Page 1

TB-6106 January 2009 Page 1 of 4

Footwear Tester Installation,

Operation and Maintenance

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

Description

The Semtronics 62090 Footwear Tester is a 3-state touch

tester designed for fast and frequent testing of ESD

personnel footwear. The 62090 tester can be used to verify

that the ESD footwear resistance circuit is within the proper

limits. It can be setup to test a 1M - 100M circuit (foot

grounders) or a 1M - 1G circuit (dissipative shoes).

This unit can be used as one of the tools to fulfill the ANSI

ESD S20.20 paragraph 6.1.3.2 Compliance Verification

Plan. "Verification should include routine checks of the

Technical Requirements of the Plan." The Footwear Tester

incorporates a unique dual test circuit design which

improves test accuracy.

ESD TR1.0-01-01 section 1.0 Introduction

"Since people are one of the greatest sources of static

electricity and ESD, proper grounding is paramount. One of

the most common ways to ground people is with a wrist

strap. Ensuring that wrist straps are functional and are

connected to people and ground is a continuous task."

ESD SP9.2 APPENDIX B - Foot Grounder Usage Guidance

"Compliance verification should be performed prior to each

use (daily, shift change, etc.). The accumulation of

insulative materials may increase the foot grounder system

resistance. If foot grounders are worn outside the ESD

protected area testing for functionality before reentry to the

ESD protected area should be considered."

OPERATION

NOTE: Refer to the technical manual for your footgrounding devices. Not all foot-grounding devices are

similar and it is very important that you review their

specifications.

INSTRUCTIONS MANUAL TB-6106

Made in America

© 2009 DESCO INDUSTRIES INC.

Employee Owned

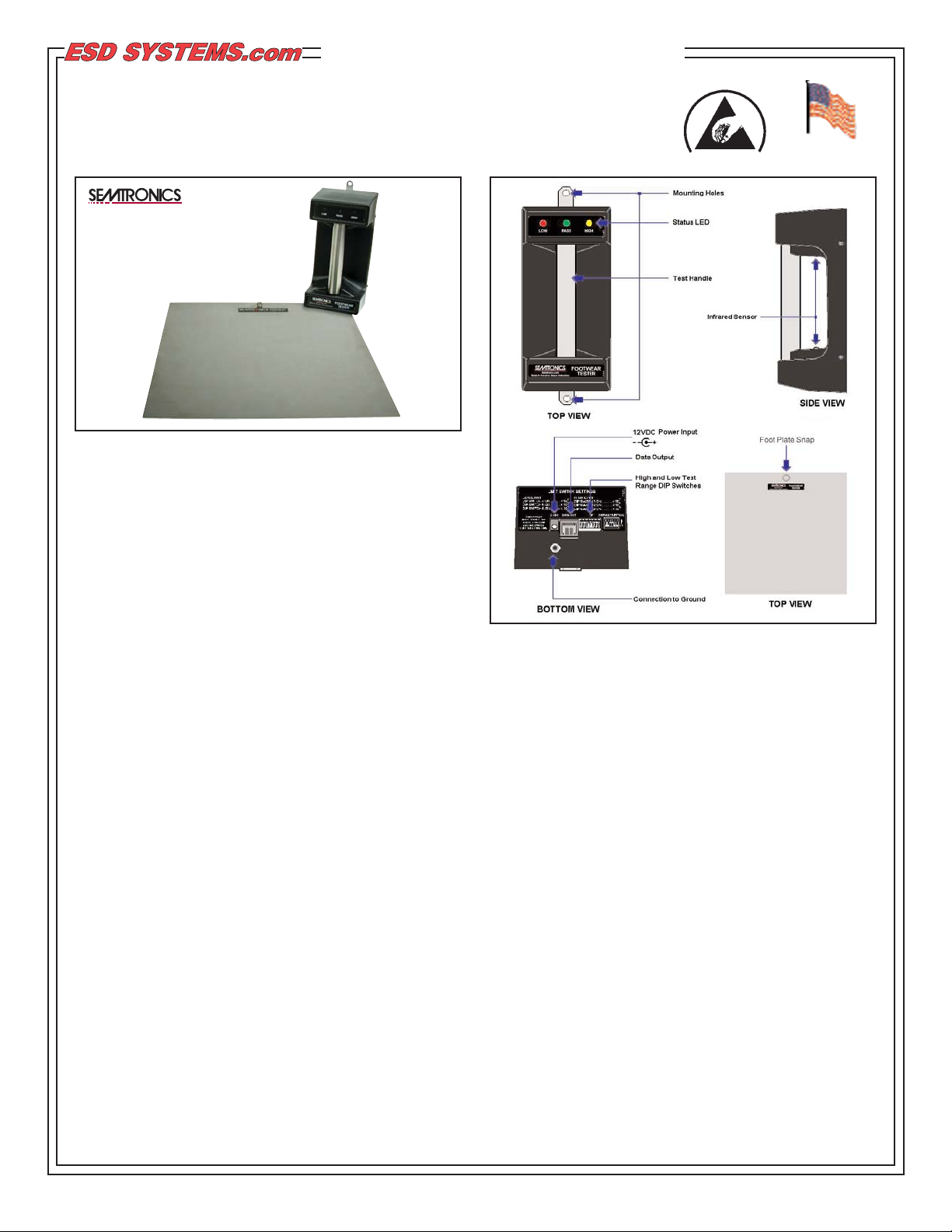

Figure 1. 62090 Footwear Tester

Figure 2. Footwear Tester and Foot Plate Features and

Components

Packaging

1 Footwear Tester

1 Foot Plate

1 12 VDC Power Adapter (500 mApositive center)

1 Banana Plug to Ring Terminal Cord

1 Snap to Ring Terminal Cord

1 NIST Certificate of Calibration

Installation

Mounting the Tester

• Verify that the correct low and high test limits are

correctly set before mounting the tester to a wall.

Refer to the overlay located on the bottom of the tester.

(See table on Page 4 for more details)

• Be sure to install the Footwear Tester and foot plate

away from any high voltage power supplies, power

boxes, chemicals, and other safety hazards.

• Place in a convenient area where waiting lines may

be allowed to form.

• Mount the tester in the upright position (See Figure 2)

approximately 4 feet above floor level.

• Place the foot plate directly below the Footwear

tester.

Page 2

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

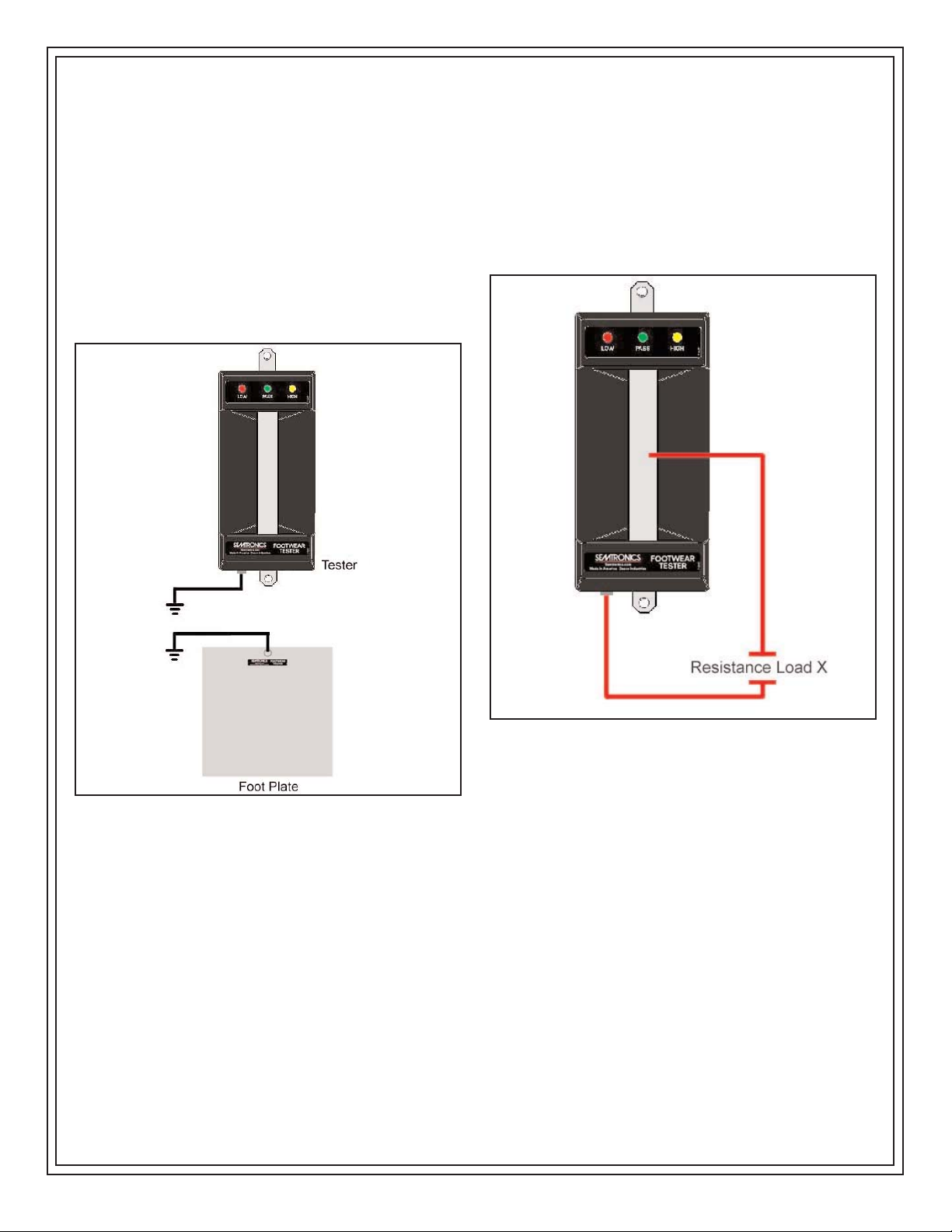

Connecting the Footwear Tester and Foot Plate

I. Using the banana plug to ring terminal cord, connect

the banana plug to the banana jack on the bottom side

of the tester and the ring terminal to a known ground.

II. Using the snap to ring terminal cord, snap the cord

to the foot plate and the ring terminal to a known

ground.

III. After all connections have been made, insert the

female plug of the power adapter to the bottom of the

tester.

IV. Plug the power adapter into an appropriate power

source. The yellow "HIGH" LED will turn on indicating

standby mode.

Calibration

ESD Handbook TR 20.20 paragraph 5.2.3 "If the

contact area between the bottom of the foot and the

floor is not continuous, charge generation may occur

especially when a person is walking. Heel straps must

be worn on both feet to minimize the amount of time

that the body of the person is isolated from ground

while walking."

Note: Consider Semtronics Continuous Monitors

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4

"Typical test programs recommend that wrist straps

that are used daily should be tested daily. However, if

the products that are being produced are of such value

that knowledge of a continuous, reliable ground is

needed, and then continuous monitoring should be

considered or even required."

TB-6106 Page 2 of 4

It is recommended that calibration of this unit be

handled by a qualified technician. There are no user

adjustable potentiometers, but there are DIP switches

to adjust the ranges.

The Footwear Tester can be calibrated by using a 1k 2G range decade box to load a resistance across the

stainless steel handle and the banana jack located on

the bottom of the tester. Resistance Load X from the

decade box is the value that will be indicated as a Fail

LOW, Fail HIGH, or PASS.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Figure 3. Connecting the Footwear Tester and Foot Plate

Figure 4. Applying a Load Resistance to the Footwear Tester

Page 3

Operation

NOTE: Refer to the technical manual for your foot-grounding devices. Not all foot-grounding devices are similar and it is

very important that you review their specifications.

The tester measures the total resistance between both of the grounding devices (heel ground, dissipative shoes, etc). With

the grounding devices properly attached to the operator's feet, the operator should then place one foot on the foot plate and

grab the stainless steel handle. The tester will react in one of the following ways:

Green PASS LED The total resistance is within the limit settings

Yellow Fail HIGH LED + Audible Alarm The total resistance is above the high limit setting

Red Fail LOW LED + Audible Alarm The total resistance is below the low limit setting

If the test results are questionable remove both feet from the foot plate and wait 8 seconds before testing again.

The test limits can be adjusted by manipulating the DIP switches located at the bottom of the tester (See table on Page 4 for

more details).

Be sure to periodically clean the foot plate to ensure accurate testing.

Specifications

Test Ranges and Limits Table

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

TB-6106 Page 3 of 4

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Dimensions

Figure 4. Footwear Tester and Foot Plate Dimensions

Weight

Tester: 0.9 lbs / 0.41 kg

Foot Plate: 1.9 lbs / 0.86 kg

Page 4

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2009 DESCO INDUSTRIES INC.

Employee Owned

TB-6106 Page 4 of 4

Troubleshooting

1. Periodically clean the stainless steel foot plate

2. Check all cords for proper connections

NOTE:

The Yellow Fail HIGH LED will remain on when the unit

is not being used (standby mode).

No Alarm will sound until the stainless steel handle is

grabbed.

Contact and Warranty

ESD Systems

432 Northboro Road Central

Marlboro, MA 01752

Tel: (508) 485-7390

Fax: (508) 480-0257

NOTE: Unauthorized servicing or modifications to

your monitor will void the product warranty and may

create dangerous conditions. Servicing should be

performed only at the factory, or by a Semtronics

approved technician.

LIMITED WARRANTY

ESD Systems expressly warrants that for a period of

one (1) year from the date of purchase, the ESD

Systems Footwear Tester will be free of defects in

material (parts) and workmanship (labor). Within the

warranty period, a unit will be tested, repaired, or

replaced at our option, free of charge. Call Customer

Service at 909-627-8178 (Chino, CA) or 781-821-8370

(Canton, MA) for Return Material Authorization (RMA)

and proper shipping instructions and address. Include

a copy of your original packing slip, invoice, or other

proof of date of purchase. Any unit under warranty

should be shipped prepaid to the Semtronics factory.

Warranty replacements will take approximately two

weeks. If your unit is out of warranty, ESD Systems

will quote repair charges necessary to bring your unit

up to factory standards. Call Customer Service at 909627-8178 for proper shipping instructions and address.

Ship your unit freight prepaid.

WARRANTY EXCLUSIONS

THE FOREGOING EXPRESS WARRANTY IS MADE

IN LIEU OF ALL OTHER PRODUCT WARRANTIES,

EXPRESSED AND IMPLIED, INCLUDING

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH ARE

SPECIFICALLY DISCLAIMED. The express warranty

will not apply to defects or damage due to accidents,

neglect, misuse, alterations, operator error, or failure to

properly maintain, clean or repair products.

LIMIT OF LIABILITY

In no event will ESD Systems or any seller be

responsible or liable for any injury, loss or damage,

direct or consequential, arising out of the use of or the

inability to use the product. Before using, users shall

determine the suitability of the product for their

intended use, and users assume all risk and liability

whatsoever in connection therewith.

Loading...

Loading...