Desco 13840 User Manual

Desiccant is a drying agent used to lower the moisture

content of air inside a closed space, such as a Moisture

Barrier Bag. Desiccant is packaged in fractional units in

order to facilitate its usage with a variety of bag sizes. One

full “unit” of packaged desiccant will absorb the following

quantities of water at equilibrium with air at 77°F (25°C):

3.00 grams @ 20% rH and 6.00 grams @ 40% rH, when

tested to MIL-D-3464.

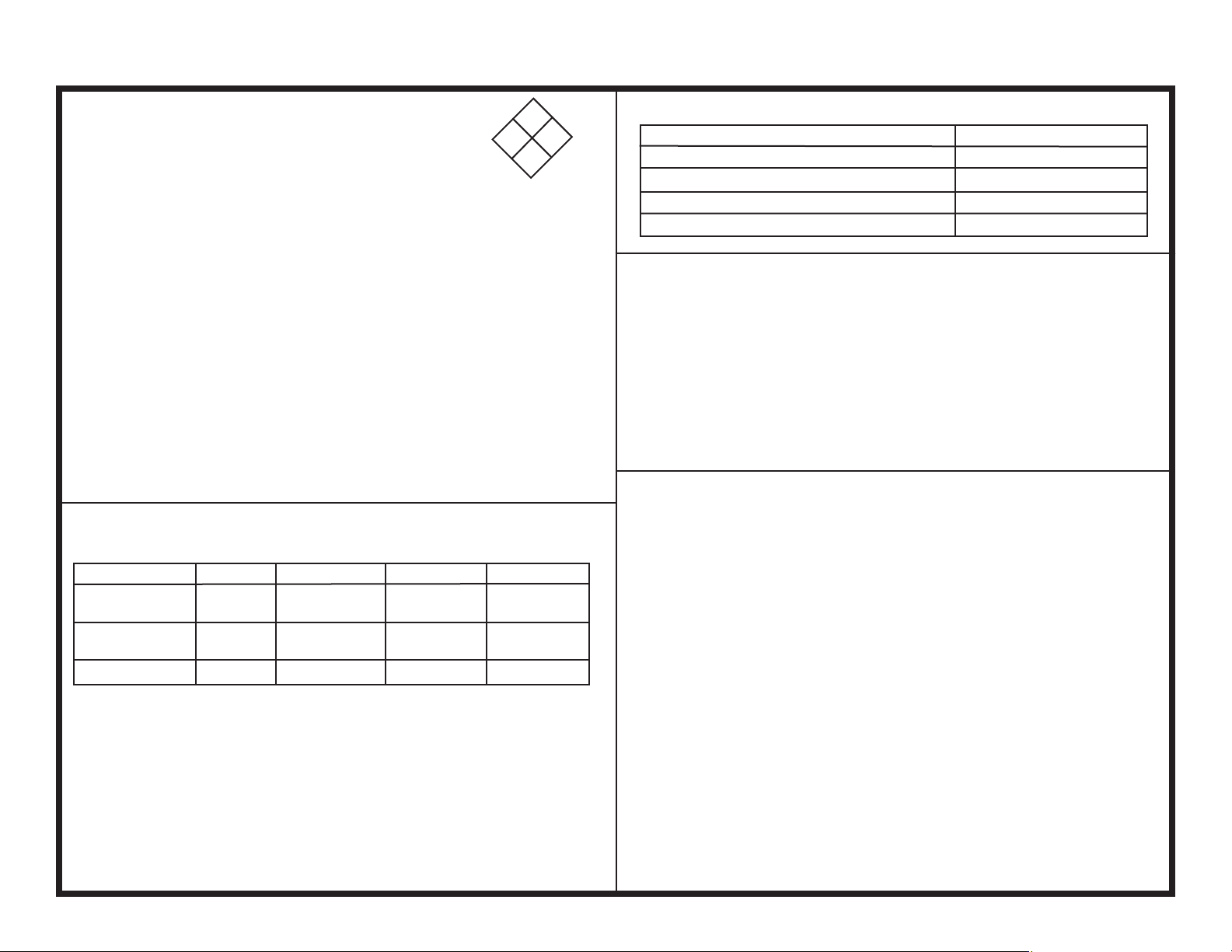

In order to provide a complete moisture barrier packaging

assembly, desiccant must be inserted into the bag, prior to

having the bag vacuum sealed. The recommended amount

of desiccant is dependent on the interior surface area of

the bag to be used. Figure 4 is a reference table indicating

recommended minimum amounts of desiccant that should be

used with Moisture Barrier Bags.

INTERIOR BAG NUMBER OF DESICCANT UNITS

SURFACE AREA* **MIH <20% MIH <30% MIH < 40%

100 sq. in. 1.5 1.0 1.0

130 sq. in. 2.0 1.5 1.0

160 sq. in. 2.0 1.5 1.5

200 sq. in. 2.5 2.0 1.5

240 sq. in. 3.0 2.0 1.5

290 sq. in. 4.0 2.5 2.0

340 sq. in. 4.5 3.0 2.5

390 sq. in. 5.0 3.5 2.5

450 sq. in. 5.5 4.0 3.0

510 sq. in. 6.5 4.5 3.5

580 sq. in. 7.5 5.0 4.0

650 sq. in. 8.0 5.5 4.0

720 sq. in. 9.0 6.0 4.5

Table for recommended desiccant usage. Information taken out of EIA-583, Table 1, Page 8.

*To measure interior bag surface area, multiply length x width x 2

**MIH = Maximum Interior Humidity (%)

Desiccant paks are available from Desco in the following

unit sizes and standard packages:

13843 & 13844

“...it is important to take possible temperature exposure into account when shipping

electronic parts. It is particularly important to consider what happens to the interior of

a package if the environment has high humidity. If the temperature varies across the

dew point of the established interior environment of the package, condensation may

occur. The interior of a package should either contain desiccant or the air should be

evacuated from the package during the sealing process. The package itself should

have a low WVTR.” (ESD Handbook ESD TR20.20 section 5.4.3.2.2)

© 2010 DESCO INDUSTRIES INC.

Employee Owned

13840 & 13850

Item # Unit Size Std. Package Dimensions

13840 1/2 unit Box of 700 1.5" x 3"

13843 1 unit Box of 450 2" x 4"

13844 1 unit Pail of 300 2" x 4"

13850

1/2 unit Pail of 550 1.5" x 3"

Desiccant paks sold by Desco meet the requirements of

MIL-D-3464.

Fill Contents:

Activated Clay

Paper: Tyvek

Specications and procedures subject to change without notice.

Desiccant Pak

DESCO WEST:3651 WALNUT AVE., CHINO, CA 91710 WEBSITE: Desco.com

PHONE (909) 627-8178 FAX (909) 627-7449

DESCO EAST: ONE COLGATE WAY, CANTON, MA 02021-1407

PHONE (781) 821-8370 FAX (781) 575-0172

DRAWING NUMBER

13850

Made in America

DATE:

May

2010

Material Safety Data Sheet

May be used to comply with

OSHA’s Hazard Communication Standard,

29 CFR 1910. 1200. Standard must be

consulted for specific requirements.

NFPA Designation 704

Degree of Hazard:

4 = Extreme

3 = High

2 = Moderate

1 = Slight

0 = Insignificant

Health

(Blue)

Special Hazard

Flammability

(Red)

0

1

0

Reactivity

0

(Yellow)

SECTION I -- PRODUCT IDENTIFICATION AND THE COMPANY

Product information

Trade Name and Synonyms: Desi Pak

Company: Desco

3651 Walnut Ave

Chino, CA. 91710

Phone: (909) 627-8178

Fax: (909) 627-7449

Chemical Family: Montmorillonite Clay Mineral

Smectite Clay Mineral

Bentonite

Calcium Aliminosilicate

Formula: (Ca)x(A12-xMgm)Si4O10(OH)2nH20

NFPA/HMIS

Health: 0

Fire: 0

Reactivity: 0

Specific Hazard: See Section X

®

SECTION II -- HAZARDOUS INGREDIENTS

Hazardous Components in the Solid Mixture

COMPONENT CAS No. % by Weight OSHA/PEL ACGIH/TLV

Montmorillonite 1302-78-9 ³ 99 5.0 mg/m

Clay Mineral respirable form respirable form

Silicon dioxide 14808-60-7 <1%

(Crystalline Quartz)

Respirable Dust Not Detectable 0.1 mg/m3 0.1 mg/m

INGREDIENT HAZARD STATEMENT - This product contains less than 1% crystalline quartz

(CAS #14808-60-7), which is in a non-respirable form. The product is in granular form, and

packed in bags for use as a desiccant. Therefore, no exposure to quartz or clay dust is

anticipated under normal use of this product.

CARCINOGENICITY

NTP? No OSHA? No

Prolonged or repeated exposure may cause lung injury. Unless otherwise noted, all values

are reported as 8-hour Time Weighted Averages (TWA’s) and total dust (particulates only). All

ACGIH TLV’s refer to the 1989-90 Standards. All OSHA PEL’s refer to 49 CFR Part 1910 Air

Contaminants: Final Rule, January 19, 1989.

3

in 5.0 mg/m

3

in

3

SECTION III -- PHYSICAL DATA

Appearance and Odor Gray granules. No odor.

Melting Point: N/A

Solubility in Water: Insoluble

Bulk Density: 57-64 lbs./cu. ft.

Percent Volatile by Weight at 150° C: <3.0%

SECTION IV -- FIRE EXPLOSION DATA

FIRE AND EXPLOSION HAZARD - Negligible fire and explosion hazard when exposed to heat

or flame by reaction with incompatible substances.

FLASH POINT - Nonflammable.

FIREFIGHTING MEDIA - Dry chemical, water spray, or foam. For larger fires, use water spray

fog or foam.

FIREFIGHTING - Nonflammable solids, liquids or gasses: Cool containers that are exposed

to flames with water from the side until well after fire is out. For massive fire in enclosed area,

use unmanned hose holder or monitor nozzles; if this is impossible, withdraw from area and

let fire burn. Withdraw immediately in case of rising sound from venting safety device or any

discoloration of the tank due to fire.

SECTION V -- HEALTH HAZARD DATA

This material is normally packaged and contained in a bag. If the bag is open, the resulting

dust is classified a nuisance dust, and may cause health hazards when inhaled, ingested or in

contact with the eyes and skin. Prolonged inhalation may cause irritation to the upper respiratory

tract and/or lung damage. If large amounts are ingested, intestinal disorders may occur. Contact

with eye tissue may result in irritation.

Prolonged or repeated contact with the skin in the absence or proper hygiene may cause

irritation.

Desi Pak® clay may contain a small amount of crystalline silica (quartz). Inhalation of crystalline

silica in the respirable range in excess of the TLV may result in an increase in the risk of serious

respiratory disease. Avoid breathing the dust. Use NIOSH/MSHA approved respirators when the

TLV for crystalline silica may be exceeded.

FIRST AID (INHALATION) - Remove to fresh air immediately. If breathing has stopped, give

artificial respiration. Keep affected person warm and at rest. Get medical attention immediately.

FIRST AID (INGESTION) - If large amounts have been ingested, give emetics to cause

vomiting. Stomach siphon may be applied as well. Milk and fatty acids should be avoided. Get

medical attention immediately.

FIRST AID (EYES) - Wash eyes immediately and carefully for 30 minutes with running water,

lifting upper and lower eyelids occasionally. Get prompt medical attention.

FIRST AID (SKIN) - To avoid repeated or prolonged contact with this chemical, use good

hygienic practices. Wash with soap and a large amount of water. Get medical attention if

irritation or inflammation develops

Loading...

Loading...