Page 1

DESCO INDUSTRIES INC. Technical Bulletin TB-7042

Statguard® Static Dissipative Floor Finish

Application Instructions & MSDS

General Guidelines

Statguard® and Statguard®-LH both eliminate

triboelectric generated charges before costly damage

can occur from personnel who approach static

sensitive parts and products. Statguard® also drains

static charges from personnel who forget to reattach

their wrist straps minimizing the damage that could

occur from handling. Even when using conductive tiles,

a triboelectric charge is generated. When Statguard®

or Statguard®-LH are applied over conductive tiles, the

enhanced floor tile eliminates charge generation due to

walking across the floor.

Generally accepted industrial stripping and floor finish

application procedures are to be followed as outlined

on pages 2 and 3 in this technical bulletin.

Figure 1. Statguard® Floor Finish

Description

Statguard® Static Dissipative Cross-Linked Floor

Finish is used to dissipate static charges as well as

prevent triboelectric (static charge generation) charges

while providing a clear, high gloss finish that resists

wear. Statguard® Static Dissipative Floor Finish is a

free flowing liquid emulsion, which can be applied on

any hard surface or sealed floor including vinyl, vinyl

asbestos, linoleum, rubber, asphalt, sealed or painted

wood, terrazzo and concrete. Statguard® technology

eliminates the need for static control tile or floor

mats. Statguard® dries in one hour and is ideal for

clean room and electronic manufacturing, assembly,

and test areas. For use in environments with relative

humidity of 30-65%; for low humidity environments use

Statguard®-LH.

SAFE WALKING SURFACE

UL Classified as to slip resistance only. Statguard®

provides superior electrical properties along with

a safe walking surface. Underwriters Laboratory

has eval uated Statguard® and tested it to their slip

resistance standards. To ensure employee safety

and to mitigate user’s liability exposure, it is important

to use floor finish that has been successfully tested

for slip resistance, and is properly installed and

maintained.

NOTE: Statguard® Static Dissipative Floor Care products

do not have a set life span. The chemicals are not known to

degrade over time when stored at the proper temperature

conditions as stated in the Material Safety Data Sheet.

We also recommend that these products be stored in their

original containers and be sealed when not in use.

GROUNDING

Conventional grounding practices like electrically

connecting Statguard® Static Dissipative Floor Finish

to earth ground or internal building ground are required

for applications of static dissipative floor finish that

are less than 50 square feet. For applications that

are greater than 50 square feet, the capacitance of

Statguard® Floor Finish is MANY, MANY times greater

than the capacitance of the human body model.

The difference in capacitance is so great that the

Statguard® treated floor acts as a theoretical reservoir

or natural ground. The capacitance and surface

resistance of the Statguard® treated floor will decay

a 5000v charge to zero in .05 sec. per FTMS 101B,

Method 4046. Statguard® has substantially less than

the maximum static decay time of 0.1 seconds.

Foot grounders should be used in conjunction with

any properly grounded conductive or static dissipative

flooring. It is recommended to wear foot grounders on

both feet.

Made in America

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 January 2011 Page 1 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 2

Figure 2. Foot grounders should be used on ESD

protective flooring.

CONCRETE

Two measures are used to determine a good concrete

surface for Statguard

®

Floor Finish:

1. The surface should be dry or sealed.

2. The surface should be cleaned of all contaminants.

SURFACE

Surface to be finished should be clean, dry, and

smooth. Heavy dirt or grease build up should be

removed with a stripper or degreaser. DO NOT use

Statguard

®

on surfaces colder than 45° F.

Statguard Dissipative Floor Finish contains zinc.

SEALING

Surface preparation is absolutely critical for porous

materials such as concrete. Proper preparation

simplifies application, increases durability, and is

essential for proper adhesion of the coating of the

substrate. Industrial grade polyurethane, vinyl, or

acrylic base sealers are recommended to seal high

porosity floors before applying the Statguard® Floor

Finish. Enamel can be used for bare wood, and

enamel undercoat with rust inhibitor for metal.

New concrete should cure for 60 days before sealing.

Not all concrete surfaces are created equal. They vary

widely in physical and chemical qualities due to the

way the concrete was originally formulated, poured or

finished.

Concrete surfaces are very porous and should be

properly sealed prior to the application of Statguard®

Floor Finish. There are several methods to prepare

problem concrete. Each method depends on the

condition of the concrete. Cleaning methods range

from: sweeping, vacuuming, wire brush, air-blasting,

water jet, steam cleaning, or stripping. Adhesion

properties for the concrete sealer can be increased

by profiling or roughing surface through acid etching,

rotary drum sanding, scarifying, or mechanically

scratching the surface. The concrete sealer will reduce

the porosity of the concrete and provide a smooth and

level surface for the finish. The sealer also provides a

barrier to prevent any water migrating up through the

concrete.

No Sealer Application: Sealing is recommended for

increasing coverage and correcting problem concrete

surfaces that are not dry or free from grease, oil, etc.

If the subfloor surface is dry, level, and free from

dirt, grease, oil, paint, sealer, old adhesives, and

other foreign materials it may be suitable to applying

Statguard® finish directly onto the concrete.

COVERAGE

Statguard® Floor Finish covers approximately 2000

square feet per gallon per coat on smooth surfaces.

Coverage is less on coarse or textured surfaces. With

18% solids, Statguard

®

Floor Finish is easier to apply

with significantly better productivity than competing

brands.

DRY TIME

It is recommended that Statguard® be allowed to dry at

room temperature in excess of 70°F for 1 hour or until

dry. At high relative humidity levels, a longer drying

time may be necessary. Do not use force air drying.

Wait 6 hours before any light traffic, 12 hours before

regular traffic, 72 hours before any wet maintenance,

buffing, burnishing, and heavy equipment and floor

truck traffic.

CLOSE CONTAINER AFTER EACH USE. KEEP

FROM FREEZING. DO NOT TAKE INTERNALLY.

Optional Base Coat

Statguard® Conductive Latex Paint can be used as a

base coat to enhance the electrical properties where

conductive applications are needed. Statguard® Static

Dissipative Floor Finish will seal out dirt, debris and

protect the conductive surface allowing for ease of

maintenance and enhanced shine. Statguard® is a

polymer base floor finish/sealer that can be used

as a top coat on the Conductive Latex Paint. Two

coats are recommended, three coats will enhance

electrical properties, durability and reduce frequency

of maintenance. Ask your Statguard Flooring

Representative for Technical Bulletin TB-7001 for more

information on Statguard® Conductive Acrylic Paint.

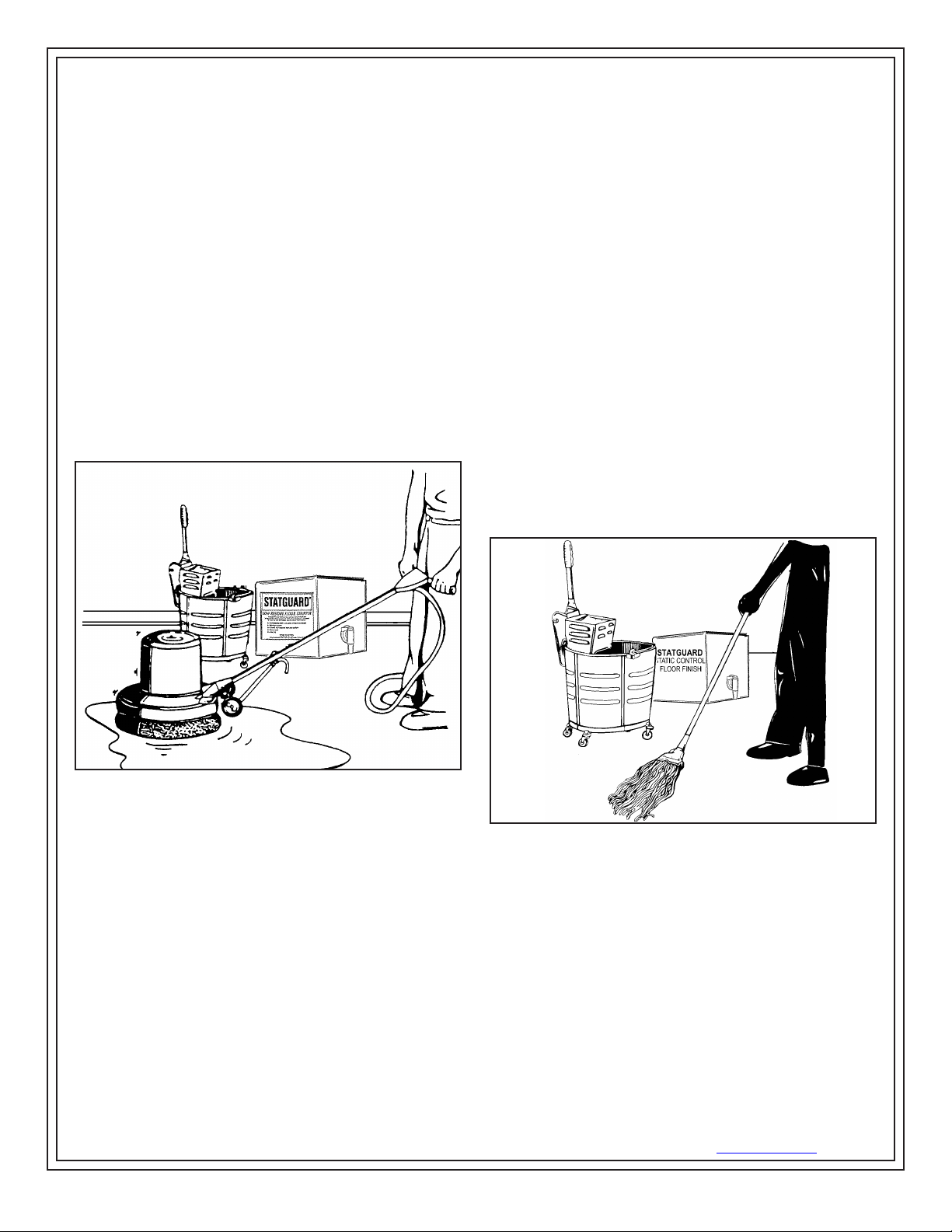

Floor Preparation - Stripping

Always use in a well ventilated area.

Stripping the floor is recommended for first time

application of any finish. New tiles are supplied with a

protective factory finish that protects during installation

but should be stripped away prior to any floor finish

application. Properly maintained floors should be

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 2 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 3

stripped two to four times annually, depending on

traffic and buildup of contaminated finish. Statguard®

Floor Stripper is recommended to strip multiple layers

of floor finish.

Equipment needed:

• Push broom

• Single pad 175 rpm swing floor machine (with a

black or brown stripping pad)

• Mops

• Buckets

• Statguard

®

Floor Stripper

• Wet vacuum

1. Sweep away all loose dirt and trash.

2. Mix Statguard

®

Floor Stripper 3:1 three (3) parts

HOT water to one (1) part stripper.

3. Apply stripper liberally to around 200 square foot

area in need of stripping. Using a cotton string mop,

uniformly distribute the solution. Let the solution

stand for 5-15 minutes. Do not let it dry.

10. Inspect floor to be sure all stripper and old polish

has been removed.

It is recommended to test the stripped surfaces after

the second rinse to ensure that high pH residues

are rinsed away. Some high pH strippers will leave a

residue behind even after several rinses. A high pH

can affect the floor finish curing time as well as other

properties of the finish. To test for high pH residue,

test either the rinse water or the floor using either a pH

measuring instrument or a piece of pH indicating litmus

paper. A safe PH will be 7.0 (neutral). Two sources for

litmus paper are Micro Essential Laboratory, Brooklyn,

NY 11210 or Fisher Scientific, Fair Lawn, New Jersey

07410.

Statguard® Application

It is recommended that you apply two coats of

Statguard® Floor Finish. After stripping the factory

finish, new tile will have an initial high porosity and will

require three coats on first application. For known high

traffic applications, three coats are recommended for

extended life.

• If Statguard® freezes, allow it to thaw to 70° F

before application.

Figure 3. Stripping the floor

4. Scrub the floor with the floor machine at 175 rpm

(using a stripping pad soaked in stripping solution).

Work methodically, with at least two passes over

each area of the floor.

5. After scrubbing, pick up the solution with a wet vac

or mop.

6. Flood rinse the floor with clean, clear water.

7. Pick up the rinse water with a wet vac or mop.

8. Repeat steps 5 and 6. Entire floor should be rinsed

twice.

9. Damp mop the floor at least twice with clean mop

and clean water (change rinse water frequently to

ensure that all stripper solution residue is removed),

and let dry.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 3 of 9

Figure 4. Applying floor finish.

Equipment needed:

• Clean rayon (or cotton blend) mop, dedicated to

Statguard® use only

• Bucket dedicated to Statguard

®

use only.

1. Pour Statguard® Floor Finish into a clean mop

bucket and apply with a clean rayon (or cotton

blend) mop using a figure 8 motion.

2. Let the first coat dry at least 60 minutes, then apply

a second coat. Do not use force air drying.

3. Let second coat dry for at least 60 minutes to yield

a bright gloss. Repeat application to attain higher

gloss and higher conductivity (two coats will provide

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 4

acceptable antistatic performance on most floors).

Keep traffic from floor for at least one hour after the

last coat is applied. See dry time recommendations

on page 2 in this technical bulletin.

4. One or preferably two additional coats of floor finish

should be applied if the floor is to be maintained by

dry burnishing or spray buffing.

5. Maintain the polish following the Dust Mop, Damp

Mop, Floor Cleaner, Dry Burnish, or Spray Buff

maintenance procedure below.

Statguard® Maintenance

DUST MOP PROGRAM

1. Keep the floor surface clean. Use an untreated dust

mop or push broom nightly or as needed to remove

accumulated dirt and insulative contaminant.

DAMP MOP PROGRAM

1. Keep the floor surface clean. Use an untreated dust

mop or push broom nightly or as needed to remove

accumulated dirt and insulative contaminant.

2. To damp mop, use a 1 to 3 dilution of Statguard®

in water (1 part Statguard® to 3 parts water). Let

dry thoroughly. The mop and bucket should be

dedicated to Statguard® use only.

3. After dry burnish, dry mop the area with an

untreated dry mop if necessary.

SPRAY BUFF PROGRAM

A spray buff program will repair scratches, marks, and

other imperfections as well as gloss.

Heavy-Moderate Traffic:

Spray buff once a week or as dictated by appearance.

Low Traffic Floors:

Spray buff as dictated by floor appearance.

Equipment needed:

• Untreated dust mop

• Spray bottle

• 175-1500 rpm buffing machine with appropriate pad

FLOOR CLEANER PROGRAM

Statguard® Floor Cleaner will clean surface stains and

heel marks. As a cleaner it will reduce the gloss of the

floor.

Heavy-Moderate Traffic:

Clean once a week, or as dictated by floor appearance.

Low Traffic Floors:

Clean floors as dictated by floor appearance.

1. Dust mop with untreated mop.

2. Dilute Statguard® Dissipative Floor Cleaner 10

parts clean water to 1 part Floor Cleaner. For

example, use five (5) gallons of clean water to two

(2) quarts of floor cleaner.

3. Damp mop floor with cleaner solution and let

dry thoroughly. The mop and bucket should be

dedicated to Statguard® use only.

DRY BURNISH PROGRAM

Heavy-Moderate Traffic:

A dry burnish program will increase gloss and remove

surface imperfections.

Dry burnish once a week or as dictated by floor

appearance.

Low Traffic Floors:

Dry burnish as dictated by floor appearance.

1. Dust mop with an untreated mop.

2. Dry burnish at 1000-2000 rpm.

Figure 5. Applying Spray Buff.

1. Dust mop with an untreated mop or push broom.

2. At 175-300 rpm, use a red pad. At 1000-1500 rpm

use a white or beige pad.

3. Spray a small area with a mixture of one part

®

Statguard

and two parts water. Spray lightly.

4. Buff the sprayed area until clean and glossy. All

black marks and scuffs should be removed.

5. After high speed spray buffing, dry mop the area, if

needed, with an untreated mop.

Physical Properties

Base: Acrylic Polymer

Description:

Aqueous Acrylic Emulsion, Non-hazardous material as

defined in (29 CFR 1915.4)

Abrasion Resistance:

Exc. Crockmeter at 50% R.H.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 4 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 5

Color: Off White Opaque

Density: 8.42 lbs/gal

Freeze/Thaw Stability:

Exc. 3 Cycles at -10°C

pH: 8.8

Slip Resistance: UL Approved*

Solids: 18%

Solvent: Water

Thermal Stability:

Exc. 50°C/1 month

Viscosity: 3.3 cps

Working Humidity:

Range 30-60% RH

ELECTRICAL PROPERTIES

Meets or exceeds ANSI/ESD S20.20 minimum

recommended technical requirements as an ESD

protective floor or as a primary grounding method

based on Low charging.

Surface Resistance:

7

9

-

10

10

Ohms per ANSI/ESD S7.1

Low Charging:

<50 volts per ESD STM 97.2

Personal Resistance:

<35 megohm per ESD STM 97.1

Charge Decay:

5000v to 0 in 0.01 sec per FTMS 101C 4046

*Underwriters Laboratory (UL) tested for slip resistance only.

Authorization and Registration Number SA6524.

CLEAN ROOM CHARACTERISTICS

Contaminant Dried Film Liquid

(Outgassing)

Sodium Zero Zero

Fluoride Zero Zero

Chloride Zero Zero

Bromide Zero Zero

Iodide Zero Zero

Testing

Figure 6. Surface Resistance Test Kit

It is recommended to test the surface resistance

periodically to ensure that insulative contaminants

such as dirt and grime are not building up on the

surface. The surface should be kept clean. Testing

either point to point resistance (RTT) or resistance

to ground (RTG) will indicate if the floor finish needs

surface maintenance. If the surface is clean, with high

resistance readings this indicates that the floor finish

is becoming thin and in need of replenishing its solids.

These solids are worn away over time due to floor

traffic. Hence, the high floor traffic areas will need more

frequent maintenance than low traffic areas.

For quick and easy verification of surface resistance

Statguard Flooring recommends the use of our Surface

Resistance Test Kit.

Limited Warranty

Desco Industries Inc. expressly warrants that for a period of one

(1) year from the date of purchase, our Reztore™ Topical Antistat

will be free of defects in material. Within the warranty period,

the material will be replaced at our option, free of charge. Call

our Customer Service Department at 781-821-8370 or 00 44 (0)

1892-665313 in Europe for a Return Material Authorization (RMA)

and proper shipping instructions and address. You should include

a copy of your original packing slip, invoice, or other proof of

purchase date. Any material under warranty should be shipped

prepaid to the Desco Industries Inc. factory. Warranty replacements

will take approximately two weeks.

• Dried film testing was completed to simulate

particulating.**

• Liquid analysis completed using GLC (gas-liquid

chromatography)**

** Analysis conducted at Armstrong Corporate Research

Center, Lancaster, PA.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 5 of 9

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU

OF ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator

error, or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will Desco Industries Inc. or any seller be responsible

or liable for any injury, loss or damage, direct or consequential,

arising out of the use of or the inability to use the product. Before

using, users shall determine the suitability of the product for their

intended use, and users assume all risk and liability whatsoever in

connection therewith.

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 6

Material Safety Data Sheet

May be used to comply with ANSI Z400.1-2004, 29 CFR

1910.1200, European 2001/58/EC, REACH 1907/2006/

EC, and GHS. Standard must be consulted for specific

requirements.

NFPA Designation 704

Degree of Hazard

4 = Extreme 1 = Slight

3 = High 0 = Insignificant

2 = Moderate

HMIS RATING: Health 1, Flammability 0, Physical Hazard 0, Personal Protection B

Health

(Blue)

2

Special Hazard

Flammability

0

0

0

(Red)

Reactivity

(Yellow)

SECTION 1 — CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Product Name/Identity: Statguard® & Statguard®-LH Static Dissipative Floor Finish

Chemical Name: Acrylic Floor Finish

Manufacturer: Desco Industries, Inc.

Address: One Colgate Way

Canton, MA 02021

Telephone: 781-821-8370

Emergency Number: 781-821-8370

Date Prepared: 2010-01-04

SECTION 2 — HAZARDS IDENTIFICATION

Routes of Entry

Eyes: A high concentration of liquid, mist, or vapor may cause irritation of the connective

tissue.

Skin: Repeated or continuous contact may cause irritation of the skin.

Ingestion: None known

Inhalation: Irritation of nose, throat, and lack of breath. Exposure to vapors in high concentration

may have same effect as with inhalation.

SECTION 3 — COMPOSITION/INFORMATION ON INGREDIENTS

Hazardous Ingredients: CAS No. Weight (%)

(Statguard)

Dipropylene Glycol Monomethyl Ether* 034590-94-8 1-5%

Diethylene Glycol Methyl Ether* 111-77-3 1-5%

Ammonia* 7664-41-7 <1%

Modified Acrylic Polymer (NonHaz) 30-60%

Emulsified Waxes (NonHaz) 5-25%

Tributoxy Ethyl Phosphate 8-51-3 1-3%

CAS No. Weight (%)

(Statguard LH)

Ethylene Glycol* 107-21-1 1-5%

Glycol Ethyl Ether* 111-90-0 1-5%

Ammonia Hydroxide* 1336-21-6 1-5%

Mod. Acrylic Polymer (NonHaz) 5-25%

Emulsified Waxes (NonHaz) 5-25%

Alkylolamine Methosulfate 1-5%

*These items are listed and subjected to the reporting requirements of the SARA Title III Section 313 Inventory of the

Emergency Planning and Community Right-To-Know Act of 1986 and of 40 CFR372.

SECTION 4 — FIRST AID MEASURES

Symptoms of Exposure: Inhalation: Minor irritation

(Acute and Delayed)

Skin: Slight irritation

Eyes: Slight Irritation

Signs and Symptoms of exposure: Prolonged skin exposure may cause minor irritation skin – dryness.

Emergency and First Aid Procedures:

Eye Contact: Flush with water for at least 15 minutes.

Skin Contact: Wash with soap and water

Ingestion: Drink several glasses of water. DO NOT induce vomiting. Contact a physician.

Inhalation: Move subject to fresh air.

Medical Conditions: Generally Aggravated by Exposure Overexposure may aggravate Asthma.

SECTION 5 — FIREFIGHTING MEASURES

Proper Extinguishing Media: Foam, CO

Unsuitable Extinguishing Methods: N/A

, DC, and water

2

Protective Equipment & Precautions: Wearing of appropriate protective equipment

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 6 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 7

Flash Point (Method Used): N/A

Flammable Limits: N/A

Special Fire Fighting Procedures: N/A

Unusual Fire and Explosion Hazards: None known.

SECTION 6 — ACCIDENTAL RELEASE MEASURES

Personal Precautions: Wearing protective clothing. Inhalation protection. Extinguish all ignition sources.

Environmental Precautions Keep spills and cleaning runoffs out of municipal sewers and open bodies of water.

Waste Disposal Method: Absorb with sand or other diminishing material. Coagulate the emulsion by the

stepwise of Ferric Chloride and Lime. Remove the clear supernatant liquid and

flush to a chemical sewer. Incinerate the solids and the contaminated diking material

according to local, state, and federal regulations.

If Material is Released/Spilled: Keep spectators away. Dike and contain spill with inert material (e.g. sand, earth).

Keep spills and cleaning runoffs out of municipal sewers and open bodies of water.

SECTION 7 — HANDLING AND STORAGE

Handling: Use in well-ventilated areas; avoid breathing vapors. Keep containers closed when

not in use. Avoid from freezing.

Storage: Storage temperature: Max. 49°C/120°F 1°C/34°F

Other Precautions: Store in a cool, dry place with adequate ventilation. Keep from freezing - product

may coagulate

SECTION 8 — EXPOSURE CONTROL / PERSONAL PROTECTION

Hazardous Ingredients: CAS No. TLV-value

(Statguard)

Dipropylene Glycol Monomethyl Ether* 034590-94-8 100 ppm

Diethylene Glycol Methyl Ether* 111-77-3 50 ppm

Ammonia* 7664-41-7 25 ppm

Modified Acrylic Polymer (NonHaz)

Emulsified Waxes (NonHaz)

CAS No. TLV-value

(Statguard LH)

Ethylene Glycol* 107-21-1 100 ppm

Glycol Ethyl Ether* 111-90-0 50 ppm

Ammonia Hydroxide* 1336-21-6 25 ppm

Mod. Acrylic Polymer (NonHaz)

mulsified Waxes (NonHaz)

Alkylolamine Methosulfate

Control Parameters: TLV-valve 25 ppm maximum for ammonia

Measures for Technical Control: Preferences of technical measure to prevent or control contact with the product.

Isolating process and personnel, mechanical ventilation (dilution and local exhaust)

and the regulation of process conditions. In case of non-prevention or non-control, a

proper protective wearing should be used.

Respiratory Protection (Specify Type): Wear MSHA/NIOSH-approved respirator where exposure limits are exceeded.

Hand Protection Impervious/Neoprene Gloves

Ventilation: Local Exhaust Special: Mechanical at point of contamination release. Special: None

Protective Gloves: Impervious/Neoprene Gloves

Eye Protection: Chemical Splash Goggles as defined in ANSI Z-87.1 or a similar standard.

Other Protective Clothing or Equipment: Eyewash station

Work/Hygienic Practices: Wash hands before eating, smoking, or using washroom facilities

SECTION 9 — PHYSICAL AND CHEMICAL PROPERTIES

Form: Liquid

Colour: Opaque, tan liquid

Odor: Wax or ammoniacal odor

Boiling Point: >200°F (100°C)

Melting Point: N/A

Specific Gravity (H2O = 1) : >1.0

Solubility in Water: Complete

pH: 8.0-9.0

Flash Point: Noncombustible

Flammability Limits: N/A

Solubility in water: Complete

Vapor Pressure (mm Hg): N/A

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 7 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 8

Vapor Density (air=1): N/A

Viscosity: 1.0 cp (Statguard® Low Humidity)

Density at 20°C: 8.6 lbs./gal

Flammability: Classification according to EC-regulations “non-flammable”

Ignition Temperature: N/A

Evaporation Rate: N/A

SECTION 10 — STABILITY AND REACTIVITY

Hazardous Polymerization: NE

Hazardous Decomposition/Byproducts: Thermal decomposition may yield acrylic monomers.

Incompatibility (Materials to Avoid): N/A

Stability: Stable product at normal conditions.

Conditions to Avoid: Temperatures above 49°C/120°F Below: 1°C/34°F

SECTION 11 — TOXICOLOGICAL INFORMATION

(Statguard)

Emulsified Acrylic Polymer

Acute Toxicity: LD50/oral/rat = >5000 mg/kg

LD50/dermal/rabbit = >5000 mg/kg

Skin irritation/rabbit = May cause transient irritation

Eye irritation/rabbit = No eye irritation

2-(2-Methoxyethoxy) Ethanol (111-77-3)

Acute Oral Toxicity: LD50: 5,500 mg/kg (rat)

Acute Dermal Toxicity: LD50: 6,540 mg/kg (rabbit)

Dipropylene Glycol Monomethyl Ether (34590-94-8)

Acute Toxicity: LD50, Rat 5,135 mg/kg

Skin Absorption: LD50, Rabbit > 20 ml/kg

Inhalation: LC50, 7 h, Aerosol, Rat > 500 ppm

Sensitization: Did not cause allergic skin reactions when tested in humans.

Tri-Butoxyethyl Phosphate (78-51-3)

Acute Inhalation: (LD50/LC50): 4.43 mg/L Rat

Acute Dermal: (LD50/LC50): 10 g/kg Rabbit

Acute Oral: LD50/LC50): 500, <5,000 mg/kg Rat

Acute Oral: (LD50/LC50): 3g/kg Rat

(Statguard LH)

Ethylene Glycol (107-21-1)

100 mg/m3 ACGIH/OSHA TLV (CBILING) (AEROSOL), 50 ppm TWA (VAPOR) 10 mg/m3 TWA (PARTICULATE)

Diethylene Glycol Monoethyl Ether (111-90-0)

NOT EASTABLISHED LD50: 5,540 mg/kg (oral-rat); 4,000 mg/kg (dermal-rabbit)

Ammonium Hydroxide (1336-21-6)

25 ppm ACGIH/OSHA TWA, 35 ppm ACGIH/OSHA STEL LD50: 350 mg/kg (oral-rat)

Waxes

10 mg/m3 (TOTAL NUISANCE DUST) (SUPPLIER RECOMMENDED) LD50: >2,500 mg/kg (oral-rat)

LD50 (ACUTE ORAL TOX.) Estimated to be greater than 5000 mg/kg (rats).

LD50 (ACUTE DERMAL TOX.) Not available.

NJ Trade Secret Registry (00850201001-5391P)

Inhalation 4 hour ALC: > 25 mg/L

Oral ALD: > 17,000 mg/kg

SECTION 12 — ECOLOGICAL INFORMATION

Mobility: The product is aqueous and will be separated in aqueous conditions

Degradability: N/A

Bioaccumulation: Not likely

Ecotoxicity None known

Reference to BimSchV: N/A

Hazard Classification: None hazardous

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 8 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Page 9

SECTION 13 — DISPOSAL CONSIDERATIONS

Product: Coagulate the emulsion by the stepwise of Ferric Chloride and Lime. Remove the

clear supernatant liquid and flush to a chemical sewer. Incinerate the solids and the

contaminated diking material according to local, state, and federal regulations.

Hazardous Waste Number: Non Hazardous

SECTION 14 — TRANSPORT INFORMATION

This product is not classified for transport under ADR/IMDG regulations

SECTION 15 — REGULATORY INFORMATION

Physical/Chemical Indication: Non-flammable

Risk-Phrase: (R36/38): irritates eyes and skin

Safety Phrase: (S2): keep away from children,

(S7): keep containers well closed,

(S24/25): avoid contact with skin and eyes,

(S62): if swallowed, do not induce vomiting; seek medical advice immediately and

show this container or label.

EU Classification: This product does not have to be classified according to the EU Regulations.

(67/548/EEC-88/379/EEC):

EINECS Status: All components are included in the EINECS inventories.

REACH: This product does not require REACH registration.

SECTION 16 — OTHER INFORMATION

HMIS RATING: Health 1, Flammability 0, Physical Hazard 0, Personal Protection B

NFPA RATING: Special Hazard 0, Health 2, Flammability 0, Reactivity 0

Disclaimer

The information given in this publication has been worked up to the best of the knowledge of Desco Industries Inc, as

well as taking into consideration the applicable laws and regulations. We cannot anticipate all conditions under which this

information and our products or the products of the manufacturers in combination with our products may be used. We accept

no responsibility for the results obtained by the application information or the safety and suitability of our product or product

combination with other products. Users are advised to make their own tests to determine the safety and suitability of each

such product or product combination for their own purposes. Unless otherwise agreed in writing, we sell the products without

warranty, and buyers end users assume responsibility and liability for loss or damage arising from the handling and use of our

products, whether used alone or in combination with other products.

N/A = Not Applicable; NE = None Established

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7042 Page 9 of 9

© 2011 DESCO INDUSTRIES, INC.

Employee Owned

Loading...

Loading...