Page 1

TB-6110 January 2009 Page 1 of 3

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

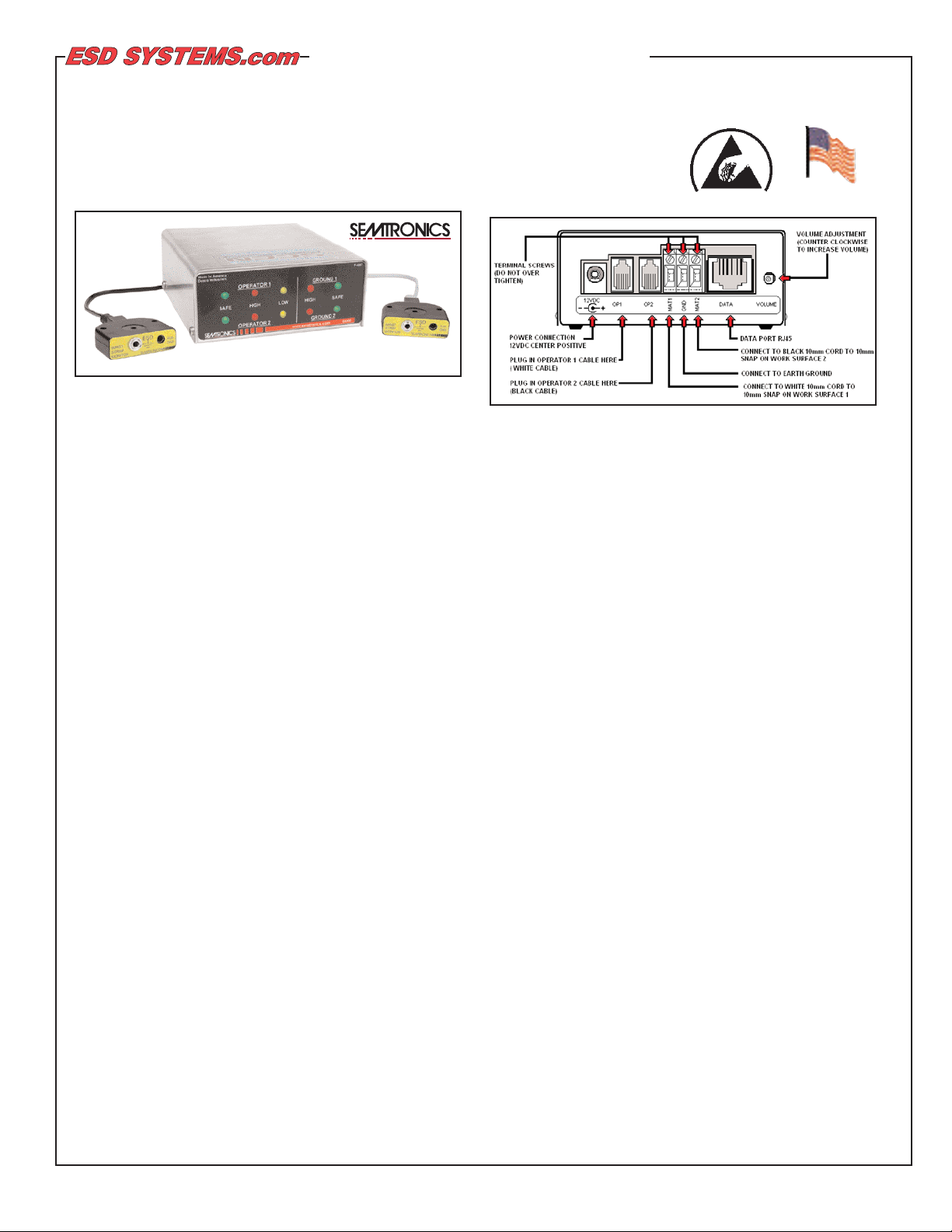

Figure 1. Dual-Wire Dual-Operator Programmable Monitor

Description

Continuous monitors pay for themselves, by improving quality,

productivity, and eliminating daily wrist strap testing and test

result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of

Functional Testing, “The wrist strap system should be tested

daily to ensure proper electrical value. Daily testing may be

omitted if constant monitoring is used.”

Per ESD Handbook TR20.20 paragraph 5.3.2.4.4, “Typical test

programs recommend that wrist straps that are used daily

should be tested daily. However, if the products that are being

produced are of such value that knowledge of a continuous,

reliable ground is needed, and then continuous monitoring

should be considered or even required.”

The Semtronics 62030 Dual-Wire Dual-Operator

Programmable Monitor can maintain two work surfaces and

two operators at ground potential to virtually eliminate the risk

of ESD damage. The highly visible LED display and audible

alarm makes it easy to monitor the status of the work surfaces

and operators. The 62030 Dual-Wire Dual-Operator

Programmable Monitor uses Semtronics patented* dual

resistive loop technology. No other method is as direct and

reliable. Both work surfaces, and individual operator resistance

limits, can be programmed and re-configured as required. If the

ground potential of either work surface or operator is lost the

62030 immediately alarms (both audible and visual). The

62030 is unaffected by capacitance variations associated with

personnel and environmental conditions.

The 62030 Dual-Wire Dual-Operator Programmable Monitor

features:

• Monitoring of two operators independently.

• Monitoring of two ground connections (work surfaces)

independently.

• Fully independent alarming conditions: audible and visual.

• Independent LED status lights for each operator and each

ground connection (work surface.)

• Two independent operator wrist strap ground point remotes

with 10’ cables.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Figure 2. 62030 Rear View

Installation

Remove the monitor from its packaging and inspect for any

shipping damage. Included with each 62030 Dual-Wire DualOperator Programmable Monitor should be:

1 Monitor 1 Hardware Kit (62012)

1 White Operator Remote 3 Grounding Wires (SE-5136)

1 Black Operator Remote 1 Mat Ground Cord (Grey)

1 AC Adapter 1 Mat Ground Cord (Black)

4 Push Clinch Snaps

A. Determine the mounting location of the 62030 monitor. The

front panel should be visible to a supervisor.

B. Determine the mounting location of the operator remotes.

The white remote is for operator #1 and the black remote is for

operator #2. Make sure that each remote is located so that the

remote leads reach the monitor but are convenient for the

operator.

C. Attach the operator remotes to the bench or other surface

using the provided screws.

D. Attach the tinned wire ends of the mat wires to the

appropriate screw terminal connection on the rear of the unit.

(See Figure 2). The white wire is for operator #1 and the black

wire is for operator #2.

E. If not already done, attach the work surface to workstation

common point ground using the pictured ground wires. For

mats, attach the grounding point snaps at the ends of the

ground monitor cords to the grounding point snaps on the work

surface. These ground monitor cords are used for sensing

whether or not the unit is properly grounded. Refer to figure 3

for snap-plate fitting diagram and for laminates or other hard

surfaces with a buried conductive layer.

F. Attach the tinned wire end of the black ground-reference

wire to the center position of the screw terminal block on the

rear of the unit. Attach the ring terminal end to an alternate

ground point. It is important that this ground wire is attached to

a separate ground point other than the work surface ground

*U.S. Patents 6,052,053 and 6,205,408

Tech Brief

Dual-Wire Dual-Operator Programmable Monitor

Installation, Operation, and Maintenance

Made in America

TECHNICAL BULLETIN TB-6110

Page 2

cords from the previous step to ensure proper independent

monitoring. The faceplate screw of a grounded AC wall outlet

may provide a convenient connection point.

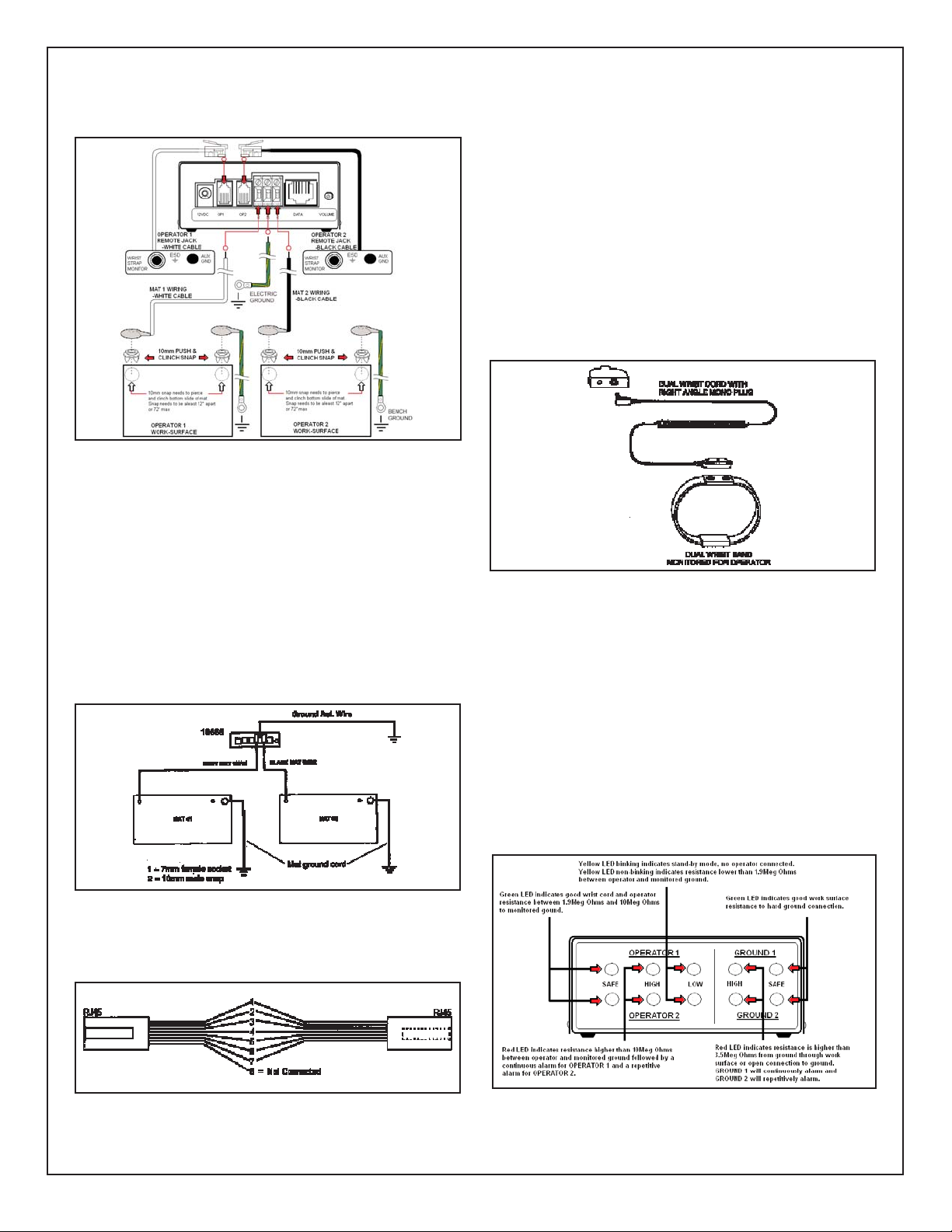

Figure 3. Mat Grounding

G. Route the work surface monitor wires from the back of the

monitor unit, to the snaps/bolts attached to the grounded

surfaces. Attach the white ground wire to the operator #1 work

surface and the black ground wire to the operator #2 work

surface.

H. Route the operator remote wires to the monitoring unit and

insert the modular plugs into the appropriate jacks on the rear

of the unit. (See Figure 2)

Mat Grounding

It is recommended to connect the mat wire (10mm snap) from

the monitor and the mat ground wire (10mm snap) to two

separate points on the bench mat as in Figure 4.

Figure 4. Mat Grounding

I. If using a TR2000 SmartHub along with the 62030, construct

a data output cable. Refer to Figure 5.

Figure 5. Data Cable

TB-6110 Page 2 of 3

J. Plug the DC power supply plug into the power jack in the

rear of the unit. Route the wire from the supply to a nearby

AC outlet and plug the power supply into the outlet. Make sure

the voltage and frequency match those listed on the AC

adapter. The monitor should now be powered.

Operation

Wrist Strap Connections

Once all the connections described above have been made

and the unit has been powered up, the unit is ready for operation. Install operator wrist straps and ground wires. Dual

snaps on the operator ground wires attach to the wristband

snaps and the mono plug on the other end inserts into the

operator remote as illustrated in Figure 6. The operator's

monitoring is in "STANDBY" mode until the operator's ground

wire is plugged into the remote jack for that station.

Figure 6. Operator Ground Cords and Wrist Snaps

NOTE: The operator remote has two jacks. One is a 3.5 mm

mono jack for use with a dual wrist strap. Adual operator

ground wire plugged into this jack will be monitored. The other

jack is a grounded banana jack for use with a single conductor

operator ground wire. This is a grounded guest hook-up that is

not monitored.

Status Indicators

The audible alarm for Operator 1 and Ground 1 is continuous.

The audible alarm for Operator 2 and Ground 2 is a repetitive

beep. If a fault condition exists for both operators and/or both

grounds, the alarm will sound continuously. The alarm volume

may be adjusted with the potentiometer on the rear of the unit.

Refer to Figure 7.

Figure 7. Status Indicator

© 2009 DESCO INDUSTRIES INC.

Employee Owned

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

Page 3

TB-6110 Page 3 of 3

© 2009 DESCO INDUSTRIES INC.

Employee Owned

The 62030 provide status indicators for the following

conditions:

• Standby - The operator is not plugged into the remote. This

condition is indicated by a flashing yellow LED in the operator

section of the display.

• Operator Fail High - The operator's series resistance is

greater than the upper resistance limit. This condition is

indicated by the red LED in the Operator section of the

display along with an audible alarm

• Operator Fail Low - The operator's series resistance is less

than 1.9Meg Ohm. This condition is indicated by the flashing

yellow LED in the Operator section of the display.

• Operator Pass/Safe - The operator's series resistance is

within the range of 1.9Meg Ohm to the upper resistance limit.

This condition is indicated by the green LED in the Operator

section of the display.

• Ground Fail High - The resistance from the mat connection

to ground is greater than 3.5Meg Ohm. This condition is

indicated by the red LED in the Ground section of the display

as well as an audible alarm.

• Ground Pass Safe - The resistance from the mat

connection to ground is less than 3.5Meg Ohm. This

condition is indicated by the green LED in the Ground section

of the display.

The resistance values quoted above are the Factory Defaults.

These numbers will vary depending on the configuration.

Changing the Test Voltage

The 62030 can be set for a test voltage of either +5V or +8V.

Reducing the test voltage will result in a lower finger-tip

voltage on the operator. To change the test voltage you must

set two jumpers inside the unit.

Remove the four case screws and open the 6110 case. BE

SURE TO OBSERVE ESD PRECAUTIONS, AS THERE ARE

ESD SENSITIVE DEVICES INSIDE THE CASE. Refer to

Figure 8 for setting the test voltage to +5V and +8V.

Specifications

• Two user selectable resistance levels of 10 Meg ohms or

35 Meg ohms.

• Two user selectable test voltage settings of +5V or +8V.

• SCCN compatible data output.

• Stainless Steel housing.

• Size: 4.3" W x 4.4" D x 1.8" H

• Plug-in power supply: 110 VAC/60Hz input, 12VDC/500mA

output or 230VAC/50Hz input, 12VDC/500mA output.

2.5mm connector - center positive. Any alternate

transformer must comply with the Safety Extra Low Voltage

(SELV) insulation requirements.

• Important: This appliance has a metal casing but the earth

connection is only used for operational purposes. It is

considered to be class I and tested as class II. The power

supply connection plug is accessible to the user and there

is no safety insulation inside the Semtronics Item #62030.

Therefore the insulation of the power supply is critical.

• Rated Power consumption: 3.6VA.

Figure 8. Jumper Setting for various test voltages

Environmental Conditions

• Suitable for indoor use only at altitudes not exceeding

6500ft. (2Km)

• Maximum relative humidity of 80% up to 88°F (31°C)

decreasing linearly to 50% @104°F (40°C)

• Pollution degree 2 per IEC 644

• Temperature range of 41°F (5°C) to 104°F (40°C)

Limited Warranty

ESD Systems.com expressly warrants that for a period of one (1) year from the date

of purchase, Semtronics Dual-Operator Programmable Monitor will be free of

defects in material (parts) and workmanship (labor). Within the warranty period, the

product will be tested, repaired, or replaced at our option, free of charge. Call our

Customer Service Department at

508-485-7390

(Marlboro, MA) for a Return

Material Authorization (RMA) and proper shipping instructions and address. Include

a copy of your original packing slip, invoice, or other proof of purchase date. Any

unit under warranty should be shipped prepaid to the ESD Systems.com factory.

Warranty repairs will take approximately two weeks.

If your unit is out of warranty, call Customer Service at

508-485-7390 (Marlboro,

MA)

for a Return Material Authorization (RMA) and proper shipping instructions

and address. ESD Systems.com will quote repair charges necessary to bring your

unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF ALL OTHER

PRODUCT WARRANTIES, EXPRESSED AND IMPLIED, INCLUDING

MERCHANTABILITYAND FITNESS FOR A PARTICULAR PURPOSE WHICH

ARE SPECIFICALLY DISCLAIMED. The express warranty will not apply to defects

or damage due to accidents, neglect, misuse, alterations, operator error, or failure

to properly maintain, clean or repair products.

Limit of Liability

In no event will ESD Systems.com or any seller be responsible or liable for any

injury, loss or damage, direct or consequential, arising out of the use of or the

inability to use the product. Before using, users shall determine the suitability of

the product for their intended use, and users assume all risk and liability

whatsoever in connection therewith.

Dip Swi t ches

Function Down Up

Switch 1 Input Vol tage 8v 5v

Switch 2 5v 8v

Switch 3

W rist Strap

High limit

35m 10m

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

Loading...

Loading...