Page 1

TB-2000 January 2009 Page 1 of 4

Inst allation and Maintenance

of ESD Protective Work Surfaces

Foreword

To enhance your understanding of this technical bulletin we

recommend that you read the following EOS/ESD Standards:

ANSI/ESD S20.20 - Development of an Electrostatic

Discharge Control Program

ESD ADV 1.0 - Glossary of Terms

ESD S4.1 - Work Surfaces

ESD S6.1 - Grounding

ANSI ESD S11.11 - Surface Resistivity

These documents can be obtained directly from the ESD

Association, 7902 Turin Rd., Building 3, Suite 2, Rome, NY 134402069, (315) 339-6937, www.esda.org.

Introduction

The purpose of an ESD protective work surface is to aid in the

prevention of damage to ESD sensitive components and

assemblies from electrostatic discharge. An ESD protective work

surface provides protection in the following two ways:

1. Providing an antistatic work surface area that will not allow

static electricity to be generated at potentially hazardous levels.

2. Removing the charge from a conductive object placed on the

work surface.

ESD protective work surfaces are catagorized into two general

categories: conductive and dissipative.

A conductive work surface is defined by most documents as a

material that has a surface resistivity of less than 1x10

5

ohms/square. Conductive materials are the quickest to ground a

charge, but they can also cause damage by discharging too

rapidly. Conductive materials are usually used as floormats or

flooring products.

A dissipative work surface is defined as being materials having a

surface resistivity of at least 1x10

5

, but less than 1x10

12

ohms/square. Dissipative materials minimize the generation of

static charges, and will dissipate a charge slow enough so that a

spark will not occur. Dissipative materials are usually the preferred

choice for bench top work surfaces.

General Guidelines

1. ANSI/ESD S20.20 requires that all conductors, including

personnel, must be electrically connected and attached to a

known ground.

2. For proper and safe grounding the ESD ground must be

tied directly to and at the same potential as the building or

“green wire” ground.

3. Per ANSI/ESD S20.20, the ESD control program can in no way

replace or supercede and requirements for personnel safety.

Ground fault circuit interrupters (GFCI) and other safety

protection should be considered wherever personnel might

come into contact with electrical sources.

4. All electrical circuits at an ESD protected workstation, especially

those used as the tie-in point to the utility ground, should be

verified for proper wiring configuration, ground impedance and

GFCI function when the station is installed and periodically

thereafter.

5. The selection of ground cords is intimately related to the

material selected for an ESD protected work area, personnel

safety, and the products’ relationship to the organization’s

material handling procedures. It is important for a user to be

familiar with their oganization’s grounding specifications and

ESD control procedures prior to selecting ground cords.

Common Point Grounds

A common point ground is defined by the EOS/ESD-S6.1,

“Recommended Grounding Practices” as:

1. A grounded device where two or more conductors are bonded.

2. A system or method for connecting two or more grounding

conductors to the same electrical potential.

Examples of conventional common point grounds and other

ground cords are illustrated below.

09835

09740

09817

09814

Figure 2. Other ground cords.

Common point grounds are designed to provide earth ground for

table mats and wrist straps. NOTE: DO NOT DAISY CHAIN.

Because of the high resistances inherent to many types of

protective surfaces, daisy chaining of these materials can severely

limit their ability to properly dissipate and protect against static

charges.

Figure 1. Typical common point grounds.

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

TECHNICAL BULLETIN TB-2000

Made in America

© 2009 DESCO INDUSTRIES INC.

Employee Owned

09837

09825

COMMON POINT GROUND

Per ANSI/EOS/ESD S6.1, Grounding paragraph 4.1.1 "Every

element to be grounded at an ESD protected station shall be

connected to the same common point ground."

ESD Handbook TR 20.20 paragraph 5.1.3 Basic Grounding

Requirements "The first step in ensuring that everything in an EPA

is at the same electrical potential is to ground all conductive

components of the work area (worksurfaces, people, equipment,

etc.) to the same electrical ground point. This point is called the

common point ground. The next step in completing the ground

circuit is to connect the common point ground to the equipment

ground (third wire, green)."

Page 2

TB-2000 Page 2 of 4

Grounding Methods

Method 1 (Grounding via ground cords)

1. Desco recommends using a common point ground cord when

grounding via ground cords. Most common point ground cords

will ground your ESD protective work surface and provide

banana jacks for two wrist strap grounds.

2. A common point ground should be installed at each workstation

and should be connected directly to a verified utility “green

wire” ground or to a verified grounding bus which is connected

to the utility ground. Only one groundable point should exist on

a work surface.

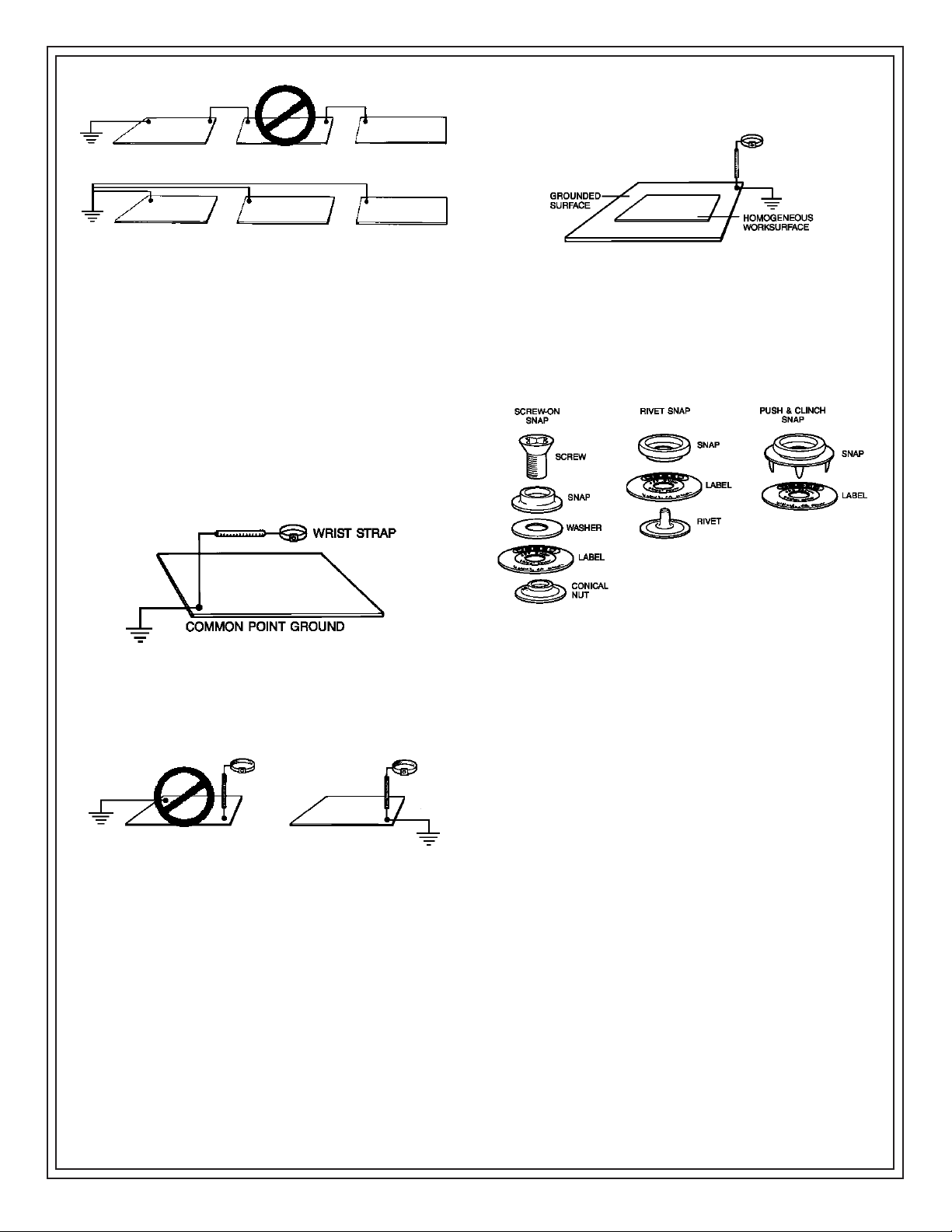

Figure 4. Common point ground for each workstation.

3. Wrist straps should never be grounded through a work surface,

as the added resistance of the work surface material will

prevent the wrist strap from operating properly.

WRONG! RIGHT!

Figure 5. Proper grounding of wrist straps.

4. A current limiting resistor in the wrist strap ground cord is

recommended. The EOS/ESD Standard S-1 calls for this to be

a one megohm resistor.

Method 2 (Grounding via a grounded conductive surface)

1. This alternate form of grounding should only be employed

when using a homogeneous dissipative material with a volume

resistivity of less than 108ohms/centimeter.

2. The dissipative or conductive work surface may be placed on a

properly grounded laminate, metal or other conductive surface.

The worksurface will electrically couple to teh grounded

surface and may not require separate grounding.

Figure 6. Alternate grounding method

For additional information on grounding we recommend Desco

Technical Bulletin TB-2007.

Groundable Point Installation

1. Before installing a groundable point on your work surface you

must first determine whether you will need a snap socket or

stud, the type of snap hardware and the location.

Figure 7. Three kinds of snaps.

2. Desco has three types of 10mm (.395") field installable mat

grounding snaps. The first type is a screw-on snap kit designed

for use on homogeneous mats, but it can also be used on twolayer work surfaces without ill effect. This is Desco item number

09864.

A. Determine the position of the grounding snap (one only

per mat) and type of fastener you will be installing (socket or

stud). Punch a hole through the material with a small phillips

screwdriver or awl.

B. Remove the release paper from the circular label and

affix it so that it aligns with the hole on the material.

C. Select one of the screws as follows:

Material less than .100" thick - short screw

Material greater than .100" thick - long screw

D. Insert the screw through the top on the snap fastener, the

washer, the label and the material. Affix the assembly with

the conical nut supplied with the kit and tighten down the

screws.

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

WRONG!

RIGHT

Figure 3. ESD work surfaces should never be grounded in series,

i.e. daisy chained.

3. When using this type of grounding method be sure to test that

the worksurface is properly grounded.

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Page 3

1 Megohm Designed for Designed for

Model # Resistor Work Surface Use Floor Mat Use

09814 X

09813 XX

09817 X

09818 XX

09820 X

09821 XX

09825 X

09826 XX

09835 X

09836 XX

09837 X

09740 X

09741 X

TB-2000 Page 3 of 4

Figure 9. Installing push and clinch mat grounding snap.

4. The third type is the rivet style mat grounding snap. This type of

snap assembly is installed using a rivetting hand tool, item

#09867. Male snap studs and rivets are available as item

#09856 and female snap sockets and rivets are available as

item #09857. Groundable point labels are not included with

either the item #09856 or #09857 snap kits.

Figure 10. Installation using a rivetting hand tool.

Selection of Common Point and

Floor Mat Grounding Systems

1. Determine the type of common point grounding system you will

use: barrier strip, bus bar, grounding block, or common point

ground cord. Desco recommends the use of common point

ground cords or our 09740 dual bench mount.

2. If you determine that you will use ground cords, you must now

determine the type of ground cord you will use for your

5. The 09740 dual bench mount allows the grounding of two

operators at one common point. The 09740 mounts easily

under the front edge of a workstation. For detailed information

on this common point grounding device ask for Technical

Bulletin TB-2003.

Figure 12. 09740 dual bench mount.

6. The 09813/09814 floor mat ground may be either attached to a

mat by snapping onto a 10mm socket, or by bolting it to the

mat with the hardware supplied with the cord. When bolting the

09814 to the mat use a 3/8" diameter hole punch to create the

hole for mounting. This will allow cord to sit flush on the mat.

Note: For both applications, remove screw from floor mat

ground before attaching to mat.

ASSEMBLE

SCREW, STUD,

WASHER, LABEL

AND CONICAL NUT

AS SHOWN

Socket

Stud

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Figure 8. Installing screw-on mat grounding snap.

3. The second type of mat grounding snap is the push and clinch

snap. This snap is designed for use with any type of soft mat

material: dissipative, conductive or multi-layered. It is

recommended for use with three-layered material, because it

provides excellent contact with the internal conductive layer. It

is recommended that before inserting this snap, the mat be

punctured with a sharp tool where the snap will be placed.

This type of snap is available as a snap stud as item #09861

and as a snap socket as item #09863.

A. Remove the release paper from the circular label and

affix it onto the material in the desired location.

B. Center the prongs on the snap assembly with the label.

Apply pressure to the snap until the prongs come through

the back of the mat, then clinch over prongs to secure snap

as shown in Figure 9.

workstation grounds. EOS/ESD-S6.1 recommends that a nonresistor ground cord be used to ground work surfaces and floor

mats. Selection of the ground cord is determined by user

needs and specifications.

3. Desco offers a variety of ground cords designed to ground

work surfaces or floor mats. See selection chart below for

details on ground cords.

USE A PHILLIPS

SCREWDRIVER OR

AWL TO PUNCH

A HOLE IN THE

MATERIAL

© 2009 DESCO INDUSTRIES INC.

Employee Owned

4. The 09837 Multi

Grounding Hub is

designed for use as

either a multiple

grounding block or as a

common point ground.

The Multi Grounding

Hub incorporates six

standard banana jacks,

and six terminations for

ring terminals (10-32

screw in threaded

holes).

Figure 11. Mounting the 09837 to a

table leg.

Page 4

TB-2000 Page 4 of 4

Figure 14. Hooking up ground cords

4. If your kit includes a floor mat, you should duplicate step

2 and attach the floor mat ground to the same point as the

worksurface ground.

5. Measure the resistance from the ground snap on the mat to

the common ground point. It should read 1 megohm ± 20

percent if you are using a ground cord with a resistor, and less

than 10 ohms if you are using a non-resistor ground cord.

6. If you have a surface resistance or resistance to ground tester

available, you may wish to test the resistance to ground from

the mat surface. Note: depending upon the accuracy of the

instrument you are using, you may get a wide range of results

in resistance to ground tests. Any reading below 10

12

Ohms

is acceptable for lower cost “field grade” instruments. In

order to get the electrical readings specified for the materials

you must use laboratory instruments under controlled

conditions per ESD S4.1. This will require a megohmmeter

with 100 volt open test circuit voltage and two five pound

electrodes per ASTM-150. Desco sells this as the Digital

Surface Resistance Test Kit, Item #19780. For more

information on the 19770, ask for Technical Bulletin TB-3014.

7. If you are using a mat kit that includes the wrist strap, install

the wrist strap directly to the common point mat ground cord.

Again, test the resistance from the backplate of the wrist strap

to the common ground point. It should read 1 Megohm ± 20

percent.

Limited Warranty

Desco expressly warrants that for a period of one (1) year from the date

of purchase, Desco grounding products will be free of defects in material

(parts) and workmanship (labor). Within the warranty period, the product

will be tested, repaired, or replaced at Desco’s option, free of charge.

Call our Customer Service Department at 909-627-8178 (Chino, CA) or

781-821-8370 (Canton, MA) for a Return Material Authorization (RMA)

and proper shipping instructions and address. Include a copy of your

original packing slip, invoice, or other proof of purchase date. Any unit

under warranty should be shipped prepaid to the Desco Charleswater

factory. Warranty repairs will take approximately two weeks.

If your unit is out of warranty call Customer Service at 909-627-8178

(Chino, CA) or 781-821-8370 (Canton, MA) for a Return Material

Authorization (RMA) and proper shipping instructions and address. Ship

your unit freight prepaid and Desco will quote repair charges necessary

to bring your unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF ALL

OTHER PRODUCT WARRANTIES, EXPRESSED AND IMPLIED,

INCLUDING MERCHANTABILITYAND FITNESS FOR APARTICULAR

PURPOSE WHICH ARE SPECIFICALLY DISCLAIMED. The express

warranty will not apply to defects or damage due to accidents, neglect,

misuse, alterations, operator error, or failure to properly maintain, clean

or repair products.

Limit of Liability

In no event will Desco or any seller be responsible or liable for any

injury, loss or damage, direct or consequential, arising out of the use of

or the inability to use the product. Before using, users shall determine

the suitability of the product for their intended use, and users assume all

risk and liability whatsoever in connection therewith.

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Figure 13. Installing 09814 to mat using supplied hardware.

Mat Installation

1. For best results, allow the mats to lay flat for about four hours

at room temperature before installing. This will give the

material time to flatten out from being rolled for shipment.

2. Test all workstation grounds for proper impedance to ground.

See Desco Technical Bulletin TB-2007 for a complete

discussion of grounds.

3. Lay the mat in position and snap the ground cord to it. Bring

the other end of the ground cord to the common ground point

and attach it using the ring terminal. Asuggested ground point

is the center screw of a standard outlet. Testing is

recommended to ensure that the screw is properly grounded.

Tie the ground wire to the bench to keep it out of the way and

neat. You may cut and strip the ground wire to a shorter length

and attach it with the extra ring terminal included with each

Desco ground cord.

Figure 15. Adding the wriststrap.

8. Your completed installation of a Desco ESD workstation should

comply with one of the electrical diagrams illustrated in Figure 16.

Figure 16. Proper wiring diagrams for conductive and dissipative

ESD workstations.

BE SURE YOU TEST ALL GROUNDS AND THE WRIST STRAP

FREQUENTLY.

The following bulletins are available from Desco:

TB-2004 Operation of 19350 Wrist Strap Tester

TB-2005 Wrist Straps, Grounding, Testing, Maintenance

TB-2007 Safe Grounding of Static Controlled Workstations

Cleaning

For optimum electrical performance, surfaces must be cleaned

regularly with a mild detergent and water solution or an anti-static

cleaner. Desco recommends our “REZTORE” Surface and Mat

cleaner, item #10435. DO NOT USE CLEANERS WITH

SILICONE. They will build up a silicone coating on the surface

which will cause the surface to become an insulator. Many

common household cleaners contain silicone.

09825/09826

“GREEN WIRE”

UTILITY

GROUND

POINTS

RING

TERMINAL

CAN BE

ATTACHED

HERE

© 2009 DESCO INDUSTRIES INC.

Employee Owned

Loading...

Loading...