TB-2039 January 2009 Page 1 of 4

TECHNICAL BULLETIN TB-2039

Operation, Installation and Calibration Instructions

N.I.S.T. Calibration Unit for Wrist S trap and Footwear Testers

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

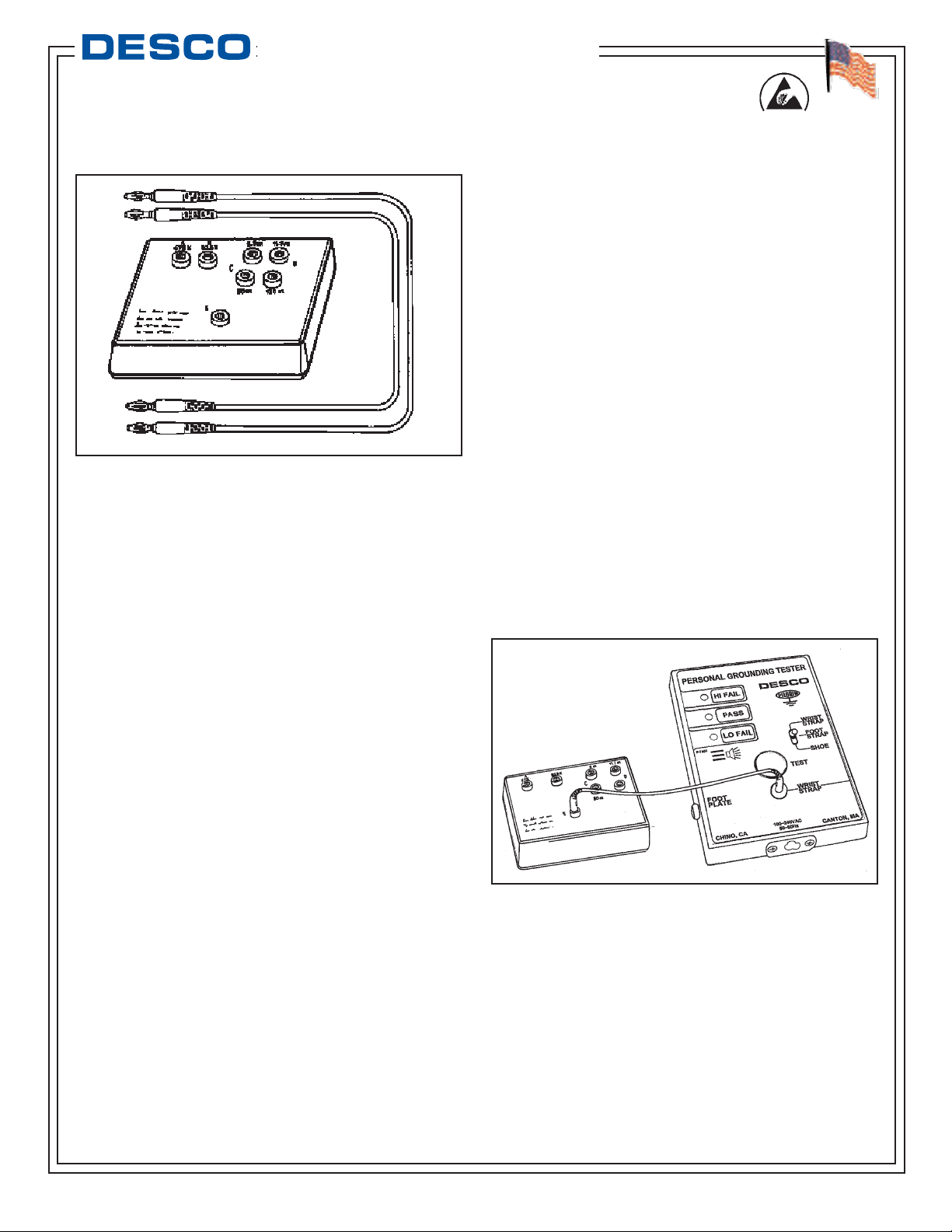

Figure 1. 07010 Calibration Unit

Description

The Desco model 07010 calibration unit is designed to

simplify the process of calibrating wrist strap and foot

ground test equipment. The calibration unit allows the

user to quickly and easily verify whether a tester is

operating within specifications. This product can be

used as one of the tools to fulfill the ANSI/ESD S20.20

paragraph 6.1.3.2 “Compliance Verification Plan”.

Verification should include routine checks of the

Technical Requirements of the Plan. Per Table 1, the

technical requirement test method for “Continuous

Monitors” is to be “per the manufacturer specifications”.

The 07010 is a passive device, and requires no power

source. The calibration unit is manufactured within

industry accepted test ranges for both wrist straps and

foot grounders. The wrist strap pass range is set at

750K - 10M, while the foot ground test range is set at

750K - 100M. The 07010 is supplied calibrated to

NIST traceable standards.

The 07010 Calibration Unit is an important tool for

optimization of an ESD control program. Aleading

corporation estimates a $95 to 1 return on every dollar

invested in ESD control. However, the ESD protective

products utilized must be working, so it is essential that

testers are in calibration that are used to verify the

parameters of wrist straps and foot grounders. The

07010 Calibration Unit easily pays for itself. Instead of

returning to Desco, a Calibration House, or even your

Metrology Department, testers can be NIST calibrated

where located in the factory being out-of-service only a

couple minutes. No need to have an extra replacement

Tester.

Remove the calibration unit from the carton and

inspect for shipping damage. Each unit should include

the following:

1 - Calibration unit, item #07010

2 - 12'' test leads

Calibration Test Procedures

The calibration unit was specifically designed for use in

calibration of Desco brand test equipment. The

following step by step procedures will cover calibration

for specific test units. The procedures will not cover

adjustment of the test equipment. For detailed

information regarding adjustment of specific Desco

brand testers contact our Customer Service

Department at 909-627-8178 (Chino, CA) or 781-8218370 (Canton, MA).

CALIBRATION OF THE MODEL 98280

WRIST STRAP TESTER

Step 1: Connect one of the test leads to common point

banana jack labeled "E" on 07010. Connect the

opposite end of test lead to 98280 tester's wrist strap

jack located on the front of the unit and switch the

selector switch to “WRIST STRAP”.

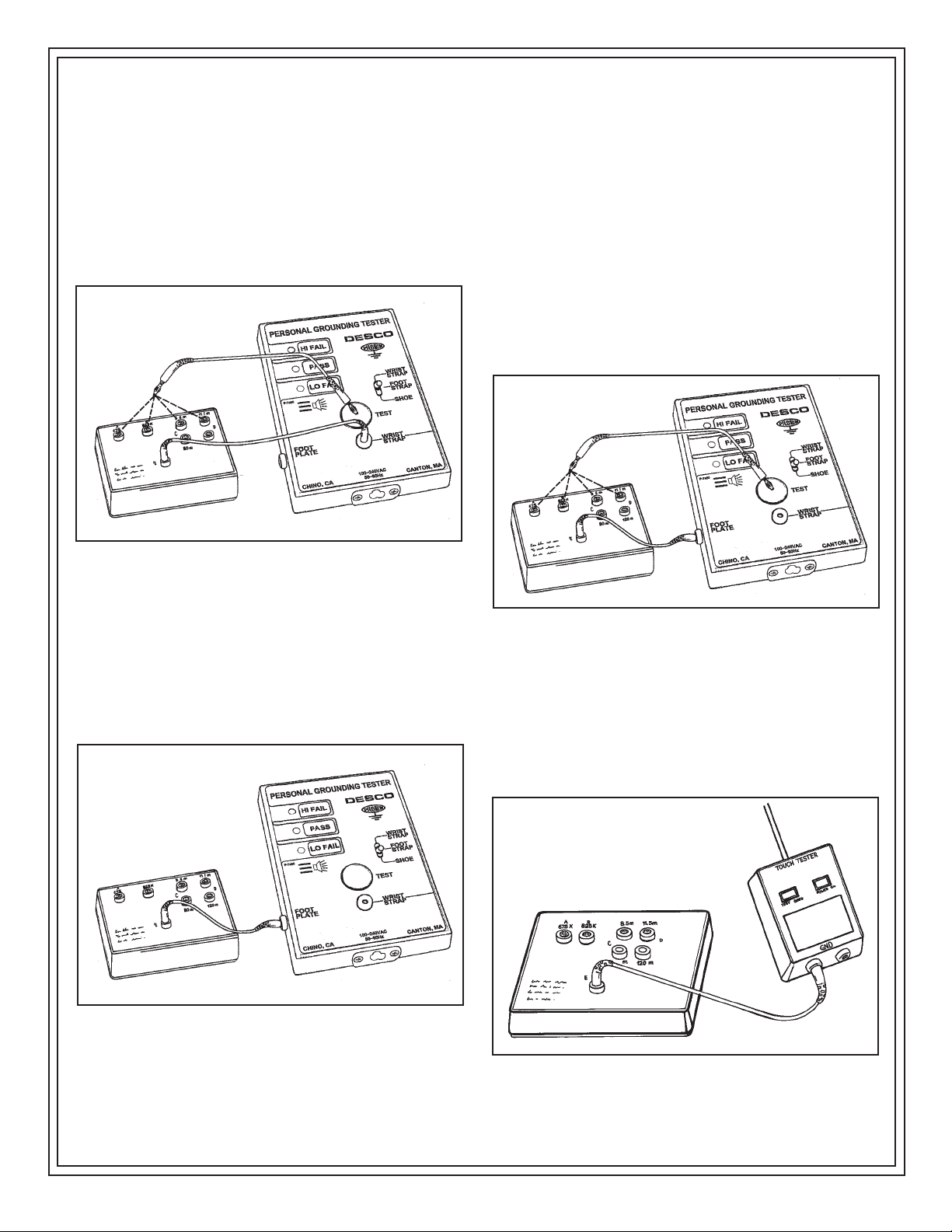

Figure 2. Connecting test lead common from 07010 to

98280.

Step 2: Connect the second test lead to the 675K jack

labeled "A" on the 07010. Touch the opposite end of

test lead to touch tester plate and press down on tester

with enough pressure to activate the test circuit.

Observe the LED's for the proper response as

indicated below. Be sure to hold the cord at an

insulated point, so that the resistance value is not

affected by the body.

Made in America

© 2009 DESCO INDUSTRIES INC.

Employee Owned

TB-2039 Page 2 of 4

DESCO WEST - 3651 Walnut Avenue, Chino, CA91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low-hazard)

Green jack “B” - 825K: Green (OK-in limits)

Green jack “C” - 8.5M: Green (OK-in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown above. If the tester does not meet

calibration specifications, contact factory for adjustment

information, or ask for Technical Bulletin TB-3000.

Figure 3. Testing 98280 for “PASS” and “FAIL” ranges

as indicated on calibration unit.

CALIBRATION OF THE MODEL 98280

FOOT STRAP TESTER

Step 1: Connect one of the test leads to common point

banana jack labeled "E" on 07010. Connect the

opposite end of test lead to 98280 tester's foot strap

jack located on the front of the unit and switch the

selector switch to “FOOT STRAP”.

Figure 4. Connecting test lead common from 07010 to

98280.

Step 2: Connect the second test lead to the 675K jack

labeled "A" on the 07010. Touch the opposite end of

test lead to touch tester plate and press down on tester

with enough pressure to activate the test circuit.

Observe the LED's for the proper response as

indicated below. Be sure to hold the cord at an

insulated point, so that the resistance value is not

affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low-hazard)

Green jack “B” - 825K: Green (OK-in limits)

Green jack “C” - 8.5M: Green (OK-in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown above. If the tester does not meet

calibration specifications, contact factory for adjustment

information, or ask for Technical Bulletin TB-3000.

Figure 5. Testing 98280 for “PASS” and “FAIL” ranges

as indicated on calibration unit.

CALIBRATION OF THE MODEL 19350

WRIST STRAP TESTER

Step 1: Connect one of the test leads to common

point banana jack labeled “E” on 07010. Connect the

opposite end of test lead to one of the 19350’s ground

jacks located on the front edge of the unit.

Figure 6. Connecting test lead common from 07010 to

19350.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

TB-2039 Page 3 of 4

DESCO WEST - 3651 Walnut Avenue, Chino, CA91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Step 2: Connect the second test lead to the 675K jack

labeled “A” on the 07010. Touch the opposite end of

test lead to the test plate. Observe the LED’s for the

proper response as indicated below. Be sure to hold

the cord at an insulated point, so that the resistance

value is not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low - hazard)

Green jack “B” - 825K: Green (OK - in limits)

Green jack “C” - 8.5M: Green (OK - in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown for the 19350. If the tester does not

meet calibration specifications, contact factory for

calibration, or ask for Technical Bulletin TB-2004.

Figure 7. Testing 19350 for “PASS” and “FAIL” ranges

as indicated on calibration unit.

CALIBRATION OF THE MODELS

19250, 19251 AND 19252

The models 19250, 19251 and 19252 testers utilize the

identical test unit. The difference between the three

models is the hardware that is included with each unit.

The model 19250 includes only the tester, model

19251 includes the tester and a metal foot plate, while

the 19252 is the tester and metal test stand assembly.

This test unit is designed with two separate test circuits

with distinct pass fail ranges. The wrist strap test

circuit incorporates a 750K - 10M pass range while the

footwear test circuit is set to pass at 750K - 100M.

Each test circuit needs to be tested individually. For

detailed information on these testers please ask for

Technical Bulletin TB-2040.

Wrist Strap Test Circuit

Step 1: Connect one of the test leads to common

point banana jack labeled “E” on 07010. Connect the

opposite end of test lead to the 19250’s wrist cord jack

located on the face of the unit.

Step 2: Connect the second test lead to the 675K jack

labeled “A” on 07010. Touch the opposite end of test

lead to tester’s test plate and press down with enough

pressure to activate the test circuit. Observe the LED’s

for the proper response as indicated below. Be sure to

hold the cord at an insulated point, so that the

resistance value is not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low - hazard)

Green jack “B” - 825K: Green (OK - in limits)

Green jack “C” - 8.5M: Green (OK - in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown above. If the tester does not meet

calibration specifications, contact factory for calibration,

or ask for Technical Bulletin TB-2040.

Figure 8. Testing 19250 for “PASS” and “FAIL”, wrist

strap test circuit.

Footwear Test Circuit

Step 1: Connect one of the test leads to common

point banana jack labeled “E” on 07010. Connect the

opposite end of test lead to the 19250’s foot plate

ground jack located on the side of the unit.

Step 2: Connect the second test lead to the 675K jack

labeled “A” on the 07010. Touch the opposite end of

test lead to tester’s test plate and press down with

enough pressure to activate the test circuit. Observe

the LED’s for the proper response as indicated below.

Be sure to hold the cord at an insulated point, so that

the resistance value is not affected by the body.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

TB-2039 Page 4 of 4

DESCO WEST - 3651 Walnut Avenue, Chino, CA91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Limited Warranty

Desco expressly warrants that for a period of one (1) year from

the date of purchase, Desco Calibration Units will be free of

defects in material (parts) and workmanship (labor). Within the

warranty period, the product will be tested, repaired, or replaced

at Desco’s option, free of charge. Call our Customer Service

Department at

909-627-8178

(Chino, CA) or 781- 821-8370

(Canton, MA) for a Return Material Authorization (RMA) and

proper shipping instructions and address. Include a copy of your

original packing slip, invoice, or other proof of purchase date. Any

unit under warranty should be shipped prepaid to the Desco

factory. Warranty repairs will take approximately two weeks.

If your unit is out of warranty, call Customer Service at

909-627-

8178

(Chino, CA) or 781-821-8370 (Canton, MA) for a Return

Material Authorization (RMA) and proper shipping instructions

and address. Desco will quote repair charges necessary to

bring your unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU

OF ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS

FOR APARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator

error, or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will Desco or any seller be responsible or liable for

any injury, loss or damage, direct or consequential, arising out of

the use of or the inability to use the product. Before using,

users shall determine the suitability of the product for their

intended use, and users assume all risk and liability whatsoever

in connection therewith.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low-hazard)

Green jack “B” - 825K: Green (OK-in limits)

Green jack “C” - 80M: Green (OK-in limits)

Yellow jack “D” - 120M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C (80M), and D (120M). The different resistance

ranges should give the display shown above. If the

tester does not meet calibration specifications, contact

factory for calibration, or ask for Technical Bulletin

TB-2040.

Figure 9. Testing 19250 for “PASS” and “FAIL” ranges

for footwear circuit as indicated on calibration unit.

Specifications

Power Source: Passive device, no power source

required

Resistance Ranges -

Wrist straps: Low - 675 Kilohm

Pass - 825 Kilohm

Pass - 8.5 Megohm

High - 11.5 Megohm

Footwear: Low - 675 Kilohm

Pass - 825 Kilohm

Pass - 80 Megohm

High - 120 Megohm

Calibration: NIST traceable

Calibration Interval: Recommended annually

Accuracy: ±2%

Weight: 10 ounces

Dimensions: 4.50" x 3.25" x 1.00"

Consider adding the 07010 to your list of “test

equipment that shall be selected to make

measurements of appropriate properties of the

technical requirements that are incorporated into the

ESD program plan” as required by paragraph 6.1.3.1 of

ANSI/ESD S20.20.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Loading...

Loading...