Page 1

DESCO INDUSTRIES INC. Technical Bulletin TB-7001

Statguard® Conductive Acrylic Paint

Application Instructions

Figure 1. Statguard® Conductive Acrylic paint.

Description

Statguard® Conductive Acrylic Paint is a one part floor coating

formulated to produce controlled dissipation of static electrical

charges. Statguard® Conductive Acrylic Paint is very effective as a

static control floor coating for electronics manufacturing, assembly,

and storage. It is available in grey (similar to PMS 432) in 1 gallon

(3.8 litres) containers and in 5 gallon (19 litres) containers; and in

light grey (similar to PMS 429) in 5 gallon (19 litres) containers.

The color may vary between production lots.

NOTE: Statguard® Conductive Acrylic Paint has a one year shelf

life from the date of invoice. The product should not be allowed to

freeze. Store at temperatures above 45 degrees as stated in the

Material Safety Data Sheet. We recommend that these products

be stored in their original containers and be sealed when not in

use. We cannot guarantee performance if not properly mixed or is

used after one year from date of sale.

General Guidelines

GROUNDING:

Conventional grounding practices like connecting painted surfaces

to ground or internal building grounds are only required for

applications of Statguard® Conductive Acrylic Paint that are not in

excess of 20 square feet (1.8 square metres). For applications that

are greater than 20 square feet (1.8 square metres), grounding

should not be required. The electrical properties of conductive

paint enable the surface to dissipate 5000 volts to zero in less than

0.01 seconds per FTMS 101C, Method 4046 without conventional

grounds. The conductive paint becomes a capacitive reservoir that

effectively drains static charges.

Foot grounders should be used in conjunction with flooring painted

with Statguard® Conductive Acrylic Paint to properly ground

personnel. For more information, please contact any of the Desco

Industries companies.

Made in America

Surface Preparation

The two most important characteristics for successful application

of Statguard® Conductive Acrylic Paint applications are:

1. The surface must be clean, dry, dull, and smooth. Heavy dirt or

grease build-up should be removed with a stripper or degreaser.

Cleaning methods range from: sweeping, vacuuming, wire brush,

air-blasting, water jet, steam cleaning, or stripping.

2. If the surface is concrete, it must be in good condition.

CONCRETE:

New concrete should cure for a minimum of 28 days before

coating with Statguard® Conductive Acrylic Paint. Not all concrete

is created equal -- concrete surfaces vary widely in physical and

chemical qualities due to the way the concrete was formulated,

poured, or finished.

There are several methods to prepare problem concrete. Each

method depends on the condition of the concrete. Adhesion

properties can be increased by profiling or roughing the surface

through acid etching, rotary drum sanding, scarifying, or

mechanically scratching the surface.

You must test for moisture in the concrete. If moisture is present,

the floor should not be coated until the source of the moisture is

determined and eliminated.

PRIMING:

Statguard® Conductive Acrylic Paint bonds well to clean, dry

concrete. However, a standard industrial primer can be used on

certain difficult to bond substrates and enhance the adhesion of

Statguard® Conductive Acrylic Paint.

PREVIOUSLY PAINTED SURFACES:

The surface should be clean and free of dust, grease, wax, and

soap residue. Wash with ordinary detergent and water. Rinse

thoroughly with clean water and let dry. Glossy surfaces can be

dulled by lightly sanding and then vacuuming and cleaning. Cracks

and holes should be repaired before applying the Statguard®

Conductive Acrylic Paint. Adhesion can be improved by using a

standard industrial type primer.

UNPAINTED SURFACES:

Adhesion can be improved by using a standard industrial type

primer. Metal should be primed with red oxide primer. Concrete,

wood, plastics, and most other surfaces should be properly

cleaned. Let dry and then apply Statguard® Conductive Acrylic

Paint.

COVERAGE:

Statguard® Conductive Acrylic Paint will cover 300 to 400 square

feet (27.87 to 37.16 square metres) at a 1 to 1.5 mil (0.0254 to

0.0381 mm) thick dry film per gallon (3.87 litres) on a smooth

surface. Coverage is less on coarse or textured surfaces. Two

coats are recommended to achieve maximum performance from

the paint.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 October 2009 Page 1 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 2

Application

Always use in a well ventilated area or wear

a suitable respirator. Wear appropriate

eye protection such as splash goggles and

impervious type protection gloves to protect

hands.

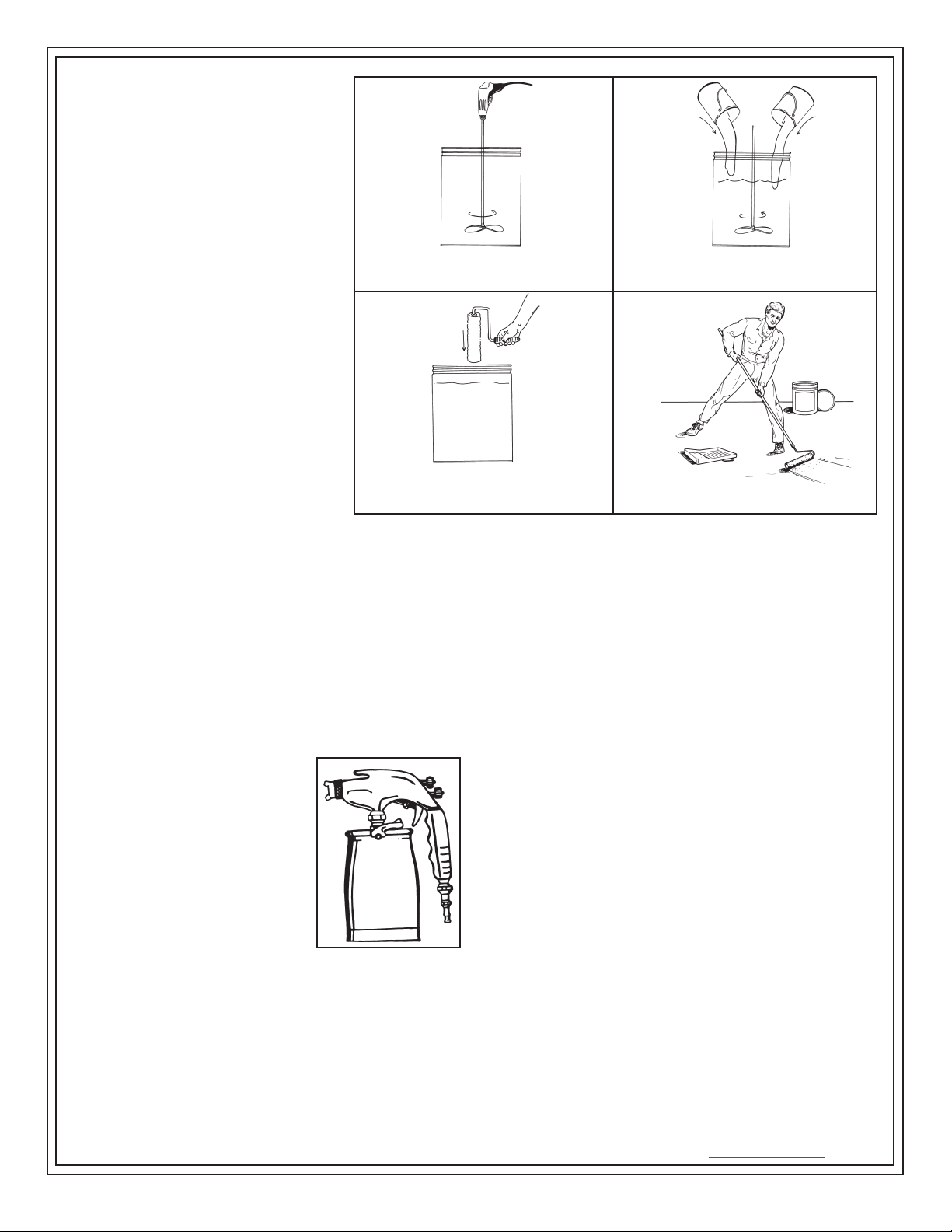

MIXING

1. Mix paint thoroughly before use (See

Figure 2) using a 500-1500 RPM variable

speed drill and paint mixing attachment or a

paint mixer.

2. If the paint, after properly mixing, is not

freely transferring from the roller to the floor,

the Statguard ESD paint can be thinned with

water up to 10% max by volume.

a. Start by slowly mixing 5% water into the

master container and apply again.

b. Do not add more than 10% of water to

the mix.

APPLICATION BY ROLLER

1. Stir paint thoroughly to mix any

settled solids to produce uniform grey

color.

1.

Mix any settled solids to produce a

uniform grey color.

3.

Saturate a 1/4” fine nap roller with paint,

remove excess paint and trapped air.

Figure 2. Paint application with roller.

2. Combine separate cans of paint into

one container to ensure uniform color distribution. It is

recommended that a

test area be coated to ensure that the adhesion and electrical

performance

of the paint is acceptable. (See Adhesion Testing, Figure 5.) If the

test areas show inadequate adhesion, use an industrial

floor primer/sealer.

3. Saturate a 1/4” (6.35 mm) fine nap roller or an industrial brush

with paint. Remove

excess paint and trapped air from the applicator by moving

applicator several times in the paint tray.

4. A minimum number of strokes from

the applicator on the substrate is

recommended to minimize air bubbles.

2.

Combine separate cans into a larger

container.

4.

A minimum number of strokes from the

applicator is recommended.

Clean Up

Wash applicators with water immediately after painting. Remove

paint spills promptly with a wet cloth. Close container after each

use. Keep container from freezing.

Drying Time

It is recommended that Statguard® Conductive Acrylic Paint be

allowed to dry at a temperature in excess of 45°F (7°C) until dry.

A minimum of 1 to 2 hours drying time should be allowed before

applying the second coat. The finish can be applied after 48-72

hours or until the last coat of paint is cured. Wait a minimum of 12

hours drying time after the last coat before allowing light traffic on

the coated area. At high humidity levels, a longer drying time may

be necessary. Do not force dry.

APPLICATION BY SPRAY

Conventional Spray Gun: “E” fluid tip

and needle and #704, 765 or 78 air

gap.

Airless Spray: Spray gun and spray

cap or suitable orifice diameter

0.020-0.025” (0.508-0.635 mm).

Mix paint thoroughly before using

and stir occasionaly when applying.

No thinning necessary for spray

applications. Room tempera ture must be above 50°F (10°C).

A minimum of two coats of Statguard® Conductive Acrylic Paint is

recommended for appropriate static protection.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 2 of 7

Figure 3. Spray paint

application

Maintenance

Use sweeper, vacuum, or broom to remove dirt. Allow two weeks

drying time before using a damp mop to clean the coated area.

Do not use abrasive cleaners, floor rinse, or scrubbing machine to

clean the floor.

Finish/Sealer

Desco Statguard® Conductive Acrylic Paint can be overcoated or

sealed with Statguard® Floor Finish static dissipative coating to

increase durability, enhance shine, improve ease of maintenance,

and seal out dirt and debris. Desco Statguard® Conductive Light

Grey Acrylic Paint needs the Statguard® Floor Finish for gloss

and ease of maintenance . Statguard® is a polymer base floor

finish/sealer that can be used as a top coat on the Conductive

Acrylic Paint. Surface resistivity will then be in the 106-107

ohms range. Two coats are recommended. Three coats will

improve electrical properties, durability and reduce frequency of

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 3

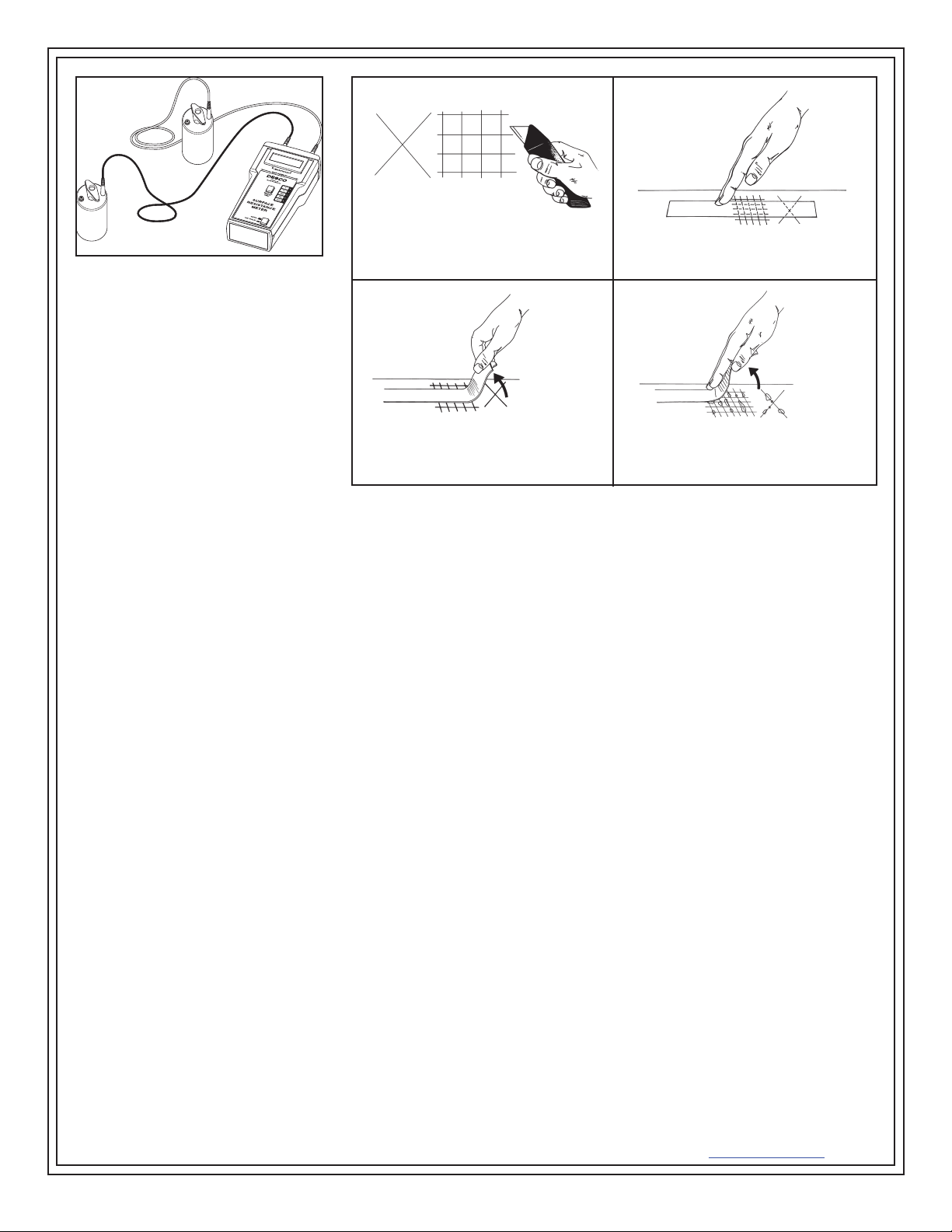

1.

2.

Use a razor to cut into a painted, dried

Figure 4. Electrical testing on

floor.

the painted floor using a Surface

Resistance Test Kit.

maintenance. Apply Statguard® Floor Finish

after 48-72 hours after last coat of paint. Paint

becomes dry to the touch, but is not fully cured

to accept a finish coat until this time. If you

notice the paint color coming off when finishing,

it is too soon to apply. Please wait for the

paint to cure fully. Ask for Technical Bulletin

TB-2088 for more information on Statguard®

Floor Finish.

Physical Properties

Type:

Water base acrylic coating

Color:

Grey, Light Grey

Vehicle Type:

Pure acrylic resin waterborne

Pigment Type:

Lead free, iron oxide, titanium dioxide and extenders

Viscosity:

Light Grey 26” #3 Zahn cup

Grey 23” #3 Zahn cup

Solids:

Light Grey 24% by volume

Grey 20% by volume

Coating Density:

Light Grey 9.54 lbs per gallon

Grey 10.27 lbs per gallon (1.0 kilograms per

litre)

Gloss:

Light Grey 2 @ 60°F

Grey 22 @ 60°F (30 @ 60°C)

Temperature Range:

Wet: 33°F - 110°F (1°C - 43°C)

Dry: 33°F - 300°F (1°C - 149°C)

(300°F [149°C] not continuous)

3.

Pull the tape off.

Figure 5. Adhesion test on the painted floor.

Electrical Properties

Surface Resistivity:

Apply tape on the precut area.

4.

Examine the degree of paint separation

from the concrete.

105 ohms/sq. per ASTM D257

Static Charge Decay:

<0.01 sec. per FTMS 101B, Method 4046

Charge Generation:

Zero per AATCC Step Test, Method 134-1979

RTT:

105 ohms per ANSI ESD-S7.1

RTG:

105 ohms per ANSI ESD-S7.1

Testing

Representative areas should be tested for adhesion and electrical

performance of the paint before applying paint to the entire floor. To

best ensure consistent results, the test should be done at various

locations.

ELECTRICAL PROPERTIES:

Test the surface resistivity, point-to-point resistance, and resistanceto-ground properties of coated area per ANSI ESD-S7.1 test method.

For quick and easy verification of the paint’s electrical properties,

we recommend the use of our a Surface Resistance Test Kit (Figure

4). For more information contact any of the Desco Industries Inc.

companies.

ADHESION:

Allow newly applied paint to dry a minimum of 48 hours before

proceeding with the test. At humidity levels over 55% RH, allow 72

hours of drying time before testing. Use a razor to cut a cross or a few

perpendicular lines over a 3” by 3” (75 mm by 75 mm) area on several

spots of the thoroughly dried area. Use a piece of masking tape to

cover the marked area. Make sure the tape is thoroughly adhered to

the test area. Pull the tape off the surface and examine the amount

of paint which has peeled off during the test. If any significant portion

is transferred to the tape, better surface preparation (acid etching,

cleaning or sanding) should be done on the substrate to enhance the

adhesion.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 3 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 4

RoHS Compliance Statement

None of the following materials are intentionally added in

manufacturing this product: lead, mercury, cadmium, hexavalent

chromium, polybrominated biphenyls (PBB) or polybrominated diphenyl

ethers (PBDE) as outlined in the Directive 2002/95/EC Article 4.1. See

Desco Industries Inc. letter on-line at

DescoIndustries.com.

Limited Warranty

Desco Industries Inc. expressly warrants that for a period

of one (1) year from the date of purchase, our Statguard®

Conductive Acrylic Paint will be free of defects in material.

Within the warranty period, the material will be replaced at our

option, free of charge. Call our Customer Service Department

at 781-821-8370 or 00 44 (0) 1892-665313 in Europe for a

Return Material Authorization (RMA) and proper shipping

instructions and address. You should include a copy of your

original packing slip, invoice, or other proof of purchase date.

Any material under warranty should be shipped prepaid to the

Desco Industries Inc. factory. Warranty replacements will take

approximately two weeks.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU

OF ALL OTHER PRODUCT WARRANTIES, EXPRESSED

AND IMPLIED, INCLUDING MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH ARE

SPECIFICALLY DISCLAIMED. The express warranty will not

apply to defects or damage due to accidents, neglect, misuse,

alterations, operator error, or failure to properly maintain, clean

or repair products.

Limit of Liability

In no event will Desco Industries Inc. or any seller be

responsible or liable for any injury, loss or damage, direct or

consequential, arising out of the use of or the inability to use

the product. Before using, users shall determine the suitability

of the product for their intended use, and users assume all risk

and liability whatsoever in connection therewith.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 4 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 5

Material Safety Data Sheet

Material Safety Data Sheet maybe used to comply with

EC, according to 91/155EC and ANSI Standard Z400.1-1998

Date: June 1, 2008

NFPA Designation 704

Degree of Hazard

4 = Extreme 1 = Slight

3 = High 0 = Insignificant

2 = Moderate

Special Hazard

Health

(Blue)

STATGUARD® Conductive Acrylic Paint

1. IDENTIFICATION OF THE PRODUCT and OF THE ENTERPRISE

Chemical name: Paint, Conductive

Manufacturer: Desco Industries Inc. Emergency Phone: (781) 821-8370

One Colgate Way Fax: (781) 575-0172

Canton, MA 02021

U.S.A.

2. INFORMATION ON INGREDIENTS/COMPOSITION

Ingredients Weight CAS-No. TLV-value R-Phrases

Ethylene Glycol Monobutyl Ether* 2.5-10% 111-76-2 25 ppm R20/21/22-36/38

n-butanol* 0-2.5% 71-36-3 50 ppm R10-22-37/38-41-67

Mineral Spirits 0-2% 64741-41-9 100 ppm

2-(2-Butoxyethoxy)ethanol 0-1% 112-34-5 NE R36

2-ethyl-1-Hexanol 0-1% 104-76-7 NE

Ammonium Hydroxide 0-1% 1336-21-6 50 ppm R34, R50

*Listed Chemical Subject To Reporting Requirement of SARA Section 313 of Title III

HMIS Rating Health 1 Reactivity 0

Flammability 0 Personal Protection B

Flammability

(Red)

1

1

0

Reactivity

0

(Yellow)

3. HAZARDS IDENTIFICATION

Hazard description: Not applicable

Information concerning particular hazards for human and environment:

The product does not have to be labeled due to the calculation procedure of the “General Classification guidelines for preparations of the

EU” in the latest valid version.

4. FIRST AID MEASURES

General information: No special measures required.

Eye Contact Flush with water for at least 15 minutes, Consult a Doctor.

Skin Contact Generally the product does not irritate the skin. Wash with soap and water. Remove contaminated

clothing. Consult a physician if any irritation persists.

Ingestion Induce vomiting, drink 2 glasses of water. Contact a physician.

Inhalation Move subject to fresh air. Consult a Doctor in case of complaints.

5. EXTINGUISHING MEASURES

Proper Extinguishing Media The National Fire Protection (NFPA) classifies ingredient liquids to be Class B fires. Therefore, any

approved Fire Extinguisher of extinguishing agent may be used for fighting purpose, e.g. CO2, dry

chemical and foam.

Protective Clothing Wearing of appropriate protective equipment including self-contained breathing apparatus should be

used.

Special Procedures Water spray may be ineffective. If water is used, fog nozzles are preferable. Water may be used to

cool closed containers to prevent pressure build-up, and possible auto ignition or explosion when

exposed to extreme heat.

6. MEASURES TO EXPOSURE OF PRODUCT

Personal Precautions Wearing protective clothing. Inhalation protection. Extinguish all ignition sources.

Environmental Precautions Dilute with plenty of water, do not allow entry to sewers or ground water

Cleaning / Collecting Procedures Dike and absorb with liquid binding material (sand, diatomite, sawdust)

7. HANDLING AND STORAGE

Handling Use in well-ventilated areas; avoid breathing vapors. Keep containers closed when not in use. Avoid

from freezing.

Storage Storage Temperature: Max. 49°C/120°F-1°C/34°F

Keep from freezing

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 5 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 6

8. EXPOSURE CONTROL/PERSONAL EXPOSURE

Control Parameters TLV-value 50 ppm maximum for n-butanol and 25 ppm for Ethylene Glycol Monobutyl Ether

Other Regulations None

Measures For Technical Control Preferences of technical measure to prevent or control contact with the product. Isolating process

and personnel, mechanical ventilation (dilution and local exhaust) and the regulation of process

conditions. In case of non- prevention or non-control, a proper protective wearing should be used.

Respiratory Protection Not required. Wear MSHA/NIOSH approved respirator where exposure limits are exceeded

Hand Protection Impervious/Neoprene Gloves

Eye Protection Chemical Splash Goggles (ANSI Z-87.1)

Work/Hygienic Practices Wash hands before eating, smoking, or using washroom facilities

9. PHYSICAL AND CHEMICAL PROPERTIES

Form Fluid

Color Grey, Opaque

Smell Mild

pH 8.5

Boiling Point at °C >100-101°C (212-214°F)

Freezing Point at °C 0.0°C (32.0 °F)

Flash Point at °C 65 °C

Explosive Limits LEL: 0.8 UEL: 25.0

Inflammability Limits N/A(vol.% in air)

Solubility in water Complete

VOC per method 24 of EPA 2.3 -2.5 lbs VOC/ gal

Vapor Pressure (mmHg) 92.43 mm @ 20 °C

Vapor Density (air=1) Heavier than air

Density at 20°C 8.17 lbs./gal or 1.14 g/cm3

Specific Gravity (H20=1) 1.21

Inflammability Classification according to OSHA and EC-regulations “non-flammable”

Ignition Temperature 240.0 °C

Evaporation Rate Slower than n-butyl acetate

% Volatile by Volume 13.229%

10. STABILITY AND REACTIVITY

Stability/Reactivity Stable product at normal conditions

Conditions to avoid Temperatures above 49°C/120°F and below 1°C/34°F, Open flames and sparks.

Materials to avoid Strong Oxidizing agents and alkalies.

Hazardous Decomposition Oxides of carbon and nitrogen. If involved in fire (from other sources) could conceivably result in

release of Carbon Dioxide and Carbon Monoxide fumes.

11. TOXICOLOGICAL INFORMATION

Ingredient-Material Description PEL TLV (twa) LD50 (mg/kg) LC50 (ppm)

mg/m3 ppm (rat) (rbt) (rat)

oral dermal inhal

Ethylene Glycol Monobutyl Ether * 50.0 0.0 25.0 470.0 220.0 0.0

Butanol* 50.0 0.0 50.0 0.0 0.0 0.0

Mineral Spirits 100.00 0.0 100.0 0.0 0.0 0.0

2-(2-Butoxyethoxy)ethanol 0.0 0.0 0.0 6560.0 4120.0 0.0

2-ethyl-1-Hexanol 0.0 0.0 0.0 3730 1970 0.0

Ammonium Hydroxide 0.0 35.0 50.0 350.0 0.0 0.0

*Listed Chemical Subject To Reporting Requirement of SARA Section 313 of Title III

• Acute toxicity

• Primary irritant effect:

• On the skin: No irritant effect

• On the eye: No irritant effect

• Sensatization: No sensitizing effects known

• Additional toxicological information:

The product in not classified according to the calculation method of the General EU Classification guideline for Preparations as issued in the

latest version. When used and handled according to specifications, the product does not have any harmful effects to our experience and the

information provided to us.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 6 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 7

12. ECOLOGICAL INFORMATION

General Notes:

Water hazard class 1 (German Regulations) (self-assessment): slightly hazardous for water. Do not allow undiluted product or large

quantities of it to reach ground water, water course or sewage system.

Mobility The product is aqueous and will be separated in aqueous conditions

Degradability N/A

Bioaccumulation Not likely

Ecotoxicity None known

Reference to BimSchV N/A

13. DISPOSAL CONSIDERATIONS

Product Dike and collect material into plastic container. Water rinse and drain, flush small amounts. Use

sanitary landfill disposal. Follow state and local regulations

(RCRA; Subtitle D).

Hazardous Waste Number Nonregulated

14. TRANSPORT INFORMATION

This product is not classified for transport under ADR/IMDG regulations.

15. REGULATORY INFORMATION

Labeling according To EU guideline: Observe the general safety regulations when handeling chemicals. The product is not subject to

identification regulations under EU Directives and the Ordinance on Hazardous Materials (Genman GefStoffV).

National Regualtions:

Waterhazard class: Water hazard class 1 (Self-assessment): slightly hazard for water

Physical/Chemical Indication Non-flammable

Safety Phrase (S2): keep away from children, (S7): keep containers well closed, (S24/25): avoid contact with skin

and eyes, (S45): in case of accident or if you feel unwell, seek medical advice immediately, show

label where possible, (S53): avoid exposure obtain special instruction before use, (S62): if

swallowed, do not induce vomiting; seek medical advice immediately and show this container or

label.

EU Classification This product does not have to be classified according to the EU Regulations.

(67/548/EEC-88/379/EEC)

EINECS Status All components are included in the EINECS Inventories except cas #104-76-7

TSCA All ingredients of this product are listed or are excluded from the listing on the U.S. Toxic Substance

Control Act (TSCA) Chemical Substance inventory.

16. OTHER INFORMATION

Further Information None Known

Disclaimer

The information given in this publication has been worked up to the best of the knowledge of Desco Industries Inc, as well as taking into

consideration the applicable laws and regulations. We cannot anticipate all conditions under which this information and our products or the

products of the manufacturers in combination with our products may be used. We accept no responsibility for the results obtained by the

application information or the safety and suitability of our product or product combination with other products. Users are advised to make

their own tests to determine the safety and suitability of each such product or product combination for their own purposes. Unless otherwise

agreed in writing, we sell the products without warranty, and buyers end users assume responsibility and liability for loss or damage arising

from the handling and use of our products, whether used alone or in combination with other products.

DESCO INDUSTRIES INC. • 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449 • Web Site: DescoIndustries.com

TB-7001 Page 7 of 7

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Loading...

Loading...