Page 1

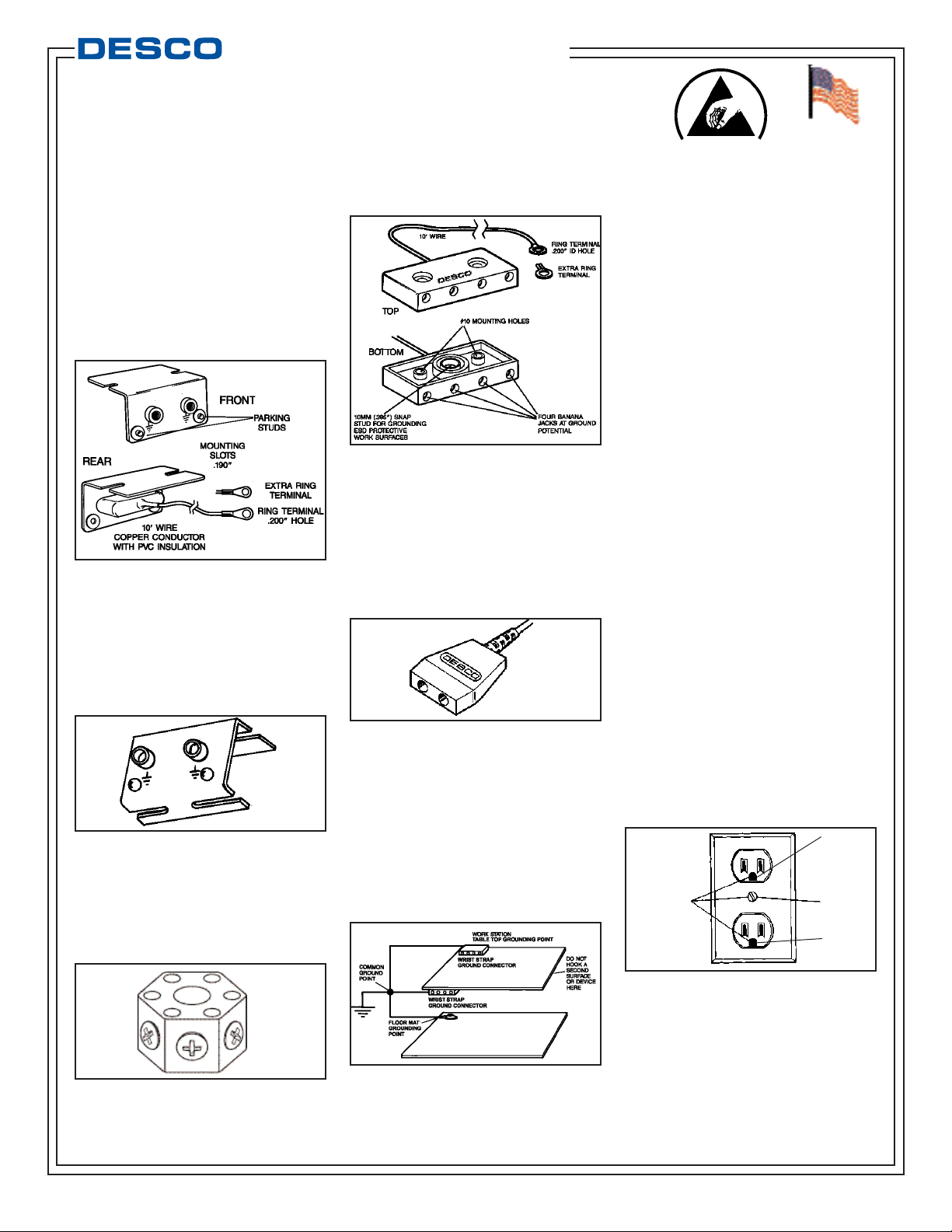

The 09740/09741, 09835/09836 and

09820/09821/09825/09826/ are shipped with an

extra ring terminal so that the ground wire may

be cut to length during installation. The

09740/09741 and 09835/09836 feature a pair of

mounting holes designed to accommodate

standard #10 screws, allowing the units to be

mounted to the work bench.

Proper Grounding

Wrist straps, work surfaces, floor mats and other

electrostatic discharge (ESD) protective

products should be grounded to a common point

ground.

COMMON POINT GROUND

Per ANSI/EOS/ESD S6.1, Grounding paragraph

4.1.1 "Every element to be grounded at an ESD

protected station shall be connected to the same

common point ground."

ESD Handbook TR 20.20 paragraph 5.1.3 Basic

Grounding Requirements "The first step in

ensuring that everything in an EPAis at the

same electrical potential is to ground all

conductive components of the work area

(worksurfaces, people, equipment, etc.) to the

same electrical ground point. This point is called

the common point ground. The next step in

completing the ground circuit is to connect the

common point ground to the equipment ground

(third wire, green)."

If all elements are connected to the common

point ground, even if the equipment ground

connection is compromised, all workstation

elements will be connected and be at equipotential or at the same charge. Being at the

same electrostatic charge will mean that no

discharge should occur.

Connect the ground wire directly to the nearest

utility “green wire” ground point. In a properly

wired building, the “green wire” equipment

ground point may be the center screw of the

standard 110VAC outlet. Some special outlets

may “float” the center screw. Test before you

hook up.

Figure 7. Recommended grounding point.

Individual work stations must be individually

grounded to the “green wire” equipment ground.

For ESD worksurface installation information,

see Desco Technical Bulletin TB-2000.

TB-2003 January 2009 Page 1 of 2

Common Point Grounding Unit s

Inst allation Instructions

Description

Per ANSI/ESD S20.20, all conductors, including

personnel, must be electrically connected and

attached to a known ground. EOS/ESD S6.1

recommends hard ground, without resistor, of

worksurface or floor mats. Per ANSI/ESD

S20.20, ground fault circuit interrupters (GFCI)

should be considered to provide personnel

protection.

Desco offers a number of common point

grounds and wrist strap ground connectors

designed to ground multiple operators or items.

Figure 1. 09740/09741 wrist strap bench ground.

The 09740/09741 wrist strap bench ground is a

wrist strap ground connector and consists of a

mounting bracket with two standard banana

jacks installed and soldered to a ten foot ground

wire terminated with a ring terminal with a

0.200" hole.

The 09741 includes a wrist strap parking station.

See figure 2.

Figure 2. 09741 premium bench mounted

ground with parking station

The 09837 Multi Grounding Hub is designed for

use as either a wrist strap ground connector or

as a common point ground for all items to be

grounded at a bench (i.e. table mat ground cord,

floor mat ground cord, banana jack ground

block, etc.). The Multi Grounding Hub

Figure 3. 09837 Multi Grounding Hub

incorporates six standard banana jacks, and six

terminations for ring terminals (10-32 screw in

threaded holes).

Figure 4. 09835/09836 quad common point

ground

The 09835/09836 quad common point ground is

designed for use as either a wrist strap ground

connector or as a common point ground. The

quad ground incorporates four standard banana

jacks, a 10mm snap stud, and ten feet of ground

wire terminated with a ring terminal with a

0.200" I.D. hole. The model 09835 also

incorporates a 1 megohm resistor in series with

the snap stud.

Figure 5. 09820/09821/09825/09826

common point ground.

The 09820/09821/09825/09826 common point

ground is designed to ground bench mats by

snapping on the mat’s stud, and to provide a

convenient wrist strap ground connector. Items

09820/09821 incorporate two standard banana

jacks, a 10mm snap socket, and 10 feet of wire

terminated with a ring terminal with a 0.200" I.D.

hole. Items 09825/09826 have a 10mm snap

stud and 15 feet of wire. Items 09821/09826

also incorporate a one megohm resistor in

series with the snap.

Figure 6. All elements at the ESD work station

should be connected to the same common point

ground, such as 09837 Multi Grounding Hub.

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

“GREEN WIRE”

EQUIPMENT

GROUND

POINTS

RING TERMINAL

CAN BE

ATTACHED

HERE

TECHNICAL BULLETIN TB-2003

Made in America

© 2009 DESCO INDUSTRIES INC.

Employee Owned

BANANA PLUG

CAN BE

ATTACHED

HERE

BANANA PLUG

CAN BE

ATTACHED

HERE

Page 2

TB-2003 Page 2 of 2

Always Test the Ground

Before You Use It and

Periodically Thereafter

You should not assume that any electrical outlet

is properly wired. Even if it was originally wired

correctly, it can become ungrounded due to

corrosion and wear. Test the equipment ground

you intend to use before you hook up. Use

Desco 98130 AC Outlet Analyzer to verify proper

wiring of the electrical outlet (equiment ground).

Installation

After you have selected and tested your

grounding point, you will need to determine the

method of installation for the type of grounding

block that you have selected. Installation of

common point units as grounding blocks is

outlined below. Installation of the 09835/09836

and 09820/09821/09825/09826 as common

point ground cords for a work surfaces is also

discussed below.

WRIST STRAP GROUND CONNECTORS

1. Select the most convenient location on the

work bench for grounding of wrist straps and

other grounding devices.

2. Position the 09740/09741 or 09835/ 09836

and use the two #10 mounting holes to secure

to the work bench.

3. Bring the wire neatly back to your grounding

point. You may wish to use wire brackets to hold

the wire in place and out of the way. Cut and

strip the end of the wire to properly fit your

ground point. Install and crimp the extra ring

terminal provided.

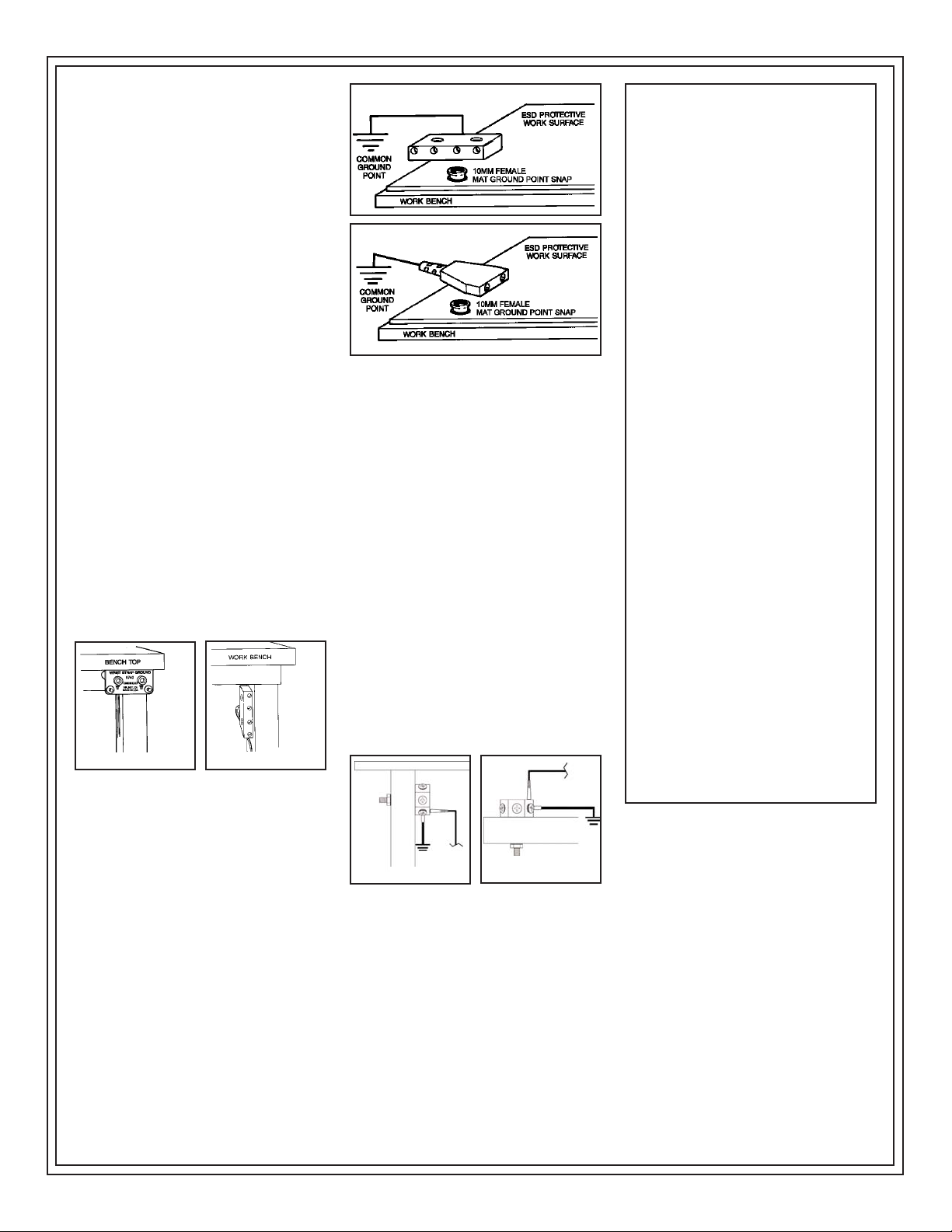

Figure 8. Installation of grounding blocks.

4. To check resistance, use an ohmmeter from

the banana jacks to the common ground point. It

should read less than 1 Ohm AC impedance for

items 09740/09741, 09820/09825 and 09835

and 1 megohm (106 ohms) for items 09836 and

09821/09826.

GROUNDING POINT

As previously mentioned, the 09835/09836 and

the 09820/09821/09825/09826 can be installed

as a wrist strap ground connector for ESD

protective work surfaces.

1. Position or lay the work surface in the desired

location. Snap the ground to it. These units

connect with a 10mm socket snap.

2. Bring the other end of the ground cord to a

verified grounding point and attach it using the

ring terminal. Tie the ground wire to the bench to

keep it neatly out of the way. You may cut and

strip the ground wire to a shorter length and

attach it using the extra ring terminal included

with each ground cord.

3. After installation, the work surface along with

the banana jacks are all electrically connected to

ground. The banana jacks will now serve as

wrist strap ground connectors.

4. To check resistance, use an ohmmeter from

the ground point snap on the mat to the

common ground point. It should read 1 megohm

±20 percent if you are using a model 09836,

09821, or 09826 ground cord, and less than 1

Ohm AC impedance if you are using a 09835,

09820, or 09825 non-resistor ground cord.

MULTI GROUNDING HUB

The 09837 Multi Grounding Hub can be

mounted either on a bench leg or table top. See

Figure 10 for installation.

Figure 10. Installation of multi grounding hub.

Maintenance

You should set up a an auditing schedule to be

sure that all ESD grounds are inspected and

tested per your compliance verification plan

required by ANSI/ESD S20.20. Some

companies test once every six months.

Figure 9. Installing the 09835/09836 and

09820/09821/09825/09826 as a common point

ground cord for a work surface.

09835/09836

09820/09821/09825/09826

Limited Warranty

Desco expressly warrants that for a period of

one (1) year from the date of purchase,

Desco grounding products will be free of

defects in material (parts) and workmanship

(labor). Within the warranty period, the

product will be tested, repaired, or replaced

at Desco’s option, free of charge. Call our

Customer Service Department at 909-6278178 (Chino, CA) or 781-821-8370 (Canton,

MA) for a Return Material Authorization

(RMA) and proper shipping instructions and

address. Include a copy of your original

packing slip, invoice, or other proof of

purchase date. Any unit under warranty

should be shipped prepaid to the Desco

factory. Warranty repairs will take

approximately two weeks.

If your unit is out of warranty call Customer

Service at 909-627-8178 (Chino, CA) or 781821-8370 (Canton, MA) for a Return Material

Authorization (RMA) and proper shipping

instructions and address. Ship your unit

freight prepaid. Desco will quote repair

charges necessary to bring your unit up to

factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY

IS MADE IN LIEU OF ALL OTHER

PRODUCT WARRANTIES, EXPRESSED

AND IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY DISCLAIMED. The express warranty

will not apply to defects or damage due to

accidents, neglect, misuse, alterations,

operator error, or failure to properly maintain,

clean or repair products.

Limit of Liability

In no event will Desco or any seller be

responsible or liable for any injury, loss or

damage, direct or consequential, arising out

of the use of or the inability to use the

product. Before using, users shall determine

the suitability of the product for their intended

use, and users assume all risk and liability

whatsoever in connection therewith.

09740/09741

09835/09836

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

© 2009 DESCO INDUSTRIES INC.

Employee Owned

09837

09837

Loading...

Loading...