Page 1

INSPIRED INNOVATION

TA and TF Walk-In Ovens

and Truck-In Ovens

Designed for industrial process

versatility and dependability

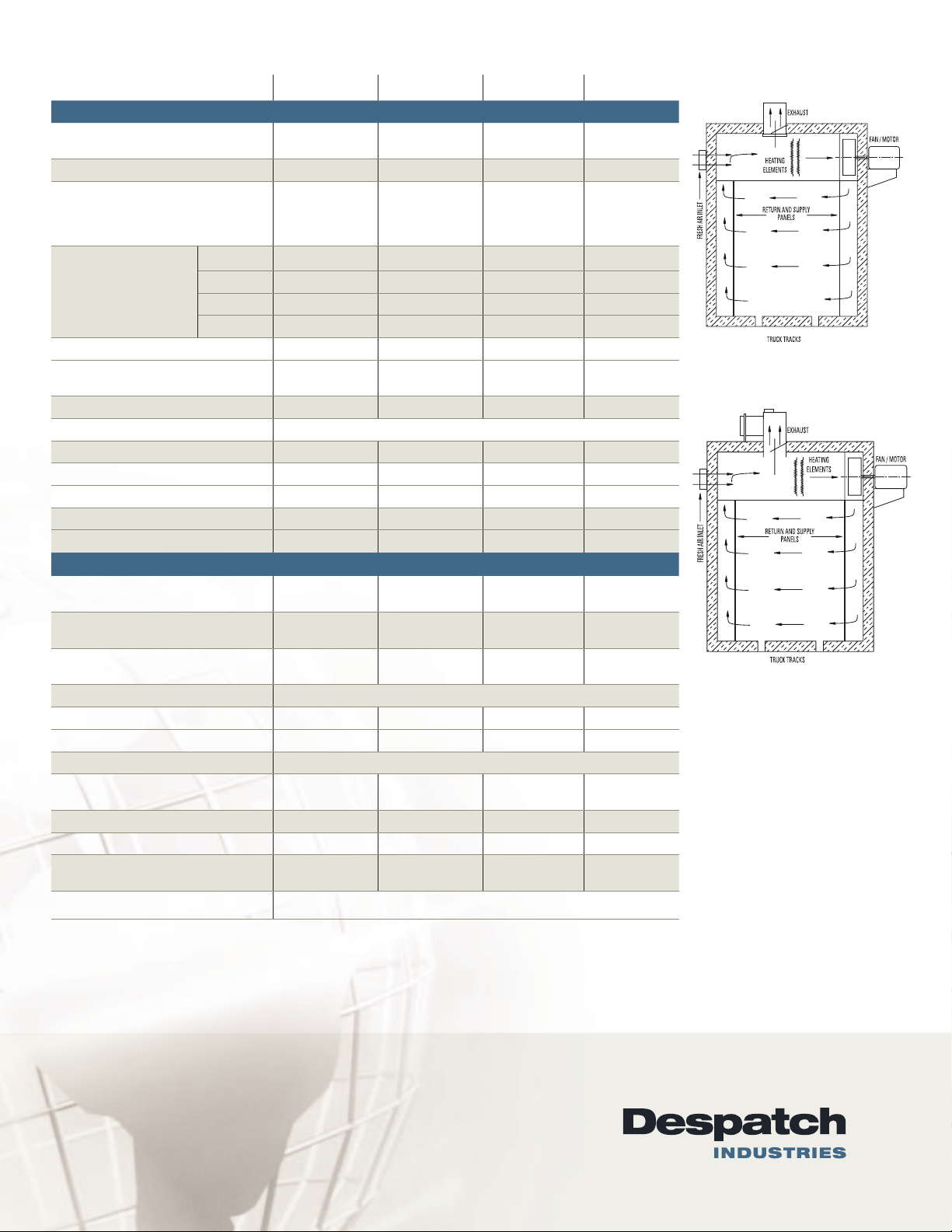

e TA/TF Truck-in/Walk-in ovens feature horizontal recirculating air ow

to ensure uniform temperatures throughout the oven. A high-volume fan

circulates air through perforated, aluminized steel walls to create a constant

horizontal air ow across all sections of the oven. e result is proven

reliability in demanding production applications, such as aging, bonding,

curing, drying, nish baking and heat treating. Multiple temperature

operations are controlled by up to eight programs, with eight ramp and

soak segments in each program.

For applications that include ammable solvents or large amounts of

moisture removal we o er the TF series. ese Class A ovens are specially

designed to meet NFPA 86 requirements. ey include a pressure relief

panel, purge timer and exhaust fan.

FEATURES AT A GLANCE

Temperatures up to 343°C (650°F)

Fully assembled and factory tested

Protocol 3

integrated data logging capabilities and USB port

for simple oven set-up and data export

Two levels of password security can limit operator

access to program parameters

TM

control with large LCD display,

OPTIONS:

Insulated fl oor with truck tracks

Despatch unique adjustable louvers

Loading trucks and shelves

Access ports for test wires

Proportioning gas fi red heater

Chart recorder

Audible alarm

Rear doors

CE compliant

End-of-cycle and high-limit indicators

Aluminized steel interior

High volume recirculating fan provides faster,

more uniform heating - saving process time and

improving product quality

Plate fl oor with truck tracks

UL and C-UL listed open industrial control panel

MinneaPolis • shanGhai • berlin • sinGaPore • hsinchu

Page 2

TAD/TFD 2-52 3-10 3-17 3-21

Physical sPecifications

Chamber size (width x depth x height) 38 x 38 x 63 in.

Capacity in cubic feet (liters) 52.6 (1490) 104 (2945) 170 (4814) 216 (6116)

Overall size (width x depth x height)

*Includes 7in (18cm) exhaust stack. For

TFD2-52 add additional 8in (20cm) to height

for exhaust.

Electrical: 60 hertz - 3 phase

480 volt standard

240 volt optional

(FLA- approx. full load amps)

50 hertz is also available

Exhaust outlet TAD 7 in. (17.8 cm) 7 in. (17.8 cm) 9 in. (22.9 cm) 9 in. (22.9 cm)

Exhaust outlet TFD 3.5 x 8.5 in.

Doors 1 2 2 2

Insulation thickness Walls: 5 in. (12.7 cm) Insulated floor option: 3 in. (7.6 cm) for all models

Truck centers 24 in. (61 cm) 32 in. (81.3 cm) 36 in. (91.4 cm) 48 in. (122 cm)

Approximate net weight TAD 1850 lbs (844 kg) 3020 lbs (1377 kg) 4750 lbs (2155 kg) 5150 lbs (2336 kg)

Approximate net weight TFD 1900 lbs (862 kg) 3070 lbs (1393 kg) 4800 lbs (2177 kg) 5200 lbs (2359 kg)

Approximate shipping weight TAD 2050 lbs (930 kg) 3220 lbs (1461 kg) 5000 lbs (2268 kg) 5400 lbs (2450 kg)

Approximate shipping weight TFD 2100 lbs (953 kg) 3270 lbs (1483 kg) 5050 lbs (2290 kg) 5450 lbs (2472 kg)

240 volts TAD

240 volts TFD 94.8 FLA / 36 KW 131 FLA / 48 KW 209 FLA / 72 KW 209 FLA / 72 KW

480 volts TAD 32.8 FLA / 24 KW 51 FLA / 36 KW 71.2 FLA / 48 KW 71.2 FLA / 48 KW

480 volts TFD 48 FLA / 36 KW 66 FLA / 48 KW 103 FLA / 72 KW 103 FLA / 72 KW

96.5 x 96.5 x 160 cm

83.3 x 48.5 x 95* in.

212 x 123 x 241* cm

65.9 FLA / 24 KW 104.1 FLA / 36 KW 140.2 FLA / 48 KW 140.2 FLA / 48 KW

(8.9 x 21.6 cm)

FUNCTIONAL SPECIFICATIONS

Time to temp with no load

40˚C to 177˚C (104˚F to 350˚F)

Time to temp with no load

40˚C to 260˚C (104˚F to 500˚F)

Time to temp with no load

40˚C to 343˚C (104˚F to 650˚F)

Temperature uniformity at set point +/- 1.5% after stabilization

Minimum operating temp above ambient TAD 20˚C (35˚F) 20˚C (35˚F) 20˚C (35˚F) 20˚C (35˚F)

Minimum operating temp above ambient TFD 14˚C (25˚F) 14˚C (25˚F) 14˚C (25˚F) 14˚C (25˚F)

Maximum Operating Temperature 343˚C (650˚F)

Exhaust capacity TFD (minimum/maximum) 143/350 CFM

TFD solvent handling capacity at 204˚C (400˚F) .15 GPH (.57 LPH) .25 GPH (.95 LPH) .33 GPH (1.25 LPH) .33 GPH (1.25 LPH)

TFD forced exhaust HP 1/3 HP 1/3 HP 2 HP 2 HP

Recirculating fan 2 HP / 1700 CFM

Control stability

15 minutes 15 minutes 15 minutes 15 minutes

30 minutes 30 minutes 30 minutes 30 minutes

50 minutes 50 minutes 50 minutes 50 minutes

(67.5/165.2 LPS)

(802 lps)

+/- 0.5˚C/5˚C on all models ( represents the change in ambient temperature.)

48 x 52 x 72 in.

122 x 132 x 183 cm

100.5x 62.5 x102 in.

255 x 159 x 259 cm

3.5 x 8.5 in.

(8.9 x 21.6 cm)

238/350 CFM

(112.3/165.2 LPS)

5 HP / 3800 CFM

(1793 lps)

60 x 68 x 72 in.

152 x 173 x 183 cm

114.5 x78.5 x102 in.

291 x 200 x 259 cm

5 x 13.5 in.

(12.7 x 34.3 cm)

315/1000 CFM

(148.7/471.9 LPS)

10 HP / 6000 CFM

(2832 lps)

72 x 72 x 72 in.

183 x 183 x 183 cm

126.5 x85.5 x102 in.

321 x 217 x 259 cm

5 x 13.5 in.

(12.7 x 34.3 cm)

315/1000 CFM

(148.7/471.9 LPS)

10 HP / 6000 CFM

(2832 lps)

TAD front view cross section

showing airflow pattern.

TFD front view cross section

showing airflow pattern.

Notes: Uniformity figures are based on a nine-point test conducted in an empty oven after stabilization period. Uniformity can vary

slightly depending on unit and operating conditions. Minimum operating temperature and cooling times are based on 20°C ambient

temperature measured at the fresh air inlet with the fresh air and exhaust dampers fully open. Specifications are subject to change

without notice. If the existing specifications differ from yours, ask about our customizing capabilities.

service and technical suPPort

service parts: 1-800-473-7373

international service/main: 1-952-469-8230

service fax: 1-952-469-8193

service@despatch.com

Global headquarters

phone: 1-888-DESPATCH (1-888-337-7282)

international/main: 1-952-469-5424

fax: 1-952-469-4513

sales@despatch.com

8860 207th Street West

Minneapolis, MN 55044 USA

www.despatch.com

© 2012 Despatch Industries. All rights reserved. Despatch is a registered trademark of Despatch Industries in the U.S. and other countries. TA-TF 4-12

Loading...

Loading...