

manual.

Since radiation emitted by the laser is completely confined within protective housing, the

laser beam cannot escape from the machine during any phase of user operation.

This machine is certified as a Class 1 product. This means the machine does not produce

hazardous laser radiation.

CAUTION: The use of controls, adjustments or performance of procedures

other than those specified in this manual may result in hazardous radiation

exposure. Because of this, Develop strongly recommends that you operate

your copy machine only as described in this documentation.

Internal Laser Radiation

Maximum Average Radiation Power: 36.7µW at laser aperture of the print head unit

Wavelength: 770-810nm

This product employs a Class

The Laser Diode and Scanning Polygon Mirror are incorporated in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM.

Therefore, the print head unit should not be opened under any circumstances.

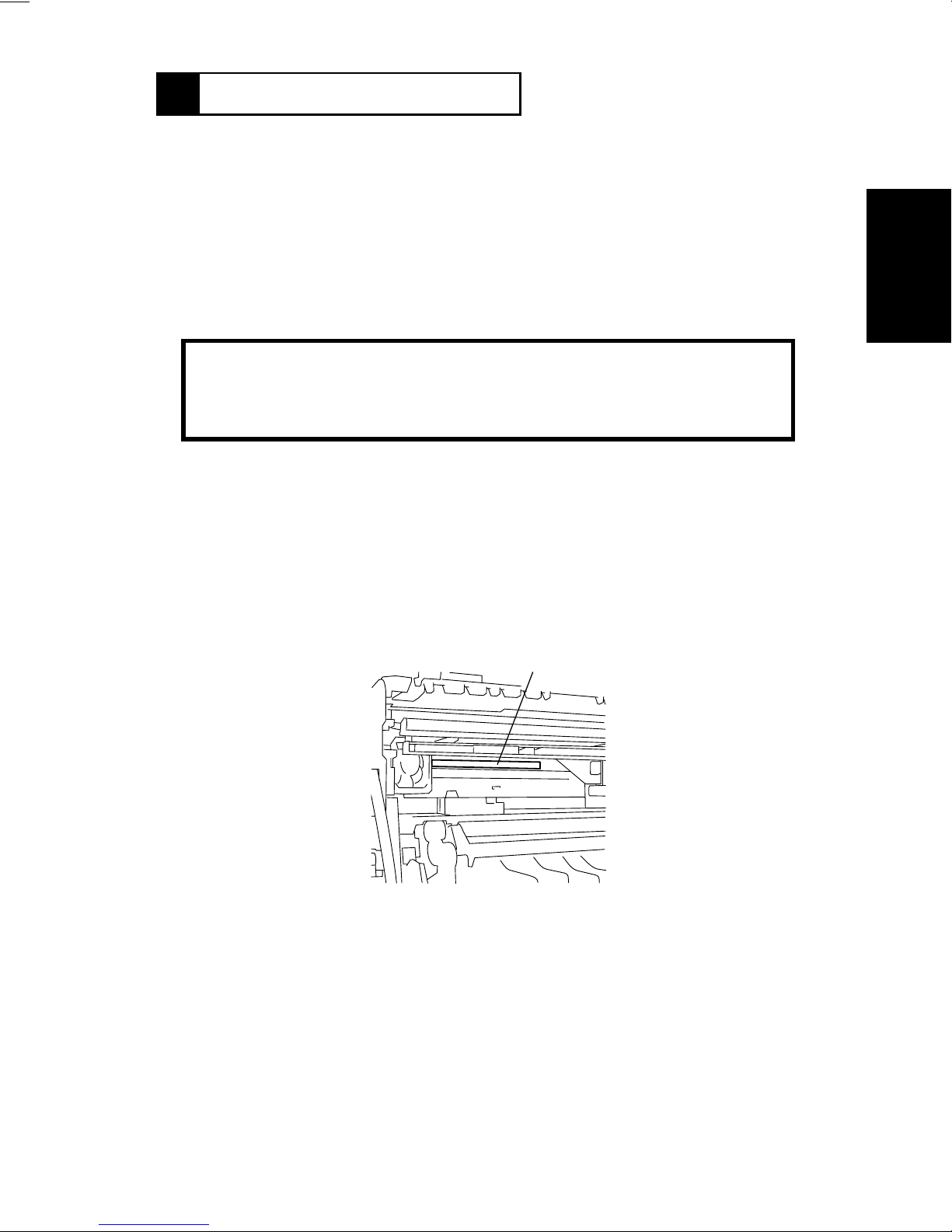

This figure shows the view inside the Right Si de Door with the

Imaging Unit removed.

III

b Laser Diode that emits an invisible laser beam.

Laser Aperture of the Print Head Unit

1166O263AA

For United States

CDRH regulation

This copier is certified as a Class 1 Laser product under the Radiation Performance

Standard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory

for Laser products marketed in the United States and is reported to the Center for Devices

and Radiological Health (CDRH) of the U.S. Food and Drug Administration of the U.S.

Department of Health and Human Services (DHHS). This means that the device does not

produce hazardous laser radiation.

G-1

Page 11

The label shown on page G-3 indicates compliance with the CDRH regulations and must

be attached to laser products marketed in the United States.

CAUTION:

specified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 5mW and the

wav elength is 770-810nm.

For Europe

CAUTION:

specified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 5mW and the

wav elength is 770-810nm.

For Denmark

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

Klasse 1 laser produkt der opfylder IEC60825 sikkerheds kravene.

Use of controls, adjustments or perf ormance of procedures other than those

Use of controls, adjustments or perf ormance of procedures other than those

For Finland

LUOKAN 1 LASERLAITE

VAROITUS

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla ta v alla saattaa alt istaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle .

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle lasersäteilylle. Älä

katso säteeseen.

For Sweden

KLASS 1 LASER APPARAT

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan

användaren utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

VARNING

Osynlig laserstråining när denna del är öppnad och spärren är urkopplad. Betrakta ej

stråien.

G-2

Page 12

For Norway

CLASS 1 LASER PRODUCT

LASER KLASSE

1 PRODUKT

MINOLTA CO., LTD

2, Higashiakatsuchi, Yawata-cho, Toyokawa-shi

Aichi-ken 442-8585, Japan

MANUFACTURED:

THIS PRODUCT COMPLIES WITH 21 CFR

CHAPTER I, SUBCHAPTER J.

0946-7101-14

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan

brukeren utsettes för unsynlig laserstrålning, som overskrider grensen for laser klass 1.

Dette en halveder laser. Maksimal effekt till laserdiode er 5mW og bφlgelengde er 770810nm.

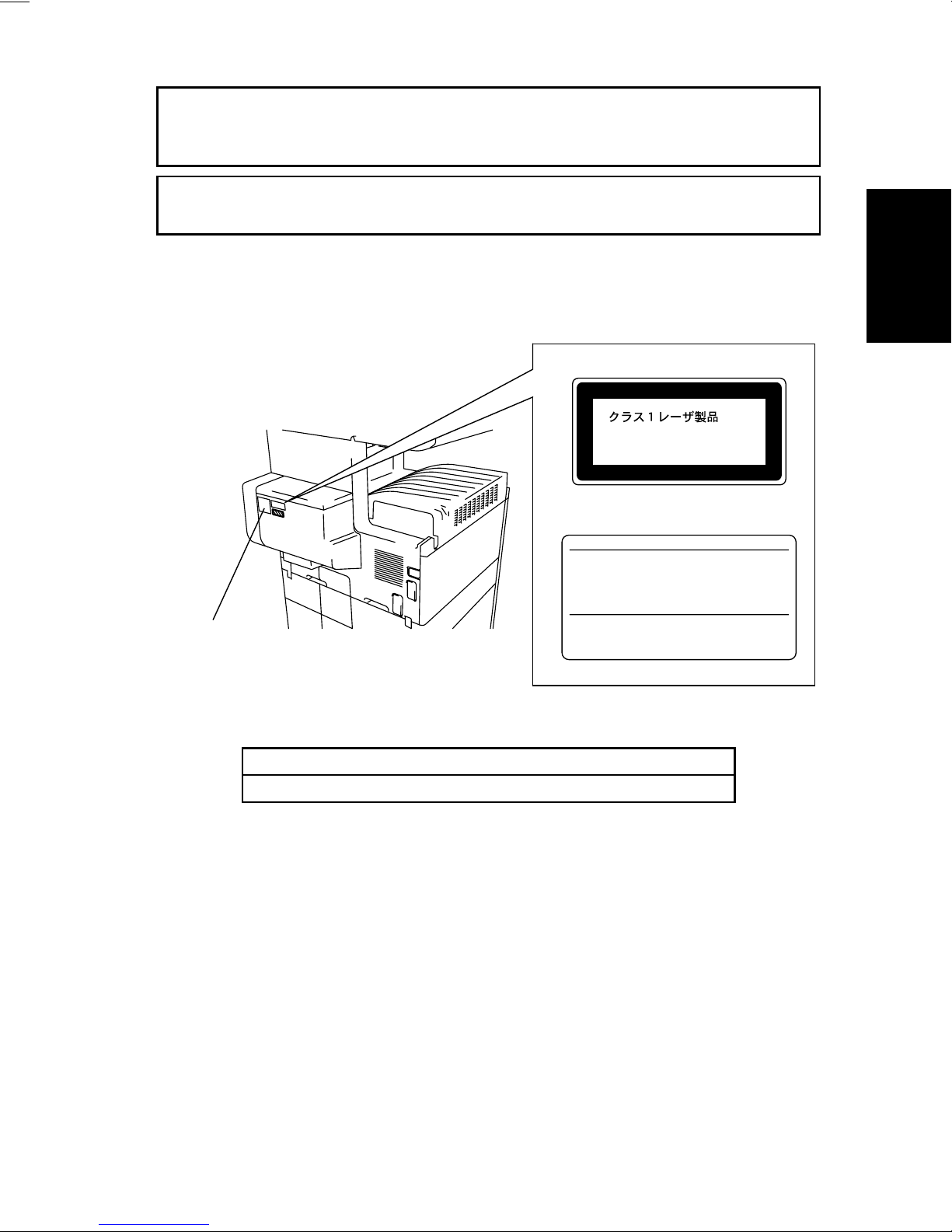

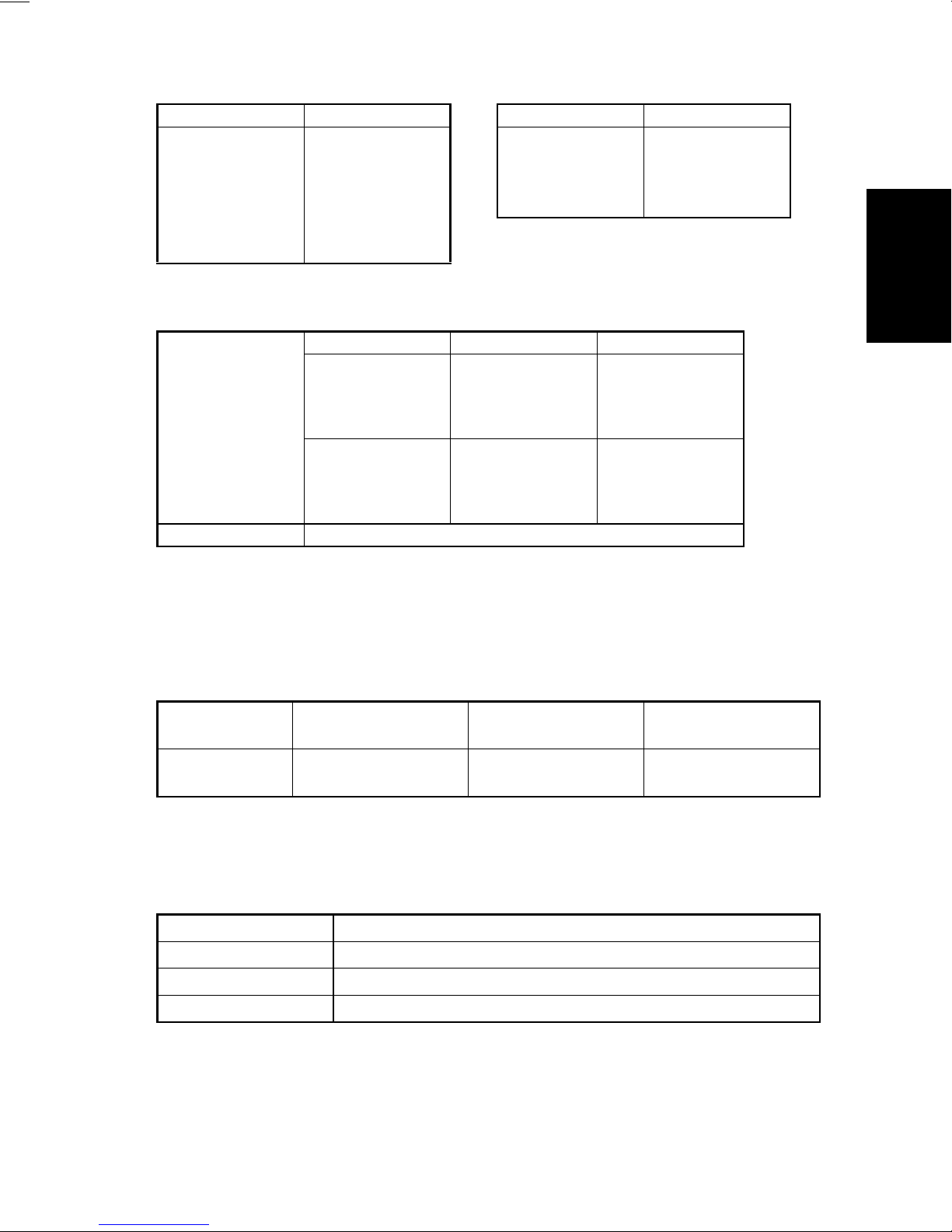

Laser Safety Label

A laser safety label is attached to the outside of the copy machine as shown below .

Laser safety label

For Europe

For United States

Manufacturer’s

Name Plate

1166O261DA

The Manufacturer’s Nam e Plate is affixed at the position illustrated above.

Please write down the Model Name and Serial No. of your copier here.

Model:

Serial No.:

1166O248AA

G-3

Page 13

Label inside copy machine

The following laser safety label will be attached inside the copy machine as shown below.

Please read the following for your own protection.

Caution

Opening the cover indicated by the Caution label may e xpose y ou to harmful laser radiation

which could cause damage or loss of eyesight. Do not open the cover when the power is

on.

1166O234AA

G-4

Page 14

ALL Areas

Germany only

Denmark only

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according

to the manufacturer’s instructions.

VORSICHT!

Explosinsgefahr bei unsachgemäßen austausch der

batterie. Ersatz nur durch denselben oder einen vom hersteller

empfohlenen ähnlichen typ. Entsorgung gebrauchter batterien

nach angaben des herstellers.

AD VARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til lever andøren.

Norway only

Sweden only

Finland only

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende

type anbefalt av appar atfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid f elaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

VAROlTUS

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä Käytetty paristo valmistajan ohjeiden

mukaisesti.

G-5

Page 15

ALL Areas

CAUTION

“Replace only with the same or equivalent type recommended by the manuf acturer.

Dispose of used IC Package according to the manufacturer’s instructions.”

Germany only

VORSICHT!

⇒

”Austausch nur durch denselben oder einen vom Hersteller empfohlenen,

gleichwertigen typ. Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

G-6

Page 16

Service Precautions

(1) Precautions

Refer to DISASSEMBLY/CLEANING for the Disassembly procedure.

1. When unplugging connectors on the P.W.B.s themselves, always make sure the power

is OFF first. Be sure to unplug the copier before disassembling and cleaning.

2. Always unplug connectors by holding the connector housing. Pulling on the wires can

lead to problems with poor contact.

3. It is recommended that a body ground not be used when carrying out any troubleshooting procedure. Be sure to ground DC lines to a ground test point on the P.W.B.

(2) At Replacement/Adjustment/Cleaning

1. Be sure to handle the Fusing Unit carefully. It remains hot a while after the copier is

turned off.

2. Do not disassemble the Imaging Cartridge or Print Head Unit.

3. Do not expose the PC Drum of the Imaging Cartridge to direct sunlight or to room lighting for more than 5 minutes.

4. Turn off the power before removing the Print Head Unit to protect the e y es from possible

exposure to the laser beam.

5. Use only a Fuse of the indicated rating.

(3) During Operation

1. Keep your hands, clothing, etc. well away from operating or rotating parts.

2. Nev er touch the terminals of electrical parts or high voltage parts.

3. This copier uses an invisible laser beam. To prevent a laser beam leak, the copier performs a trial run to make sure the covers are in position.

Handling the P.W.B.

Observe the following precautions when handling a P.W. B. with ICs.

(1) During Transportation/Storage

1. During transport and storage, P.W.B.s should be kept in conductive bags or on mats

and not taken out unless absolutely necessary.

2. P.W.B.s should be stored in a place where direct sunlight does not strike them.

3. Do not touch IC terminals with your hands.

(2) At Replacement

1. Before removing connectors from a P.W.B., make sure the copier has been unplugged.

2. When P.W .B.s are tak en out of their conductiv e bags or off their mats, hold them by their

edges to avoid touching the terminals or the patterned surfaces.

3. Before installing connectors on a P.W.B., make sure the copier has been unplugged.

G-7

Page 17

1170SBG0200A

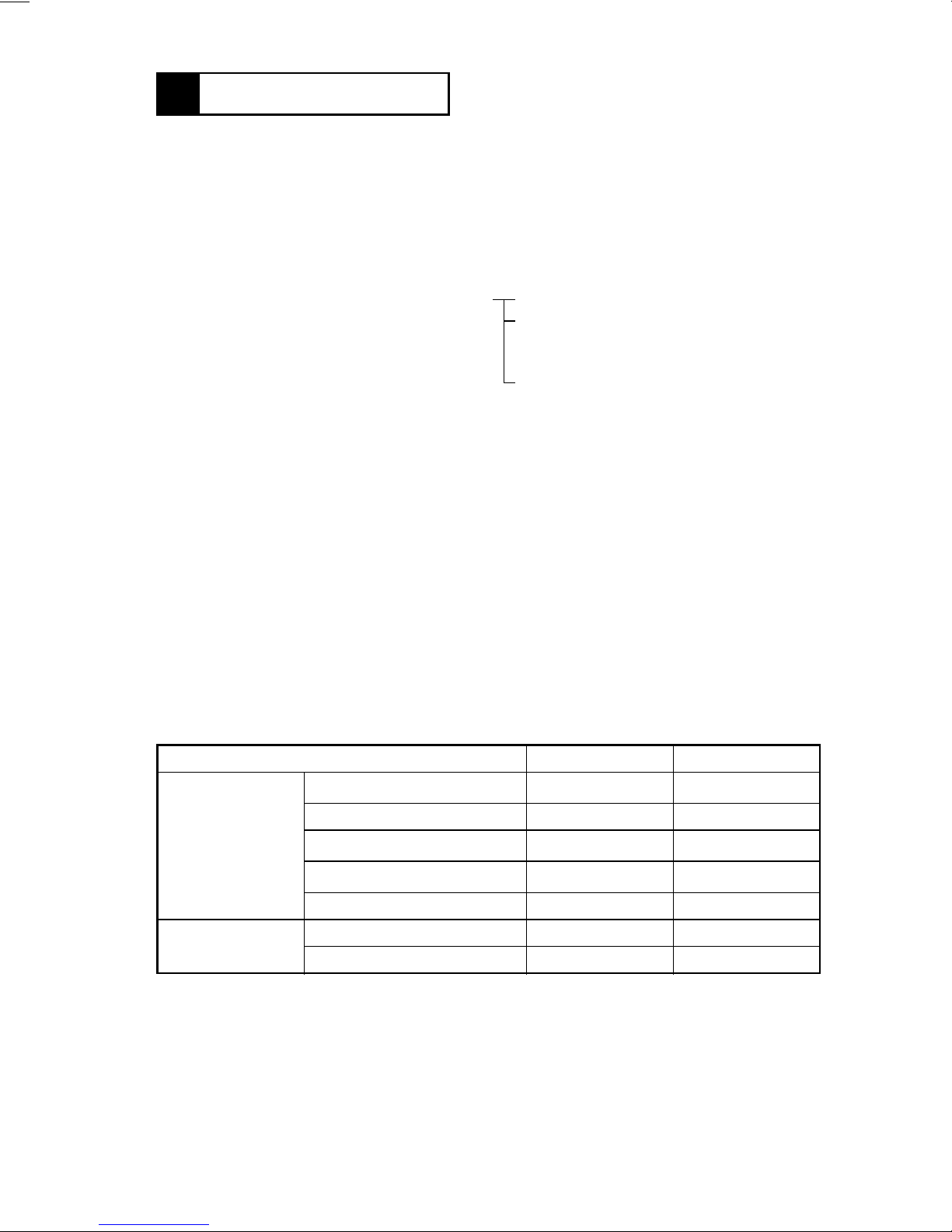

2 SPECIFICATIONS

TYPE : Console/Desktop Type

PHOTOCONDUCTOR : Organic Photoconductor

COPYING SYSTEM : Electrostatic Dry Powdered Image Transfer to Plain Paper

with a Laser

ORIGINAL SCANNING

RESOLUTION

PAPER FEEDING

SYSTEM

EXPOSURE SYSTEM : Mirror Scanning, Slit Exposure

DEVELOPING SYST EM : MT-HG System

CHARGING SYSTEM : Comb Electrode (1) DC Negative Corona with Scorotron

IMAGE TRANSFER : Roller Image Transfer

PAPER SEPARATING

SYSTEM

FUSING SYSTEM : Heat Roller

PAPER DISCHARGING

SYSTEM

MAXIMUM ORIGINAL

SIZE

: 600 dpi

: 3-way system Manual Feed Tray: Single sheet feeding

Multi-Purpose (MP) Cassette:

Plain paper: Approx. 250 sheets

Special paper: Approx. 20 sheets

500-Sheet Cassette: Approx. 500 sheets

System

: Paper Separator Fingers and Charge Neutralizing Plate

: Charge Neutralizing Brush

: A3L, 11” × 17”L

COPY MEDIUM

Paper Source MP Cassette Manual Feed Tray

2

Plain paper (60 to 90 g/m

Transparencies

Medium

Dimensions

❍

: Permissible−: Not permissible

MULTIPLE COPIES : 1 to 99

WARMING-UP TIME : 60 sec. or less with room temperature of 23°C and rated

FIRST COPY TIME : 5.8 sec. (A4C, MP Cassette, full size mode)

Thick paper (91 to 157 g/m

Postcards (190 g/m

Recycled paper

Maximum (Width × Length) 297 × 432 mm 297 × 432 mm

Minimum (Width × Length) 90 × 140 mm 90 × 140 mm

power voltage

5.9 sec. (8-1/2” × 11”C, MP Cassette, full size mode)

2

)

2

)

)

❍❍

❍❍

❍❍

❍❍

❍❍

G-8

Page 18

CONTINUOUS COPY SPEED (copies/min.)

- Metric - - Inch -

Size Speed Size Speed

A3L 14 11” × 17”L 14

B4L 16 8-1/2” × 14”L 17

A4L 19 8-1/2” × 11”L 20

A4C 25 8-1/2” × 11”C 25

B5L 22

B5C 29

ZOOM RATIOS

- Metric - - Inch -

Full Size

Enlargement

Fixed

Reduction

Variable 25% to 400% (in 0.1% increments)

×

1.000

×

2.000

×

1.414

×

1.224

×

1.154

×

0.866

×

0.816

×

0.707

×

0.500

×

1.000

×

2.000

×

1.545

×

1.294

×

1.214

×

0.785

×

0.733

×

0.647

×

0.500

LENS : Through Lens (F = 4.0, f = 62 mm)

EXPOSURE LAMP : Fluorescent Lamp

FUSING TEMPERATURE : 190°C

POWER/CURRENT CONSUMPTION (Copier Only)

Exposure Lamp

(Rating)

24V

20W

POWER

REQUIREMENTS

ENVIRONMENTAL CONDITIONS

Temperature 10 to 32°C with a fluctuation of 10°C or less per hour

Humidity 15 to 85% RH with a fluctuation of 10% RH or less per hour

Ambient Illumination 3,000 lux or less

Lev elness 1° (1.75 mm/100 mm)

Fusing Roller Heater

Lamp (Rating)

660W 850W

: 120V, 230V, 50/60Hz

Max. Power Consump-

tion (full system)

Max. Current Con-

sumption (full system)

120V, 8A

230V, 4A

DIMENSIONS : Width ... 566 mm, 22-1/4”

WEIGHT : 53.5 kg, 118 lbs.

Depth ... 707 mm, 27-3/4”

Height ... 635 mm, 25”

G-9

Page 19

1170SBG0300A

3 PRECAUTIONS FOR INSTALLATION

Installation Site

To ensure safety and utmost performance of the copier, the copier should NOT be used in a

place:

•

Where it will be subjected to extremely high or low temperature or humidity.

•

Which is exposed to direct sunlight.

•

Which is in the direct air stream of an air conditioner, heater or ventilator.

•

Which puts the operator in the direct stream of exhaust from the copier.

•

Which has poor ventilation.

•

Where ammonia gas might be generated.

•

Which does not have a stable, level floor.

•

Where it will be subjected to sudden fluctuations in either temperature or humidity. If a

cold room is quickly heated, condensation forms inside the copier, resulting in blank

spots in the copy.

•

Which is near any kind of heating device.

•

Where it may be splashed with water.

•

Which is dirty or where it will receive undue vibration.

•

Which is near volatile flammables or curtains.

Power Source

Use an outlet with a capacity of 120V/8A, or 220V to 240V/4A or more.

•

If any other electrical equipment is sourced from the same power outlet, make sure that

the capacity of the outlet is not exceeded.

•

Use a power source with little voltage fluctuation.

•

Never connect by means of a multiple socket any other appliances or machines to the

outlet being used for the copier.

•

Make the follo wing checks at frequent intervals:

✽

Is the power plug abnormally hot?

✽

Are there any cracks or scrapes in the cord?

✽

Has the power plug been inserted fully into the outlet?

✽

Does something, including the copier itself, ride on the power cord?

•

Ensure that the copier does not ride on the power cord or communications cable of other

electrical equipment, and that it does not become wedged into or underneath the mechanism.

Grounding

To prevent receiving electrical shocks in the case of electrical leakage, always ground the

copier.

•

Connect the ground wire to:

✽

The ground terminal of the outlet.

✽

A grounding contact which complies with the local electrical standards.

•

Nev er connect the ground wire to a gas pipe, the ground wire for a telephone, or a water

pipe.

G-10

Page 20

1170SBG0400A

4 PRECAUTIONS FOR USE

To ensure that the copier is used in an optimum condition, observe the following precautions.

•

Never place a heavy object on the copier or subject the copier to shocks.

•

Insert the power plug all the way into the outlet.

•

Do not attempt to remove any panel or cover which is secured while the copier is making

copies.

•

Do not turn OFF the Power Switch while the copier is making copies.

•

Provide good ventilation when making a large number of copies continuously.

•

Nev er use flammable sprays near the copier.

•

If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

•

Do not turn ON the Power Switch at the same time when you plug the po wer cord into the

outlet.

•

When unplugging the power cord, do not pull on the cord; hold the plug and pull it out.

•

Do not bring any magnetized object near the copier.

•

Do not place a vase or vessel containing water on the copier.

•

Be sure to turn OFF the P ower Switch at the end of the workday or upon power failure.

•

Use care not to drop paper clips, staples, or other small pieces of metal into the copier.

Operating Environment

The operating environmental requirements of the copier are as follows:

•

Temperature: 10°C to 32°C with a fluctuation of 10°C per hour

•

Humidity: 15% to 85% RH with a fluctuation of 10% RH per hour

Power Requirements

The power source voltage requirements are as follows:

•

Voltage Fluctuation: AC120/230V

±10% (Copying performance assured)

+10%

-15%

•

Frequency Fluctuation: 50/60 Hz ±0.3%

(Paper feeding performance assured)

G-11

Page 21

1170SBG0500A

5 HANDLING OF THE CONSUMABLES

Before using any consumable, always read the label on the container carefully.

•

Use the right toner. The applicable copier model name is indicated on the toner bottle.

•

Paper is easily damaged by dampness. To prevent absorption of moisture, store paper,

which has been removed from its wrapper but not loaded into the drawer, in a sealed

plastic bag in a cool, dark place.

•

Keep consumables out of the reach of children.

•

Do not touch the PC Drum with bare hands.

•

Store the paper, toner, and other consumables in a place free from direct sunlight and

away from any heating apparatus.

•

The same sized paper is of two kinds, short grain and long grain. Shor t grain paper

should only be fed through the copier crosswise, long grain paper should only be fed

lengthwise.

•

If your hands become soiled with toner, wash them with soap and water immediately.

•

Do not throw aw ay any used consumables (PC Drum, starter, t oner, etc.). They are to be

collected.

NOTE

Do not burn, bury in the ground, or throw into the water any consumables (PC Drum,

starter, toner, etc.).

1170SBG0600A

6 O T HE R PRECAUTIONS

The Print Head Unit of this copier uses a laser diode that emits a laser beam. Use the following precautions when performing service jobs at the users’ premises.

•

When a service job needs to be performed in the laser beam path, such as when working

around the Print Head Unit and PC Drum, be sure first to turn the copier OFF.

•

If the job requires that the power cord be left plugged in, observe the follo wing precautions

1. Take off your watch, ring, and any other reflective object and wear laser protective goggles.

2. At the job site, select a place that is as far as possible away from the users and that is

enclosed by walls.

3. Do not bring a highly reflective tool into the laser beam path during the service job.

G-12

Page 22

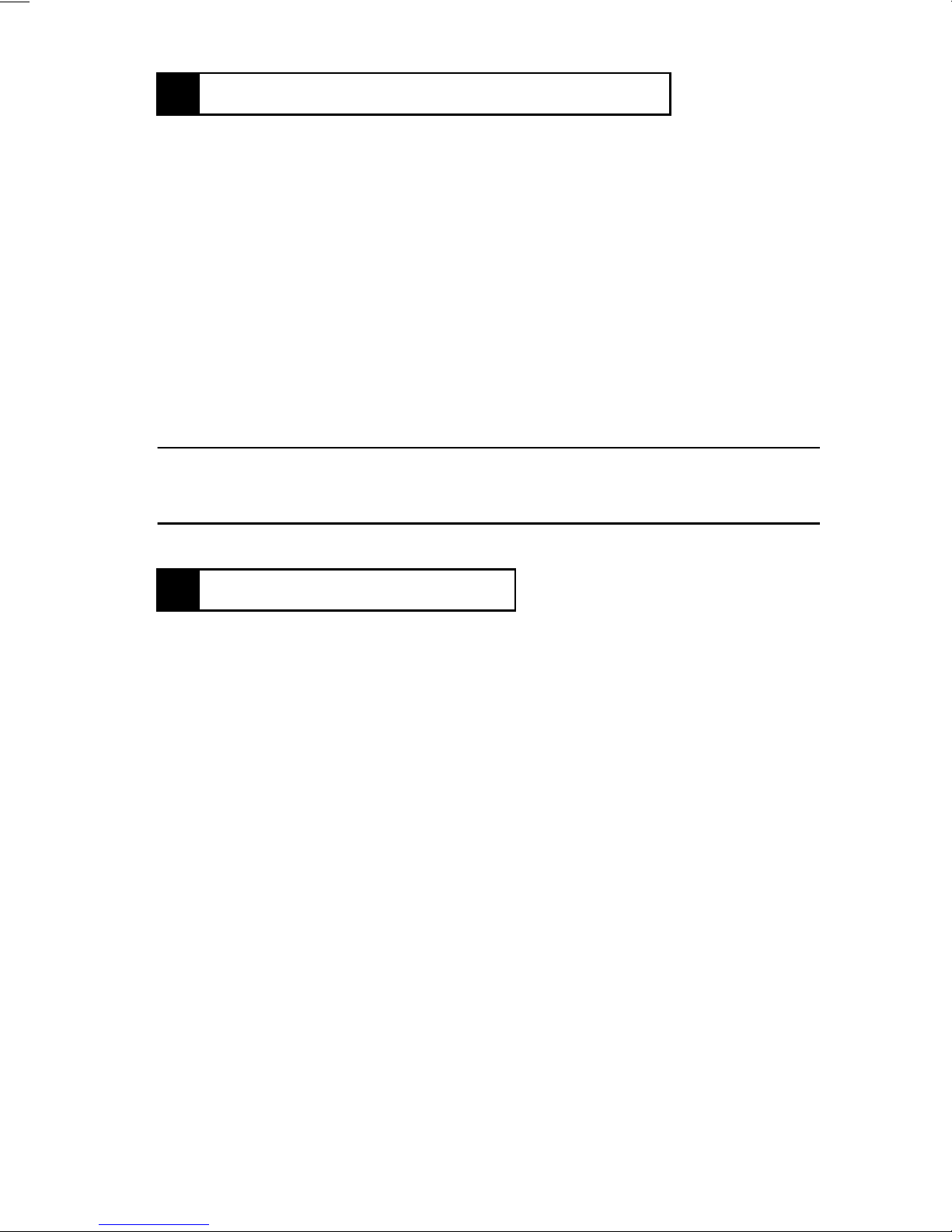

1170SBG0700A

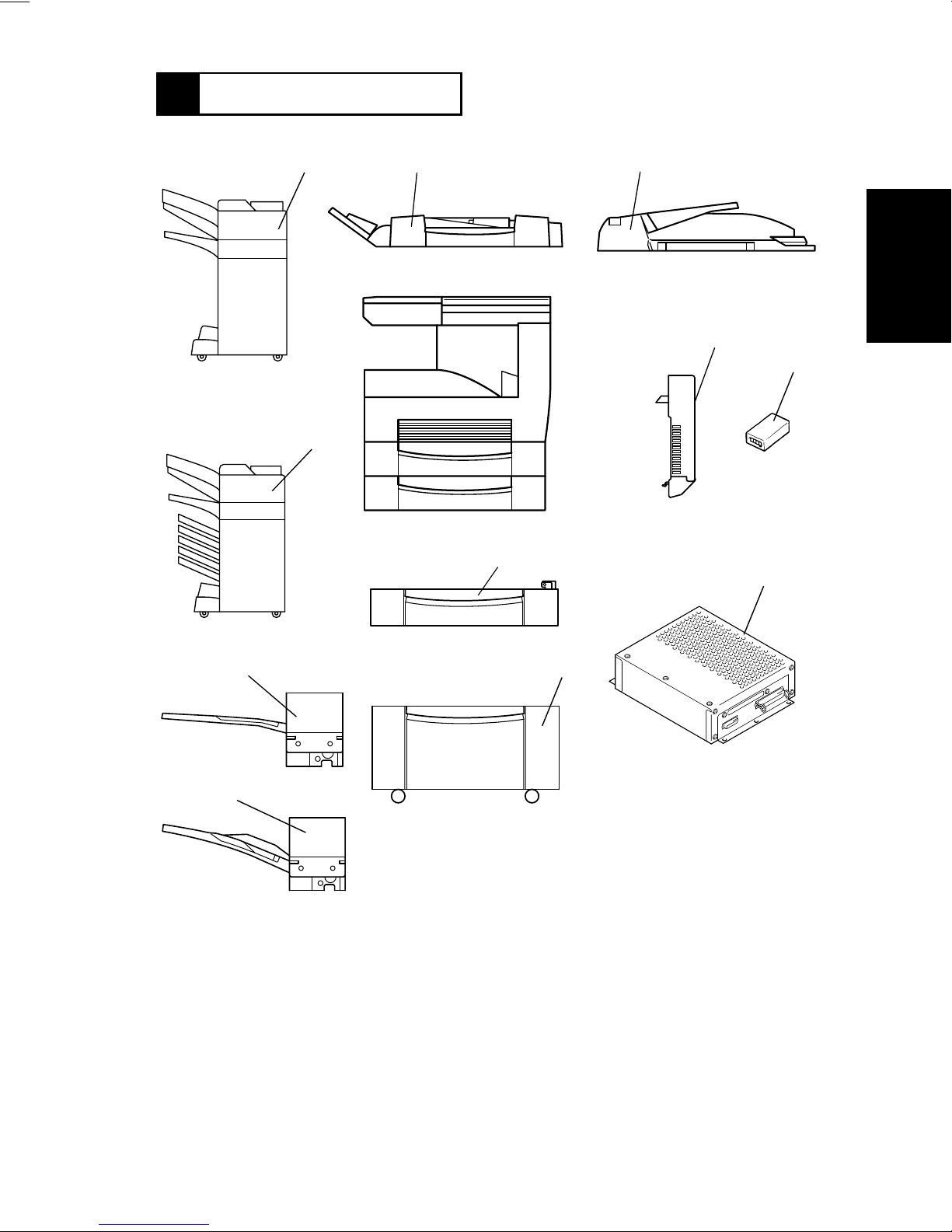

7 SYSTEM OPTIONS

1166O120AA

12

1

1166O014AA

2

1166O008AA

5

3

11

1166O015AA

1171G001AA

1145M035AA

7,8

4

1166O121AA

10

1166O012AA

9

1166O011AA

1. Duplexing Document F eeder (AFR-14)

2. Automatic Document Feeder (AF-6)

3. Plug-In Counter

4. Printer Controller (Pi3500)

5. Duplex Unit (AD-10)

6. Large Capacity Cabinet (PF-106)

1166O009AA

6

4608D018AA

1166O010AB

7. Paper Feed Unit (PF-108)

8. Paper Feed Unit (PF-110)

9. Shift Tray (OT-100)

10. Job Tray (JS-200)

11. Mailbin Finisher (FN-500)

12. Finisher (FN-100)

G-13

Page 23

D 2500iD

MECHANICAL/

ELECTRICAL

Page 24

CONTENTS

1. CROSS-SECTIONAL VIEW ............................................................................M-1

2. COPYING PROCESS ............................................. .................................. .......M-2

3. DRIVE SYSTEM ..............................................................................................M-4

4. OPERATING SEQUENCE ..............................................................................M-5

5. CPU OVERRUN MONITOR FUNCTION .........................................................M-8

6. IMAGE STABILIZATION SYSTEM ..................................................................M-9

7. IMAGING CARTRIDGE (I/C) ...........................................................................M-10

7-1. I/C Drive Mechanism .................................. ............. ............ ............. .......M-11

7-2. Identification and Life of I/C .....................................................................M-11

8. PC DRUM ........................................................................................................ M-12

9. DRUM CHARGING ..........................................................................................M-13

10. ERASE LAMP ..................................................................................................M-14

11. IR SECTION .................................................................................................... M-15

11-1. Exposure Section: Construction and Function .......................................M-16

11-2. Image Processing Flow ..........................................................................M-17

11-3. Original Size Detection ...........................................................................M-18

11-4. Original Size Detection Timing ............................................................... M-20

11-5. Scanner and 2nd/3rd Mirrors Carriage Moving Mechanism ...................M-21

12. PH SECTION ...................................................................................................M-22

12-1. PH Components .....................................................................................M-23

12-2. Laser Emission Timing (SOS Signal) .....................................................M-24

13. DEVELOPING UNIT .......... ............................................ ................................. .M-25

13-1. Sleeve/Magnet Roller .............................................................................M-26

13-2. Developing Bias ......................................................................................M-27

13-3. ATDC Sensor .........................................................................................M-28

13-4. Sub Hopper Toner Replenishing Mechanism .........................................M-29

13-5. Sub Hopper Toner Empty Detecting Mechanism ...................................M-30

13-6. Main Hopper Toner Replenishing Mechanism .......................................M-31

13-7. I/C Cooling Fan Motor ............................................................................M-32

13-8. Ozone Fan Motor ....................................................................................M-32

14. PAPER TAKE-UP/FEED SECTION ................................................................M-33

14-1. MP Cassette Paper Lifting Plate .............................................................M-33

14-2. MP Cassette-in-Position Detection .........................................................M-34

14-3. MP Cassette Paper Empty Detection .....................................................M-35

14-4. MP Cassette Paper Size Detection ........................................................M-36

14-5. Paper Take-Up Mechanism ....................................................................M-37

14-6. Manual Bypass Tray ...............................................................................M-37

14-7. Paper Take-Up Retry Mechanism ...................... .............. ......................M-38

15. SYNCHRONIZING ROLLERS .........................................................................M-39

15-1. Synchronizing Roller Drive Mechanism/Control .....................................M-39

15-2. Paper Dust Remover ..............................................................................M-40

16. IMAGE TRANSFER AND PAPER SEPARATION ...........................................M-41

17. PC DRUM PAPER SEPARATOR FINGERS ...................................................M-42

18. PC DRUM CLEANING ..................................................................................... M-43

i

Page 25

19. FUSING UNIT ..................................................................................................M-44

19-1. Drive Mechanism .................................................................................... M-45

19-2. Fusing Rollers Pressure Mechanism ......................................................M-45

19-3. Fusing Temperature Control ...................................................................M-46

19-4. CPM Control ...........................................................................................M-47

20. PAPER EXIT UNIT ..........................................................................................M-48

21. FUSING COOLING FAN MOTOR ...................................................................M-49

22. POWER UNIT COOLING FAN MOTOR ..........................................................M-50

ii

Page 26

1170SBM0100A

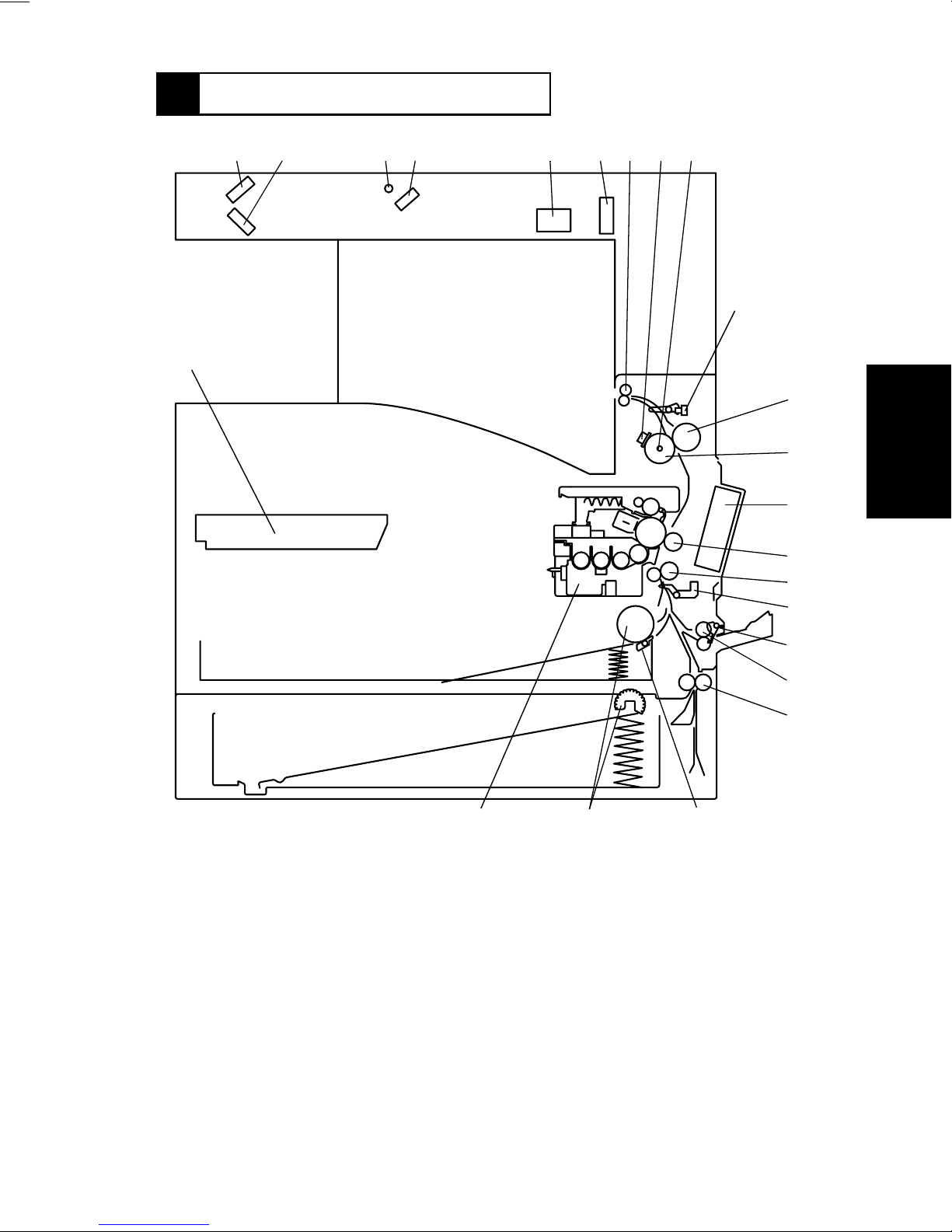

1 CROSS-SECTIONAL VIEW

23

12 5 6789

43

10

11

12

13

14

15

16

1. 2nd Mirror

2. 3rd Mirror

3. Exposure Lamp

4. 1st Mirror

5. Lens

6. CCD Unit

7. Paper Exit Roller

8. Fusing Roller Thermostat (TS1)

9. Fusing Roller Heater Lamp (H1)

10. Paper Exit Sensor (PC3)

11. Right Fusing Roller

12. Left Fusing Roller

2122

13. Fusing Cooling Fan Motor (M3)

14. Image Transfer Roller

15. Synchronizing Roller

16. Synchronizing Roller Sensor (PC2)

17. Manual Feed Paper Take-Up Sensor

(PC8)

18. Manual Feed Paper Take-Up Roll

19. Vertical Transpor t Roller

20. Paper Separator Pad

21. Paper Take-Up Roll

22. Imaging Cartridge (I/C)

23. PH Unit

20

1171M037AB

17

18

19

M-1

Page 27

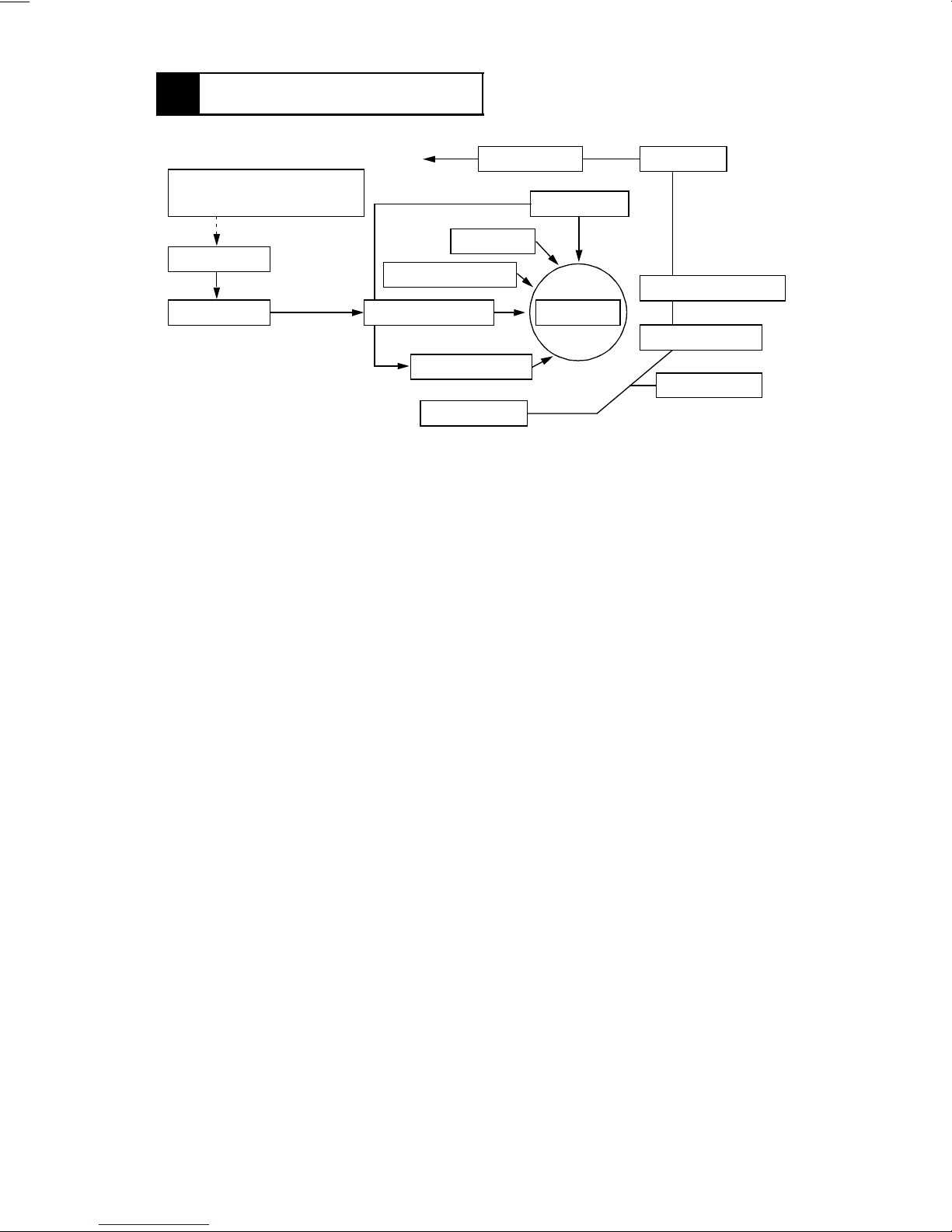

1170SBM0200A

2 COPYING PROCESS

14. Paper Exit 13. Fusing

3. Photoelectric Conversion

Section

12. Erase

4. H GB Board

2. Drum Charging

5. MFB Board 1. PC Drum

6. Laser Exposure

7. Development

8. Paper Feed

1. PC Drum

•

The drum is an aluminum cylinder coated with photosensitive material on which an electrostatic latent image is produced.

11. Cleaning

10. Paper Separation

9. Image Transfer

8. Paper Feed

2. Drum Charging

•

A scorotron charger employing a comb electrode generates a negative DC charged

layer on the surface of the PC Drum.

3. Photoelectric Conversion Section

•

The Exposure Lamp directs light onto the original. The light reflected off the original is

directed and resized by the mirrors and lens so as to produce a reduced-size image on

the CCD Sensor.

4. HGB Board

•

Converts an electric signal into a corresponding 8-bit digital image signal (A/D conversion), makes various corrections, and outputs the results to the MFB Board.

5. MFB Board

•

Compresses the image data received from the HGB Board, stores it, and uncompresses it.

6. Laser Exposure

•

The laser beam emitted from the LD (laser diode) strikes the surface of the PC Drum,

creating an electrostatic latent image.

7. Development

•

Negatively charged toner adheres to the latent image on the PC Drum surface, creating

a visible image.

8. Paper Feed

•

Feeds sheets of paper from the appropriate paper source.

9. Image Transfer

•

An Image Transfer Roller is used. A positive charge applied to the roller causes the visible image on the surface of the PC Drum to transfer onto the front side of the paper.

M-2

Page 28

10. Paper Separation

•

The PC Drum Separator Fingers remove paper from the surface of the PC Drum.

11. Cleaning

•

The Cleaning Blade scrapes residual toner off the surface of the PC Drum and the toner

is recycled back to the Developing Unit.

12. Erase

•

The PC Drum is exposed to light, which effectively removes any residual charge from

the drum surface.

13. Fusing

•

Heat and pressure applied by the Right and Left Fusing Rollers fuse toner on the paper.

14. Paper Exit

•

Feeds paper out of the copier.

M-3

Page 29

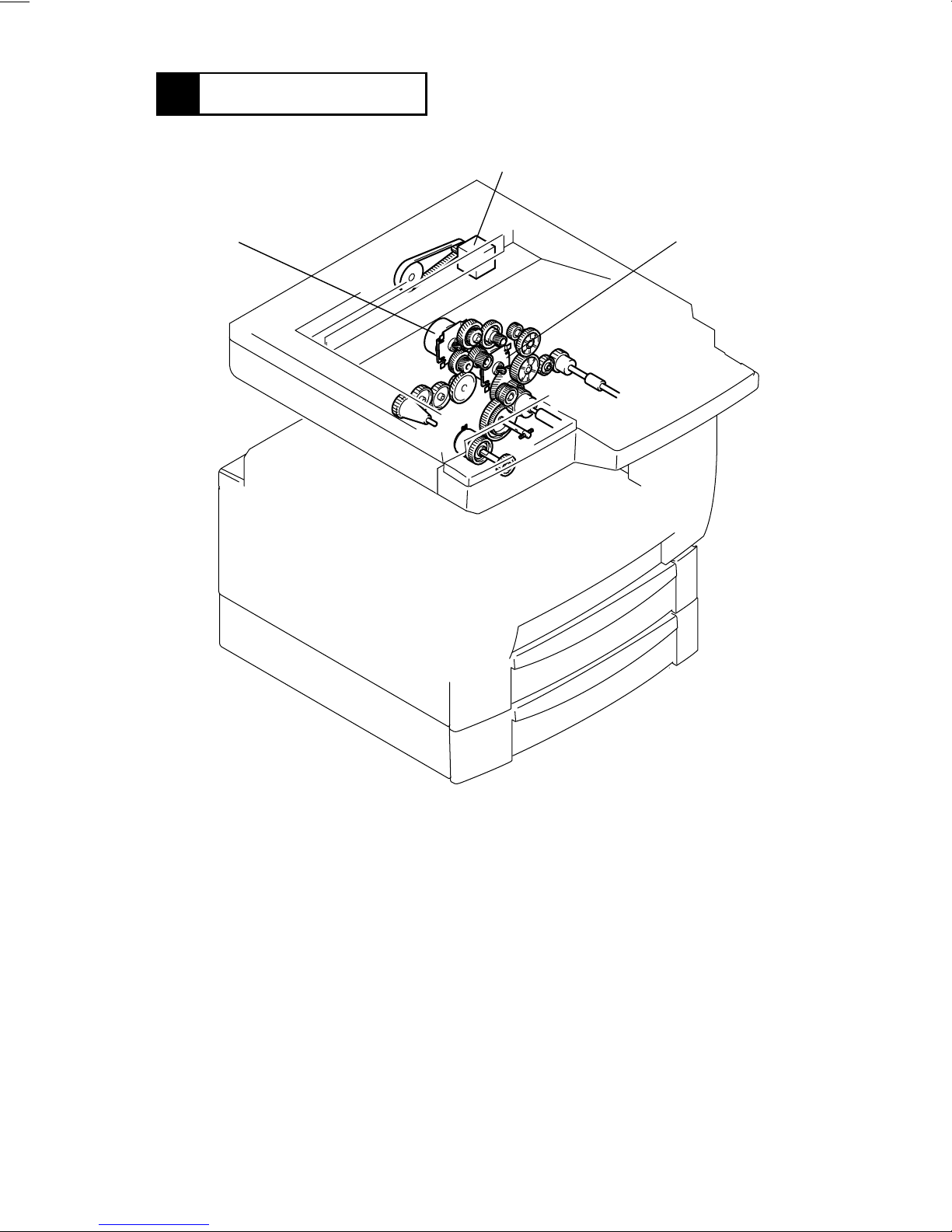

1170SBM0300A

3 DRIVE SYSTEM

A

B

C

A. Scanner Motor (M5)

Drives the Scanner and 2nd/3rd Mirrors Carriage.

B. I/C Moto r (M1)

Drives the I/C Unit.

C. Main Motor (M2)

Drives the P aper Take-Up Roll, Manual Feed Paper Take-Up Roll, Synchronizing Roller,

Image Transfer Roller, and Fusing Unit.

1171M024AB

M-4

Page 30

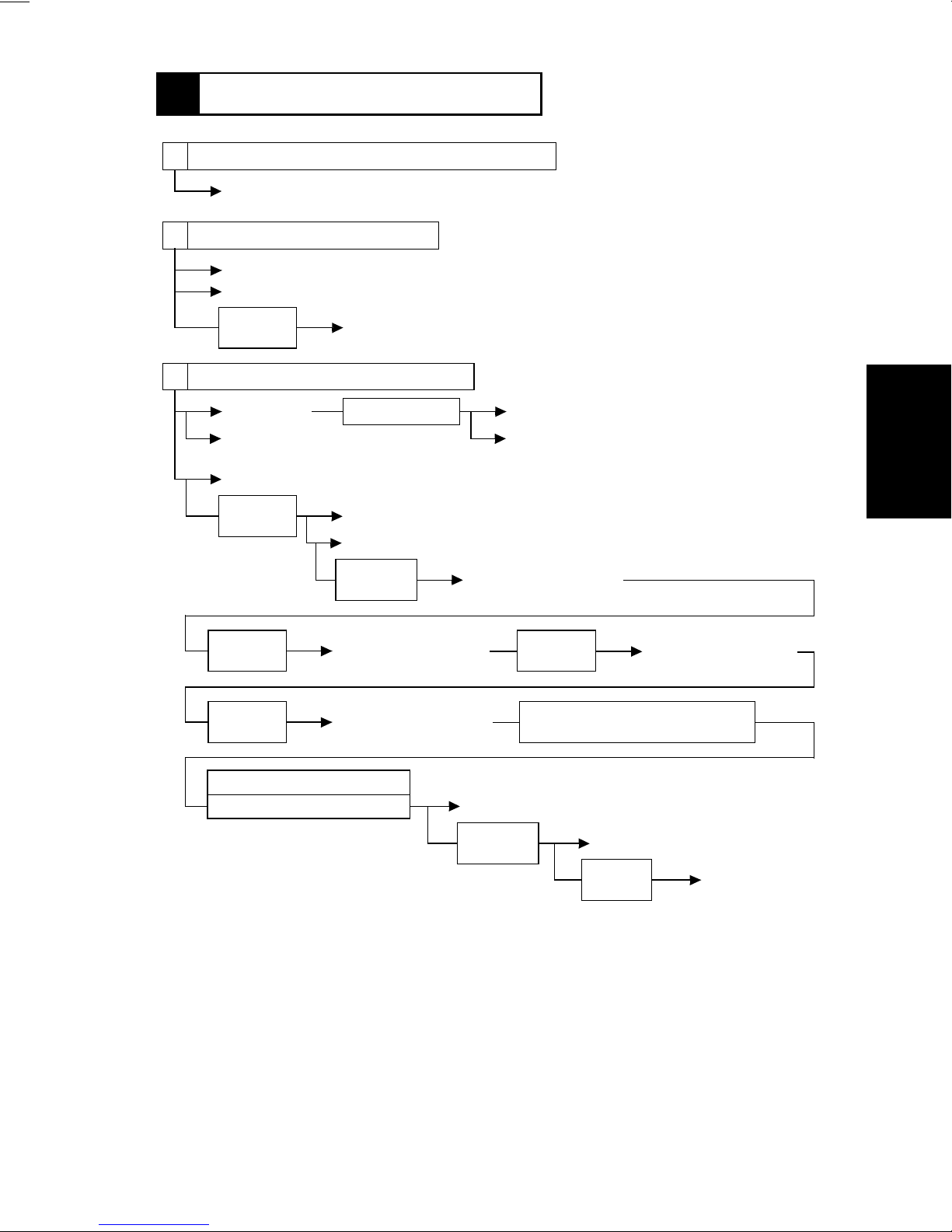

1170SBM0400A

4 OPERATING SEQUENCE

A The power cord is plugged into the power outlet.

ON

B The Power Switch is turned ON.

ON

ON

The Power Supply Unit outputs DC24V for the Dehumidifying Heater (option).

DC voltage output

Control panel display

Approx.

560 msec.

ON

Fusing Roller Heater Lamp

C The warming-up cycle is completed.

ON

ON

Main Motor

Powe r Unit Co oling Fan Motor turns

at full speed.

Developing bias (DC)

Approx.

100 msec.

Approx.

400 msec.

Approx.

400 msec.

ON

ON

ON

Approx. 20 sec.

I/C Motor

ON

Image transfer output: - voltage

Approx.

700 msec.

Image transfer output:

- voltage

Image transfer output:

- voltage

ON

OFF

Predrive stops

Powe r Unit Cooling Fan Motor turns

at half speed.

Image transfer output:

+ voltage

Approx.

400 msec.

T/C ratio is checked for abnormality

for approx. 28 sec.

ON

Image transfer output:

+ voltage

Normal T/C

Abnormal T/C: approx. 31 sec.

OFF

I/C Motor

Approx.

400 msec.

M-5

OFF

Image transfer output

Approx.

15 min.

OFF

Developing bias

(DC)

Page 31

D The Start key is pressed.

ON

ON

Polygon Motor

Fusing Cooling Fan Motor

Approx. 6 sec.

ON

ON

Laser

Developing bias (DC)

Approx.

100 msec.

ON

Image transfer output: - voltage

ON

I/C Motor

Approx.

140 msec.

ON

Approx.

700 msec.

Main Motor

The Power Unit Cooling Fan Motor turns at full

speed.

The Ozone Fan Motor turns at full speed.

E The Synchronizing Roller Sensor is activated.

Approx.

110 msec.

VSYNC signal ON:

approx. 50 msec. later

OFF

Paper Take-Up Solenoid

ON

Paper Take-Up Solenoid

ON

Synchronizing Clutch

ON

Developing bias (AC)

Approx.

160 msec.

ON

Approx.

1.1 sec.

ON

Image transfer current value for printing

ON

Paper Take-Up Solenoid

Approx.

90 msec.

Image transfer current

value for non-printing

timing between sheets of

paper

OFF

Paper Take-Up

Solenoid

F The Synchronizing Roller Sensor is deactivated.

Approx.

130 msec.

Approx.

170 msec.

Approx.

320 msec.

OFF

OFF

ON

OFF

Synchronizing Clutch

Developing bias (AC)

Image transfer output: - voltage

Approx.

650 msec.

Laser

OFF

I/C Motor

Approx.

15 min.

M-6

OFF

Developing bias (DC)

Page 32

G T he Paper Exit Sensor is deactivated.

Approx.

680 msec.

OFF

OFF

Main Motor

The Power Unit Cooling Fan Motor turns at half speed.

Polygon Motor

Approx. 10 sec.

Approx. 20 sec.

OFF

OFF

Ozone Fan Motor

Fusing Cooling Fan Motor

M-7

Page 33

1170SBM0500A

5 CPU OVERRUN MONITOR FUNCTION

•

CPU Overrun Monitor Function (Watchdog Function)

The watchdog function is a self-monitoring function that determines whether any of the

CPUs mounted on the control board overrun.

•

If this function detects that a CPU overruns, the copier automatically resets the CPU,

thereby restarting the logic circuit and mechanism.

•

Even if a copier CPU operates erratically due to electrical noise, therefore, the copier is

able to recover from the f aulty condition so that the number of visits made by the Tech.

Rep. for CPU overrun can be minimized.

•

Processing performed during watchdog function:

If a faulty condition is detected, the copier resets the CPU and performs a restart

sequence. Since this sequence of operations is performed even during a copy cycle, the

copier detects a sheet or sheets of paper left inside it as a misfeed while it is being

restarted.

M-8

Page 34

1170SBM0600A

6 IMAGE STABILIZATION SYSTEM

•

The following image stabilization controls are provided to ensure stabilized copy image.

Item Purpose Control

PC Drum temperature

correction

PC Drum deterioration

correction

Grid Voltage: (Vg)

To compensate for any change

in ID due to changing PC Drum

temperatures.

To compensate for degraded

sensitivity caused by a deteriorating PC Drum.

PC Drum

Sleeve/

Magnet Roller

Developing Bias: (Vb)

The I/C Thermistor is used to

detect temperature and,

according to the detected temperature, Vg/Vb is corrected.

Corrects Vg according to the

period of time during which the

PC Drum has turned.

PC Drum Charge Corona

I/C Thermistor (TH2)

PC Drum Revolution

Counter

M-9

CPU

1171M028AA

Page 35

1170SBM0700A

7 IMAGING CARTRIDGE (I/C)

•

This copier employs an Imaging Cartridge (“I/C” in this manual) that contains a PC Drum,

PC Drum Charge Corona, Developing Unit, and Cleaning Unit as one unit.

Toner Supply Port

1171M002AA

ATDC Sensor (E1)

1171M001AA

1171M003AA

M-10

Page 36

1170SBM0701A

7-1. I/C Drive Mechanism

•

Drive from the I/C Motor is transmitted via a gear train to the PC Drum and Hopper.

PC Drum Drive Gear

I/C Motor (M1)

Hopper Drive Gear

1171M004AA

Electrical Component Control Signal ON O FF

M1 PJ16A-3 L H

1170SBM0702A

7-2. Identification and Life of I/C

•

When the Start key is pressed or the Side Cover is opened and closed, the copier determines whether the I/C is new or one which has been used previously.

•

The copier monitors the I/C life by storing in memory the period of time during which the

PC Drum has turned. The data is cleared when a new I/C is installed in the copier.

M-11

Page 37

1170SBM0800A

8 PC DRUM

•

The PC Drum used in this copier is the organic photoconductor (OPC) type.

The drum consists of an aluminum base coated with a charge generation layer and a

charge transport layer.

Handling Precautions

Prolonged exposure to light can cause the photoconductor surface of the drum to suffer

light fatigue, resulting in a loss of photosensitivity. If the I/C is removed from the copier, it

should be wrapped in a soft, clean, opaque cloth or other protective cover ing to prevent

exposure to light.

PC Drum Cross-Section

PC Drum

Charge Transport Layer

Charge Generation Layer

Aluminum Base

1139M007AA1167M007AA

Gear

•

Grounding of the PC Drum

The PC Drum ground point is located inside and at the front end of the I/C as viewed

from the front of the copier and in constant contact with the Drum Holding Shaft. When

the I/C is installed in the copier, the Drum Holding Shaft contacts the ground point. This

provides for assured grounding of the PC Drum through the ground plate in the rear to

the frame of the copier.

Ground Point

Ground Plate

PC Drum

Shaft

1171M005AA

M-12

Page 38

1170SBM0900A

9 DRUM CHARGING

•

A scorotron charger system generates a negative DC corona discharge onto the PC

Drum surface. The grid mesh ensures uniform charging.

•

The grid voltage (Vg) applied to the grid mesh is controlled by the constant voltage circuitry within the High Voltage Unit. It is varied through image stabilization control.

•

To restrict ozone production, the copier uses a PC Drum Charge Corona with a comb

electrode.

PC Drum Charge Corona

PC Drum

1171M006AB

1171M008AC

Comb Electrode

Grid Mesh

Electrical Component Control Signal ON O FF

Drum charging output PJ14A-3A L H

M-13

Page 39

1170SBM1000A

10 ERASE LAMP

•

Any potential remaining on the surface of the PC Drum is neutralized by both light from

the Erase Lamp and a DC negative voltage applied by the Charge Neutralizing Sheet.

•

The Charge Neutralizing Sheet applies a negative charge on the surface of t he PC Drum

which is positively charged by the Image Transfer Roller. A voltage of -820V is applied to

the Charge Neutralizing Sheet from the High V oltage Unit. The Erase Lamp then illuminates the surface of the PC Drum to further neutralize it.

•

The Erase Lamp consists of ten tungsten lamps.

Erase Lamp (LA1)

I/C

PC Drum

1171M009AD

Cleaning Blade

Charge Neutralizing Sheet

PC Drum

Erase Lamp (LA1)

PC Drum Charge Corona

1171M010AD

Sleeve/Magnet Roller

Electrical Component Control Signal All lamps ON Standby ON

LA1 PJ11A-6A H L

M-14

Page 40

1170SBM1100A

11 IR SECTION

•

Light reflected from the original passes through three mirrors and a lens to form a

reduced image on the CCD Sensor as the Scanner is moved by the Scanner Motor. The

CCD sensor converts the light pattern (image data) into an electrical image signal.

•

The electrical image signal is then output to the MFB Board.

8

7

6

5

4

3

2

9

10

11

1

20

19

18

1. BCR Board (BCR)

2. Original Size Detecting Sensor 5 (UN8)

3. Original Cover Detecting Sensor (PC14)

4. Original Size Detecting Sensor 4 (UN7)

5. Exposure Lamp (LA2)

6. Original Size Detecting Sensor 6 (UN9)

7. Scanner Motor (M5)

8. HGB Board (HGB)

9. Original Size Detecting Sensor 1 (UN4)

10. Original Size Detecting Sensor 2 (UN5)

11. Original Size Detecting Sensor 3 (UN6)

14

15

16

17

12. Scanner Home Position Sensor 1

(PC12)

13. Size Reset Switch (S5)

14. CCD Board (CCD)

15. Lens

16. Scanner

17. 1st Mirror

18. Scanner Home Position Sensor 2

(PC13)

19. 2nd/3rd Mirrors Carriage

20. Inv erter Board (INV)

1167M110AD

12

13

M-15

Page 41

1170SBM1101A

11-1. Exposure Section: Construction and Function

1. Auxiliary Reflector

2. Exposure Lamp

3. 1st Mirror

1. Auxiliary Reflector

When a book or other bound original is copied, the paper in the area near the binding

generally fails to come flush against the glass, so that the copy of these areas is generally too dark. The Auxiliary Reflector reduces this problem by reflecting light from the

Exposure Lamp onto these areas of the original.

2. Exposure Lamp

A fluorescent lamp is used to illuminate the original.

3. 1st Mirror

Directs the reflected light from the original to the 2nd Mirror.

Electrical Component Control Signal ON O FF

LA2 CN13BCR-1 L H

1167M089AA

M-16

Page 42

1170SBM1102A

11-2. Image Processing Flow

•

Image processing is made up of the following blocks.

1. Photoelectric Conversion (CCD Sensor)

2. HGB Board

Transmitted over an optical cable.

3. MFB Board

4. PH (Laser Emission)

1. Photoelectric Conversion (CCD Sensor)

•

Light reflected off the original is received through mirrors and lens by the CCD Sensor

which, in turn, outputs the corresponding data to the HGB Board.

2. HGB Board

•

After converting the data received from the CCD to an analog signal, the board converts

it to 8-bit image data (A/D conversion). It further makes various corrections and outputs

the resultant image data to the MFB Board over an optical cable.

3. MFB Board

•

This board compresses the image data received from the HGB Board, stores it, and

uncompresses it.

•

The image memory has a standard capacity of 16MB and can be expanded up to 64MB

(optional).

4. PH

•

Emits a laser beam according to the image data provided by the MFB Board to expose

the surface of the PC Drum.

M-17

Page 43

1170SBM1103A

11-3. Original Size Detection

•

When the copier is in Auto Pape r or Auto Size, the sensors mounted in the IR receive

light reflected off the original to allow the copier to determine the original size.

Original Size Detecting Sensor 6 (UN9)

Original Size Detecting Sensor 4

(UN7)

Original Size

Detecting Sensor

5 (UN8)

Original Size Detecting Sensor 1 (UN4)

Original Size Detecting Sensor 2

(UN5)

Original Size

Detecting Sensor

3 (UN6)

1171M025AD

Electrical Component Control Signal Blocked Unblock ed

UN4 CN4BCR-4 L H

UN5 CN5BCR-7 L H

UN6 CN11HGB-4 L H

UN7 CN6BCR-4 L H

UN8 CN9HGB-1 L H

UN9 CN8BCR-4 L H

M-18

Page 44

<Original Size Identification: Metric Areas>

Original Size

11” × 17”

A3L

A4L

A4C

A5L

B4L

FLS

Letter L

Letter C

Legal

❍

: Detected by sensor; L: Lengthwise; C: Crosswise

UN4 UN5 UN6 UN7 UN8 UN9

S1 S2 S3 S4 S5 S6 S7 S8 S9

❍❍❍❍ ❍❍❍❍

❍❍❍❍❍❍❍❍❍

❍❍ ❍ ❍

❍❍❍❍❍ ❍

❍❍❍ ❍❍❍❍

❍❍ ❍❍ ❍

❍❍ ❍

❍❍❍❍ ❍

❍❍ ❍❍❍❍

NOTE

UN4, UN6 and UN8 are options.

<Original Size Identification: Inch Areas>

❍

Original Size

11” × 17”

A3L

A4L

A4C

B4L

5-1/2” × 8-1/2”L

FLS

B5C

Letter L

Letter C

Legal

❍

: Detected by sensor; L: Lengthwise; C: Crosswise

S2 S3 S4 S5 S6 S7 S8 S9

❍❍❍ ❍❍❍❍

❍❍❍❍❍❍❍❍

❍❍❍

❍❍❍❍ ❍

❍❍ ❍❍❍❍

❍❍❍❍

❍❍ ❍

❍❍

❍❍❍ ❍

❍ ❍❍❍❍

UN5 UN6 UN7 UN8 UN9

NOTE

UN6, UN8 and UN9 are options.

❍

M-19

Page 45

1170SBM1104A

11-4. Original Size Detection Timing

The copier CPU affirms and resets the readings of the original size at the following timings.

•

Takes size readings:

When the Original Cover Detecting Sensor is deactivated.

•

Affirms size readings:

When the Start key is pressed with the Original Cover Detecting Sensor activated or the

Size Reset Switch deactuated.

•

Resets size readings:

When the Size Reset Switch is deactuated.

Magnet

Original Cover

Detecting Sensor

(PC14)

Size Reset Switch (S5)

Electrical Component Control Signal ON O FF

S5 CN9BCR-2 L H

Electrical Component Control Signal Unblocked Blocked

PC14 CN10BCR-2 L H

1167M113AB

M-20

Page 46

1170SBM1105A

11-5. Scanner and 2nd/3rd Mirrors Carriage Moving Mechanism

<Scanner>

•

During a scan, the Scanner projects an even amount of light from the Exposure Lamp

onto the entire surface of the original. The light is reflected from the original to the 1st

Mirror of the scanner and then to the 2nd and 3rd Mirrors.

•

The Scanner is driven by the Scanner Motor and front and rear Scanner Drive Cables.

•

Scanner speed is determined by the set zoom ratio in reference to the full size mode.

•

The Scanner is at home position when Scanner Home Position Sensor 1 is block ed. This

position serves as the reference for the scan motion.

•

Scanner Home Position Sensor 2 determines the home position of the Scanner when

AF-7 is used.

<2nd/3rd Mirrors Carriage>

•

The 2nd and 3rd Mirrors are mounted to their holder at right angles to each other. They

direct the light reflected off the 1st Mirror through the lens to the CCD.

•

The 2nd/3rd Mirrors Carriage is also moved by the Scanner Drive Cables and pulleys

driven by the Scanner Motor . It trav els at a speed half that of the Scanner, thereby keeping constant the optical path length between the Original Glass and lens.

Scanner Motor (M5)

Scanner Home

P osi tion Sensor 1

(PC12)

Scanner

2nd/3rd Mirrors Carriage

Electrical Component Control Signal

M5 CN3BCR-1~3 Pulse output

Electrical Component Control Signal Blocked Unblock ed

PC12 CN11BCR-1 L H

PC13 CN12BCR-1 L H

Scanner Home Position

Sensor 2 (PC13)

Forward

Rotation

1167M112AA

Backward

Rotation

M-21

Page 47

1170SBM1200A

12 PH SECTION

•

Based on the image data output from the MFB Board, the LD (laser diode) is activated

and the corresponding light strikes the surface of the PC Drum.

PH Unit

1171M035AB

M-22

Page 48

1170SBM1201A

12-1. PH Components

4

3

2

1

5

6

7

1. Polygon Motor (M10)

2. Cylindrical Lens

3. SOS Mirror

4. Collimator Lens

Electrical Component Control Signal ON O FF

M10 PJ8A-3 L H

5. Laser Diode Board (PWB-B)

6. SOS Sensor

7. f-θ Lens

1167M023AB

M-23

Page 49

1170SBM1202A

12-2. Laser Emission Timing (SOS Signal)

•

The signal output from the Master Board triggers the firing of the laser. The laser beam

travels to the Polygon Mirror, lens, and SOS Mirror to eventually hit the SOS Sensor,

which generates an SOS signal.

•

The SOS signal determines the laser emission timing for each line in the main scanning

direction.

P olygon Motor

(M10)

Polygon Mirror

f-θ Lens

Cylindrical Lens

SOS Mirror

Collimator Lens

Laser Diode Board

(PWB-B)

SOS Sensor

PC Drum

PC Drum

SOS Mirror

A to B: LD activation

B to C: LD OFF

C to D: Laser beam exposure area according to the image data

1167M024AC

SOS

Sensor

SOS Signal

ABCD

1171M038AA

M-24

Page 50

1170SBM1300A

13 DEVELOPING UNIT

•

The Toner Conveying Rollers mix the toner and carrier particles together and carry the

toner/carrier mixture up to the Sleeve/Magnet Roller . The magnetic brush formed on the

surface of the roller allows the toner to come into contact with the charges on the surface

of the PC Drum, thus forming an electrostatic latent image.

14

12345

6

7

8

9

1171M011AB

10111213

1. Spent Toner Recycling Coil

2. PC Drum Charge Corona

3. Spent Toner Feed Roller 2

4. Cleaning Blade

5. Spent Toner Feed Roller 1

6. PC Drum Paper Separator Finger

7. PC Drum Protective Shutter

8. PC Drum

9. Sleeve/Magnet Roller

10. 1st Toner Conveying Roller

11. ATDC Sensor (E1)

12. 2nd Toner Conveying Roller

13. 3rd Toner Conveying Roller

14. Spent Toner Recycling Duct

M-25

Page 51

1170SBM1301A

13-1. Sleeve/Magnet Roller

•

This copier employs the MT-HG system with a Sleeve/Magnet Roller ha ving the f ollo wi ng

magnetic characteristics.

•

Turning of the sleeve surrounding the Magnet Roller ensures that fresh developer from

the Developer Mixing Chamber is always being conveyed to the point of development

with respect to the PC Drum.

N1 : The point of development with the maximum magnetic flux density which

ensures that the carrier is firmly held onto the Sleeve Roller when toner is

attracted to the latent image.

S1, N2 : The magnetic flux density between these two poles is made low to ensure that

the developer remaining on the surface of the Sleeve Roller is smoothly recycled. They also prevent developer from scattering.

N3 : The developer brush is formed by this pole and its height is moderated before

the brush is regulated by the Doctor Blade.

S2a : This pole ensures that the developer is conveyed to the point of development

over the wide interval between N3 and N1.

S2b : If developer is compacted and clogs at the Doctor Blade and, as a result, part

of the surface of the Sleeve/Magnet Roller is not covered with developer, the

nearby developer around this pole with a weak magnetic force goes to those

uncovered areas. This helps prevent white lines from occurring on the copy.

S2a

S2b

N3

N1

N2

1171M027AA

PC Drum

S1

Sleeve/

Magnet Roller

1st Toner Conveying Roller

1167M076AB

M-26

Page 52

1170SBM1302A

13-2. Developing Bias

•

The amount of toner attracted onto the surface of the PC Drum is controlled by varying

the developing bias voltage.

•

As the PC Drum deteriorates and its photoconductive layer begins to wear, it becomes

more sensitive to the increase in the amount of toner. As a countermeasure against this

problem, the dev eloping bias v oltage is automatically swi tched according to the PC Drum

temperature, thereby stabilizing the image quality level.

PC Drum

Sleev e/Magnet Roller

1171M012AB

Developing Bias Contact Terminal

Electrical Component Control Signal ON O FF

Vb PJ14A-1A L H

M-27

Page 53

1170SBM1303A

13-3. ATDC Sensor

•

The ATDC Sensor automatic adjustment is made when a new I/C is installed in the

copier. Toner replenishing control is thereafter controlled as detailed in the following.

1. ATDC Sensor Automatic Adjustment

•

The ATDC Sensor is automatically adjusted when a new I/C is loaded in the copier. During this sequence, the copier reads the sensor output value and sets it as the reference.

This reference value is stored in memory and used until the I/C reaches its service life.

2. Toner Replenishing Control

•

While the I/C Motor is turning, the ATDC Sensor samples T/C and, according to the readings, the copier provides the following controls.

T/C Ratio (%) Sampling Data (V) Control Details

More than 19 Less than 1.41 Defective ATDC Sensor

14 to 19 2.32 to 1.41 Toner replenished for 0 msec.

13 to 14 2.50 to 2.32

12 to 13 2.68 to 2.50

10 to 12 3.10 to 2.68

7 to 10 3.92 to 3.10 Passed onto the T/C recov ery mode.

Less than 7 More than 3.92 Defective ATDC Sensor

✽

Toner replenishment represents the operation of the Sub Hopper Toner Replenishing

Motor.

3. Toner Empty Control (T/C Recovery Mode)

•

When the control is passed onto the T/C recovery mode, the Sub Hopper Toner Replenishing Motor is energized to replenish the supply of toner into the Developing Unit and, if

T/C is recovered to a lev el of 14% or higher (2.32V or less) within 150 sec., it resets the

toner-empty condition.

Toner replenished for 54 msec. at intervals of

approx. 1 sec.

Toner replenished for 150 msec. at intervals of

approx. 1 sec.

Toner replenished for 378 msec. at intervals of

approx. 500 msec.

M-28

Page 54

1170SBM1304A

13-4. Sub Hopper Toner Replenishing Mechanism

•

Toner is replenished from the Sub Hopper to the Developing Unit by turning the Sub Hopper Toner Replenishing Motor for the period of time controlled by the ATDC output voltage (T/C).

Sub Hopper

1171M013AC

Sub Hopper Toner Replenishing Motor (M7)

Electrical Component Control Signal ON O FF

M7 PJ11A-8A DC24V L

M-29

Page 55

1170SBM1305A

13-5. Sub Hopper Toner Empty Detecting Mechanism

•

A toner-empty condition in the Sub Hopper is detected by the Magnet Lever that moves

up and down as the Sub Hopper Toner Agitating Lev er turns and actuates and deactuates the Sub Hopper Toner Empty Switch.

•

While the amount of toner in the Sub Hopper is more than the predetermined amount,

the Magnet Lever rests on the toner, keeping the Sub Hopper Toner Empty Switch deactuated even when the Sub Hopper Toner Agitating Lever turns. As toner is consumed,

the Magnet Lever lowers to eventually actuate the Sub Hopper Toner Empty Switch, at

which timing the copier detects a toner-empty condition in the Sub Hopper.

Magnet Lever

Magnet

Sub Hopper Toner Agitating Lever

1171M021AA

Sub Hopper Toner Empty Switch (S4)

Electrical Component Control Signal ON O FF

S4 PJ11A-7B L H

M-30

Page 56

1170SBM1306A

13-6. Main Hopper Toner Replenishing Mechanism

•

When a toner-empty condition in the Sub Hopper is detected, the Main Hopper Toner

Replenishing Motor is energized to turn the Toner Bottle, thereby supplying toner from

the Main Hopper to the Sub Hopper.

•

The Toner Bottle Home Position Sensor mounted on the coupling ensures that the Toner

Supply Port in the Toner Bottle is positioned at the top whenever the bottle is stopped.

•

The Toner Bottle Cover Sensor detects whether the Toner Bottle Cover is open. If the

cover is open, the copier does not authorize the initiation of a new copy cycle. If the

cover is opened during a copy cycle, the copier interrupts the cycle.

Toner Bottle

Main Hopper Toner

Replenishing Motor (M6)

Sub Hopper

Toner Bottle Home

Position Sensor (PC10)

1171M020AB

Electrical Component Control Signal ON O FF

M6 PJ11A-4A DC24V L

Electrical Component Control Signal Unblocked Blocked

PC10 PJ11A-2B L H

M-31

Page 57

1170SBM1307A

13-7. I/C Cooling Fan Motor

•

The I/C Cooling Fan Motor pre vents the temperature inside the copier (around the entire

I/C) from rising inordinately.

I/C

I/C Cooling Fan

Motor (M9)

1171M032AB

Electrical Component Control Signal ON O FF

M9 PJ18A-10 DC24V L

1170SBM1308A

13-8. Ozone Fan Motor

•

Ozone produced by the PC Drum Charge Corona is absorbed by the Ozone Filter from

the air being drawn out of the copier by the Ozone F an Motor.

Ozone Fan Motor (M8)

Ozone Filter

I/C

1171M023AC

Electrical Component Control Signal ON O FF

M8 PJ11A-1A DC24V L

M-32

Page 58

1170SBM1400A

14 PAPER TAKE-UP/FEED SECTION

NOTE

•

For the details of the 2nd Cassette (500-Sheet Cassette), see the relevant option service

manual.

•

This copier employs the Multi-Purpose (MP) Cassette whose capacity is about 250

sheets (about 20 sheets for special paper).

Paper Size Detecting Board (PWB-I)

Paper Take-Up Roll

Trailing Edge Stop

1170SBM1401A

1167M055AA

14-1. MP Cassette Paper Lifting Plate

•

The Paper Lifting Plate installed in the MP Cassette is spring-loaded to push the paper

stack upward. When the cassette is slid into the copier, the lever located on the bottom

of the cassette and used to lock down the Paper Lifting Plate is pushed and unlocked,

allowing the Paper Lifting Plate to push the paper stack upward.

Lever

Paper Lifting Plate

1167M080AA

M-33

Page 59

1170SBM1402A

14-2. MP Cassette-in-Position Detection

•

When the MP Cassette is slid into the copier , the light bloc king plate located in the rear of

the cassette blocks the Cassette Set Sensor and the copier determines that the MP Cassette has been slid into position.

Cassette Set Sensor (PC6)

Light Blocking Plate

1167M052AB

Electrical Component Control Signal Unblocked Blocked

PC6 PJ13A-5B H L

M-34

Page 60

1170SBM1403A

14-3. MP Cassette Paper Empty Detection

•

Two sensors are used in this copier: the Paper Empty Sensor detects a paper-empty

condition, while the Paper Near-Empty Sensor detects a paper near-empty condition.

Paper Near-Empty Detection:

•

A paper near-empty condition is detected as the paper is consumed and when the NearEmpty Lever lowers to eventually block the sensor (L).

•

At this time, the MP Cassette Paper Empty LED starts blinking.

•

A paper-empty condition results when about 50 more sheets of paper are used after the

near-empty condition has been detected.

Near-Empty Lever

Paper Lifting Lever

Paper Near-Empty

1167M071AC

Sensor (PC4)

Paper Empty Detection:

•

A paper-empty condition is detected as the paper is consumed and when the Empty

Lev er lowers to eventually b lock the sensor (L).

•

At this time, the MP Cassette Paper Empty LED lights up steadily.

Paper Empty Sensor

(PC5)

Empty Lever

1167M073AD

Electrical Component Control Signal Unblocked Blocked

PC4 PJ14A-13A H L

PC5 PJ13A-2B H L

M-35

Page 61

1170SBM1404A

14-4. MP Cassette Paper Size Detection

•

The Paper Size Detecting Board detects the length of the paper (FD).

•

A lever is connected to the Trailing Edge Stop of the cassette and, as the stop is slid to

the size of the paper loaded in the cassette, the leve r is moved to turn ON and OFF the

size detecting switches mounted on the copier side.

•

The control panel settings are necessary for any paper size other than the following.

Paper Size Detecting Switches (PWB-I)

1234

ON OFF OFF OFF A3L, 11”×17”L

OFF OFF OFF OFF B4L, 8-1/2”×14”L

OFF ON ON ON A4L

ON ON ON ON B5L, 8-1/2”×11”L

ON ON OFF OFF A4C/A5L

ON OFF OFF ON B5C

OFF ON OFF OFF A5C

ON ON ON OFF 8-1/2”×11”C

Paper Size Detecting Board (PWB-I)

12 34

Paper Size

Trailing Edge Stop

Electrical Component Control Signal ON O FF

PWB-I (1) PJ14A-1B L H

PWB-I (2) PJ14A-2B L H

PWB-I (3) PJ14A-3B L H

PWB-I (4) PJ14A-4B L H

1167M060AC

M-36

Page 62

1170SBM1405A

14-5. Paper Take-Up Mechanism

•

Drive from the Main Motor is transmitted to the Paper Take-Up Clutch (spring clutch) and,

by energizing the Paper Take-Up Solenoid, the Paper Take-Up Roll is turned.

•

The paper separating mechanism employs a Paper Separator Pad.

Main Motor (M2)

Paper Take-Up Clutch

Paper Take-Up Roll

Paper Separator

Pad

Paper Take-Up Solenoid

(SL1)

1167M054AB1167M038AB

1170SBM1406A

14-6. Manual Bypass Tray

1. Construction of the Manual Bypass Tray

•

Drive from the Main Motor is transmitted to the Manual Paper Feed Take-Up Clutch and,

by energizing this clutch, the Manual Feed Paper Take-Up Roll is turned.

Main Motor (M2)

Manual Paper Feed Ta ke-Up Clutch (CL3)

Manual Feed Paper Ta ke-Up Roll

Manual Feed Paper Take-Up Sensor (PC8)

Manual Bypass Tray

1167M067AC

Electrical Component Control Signal ON O FF

M2 PJ16A-1 L H

SL1 PJ13A-13B L H

CL3 PJ4A-9A L H

M-37

Page 63

2. Manual Feed Paper Take-Up Detection

•

The Manual Feed Paper Take-Up Sensor detects a sheet of paper that is fed via the Manual Bypass Tray.

•

The size and type of the paper for manual feed are set on the control panel.

<Paper Present: Unblocked (H)>

Manual Feed Paper Take-Up Sensor (PC8)

1167M086AA

<Paper Not Present: Blocked (L)>

1167M085AA

Electrical Component Control Signal Unblocked Blocked

PC8 PJ4A-7B H L

1170SBM1407A

14-7. Paper Take-Up Retry Mechanism

•

To minimize the occurrence of a paper misfeed due to a slippery Paper Take-Up Roll, the

Paper Take-Up Solenoid is energized a second time if a sheet of paper fails to reach the

Synchronizing Roller Sensor within a given period of time after the solenoid has been

energized first.

•

A paper take-up misfeed results if the sheet of paper does not reach the Synchronizing

Roller Sensor even after two paper take-up sequences.

M-38

Page 64

1170SBM1500A

15 SYNCHRONIZING ROLLERS

•

The Synchronizing Rollers of this copier are located inside the Right Door. The y are easily accessible for misfeed clearing by just opening the Right Door.

Synchronizing Roller

1171M029AA

1170SBM1501A

15-1. Synchronizing Roller Drive Mechanism/Control

•

The Synchronizing Rollers are turned by the drive from the Main Motor transmitted to the

Synchronizing Clutch.

•

The rollers are started when the Synchronizing Clutch is deenergized.

Main Motor (M2)

Synchronizing Clutch (CL1)

Left Synchronizing Roller

Right Synchronizing Roller

1167M064AA

Electrical Component Control Signal ON O FF

M2 PJ16A-1 L H

CL1 PJ13A-2A L H

M-39

Page 65

1170SBM1502A

15-2. Paper Dust Remover

•

The Paper Dust Remover is installed so that it mak es contact with the Lef t Synchronizing

Roller. It is intended for preventing paper dust from sticking to the surface of the PC

Drum.

•

As the roller turns in contact with the Paper Dust Remover, triboelectric charging occurs,

which attracts paper dust from the paper that passes between the two rollers and the

dust is, in turn, transferred onto the Paper Dust Remover.

Synchronizing Roller

Paper Dust Remover

Synchronizing Roller Sensor (PC2)

1171M026AB

M-40

Page 66

1170SBM1600A

16 IMAGE TRANSFER AND PAPER SEPARATION

Image Transfer

•

This copier employs an Image Transfer Roller to transfer the image to the paper. The

High Voltage Unit applies an image transfer current to this roller. To ensure that image

transfer effici ency is stabilized, the image transfer current is automatically varied according to the paper size, paper type, and the B/W ratio of the original.

•

To prevent toner from sticking to the Image Transfer Roller, an image transfer voltage of

-975V is applied to the roller for cleaning.

Paper Separation

•

To neutralize any charge left on the paper, to which the image has been transferred, the