Page 1

TB-5531 December 2008 Page 1 of 6

plywood, fiber board, partical board tables and bench

tops with conventional contact adhesives. It is

resistant to most solvents and greatly exceeds the

NEMA specification for wear resistance. The NVMT

brand and ESD protective symbols are featured on

laminate sheets for protection and auditing purposes.

Installation

NVMT is designed to be used as a portable

worksurface or laminated to wooden tables or bench

tops with conventional contact adhesive.

1. Prepare the face of the substrate. It should be

clean, dry and free of all contaminants which would

interfere with adhesion. All the materials, NVMT,

substrate and cement, must be allowed to condition

at 70°F to 75°F and 45-50 percent relative humidity

for 48 hours prior to assembly.

2. Stir the adhesive thoroughly and apply an even coat

of adhesive by either spray, roller or brush to both

the substrate face and the NVMT back. Do not

allow coated surfaces to touch. Allow the cement to

dry. When bonding to plywood, apply a second coat

if the first coat completely penetrates the wood. Use

uncoated wood strips to assist in connecting coated

surfaces.

3. Place thin, uncoated, wooden strips 12 inches apart

across the substrate face. This will keep coated

surfaces apart; bonding will occur once contact is

made.

4. Position the over-cut NVMT sheet on top of the

wooden strips.

Figure 3. NVMT sheet on wooden strips

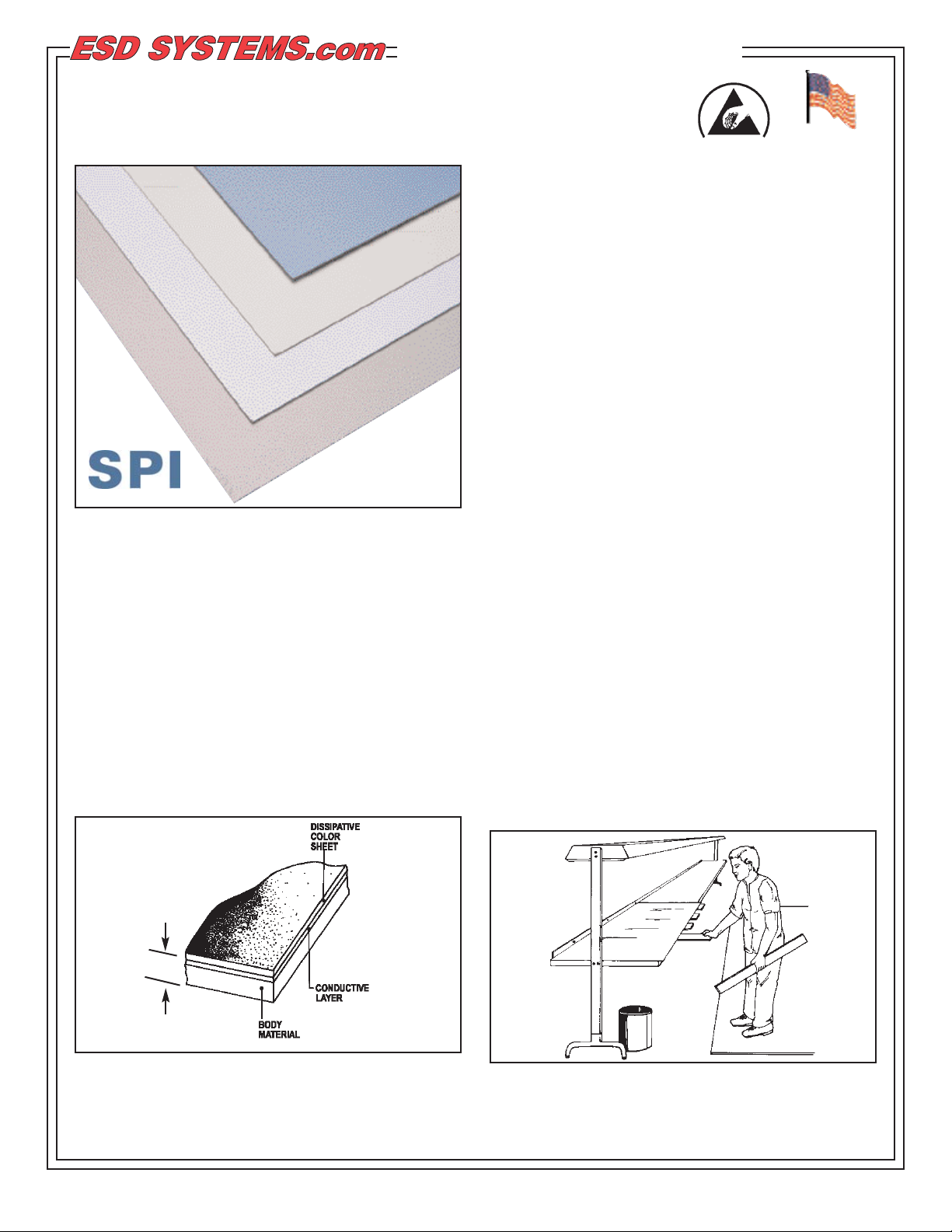

Figure 1. NVMT Protective Laminate

Blue, Gray, Beige, White, Almond

Description

NVMT is a high pressure static dissipative laminate

designed for workbench tops used in the manufacture

and assembly of ESD susceptible electronic

components. NVMT meets ANSI/ESD S20.20

requiring RTG <109Ohms per ESD S4.1 and

antistatic low tribocharging materials <200 volts per

ESD STM 4.2. Its multi-layer construction features a

conductive layer which ensures dissipative properties

independent of ambient humidity. NVMT shows

superior abrasion resistance and provides rapid, nonsparking charge dissipation. It can be laminated to

Figure 2. NVMT layered construction

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

NVMT St atic Protective Laminate

Inst allation and Maintenance

0.038 IN.

THICK

Made in America

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

TECHNICAL BULLETIN TB-5531

Page 2

TB-5531 Page 2 of 6

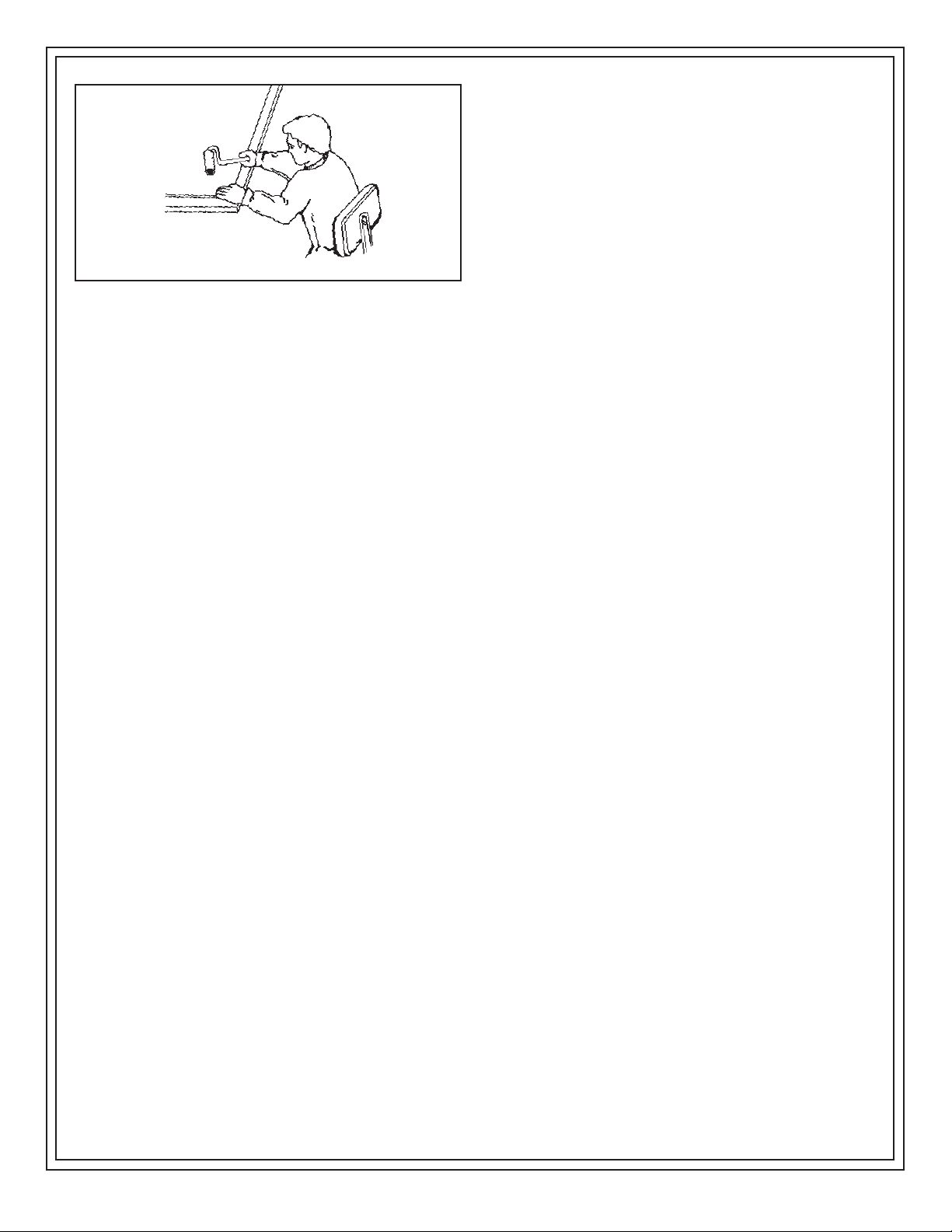

Figure 4. Wooden block and rubber mallet and “J”

roller technique.

5. Slowly remove strips of wood taking care to keep

the NVMT in position. The NVMT should fall into

position.

6. Push the laminate down with even hand pressure.

7. If the NVMT falls out of position, squirt solvent (SPI

Westek recommends the use of ST102 solvent

from Pionite) between the two surfaces and gently

lift the NVMT sheet up. Wait a minimum of 4 hours

before reapplying another coat of adhesive, solvent

must evaporate totally. Apply another coat of

adhesive to both surfaces and reposition.

8. When NVMT is in the correct position, seal the

bond with a rubber “J” roller or a carpeted block

and rubber mallet. Use either roller or block and

mallet in a pattern that forces any air bubbles out

from underneath laminate. If NVMT sheet is

oversized, sheet can now be trimmed with a router.

After trimming, edges should be filed for a smooth

splinter free edge.

Once installed, NVMT must be grounded to ensure

proper charge dissipation. Refer to general grounding

guidelines on this page.

Fabrication Tips

1. All saw blades and router bits used for cutting

should be carbide tipped. Feed rate should be slow

and tool speed should be high. To minimize the

development of surface scratches caused by router

bits, lubricating the laminate edge with a wax stick

is recommended prior to tooling.

2. Inside corners of cutouts for electrical outlets, sinks,

etc., should have a minimum radius of 1/8"

(3mm) and should be filed smooth. This reduces

the likelihood of stress cracks.

3. All edges of laminate should be filed smooth with

file direction towards substrate to help

prevent stress cracks and to minimize chipping.

4. When nails or screws must be used, it is advisable

to first drill an oversized hole through the laminate.

This reduces the likelihood of stress cracks.

5. NVMT is intended for interior use only, and should

not be exposed to extreme humidity, continuous

sunlight, or temperatures above 275°F (135°C) for

extended periods of time.

6. Work surfaces must be grounded for proper static

dissipation.

For more information on the characteristics of

nonindustrial laminates related to end-user

applications please refer to National Electrical

Manufacturers Association, publication LD 3-1995.

The address for NEMA is:

NEMA

1300 North 17th Street, Suite 1847

Rosslyn, Virginia 22209

Phone: 703-841-3200

Web: www.nema.org.

Once installed, NVMT must be grounded to ensure

proper charge dissipation. See below.

General Grounding Guidelines

1. When grounding NVMT, it is essential to make

intimate contact with the conductive layer which is

directly below the dissipative, color layer. See the

diagram on page 1 showing the multi-layered

construction.

2. For proper and safe ESD protection, the grounding

wire must be tied directly to and at the same

potential as the facility power ground or “green

wire” ground. Atypical “green wire” ground if

properly wired is the screw of a switch or outlet

cover plate.

3. If power is to be used at the ESD protected

workstation, per ANSI/ESD S20.20 paragraph 5, a

Ground Fault Circuit Interrupter (GFCI) is

recommended.

4. Test all workstation grounds for proper resistance to

ground. For information on instruments and

procedures for the proper testing of grounds we

recommend that you contact ECOS Electronics,

205 Harrison Street, Oak Park, IL 60304, (708) 3832505, Fax (708) 383-2137.

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

Page 3

TB-5531 Page 3 of 6

Figure 5. Outlet plate with “green wire” ground

5. The selection of ground cords is intimately related

to the organization’s material handling procedures.

It is important for a user to be familiar with his/her

own organization’s grounding specifications and

ESD procedures prior to selecting ground cords.

See paragraph 2 in Cautions section of this

Technical Bulletin.

Grounding Methods for Installed Sheet Goods

SPI Westek offers two styles of ground systems that

will ground your static dissipative laminate

worksurface: Item No. 96580 and 96581. These

ground assembly kits are for use when the laminate

sheet is installed on a wooden workbench top.

1. Item No. 96580, our Laminate Grounding System

contains all the items needed to properly ground a

permanently installed NVMT top. This includes a 10

foot grounding wire terminated with a one megohm

resistor and No. 10 ring terminal and a grounding

bolt complete with single wrist strap banana jack

connection terminal.

Figure 6. Installation of 96580.

2. Item No. 96581, our Flush Mount Laminate

Ground Insert with Bench Ground is also available

without a dual wrist strap ground sold as Item No.

96584. Both 96584 and 96581 can be easily

installed with our Drill Kit Item No. 96582.

Figure 7. Component Parts and Installation of 96584 and

96581.

Installing the Flush Mount Insert

Ground System

The following instructions are based on a top with a

thickness of 1-1/4" (30mm) tops.

2.1. Using drill tool 96582:

Figure 8. Drill Tool 96582.

a. Set the 1/4" (6mm) drill bit and adjustable

counterbore so that the 1/4" (6mm) bit will drill

clear through the work surface.

b. Set the drill stop so the drilling depth of the 1/2"

(12mm) counterbore is .200" (+.000" - .010")

2.2. Using the drill kit 96582 as adjusted above,

position drill bit on the top of the worksurface at

the point you want to install the flush mount

insert.

2.3. Drill perpendicular from the top surface straight

into the work surface until the drill stop touches

the laminate surface. This should be at a depth

of .200".

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

A. 8-32-1 Cap screw D. Ring Terminal

B. Brass insert 1/2" dia. E. 8-32 Nut

C. 1/2" dia. flat washer F. Item 96583 (sold with item 96581 only)

A

B

C

D

E

F

A. 1/4" (6mm) Drill bit

B. 1/2" (12mm) x 1/4" (6mm) Adj. counterbore

C. Drill stop

A

B

C

Page 4

TB-5531 Page 4 of 6

2.4. Using the 1/4" (6mm) pilot hole on the bottom of

the work surface drill a 1 1/2" (37mm) diameter

counterbore 5/8" (16mm) deep, of no more than

1/2 the thickness of the worksurface.

2.5. Seat the 8-32 cap screw through the brass insert

so that it sits flat with the top of the insert.

2.6. Push the cap screw and brass insert assembly

into the 1/2" (12mm) diameter hole on top of the

worksurface. Attach and tighten the 8-32 nut until

the brass insert is flush with the laminate

surface.

2.7. Remove the 8-32 nut and install the flat washer,

ring terminal and 8-32 nut as shown above. The

ring terminal is for a ground wire attachment.

2.8. Using approximately 22 gauge wire, crimp the

supplied ring terminal to the wire and secure it to

the 8-32 cap screw using the 8-32 nut. Attach

the unterminated wire end to a building ground.

THE NVMT WORKSURFACE IS NOW

GROUNDED.Recommended practice per

ANSI/EOS/ESD S6.1-1991 is no resistor

between the common point ground terminal and

a worksurface, floor mat, or shelving.

2.9. FOR INSTALLING dual wrist strap ground (item

09740) included with item 96581 ONLY. Place

item 96583 at the position desired to install,

screw in place using enclosed screws.

2.10. Using the ground wire from the 96583, cut the

length of the ground cord so that it will reach

from the 96583 to the underside of the

worksurface at the 8-32 screw. Crimp the extra

ring terminal to the end of the wire and bolt it to

the underside of the work surface using the 8-32

cap screw and nut.

2.11. Using the remaining wire cut from the 96583,

attach the ring terminal end to the 8-32 cap

screw and nut. Using the ring terminal enclosed,

terminate the other end to a ground source. This

will GROUND both the NVMT

®

top and the dual

wrist strap ground.

Testing

There are two types of tests for monitoring NVMT

surface electrical characteristics. One type of test is

RTG - Resistance To Ground (see Figure 9). In this

test you measure the resistance of the laminate

surface to the installed ground bolt (or snap on a

NVMT Pad). When performing this test on NVMT

Pads the snap serves as the ground point.

A second type of test is RTT (Resistance, Point to

Point). Here you measure the resistance from one 5

lb. electrode to another 5 lb. electrode; see electrode

test positions A, B, C, and D in RTT test diagram,

Figure 10. This is the test that is more typically used in

the laboratory to determine NVMT compliance with

electrical specifications.

Both test procedures are outlined in this Technical

Bulletin using the SPI Westek Surface Resistance Test

Kit Item No. 94057.

Figure 9. Electrode positions on surface of pad, RTG

test.

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

Resistance To Ground (RTG):

1. Locate the five pound electrode positions, as

described below, to be used on the NVMT surface

in relationship to the installed ground bolt (or snap

on the NVMT Pad). Use the relative positions

shown above.

A - At least 2" from any surface edge and 3"

from the ground bolt.

B, C & D - The farthest corners from the ground bolt

and 2" from any surface edge.

E - The geometric center of the surface.

2. Disconnect the surface to be tested from its normal

ground connection.

3. Connect one black lead to the meter and the other

end of this lead to the 5 lb. electrode.

Page 5

TB-5531 Page 5 of 6

Figure 10. Proper connection of leads.

4. Connect the other black lead to the meter and the

groundable point on the mat.

5. Place the electrode at position Aon the mat (see

the RTG diagram) and set the meter selector switch

to 100V.

6. Push on On/Off button, for the 15 second

electrification period and then record the reading in

ohms.

7. Release the On/Off button. Move the electrode to

each of the other four positions on the surface and

repeat the test.

8. Average the results of the five readings to obtain an

average measurement of the resistance of surface

to ground.

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

Resistance Point to Point (RTT):

1. Locate the four pair of electrode positions to be

used approximately as shown in the RTT test

diagram above. Position electrodes at least 10

inches apart and not less than two inches from any

edge.

2. Disconnect the surface to be tested from its normal

ground connection.

3. Connect one end of the black lead to the meter

connect the other end of this lead to either one of

the electrodes. It does not matter which lead is

connected to which weighted electrode.

4. Connect the other lead to the meter. Connect the

other end to the other weighted electrode.

F

igure 11. Electrode positions on surface of pad, RTT

test.

5. Place the electrodes in position Aas shown in RTT

test diagram (Fig. 9). Set the meter selector switch

to 100V.

6. Push the On/Off button, for the 15 second

electrification period and then record the reading in

ohms.

7. Release the On/Off button. Move the electrode to

each of the other three positions on the surface and

repeat the test.

8. Average results of the four readings to obtain an

average measurement of the resistance of the

surface between two points.

Maintenance

1. It is important to store NVMT laminate sheets at the

same relative humidity as the material to which it

will be bonded. This will prevent a moisture

imbalance in application.

2. NVMT may swell slightly if a damp object is kept in

continuous contact with the surface for more than

12 hours. This is normal; the swelling will disappear

soon after the damp object is removed.

Page 6

TB-5531 Page 6 of 6

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

Limited Warranty

SPI Westek expressly warrants that for a period of one (1) year

from the date of purchase, SPI Westek NVMT Static Protective

Laminate will be free of defects in material (parts) and

workmanship (labor). Within the warranty period, a unit will be

tested, repaired or replaced at SPI Westek’s option, free of

charge. Call our Customer Service Department at 909-6649986 for a Return Material Authorization (RMA) and proper

shipping instructions and address. Please include a copy of

your original packing slip, invoice, or other proof of date of

purchase. Any unit under warranty should be shipped prepaid

to the SPI Westek factory. Warranty replacements will take

approximately two weeks.

If your unit is out of warranty, call our Customer Service

Department at 909-664-9986 for a Return Material

Authorization (RMA) and proper shipping instructions and

address. SPI Westek will quote repair charges necessary to

bring your unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU

OF ALL OTHER PRODUCT WARRANTIES, EXPRESSED

AND IMPLIED, INCLUDING MERCHANTABILITY AND

FITNESS FOR APARTICULAR PURPOSE WHICH ARE

SPECIFICALLY DISCLAIMED. The express warranty will not

apply to defects or damage due to accidents, neglect, misuse,

alterations, operator error, or failure to properly maintain, clean

or repair products.

Limit of Liability

In no event will SPI Westek or any seller be responsible or

liable for any injury, loss or damage, direct or consequential,

arising out of the use of or the inability to use the product.

Before using, users shall determine the suitability of the product

for their intended use, and users assume all risk and liability

whatsoever in connection therewith.

© 2008 DESCO INDUSTRIES, INC.

Employee Owned

RoHS Compliance Statement

None of the following materials are intentionally added in

manufacturing this product: lead, mercury, cadmium, hexavalent

chromium, polybrominated biphenyls (PBB) or polybrominated

diphenyl ethers (PBDE) as outlined in the Directive 2002/95/EC

Article 4.1. See Desco Industries Inc. letter on-line at

SPIwestek.com.

3. NVMT may be cleaned with Resque 2 Antistatic

Surface and Mat Cleaner, Item No. 96565 or any

household soap solution. Be careful that household

soaps are silicone free and do not leave an

insulative layer behind. This will reduce electrical

properties. Difficult stains may be removed with

organic solvents such as acetone, alcohol,

methylethyl ketone (MEK) or paint thinner.

Loading...

Loading...