Desco TB-2031 Service Manual

TB-2031 November 2008 Page 1 of 3

TECHNICAL BULLETIN TB-2031

Statshield®Moisture Barrier Bags

Application Instructions

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Figure 1. Desco Statshield® Moisture Barrier Bag

Introduction

Corrosion and thus moisture protection is becoming

increasingly important. From ESD Association 22nd

EOS/ESD Symposium Proceedings*, “As electronic

components use less material they become more

sensitive to voltage and current variations. This

increases their operational speed and functionality.

Corrosion that was heretofore inconsequential now

becomes a major factor in the current electronic

components. . . . This underlines the importance of

protection from angstrom level corrosion of surfaces

beyond the normal solderability level problems on

circuitry.” Statshield®EMI/RFI ESD Moisture Barrier

Bags addresses this concern providing physical, ESD,

EMI/RFI, and moisture protection.

"...it is important to take possible temperature exposure into

account when shipping electronic parts. It is particularly

important to consider what happens to the interior of a

package if the environment has high humidity. If the

temperature varies across the dew point of the established

interior environment of the package, condensation may

occur. The interior of a package should either contain

desiccant or the air should be evacuated from the package

during the sealing process. The package itself should have a

low WVTR." (ESD Handbook ESD TR20.20 section 5.4.3.2.2)

Description

Desco Statshield®Moisture Barrier Bags combine the

properties of a MOISTURE BARRIER constitution with

EMI-RFI-ESD shielding. Statshield®Moisture Barrier

Bags meet the electrical and physical requirements of

ANSI/ESD S541, EIA 583, EIA 541, EIA 625, and MILPRF-81705D, Type I. All Statshield®Moisture Barrier

Bags are amide and amine free and pass outgassing

and corrosion tests. All bags are printed with ESD and

moisture warning symbols and are dated and lot coded

for ease of traceability.

Desco offers three styles of Moisture Barrier Bags. The

first is a .0065” (.1651mm) thick heavy-duty bag with

EMI shielding, the second is a .0040” (.1016mm) thick

foil bag with EMI/RFI shielding, and the third is a

.0035” (.0889mm) bag with EMI/RFI shielding

properties. All three bags are available in a wide range

of sizes. Also, custom sizes and custom imprinting are

available.

Construction

Desco Statshield® Moisture Barrier Bags are

manufactured out of a laminated film which features

static dissipative surfaces. The configuration is similar

to the metal-in shielding material, but with two metal

layer being placed between layers of dissipative film. A

polyester layer provides pull strength and heat seal

capability. The metal layer is approximately ten times

thicker than that of traditional static shielding material

and provides the EMI attenuation and moisture barrier

properties.

The metal layer within the Moisture Barrier Bag is

vacuum deposited rather than being a foil layer. This

difference allows the bag to be much softer and

flexible, therefore the metal portion of the bag is less

likely to tear or rip providing a more reliable barrier

against moisture and static electricity.

Made in America

Static Dissipative

Polyester

Aluminum

Shielding

Layer

Polyester Layer

Aluminum Shielding Layer

High Performance Static

Dissipative Polyethylene

*Paper entitled “Corrosion Induced Electrostatic Damage” by

John P. Franey of Lucent Technologies Bell Labs

© 2008 DESCO INDUSTRIES INC.

Employee Owned

Figure 2. Statshield® MBB bag construction.

TB-2031 Page 2 of 3

DESCO WEST - 3651 Walnut Avenue, Chino, CA91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

General Information

Failures in certain electronic devices and microcircuits

have been linked to the rapid expansion of internally

absorbed moisture during the soldering process.

Moisture absorption into these devices has been

traced to have taken place primarily during shipping

and storage in non-humidity controlled environments.

Additionally, “Dry Packaging” is usually required for

electronic assemblies or devices that are to be placed

into long term storage or for use in military

applications.

The Statshield®Moisture Barrier Bag, Desiccant Packs

and Humidity Indicator Cards have been developed for

use in “DRY PACKAGING” applications. In order for

the MBB bag and its accessories to perform properly,

Desco recommends the user follow procedures

defined in IPC/JEDEC J-STD-033B.

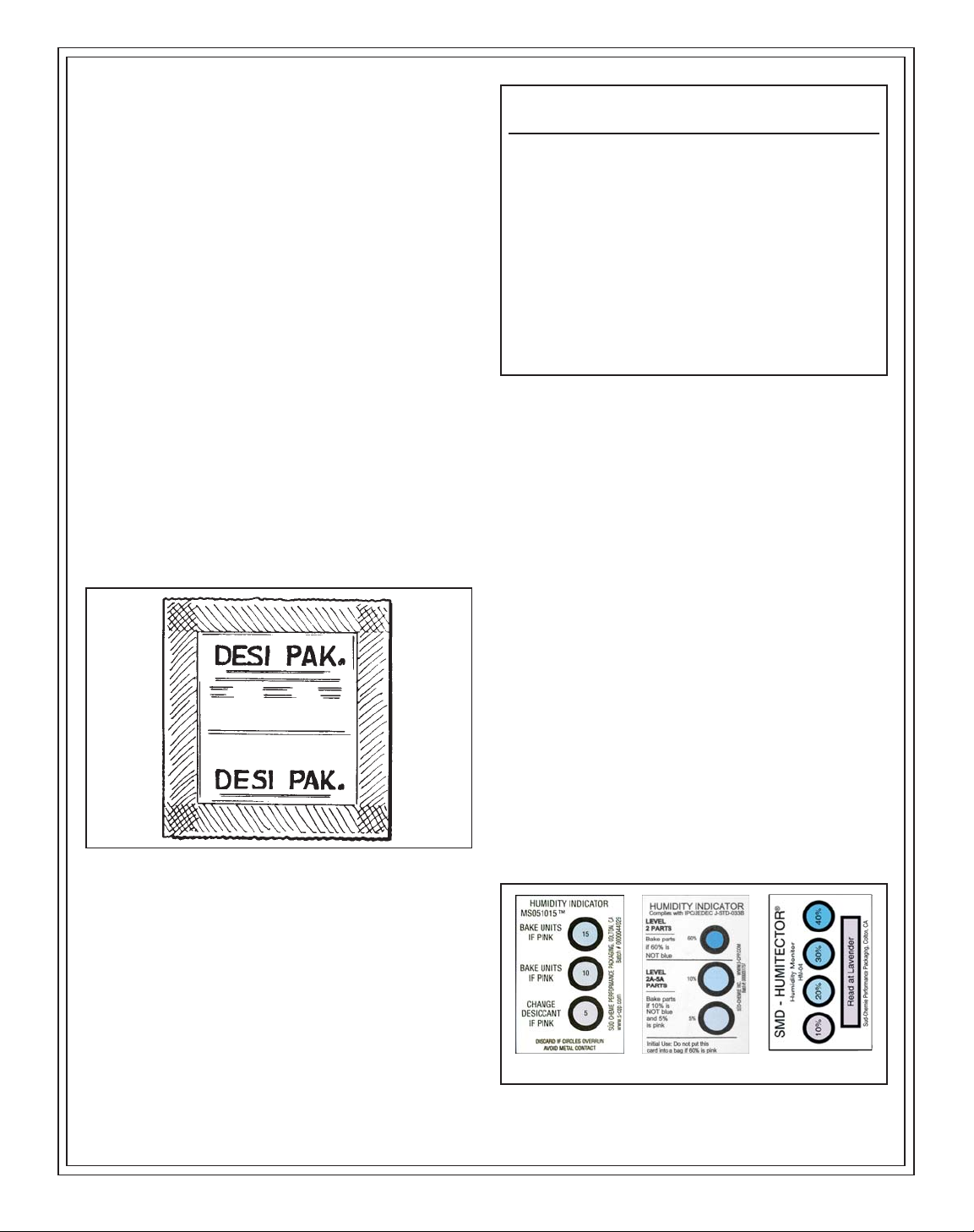

DESICCANT

Desiccant is a drying agent used to lower the moisture

content of air inside a closed space, such as an

Moisture Barrier bag. Desiccant is packaged in

fractional units in order to facilitate its usage with a

variety of bag sizes. One full “unit” of packaged

desiccant will absorb the following quantities of water

at equilibrium with air at 77°F (25°C): 3.00 grams @

20% rH and 6.00 grams @ 40% rH, when tested to

MIL-D-3464.

Desiccant packs are available from Desco in the

following unit sizes and standard packages:

ITEM # UNIT SIZE STANDARD PKG.

13840 1/2 unit - 1.5" x 3" Box of 700

13842 1 unit - 3" x 4" Box of 500

13850 1/2 unit - 1.5" x 3" Pail of 550

13852 1 unit - 3" x 4" Pail of 300

Desiccant packs sold by Desco meet the requirements

of MIL-D-3464. For more detailed information, see

Drawing 13850.

HUMIDITY INDICATOR CARDS

Another integral part of a moisture barrier packaging

assembly system is the Humidity Indicator Card. The

Indicator Card contains chemically impregnated,

humidity sensitive, indicating spots that will change

color with moisture. The comparison bar is used to

determine relative humidity of air. Select the indicating

spot that most closely matches the color of the

comparison bar. The measured relative humidity is the

percentage indicated on the matching spot. The

chemical reaction of the indicating spots is completely

reversible; the spots will continue to change color as

the moisture levels change.

INTERIOR BAG NUMBER OF DESICCANT UNITS

SURFACE AREA *MIH <20% MIH <30% MIH < 40%

100 sq. in. 1.5 1.0 1.0

130 sq. in. 2.0 1.5 1.0

160 sq. in. 2.0 1.5 1.5

200 sq. in. 2.5 2.0 1.5

240 sq. in. 3.0 2.0 1.5

290 sq. in. 4.0 2.5 2.0

340 sq. in. 4.5 3.0 2.5

390 sq. in. 5.0 3.5 2.5

450 sq. in. 5.5 4.0 3.0

510 sq. in. 6.5 4.5 3.5

580 sq. in. 7.5 5.0 4.0

650 sq. in. 8.0 5.5 4.0

720 sq. in. 9.0 6.0 4.5

© 2008 DESCO INDUSTRIES INC.

Employee Owned

13868 13869 13870

Figure 3. Desiccant packs.

In order to provide a moisture barrier packaging

assembly system, desiccant must be inserted into the

bag, prior to having the bag vacuum sealed. The

recommended amount of desiccant is dependent on

the interior surface area of the bag to be used. Figure

4 is a reference table indicating recommended

minimum amounts of desiccant that should be used

with Moisture Barrier Bags.

Figure 4. Table for recommended desiccant usage.

Information taken out of EIA-583, Table 1, Page 8.

Figure 5. Humidity Indicator Cards

Loading...

Loading...