Desco 94401 Installation Manual

TB-5541 December 2008 Page 1 of 4

TECHNICAL BULLETIN TB-5541

Made in America

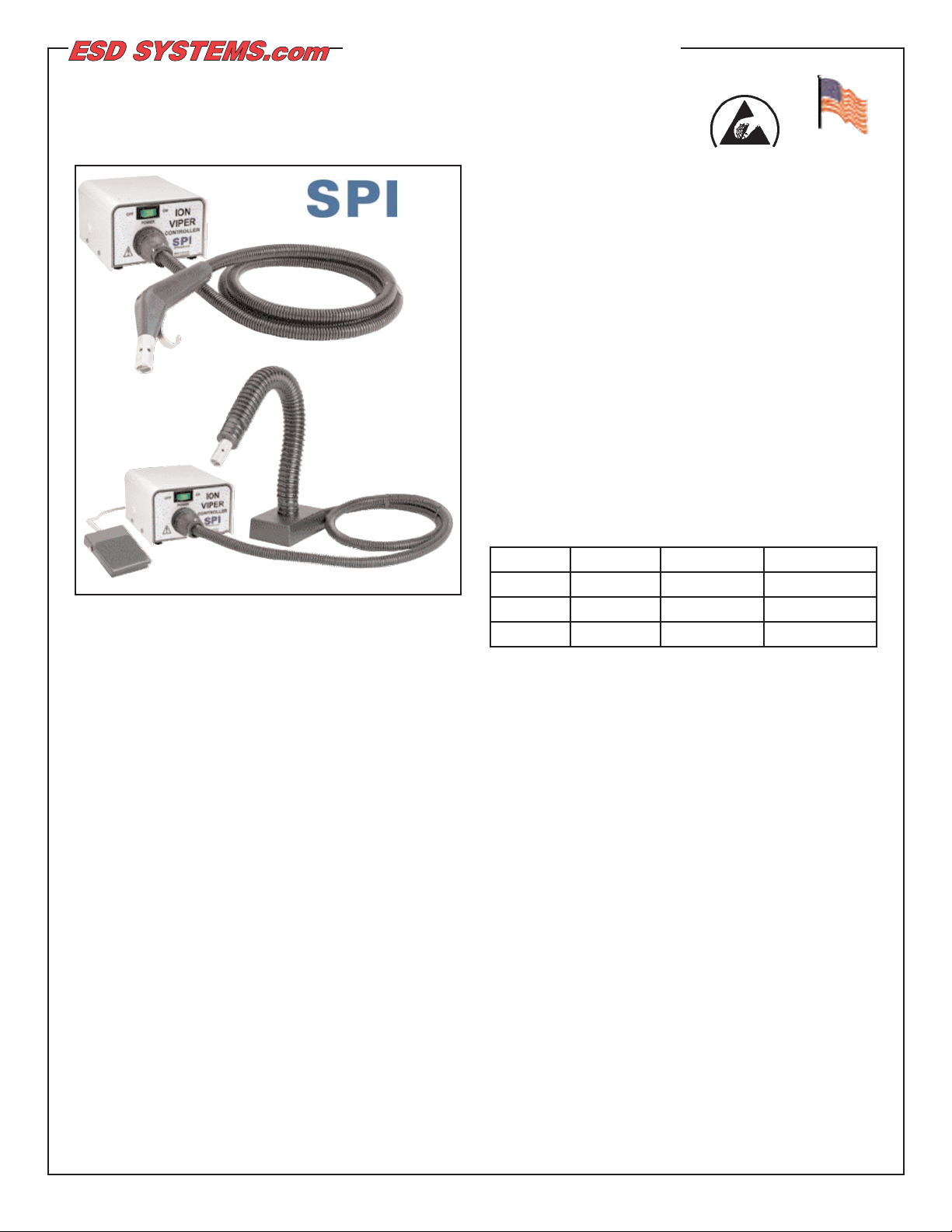

Figure 1. SPI Ion Viper Air Nozzles

94400/94401 Ion Viper (Controller and Foot Switch)

94402 Hand Gun (Controller with Hose)

Description

The SPI Ion Viper Air Nozzle and Neutralizing Hand Gun are

ready-to-use units designed for use in applications and areas

where static can create manufacturing or handling problems. The

units quickly and effectively neutralize bulk static charges and aid

in controlling contamination by dislodging dust and debris attracted

by static electricity. Airflow may be easily adjusted from a gentle

stream to a powerful blast. These units are designed for use in

applications and areas where ElectroStatic Attraction

contamination create manufacturing or handling problems (Ref:

ESD Handbook TR 20.20 paragraph 5.3.6.5.2.4 Point of Use

Ionization). The Ion Viper meets or exceeds the recommended

technical requirements of ANSI/ESD S20.20 tested in accordance

with ANSI/ESD S3.1.

The Ion Viper Air Nozzle is designed for point-of-use fixed

mounting applications, while the Ion Viper Hand Gun is a more

portable unit. The air hose of both units is designed to be easily

disconnected or replaced by the user. Replacement nozzle/air

hose assemblies for the Ion Viper Hand Gun are sold separately

as SPI Item #99403.

Ionizers are useful in preventing electrostatic charge generation,

ElectroStatic Discharge, ElectroStatic Attraction, as well as

preventing equipment latch-up and safety related shock.

ANSI/ESD S20.20 Paragraph 6.2.3.1 Protected Areas

Requirement states: "Ionization or other charge mitigating

techniques shall be used at the workstation to neutralize

electrostatic fields on all process essential insulators if the

electrostatic field is considered a threat." Ionization is used to

neutralize charges on process necessary insulators and isolated

semiconductors. Some examples of process necessary insulators

are: the PC board itself, plastic test stands, plastic housing where

a PCB may be mounted, as well as computer monitor screens and

regular cleaning wipes. Examples of floating or isolated

conductors are: loaded PCB mounted in a stand where the pins

are not contacting the dissipative workstation. Ionization is not

effective on items that have large capacitance, like people and

carts; however, ionizers should be considered as a method for

charge neutralization in cases where grounding cannot be

achieved.

Air ionization can neutralize the static charge on insulated and

isolated objects by producing separate charges in the molecules

of the gases of the surrounding air. When an electrostatic charge

is present on objects in the work environment, it will be neutralized

by attracting opposite polarity charges from the ionized air. Note

that ionization systems should not be used as a primary means of

charge control on conductors or people. (Reference: IEC 61340-52:1 paragraph 5.2.9).

Both the Ion Viper and Neutralizing Hand Gun are NIST

calibrated. They come equipped with universal IEC cord

connectors.

NOTE: These units are not recommended for continuous use.

IONIZER SELECTION

ANSI/ESD S20.20 paragraph 6.1.1.2. ESD Control Program

Plan Guidance states: "The Plan should include a listing of the

specific type of ESD protective materials and equipment used

in the Program." When selecting an ionizer life cycle costs

should be considered including: equipment cost; installation

cost; and operation and maintenance cost.

Air Requirements

Always supply the Ion Viper and Hand Gun with filtered, dry

noncombustible gases, such as compressed shop air or nitrogen.

(If nitrogen is used, the tip will need to be replaced and the unit

recalibrated. This MUST be done by the factory.) If the air is not

dry, damage to the equipment may result and the warranty will be

voided. Dirty air can introduce moisture and oil, contaminating the

units’ emitter assembly along with the materials to be cleaned or

neutralized. Filters must therefore be used at all times upstream of

the air nozzle. Awater trap-type pre-filter should be used in

conjunction with an oil coalescing-type filter. Also drain all

moisture traps regularly to prevent moisture in the line. Several

drainings per day may be necessary, especially in areas of high

humidity.

The Neutralizing Ion Viper and Hand Gun may be operated over a

range of 30 PSI to 100 PSI. The specific pressure needed will

depend upon the application. Pressures exceeding 100 PSI are

Neutralizing Ion Viper and Hand Gun

Operation and Maintenance

© 2008 DESCO INDUSTRIES INC.

Employee Owned

94400/94401

94402

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

MODEL STYLE VOL TAGE AC IEC CORD

94400 Ion Viper 120 Yes

94401 Ion Viper 220 No

94402 Hand Gun 120 Yes

TB-5541 Page 2 of 4

not recommended since these higher pressures are detrimental to

effective ion production. An air pressure setting of 60 PSI is

recommended. Use the needle valve located on the back of the

controller to properly adjust the air flow.

Air Supply Connection

Turn off air at regulator (or compressor). Insert the brass male

connector (1/4" tubing to 1/8" pipe thread) into an available port on

the regulator. If all ports are being used, a “T” or “+” may be added

to create more ports. Connect the 1/4" tubing to the male

connector on the needle valve on back side of the unit, following

the instructions given below.

To connect tubing or filter to quick connect fitting:

Cut end of plastic tubing square and clean. Push against the collar

with thumbnail. While holding collar in, push tubing into the fitting

until it bottoms out completely.

To release tubing or filter from quick connect fitting:

Push against the collar with thumbnail. While holding collar in,

push tubing inward slightly, then pull tubing out.

IMPORTANT NOTE: User should exercise caution when using

any compressed air device.

Figure 2. Connecting the filter.

Electrical Requirements

The Ion Viper and Neutralizing Hand Gun must be connected to a

properly grounded receptacle for the units to operate properly. It is

recommended that the AC outlet be checked for proper wiring and

grounding.

Do not under any circumstances remove the ground pin from

the plug of these units.

NOTE: Grounding of these units is necessary not only to

ensure that they operate properly, but to eliminate the

possibility of an electrical shock.

Operation

Turn on unit with switch on the front panel. The green light

indicates that the air nozzle is ready for use. Point nozzle at object

to be cleaned or neutralized.

When using the Ion Viper, actuate foot pedal switch to initiate the

flow of air and neutralizing ions. Best results are normally obtained

when holding the nozzle within .5' to 1.5 feet of the item being

neutralized.

For the Neutralizing Hand Gun, push button on the nozzle body to

initiate the flow of air and neutralizing ions. Best results are

normally obtained when holding the nozzle within 2 or 3 feet of the

item being neutralized; hold the nozzle closer when required.

NOTE: Unit is not designed for continuous duty.

A needle valve is located on the back of the unit for fine

adjustments to the air flow, or for shutting off the air to the nozzle.

Airflow on the unit can be adjusted from a gentle blow to a strong

blast, allowing for use in most applications. Do not obstruct the air

jet with fingers or other objects. Do not force any object into the

air jet hole; this action

can easily damage the

emitter pin and prevent

the controller from

producing the ionization

necessary for neutralizing static charges.

The ion balance is

affected by many factors, such as distance,

air flow, humidity, and

emitter contamination.

Therefore, before using

this device around

components and

assemblies which are highly sensitive to ESD, it is recommended

that the user thoroughly evaluate the application prior to its use.

Avoid sharply bending or crushing the black convoluted tubing

under feet, rolling chairs or other furniture.

IMPORTANT NOTE: These air nozzles are not explosion proof.

Do not use in environments where volatile materials are

present.

SPI solid-state electronic equipment is compact and rugged but

should be treated as sensitive electronic equipment. With proper

installation and a continued preventive maintenance program you

will ensure the proper performance of the unit.

Theory of Operation

The Ion Viper and Neutralizing Hand gun employ high voltage AC

to create a balanced ion field. AC systems utilize emitters that are

switched rapidly between positive and negative high voltage,

usually at the power line frequency (50/60 Hz). The emitter is

located at the end of the nozzle. This emitter produces large

amounts of positive and negative ions, which mix with the air

supply and create a highly effective neutralizing field. Any material

within this field will be neutralized rapidly. The air nozzles also

eliminate contamination by dislodging dust and debris which is

attracted to a material’s surface by static charges. Once static

charges are neutralized, dust particles and other forms of

contamination are freed and carried away by the air stream. SPI

ionizers meet the ANSI/ESD S20.20 minimum recommended

technical requirement range of less than ±50 volts voltage offset

tested in accordance with ANSI EOS/ESD S3.1. Air Nozzle

Ionizers provide ±20 volt balance.

Maintenance

"As with all ionizers, periodic maintenance will be needed to

provide optimum performance." (Reference: IEC 61340-5-2:1

paragraph 5.2.9).

The frequency of monitoring ionizers really depends on how and

where they are used. Since the majority of them use a fan to

transport the ions to the working area, the cleanliness of the air

directly affects their performance over time and how often the

emitters should be cleaned.

EIA-625 recommends checking ionizers every 6 months, but this

may not be suitable for many programs particularly since an outof-balance may exist for months before it is checked again.

ANSI/ESD S20.20 paragraph 6.1.3.1 Compliance Verification Plan

Requirement states: "Test equipment shall be selected to make

measurements of appropriate properties of the technical

requirements that are incorporated into the ESD

program plan."

And paragraph 6.1.3.2. Compliance Verification Plan Guidance

states: "In addition to internal audits, external audits (Organization

and supplier of ESDS items) should be performed to ensure

Air supply

conection

Needle

valve

Figure 3. Airflow adjustment valve.

© 2008 DESCO INDUSTRIES INC.

Employee Owned

Filter (when used)

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website: ESDSystems.com

Loading...

Loading...