Desco 60600 Installation Manual

TECHNICAL BULLETIN TB-3006

High Output Overhead Ionizer

Installation, Operation and Maintenance

screens and regular cleaning wipes. Examples of floating

or isolated conductors are: loaded PCB mounted in a

stand where the pins are not contacting the dissipative

workstation. Ionization is not effective on items that have

large capacitance, like people and carts; however, ionizers

should be considered as a method for charge neutralization

in cases where grounding cannot be achieved.

“Ionizers should be considered as a method for charge

neutralization in cases where grounding cannot be

achieved.” …“Air ionization can neutralize the static charge

on insulated and isolated objects by producing separate

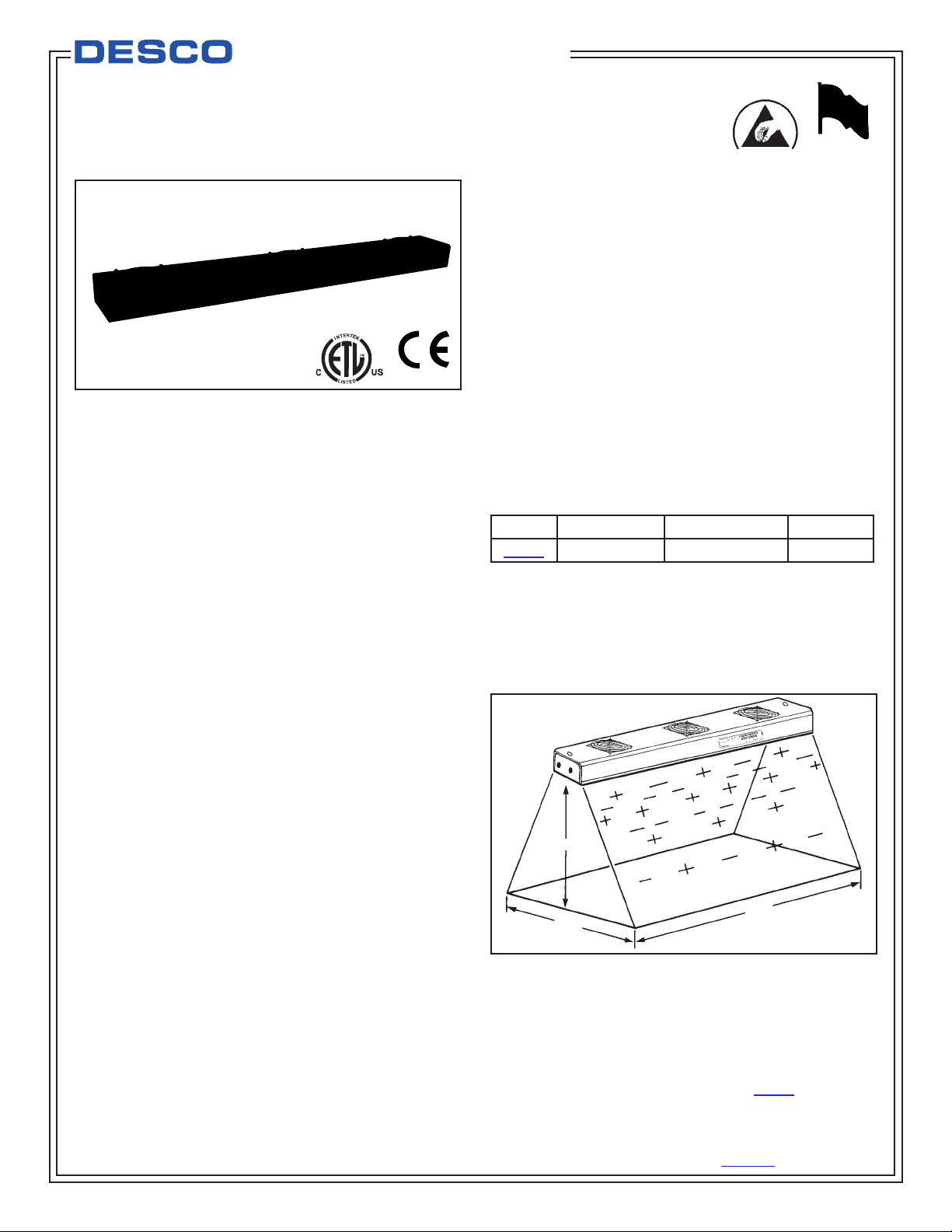

Figure 1. High Output Overhead Ionizer

Description

The Desco 40" High Output Overhead Ionizer is designed

to neutralize electrostatic charges over a large work

area. The unique active feedback and balance circuit

automatically ensures and maintains the unit’s ion offset

voltage balance, despite variations in line voltage, air speed

or emitter electrode condition. The ionizer’s feedback circuit

also gives an audible and visual alarm indication when

maintenance is required. The overhead mounting design of

this ionizer allows it to provide maximum coverage without

consuming valuable work bench space. The need for

maintenance is minimized, while maximum neutralization

efficiency and overall performance is attained.

This overhead ionizer is unique - it comes equipped with

two factory installed lights and three heaters. The lights

are on continuously whenever the ionizer is turned on and

allow for better vision at the workstation. The heaters

are activated by a switch on the face of the ionizer. The

heaters will raise the temperature of the output air to about

10° above ambient. The heaters are only to offset the chill

factor of the moving air. They are not intended to warm the

workstation.

charges in the molecules of the gases of the surrounding

air. When a static charge is present on objects in the work

environment, it will be neutralized by attracting opposite

polarity charges from the ionized air.” (EN 61340-5-2

paragraph 5.2.9)

This ionizer is NIST calibrated and comes equipped with

universal IEC cord connectors.

Model Voltage / Hz Light & Heater IEC Cord

60600 120 / 50-60 Yes 7' 6"

IONIZER SELECTION

ANSI/ESD S20.20 paragraph 6.1.1.2. ESD Control Program

Plan Guidance states: “The Plan should include a listing of

the specific type of ESD protective materials and equipment

used in the Program.” When selecting an ionizer life cycle

costs should be considered including: equipment cost,

installation cost, and operation and maintenance cost.

Made in America

Ionizers are useful in preventing electrostatic charge

generation, ElectroStatic Discharge, ElectroStatic Attraction,

as well as preventing equipment latch-up and safety related

shock. Per ANSI/ESDS20.20-2007 section 8.3 “In order

to mitigate field-induced CDM [Charged Device Model]

damage, the ESD program shall include a plan for the

handling of process-required insulators. If the field exceeds

2,000 volts/inch, steps shall be taken to either: A) Separate

the insulator from the ESD-sensitive device by a distance

of 30 cm (12 inches); or B) Use ionization or other charge

mitigating techniques to neutralize the charge.”

Ionization is used to neutralize charges on process

necessary insulators and isolated semiconductors. Some

examples of process necessary insulators are: the PC

board itself, plastic test stands, plastic housing where

a PCB may be mounted, as well as computer monitor

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: Desco.com

TB-3006 July 2010 Page 1 of 4

24 IN.

OPTIMUM

PERFORMANCE ZONE

24 IN.

48 IN.

Figure 2. Area of optimum charge neutralization

The unit provides better coverage without using excessive

bench space. The ionizer’s discharge times (neutralization

efficiency) is optimal at approximately 12" to 24" above the

work surface, and will drop off as the distance from the unit

increases.

*Never use incandescent lamps in the 60600 ionizer.

Contact Desco Customer Service at (909) 627-8178 for

lamp replacement information.

© 2010 DESCO INDUSTRIES INC.

Employee Owned

Installation

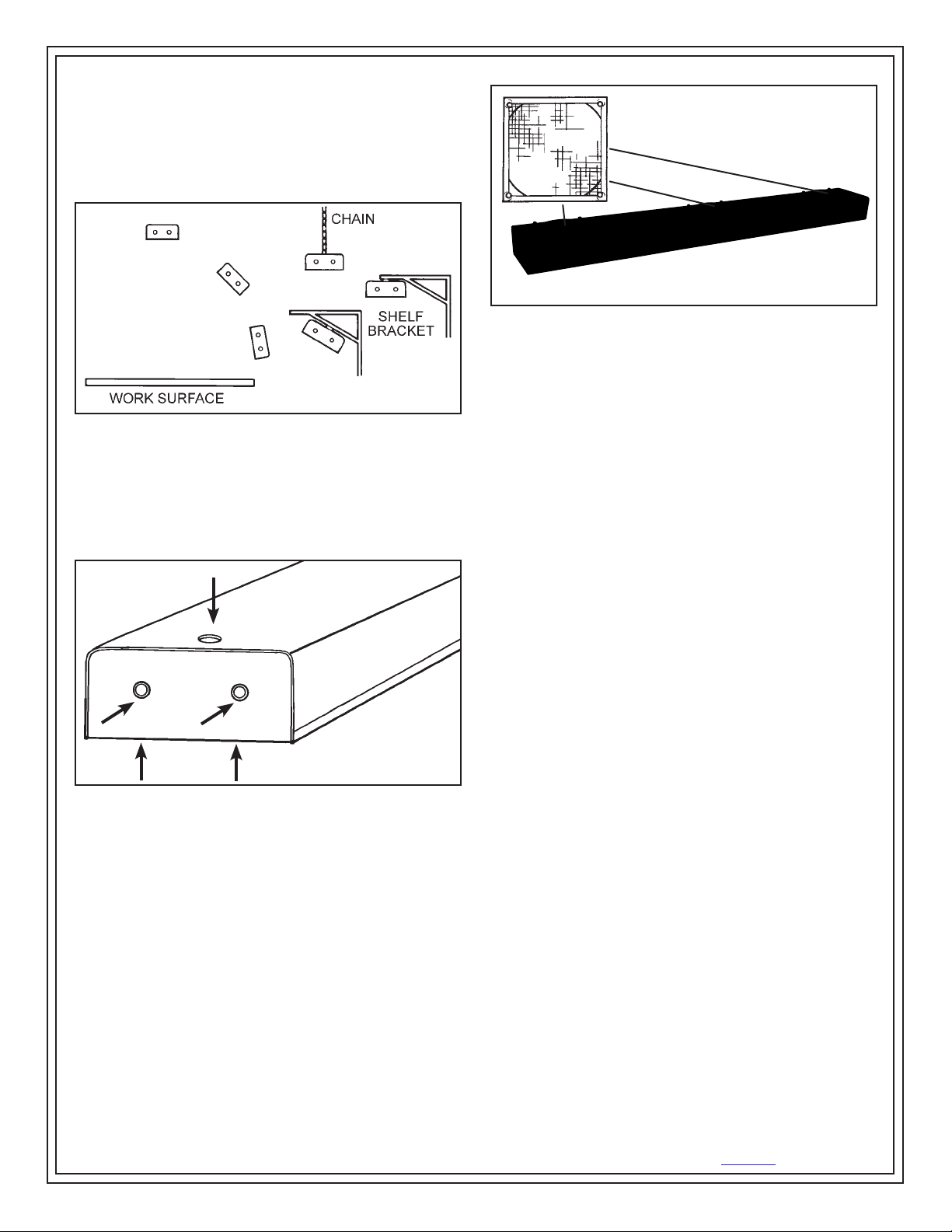

Figure 3 shows multiple mounting positions relative to the

bench top. Mounting may be accomplished by brackets

from shelving, vertical uprights, lights, or with chains hung

from the ceiling. Ensure that air flow is not impeded by the

method used.

Figure 3. Mounting alternatives relative to the bench top

Mounting Suggestions

Mounting the ionizer is facilitated by five 1/4"-20 threaded

holes on each end and universal brackets supplied with

the unit. To avoid a potential shock hazard, be sure that

fasteners do not extend more than 1/2" into unit.

Air filter

Figure 5. Filter for ionizer

Operation

After the ionizer has been securely mounted, connect

the power cord to the IEC connector on the back of the

unit and then to a convenient grounded receptacle. It is

recommended that the AC outlet be checked for proper

wiring and grounding, as the ionizer depends on a good

ground for offset voltage balancing.

Set the front panel rocker fan switch to either “HIGH” or

“LOW” speed fan. Higher air flow will result in a faster

neutralization rate.

If the ionizer is used in a manner not specified by the

manufacturer, the protection provided by the ionizer

may be impaired.

Figure 4. 1/4"-20 threaded mounting holes

Filter for Ionizer (Optional)

A filter is available for the High Output Overhead Ionizer.

Overhead ionizers operate more effectively when the air

is free of contaminants. The filter will allow the overhead

ionizer to operate longer between maintenance intervals.

Ensure that ionizer is turned off. Remove grills and install

filters on the ionizer using screws supplied (do not re-install

grills over filters). Replacement filters (Desco item #60455)

are available. For more information on the filter, call our

customer service department at 909-627-8178 (Chino, CA)

or 781-821-8370 (Canton, MA).

Maintenance

“As with all ionizers, periodic maintenance will be needed to

provide optimum performance.” (Reference: IEC 61340-52:1paragraph 5.2.9).

The frequency of monitoring ionizers really depends on how

and where they are used. Since the majority of them use a

fan to transport the ions to the working area, the cleanliness

of the air directly affects their performance over time and

how often the emitters should be cleaned.

ANSI/ESD S20.20 specifies that the compliance

verification of ionizers be tested per ESD TR53. EIA-625

recommends checking ionizers every 6 months, but

this may not be suitable for many programs particularly

since an out-of-balance may exist for months before it

is checked again. ANSI/ESD S20.20 paragraph 6.1.3.1

Compliance Verification Plan Requirement states: “Test

equipment shall be selected to make measurements of

appropriate properties of the technical requirements that are

incorporated into the ESD program plan.” And paragraph

6.1.3.2. Compliance Verification Plan Guidance states: “In

addition to internal audits, external audits (Organization and

supplier of ESDS items) should be performed to ensure

compliance with planned requirements. Verifications should

include routine checks of the Technical Requirements in the

Plan. The frequency of verification checks should be based

on the control item usage, its durability and associated risk

of failure.”

TB-3006 Page 2 of 4

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: Desco.com

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

© 2010 DESCO INDUSTRIES INC.

Employee Owned

Loading...

Loading...