desmon GBF-3GN2/3, GBC-5G, GBF-5G, GBF-5P, GBC-7 Service Manual

...

Service Manual

Blast Chiller

Rev 07/04/2015

2

Blast chiller Service Manual

3

Rev 07/04/2015

Safety Precautions

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL,

MAINTAIN AND REPAIR ELECTRICAL REFRIGERATION EQUIPMENT, WHO

SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF THE

EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING,

PERFORMING MAINTENANCE ON, OR REPAIRING THE EQUIPMENT.

WARNING Failure to follow all the instructions in this manual can cause

property damage, injury or death.

WARNING Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

WARNING Electrical connections should be performed only by a certified

professional.

Electrical and grounding connections must comply with the applicable portions of

the National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING Before connecting the unit to the electrical supply, verify that the

electrical and grounding connections comply with the applicable portions of the

National Electric Code and/or other local electrical codes. Failure to comply with

this procedure can cause property damage, injury or death.

WARNING Before connecting the unit to the electrical supply, verify that the

electrical connection agrees with the specifications on the data plate. Failure to

comply with this procedure can cause property damage, injury or death.

WARNING Appliance must be connected to a grounded, metal, permanent

wiring system. Or an equipment-grounding conductor must be run with the circuit

conductors and connected to the equipment-grounding terminal or lead on the

appliance. Failure to comply with this procedure can cause property damage, injury

or death.

WARNING Appliances equipped with a flexible electric supply cord, are

provided with a three-prong grounding plug. It is imperative that this plug be

connected into a properly grounded three-prong receptacle. Failure to comply with

this procedure can cause property damage, injury or death.

WARNING If the receptacle is not the proper grounding type, contact an

electrician. Do not remove the grounding prong from the plug. Failure to comply

with this procedure can cause property damage, injury or death.

WARNING Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always perform the

Rev 07/04/2015

4

Blast chiller Service Manual

Electrical LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply

with this procedure can cause property damage, injury or death.

WARNING Before removing any sheet metal panels, always perform the

Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected.

Failure to comply with this procedure can cause property damage, injury or death.

WARNING Do not operate this equipment without properly placing and securing

all covers and access panels. Failure to comply with this procedure can cause

property damage, injury or death.

WARNING Do not use or store gasoline or other flammable vapors or liquids in

the vicinity of this or any other appliance. Failure to comply can cause property

damage, injury or death.

WARNING In the event of a power failure, do not attempt to operate this

appliance. Failure to comply can cause property damage, injury or death.

General Safety

WARNING Desmon accepts no responsibility for any situation resulting from

work carried out in an unprofessional manner, or from the incorrect interpretation or

application of regulations.

General Installation

WARNING Incorrect installation or any modifications made to the appliance

may damage property or result in injury or death.

Electrical

WARNING Electrical connections or any work required on the electrical circuits

inside the appliance must be performed by certified technicians in compliance with

local, state, and federal regulations.

WARNING Make sure all facility electrical connections are in compliance with

all local and federal electrical code regulations.

Inspection and Maintenance

WARNING Appliance maintenance must be carried out by only by suitably

trained personnel.

WARNING Before any maintenance work is performed, the appliance must be

disconnected from the electrical supply. Apply a lockout tag to the electrical supply

connection.

WARNING All replacement parts that are not supplied by Desmon must be preapproved before installation.

5

Rev 07/04/2015

Repair Work Safety

WARNING Repair work must only be performed by Desmon’s approved

distributors or one of its authorized representatives. Desmon accepts no

responsibility for any situation resulting from work performed by untrained and/or

unauthorized technicians.

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE

WARNING Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always follow the

Electrical LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply

can cause property damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is used to protect personnel working

on an electrical appliance. Before performing any maintenance or service that

requires exposure to electrical components, follow these steps:

1. In electrical box, place appliance circuit breaker into OFF position.

2. Place a lock or other device on electrical box cover to prevent someone from

placing circuit breaker ON.

3. Place a tag on electrical box cover to indicate that appliance has been

disconnected for service and power should not be restored until tag is removed by

maintenance personnel.

4. Disconnect appliance power cord from electrical outlet.

5. Place a tag on the cord to indicate that unit has been disconnected for service

and power should not be restored until tag is removed by maintenance personnel.

Rev 07/04/2015

6

TABLE OF CONTENTS

Blast chiller Service Manual

1. BASIC SERVICE DIAGNOSTIC (STANDARD CONTROLLER) ............................................................ 9

1.1. ALARM/FAILURE LIST ....................................................................................... 10

1.2. FAILURE CODE DETAILS .................................................................................. 11

1.3. SERVICE MENU – CONFIGURATION PARAMETER ........................................ 11

1.3.1 Entering the configuration parameter ........................................................................................ 11

1.3.2 Parameter list (factory setting) ................................................................................................... 11

1.3.3 Temperature Probes Display ..................................................................................................... 28

2. BASIC SERVICE DIAGNOSTIC (TOUCH SCREEN CONTROLLER) .................................................. 33

2.1. ALARM/FAILURE LIST ....................................................................................... 34

2.2. FAILURE CODE DETAILS .................................................................................. 36

2.3. SERVICE MENU – CONFIGURATION PARAMETERS ...................................... 37

2.3.1 Entering the configuration parameter ........................................................................................ 37

2.3.2 Parameter list (factory settings) ................................................................................................... 1

2.3.3 Temperature Probes Display ....................................................................................................... 5

3. TROUBLESHOOTING ............................................................................................................................. 7

3.1. PROBES ............................................................................................................... 7

3.1.1. Checking the Probes ............................................................................................. 8

3.1.2. NTC (10kOhms@25°C/77°F) Diagram .................................................................. 9

3.1.3. NTC (10kOhms@25°C/77°F) Chart Table........................................................... 11

3.1.4. Pt1000 (1kOhms@0°C/32°F) Diagram ................................................................ 12

3.1.5. Pt1000 (1kOhms@0°C/32°F) Chart Table........................................................... 12

3.2. DOOR SWITCH ................................................................................................... 13

3.2.1 Checking the door switch ........................................................................................................... 13

3.3. PRESSURE SWITCH .......................................................................................... 14

3.3.1 Pressure Switch Working Principles – Alarm Connection ......................................................... 14

3.3.2 Pressure Switch Working Principles – Pump Down .................................................................. 15

3.3.3 Pressure Switch Factory Setting ................................................................................................ 15

3.4. DOOR FRAME HEATER ..................................................................................... 15

3.4.1 Heater cable features ................................................................................................................. 16

3.5. MAIN BOARD – STANDARD CONTROLLER ..................................................... 16

3.5.1 Checking Relay Outputs ............................................................................................................ 16

3.6. KEYPAD – STANDARD CONTROLLER ............................................................. 18

3.6.1 Keypad Troubleshooting ............................................................................................................ 18

3.7. MAIN BOARD – TOUCH SCREEN CONTROLLER ............................................ 18

3.7.1 Checking Relay Outputs ............................................................................................................ 19

3.8. DISPLAY – TOUCH SCREEN VERSION ............................................................ 22

3.8.1 Touch Screen Display Troubleshooting ..................................................................................... 22

3.9. REFRIGERANT PRESSURES CHECKS ............................................................ 23

4 SERVICE AND REPAIR ......................................................................................................................... 24

4.1 REMOVE THE FRONT PANEL ........................................................................... 24

4.1.1. Units from 5 to 18 shelves ................................................................................... 24

4.1.2 GBF-GN2/3 (smallest self-contained unit) ................................................................................. 25

4.1.3 Latest version of self-contained (5 to 18 pans) Effective June 2014 .............................. 26

4.2. REVERSING THE DOOR SWING (ONLY NON TOUCH SCREEN) ................... 27

4.3. ACCESSING THE CONDENSING UNIT ............................................................. 32

4.3.1 Unit from 5 to 18 shelves ........................................................................................................... 32

4.3.2 5 shelves units ........................................................................................................................... 37

7

Rev 07/04/2015

4.3.3 GBF-3GN2/3 (smallest self-contained unit) ............................................................................... 38

4.3.4 Remote units, units GBF20GN2/1, GBF40GN2/1,GBF20GN1/1 .............................................. 39

4.4. HOW TO ACCESS EVAPORATOR ASSEMBLY ................................................ 39

4.4.1 Evaporator Assembly Description .............................................................................................. 39

4.4.2 Accessing the Evaporator .......................................................................................................... 41

4.4.3 Replacing the Temperature Sensing Probes ............................................................................. 41

4.5. REPLACING THE EVAPORATOR FAN .............................................................. 44

4.6. REPLACING THE DOOR SWITCH ..................................................................... 44

4.6.1 GBF-3GN2/3 (smallest self-contained unit) ............................................................................... 44

4.6.2 Units from 5 up to 18 shelves ................................................................................................... 44

4.7 REPLACING THE PRESSURE SWITCH ............................................................ 45

4.8 REPLACING THE DOOR FRAME HEATER ....................................................... 46

4.9 REPLACING THE RELAY BOARD ..................................................................... 47

4.10 REPLACING THE KEYPAD ................................................................................ 48

5 VACUUM AND CHARGE PROCEDURE ............................................................................................... 49

5.1 VACUUM AND CHARGING INSTRUCTION ....................................................... 49

5.1.1 Self Contained Models ............................................................................................................... 49

5.1.2 Remote Models .......................................................................................................................... 50

5.1.3 Vacuum and Charging Recommendations ................................................................................ 50

6 SCHEMATICS ........................................................................................................................................ 51

6.1 SCHEME OF COMPONENTS ............................................................................. 51

6.2 AIRFLOW REQUIREMENTS .............................................................................. 52

6.2.1 Self Contained - Airflow Requirements ................................................................ 52

6.2.2 Remote - Airflow Requirements ........................................................................... 53

6.3 CONNECTION OF REMOTE CABINET TO “NON-DESMON” CONDENSING

UNIT 55

6.3.1 Connection with existing refrigerant lines ............................................................ 55

6.3.2 Hook the electrical power to the unit .................................................................... 56

I. HOW TO READ THE MODEL NUMBER ............................................................................................... 58

II. DATA CHART TABLE ........................................................................................................................... 59

Rev 07/04/2015

8

Blast chiller Service Manual

1. Basic Service Diagnostic (Standard Controller)

The Controller will display alarms and failure codes that will assist in identifying

the cause of a problem and direct attention to the components and circuits

involved. In addition, a diagnostic service menu allows technicians to quickly

check the temperature sensors, such as the needle probe, the chamber probe or

the evaporator probe.

9

Rev 07/04/2015

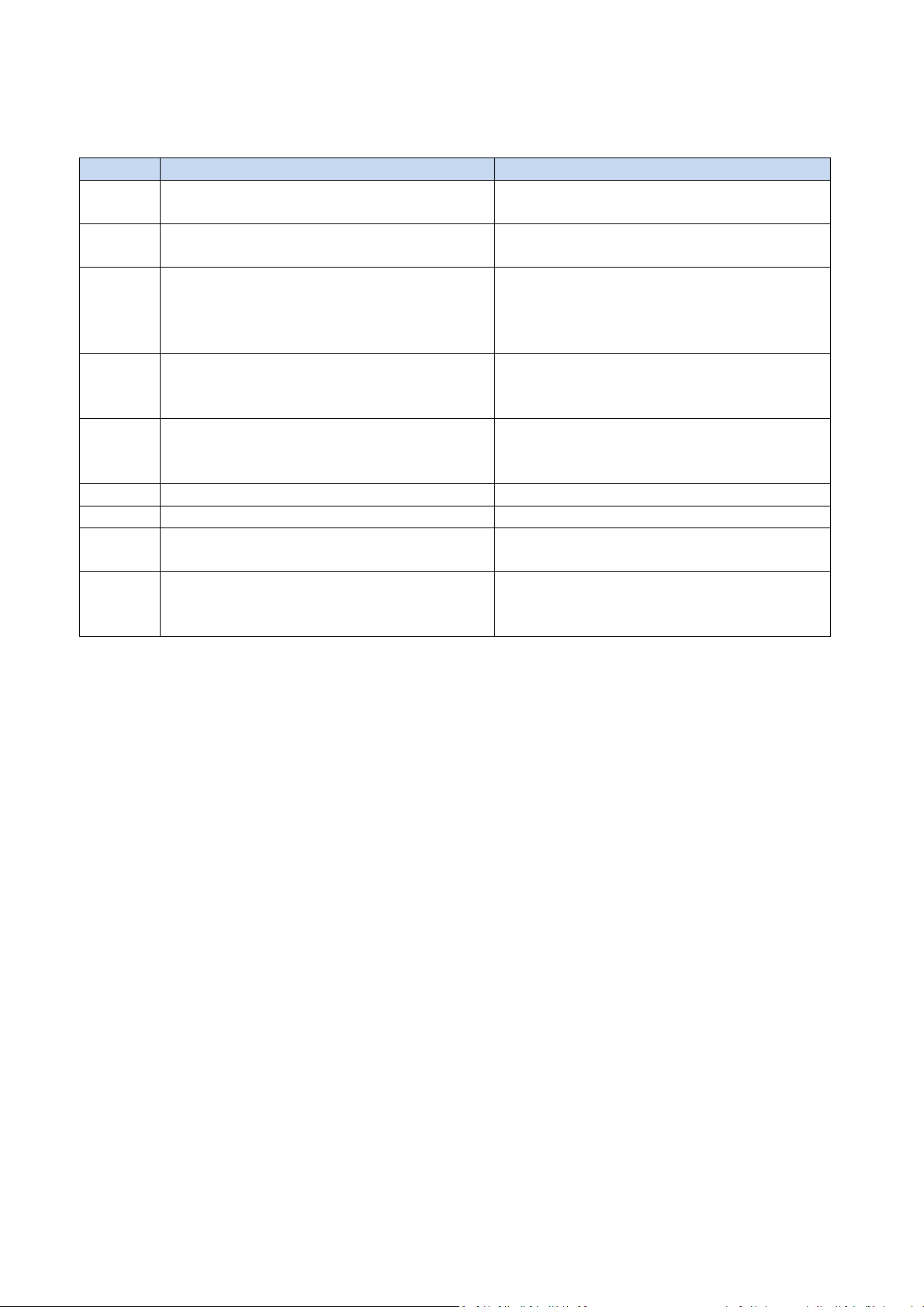

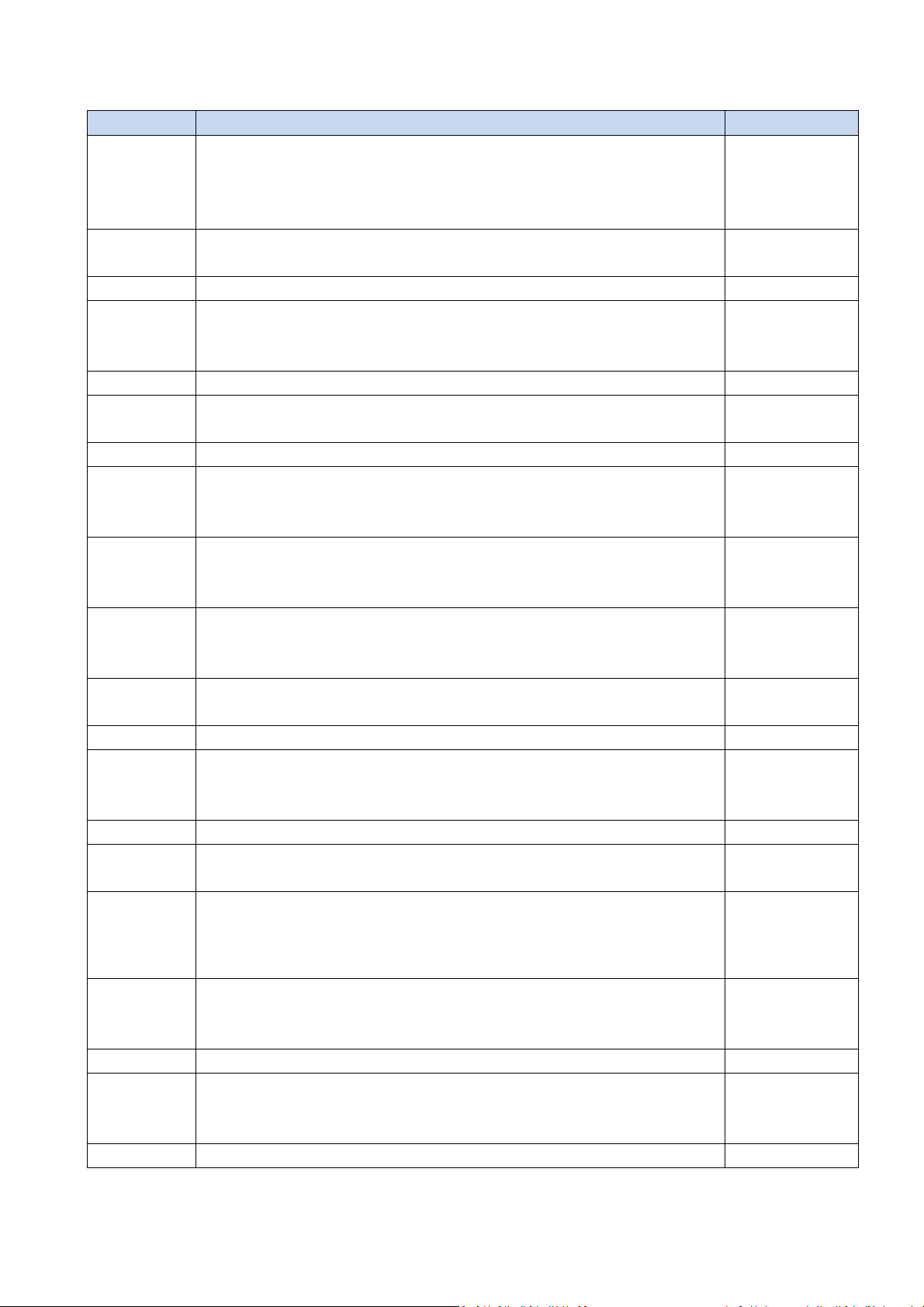

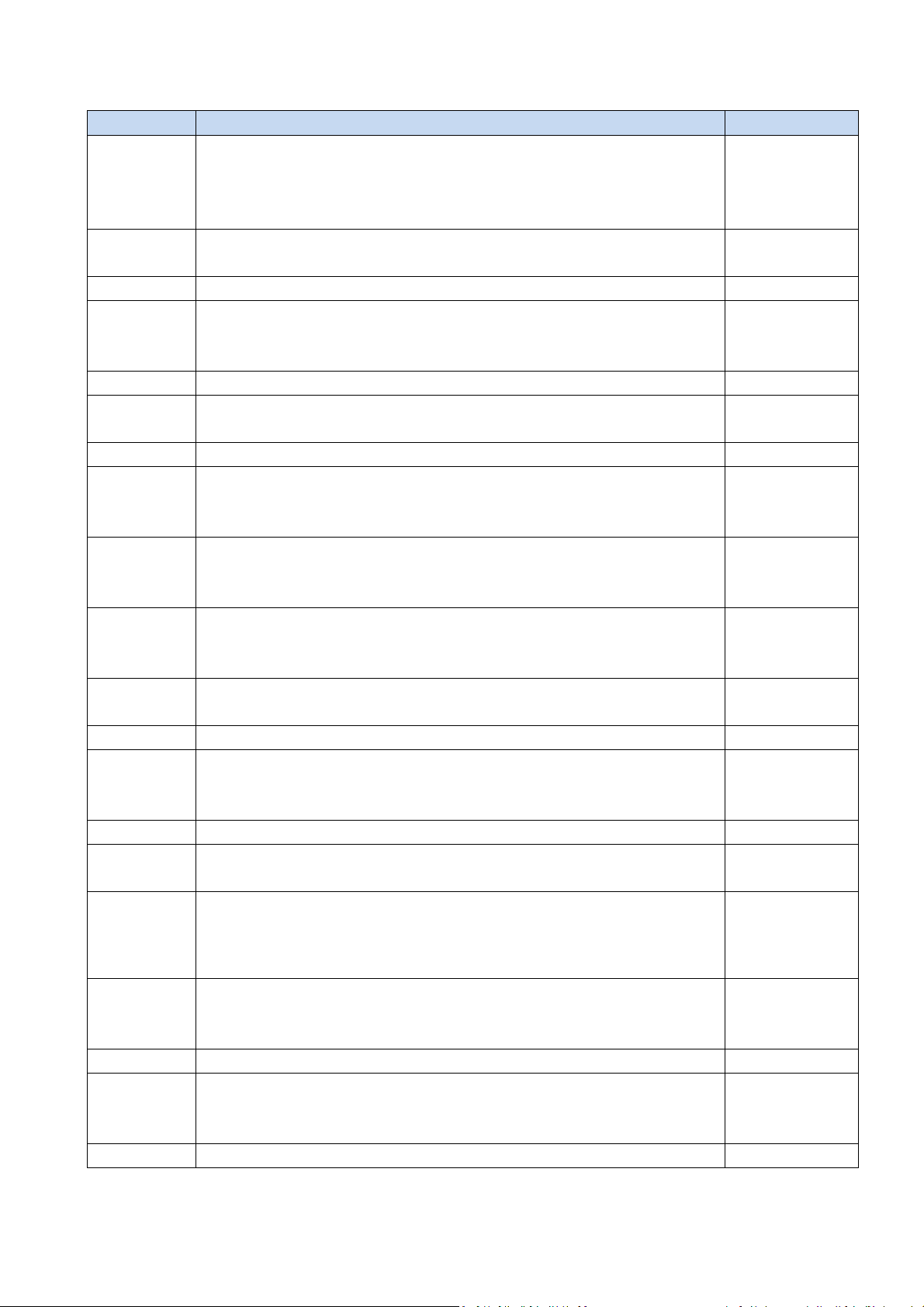

1.1. ALARM/FAILURE LIST

CODE

CAUSE

CONSEQUENCE

Tab 1

Er0 ROOM PROBE FAILURE Does not allow unit to cycle. If running,

cycle will stop.

Er1 EVAPORATOR PROBE FAILURE During storage cycle, evaporator fans

do not run.

Er3 NEEDLE PROBE FAILURE Does not allow a needle probe set

temperature cycle to run. Unit will stop

if running on needle probe set

temperature cycle.

HP HIGH DISCHARGE PRESSURE (OR

LOW SUCTION PRESSURE)1

d-r DOOR IS OPEN FOR MORE THAN

P39

AH HIGHT ROOM TEMPERATURE None

AL LOW ROOM TEMPERATURE None

Err MOTHER BOARD-KEYBOARD

CONNECTION FAILURE 2

Res POWER FAILURE DURING

RUNNING OF CYCLE

1

The pressure switch in this model series provides a single output, open or closed. The

circuit is normally open and will close when either the High or Low Pressure limits are

reached. In effect, the failure code, HP, could mean either high discharge pressure as well

as low suction pressure.

2

Additional troubleshooting at the Key Pad – Control Module connections:

No Ground connection – Display flashes and/or dims

No Negative (-) connection – Display may work normally without failure code

No Positive (+) connection – Failure Code Error is displayed

No 12V connection – Display will not light up.

Unit will not operate in any cycle. If

running, compressor, evaporator and

condenser fans will stop.

Compressor and condenser fan will

stop. Evaporator fan will cycle

according to P37

None

Cycle will restart when power is

restored. Message will flash to

indicate cycle has restarted.

Rev 07/04/2015

10

FAILURE CODE DETAILS

The HACCP feature provides the ability to get additional information such as

failure code, date of occurrence, min/max temperature (if applicable), and

To access previous failure codes, press and hold

the PROGRAM key for 5 seconds.

Use the UP and DOWN arrow keys to scroll

SERVICE MENU

configurat

The service menu can be accessed only during OFF mode.

for 5 seconds to enter the menu.

controller doesn’t need actually any password to

the up arrow key the parameter list can be accessed directly

the parameter by pressing Up/do

Change the value by up/down keys. Pr

ist

The following table shows parameter factory settings for both Blast

Selecting a freezing cycle on a GBC unit

(Cabinet at 0°C, needle probe end cycle temperature at 3°C)

Blast ch

through the previous failure codes. Press the

PARAMETER

will be shown as first

configure the parameters. By pressing

(first parameter is P0).

parameter by pressing

to save and go back to the list.

will run a normal chilling cycle

iller Service Manual

1.2.

duration of alarm condition.

PROGRAM key to exit.

1.3.

1.3.1 Entering the

Press the up/down keys

together

– CONFIGURATION

ion parameter

Label PA (password)

. The

1.3.2 Parameter l

and Shock Freezers (GBF).

NOTE:

wn keys. Select a

ess again time key

(factory setting)

the time key

chillers units (GBC)

Scroll

11

Rev 07/04/2015

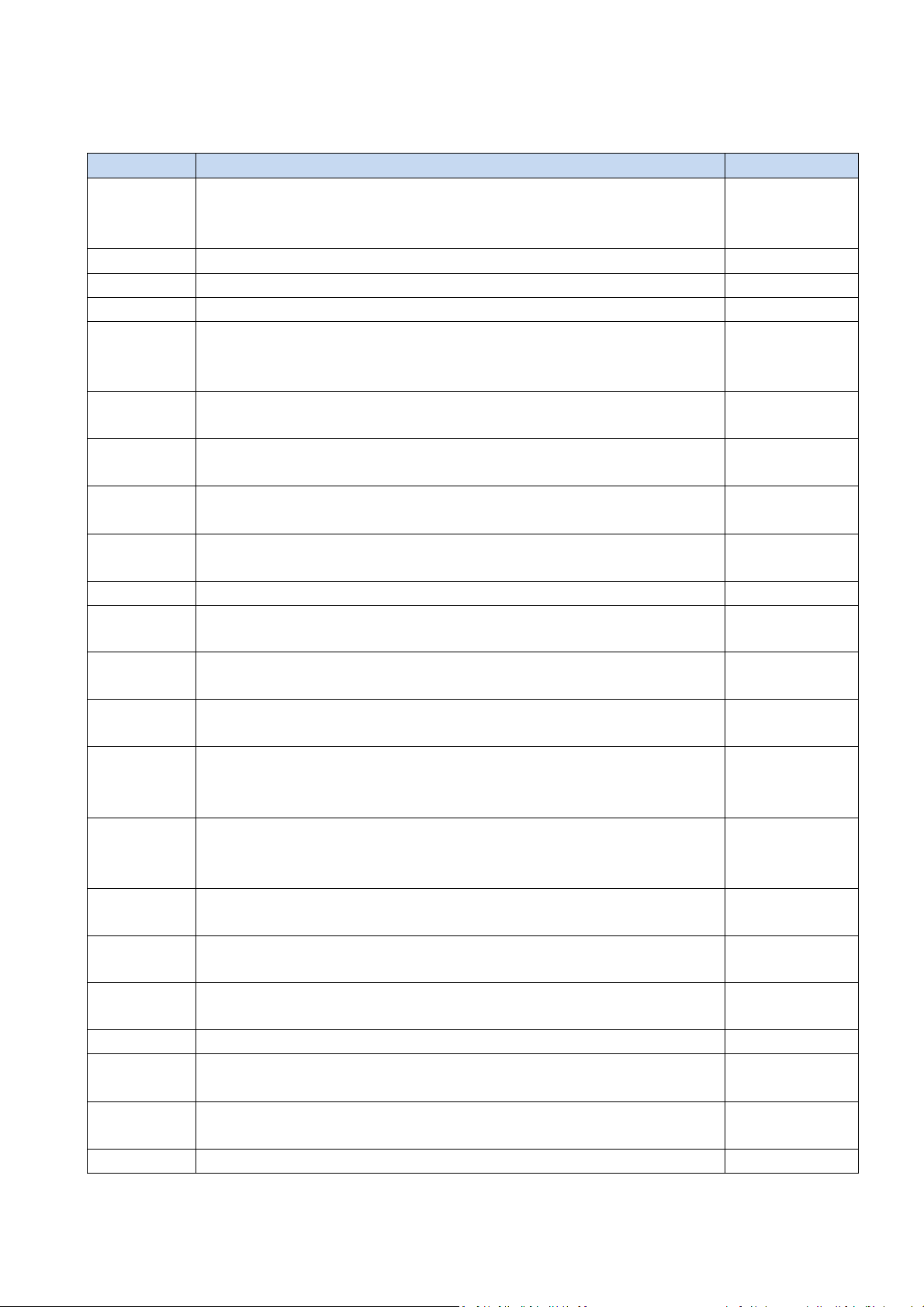

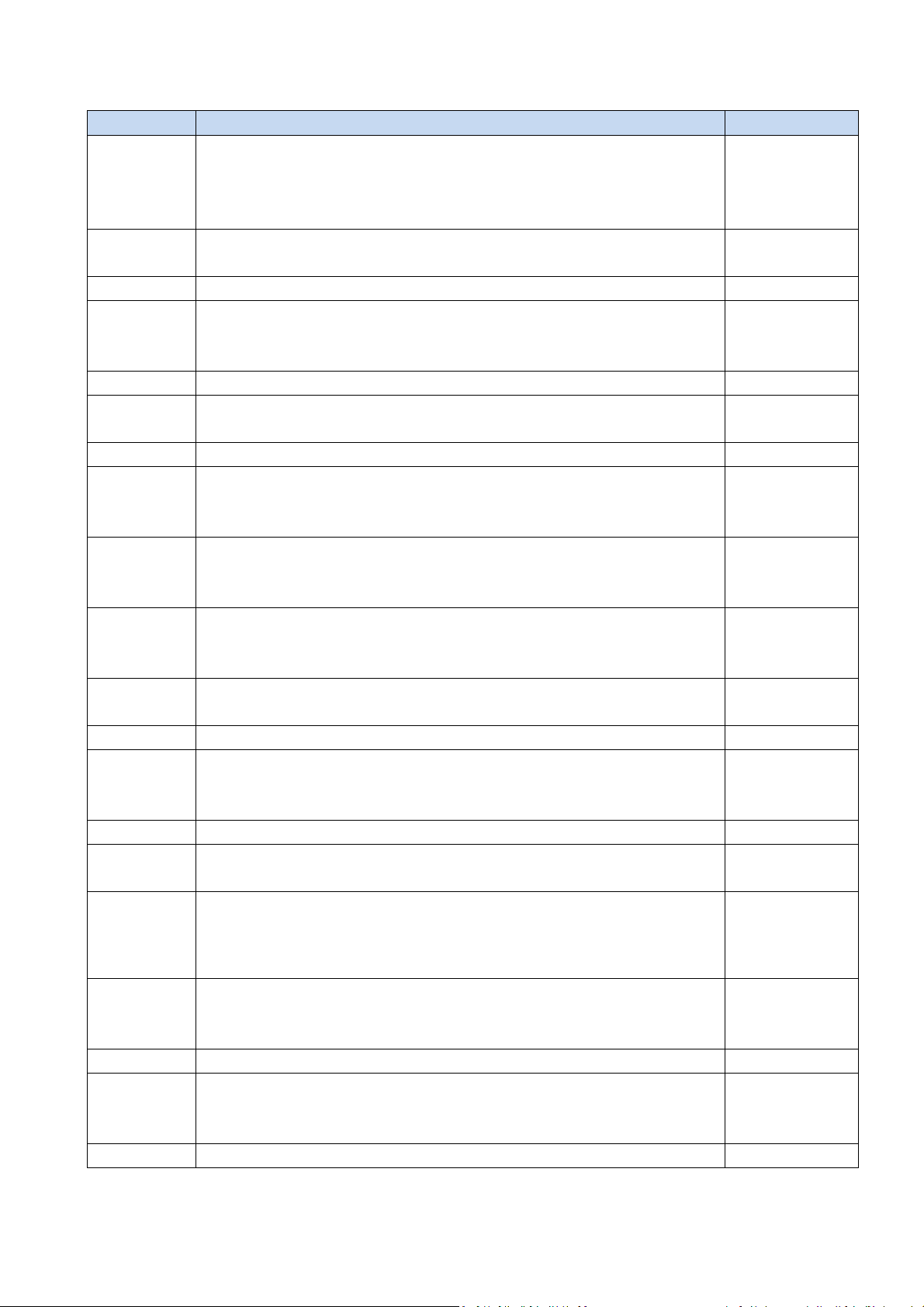

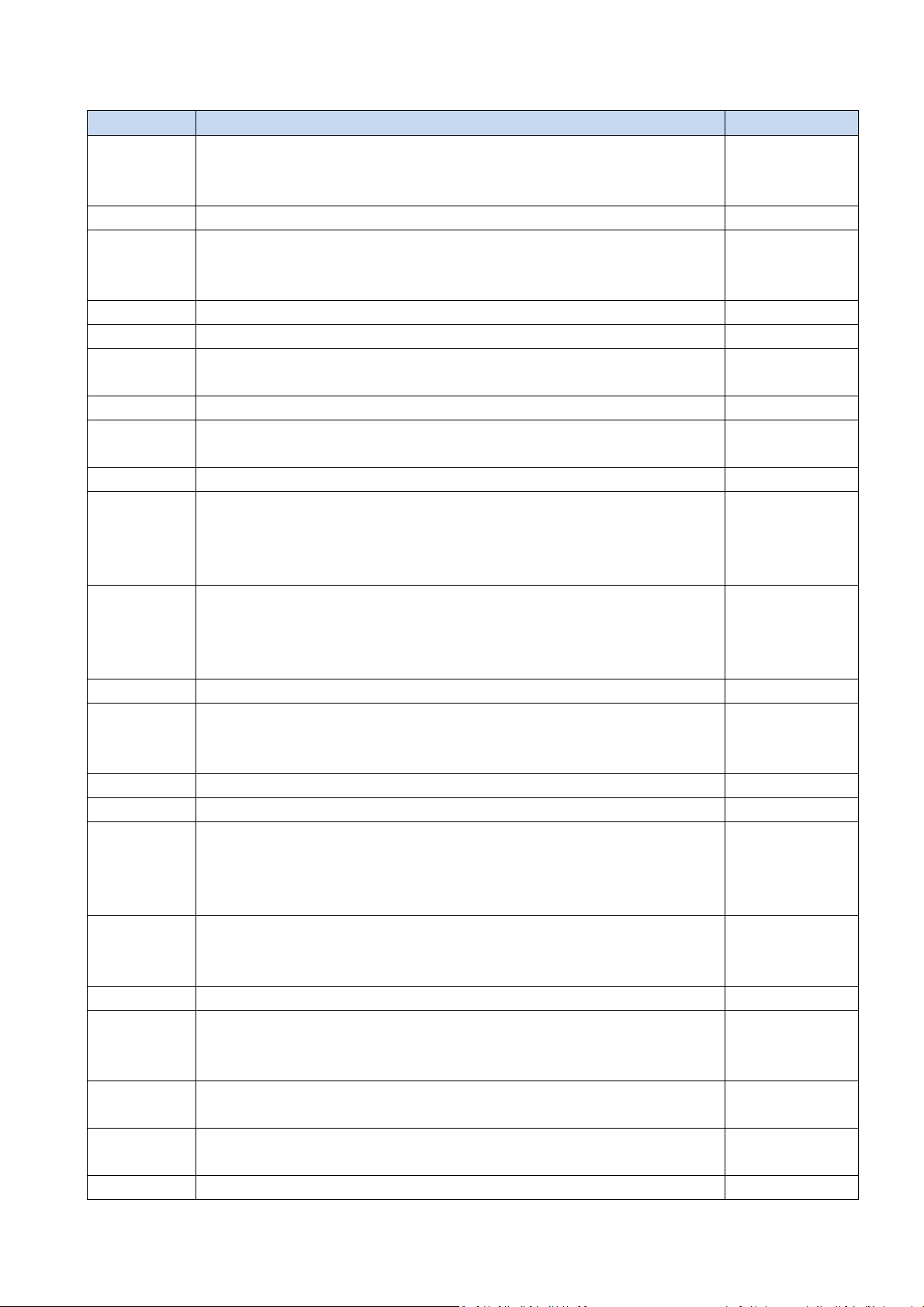

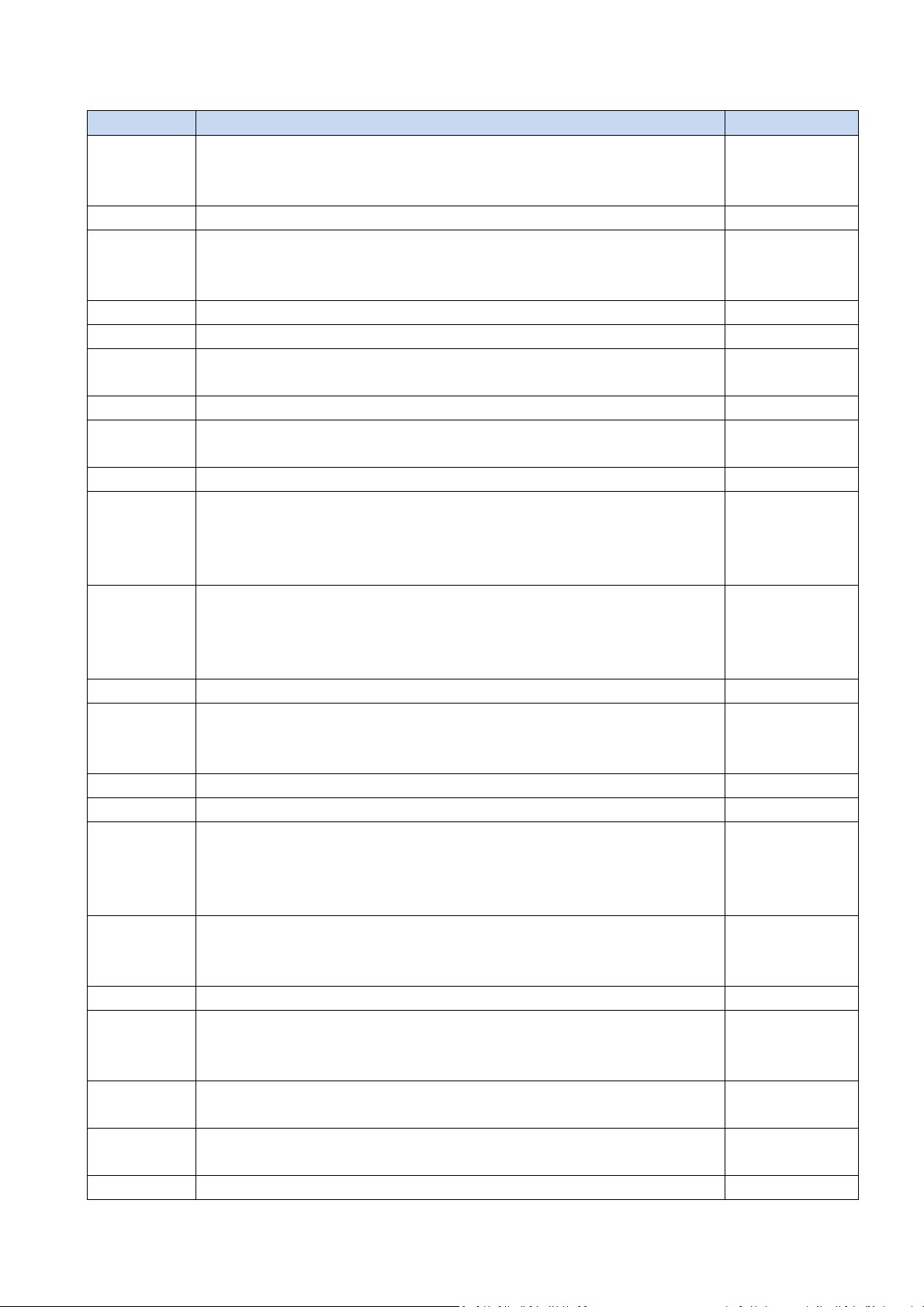

GBF-3GN2/3 and all GBF Trolley Units (Cycle Off Defrost)

Parameter

Description

Factory Value

P0 unit of temperature measurement

1

0 = °F

1 = °C

P1 cabinet probe offset 0

P2 evaporator probe offset 0

P3 needle probe offset 0

P4 operational setpoint during the second hard chill step; also,

0

operational setpoint during normal chilling (with reference to

the cabinet probe)

P5 operational setpoint during freezing (with reference to the

-40

cabinet probe)

P6 operational setpoint during the first hard chill step (with

-20

reference to the cabinet probe)

P7 operational setpoint during post-chill storage (with reference to

3

the cabinet probe)

P8 operational setpoint during post-freeze storage (with reference

-20

to the cabinet probe)

P9 P4, P5, P6, P7 and P8 differential 1

P10 set temperature chill end temperature (with reference to the

3

needle probe)

P11 set temperature freeze end temperature (with reference to the

-18

needle probe)

P12 temperature at which the hard chill switches from the first step

20

to the second (with reference to the needle probe)

P13 temperature above which it is not possible to start a set-

99

temperature operational cycle (with reference to the needle

probe)

P14 needle probe and the cabinet temperature for verification of

P15 duration of the second test to check correct needle probe

P16 maximum set temperature chill duration; also timed chill

P17 maximum set temperature freeze duration; also timed freeze

P18 first hard timed chill step duration 45

P19 compressor delay from device power on (from restoration of

P20 minimum elapsed time period between two consecutive

P21 minimum compressor shut-down time 0

correct needle probe insertion

0 = the test will not be performed

insertion; see also P14

duration

duration

power)

compressor start-up operations

0

60

90

240

0

0

Rev 07/04/2015

12

Blast chiller Service Manual

Parameter

Description

Factory Value

P22 defrost type

0 = electric (defrost on relay)

1 = hot gas (defrost compressor and relay on)

2 = air (evaporator fan on)

P23 defrost end temperature (with reference to the evaporator

probe)

P24 maximum defrost duration 10

P25 defrost interval during storage; see also P26

0 = intermittent defrosting will never be activated (only the first

will be activated)

P26 first defrost delay from start of storage; see also P25 1

P27 defrosting at start of chilling and freezing

1 = YES

P28 drip-drain duration 2

P29 resetting of compressor protections at start of defrosting (only

if P22 = 1)

1 = YES

P30 elapsed time between the defrost request and switching on the

compressor (only if P22 = 1 and providing that the compressor

is off when the defrost is requested); see P31 (7) (8)also

2

8

6

0

0

30

P31 elapsed time between the defrost request and activation of the

solenoid valve (only if P22 = 1 and on condition that the

compressor is off when defrosting is requested); see also P30

P32 temperature above which the evaporator fan is switched off

during storage (with reference to the evaporator probe)

P33 P32 differential 1

P34 evaporator fan activity during defrosting (only if P22 = 0 or 1)

0 = on

1 = off

P35 evaporator stop time after dripping 3

P36 temperature above which the evaporator fan is switched off

(with reference to the cabinet probe)

P37 effect caused by activation of microport input on evaporator

fan

0 = no effect

1 = the evaporator fan will be switched off

P38 microport input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P39 micro port input alarm delay 0

P40 high pressure input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

0

3

0

90

1

1

0

P41 high pressure input alarm delay 120

13

Rev 07/04/2015

Parameter

Description

Factory Value

P42 low pressure input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P43 low pressure input alarm delay 0

P44 compressor thermal protection input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P45 compressor thermal protection input alarm delay 0

P46 UV light on duration (duration of cabinet sterilisation) 5

P47 needle probe heating end temperature (with reference to the

45

needle probe)

P48 maximum duration of needle probe heating 15

P49 the temperature, below which the door elements are switched

5

on (with reference to the cabinet probe)

P50 P49 differential 2

P51 condenser fan activity in the absence of the condenser probe

1

(P61 = 0)

0 = in parallel with compressor

1 = on

P52 the temperature below which the condenser fan is switched off

20

in the presence of the condenser probe (P61 = 1) and on

condition that the compressor is on (with reference to the

condenser probe); see also P54

P53 P52 differential 5

P54 condenser fan switch off delay on switching off the compressor

30

in the presence of the condenser probe (P61 = 1); see also

P52

P55 chill and freeze cycle completion buzzer duration 3

P56 maximum buzzer duration during an alarm state 15

P57 elapsed time between switching on the compressor and pump

10

down valve activation (pump down in power up); also elapsed

time between deactivation of the pump down valve and

switching off the compressor (pump down in power down)

P58 defrost parameter units of measurement

0

0 = P25 h, P24, P26, P28 and P35 min

1 = P25 min, P24, P26, P28 and P35 s

P59 reserved 0

P60 probe type

0

0 = NTC

1 = PTC

P61 condenser probe enabling

P62 the temperature above which the condenser temperature

P63 P62 differential 10

1 = YES

alarm is activated (with reference to the condenser probe)

Rev 07/04/2015

0

70

14

Blast chiller Service Manual

Parameter

Description

Factory Value

P64 temperature below which the minimum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P64" (with reference to the cabinet probe)

0 = no alarm

P65 temperature above which the maximum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P65" (with reference to the cabinet probe)

0 = no alarm

P66 temperature below which the minimum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P66" (with reference to the cabinet probe)0 = no alarm

P67 temperature above which the maximum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P67" (with reference to the cabinet probe)

0 = no alarm

P68 P64, P65, P66 and P67 differential 2

P69 storage operation start-up temperature alarm delay 0

P70 temperature alarm delay 0

P71 enable printing

1 = YES

P72 print interval 5

P73 HACCP alarm list deletion

1 = YES

P74 Baudrate

0=2400

1=4800

2=9600

3=19200

0

0

0

0

0

0

2

P75 Bit polarity

P76 Board address 1

15

0=no polarity

1=even

2=odd

Rev 07/04/2015

2

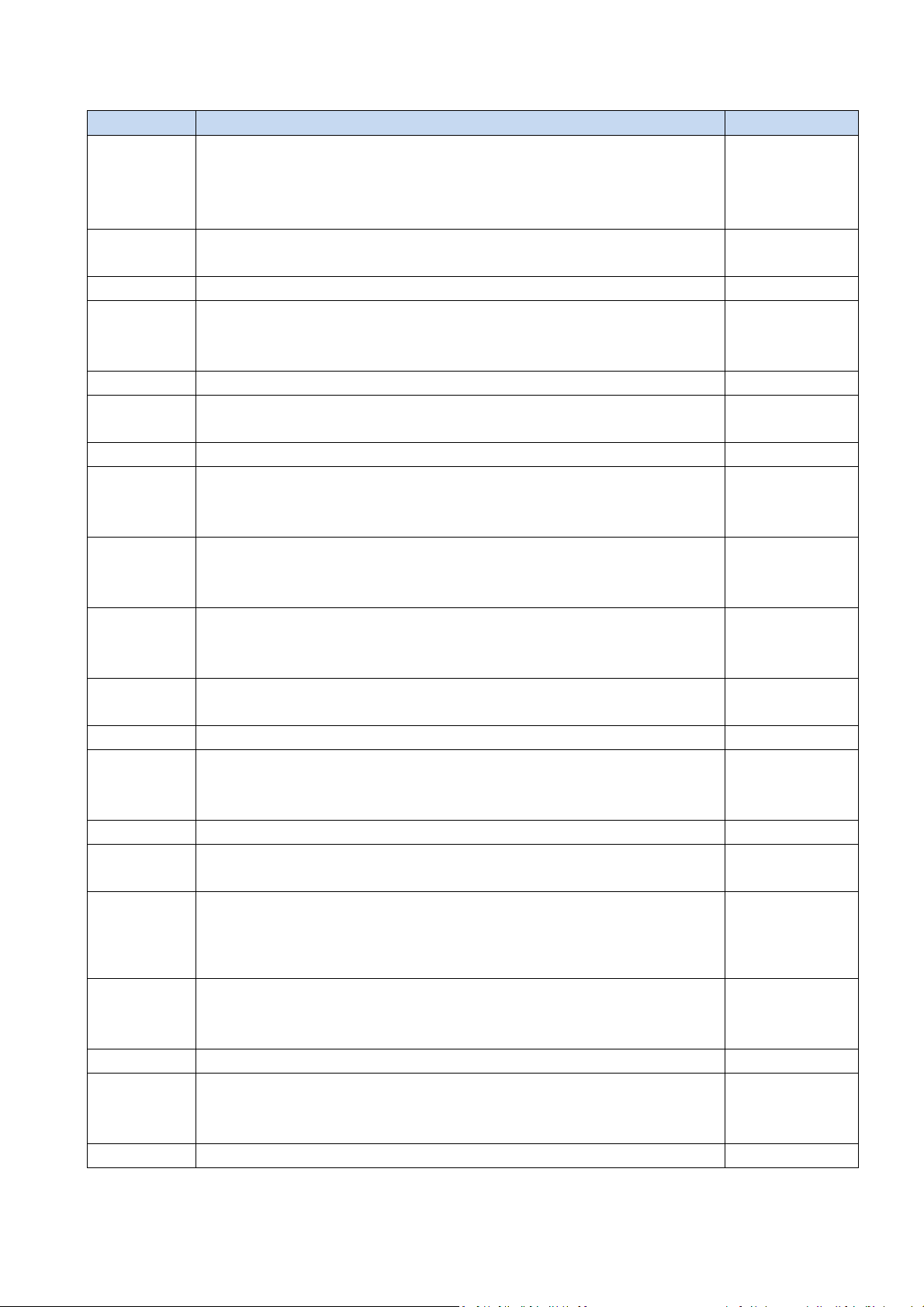

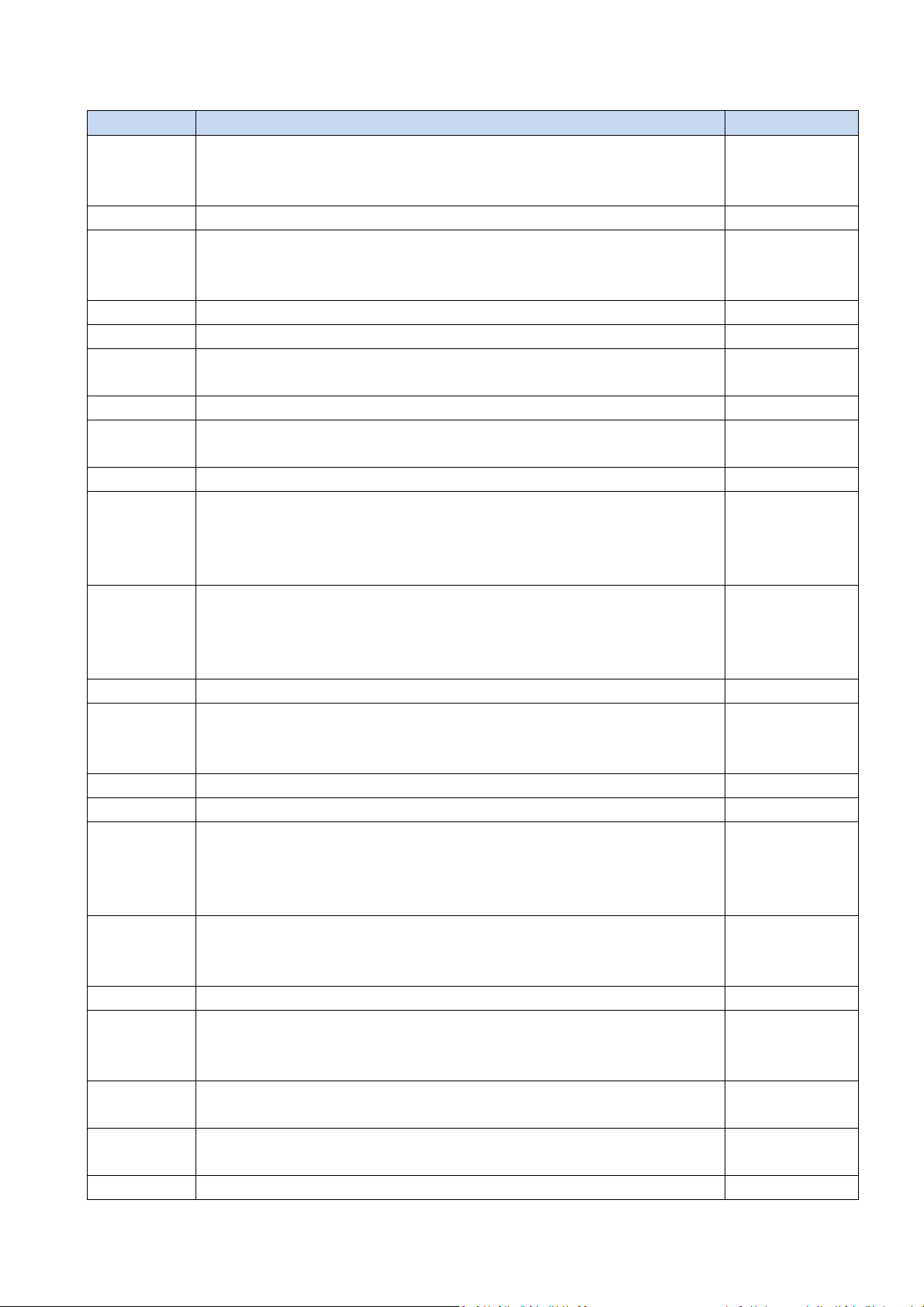

All GBF units from 5 to 18 Shelves (Hot gas Defrost)

Parameter

Description

Factory Value

P0 unit of temperature measurement

1

0 = °F

1 = °C

P1 cabinet probe offset 2

P2 evaporator probe offset 0

P3 needle probe offset 0

P4 operational setpoint during the second hard chill step; also,

0

operational setpoint during normal chilling (with reference to

the cabinet probe)

P5 operational setpoint during freezing (with reference to the

-40

cabinet probe)

P6 operational setpoint during the first hard chill step (with

-20

reference to the cabinet probe)

P7 operational setpoint during post-chill storage (with reference to

3

the cabinet probe)

P8 operational setpoint during post-freeze storage (with reference

-20

to the cabinet probe)

P9 P4, P5, P6, P7 and P8 differential 1

P10 set temperature chill end temperature (with reference to the

3

needle probe)

P11 set temperature freeze end temperature (with reference to the

-18

needle probe)

P12 temperature at which the hard chill switches from the first step

20

to the second (with reference to the needle probe)

P13 temperature above which it is not possible to start a set-

99

temperature operational cycle (with reference to the needle

probe)

P14 needle probe and the cabinet temperature for verification of

P15 duration of the second test to check correct needle probe

P16 maximum set temperature chill duration; also timed chill

P17 maximum set temperature freeze duration; also timed freeze

P18 first hard timed chill step duration 45

P19 compressor delay from device power on (from restoration of

P20 minimum elapsed time period between two consecutive

P21 minimum compressor shut-down time 0

correct needle probe insertion

0 = the test will not be performed

insertion; see also P14

duration

duration

power)

compressor start-up operations

0

60

90

240

0

0

Rev 07/04/2015

16

Blast chiller Service Manual

Parameter

Description

Factory Value

P22 defrost type

0 = electric (defrost on relay)

1 = hot gas (defrost compressor and relay on)

2 = air (evaporator fan on)

P23 defrost end temperature (with reference to the evaporator

probe)

P24 maximum defrost duration 10

P25 defrost interval during storage; see also P26

0 = intermittent defrosting will never be activated (only the first

will be activated)

P26 first defrost delay from start of storage; see also P25 1

P27 defrosting at start of chilling and freezing

1 = YES

P28 drip-drain duration 2

P29 resetting of compressor protections at start of defrosting (only

if P22 = 1)

1 = YES

P30 elapsed time between the defrost request and switching on the

compressor (only if P22 = 1 and providing that the compressor

is off when the defrost is requested); see P31 (7) (8)also

1

8

6

0

0

30

P31 elapsed time between the defrost request and activation of the

solenoid valve (only if P22 = 1 and on condition that the

compressor is off when defrosting is requested); see also P30

P32 temperature above which the evaporator fan is switched off

during storage (with reference to the evaporator probe)

P33 P32 differential 1

P34 evaporator fan activity during defrosting (only if P22 = 0 or 1)

0 = on

1 = off

P35 evaporator stop time after dripping 3

P36 temperature above which the evaporator fan is switched off

(with reference to the cabinet probe)

P37 effect caused by activation of microport input on evaporator

fan

0 = no effect

1 = the evaporator fan will be switched off

P38 microport input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P39 micro port input alarm delay 0

P40 high pressure input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

0

3

0

90

1

1

1

P41 high pressure input alarm delay 120

17

Rev 07/04/2015

Parameter

Description

Factory Value

P42 low pressure input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P43 low pressure input alarm delay 0

P44 compressor thermal protection input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P45 compressor thermal protection input alarm delay 0

P46 UV light on duration (duration of cabinet sterilisation) 5

P47 needle probe heating end temperature (with reference to the

45

needle probe)

P48 maximum duration of needle probe heating 15

P49 the temperature, below which the door elements are switched

5

on (with reference to the cabinet probe)

P50 P49 differential 2

P51 condenser fan activity in the absence of the condenser probe

1

(P61 = 0)

0 = in parallel with compressor

1 = on

P52 the temperature below which the condenser fan is switched off

20

in the presence of the condenser probe (P61 = 1) and on

condition that the compressor is on (with reference to the

condenser probe); see also P54

P53 P52 differential 5

P54 condenser fan switch off delay on switching off the compressor

30

in the presence of the condenser probe (P61 = 1); see also

P52

P55 chill and freeze cycle completion buzzer duration 3

P56 maximum buzzer duration during an alarm state 15

P57 elapsed time between switching on the compressor and pump

10

down valve activation (pump down in power up); also elapsed

time between deactivation of the pump down valve and

switching off the compressor (pump down in power down)

P58 defrost parameter units of measurement

0

0 = P25 h, P24, P26, P28 and P35 min

1 = P25 min, P24, P26, P28 and P35 s

P59 reserved 0

P60 probe type

0

0 = NTC

1 = PTC

P61 condenser probe enabling

P62 the temperature above which the condenser temperature

P63 P62 differential 10

1 = YES

alarm is activated (with reference to the condenser probe)

Rev 07/04/2015

0

70

18

Blast chiller Service Manual

Parameter

Description

Factory Value

P64 temperature below which the minimum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P64" (with reference to the cabinet probe)

0 = no alarm

P65 temperature above which the maximum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P65" (with reference to the cabinet probe)

0 = no alarm

P66 temperature below which the minimum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P66" (with reference to the cabinet probe)

0 = no alarm

P67 temperature above which the maximum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P67" (with reference to the cabinet probe)

0 = no alarm

P68 P64, P65, P66 and P67 differential 2

P69 storage operation start-up temperature alarm delay 0

P70 temperature alarm delay 0

P71 enable printing

1 = YES

P72 print interval 5

P73 HACCP alarm list deletion

1 = YES

P74 Baudrate

0=2400

1=4800

2=9600

3=19200

0

0

0

0

0

0

2

P75 Bit polarity

P76 Board address 1

19

0=no polarity

1=even

2=odd

Rev 07/04/2015

2

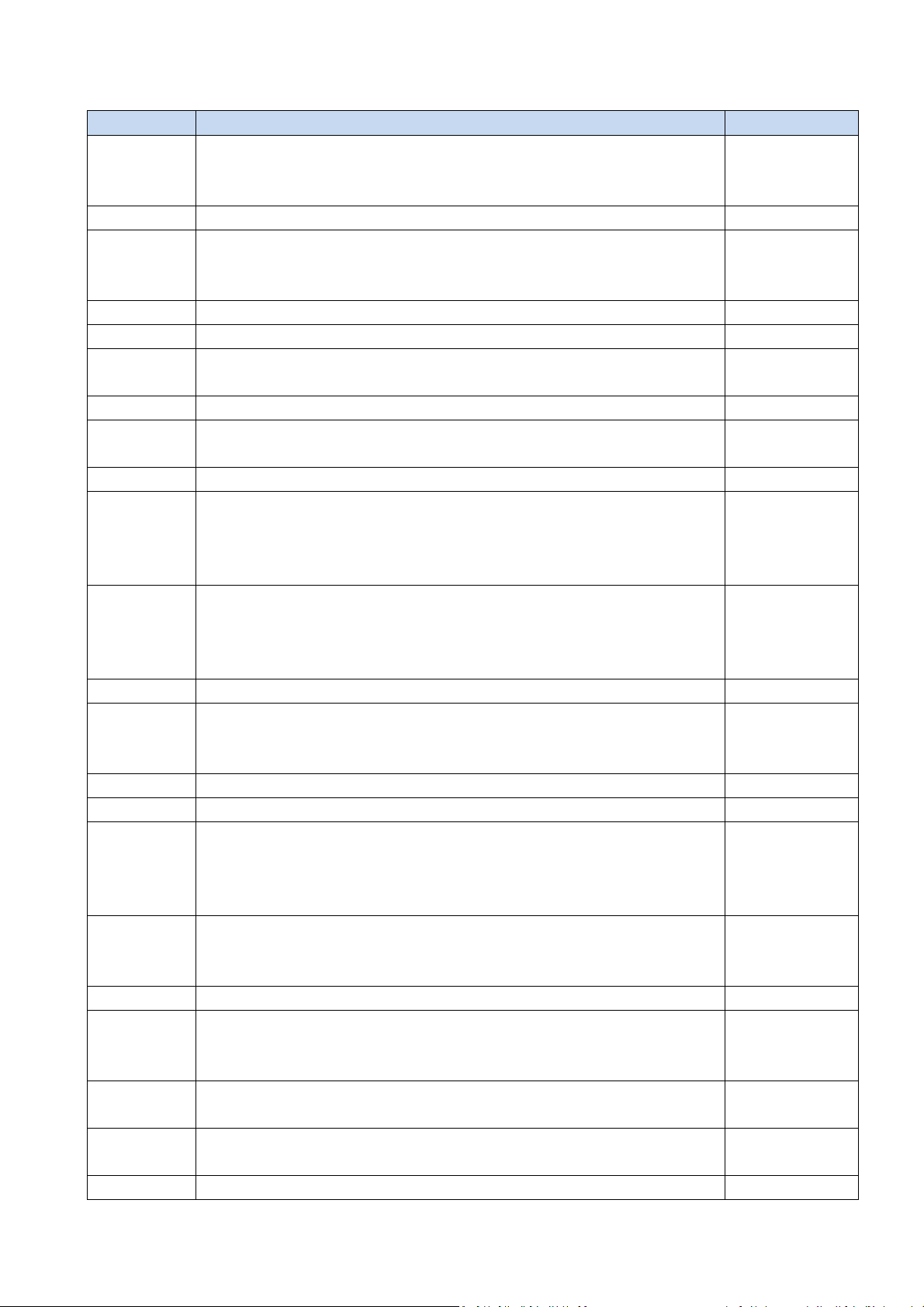

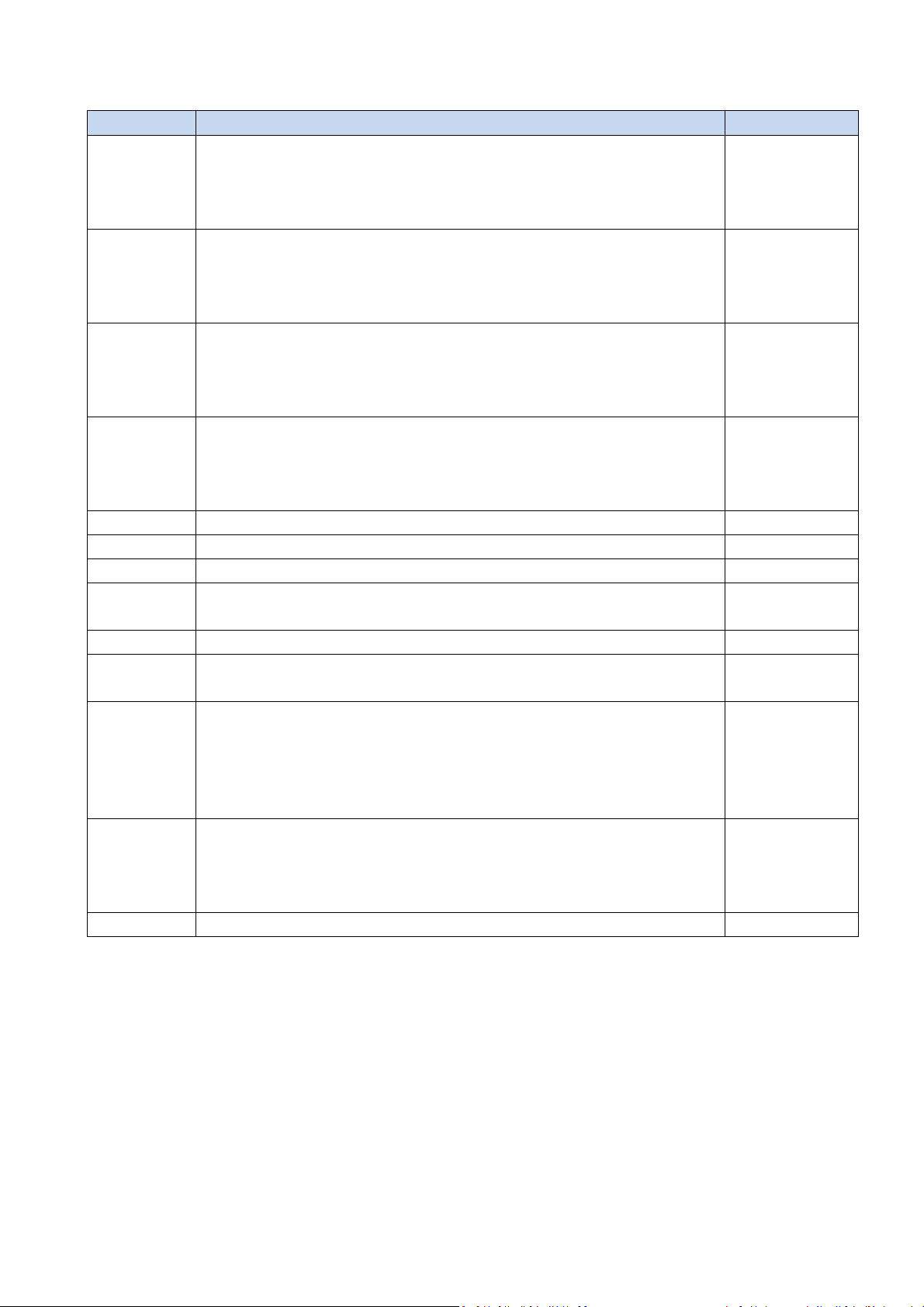

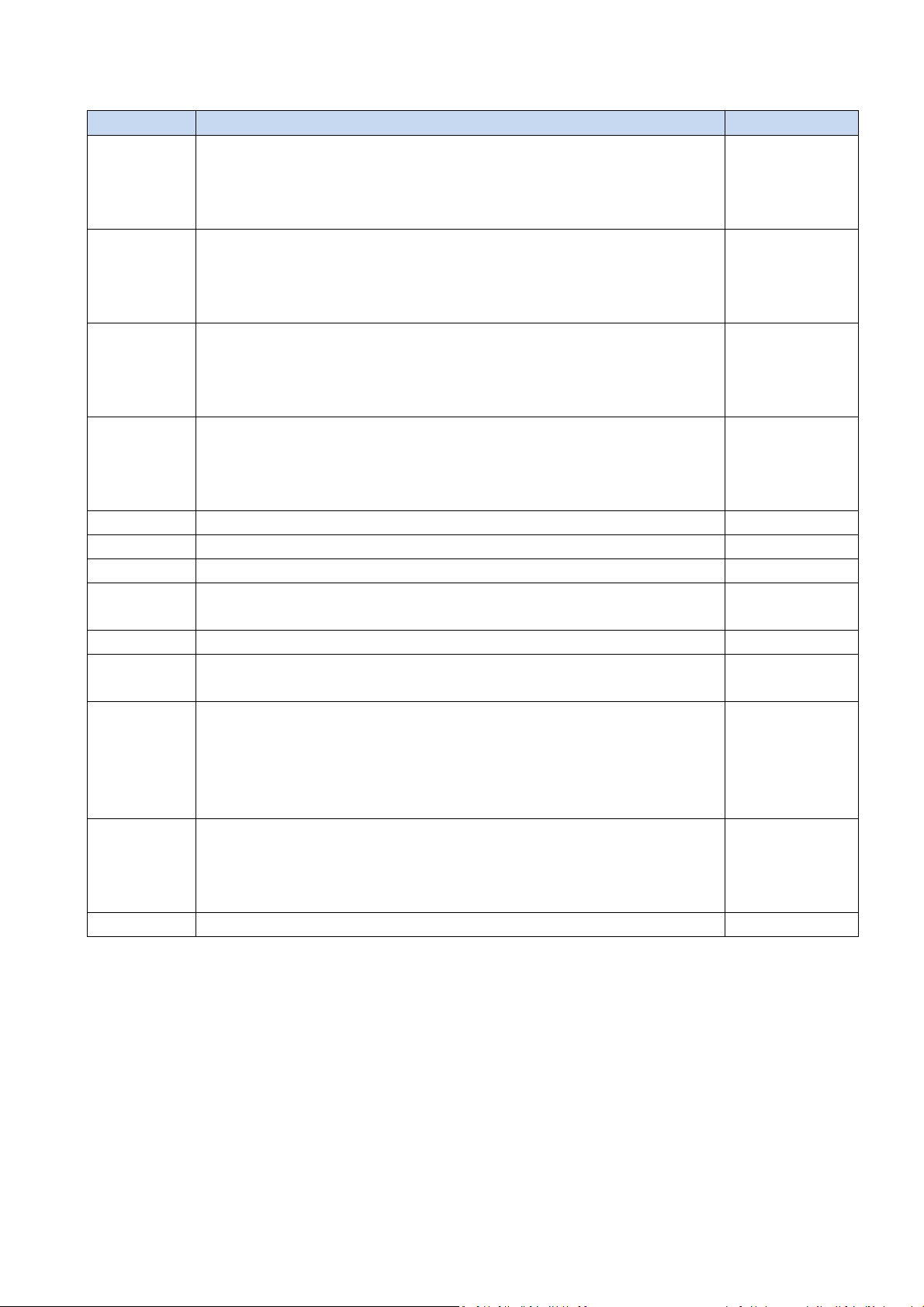

All GBC units from 5 to 18 Shelves (Hot gas Defrost)

Parameter

Description

Factory Value

P0 unit of temperature measurement

1

0 = °F

1 = °C

P1 cabinet probe offset 2

P2 evaporator probe offset 0

P3 needle probe offset 0

P4 operational setpoint during the second hard chill step; also,

0

operational setpoint during normal chilling (with reference to

the cabinet probe)

P5 operational setpoint during freezing (with reference to the

0

cabinet probe)

P6 operational setpoint during the first hard chill step (with

-20

reference to the cabinet probe)

P7 operational setpoint during post-chill storage (with reference to

3

the cabinet probe)

P8 operational setpoint during post-freeze storage (with reference

3

to the cabinet probe)

P9 P4, P5, P6, P7 and P8 differential 1

P10 set temperature chill end temperature (with reference to the

3

needle probe)

P11 set temperature freeze end temperature (with reference to the

3

needle probe)

P12 temperature at which the hard chill switches from the first step

20

to the second (with reference to the needle probe)

P13 temperature above which it is not possible to start a set-

99

temperature operational cycle (with reference to the needle

probe)

P14 needle probe and the cabinet temperature for verification of

P15 duration of the second test to check correct needle probe

P16 maximum set temperature chill duration; also timed chill

P17 maximum set temperature freeze duration; also timed freeze

P18 first hard timed chill step duration 45

P19 compressor delay from device power on (from restoration of

P20 minimum elapsed time period between two consecutive

P21 minimum compressor shut-down time 0

correct needle probe insertion

0 = the test will not be performed

insertion; see also P14

duration

duration

power)

compressor start-up operations

0

60

90

90

0

0

Rev 07/04/2015

20

Blast chiller Service Manual

Parameter

Description

Factory Value

P22 defrost type

0 = electric (defrost on relay)

1 = hot gas (defrost compressor and relay on)

2 = air (evaporator fan on)

P23 defrost end temperature (with reference to the evaporator

probe)

P24 maximum defrost duration 10

P25 defrost interval during storage; see also P26

0 = intermittent defrosting will never be activated (only the first

will be activated)

P26 first defrost delay from start of storage; see also P25 1

P27 defrosting at start of chilling and freezing

1 = YES

P28 drip-drain duration 2

P29 resetting of compressor protections at start of defrosting (only

if P22 = 1)

1 = YES

P30 elapsed time between the defrost request and switching on the

compressor (only if P22 = 1 and providing that the compressor

is off when the defrost is requested); see P31 (7) (8)also

1

8

6

0

0

30

P31 elapsed time between the defrost request and activation of the

solenoid valve (only if P22 = 1 and on condition that the

compressor is off when defrosting is requested); see also P30

P32 temperature above which the evaporator fan is switched off

during storage (with reference to the evaporator probe)

P33 P32 differential 1

P34 evaporator fan activity during defrosting (only if P22 = 0 or 1)

0 = on

1 = off

P35 evaporator stop time after dripping 3

P36 temperature above which the evaporator fan is switched off

(with reference to the cabinet probe)

P37 effect caused by activation of microport input on evaporator

fan

0 = no effect

1 = the evaporator fan will be switched off

P38 microport input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P39 micro port input alarm delay 0

P40 high pressure input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

0

3

0

90

1

1

1

P41 high pressure input alarm delay 120

21

Rev 07/04/2015

Parameter

Description

Factory Value

P42 low pressure input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P43 low pressure input alarm delay 0

P44 compressor thermal protection input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P45 compressor thermal protection input alarm delay 0

P46 UV light on duration (duration of cabinet sterilisation) 5

P47 needle probe heating end temperature (with reference to the

45

needle probe)

P48 maximum duration of needle probe heating 15

P49 the temperature, below which the door elements are switched

5

on (with reference to the cabinet probe)

P50 P49 differential 2

P51 condenser fan activity in the absence of the condenser probe

1

(P61 = 0)

0 = in parallel with compressor

1 = on

P52 the temperature below which the condenser fan is switched off

20

in the presence of the condenser probe (P61 = 1) and on

condition that the compressor is on (with reference to the

condenser probe); see also P54

P53 P52 differential 5

P54 condenser fan switch off delay on switching off the compressor

30

in the presence of the condenser probe (P61 = 1); see also

P52

P55 chill and freeze cycle completion buzzer duration 3

P56 maximum buzzer duration during an alarm state 15

P57 elapsed time between switching on the compressor and pump

10

down valve activation (pump down in power up); also elapsed

time between deactivation of the pump down valve and

switching off the compressor (pump down in power down)

P58 defrost parameter units of measurement

0

0 = P25 h, P24, P26, P28 and P35 min

1 = P25 min, P24, P26, P28 and P35 s

P59 reserved 0

P60 probe type

0

0 = NTC

1 = PTC

P61 condenser probe enabling

P62 the temperature above which the condenser temperature

P63 P62 differential 10

1 = YES

alarm is activated (with reference to the condenser probe)

Rev 07/04/2015

0

70

22

Blast chiller Service Manual

Parameter

Description

Factory Value

P64 temperature below which the minimum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P64" (with reference to the cabinet probe)

0 = no alarm

P65 temperature above which the maximum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P65" (with reference to the cabinet probe)

0 = no alarm

P66 temperature below which the minimum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P66" (with reference to the cabinet probe)

0 = no alarm

P67 temperature above which the maximum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P67" (with reference to the cabinet probe)

0 = no alarm

P68 P64, P65, P66 and P67 differential 2

P69 storage operation start-up temperature alarm delay 0

P70 temperature alarm delay 0

P71 enable printing

1 = YES

P72 print interval 5

P73 HACCP alarm list deletion

1 = YES

P74 Baudrate

0=2400

1=4800

2=9600

3=19200

0

0

0

0

0

0

2

P75 Bit polarity

P76 Board address 1

23

0=no polarity

1=even

2=odd

Rev 07/04/2015

2

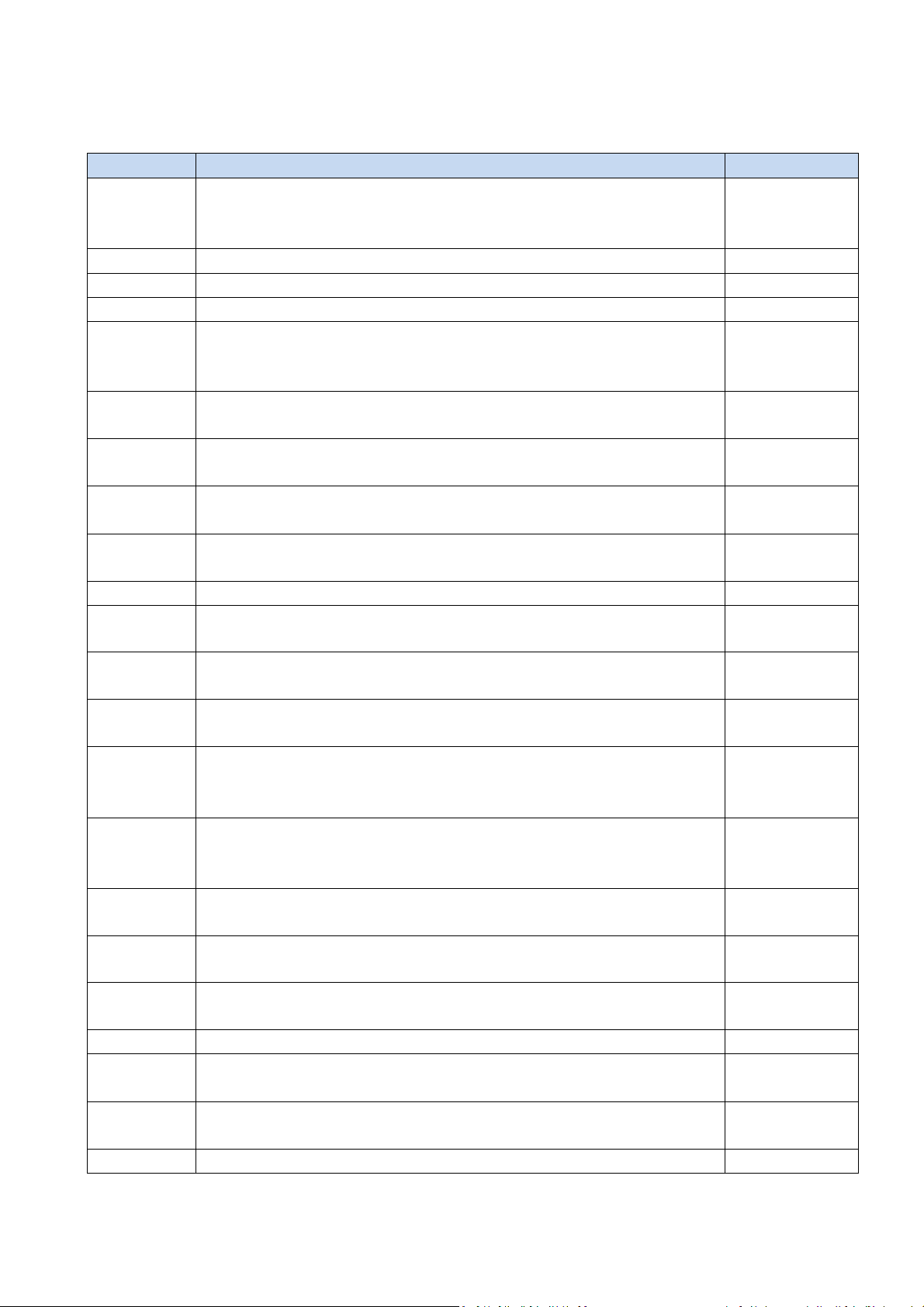

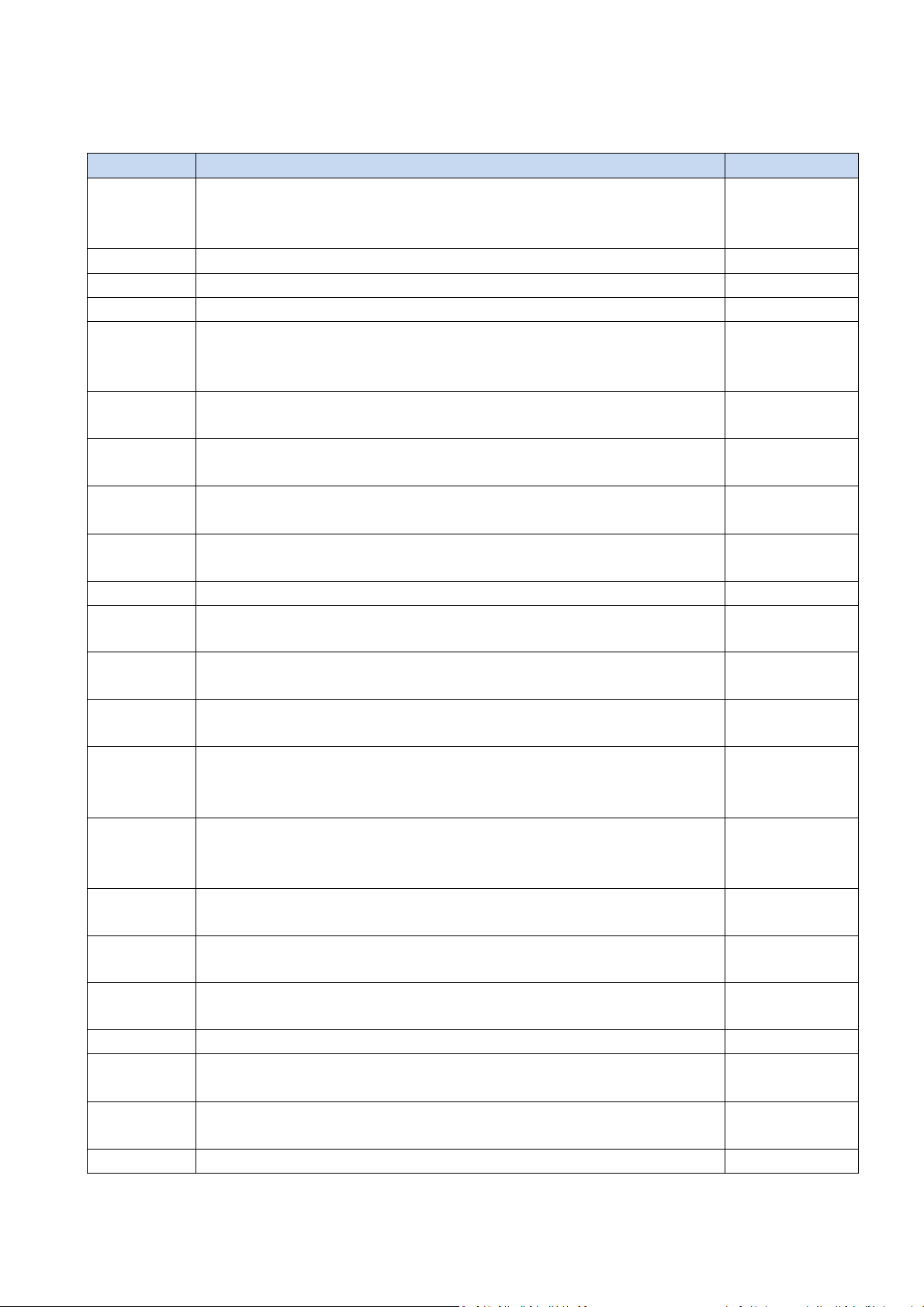

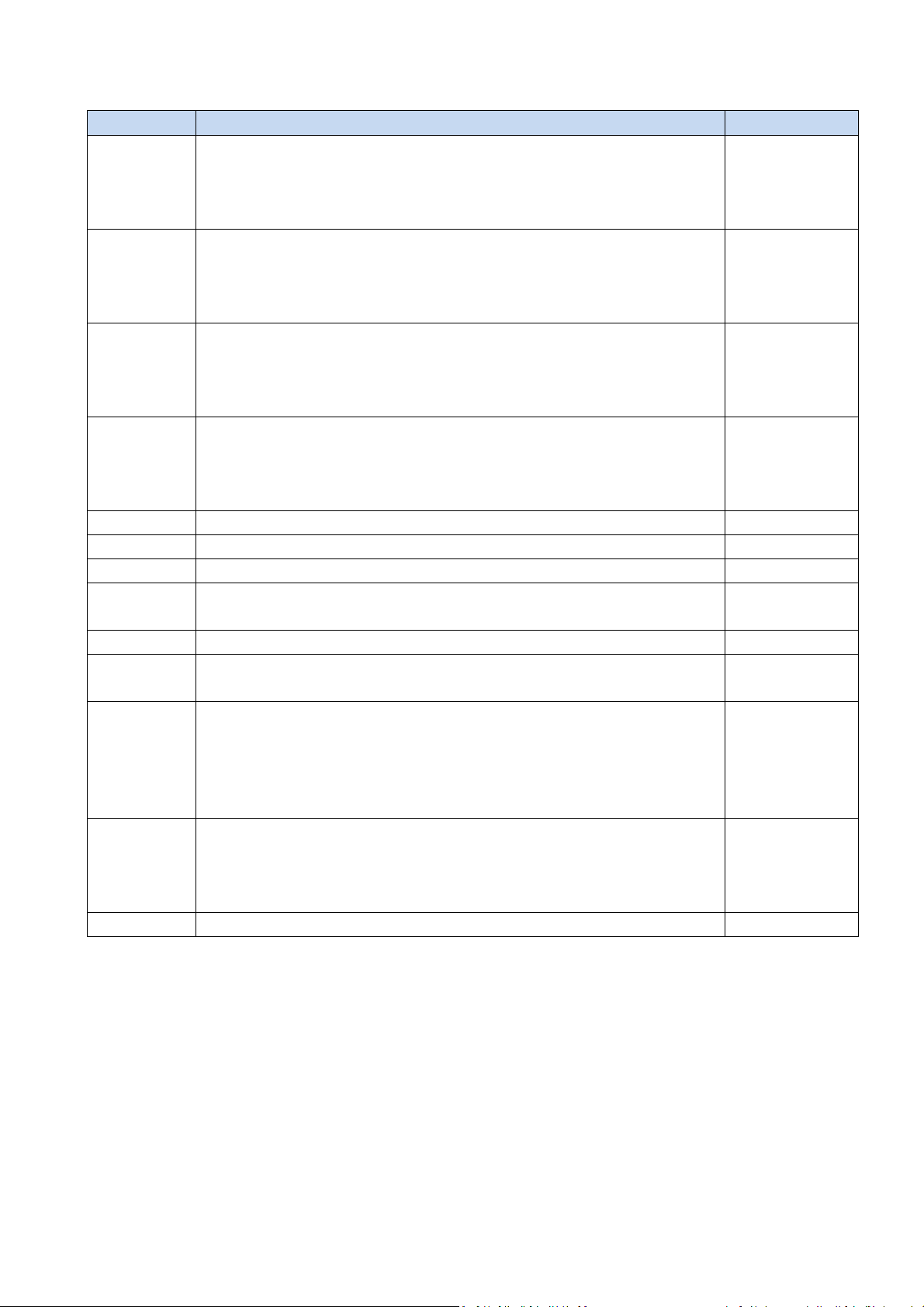

All GBC Trolley Units (Cycle Off Defrost)

Parameter

Description

Factory Value

P0 unit of temperature measurement

1

0 = °F

1 = °C

P1 cabinet probe offset 0

P2 evaporator probe offset 0

P3 needle probe offset 0

P4 operational setpoint during the second hard chill step; also,

0

operational setpoint during normal chilling (with reference to

the cabinet probe)

P5 operational setpoint during freezing (with reference to the

0

cabinet probe)

P6 operational setpoint during the first hard chill step (with

-20

reference to the cabinet probe)

P7 operational setpoint during post-chill storage (with reference to

3

the cabinet probe)

P8 operational setpoint during post-freeze storage (with reference

3

to the cabinet probe)

P9 P4, P5, P6, P7 and P8 differential 1

P10 set temperature chill end temperature (with reference to the

3

needle probe)

P11 set temperature freeze end temperature (with reference to the

3

needle probe)

P12 temperature at which the hard chill switches from the first step

20

to the second (with reference to the needle probe)

P13 temperature above which it is not possible to start a set-

99

temperature operational cycle (with reference to the needle

probe)

P14 needle probe and the cabinet temperature for verification of

P15 duration of the second test to check correct needle probe

P16 maximum set temperature chill duration; also timed chill

P17 maximum set temperature freeze duration; also timed freeze

P18 first hard timed chill step duration 45

P19 compressor delay from device power on (from restoration of

P20 minimum elapsed time period between two consecutive

P21 minimum compressor shut-down time 0

correct needle probe insertion

0 = the test will not be performed

insertion; see also P14

duration

duration

power)

compressor start-up operations

0

60

90

90

0

0

Rev 07/04/2015

24

Blast chiller Service Manual

Parameter

Description

Factory Value

P22 defrost type

0 = electric (defrost on relay)

1 = hot gas (defrost compressor and relay on)

2 = air (evaporator fan on)

P23 defrost end temperature (with reference to the evaporator

probe)

P24 maximum defrost duration 10

P25 defrost interval during storage; see also P26

0 = intermittent defrosting will never be activated (only the first

will be activated)

P26 first defrost delay from start of storage; see also P25 1

P27 defrosting at start of chilling and freezing

1 = YES

P28 drip-drain duration 2

P29 resetting of compressor protections at start of defrosting (only

if P22 = 1)

1 = YES

P30 elapsed time between the defrost request and switching on the

compressor (only if P22 = 1 and providing that the compressor

is off when the defrost is requested); see P31 (7) (8)also

2

8

6

0

0

30

P31 elapsed time between the defrost request and activation of the

solenoid valve (only if P22 = 1 and on condition that the

compressor is off when defrosting is requested); see also P30

P32 temperature above which the evaporator fan is switched off

during storage (with reference to the evaporator probe)

P33 P32 differential 1

P34 evaporator fan activity during defrosting (only if P22 = 0 or 1)

0 = on

1 = off

P35 evaporator stop time after dripping 3

P36 temperature above which the evaporator fan is switched off

(with reference to the cabinet probe)

P37 effect caused by activation of microport input on evaporator

fan

0 = no effect

1 = the evaporator fan will be switched off

P38 microport input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P39 micro port input alarm delay 0

P40 high pressure input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

0

3

0

90

1

1

0

P41 high pressure input alarm delay 120

25

Rev 07/04/2015

Parameter

Description

Factory Value

P42 low pressure input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P43 low pressure input alarm delay 0

P44 compressor thermal protection input contact type

0

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

P45 compressor thermal protection input alarm delay 0

P46 UV light on duration (duration of cabinet sterilisation) 5

P47 needle probe heating end temperature (with reference to the

45

needle probe)

P48 maximum duration of needle probe heating 15

P49 the temperature, below which the door elements are switched

5

on (with reference to the cabinet probe)

P50 P49 differential 2

P51 condenser fan activity in the absence of the condenser probe

1

(P61 = 0)

0 = in parallel with compressor

1 = on

P52 the temperature below which the condenser fan is switched off

20

in the presence of the condenser probe (P61 = 1) and on

condition that the compressor is on (with reference to the

condenser probe); see also P54

P53 P52 differential 5

P54 condenser fan switch off delay on switching off the compressor

30

in the presence of the condenser probe (P61 = 1); see also

P52

P55 chill and freeze cycle completion buzzer duration 3

P56 maximum buzzer duration during an alarm state 15

P57 elapsed time between switching on the compressor and pump

10

down valve activation (pump down in power up); also elapsed

time between deactivation of the pump down valve and

switching off the compressor (pump down in power down)

P58 defrost parameter units of measurement

0

0 = P25 h, P24, P26, P28 and P35 min

1 = P25 min, P24, P26, P28 and P35 s

P59 reserved 0

P60 probe type

0

0 = NTC

1 = PTC

P61 condenser probe enabling

P62 the temperature above which the condenser temperature

P63 P62 differential 10

1 = YES

alarm is activated (with reference to the condenser probe)

Rev 07/04/2015

0

70

26

Blast chiller Service Manual

Parameter

Description

Factory Value

P64 temperature below which the minimum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P64" (with reference to the cabinet probe)

0 = no alarm

P65 temperature above which the maximum temperature alarm is

activated during post-chill storage, with relation to P7, i.e. "P7

+ P65" (with reference to the cabinet probe)

0 = no alarm

P66 temperature below which the minimum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P66" (with reference to the cabinet probe)

0 = no alarm

P67 temperature above which the maximum temperature alarm is

activated during post-freezing storage, with relation to P8, i.e.

"P8 + P67" (with reference to the cabinet probe)

0 = no alarm

P68 P64, P65, P66 and P67 differential 2

P69 storage operation start-up temperature alarm delay 0

P70 temperature alarm delay 0

P71 enable printing

1 = YES

P72 print interval 5

P73 HACCP alarm list deletion

1 = YES

P74 Baudrate

0=2400

1=4800

2=9600

3=19200

0

0

0

0

0

0

2

P75 Bit polarity

P76 Board address 1

27

0=no polarity

1=even

2=odd

Rev 07/04/2015

2

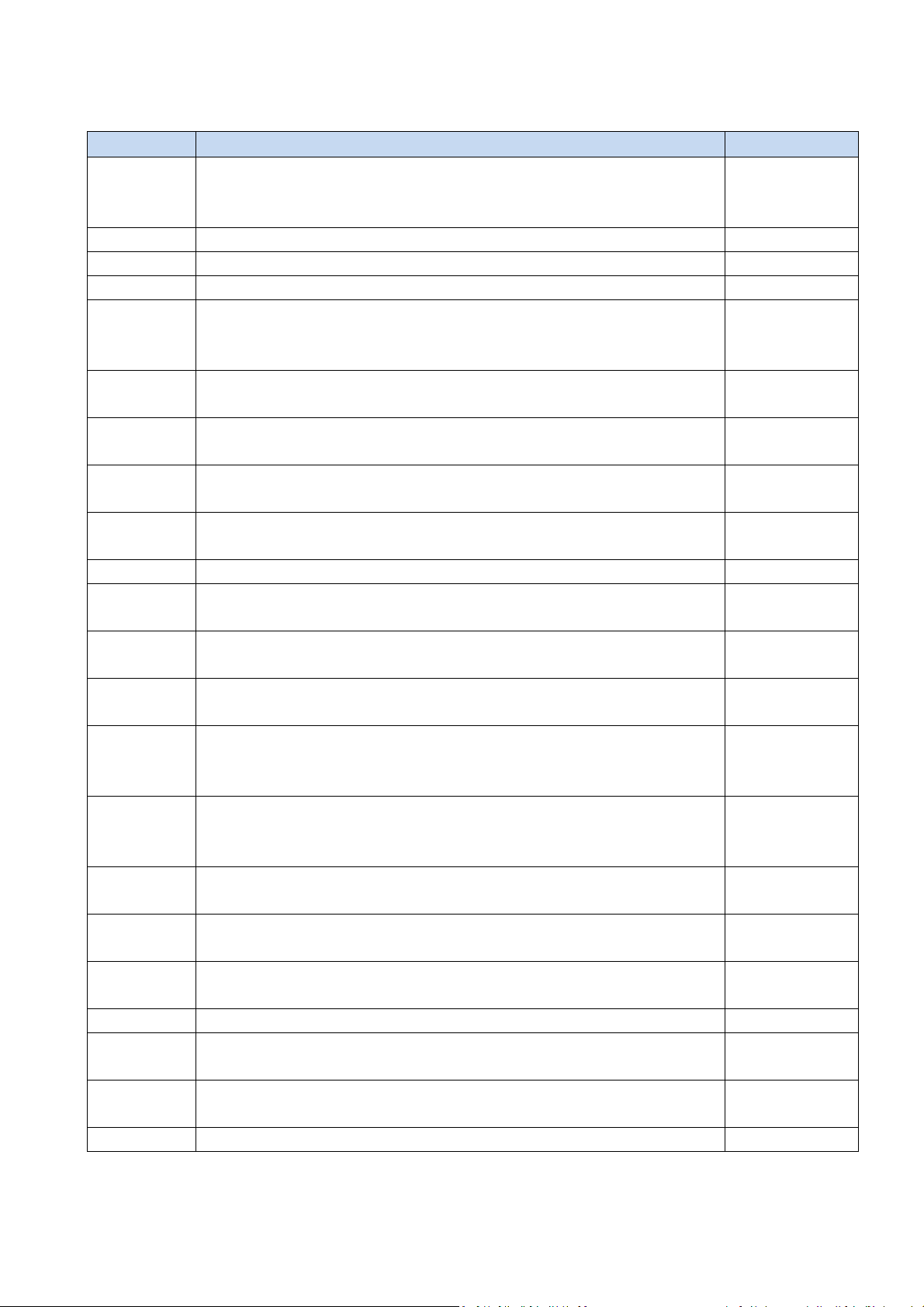

1.3.3 Temperature Probes Display

DISPLAY

PROBE

To check the reading of the unit’s temperature sensing probes, first make sure

the unit is in the OFF mode.

1. Press the NEDLE PROBE key and the DOWN arrow key together and hold

for five (5) seconds.

2. T o scroll through the reading use the UP or DOWN arrow key.

Tab 2

Pr1 Cabinet Probe

Pr2 Needle Probe

Pr3 Evaporator Probe

Valuable information can be obtained by checking the evaporator probe when

the unit is struggling to reach the cabinet temperature setpoint, (i.e. -40°F).

This may indicate that the evaporator coil is not being supplied with sufficient

refrigerant. With a cabinet setpoint of -40°F the actual evaporator temperature is

approximately -45°C at 0 Barg. In this case, the controller evaporator probe

reading MUST BE at least -42°C, which is the minimum readable temperature.

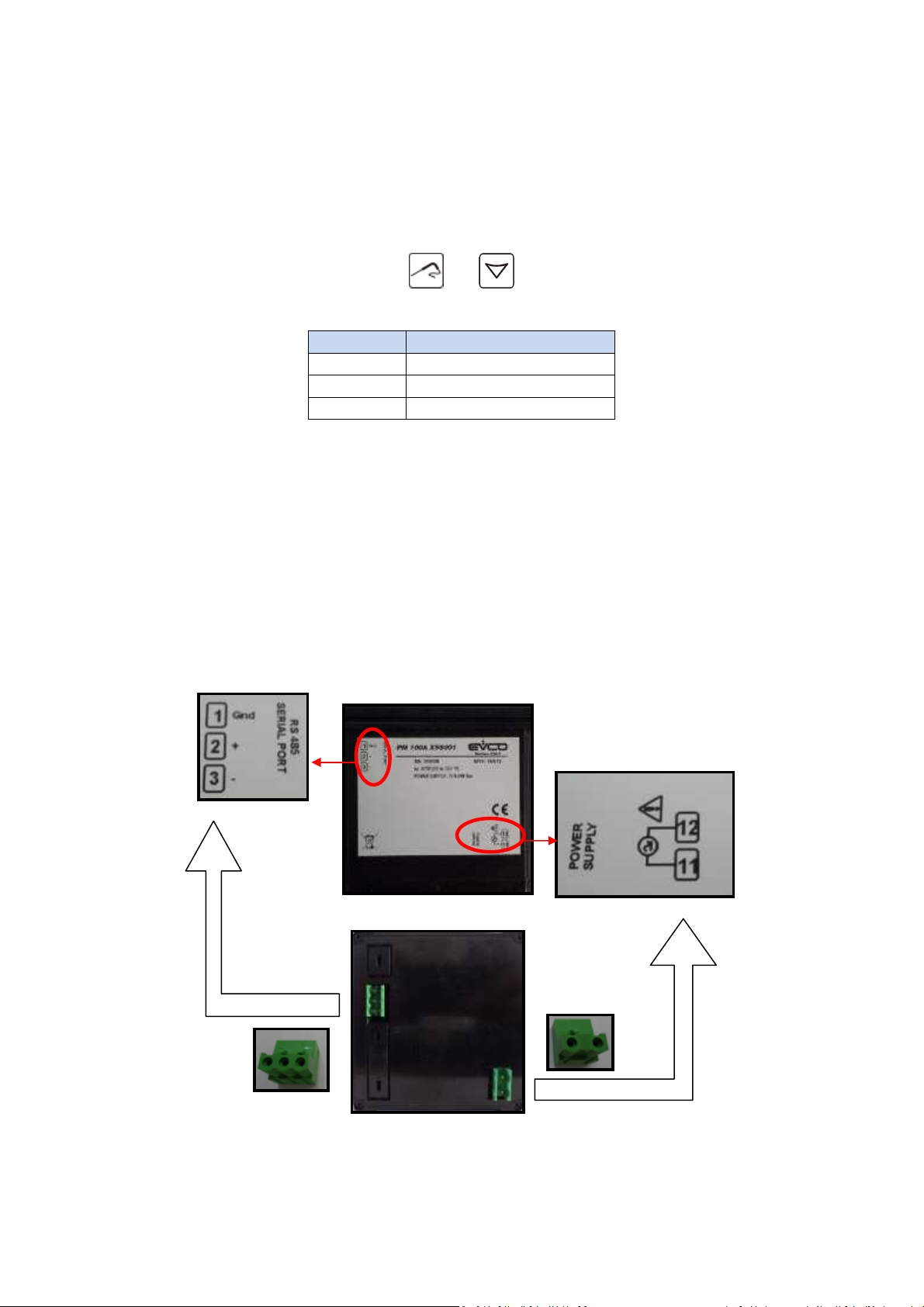

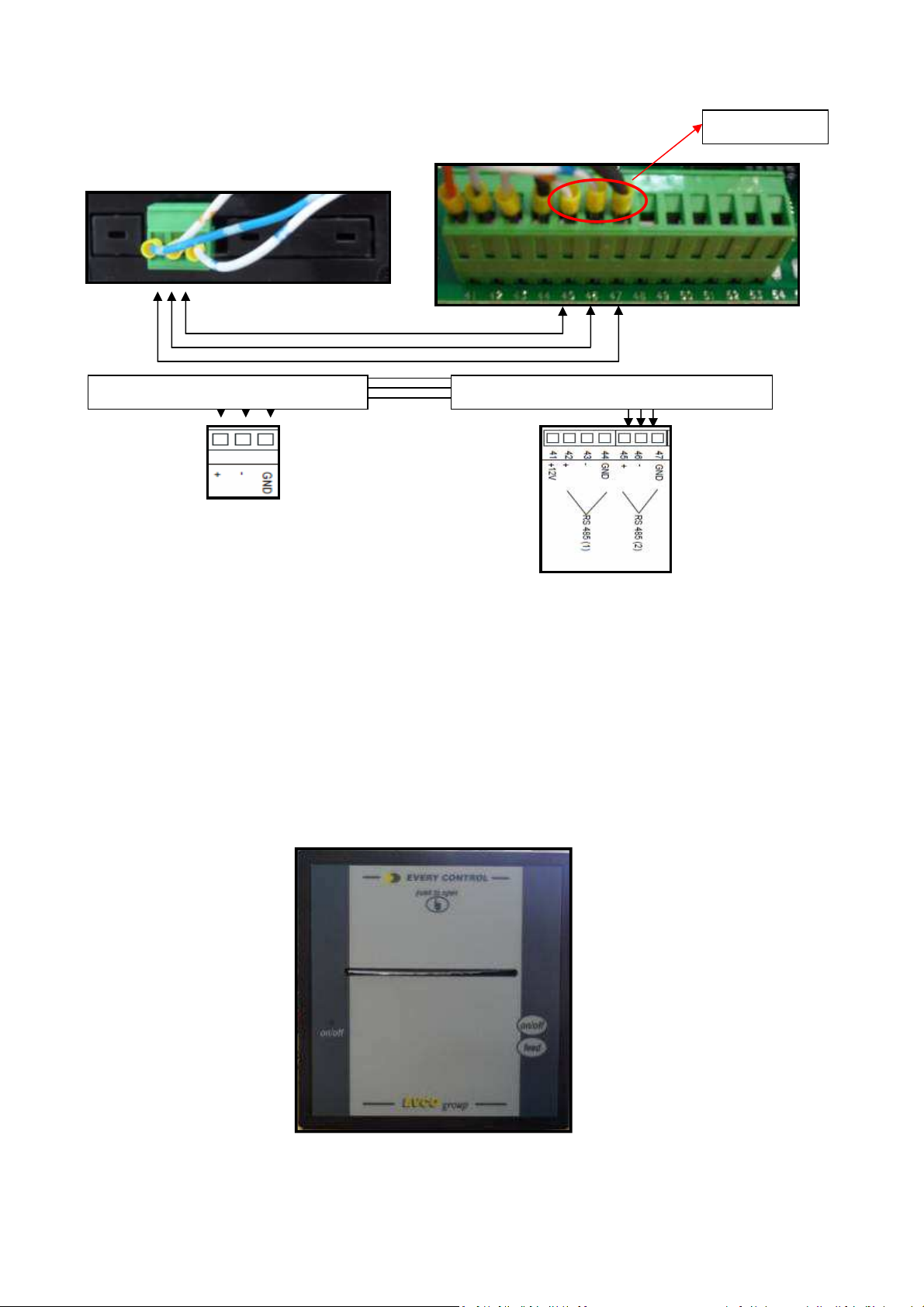

HACCP PRINTER

Blast Chillers can be ordered with an optional printer, or one can be installed as

a retrofit. The printer has its own power supply connection (110VAC – 240VAC

50/60 Hz). The printer is connected to the Main Board at the second RS 485

connection port (shown).

Rev 07/04/2015

28

Blast chiller Service Manual

45 46 47

PRINTER TERMINAL BLOCK

MAIN BOARD

TERMINAL BLOCK

A belden shielded cable (3 wires) must be used.

Connect the printer to the Main Board using coaxial shielded cables.

The main controller must be set to recognize the printer and enable

communication. Set configuration parameter P71 to 1 to enable the printer

port on the Main Board. In addition, ensure that the following parameters

are set as shown:

P76 – 1

P75 – 2

An LED on the printer will indicate its status: RED = ON.

Press the feed key to output blank paper in either ON or OFF status.

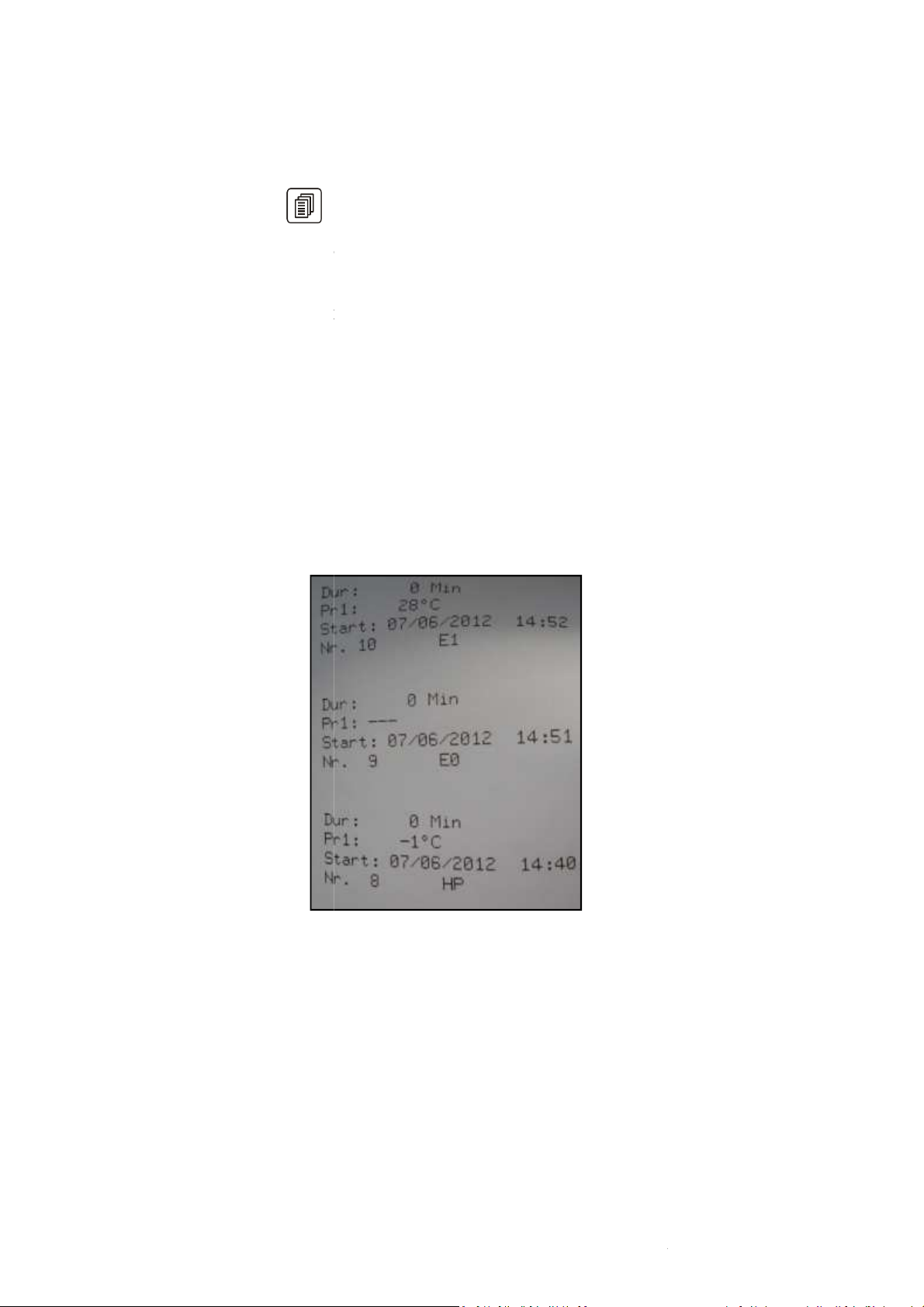

Printing alarm list

RS485 (2)

29

Rev 07/04/2015

To print the alarm list, the controller must be in the OFF mode.

Press the PROGRAM key for five (5) seconds.

f the printer communication has been enabled, the first display shown is

the alarm code, press the PROGRAM key.

To exit from printing, press either the UP or DOWN arrow key and the alarm

list will be shown in the display.

The controller will only save the previous 10 alarms.

Printed codes will be as shown:

With the HACCP printer, it is also possible to print data history related to the

If the printer is left ON and a cycle is started, the

capture frequency is set in Parameter P72 (example: If P72 = 1, device will print

every minute) and give the following information:

• Time, Cabinet and Needle Probe temperatures (each capt

ev

data will be captured. Data

I

To print

• Alarm duration

• Max/Min Temperature

• Date /Time

• Alarm Code

Printing Cycle Data

freezing and chilling cycles.

• Type of cycle

• Start date and time

“Prt”.

ure line)

R

07/04/2015

30

Loading...

Loading...