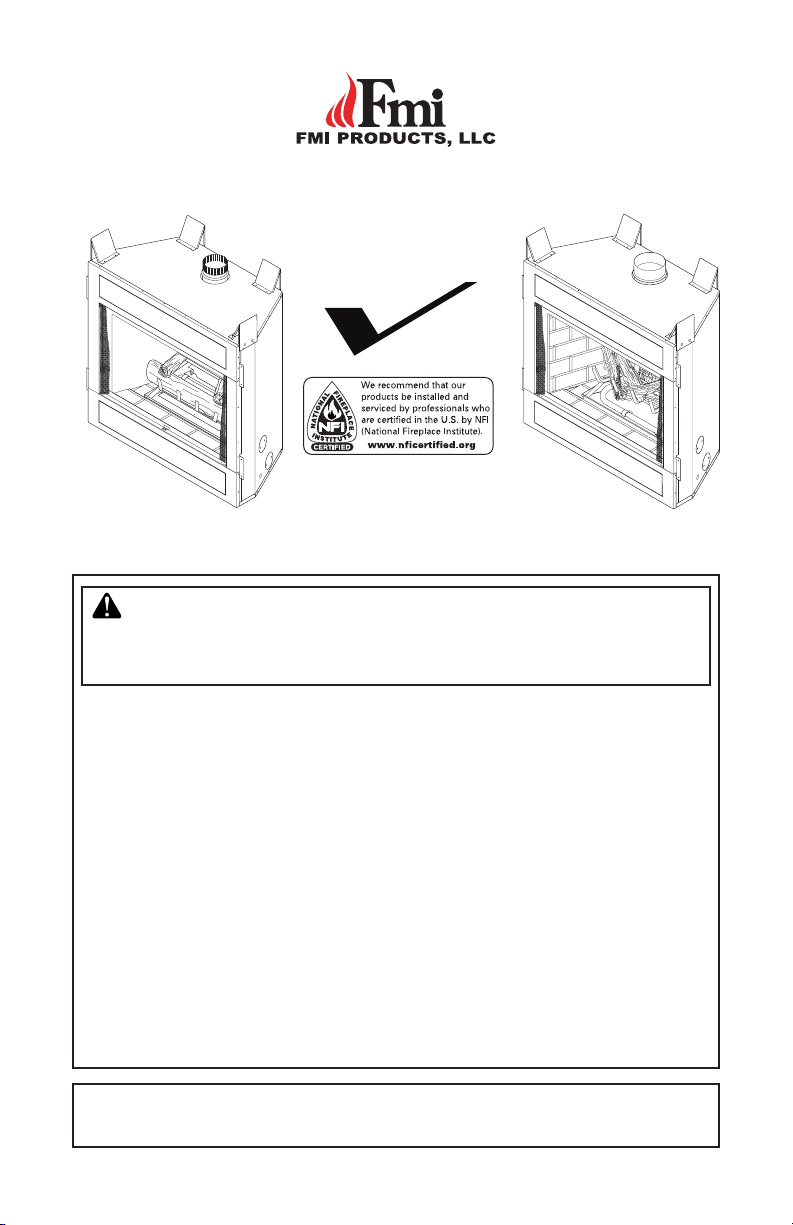

Desa Tech VP325B1, VP3251 Owner's Manual

B-VENT DECORATIVE GAS FIREPLACE

PFS

®

US

OWNER’S OPERATION AND INSTALLATION MANUAL

MODELS P324, VP324, P325(B) AND VP325(B)

NATURAL GAS

WARNING: If the information in this manual is not

followed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

— Installation and service must be performed by a quali-

ed installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.fmiproducts.com

TABLE OF CONTENTS

Safety .................................................................. 2

Unpacking............................................................ 4

Introduction .......................................................... 4

Product Specication ........................................... 6

Selecting Location ............................................... 7

PreInstallation Preparation .................................. 7

Venting Installation .............................................. 9

Installation ..........................................................11

Operation ........................................................... 19

Inspecting Burners............................................. 20

SAFETy

Cleaning and Maintenance ................................ 21

Troubleshooting ................................................. 22

Replacement Parts ............................................ 25

Service Hints ..................................................... 25

Technical Service............................................... 25

Accessories ....................................................... 25

Parts .................................................................. 26

Wiring Diagram .................................................. 31

Warranty .............................................. Back Cover

WARNING: Improper instal-

lation, adjustment, alteration,

service or maintenance can

cause injury or property damage.

Refer to this manual for correct

installation and operational

procedures. For assistance or

additional information consult

a qualified installer, service

agency or the gas supplier.

This appliance may be installed

in an aftermarket,* permanently

located, manufactured (mobile)

home, where not prohibited by

local codes.

This appliance is only for use

with the type of gas indicated on

the rating plate. This appliance

is not convertible for use with

other gases, unless a certied

kit is used.

* Aftermarket: Completion of sale, not for

purpose of resale, from the manufacturer

NOT FOR USE WITH SOLID

FUEL

CHECK LOCAL CODES PRIOR

TO INSTALLATION

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how

to install and maintain your

appliance, it also contains information that will enable you

to obtain replacement parts or

optional accessory items when

needed. Keep it with your other

important papers.

State of Massachusetts: The

installation must be made by a

licensed plumber or gas tter

in the Commonwealth of Mas-

sachusetts.

www.fmiproducts.com

108660-01G2

SAFETy

Continued

WARNING: This product

cont a i n s an d / or g e n e r ates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate or service this replace.

Improper use of this replace

can cause serious injury or death

from burns, re, explosions,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

This replace is a vented product. This replace will not produce any gas leakage into

your home if properly installed. This replace

must be properly installed by a qualified

service person. If this unit is not properly

installed by a qualied service person, gas

leakage can occur.

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the u,

with headaches, dizziness or nausea. If you

have these signs, the replace may not have

been installed properly. Get fresh air at once!

Have replace inspected and serviced by a

qualied service person. Some people are

more affected by carbon monoxide than oth-

ers. These include pregnant women, people

with heart or lung disease or anemia, those

under the inuence of alcohol and those at

high altitudes.

Propane/LP and Natural Gas: Both are odor-

less. An odor-making agent is added to each

of these gases. The odor helps you detect a

gas leak. However, the odor added to these

gases can fade. Gas may be present even

though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this replace.

108660-01G 3

www.fmiproducts.com

WARNING: Any change to

this replace or its controls can

be dangerous.

1. This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases unless a certied kit is

used.

2. For propane/LP replace, do not place

propane/LP supply tank(s) inside any

structure. Locate propane/ LP supply

tank(s) outdoors. To prevent performance

problems, do not use propane/LP fuel tank

of less than 100 lb capacity.

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not

use any phone in your building

• immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier's instructions

• if you cannot reach you gas supplier, call

the re department.

4. Never install the replace

• in a recreational vehicle

• where curtains, furniture, clothing or

other ammable objects are less than

42" from the front, top or sides of the

replace

• in high trafc areas

• in windy or drafty areas

5. This replace reaches high temperatures.

Keep children and adults away from hot

surfaces to avoid burns or clothing ignition. Fireplace will remain hot for a time

after shutdown. Allow surfaces to cool

before touching.

6. Carefully supervise young children when

they are in the room with replace.

7. A hearth extension is not required with this

appliance. If one is installed, it is for aesthetic purposes only and does not have

to meet the standard requirements.

8. Turn replace off and let cool before servicing or repairing. Only a qualied service

person should install, service or repair

this replace. Have replace inspected

annually by a qualied service person.

SAFETy

Continued

9. You must keep control compartments,

burners and circulating air passages

clean. More frequent cleaning may be

needed due to excessive lint and dust

from carpeting, bedding material, etc.

Turn off the gas valve and pilot light before

cleaning replace.

10. Have venting system inspected annually by

a qualied service person. If needed, have

venting system cleaned or repaired. See

Cleaning and Maintenance, page 21.

11. Keep the area around your fireplace

clear of combustible materials, gasoline

and other ammable vapor and liquids.

Do not run fireplace where these are

used or stored. Do not place items such

as clothing or decorations on or around

replace.

12. Do not use this replace to cook food or

burn paper or other objects.

13. Do not use any solid fuels (wood, coal,

paper, cardboard, etc.) in this replace.

Use only the gas type indicated on re-

place nameplate.

UNPACkING

The following items are packed inside the

rebox. Remove before positioning rebox

into framing.

• Ceramic Log Pack - Shrink wrapped on

cardboard

• 3 plastic bags containing lava rock, pan and

ember materials

14. This appliance, when installed, must be

electrically grounded in accordance with

local codes or, in the absence of local

codes, with the National Electrical Code,

ANSI/NFPA 70.

15. Do not install replace directly on carpeting, vinyl tile or any combustible material

other than wood. The replace must set

on a metal or wood panel extending the

full width and depth of the replace.

16. Do not use replace if any part has been

exposed to or under water. Immediately

call a qualied service person to arrange

for replacement of the unit.

17. Do not operate fireplace if any log is

broken.

18. Do not use a blower insert, heat exchanger insert or other accessory not approved

for use with this replace.

19. Provide adequate clearances around air

openings.

• Rear Log (P325/VP325 Models Only).

Remove 2 plastic quick ties from around

burner and grate

• Grate Stand - Lift off of burner pan

Check all items for any shipping damage. If

damaged, promptly inform dealer or distributor

where you bought the product.

Retain these items for later installation.

INTRODUCTION

These replace models are vented gas replaces that use a millivolt gas control valve

with a millivolt ignition system. P325/VP325

models have a 5" B-vent and P324/VP324

models have a 4" B-vent. A properly sized

B-Type venting system and listed type vent

cap are not supplied but are required for

proper operation. See venting instructions

on page 9.

WARNING: This gas appliance must not be connected to

a chimney ue servicing a solid

fuel burning appliance.

www.fmiproducts.com

These models are factory equipped for use

with natural gas and must be converted

when intended for use with propane/LP gas.

Conversion kits PCBM-324 and PCBM-325

may be purchased for simple conversion to

propane/LP gas. See Accessories, page 25.

BEFORE YOU BEGIN

Before beginning the installation of your appli-

ance, read these instructions completely.

This FMI PRODUCTS, LLC appliance and its

approved components are safe when installed

according to this installation manual and are

operated as recommended by FMI PRODUCTS,

LLC. Using any component fon FMI PROD-

UCTS, LLC approved and tested for use with this

appliance MAY CAUSE A FIRE HAZARD!

108660-01G4

INTRODUCTION

Continued

The FMI PRODUCTS, LLC warranty will

be voided by, and FMI PRODUCTS, LLC

disclaims any responsibility for the following

actions:

A) Modication of the appliance or any of the

components.

B) Use of any component part not approved

by FMI PRODUCTS, LLC in combination

with this appliance.

C) Installation and/or operation in a manner

other than instructed in this manual.

D) The burning of anything other than the

type of gas approved for use in this gas

appliance.

Installation must conform with local codes or,

in the absence of local codes, with the current

National Fuel Gas Code, ANSI Z223.1. This

appliance complies with ANSI Z21.50.

NOTICE: This appliance is not

intended to be used as a primary

source of heat.

WARNING: Installation of

this appliance should be done

by a qualied service person

well trained in the installation

of such appliances. You will

also need a building permit from

your local Building and Safety

Commissioner before installing

this appliance; otherwise your

insurance co. may not cover this

appliance.

CAUTION: Do not connect

appliance before pressure testing gas piping. Damage to gas

valve may result and an unsafe

condition may be caused.

The appliance and it’s individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 1/2

psig (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig

(3.5 kPa).

For the purpose of input adjustment two

pressure taps (for IN and OUT pressures)

are provided on the gas control valve for test

gauge connections to the appliance.+

108660-01G 5

www.fmiproducts.com

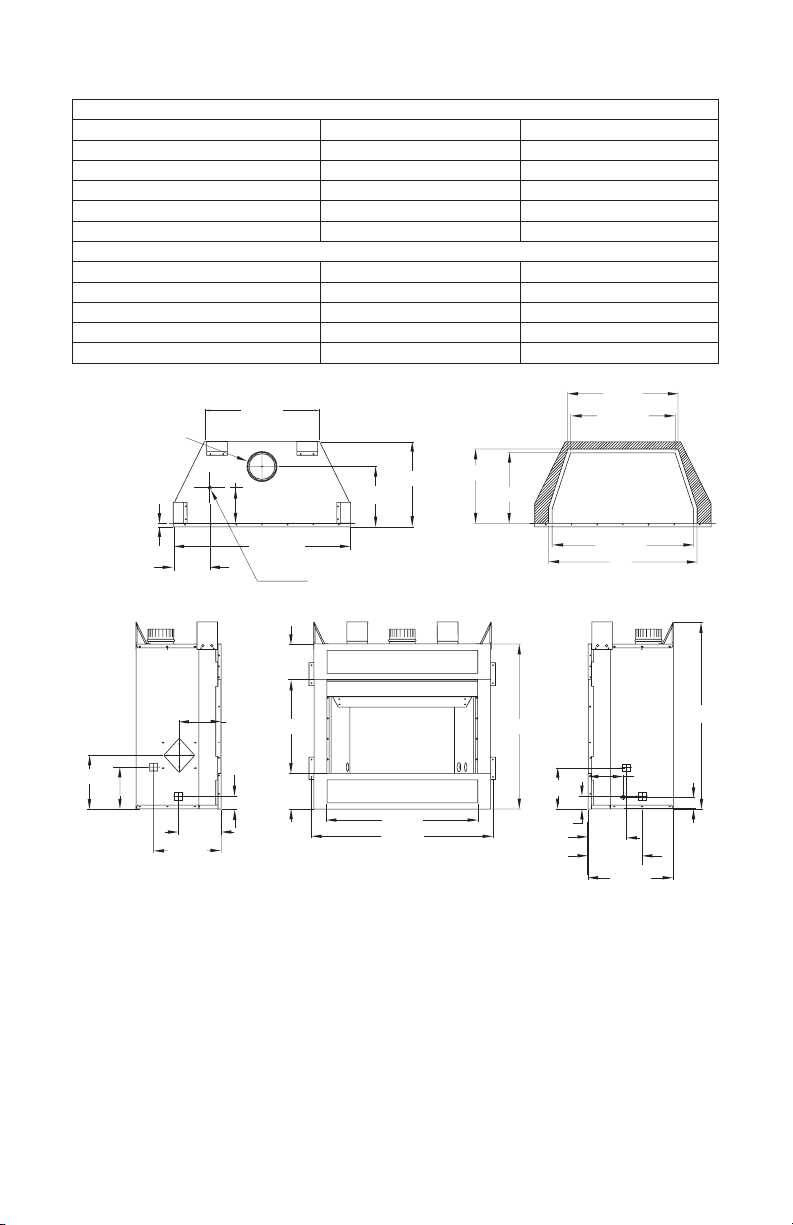

PRODUCT SPECIFICATION

6 7/8"

2 1/4"

7"

7"

Alternate Gas

Supply Inlet

13

1

/4"

32

1

/4"

* 27

1

/2"

29"

* 13

3

/4"

14

1

/2"

* 20

3

/8"

21

1

/2"

2

1

/2"

8

1

/4"

11

3

/4"

22

3

/8"

For Use

With B-1

Ve nt Pipe

Only

16

3

/4"

7

5

/8"

10

5

/8"

8

1

/8"

10

1

/2"

8

3

/8"

2

1

/2"

8

1

/4"

5/8"

34

1

/2"

35

3

/8"

29

1

/2"

18

1

/4"

7"

7"

16

3

/4"

36

1

/2"

* WITH REFRACTORY

DIMENSIONS

HEARTH AREA

GAS RATING - NATURAL

P324, VP324 P325(B), VP325(B)

Max. Input Rating 15,000 Btu/Hr 25,000 Btu/Hr

Manifold Pressure 3.5" WC (0.87 kPa) 3.5" WC (0.87 kPa)

Minimum Supply Pressure 4.5" WC (1.12 kPa) 4.5" WC (1.12 kPa)

Maximum Supply Pressure 10.5" WC (2.66 kPa) 10.5" WC (2.66 kPa)

Orice Size # 49 # 40

GAS RATING - PROPANE/LP

Max. Input Rating 15,000 Btu/Hr 25,000 Btu/Hr

Manifold Pressure 10" WC (2.49 kPa) 10" WC (2.49 kPa)

Minimum Supply Pressure 11" WC (2.74 kPa) 11" WC (2.74 kPa)

Maximum Supply Pressure 13" WC (3.23 kPa) 13" WC (3.23 kPa)

Orice Size # 56 # 54

Figure 1 - Appliance Dimensions

108660-01G6

www.fmiproducts.com

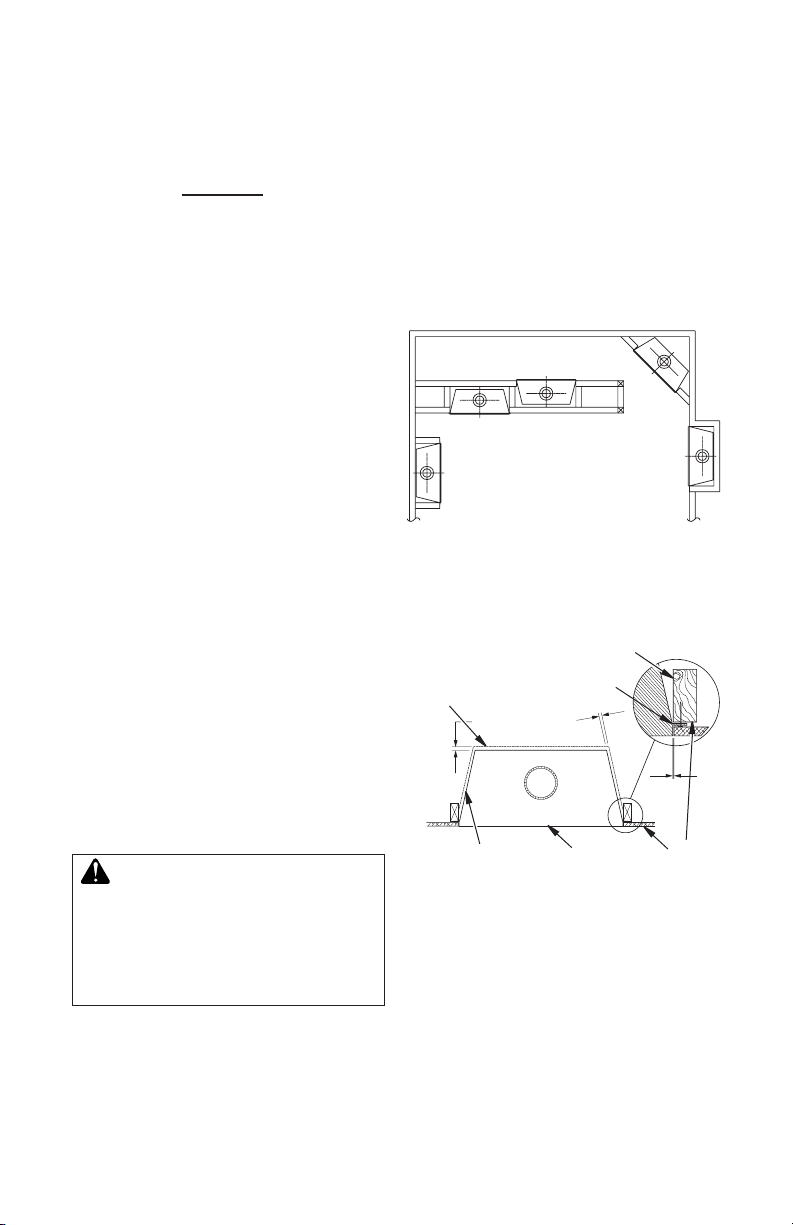

INTERNAL WALL

INSTALLATION

CORNER

INSTALLATION

FULL

PROJECTION

INSTALLATION

FLUSH

INSTALLATION

0"

0" Clearance

SELECTING LOCATION

To determine the safest and most efcient

location for your appliance, you must take into

consideration the following guidelines:

1. The location must allow for proper clearances (see Clearances).

2. Consider a location where heat output

would not be affected by drafts, air conditioning ducts, windows, or doors.

3. A location that avoids the cutting of joists

or roof rafters will make installation easier.

Figure 2 shows a plan view of a few common locations.

Flush installations are recommended where

living space is limited or at a premium, and

since the space required to enclose the appliance would be located beyond an outside

wall, this would also reduce the cutting of

joists, roof rafters, and such. Check local

codes for any restrictions.

PREINSTALLATION PREPARATION

CLEARANCES

Minimum clearances to combustibles are:

Top of Spacers 0" min.

Back and Sides of Outer Surround 0" min.

Drywall to Sides of Front

Face (Nailing Flanges) 0" min.

“B” Vent Surfaces 1" min.

Ceiling to Opening 42" min.

Floor 0" min.

Perpendicular Wall See Figure 6, page 8

CAUTION: Do not block

required air spaces with insulation or any other material. Do

not obstruct effective opening

of appliance with any type of

facing material.

Projected installations can extend any

distance into the room. A projection may

be ideal for a new addition on an existing,

nished wall.

Corner installations make use of space

that may not normally be used and provides

a wider and more efcient range for radiant

heat transference.

Internal wall installations provide a discreet

option for room separation and can also be

ideal as an addition to an existing wall.

Figure 2 - Possible Locations for

Installing Fireplace

2 x 4 Stud

Nailing

Back

Left Side Surround

Flange

Front Face

Drywall

Figure 3 - Minimum Clearances

(Top View)

108660-01G 7

www.fmiproducts.com

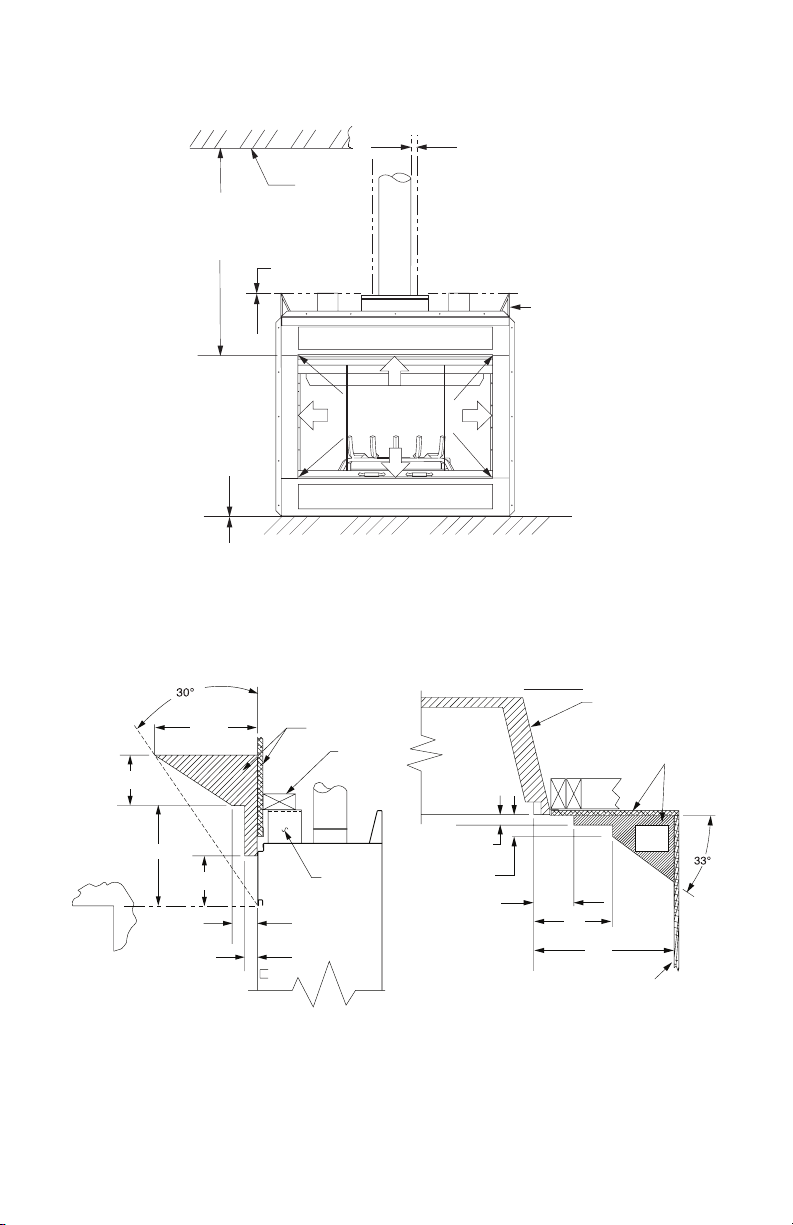

PRE-INSTALLATION PREPARATION

Spacer

3" (7.6 cm)

1

1

/2"

(3.8 cm) Max.

8" (20.3 cm)

6" (15.2 cm)

13" (33 cm)

12"

(22.9 cm)

Combustible

Materials

Header

1 1/2" (3.8 cm)

Max.

3" (7.6 cm)

Max.

6" (15.2 cm)

Max.

9"

(22.86 cm)

12"

(30.48 cm)

Outer Surround

Combustible

Material May

Be Used

TOP VIEW

SAFE

ZONE

Perpendicular

Wa ll

*

*

**

42" (10.67 cm)

Min. Clearance

from Opening to

Ceiling

0" Clearance

Ceiling

1" (2.5 cm) Min.

Clearance to

"B" Vent's Outer Pipe

Required

Air Spaces

are Indicated

with an "

*

".

Do Not

Pack with

Insulation or

Any Other

Material

DO NOT BLOCK

OR OBSTRUCT

OPENINGS

Continued

Figure 4 - Minimum Clearances (Front View)

MANTEL CLEARANCES AND WALL DETAILS

A combustible mantle shelf maybe installed a maximum 12" (22.9 cm) from the wall. Figures

5 and 6 show the minimum allowable distances from various combustible mantle components

in relation to the replace opening.

Figure 5 - Mantel Clearances - Side View

(Cross Section)

www.fmiproducts.com

Figure 6 - Side Clearances - Top View

(Cross Section)

108660-01G8

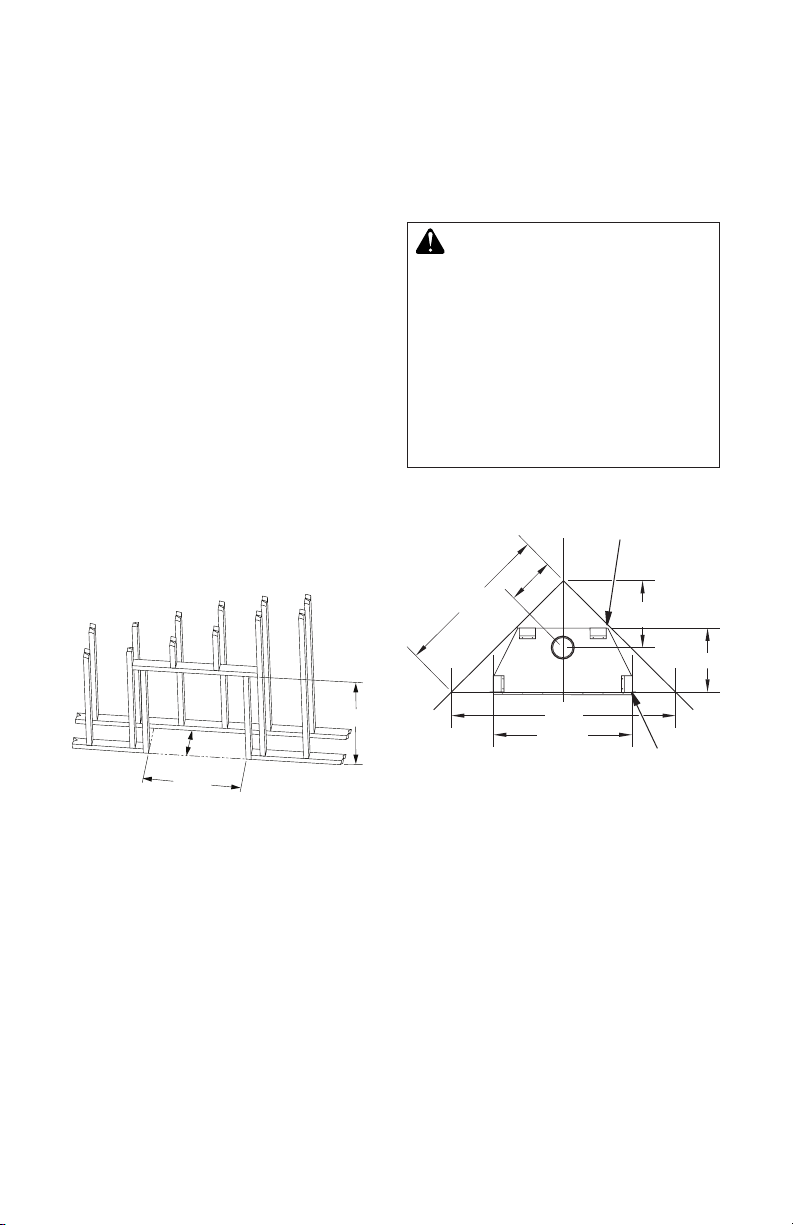

PRE-INSTALLATION PREPARATION

16 1/8"

34

3

/4"

36

5

/8"

16 3/4"

12"

39

3

/8"

55

5

/8"

34

1

/2"

16"

Continued

FRAMING

1. Frame appliance enclosure as illustrated

in Figures 7 and 8.

Note: If a wall covering is used to line the

enclosure, then all measurements must

be from the surface of the covering.

2. Place the appliance into the framing and

secure it.

Note: If appliance is to be raised above

oor level, a platform must be built to

support the appliance.

3. Install the supply line to the appliance

using a 1/2" NPT black iron gas line terminating 2 5/16" above the bottom of the

appliance. The gas line may be installed

from either side or from the rear of the

appliance (see Figure 18, page 13).

4. Feed exible gas line through one of three

gas line conduit sleeves and repack insulation to cover any openings. Prepare the

incoming gas line with Teon tape or pipe

joint compound and hookup incoming gas

line to exible gas line.

Note: If 1/2" NPT black iron pipe does not

mate with tting at the end of exible gas

line, remove tting and replace with a 37

degree are 3/4"-12, 1/2" NPT (female)

tting.

WARNING: When nishing

appliance, do not overlap combustible material onto the black

front face. Brick, tile, or other

noncombustible materials may

be applied to the face provided

that any gap is between the

material used and the face is

caulked with a noncombustible

caulking.

These Dimensions Allow for a 3/4"

Clearance at Sides and Back of

Fireplace. 0" Clearance is Permitted

3/4" Clearance Not Required

at Nailing Flanges

Figure 7 - Rough Opening for Installing

Figure 8 - Corner Installation Guidelines

in Wall

VENTING INSTALLATION

A B-type venting system must be connected

to the appliance for venting to the outside of

the building.

The following section is provided as a guide

to a standard B-type vent installation.

Standing codes requirements concerning Btype vent installations may vary within your

state, province or local codes jurisdiction.

Therefore, it is recommended that you check

with your local building codes for specic

requirements or in absence of local codes,

follow Section 7.0 of the current National Fuel

Gas Code NFPA No. 54/ANSI Z223.1.

108660-01G 9

www.fmiproducts.com

This gas appliance must be vented to the

outdoors only and may not be terminated into

an attic space or into a chimney ue servicing

a solid fuel burning appliance.

This appliance may be vented through a

manufactured chimney system or a masonry

chimney using a B-vent adapter or a chim-

ney liner system if all are listed, inspected

and approved by local codes and/or building

authorities.

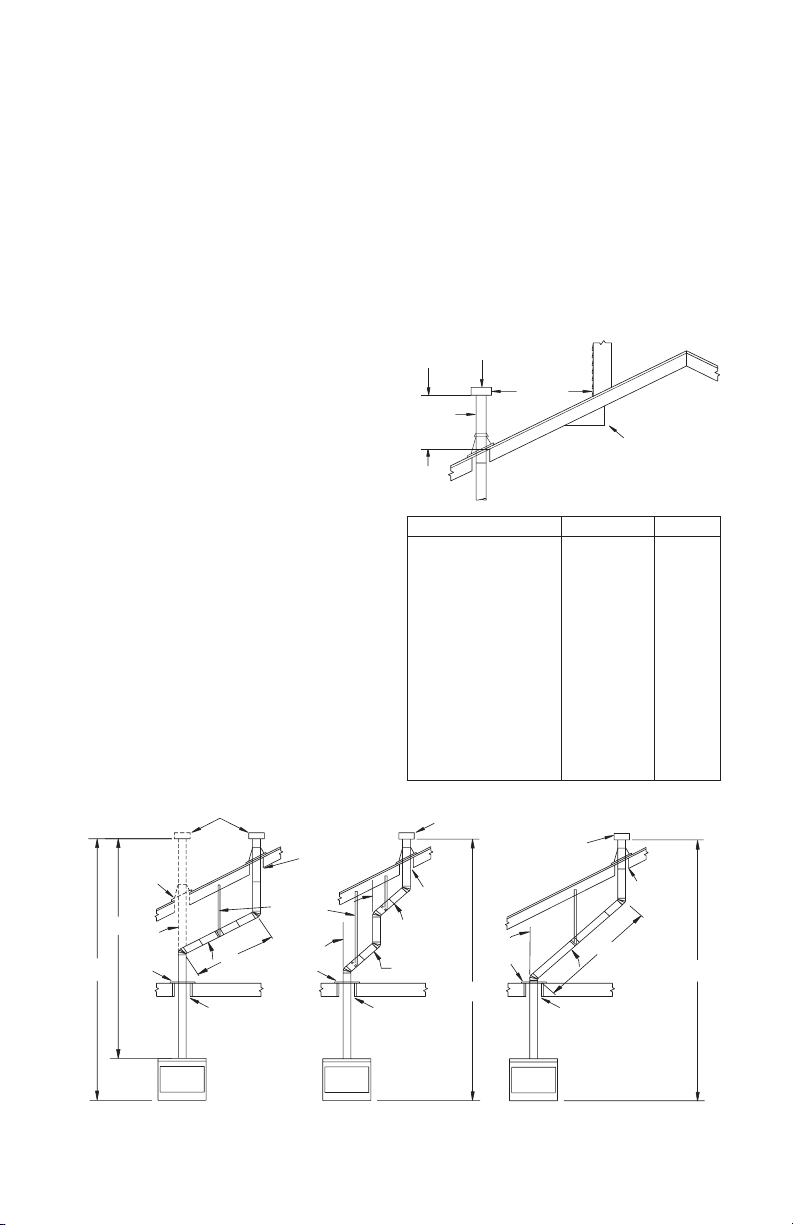

The examples shown in Figure 9, page 10

are typical of most B-vent installations and

code practices.

Maintain

Listed

Clearance

12' Min.

45°

6'

8'

12' Min.

60°

45°

Position

Firestop

Position

Firestop

Listed

Ve nt Cap

Listed Vent Cap

Maintain

Listed

Clearance

Maintain

Listed

Clearance

Maintain

Listed

Clearance

Support

Each

Lateral

At Least

Every

6 Feet

Maintain

Listed

Clearance

EXAMPLE 2

EXAMPLE 1

Maintain

Listed

Clearance

12' Min.

45°

Position

Firestop

Listed

Ve nt Cap

Maintain

Listed

Clearance

10'

EXAMPLE 3

Lowest

Discharge

Opening

Listed

Ve nt Cap

8 Ft. Min.

Roof Pitch x/12

Listed Clearance

12

x

Listed

Gas

Ve nt

H (Min)

Height

From Roof

VENTING INSTALLATION

Continued

Example 1 shows the minimum allowable

system height and lateral offset for a 60° or

greater inclination. Code species that offsets

at 60° or greater are considered horizontal

and must follow the 75% rule for lateral to

total vertical system height. Codes also allows only one offset in the total system when

at 60° or greater. The total vertical height in

this example represents the minimum height

of 8 feet and therefore the allowable lateral

is 6 feet when the 75% rule applies. If the

lateral length must exceed 75% then the

system must be sized in accordance with the

Category I venting tables.

Example 2 shows a multiple offset each at 45°

of inclination. Multiple offsets are permitted if

they do not exceed 45° of inclination. The total

lengths of the two offsets are not required to

meet the 75% allowable rule.

Example 3 shows a single offset at 45° of

inclination and therefore the lateral length at

10 feet of offset does not have to meet the

75% rule.

In each case the offsets must be supported

and restops must be positioned wherever

the vent must pass through a suboor, ceiling joist or an attic overhang. The vent pipe

must terminate vertically into a listed type vent

cap and extend a sufcient height through

an approved roof ashing, roof jack or a roof

thimble. At all points the listed clearances

must be maintained.

Vent terminations must be located in accordance with height and proximity rules of

NFPA No. 54. These rules apply to vents at

12" diameter or less and require a minimum

height in accordance with the roof pitch and

a minimum of 8 feet distance from a vertical

wall or obstruction (see Figure 10).

If venting horizontally through a side wall becomes necessary, a listed thimble approved

for use with B-type vent must be used. Check

with your local codes before venting through

a side wall.

Roof Pitch H (Min.) Ft. m

Flat to 6/12 1.0 0.30

6/12 to 7/12 1.25 0.38

Over 7/12 to 8/12 1.5 0.46

Over 8/12 to 9/12 2.0 0.61

Over 9/12 to 10/12 2.5 0.76

Over 10/12 to 11/12 3.25 0.99

Over 11/12 to 12/12 4.0 1.22

Over 12/12 to 14/12 5.0 1.52

Over 14/12 to 16/12 6.0 1.83

Over 16/12 to 18/12 7.0 2.13

Over 18/12 to 20/12 7.5 2.27

Over 20/12 to 21/12 8.0 2.44

Figure 10 - B-Vent Terminations

Figure 9 - Typical B-Vent Conguration

www.fmiproducts.com

108660-01G10

Loading...

Loading...