Page 1

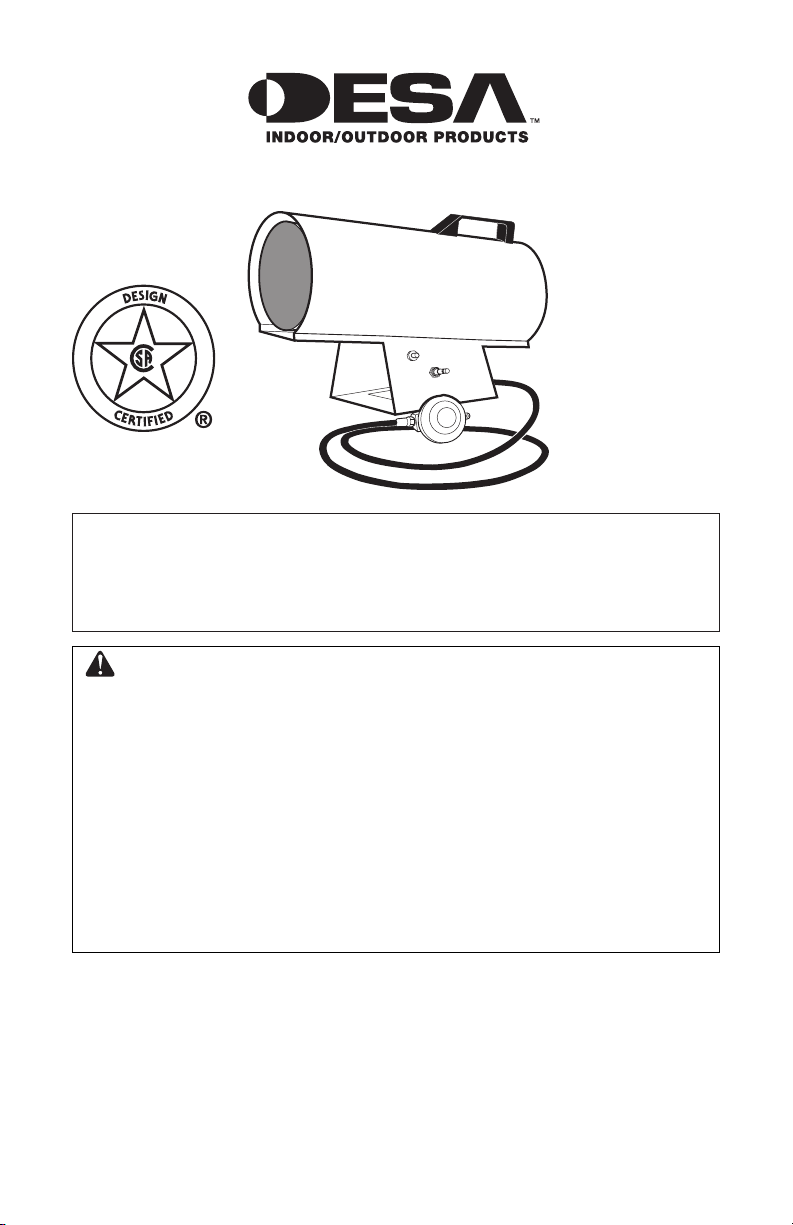

PROPANE CONSTRUCTION FORCED AIR HEATER

OWNER'S MANUAL

30/35/40,000

BTU/HR

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide

poisoning and/or electrical shock.

Only persons who can understand and follow the instructions should use or service this heater.

If you need assistance or heater information such as an instructions manual, labels, etc. contact the manufacturer.

Safety Information ............................................... 2

Unpacking ........................................................... 3

Product Identifica

Theory of Operation ............................................ 3

Assembly ............................................................. 4

Propane Supply ................................................... 4

Installation ........................................................... 5

Ventilation

Operation ............................................................ 6

Storage ................................................................ 6

tion ........................................... 3

........................................................... 5

TABLE OF CONTENTS

Maintenance ........................................................ 7

Service Procedures ............................................. 7

Specifications

Troubleshooting ................................................. 10

Accessories ........................................................11

Technical Service ...............................................

Replacement Parts .............................................11

Illustrated Parts Breakdown and Parts List ....... 12

Warranty and Repair Service ..............Back Cover

Save this manual for future reference.

For more information, visit www.desatech.com

..................................................... 9

11

Page 2

SAFETY INFORMATION

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

WARNING: Fire, burn, inhalation and explosion hazard.

Keep solid combustibles, such

as building materials, paper or

cardboard, a safe distance away

from the heater as recommended

by the instructions. Never use

the heater in spaces which do or

may contain volatile or airborne

combustibles or products such

as gasoline, solvents, paint thinner, dust particles or unknown

chemicals.

WARNING: Not for home or

recreational vehicle use.

The heater is designed for use as a construction

heater in accordance with ANSI Z83.7•CGA2.14-

2000. Other standards govern the use of fuel

gases and heating products for specific uses.

Your local authority can advise you about these.

The primary purpose of construction heaters is

to provide temporary heating of buildings under

construction, alteration or repair. Properly used,

the heater provides safe economical heating.

Products of combustion are vented into the area

being heated.

We cannot foresee every use which may be made of

our heaters. Check with your local fire safety au

thority if you have questions about heater use.

Other standards govern the use of fuel gases and

heat producing products for specific uses. Your

local authorities can advise you about these.

Carbon Monoxide Poisoning: Some people are

more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness and/or

nausea. If you have these signs, the heater may not

be working properly. Get fresh air at once! Check

for proper ventilation and have heater serviced.

Propane Gas: Propane gas is odorless. An odor-

making agent is added to propane gas. The odor

helps you detect a propane gas leak. However, the

odor added to propane gas can fade. Propane gas

may be present even though no odor exists.

Make certain you read and understand all warn

ings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

1. Install and use heater with care. Follow all

local ordinances and codes. In the absence

of local ordinances and codes, refer to the

Standard for Storage and Handling of Lique

fied Petroleum Gas, ANSI/NFPA 58 and the

Propane Gas Installation Code, CAN/CGA

B149.2. This instructs on the safe storage and

handling of propane gases.

2. Use only the electrical voltage and frequency

specified on model plate. The electrical con

nections and grounding of the heater shall fol

low the National Electric Code, ANSI/NFPA

70 or the Canadian Electrical Code, Part 1.

3. Electrical grounding instructions: This appli

ance is equipped with a three-prong (ground

ing) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle or

extension cord.

4. This product has been approved for use in the

Commonwealth of Massachusetts.

5. Use only a three-prong, grounded extension

cord.

6. Use only the hose and factory preset regulator

provided with the heater.

7. Use only propane gas set up for vapor with

drawal.

8. Provide adequate ventilation. Before using

heater, provide at least a 1.5 square-foot

(1400 cm

9. For indoor use only. Do not use heater out

doors.

10. Do not use heater in occupied dwellings or in

-

living or sleeping quarters.

11. Do not use heater in basement or below ground

level. Propane gas is heavier than air. If a leak

occurs, propane gas will sink to the lowest

possible level.

12. Keep appliance area clear and free from com

bustible materials, gasoline, paint thinner and

other flammable vapors and liquids.

13. Do not use heater in areas with high dust

content. Dust is combustible.

2

) opening of fresh, outside air.

-

-

-

-

-

-

-

-

-

2

www.desatech.com

111656-01E

Page 3

SAFETY INFORMATION

Air For Combustion

Air For Heating

Continued

14.

Minimum heater clearances from combustibles: Outlet: 6 Ft. (1.83 m) Sides: 2 Ft. (0.61 m)

Top: 6 Ft. (1.83 m) Rear: 2 Ft. (0.61 m)

15. Keep heater at least six feet from propane

tank(s). Do not point heater at propane tank(s)

within 20 feet.

16. Keep propane tank(s) below 100° F (37.8° C).

17. Check heater for damage before each use. Do

not use a damaged heater.

18. Check hose before each use of heater. If highly

worn or cut, replace with hose specified by

manufacturer before using heater.

19. Locate heater on stable and level surface if

heater is hot or operating.

20. Not intended for use on finished floors.

21. Never block air inlet (rear) or air outlet (front)

of heater.

22. Keep heater away from strong drafts, water

spray, rain or dripping water.

23. Do not leave heater unattended.

24. Keep children and animals away from

heater.

25. Never move, handle or service a hot, operat

ing or plugged-in heater. Severe burns may

result. You must wait 15 minutes after turning

heater off.

26. To prevent injury, wear gloves when handling

heater.

27. Never attach duct work to front or rear of

heater.

28. Do not alter heater. Keep heater in its original

state.

29. Do not use heater if altered.

30. Turn off propane supply and unplug heater

when not in use.

31. Use only original replacement parts. This heater

must use design-specific parts. Do not substi

tute or use generic parts. Improper replacement

parts could cause serious or fatal injuries.

PRODUCT

IDENTIFICATION

Hot Air Outlet

(Front)

Outer Shell

Handle

Piezo

Ignitor

Button

Automatic

Control Valve

Button

Hose/

Regulator

Assembly

-

Figure 1 - 30,000 Btu/Hr Model Shown

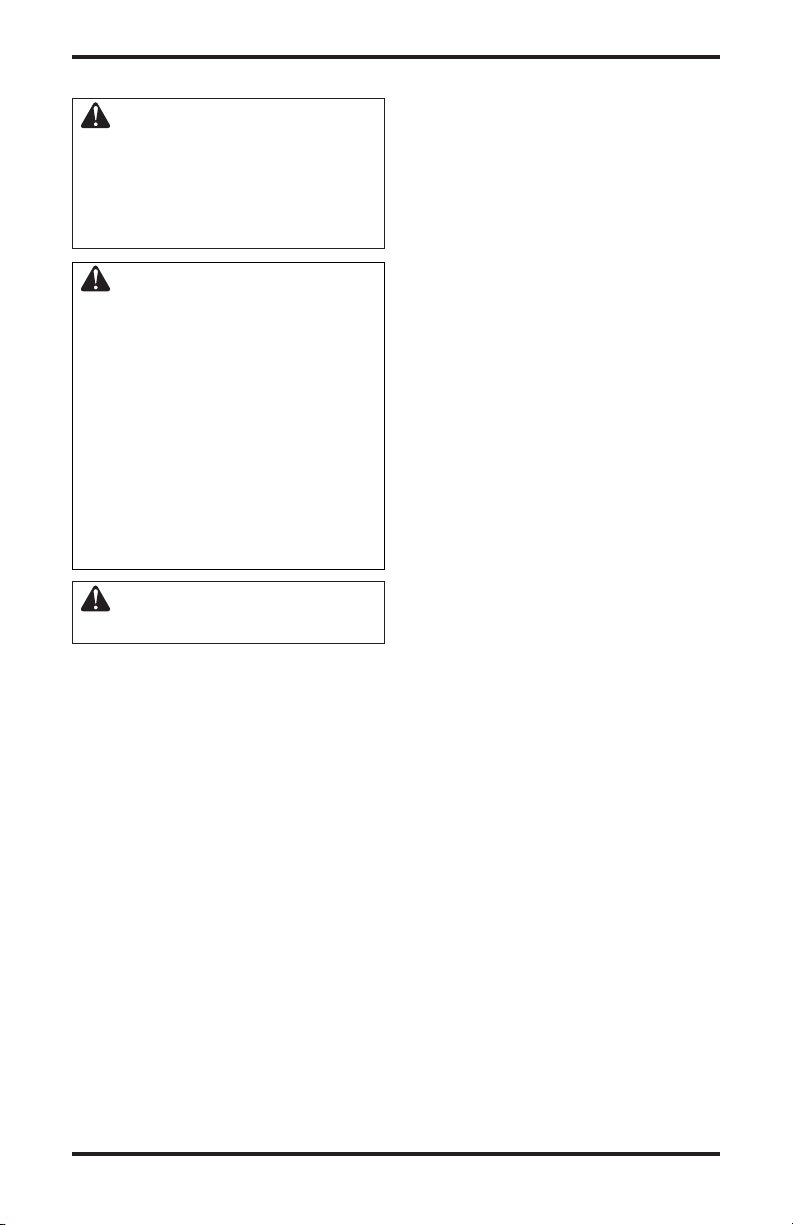

THEORY OF OPERATION

The Fuel System: The hose/regulator assembly

attaches to the propane gas supply. This provides

fuel to the heater.

The Air System: The motor turns the fan. The

fan pushes air into and around the combustion

chamber. This air is heated and provides a stream

of clean, hot air.

The Ignition System: The piezo ignitor lights

the burner.

The Automatic Control System: This system causes

the heater to shut down if the flame goes out.

-

Clean Heated

Air Out (Front)

Fan

Motor

Motor

Power

Cord

UNPACKING

1. Remove all packing items applied to heater for

shipment. Keep plastic cover caps (attached to

inlet connector and hose/regulator assembly)

for storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater

is damaged, promptly inform dealer where you

bought heater.

111656-01E

www.desatech.com

Cool

Air In

(Back)

Combustion

Chamber

Air For

Combustion

Air For

Heating

Hose/Regulator Assembly

Figure 2 - Cross Section Operational View

3

Page 4

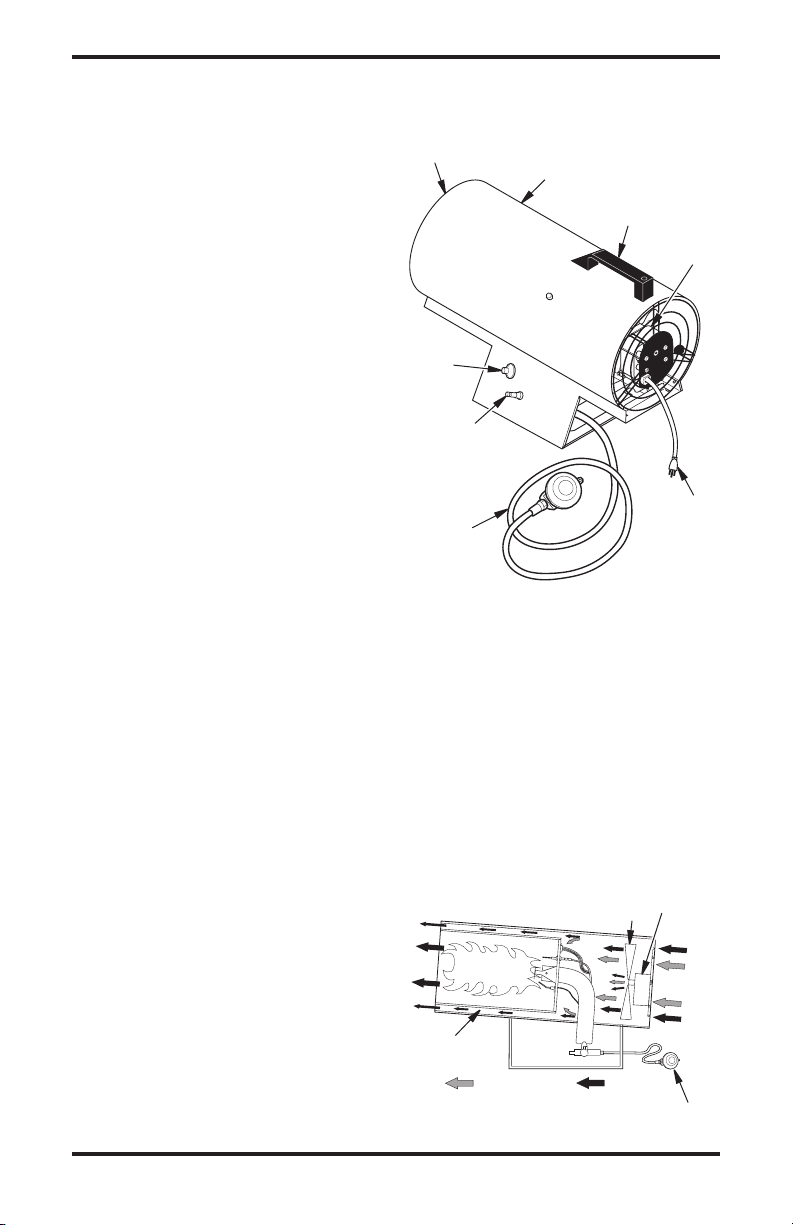

ASSEMBLY

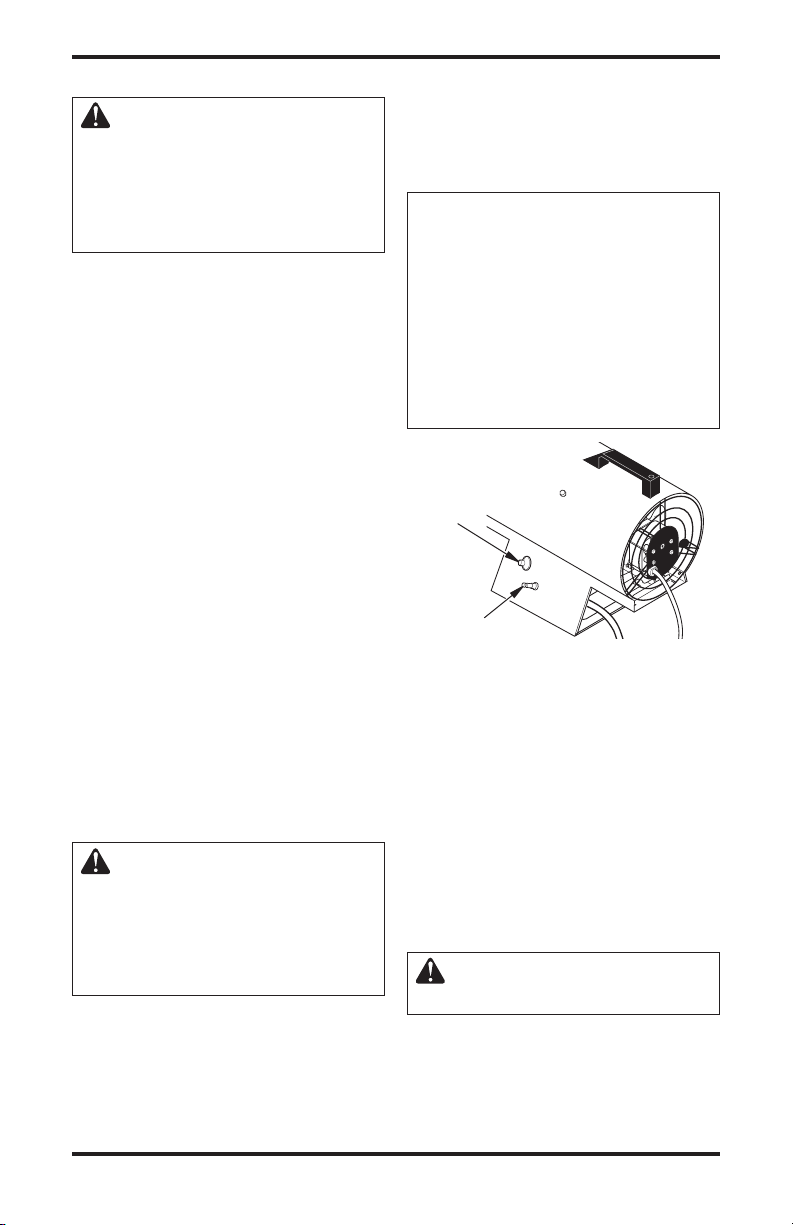

1. Remove screw from top of fan guard (see

Figure 3). Discard screw.

2. Insert nut clip (provided with handle) with

flat side facing up through slot in top of shell.

Align holes in nut clip with screw hole behind

slot in top of shell (see Figure 4).

3. Place handle over hole and clip. Insert two

screws (provided with handle) through

handle and tighten into shell (see Figure 3).

Make sure rear screw goes through shell and

into fan guard. Tighten screws firmly.

Remove

Screw

Figure 3 - Removing Screw from Top of

Fan Guard

Flat Side

Facing Up

Nut Clip

Shell

Slot

Figure 4 - Installing Nut Clip

Screws

Nut Clip

Figure 5 - Attaching Handle

Handle

Rear of

Heater

PROPANE SUPPLY

Propane gas and propane tank(s) are to be furnished by the user.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5 of the

Standard for Storage and Handling of Liquefied

Petroleum Gas, ANSI/NFPA 58

B149.2. Your local library or fire department will

have this booklet.

The amount of propane gas ready for use from

propane tanks varies. Two factors decide this

amount:

1. The amount of propane gas in tank(s)

2. The temperature of tank(s)

This heater is designed to operate with a minimum

20 pound (9 kg) propane tank. You may need two

or more tanks or one larger tank in colder weather.

Use a 100 pound (45 kg) tank for longer operation

or in very cold weather. Less gas is vaporized at

lower temperatures. Your local propane gas dealer

will help you select the proper supply system. The

minimum surrounding air temperature rating for

each heater is -20° F (-29° C).

Average Temp Number Of Tanks

At Tank Location 100 pound (45 kg)

above 0° F (-18° C) 1

below 0° F (-18° C) 2

Smaller tanks can be used for limited run times

but it is recommended to use larger tanks for

optimum performance.

and/or CAN/CGA

4

www.desatech.com

111656-01E

Page 5

INSTALLATION

WARNING: Review and understand the warnings in the

Safety Information section, page

2. They are needed to safely operate this heater. Follow all local

codes when using this heater.

WARNING: Test all gas piping

and connections for leaks after

installation or servicing. Never

use an open flame to check for

a leak. Apply a mixture of liquid

soap and water to all joints.

Bubbles forming show a leak.

Correct all leaks at once.

1. Provide propane supply system (see Propane

Supply, page 4).

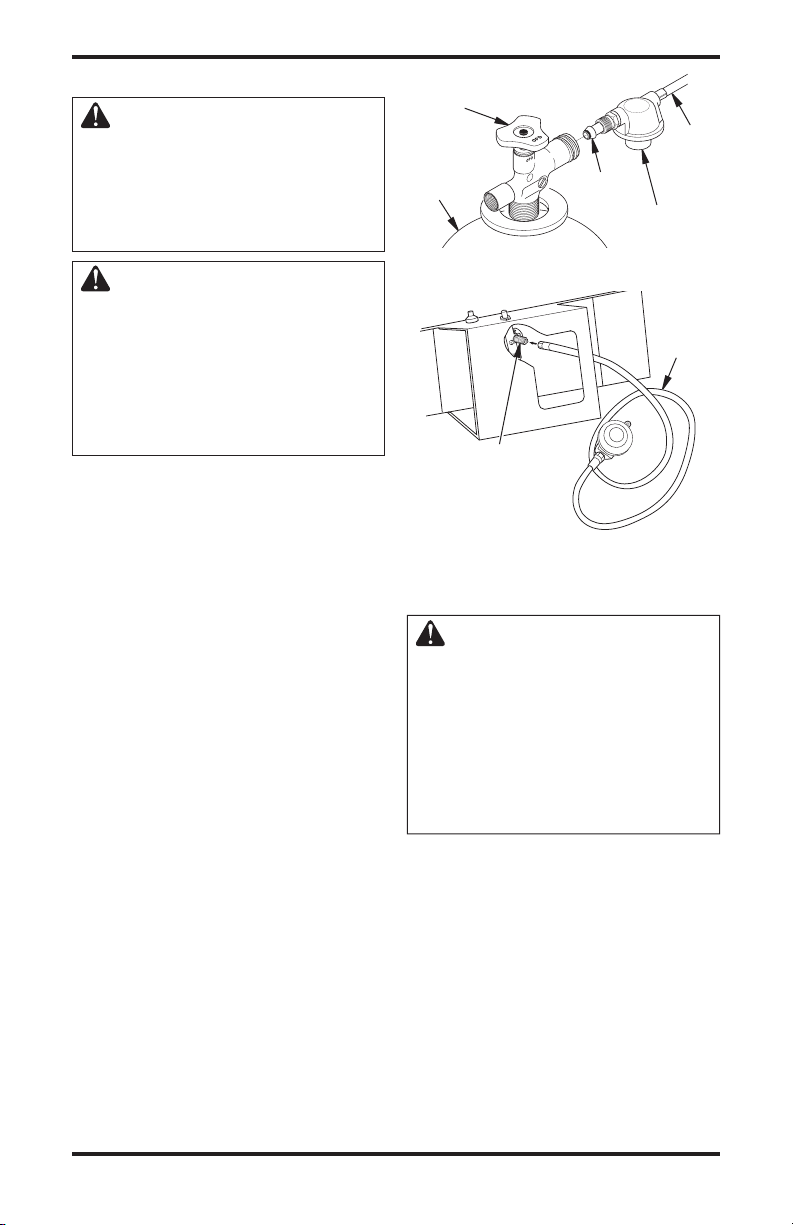

2. Connect POL fitting on hose/regulator as

sembly to propane tank(s). Turn POL fitting

counterclockwise into threads on tank. Tighten

firmly using wrench. IMPORTANT: Position

regulator so that hose leaving the regulator is

in a horizontal position (see Figure 6). This

places the regulator vent in the proper position

to protect it from the weather.

3. Connect hose to valve inlet (see Figure 7).

Tighten firmly using a wrench.

IMPORTANT: Use extra hose or piping if

needed. Install extra hose or piping between

hose/regulator assembly and propane tank. You

must use the regulator supplied with heater.

4. Open propane supply valve on propane

tank(s) slowly.

excess-flow check valve on propane tank will

stop gas flow. You may hear a click from the

excess-flow check valve closing. If this hap

pens, reset the excess-flow check valve by

closing propane supply valve and open again

slowly.

5. Check all connections for leaks. Apply mix

ture of liquid soap and water to gas joints.

Bubbles forming show a leak that must be

corrected.

6. Close propane supply valve.

Note: If not opened slowly,

Propane Supply

Valve

Propane

Tank

Figure 6 - Regulator Position

Inlet Connector

-

Figure 7 - Hose and Inlet Connector

POL

Fitting

VENTILATION

WARNING: Provide at least

a 1.5 square foot (1400 cm

opening of fresh, outside air

while running heater. If proper

fresh, outside air ventilation is

not provided, carbon monoxide

poisoning can occur. Provide

proper fresh, outside air ventilation before running heater.

-

-

Hose

Regulator

Hose

2

)

111656-01E

www.desatech.com

5

Page 6

OPERATION

WARNING: Review and understand the warnings in the

Safety Information section, page

2. They are needed to safely operate this heater. Follow all local

codes when using this heater.

TO START HEATER

1. Follow all installation, ventilation and safety

information.

2. Locate heater on stable and level surface.

Make sure strong drafts do not blow into front

or rear of heater.

3. Plug power cord of heater into a three-prong,

grounded extension cord. Extension cord must

be at least six feet long. Extension cord must

be UL listed.

Extension Cord Wire Size Requirements

Up to 50 ft (15.24 m) long, use 18 AWG rated

cord.

51 to 100 ft (15.54 to 30.48 m) long, use 16

AWG rated cord.

101 to 200 ft (30.78 to 60.96 m) long, use 14

AWG rated cord.

4. Plug extension cord into a 120 volt/60 hertz,

3-hole, grounded outlet. Motor will start. Fan

will turn, forcing air out front of heater.

5. Open propane supply valve on propane

tank(s) slowly.

excess-flow check valve on propane tank will

stop gas flow. You may hear a click from the

excess-flow check valve closing. If this happens, reset the excess-flow check valve by

closing propane supply valve and open again

slowly.

WARNING: Be sure motor

and fan are running before

pushing in automatic control

valve button. Flames could flash

outside heater if motor and fan

are not running.

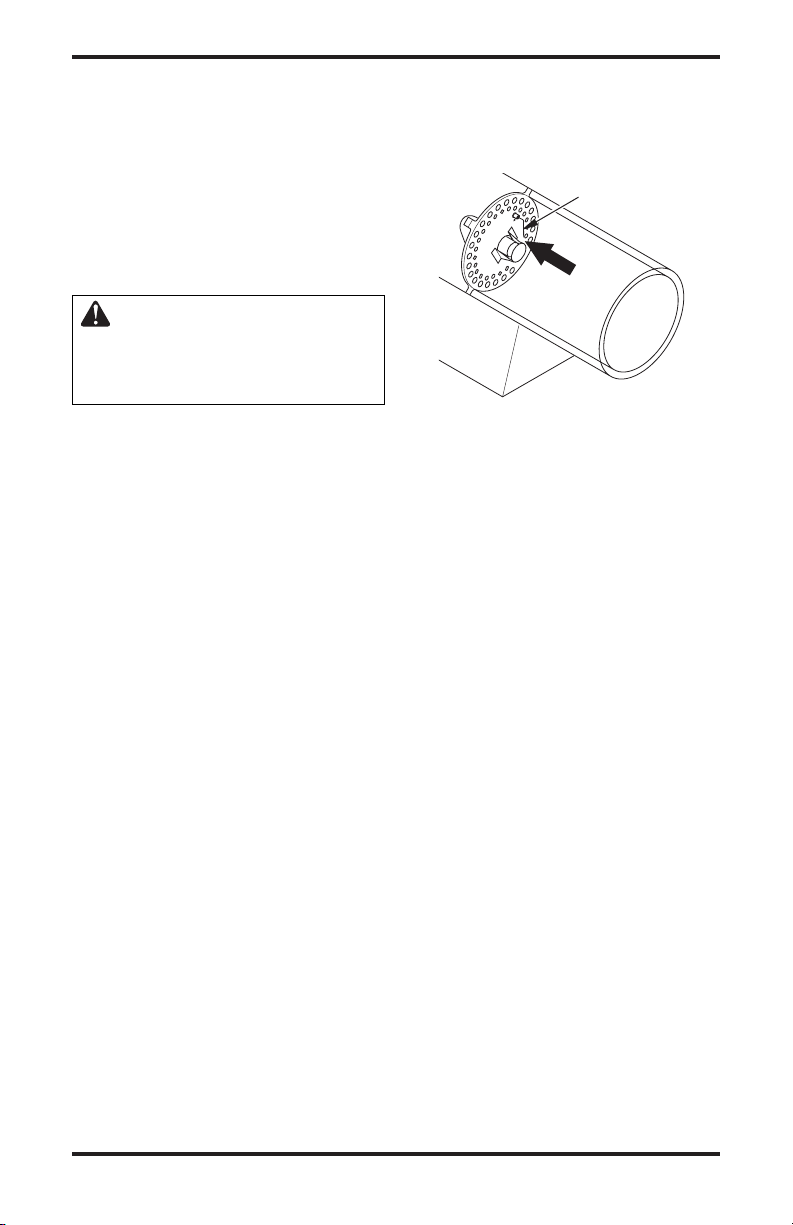

6. Push in and hold automatic control valve button (see Figure 8). Push piezo ignitor button

(see Figure 8). Keep pushing ignitor button

until the burner lights. When burner lights,

keep automatic control valve button pushed in.

Release button after 30 seconds. This activates

the automatic control system.

Note: If not opened slowly,

Note: If heater fails to ignite, hose may have

air in it. If so, keep automatic control valve

button pressed and wait 20 seconds. Release

automatic control valve button and wait 20

seconds for unburned fuel to exit heater.

Repeat this step.

NOTICE: If heater is unplugged or

power outage occurs while heater

is running, the thermal limit device

will stop fuel flow. A few seconds

occur before the thermal limit device activates. During this short

time, flames may appear outside

the heater. This is normal. The

flames will go out when thermal

limit device activates.

Piezo

Ignitor

Button

Automatic Control

Valve Button

Figure 8 - Automatic Control Valve

Button and Piezo Ignitor Button

TO STOP HEATER

1. Tightly close propane supply valve on propane

tank(s).

2. Wait a few seconds. Heater will burn gas left

in supply hose.

3. Unplug heater.

TO RESTART HEATER

1. Wait five minutes after stopping heater.

2. Repeat steps under To Start Heater

.

STORAGE

CAUTION: Disconnect heater

from propane supply tank(s).

1. Store propane tank(s) in safe manner. See

Chapter 5 of Standard for Storage and Han

dling of Liquefied Petroleum Gases, ANSI/

NFPA 58. Follow all local codes. Always store

propane tanks outdoors.

-

6

www.desatech.com

111656-01E

Page 7

STORAGE

Continued

2. Place plastic cover caps over brass fittings on

inlet connector and hose/regulator assembly.

3. Store in dry, clean and safe place. Do not

store hose/regulator assembly inside heater

combustion chamber.

4. When taking heater out of storage, always

check inside of heater. Insects and small

animals may place foreign objects in heater.

Remove motor and other internal parts if

needed to remove foreign objects (see Service

Procedures

).

MAINTENANCE

WARNINGS

• Never service heater while it

is plugged in, connected to

propane supply, operating or

hot. Severe burns and electri

cal shock can occur.

• Keep heater clear and free

from combustible materials,

gasoline and other flammable

vapors and liquids.

• Do not block the flow of combustion or ventilation air.

1. Keep heater clean. Clean heater annually or as

needed to remove dust and debris. If heater is

dirty or dusty, clean heater with a damp cloth.

Use household cleaners on difficult spots.

2. Inspect heater before each use. Check connec

tions for leaks. Apply mixture of liquid soap

and water to connections. Bubbles forming

show a leak. Correct all leaks at once.

3. Inspect hose/regulator assembly before each

use. If hose is highly worn or cut, replace with

hose specified by manufacturer.

4. Have heater inspected yearly by a qualified

service agency.

5. Keep inside of heater free from combustible

and foreign objects. Remove motor and other

internal parts if needed to clean inside of

heater (see Service Procedures).

6. Clean fan blades each season or as needed (see

Fan, page 8).

-

SERVICE PROCEDURES

WARNING: Never service

heater while it is plugged in,

connected to propane supply,

operating or hot. Severe burns

and electrical shock can occur.

ELECTRICAL SYSTEM

The entire electrical system for this heater is contained within the motor. If any part of the electrical

system is damaged, you must replace motor.

MOTOR

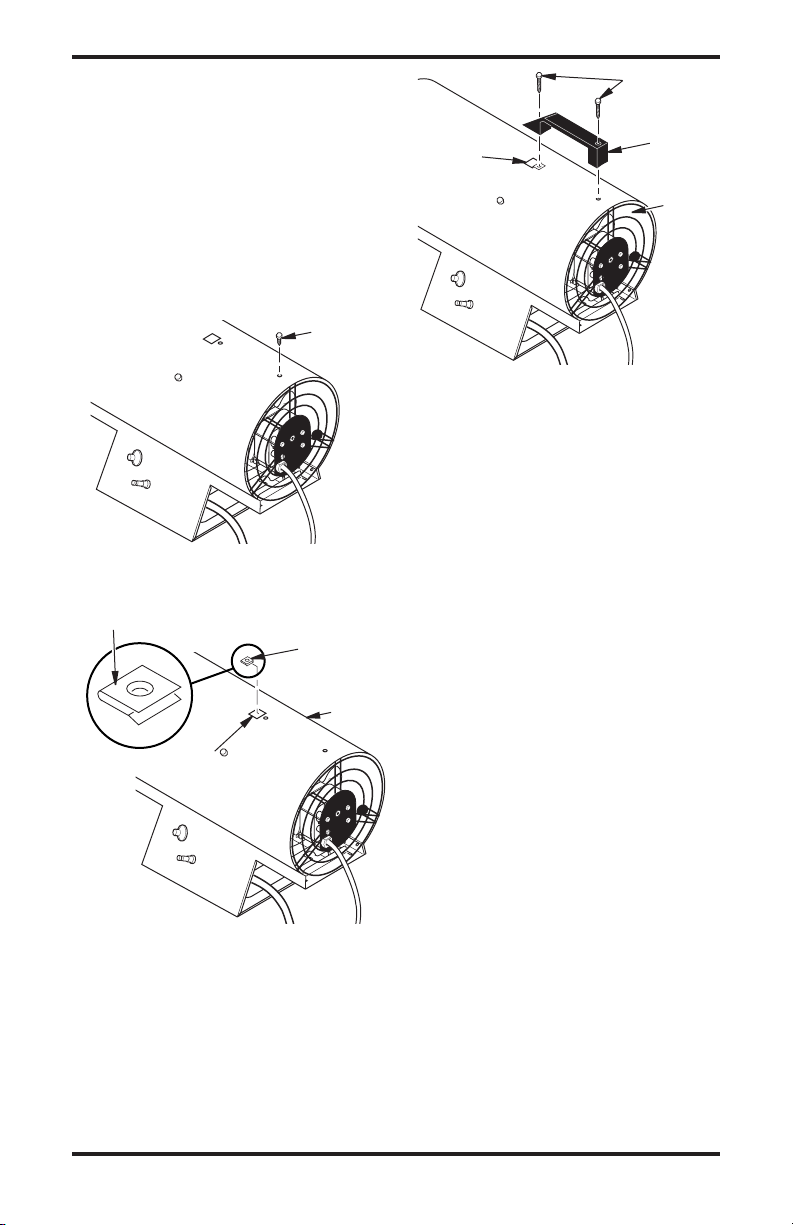

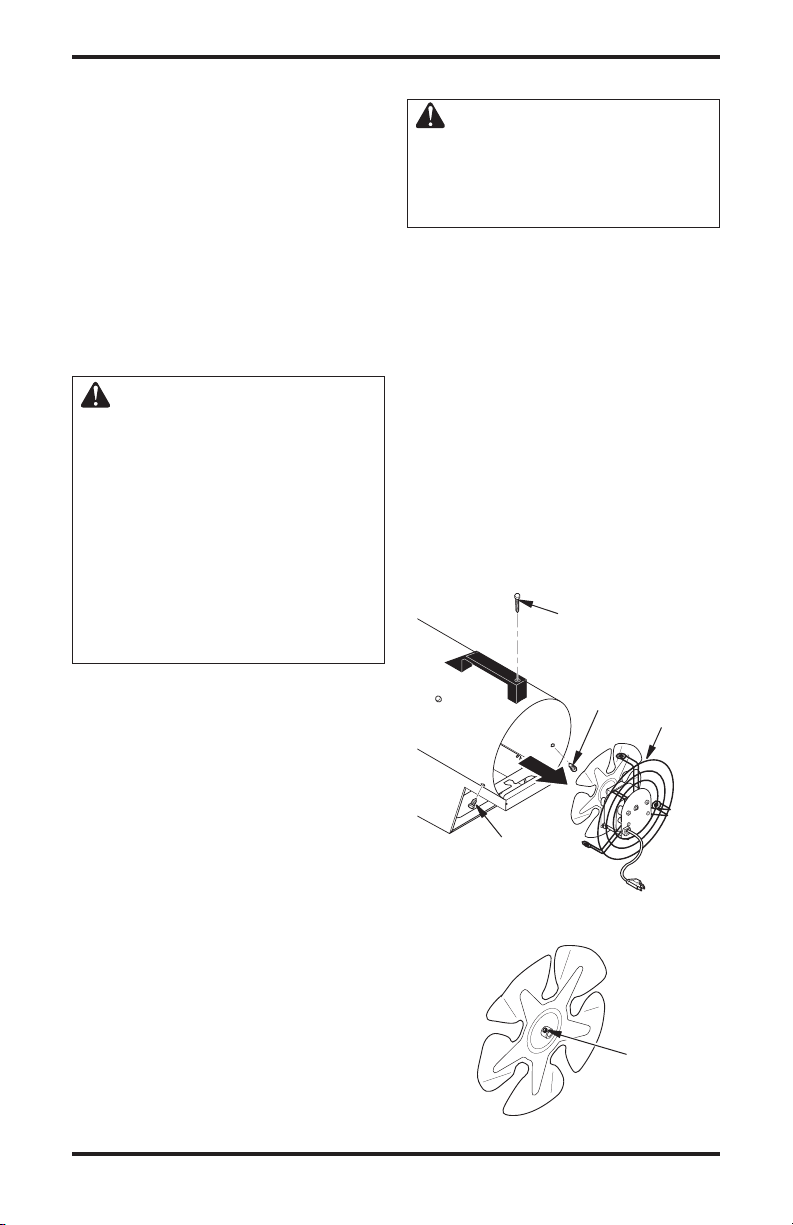

1. Remove three screws that attach fan guard to

heater shell.

2. Remove motor and fan guard from heater shell

(see Figure 9).

3. Use hex wrench to loosen set screw which

holds fan to motor shaft (see Figure 10). Re

move fan. Be careful not to damage the fan

blade pitch.

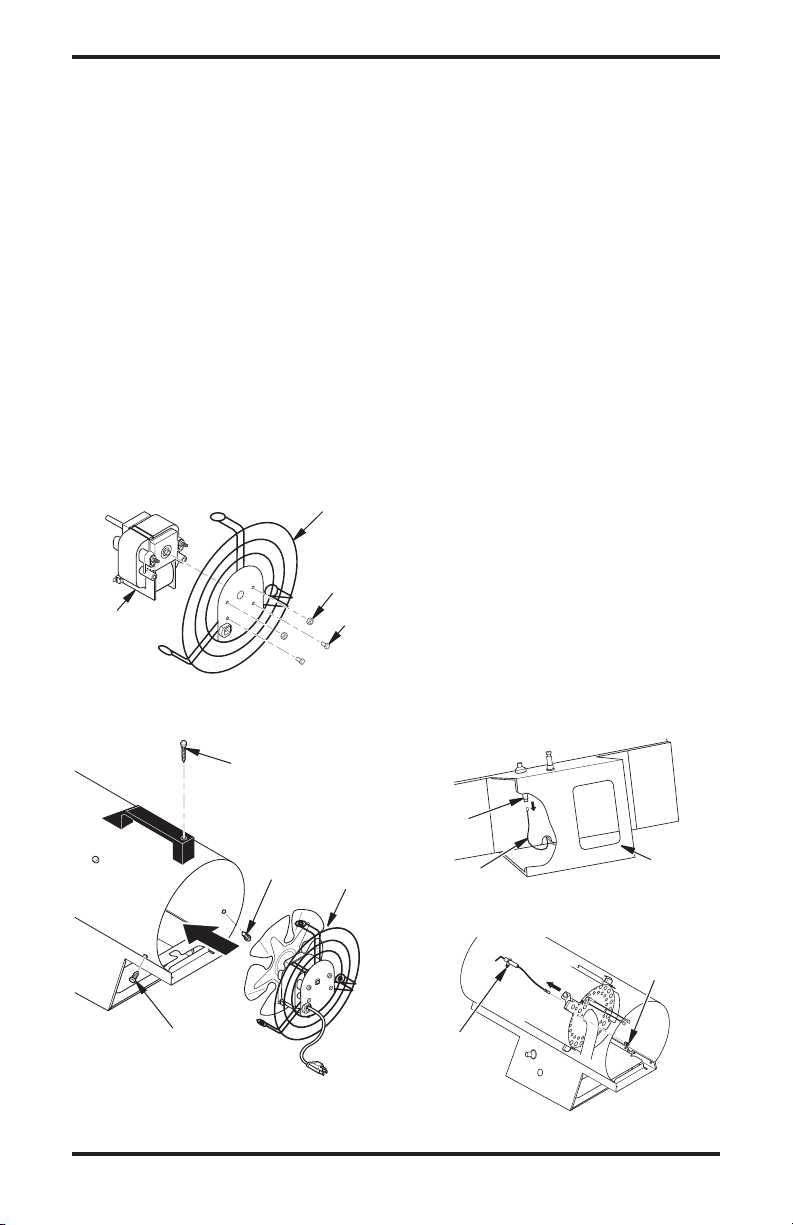

4. Remove two nuts and two screws that attach

fan guard to motor using nut-driver. Remove

fan guard from motor (see Figure 11, page 8).

Screw

Screw

-

Screw

Figure 9 - Removing Motor and Fan

Guard from Heater

Motor and

Fan Guard

Setscrew

-

111656-01E

Figure 10 - Setscrew Location

www.desatech.com

7

Page 8

SERVICE PROCEDURES

Continued

5 Disconnect the green power cord wire from

motor and remove black and white wire ter

minals.

6. Discard old motor.

7. Attach green power cord wire to motor.

8. Attach fan guard to new motor with two nuts

and two screws.

9. Replace black and white terminals.

10. Place fan onto motor shaft of new motor.

Make sure set screw contacts flat surface on

motor shaft. Tighten set screw firmly (40-50

inch-pounds [46.08-57.60 kg-cm]).

11. Place motor and fan guard into rear of heater

shell. Make sure power cord is properly lo

cated (see Figure 12).

12. Insert three screws through heater shell and

into fan guard (see Figure 12). Tighten screws

firmly.

Fan Guard

Nut

Motor

Figure 11 - Removing or Attaching Fan

Guard from Motor

Screw

FAN

1. Remove three screws that attach fan guard to

heater shell.

2. Remove motor and fan guard from heater shell

-

(see Figure 9, page 7).

3. Use hex wrench to loosen set screw that holds

fan to motor shaft (see Figure 10, page 7).

4. Remove fan. Be careful not to damage the fan

blade pitch.

5a. If replacing fan, remove old fan and discard.

Go to step 7 below.

5b. If cleaning fan, use soft cloth moistened with

kerosene or solvent.

6. Dry fan thoroughly.

7. Place fan onto motor shaft. Make sure set

screw contacts flat surface on motor shaft.

-

Tighten set screw firmly (40-50 inch-pounds

[46.08-57.60 kilogram-centimeters]).

8. Place motor and fan guard into rear of heater

shell. Make sure power cord is properly lo

cated (see Figure 12).

9. Insert three screws through heater shell and

into fan guard. Tighten screws firmly.

IGNITOR

1. Remove motor and fan guard from heater (see

Motor, page 7, steps 1 and 2).

2. Remove black ignitor wire from piezo ignitor.

Access ignitor wire through underside of

heater base (see Figure 13). Push wire up

through notch in filler panel.

3. Remove ignitor mounting screw from rear

head using nut-driver or standard screwdriver

(see Figure 14).

-

Screw

Screw

Screw

Figure 12 - Replacing Motor and Fan

Guard Into Heater

8

Motor and

Fan Guard

Piezo

Ignitor

Ignitor Wire

Figure 13 - Removing Ignitor Wire from

Ignitor

Figure 14 - Removing Ignitor Mounting

www.desatech.com

Underside

of Heater

Piezo Ignitor

Mounting

Screw

Screw and Ignitor

111656-01E

Page 9

SERVICE PROCEDURES

Continued

4. Remove ignitor from rear head.

5. Install new ignitor. Attach ignitor to rear head

with ignitor mounting screw.

6. Run ignitor wire from new ignitor through

notch in filler panel. Attach ignitor wire to

piezo ignitor.

7. Set gap between ignitor electrode and target

plate to .17" (0.43 cm) (see Figure 15).

8. Test for spark. Push piezo ignitor button and

watch for spark between ignitor electrode and

target plate.

9. Place motor and fan guard into rear of heater

shell (see Motor, page 7, steps 9 and 10).

Ignitor Electrode

Gap

Area

WARNING: Make sure heater

is disconnected from propane

supply. Heater could ignite causing severe burns.

Figure 15 - Clearance Between Ignitor

Electrode and Target Plate

SPECIFICATIONS

BLP30, NLP30, REM30LP, RLP30

• Output Rating: 30,000 Btu/Hr

• Fuel: Propane Vapor Only

• Ignition: Manual, Piezo

• Fuel Consumption/Hour: 0.33 gal (1.25 liters)

1.4 lb (0.63 kg)

• Supply Pressure To Regulator:

Min* - 20 psi, Max - Tank Pressure or 200 psi

• Regulator Outlet Pressure: 10 PSI

• Manifold Pressure: 10.1 PSI

RLLP35

• Output Rating: 35,000 Btu/Hr

• Fuel: Propane Vapor Only

• Ignition: Manual, Piezo

• Fuel Consumption/Hour: 0.38 gal (1.44 liters)

1.62 lb (0.74 kg)

• Supply Pressure To Regulator:

Min* - 20 psi, Max - Tank Pressure or 200 psi

• Regulator Outlet Pressure: 10 PSI

• Manifold Pressure: 9.7 PSI

* For purposes of input adjustment

** When running heater in temperatures above 85° F (29.44° C), high internal temperatures may cause

thermal limit device to shut down heater.

RM40LP, RM40SP, SPC-40B

• Output Rating: 40,000 Btu/Hr

• Fuel: Propane Vapor Only

• Ignition: Manual, Piezo

• Fuel Consumption/Hour: 0.44 gal (1.65 liters)

1.86 lb (0.84 kg)

• Supply Pressure To Regulator:

Min* - 20 psi, Max - Tank Pressure or 200 psi

• Regulator Outlet Pressure: 10 PSI

• Manifold Pressure: 9.7 PSI

REMAINDER OF LIST APPLIES TO

ALL MODELS

• Hot Air Output (CFM Approx): 175

• Motor: 3045 RPM, 1/40 HP

• Electric Input: 120 volt/60 hertz

• Amperage: 0.6

• Temperature Range for Heater Operation:

-20° F to 85° F** (-29° C to 29.4° C)**

111656-01E

www.desatech.com

9

Page 10

TROUBLESHOOTING

WARNING: Never service heater while it is plugged in, connected

to propane supply, operating or hot. Severe burns and electrical

shock can occur.

OBSERVED FAULT

Fan does not turn when heater is

plugged in.

Heater will not ignite.

Heater shuts down while run

ning

POSSIBLE CAUSE

1. No electrical power to heater

2. Fan hitting inside of heater

shell

3. Fan blades bent

4. Defective motor

1. User did not follow installa

tion or operation instructions

properly

2. No spark at ignitor. To test for

spark, follow step 8 under

nitor, page 8. If you see spark

at ignitor, have heater serviced

by qualified service person. If

no spark seen:

A) Loose or disconnected

ignitor wire

B) Wrong spark gap

C) Piezo ignitor loose

D) Bad ignitor electrode

1. High surrounding air tem

perature causing thermal limit

device to shut down heater

2. Restricted air flow

3. Damaged fan

4. Excessive dust or debris in

surrounding area

REMEDY

1. Check voltage to electrical

outlet. If voltage is good,

check heater power cord for

breaks

2. Adjust motor/fan guard to

keep fan from hitting inside of

heater shell. Bend fan guard if

necessary

3. Replace fan. See

4. Replace motor. See Motor,

page 7

1. Repeat installation and opera

tion instructions. See Instal

lation, page 5 and Operation,

page 6

2. A) Check ignitor wire. Tighten

or reattach loose ignitor wire.

Ig-

See Figure 14, page 8 for

ignitor wire location

B) Set gap between ignitor

electrode and target plate to

0.17" (0.43 cm)

C) Tighten nut holding piezo

ignitor to base of heater

D) Replace ignitor electrode.

See Ignitor, page 8

1. This can happen when running

heater in temperatures above

85°F (29.44° C). Run heater

in cooler temperatures

2 Check heater inlet and outlet.

Remove any obstructions

3. Replace fan. See Fan, page 8

4. Clean heater. See Mai nt e

nance, page 7

Fan, page 8

-

-

-

WARNING: Use only in areas

free of high dust content.

10

www.desatech.com

111656-01E

Page 11

ACCESSORIES

Purchase accessories and parts from your nearest

dealer or service center. If they can not supply an

accessory or part, either contact your nearest Parts

Central (listed in the separate Authorized Service

Center booklet) or contact DESA Heating Products

for referral information.

Propane Gas Regulator - LPA2170

U.L. listed.

Hose/Regulator Assembly - LPA3120

U.L. listed.

Fuel Gas Connector - LPA4020

Connects regulator to all standard propane tanks.

U.L. and AGA listed.

TECHNICAL SERVICE

You may have further questions about this heater.

If so, contact DESA Heating Productsʼ Technical

Service Department at 1-866-672-6040. When

calling, please have your model and serial numbers

of your heater ready.

You can also visit DESA Heating Productsʼ Techni

cal Service web site at www.desatech.com.

REPLACEMENT PARTS

WARNING: Use only original

replacement parts. This heater

must use design-specific parts.

Do not substitute or use generic

parts. Improper replacement

parts could cause serious or fatal injuries. This will also protect

your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), either

contact your nearest Parts Central or call DESA

Heating Productsʼ Technical Service Department

at 1-866-672-6040.

When calling DESA Heating Products, have ready

• your name

• your address

-

• model number of your heater

• how heater was malfunctioning

• purchase date

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If

they canʼt supply original replacement part(s),

either contact your nearest Parts Central (listed in

Authorized Service Center booklet) or call DESA

Heating Products at 1-866-672-6040 for referral

information.

When calling DESA Heating Products, have ready

• model number of your heater

• the replacement part number

111656-01E 11

www.desatech.com

Page 12

ILLUSTRATED PARTS BREAKDOWN

20

2

9

10

17

11

3

22

12

15

5

19

18

13

7

8

4

16

21

14

23

6

1

MODELS BLP30, NLP30, REM30LP, RLP30, RLLP35, BLP42, RM40LP,

RM40SP AND SPC-40B

12

www.desatech.com

111656-01E

Page 13

PARTS LIST

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 11 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 ** Combustion Chamber • • • • • • • • • 1

2 ** Unichassis • • • • • • • • • 1

3 M11143-1 Bushing, Strain Relief • • • • • • • • • 1

4 M11084-27 Screw • • • • • • • • • 5

5 099237-01 Thermocouple Nut • • • • • • • • • 2

6 103894-01 Target Bracket Kit • • • • • • • • • 1

7 104784-01 Electrode Ignitor • • • • • • • • • 1

8 M11084-38 Hex Tap Screw, #8-18 x 3/8" • • • • • • • • • 1

9 101478-02 Fan • • • • • • • • • 1

10 104156-01 Motor Assembly • • • • • • • • • 1

103863-01 Fan Guard • • • • • • • • • 1

11

12 097384-02 Captive Washer Nut • • • • • • • • • 2

13 101480-12 Wire Assembly • • • • • • • • • 1

14 104786-01 Handle Assembly • • • • • • • • • 1

15 101732-05 Thermal Switch Kit • • • • • 1

101732-06 Thermal Switch Kit • • • • 1

16 103895-01 Rear Head Kit • • • • • • • • • 1

17 098219-17 Cord, Power Supply • • • • • • • • • 1

18 104146-02 Thermocouple • • • • • • • • • 1

19 104144-01 Valve/Orifice/Burner Tube Assembly • • • • 1

104144-03 Valve/Orifice/Burner Tube Assembly • 1

104144-04 Valve/Orifice/Burner Tube Assembly • • • • 1

20 102445-01 Piezo Ignitor Kit • • • • • • • • • 1

21 ** Filler Panel • • • • • • • • • 1

22 M12461-14 Hex Screw, 8-32 x 3/8 • • • • • • • • • 4

23 097403-01 Screw, Phillips Head #10 x 1.25 • • • • • • • • • 2

PARTS AVAILABLE - NOT SHOWN

097650-01 Tradename Decal • • 2

115441-01 Tradename Decal

110789-01 Tradename Decal

109111-02 Tradename Decal

110396-02 Tradename Decal

113858-01 Tradename Decal

104161-04 General Information Decal • • • • • • • • • 1

104160-03 Operation Decal • • • • • • • • • 1

111632-01

111632-02

111632-03

Model Data Decal • • • • 1

Model Data Decal • 1

Model Data Decal • • • • 1

** Not a field replaceable part.

BLP30

NLP30

REM30LP

RLLP35

BLP42

RM40LP

RLP30

RM40SP

• 2

• 2

• • 2

• • 2

SPC-40B

• 2

111656-01E

www.desatech.com

13

Page 14

WARRANTY AND REPAIR SERVICE

KEEP THIS WARRANTY

Model

Serial No.

Date of Purchase

LIMITED WARRANTIES FOR NEW AND FACTORY

RECONDITIONED PRODUCTS

New Products: DESA Heating Products warrants this heater and any parts thereof, to be free of defects in materials

and workmanship for one (1) year from the date of first purchase, when operated and maintained in accordance

with the manufacturer's instructions. These warranties are extended only to the original retail purchaser, when

proof of purchase is provided.

Factory Reconditioned Heaters: DESA Heating Products warrants this factory reconditioned heater and any parts

thereof, to be free of defects in materials and workmanship for thirty (30) days from the date of first purchase,

when operated and maintained in accordance with the manufacturer's instructions. These warranties are extended

only to the original retail purchaser, when proof of purchase is provided.

These warranties cover only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of proper mainte

nance, normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts or repair by

anyone other than an authorized dealer or service center. Routine maintenance is the responsibility of the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

DESA Heating Products assumes no responsibility for indirect, incidental or consequential damages. Some states

do not allow the exclusion or limitation of incidental or consequential damages or limitations or exclusions may

not apply to you. This limited warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our

standard written warranty. We make no other warranty, expressed or implied.

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase must be

presented with the heater. The heater will be inspected. A defect may be caused by faulty materials or workmanship. If so, DESA Heating Products will repair or replace the heater without charge.

REPAIR SERVICE

Return your heater to your nearest authorized service center. Repairs not covered by the warranty will be billed at

standard prices. Each Service Center is independently owned and operated. We reserve the right to amend these

specifications at any time without notice. When writing, always include model number and serial number. For

information, write:

-

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

ATTN: Customer Service Department

Page 15

CALENTADOR DE AIRE FORZADO DE PROPANO PARA

CONSTRUCCIÓN

MANUAL DEL PROPIETARIO

30/35/40,000

BTU/H

IMPORTANTE: lea y comprenda este manual antes de

ensamblar, encender o dar servicio al calentador. El uso

inadecuado del calentador puede causar lesiones graves. Conserve este manual para referencias futuras.

ADVERTENCIA GENERAL DE PELIGRO:

El incumplimiento de las precauciones e instrucciones

proporcionadas con este calentador puede causar la muerte,

lesiones físicas graves y pérdidas o daños a la propiedad

ocasionados por incendios, explosiones, quemaduras, asfixia,

intoxicación con monóxido de carbono y/o electrocución.

Únicamente las personas que puedan entender y seguir las

instrucciones deberán usar o dar servicio a este calentador.

Si necesita ayuda o información sobre el calentador, como

por ejemplo un manual de instrucciones, etiquetas, etc.,

comuníquese con el fabricante.

Información de seguridad .................................... 2

Desempaque ....................................................... 3

Identificación del producto ................................... 3

Teoría de funcionamiento ....................................

Ensamblaje .......................................................... 4

Suministro de propano ........................................ 4

Instalación ........................................................... 5

Ventilación ........................................................... 5

Funcionamiento ................................................... 6

Almacenamiento .................................................. 7

Para obtener más información, visite www.desatech.com

TABLA DE CONTENIDO

Mantenimiento ..................................................... 7

Procedimientos de servicio ................................. 7

Especificaciones .................................................. 9

3

Solución de problemas ...................................... 10

Accesorios ..........................................................11

Servicio técnico ..................................................11

Piezas de repuesto .............................................11

Clasificación ilustrada de piezas y lista de piezas ...12

Garantía y servicio de reparación .. Contraportada

Guarde este manual para referencias futuras.

Page 16

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA: este producto contiene y/o genera químicos

reconocidos por el Estado de California como causantes de cáncer

o de defectos de nacimiento, u

otros daños reproductivos.

ADVERTENCIA: peligro de

incendio, quemaduras, inhalación y explosión. Mantenga los

combustibles sólidos, como materiales de construcción, papel o

cartón a una distancia segura del

calentador según se recomienda

en las instrucciones. Nunca use

el calentador en áreas que contengan o que puedan contener

combustibles volátiles o que se

acumulan en el aire o bien productos como gasolina, solventes,

diluyente de pintura, partículas de

polvo o químicos desconocidos.

ADVERTENCIA: no usar en residencias ni en vehículos recreativos.

El calentador está diseñado para usarse como calentador para construcción conforme a la norma ANSI

Z83.7•CGA2.14-2000. Otras normas rigen el uso de

gases combustibles y productos de calefacción para usos

específicos. La autoridad local puede informarle acerca

de éstas. El propósito principal de los calentadores para

construcción es proporcionar calefacción temporal a

edificios en construcción, modificación o reparación.

Cuando se usa correctamente, el calentador proporciona

calefacción económica y segura. Los productos de com

bustión se ventilan al área que se está calentando.

No podemos prever todos los usos que se les pueden

dar a nuestros calentadores. Consulte a la autoridad

local de seguridad contra incendios si tiene pregun

tas acerca del uso de calentadores.

Otras normas rigen el uso de gases combustibles y

productos que producen calor para usos específicos. Las

autoridades locales pueden informarle acerca de éstas.

Intoxicación con monóxido de carbono:

personas sufren mayores efectos del monóxido de

carbono que otras. Los primeros signos de intoxicación

con monóxido de carbono son semejantes a los de la

gripe, con dolor de cabeza, mareo o náusea. Si usted

presenta estos síntomas, es posible que el calentador no

2

Algunas

www.desatech.com

esté funcionando correctamente. ¡Respire aire fresco

inmediatamente! Compruebe que haya ventilación

adecuada y haga que reparen el calentador.

Gas propano:

pano se le agrega un agente con olor. El olor le ayuda

a detectar las fugas de gas propano. Sin embargo, el

olor que se añade al gas propano puede desvanecerse.

Es posible que haya gas propano presente aunque no

haya ningún olor.

Asegúrese de leer y comprender todas las advertencias.

Conserve este manual como referencia. Es su guía para

la operación segura y correcta de este calentador.

1. Instale y use el calentador cuidadosamente. Siga

2. Use solamente la tensión eléctrica y la frecuen-

3. Instrucciones para la conexión eléctrica a tierra:

4. Este producto ha sido aprobado para su uso en

5. Use solamente un cable de extensión con co-

6. Use sólo la manguera y el regulador preinstalado

7. Use solamente el montaje de gas propano para

8. Proporcione una ventilación adecuada. Antes

-

9. Para uso en interiores solamente. No use el

10. No use el calentador en viviendas ocupadas ni

-

11. No use el calentador en un sótano ni debajo del

12. Mantenga el área cerca del aparato despejada

13. No use el calentador en áreas con un alto conte-

el gas propano es inodoro. Al gas pro-

las ordenanzas y los códigos locales. A falta de

decretos y códigos locales, consulte la

de almacenamiento y manejo de gas licuado

de petróleo, ANSI/NFPA 58 y el Código de

instalación de gas propano, CAN/CGA B149.2.

Ésta proporciona instrucciones acerca del almacenamiento y manejo seguro del propano.

cia especificadas en la placa del modelo. Las

conexiones eléctricas y de tierra del calentador

deberán estar de acuerdo al Código eléctrico

nacional, ANSI/NFPA 70 o al Código eléctrico

canadiense, parte 1.

este aparato está equipado con un enchufe de tres

clavijas (con conexión a tierra) para protegerlo

contra el riesgo de descargas eléctricas y se tiene

que conectar directamente a un enchufe de pared

o un cable de extensión de tres ranuras conectado

a tierra correctamente.

el Estado de Massachusetts.

nexión a tierra de tres clavijas.

en la fábrica que se incluyen con el calentador.

la extracción de vapores.

de usar el calentador, proporcione una apertura

de al menos 1400 cm2 (1.5 pies cuadrados) de

aire fresco del exterior.

calentador en exteriores.

en dormitorios o alojamientos.

nivel del suelo. El gas propano es más pesado

que el aire. Si se produce una fuga, el gas propano se asentará en el nivel más bajo posible.

y libre de materiales combustibles, gasolina,

diluyentes para pintura y otros vapores y líquidos

inflamables.

nido de polvo. El polvo es combustible.

111656-01E

Norma

Page 17

INFORMACIÓN DE SEGURIDAD

Air For Combustion

Air For Heating

14. Distancia mínima entre el calentador y el combustible: enchufe: 1.83 m (6 pies) laterales: 0.61 m (2 pies)

parte superior: 1.83 m (6 pies) parte posterior:

0.61 m (2 pies)

15. Mantenga el calentador alejado de los tanques

de propano a una distancia de al menos 1.8 m

(6 pies). No apunte el calentador a los tanques

de propano que se encuentren a menos de 6.1

metros (20 pies).

16. Mantenga los tanques de propano por debajo de

los 37.8º C (100° F).

17. Antes de cada uso, verifique si el calentador ha sufrido algún daño. No use un calentador dañado.

18. Revise la manguera antes de cada uso del calentador. Si la manguera está muy desgastada o con

roturas, reemplácela con una manguera especificada por el fabricante antes de usar el calentador.

19. Sitúe el calentador en una superficie estable

y nivelada si el calentador está caliente o en

funcionamiento.

20.

No está diseñado para su uso en pisos terminados.

21. Nunca bloquee la entrada de aire (parte posterior)

ni la salida de aire (parte anterior) del calentador.

22. Mantenga el calentador alejado de corrientes

fuertes de aire, rocío, lluvia o goteos de agua.

23. No deje el calentador desatendido.

24. Evite que los niños y los animales se acerquen

al calentador.

25. Nunca mueva, maneje o repare un calentador

en funcionamiento caliente o conectado.Pueden

producirse quemaduras graves. Debe esperar 15

minutos después de apagar el calentador.

26. Para evitar lesiones, use guantes cuando manipule el calentador.

27. Nunca conecte conductos a la parte anterior o

posterior del calentador.

28. No altere el calentador. Mantenga el calentador

en su estado original.

29. No use el calentador si éste ha sido alterado.

30. Cierre el suministro de propano al calentador y

desconéctelo cuando no se esté usando.

31. Use sólo piezas de repuesto originales. Este calentador debe usar piezas diseñadas específicamente.

No las sustituya ni use piezas genéricas. El uso de

piezas de repuesto inadecuadas puede ocasionar

lesiones graves o fatales.

Continuación

DESEMPAQUE

1. Retire todos los elementos de empaque que

acompañan al calentador para su envío. Mantenga

los tapones de plástico (fijados al ensamblaje de

manguera-regulador y al conector de entrada)

puestos cuando se guarde.

2. Saque todos los elementos de la caja.

3. Revise todos los elementos para ver si hay daños debidos al transporte. Si el calentador está

dañado, informe de inmediato al distribuidor a

quien se lo compró.

111656-01E

www.desatech.com

IDENTIFICACIÓN DEL

PRODUCTO

Salida de aire caliente

(parte anterior)

Cubierta exterior

Manija

Motor

Botón del

encendido

piezoeléctrico

Botón de la

válvula de control

automático

Ensamblaje

de manguera-

Cable de

alimentación

regulador

Figura 1 - Modelo de 30,000 BTU/h

TEORÍA DE

FUNCIONAMIENTO

El sistema de combustible:

guera-regulador se fija al suministro del gas propano.

Esto proporciona combustible al calentador.

El sistema de aire:

El ventilador empuja aire al interior y alrededor de la

cámara de combustión. Este aire se calienta y proporciona una corriente de aire limpio y caliente.

El sistema de encendido:

trico enciende el quemador.

El sistema de control automático:

na que el calentador se apague si se extingue la llama.

Salida de aire

caliente y limpio

(parte anterior)

Cámara de

combustión

Aire para

combustión

Figura 2 - Vista lateral de operación

el ensamblaje de man-

el motor hace girar el ventilador.

el encendido piezoeléc-

este sistema ocasio-

Ventilador

Motor

Entrada

de aire

frío (parte

posterior)

Aire para

calefacción

Ensamblaje de

manguera-regulador

3

Page 18

ENSAMBLAJE

1. Extraiga el tornillo de la parte superior del

resguardo del ventilador (consulte la figura 3).

Deseche el tornillo.

2. Inserte el clip de la tuerca (proporcionado

junto con la manija) con el lado plano hacia

arriba a través de la ranura en la parte superior

de la cubierta. Alinee los orificios en el clip

de la tuerca con el orificio de tornillo situado

detrás de la ranura en la parte superior de la

cubierta (consulte la figura 4).

3. Coloque la manija sobre el orificio y el clip.

Inserte dos tornillos (proporcionados con la

manija) a través de la manija y apriételos hacia

la cubierta. (consulte la figura 3). Asegúrese de

que el tornillo posterior atraviese la cubierta

hacia el resguardo del ventilador. Apriete los

tornillos firmemente.

Extraiga

el tornillo

Figura 3 - Extracción del tornillo de la

parte superior del resguardo del ventilador

Lado plano

hacia arriba

Ranura

Clip de

la tuerca

Cubierta

Tornillos

Clip de

la tuerca

Figura 5 - Fijación de la manija

Manija

Parte

posterior

del

calentador

SUMINISTRO DE PROPANO

El gas propano y el(los) tanque(s) de propano los

debe aprovisionar el usuario.

Use el calentador solamente con un sistema de

suministro con extracción de vapores de propano.

Consulte el capítulo 5 de la Norma de almace

namiento y manejo de gas licuado de petróleo,

ANSI/NFPA 58 y/o la norma CAN/CGA B149.2.

La biblioteca local o el departamento de bomberos

deben tener este folleto.

La cantidad de gas disponible para usarse de los

tanques de propano varía. Dos factores determinan

esta cantidad:

1. La cantidad de gas propano en el (los)

tanque(s)

2. La temperatura del(de los) tanque(s)

Este calentador está diseñado para funcionar con

un tanque de al menos 9 kg (20 libras). Es posible

que necesite dos o más tanques o un tanque de

mayor tamaño durante clima frío. Use un tanque

de 45 kg (100 libras) para operar durante un

tiempo más prolongado o en clima muy frío A

temperaturas más bajas se vaporiza menos gas.

Su proveedor local de gas propano le ayudará a

seleccionar el sistema de suministro adecuado. El

nivel mínimo de temperatura del aire circundante

para cada calentador es -29° C (-20° F).

Temperatura promedio De los tanques

En la ubicación del tanque 45 kg (100 libras)

superior a 0° F (-18° C) 1

inferior a 0° F (-18° C) 2

-

Figura 4 - Instalación del clip de la tuerca

4

www.desatech.com

111656-01E

Page 19

INSTALACIÓN

ADVERTENCIA: revise y entienda las advertencias en la sección Información de seguridad, en

la página 2. Son necesarias para

hacer funcionar este calentador

de manera segura. Siga todos

los códigos locales al utilizar este

calentador.

5. Revise todas las conexiones en busca de

fugas. Aplique una mezcla de jabón líquido y

agua a todas las uniones de la línea de gas. La

formación de burbujas indica una fuga que se

debe corregir.

6. Cierre la válvula del suministro de propano.

Manguera

Válvula de suministro

de propano

ADVERTENCIA: pruebe todas las tuberías de gas y sus

conexiones para saber si hay

fugas después de instalar o dar

servicio. Nunca use una llama

al descubierto para verificar una

fuga. Aplique una mezcla de jabón

líquido y agua en todas las uniones. La formación de burbujas

indicará una fuga. Repare todas

las fugas inmediatamente.

1.

Instale un sistema de suministro de propano (consulte Suministro de propano, en la página 4).

2.

Conecte el niple de rosca invertida del ensamblaje

de manguera-regulador a los tanques de propano.

Gire el niple de rosca invertida en sentido contra

rio al de las manecillas del reloj en la rosca del

tanque. Apriete firmemente usando una llave.

IMPORTANTE: coloque el regulador de manera

que la manguera que sale del regulador esté en

posición horizontal (consulte la figura 6). Esto

coloca la ventila del regulador en la posición

correcta para protegerla de la intemperie.

3. Conecte la manguera a la entrada de la válvula

(consulte la figura 7). Apriete firmemente

usando una llave.

IMPORTANTE: use una manguera o tubería

adicional si es necesario. Instale la manguera o

tubería adicional entre el ensamblaje de mangue

ra-regulador y el tanque de propano. Debe usar

el regulador que se incluye con el calentador.

4. Abra lentamente la válvula del suministro

de propano en el(los) tanque(s) de propano.

Nota: si no se abre lentamente, la válvula de

exceso de flujo del tanque de propano detendrá

el flujo de gas. Es posible que se escuche un

chasquido al cerrar la válvula de exceso de flu

jo. Si esto ocurre, reajuste la válvula de exceso

de flujo cerrando la válvula de suministro de

propano y vuelva a abrirla lentamente.

111656-01E

www.desatech.com

Tanque de

propano

Figura 6 - Posición del regulador

Conector de

entrada

-

Figura 7 - Manguera y conector de

Niple de

rosca

invertida

entrada

VENTILACIÓN

ADVERTENCIA: procure

mantener un espacio abierto al aire fresco del exterior de al menos 1400 cm

(1.5 pies cuadrados) mientras el

calentador está encendido.Si no

se proporciona una ventilación

-

de aire fresco del exterior, puede

haber una intoxicación con monóxido de carbono. Proporcione

una ventilación adecuada de

aire fresco del exterior antes de

encender el calentador.

-

Regulador

Manguera

5

Page 20

FUNCIONAMIENTO

ADVERTENCIA: revise y entienda las advertencias en la sección

Información de seguridad, en la

página 2. Son necesarias para hacer

funcionar este calentador de manera segura. Siga todos los códigos

locales al utilizar este calentador.

PARA ENCENDER EL CALENTADOR

1. Siga toda la información de instalación, ventilación y seguridad.

2. Sitúe el calentador sobre una superficie estable

y nivelada. Asegúrese de que no haya corrientes

fuertes de aire entrando en la parte anterior o

posterior del calentador.

3. Conecte el cable de alimentación del calentador

a un cable de extensión con conexión a tierra de

tres clavijas. El cable de extensión debe tener al

menos 1.8 m (6 pies) de longitud. El cable de

extensión debe estar aprobado por Underwriters

Laboratories.

Requisitos de medida del cable de extensión

Hasta 15.24 m (50 pies) de largo, use cable de

calibre 18 AWG.

De 15.54 a 30.48 m (de 51 a 100 pies) de largo,

use cable de calibre 16 AWG.

De 30.78 a 60.96 m (de 101 a 200 pies) de largo,

use cable de calibre 14 AWG.

4. Conecte el cable de extensión a un enchufe con

conexión a tierra de tres orificios de 120 voltios/60 hercios. El motor arrancará. El ventilador

se encenderá, haciendo que el aire salga por la

parte anterior del calentador.

5. Abra lentamente la válvula del suministro de

propano en el(los) tanque(s) de propano. Nota:

si no se abre lentamente, la válvula de exceso

de flujo del tanque de propano detendrá el flujo

de gas. Es posible que se escuche un chasquido

al cerrar la válvula de exceso de flujo. Si esto

ocurre, reajuste la válvula de exceso de flujo

cerrando la válvula de suministro de propano y

vuelva a abrirla lentamente.

ADVERTENCIA: antes de presionar el botón de la válvula de

control automático, asegúrese que

el motor y el ventilador estén funcionando. Si el motor y el ventilador

no están funcionando, pueden salir

llamaradas del calentador.

6. Presione y mantenga presionado el botón de

la válvula de control automático (consulte

la figura 8). Presione el botón del encendido

piezoeléctrico (consulte la figura 8). Continúe

6

www.desatech.com

presionando el botón del encendido hasta que

se encienda el quemador. Cuando el quemador

se encienda, mantenga el botón de la válvula de

control automático oprimido. Suéltelo luego de

30 segundos. Esto activará el sistema de control

automático.

Nota: si el calentador no se enciende, es posible

que la manguera tenga aire en el interior. Si es así,

mantenga presionado el botón de la válvula de

control automático y espere 20 segundos. Suelte

el botón de la válvula de control automático y

espere 20 segundos a que salga del calentador el

combustible que no se encendió. Repita este paso.

AVISO: si el calentador está desconectado o si se presenta una

interrupción de la energía eléctrica

mientras el calentador está encendido, el dispositivo de limitación térmi

ca detendrá el flujo de combustible.

Pasarán unos cuantos segundos

antes de que se active el dispositivo

de limitación térmica. Durante este

breve lapso, es posible que salgan

llamaradas del calentador. Esto es

normal. Las llamas se extinguirán

cuando se active el dispositivo de

limitación térmica.

Botón del

encendido

piezoeléctrico

Botón de la válvula

de control automático

Figura 8 - Botón de la válvula de control

automático y botón del encendido

PARA APAGAR EL CALENTADOR

1. Cierre firmemente la válvula del suministro de

propano en el(los) tanque(s) de propano.

2. Espere unos cuantos segundos. El calentador

quemará el gas restante en la manguera de

suministro.

3. Desenchufe el calentador.

PARA VOLVER A ENCENDER EL

CALENTADOR

1. Espere cinco minutos después de detener el

calentador.

2. Repita los pasos de Para encender el calentador.

piezoeléctrico

111656-01E

Page 21

ALMACENAMIENTO

PRECAUCIÓN: desconecte el

calentador del(de los) tanque(s) de

suministro de propano.

1. Guarde los tanques de propano de forma segura.

Consulte el capítulo 5 de la Norma de almacena-

miento y manejo de gas licuado de petróleo, ANSI/

NFPA 58. Siga todos los códigos locales. Guarde

siempre los tanques de propano en el exterior.

2. Ponga los tapones de plástico en los niples de

latón en el conector de entrada y el ensamblaje

de manguera-regulador.

3.

Guárdelo en un lugar seco, limpio y seguro. No

guarde el ensamblaje de manguera-regulador en el

interior de la cámara de combustión del calentador.

4. Siempre revise el interior del calentador cuando lo saque del lugar de almacenamiento. Los insectos y animales pequeños pueden haber introducido cuerpos extraños en el calentador. Si es necesario, extraiga el motor y otras piezas internas para sacar los cuerpos extraños (consulte Procedimientos de servicio).

MANTENIMIENTO

ADVERTENCIAS

• Nunca intente reparar un calentador mientras esté enchufado,

conectado al suministro de propano, funcionando o caliente.

Pueden ocurrir quemaduras

graves y electrocución.

• Mantenga el calentador limpio

y libre de materiales combustibles, gasolina y otros vapores

y líquidos inflamables.

• No bloquee el flujo de la com

bustión o de la ventilación.

1.

Mantenga limpio el calentador. Limpie el calentador

anualmente o según sea necesario para retirar el

polvo y los residuos. Si el calentador está sucio o

con polvo, límpielo con un paño húmedo. Utilice

limpiadores domésticos en las manchas difíciles.

2. Inspeccione al calentador antes de cada uso.

Revise las conexiones en busca de fugas. Aplique

una mezcla de jabón líquido y agua en todas las

conexiones. La formación de burbujas indicará una

fuga. Repare todas las fugas inmediatamente.

3. Inspeccione el ensamblaje de mangueraregulador antes de cada uso. Si la manguera está

muy desgastada o con roturas, reemplácela con

una manguera especificada por el fabricante.

4. Haga que una agencia de servicio calificada

inspeccione el calentador anualmente.

111656-01E

-

www.desatech.com

5. Mantenga el interior del calentador libre de

objetos combustibles y extraños. Si es necesario,

extraiga el motor y otras piezas internas para

limpiar el interior del calentador (consulte

Procedimientos de servicio).

6.

Limpie las aspas del ventilador cada temporada o

según sea necesario (consulte Ventilador, página 8).

PROCEDIMIENTOS DE

SERVICIO

ADVERTENCIA: nunca intente

reparar un calentador mientras esté

enchufado, conectado al suminis

tro de propano, esté funcionando o

esté caliente. Pueden ocurrir que

maduras graves y electrocución.

SISTEMA ELÉCTRICO

Todo el sistema eléctrico de este calentador está en

el interior del motor. Si cualquier parte del sistema

eléctrico se daña, deberá reemplazar el motor.

MOTOR

1. Quite los tres tornillos que fijan el resguardo del

ventilador a la cubierta del calentador.

2. Extraiga de la cubierta del calentador el motor y el

resguardo del ventilador (consulte la figura 9).

3. Use una llave hexagonal para aflojar el tornillo de

fijación que sostiene el eje del motor (consulte la

figura 10). Retire el ventilador. Tenga cuidado de no

dañar la inclinación de las aspas del ventilador.

Tornillo

Motor y

resguardo

Tornillo

del ventilador

Tornillo

Figura 9 - Desmontaje del motor y el

resguardo del ventilador del calentador

Tornillo de

fijación

Figura 10 - Ubicación del tornillo de fijación

-

-

7

Page 22

PROCEDIMIENTOS DE

SERVICIO Continuación

4. Con un destornillador para tuercas, quite las dos

tuercas y los dos tornillos que fijan el resguardo

del ventilador al motor. Extraiga del motor el

resguardo del ventilador (consulte la figura 11).

5

Desconecte el cable verde de alimentación del motor

y retire las terminales de los cables negro y blanco.

6. Deseche el motor usado.

7. Fije el cable verde de alimentación al motor.

8. Fije el resguardo del ventilador al motor nuevo

con dos tuercas y dos tornillos.

9. Vuelva a colocar las terminales negra y blanca.

10. Coloque el ventilador en el eje del motor nuevo.

Asegúrese de que el tornillo de fijación haga

contacto con la superficie plana del eje del motor.

Apriete el tornillo de fijación firmemente (46.08-

57.60 kg-cm [40-50 pulgadas-libra]).

11. Coloque el motor y el resguardo del ventilador

en la parte posterior de la cubierta del calentador.

Asegúrese que el cable de alimentación esté

situado correctamente (consulte la figura 12).

12. Inserte tres tornillos a través de la cubierta del

calentador y hacia el interior del resguardo del

ventilador (consulte la figura 12). Apriete los

tornillos firmemente.

Resguardo del ventilador

Tuerca

Motor

Figura 11 - Desmontaje y montaje del

resguardo del ventilador en el motor

Tornillo

VENTILADOR

1. Quite los tres tornillos que fijan el resguardo del

ventilador a la cubierta del calentador.

2. Extraiga de la cubierta del calentador el motor

y el resguardo del ventilador (consulte la figura

9, página 7).

3. Use una llave hexagonal para aflojar el tornillo de

fijación que sujeta el ventilador al eje del motor

(consulte la figura 10, página 7).

4. Retire el ventilador. Tenga cuidado de no dañar

la inclinación de las aspas del ventilador.

5a. Si va a reemplazar el ventilador, quite el ventilador

usado y deséchelo. Ir al paso 7 a continuación.

5b. Si va a limpiar el ventilador, use un paño suave

humedecido con keroseno o solvente.

6. Seque completamente el ventilador.

7. Coloque el ventilador en el eje del motor. Asegúrese de que el tornillo de fijación haga contacto

con la superficie plana del eje del motor. Apriete

el tornillo de fijación firmemente (46.08-57.60

kg-cm) (40-50 pulgadas-libra).

8. Coloque el motor y el resguardo del ventilador

en la parte posterior de la cubierta del calentador.

Asegúrese que el cable de alimentación esté

situado correctamente (consulte la figura 12).

9. Inserte los tres tornillos a través de la cubierta

del calentador y al interior del resguardo del

ventilador. Apriete los tornillos firmemente.

ENCENDIDO

1. Extraiga del calentador el motor y el resguardo

del ventilador (consulte Motor, página 7, pasos

1 y 2).

2. Quite del encendido piezoeléctrico el cable negro

de encendido. Acceda al cable del encendido

por el fondo de la base del calentador (consulte

la figura 13). Empuje el cable hacia arriba y a

través de la muesca en el panel de relleno.

Tornillo

Motor y

resguardo

Tornillo

Tornillo

Figura 12 - Reemplazo del motor y el

resguardo del ventilador en el calentador

8

del

ventilador

www.desatech.com

Encendido

piezoeléctrico

Cable del

encendido

Figura 13 - Retiro del cable de encendido

del encendido piezoeléctrico

Encendido

Figura 14 - Extracción del tornillo de

montaje del encendido y el encendido

Fondo del

calentador

Tornillo de

montaje

111656-01E

Page 23

PROCEDIMIENTOS DE

SERVICIO Continuación

3. Quite de la cabeza posterior el tornillo de montaje del encendido utilizando un destornillador

para tuercas o un destornillador convencional

(consulte la figura 14, página 8).

4. Saque el encendido de la cabeza posterior.

5. Instale el encendido nuevo. Fije el encendido a

la cabeza posterior con el tornillo de montaje del

encendido.

6. Pase el cable de encendido del nuevo encendido a

través de la muesca en el panel de relleno. Fije el

cable de encendido al encendido piezoeléctrico.

7. Ajuste la distancia entre el electrodo del encendido y la placa de fijación 0.43 cm (0.17")

(consulte la figura 15).

8. Compruebe que haya chispa. Oprima el botón

del encendido piezoeléctrico y observe si hay

chispa entre el electrodo del encendido y la placa

de fijación.

9. Coloque el motor y el resguardo del ventilador

en la parte posterior de la cubierta del calentador

(consulte Motor, página 7, pasos 9 y 10).

Electrodo del

encendido

Área de la

separación

ADVERTENCIA: asegúrese

que el calentador esté desconec

tado del suministro de propano.

El calentador se podría encender

y ocasionar quemaduras graves.

Figura 15 - Distancia mínima entre el

electrodo del encendido y la placa de fijación

ESPECIFICACIONES

BLP30, NLP30, REM30LP, RLP30

• Potencia nominal de salida: 30,000 Btu/Hr

• Combustible: Sólo vapor de propano

• Encendido: Manual, piezoeléctrico

•

Consumo de combustible/Hora: 1.25 litros (0.33 gal)

0.63 kg (1.4 lb)

•

Presión del suministro al regulador: Min* - 20 psi,

Max - Presión del tanque o 200 PSI

• Presión de salida del regulador: 10 PSI

• Presión del tubo múltiple: 10.1 PSI

RLLP35

• Potencia nominal de salida: 35,000 Btu/Hr

• Combustible: Sólo vapor de propano

• Encendido: Manual, piezoeléctrico

•

Consumo de combustible/Hora: 1.44 litros (0.38 gal)

0.74 kg (1.62 lb)

•

Presión del suministro al regulador: Min* - 20 psi,

Max - Presión del tanque o 200 PSI

• Presión de salida del regulador: 10 PSI

• Presión del tubo múltiple: 9.7 PSI

* Para propósitos de ajustes de entrada

** Cuando se hace funcionar el calentador a temperaturas por encima de los 29.44° C (85° F), las altas

temperaturas internas pueden ocasionar que el dispositivo de limitación térmica apague el calentador.

RM40LP, RM40SP, SPC-40B

• Potencia nominal de salida: 40,000 Btu/Hr

• Combustible: Sólo vapor de propano

• Encendido: Manual, piezoeléctrico

•

Consumo de combustible/Hora: 1.65 litros (0.44 gal)

0.84 kg (1.86 lb)

•

Presión del suministro al regulador: Min* - 20 psi,

Max - Presión del tanque o 200 PSI

• Presión de salida del regulador: 10 PSI

• Presión del tubo múltiple: 9.7 PSI

EL RESTO DE LA LISTA SE APLICA

A TODOS LOS MODELOS

• Salida de aire caliente (pies cúbicos por minuto

aproximados): 175

• Motor: 3045 RPM, 1/40 HP

• Entrada eléctrica: 120 voltios/60 hercios

• Amperaje: 0.6

• Rango de temperaturas para el funcionamiento

del calentador: -29° C a 29.4° C** (-20° F a 85°

F** )

111656-01E

www.desatech.com

9

Page 24

SOLUCIÓN DE PROBLEMAS

ADVERTENCIA: nunca intente reparar un calentador mientras esté

enchufado, conectado al suministro de propano, esté funcionando o

esté caliente. Pueden ocurrir quemaduras graves y electrocución.

FALLA OBSERVADA

El ventilador no gira cuando se

conecta el calentador

El calentador no se encenderá

CAUSA POSIBLE

1. No llega energía eléctrica al

calentador

2. El ventilador golpea la parte

interior de la cubierta del

calentador

3. Las aspas del ventilador están

dobladas

4. El motor está defectuoso

1. El usuario no siguió las instrucciones de instalación y

operación correctamente

2. No hay chispa en el encendido. Para comprobar que haya

chispa, realice el paso 8 en En-

cendido, en la página 8. Si hay

chispa en el encendido, haga

que una persona capacitada de

servicio repare el calentador. Si

no hay chispa:

A) El cable del encendido está

suelto o desconectado

B) La distancia intermedia es

incorrecta

C) El encendido piezoeléctrico

está flojo

D) El electrodo del encendido

está dañado

REMEDIO

1. Revise la tensión del enchufe

eléctrico. Si la tensión es la

correcta, revise que no haya

roturas en cable de alimentación del calentador

2. Ajuste el motor o resguardo

del ventilador de manera que

el ventilador no golpee el

interior de la cubierta del calentador. Si es necesario, doble

el resguardo del ventilador

3. Reemplace el ventilador. Consulte Ventilador, página 8

4. Reemplace el motor. Consulte

Motor, página 7

1.

Repita las instrucciones de instalación y operación. Consulte

Instalación, en la página 5 y

Funcionamiento, en la página 6

2. A) Revise el cable del encendido. Apriete o vuelva a fijar

el cable flojo del encendido.

Consulte la figura 14, en la

página 8, para ver la ubicación

del cable del encendido

B) Ajuste la distancia entre

el electrodo del encendido y

la placa de fijación a 0.43 cm

(0.17")

C) Apriete la tuerca que sujeta

el encendido piezoeléctrico a

la base del calentador

D) Reemplace el electrodo del

encendido. Consulte Encendi-

do, página 8

El calentador se apaga en pleno

funcionamiento

ADVERTENCIA:

úsese únicamente

en áreas que estén

libres de un alto contenido de polvo.

10

1. La elevada temperatura del

aire circundante ocasiona que

el dispositivo de limitación

térmica apague el calentador

2. El flujo de aire está restringido

3. El ventilador está dañado

4. Hay un exceso de polvo o re

siduos en el área circundante

www.desatech.com

1. Esto se puede presentar cuando

se hace funcionar el calentador

a temperaturas superiores a

los 29.44° C (85° F). Utilice

el calentador a temperaturas

más bajas

2 Revise la entrada y la salida

del calentador. Quite las obstrucciones que haya

3. Reemplace el ventilador. Consulte Ventilador, página 8.

4. Limpie el calentador. Consulte

Mantenimiento, página 7

111656-01E

Page 25

ACCESORIOS

Adquiera accesorios y piezas con su distribuidor o

centro de servicio más cercano. Si ellos no pueden

proveer un accesorio o pieza, comuníquese con

la Central de piezas más cercana (se muestran en

una lista por separado en el folleto de Centros de

servicio autorizados), o bien, comuníquese con

DESA Heating Products para obtener información

de referencia.

Regulador de gas propano: LPA2170

Aprobado por Underwriters Laboratories.

Ensamblaje de manguera/regulador:

LPA3120

Aprobado por Underwriters Laboratories.

Conector de gas combustible: LPA4020

Conecta el regulador a todos los tanques de

propano estándar. Aprobado por Underwriters

Laboratories y American Gas Association.

SERVICIO TÉCNICO

Es posible que tenga más preguntas acerca de

este calentador. De ser así, póngase en contacto

con el departamento de servicio técnico de DESA

Heating Products al teléfono 1-866-672-6040. Al

llamar, tenga a la mano los números de modelo y

serie de su calentador.

También puede visitar el sitio web de servicio

técnico de DESA Heating Products en

www.desatech.com.

PIEZAS DE REPUESTO

ADVERTENCIA: use sólo

piezas de repuesto originales.

Este calentador debe usar piezas

diseñadas específicamente.

No las sustituya ni use piezas

genéricas. El uso de piezas de

repuesto inadecuadas puede

ocasionar lesiones graves o

fatales. Esto también protegerá

la cobertura de su garantía

para piezas reemplazadas con

garantía.

PIEZAS CON GARANTÍA

Póngase en contacto con los distribuidores

autorizados de este producto. Si ellos no pueden

suministrar piezas de repuest o originales,

comuníquese con la central de piezas más

cercana o llame al Departamento de servicios

técnicos de DESA Heating Products al teléfono

1-866-672-6040.

Cuando llame a DESA Heating Products, tenga

listo:

• su nombre

• su dirección

• el número de modelo de su calentador

• la falla del calentador

• la fecha de compra

PIEZAS SIN GARANTÍA

Póngase en contacto con los distribuidores

autorizados de este producto. Si ellos no pueden

suministrar piezas de repuest o originales,

comuníquese con la Central de piezas más

cercana (listada en el folleto de Centros de

servicio autorizados), o bien, llame a DESA

Heating Products al 1-866-672-6040 para obtener

información de referencia.

Cuando llame a DESA Heating Products, tenga

listo:

• el número de modelo de su calentador

• el número de la pieza de repuesto

111656-01E 11

www.desatech.com

Page 26

CLASIFICACIÓN ILUSTRADA DE PIEZAS

20

2

9

10

17

11

3

22

12

15

5

19

18

13

7

8

4

16

21

14

23

6

1

MODELOS BLP30, NLP30, REM30LP, RLP30, RLLP35, BLP42, RM40LP,

RM40SP Y SPC-40B

12

www.desatech.com

111656-01E

Page 27

LISTA DE PIEZAS

Esta lista contiene las piezas reemplazables utilizadas en el calentador. Al hacer un pedido de piezas,

siga las instrucciones enumeradas en Piezas de repuesto en la página 11 de este manual.

NÚMERO DE

N°

PIEZA DESCRIPCIÓN CANT

1 ** Cámara de combustión • • • • • • • • • 1

2 ** Monochasis • • • • • • • • • 1

3 M11143-1 Buje, atenuación de deformaciones • • • • • • • • • 1

4 M11084-27 Tornillo • • • • • • • • • 5

5 099237-01 Tuerca termopar • • • • • • • • • 2

6 103894-01 Paquete de soporte de fijación • • • • • • • • • 1

7 104784-01 Encendedor del electrodo • • • • • • • • • 1

8 M11084-38 Tornillo hexagonal con rosca cortante,

#8-18 x 3/8"

9 101478-02 Ventilador • • • • • • • • • 1

10 104156-01 Ensamblaje del motor • • • • • • • • • 1

103863-01 Resguardo del ventilador • • • • • • • • • 1

11