Desa Tech 6BY70, 6BY72 Owner's Manual

Operating Instructions and Parts Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

6BY70 and 6BY72

Dayton® Natural Gas Radiant

Construction Heaters

Description

Dayton Model 6BY70 is a 125,000 Btu/Hr construction heater.

Dayton Model 6BY72 is a 250,000 Btu/Hr construction heater.

These heaters use natural gas for combustion and are intended for

indoor use only and the temporary heating of well-ventilated buildings under construction, alteration, or repair. These heaters should

never be used in occupied dwellings. Products of combustion are

vented into the area being heated.

Figure 1 - Model 6BY70

Figure 2 - Model 6BY72

Unpacking

1. Remove all packing items

applied to heater for shipment. Keep plastic cover

caps (attached to valve inlet

and regulator assembly) for

storage.

2.

Remove all items from carton.

3. Check all items for ship-

Model 6BY70 Only

Form 5S5383

ping damage. If heater is

damaged, promptly inform

dealer where you bought

heater.

Printed in China or Mexico

09663

1105/382/VCPVP

GENERAL HAZARD

WARNING

Failure to comply

with the precautions and instructions provided with

this heater, can

result in death, serious bodily injury

and property loss

or damage from

hazards of fire,

explosion, burn,

asphyxiation, carbon monoxide

poisoning and/or

electrical shock.

Only persons who

can understand and

follow the instructions should use or

service this heater.

If you need assistance or heater information such as an

instructions manual,

labels, etc. contact

the manufacturer.

DES003

117163-01

05/05

Rev. D

11/05

Dayton Operating Instructions and Parts Manual

Dayton

®

Natural Gas Radiant

Construction Heaters

6BY70 and 6BY72

General Safety

Information

Make certain you read and

understand all warnings. Keep

these instructions for reference.

They are your guide to safe and

proper operation of this heater.

Safety information appears

throughout these instructions. Pay close attention to

them. Below are definitions for

the safety information listed

throughout this manual.

Under this heading, installation,

operating and maintenance

procedures or practices will

be found that, if not carefully followed, WILL result in

IMMEDIATE serious personal

injury or death.

Under this heading, installation,

operating, and maintenance

procedures or practices will be

found that, if not carefully followed, COULD result in severe

personal injury or death.

Under this heading, installation,

operating, and maintenance

procedures or practices will be

found that, if not carefully followed, MAY result in minor personal injury, product or property

damage.

IMPORTANT: Not every possible

circumstance that might involve

a hazard can be anticipated. The

warnings in this manual and on

tags or decals affixed to the unit

are therefore not all-inclusive. If

a procedure, work method, or

operating technique not specifically recommended by Dayton is

used, you must make sure it is

safe for you and others. You

should also ensure that equipment will not be damaged or

made unsafe by the operating or

maintenance method you choose.

Not for home or recreational vehicle use.

This product contains

and/or generates chemicals known to the State

of California to cause

cancer or birth defects, or

other reproductive harm.

Fire, burn, inhalation

and explosion hazard.

Keep solid combustibles, such as building

materials, paper or

cardboard, a safe distance away from the

heater as recommended by the instructions.

Never use the heater

in spaces which do or

may contain volatile or

airborne combustibles

or products such as gasoline, solvents, paint

thinner, dust particles

or unknown chemicals.

For 125,000 Btu models, do not exceed 1/2

psi (14" w.c.) gas pressure to the gas control

valve.

The heater is designed for use as

a construction heater in accordance with ANSI Z83.7/CGA

2.14. Other standards govern

the use of fuel gases and heating products for specific uses.

Your local authority can advise

you about these. The primary

purpose of construction heaters

is to provide temporary heating

of buildings under construction,

alteration or repair. Properly

used, the heater provides safe

economical heating. Products of

combustion are vented into the

area being heated.

We cannot foresee every use

which may be made of our heaters. Check with your local fire

safety authority if you have

questions about heater use.

Carbon Monoxide Poisoning:

Some people are more affected

by carbon monoxide than others. Early signs of carbon monoxide poisoning resemble the flu,

with headaches, dizziness and/or

nausea. If you have these signs,

the heater may not be working

properly. Get fresh air at once!

Check for proper ventilation and

have heater serviced.

Natural Gas: Natural gas is odor-

less. An odor-making agent is

added to this gas. The odor helps

you detect a gas leak. However,

the odor added to the gas can

2

Dayton Operating Instructions and Parts Manual

Models 6BY70 and 6BY72

General Safety

Information (Continued)

fade. Gas may be present even

though no odor exists.

Make certain you read and

understand all warnings. Keep

this manual for reference. It is

your guide to safe and proper

operation of this heater.

1. Install and use heater with

care. Follow all local ordinances and codes. In the

absence of local ordinances

and codes, refer to the

National Fuel Gas Code

Handbook, ANSI Z223.1/

NFPA 54. This instructs on

the safe storage and handling of flammable gases.

2. Use only with natural gas.

Do not attempt to use with

propane gas.

3. Use only the factory preset

regulator provided with the

heater.

4. Provide adequate ventilation. Before using heater,

provide at least a 0.28 m2

(3 ft2) opening of fresh,

outside air for each

100,000 Btu/hr of rating.

[Or for 125,000 Btu/hr

models 0.35 m2 (3.75 ft2)

and 250,000 Btu/hr models

0.7 m2 (7.5 ft2).]

5. For indoor use only. Do not

use heater outdoors.

6. Do not use heater in occupied dwellings or in living

or sleeping quarters.

7.

Do not use heater in basement or below ground level.

8. Keep appliance area clear

and free from combustible

materials, gasoline, paint

thinner and other flammable vapors and liquids. Dust

is combustible. Do not use

heater in areas with high

dust content.

9. Minimum heater clearances

from combustibles

125,000 Btu/Hr: Sides 1.54 m

(5 ft), Top 1.22 m (4 ft)

250,000 Btu/Hr: Sides 1.83 m

(6 ft), Top 1.54 m (5 ft)

10. Check heater for damage

before each use. Do not

use a damaged heater.

11. Check hose (if used) before

each use of heater. If highly

worn or cut, replace.

12. Locate heater on stable

and level surface if heater

is hot or operating.

13. Not intended for use on

finished floors.

14. Never block any air inlet

or air outlet openings of

heater.

15. Keep heater away from

strong drafts, wind, water

spray, rain or dripping water.

16. Do not leave heater unattended.

17. Keep children and animals

away from heater.

18. To prevent burns, remove

19. Never move, handle or

20.

21. Never attach duct work to

22. Do not alter heater. Keep

23. Do not use heater if

24. Turn off gas supply to

25. Use only original replace-

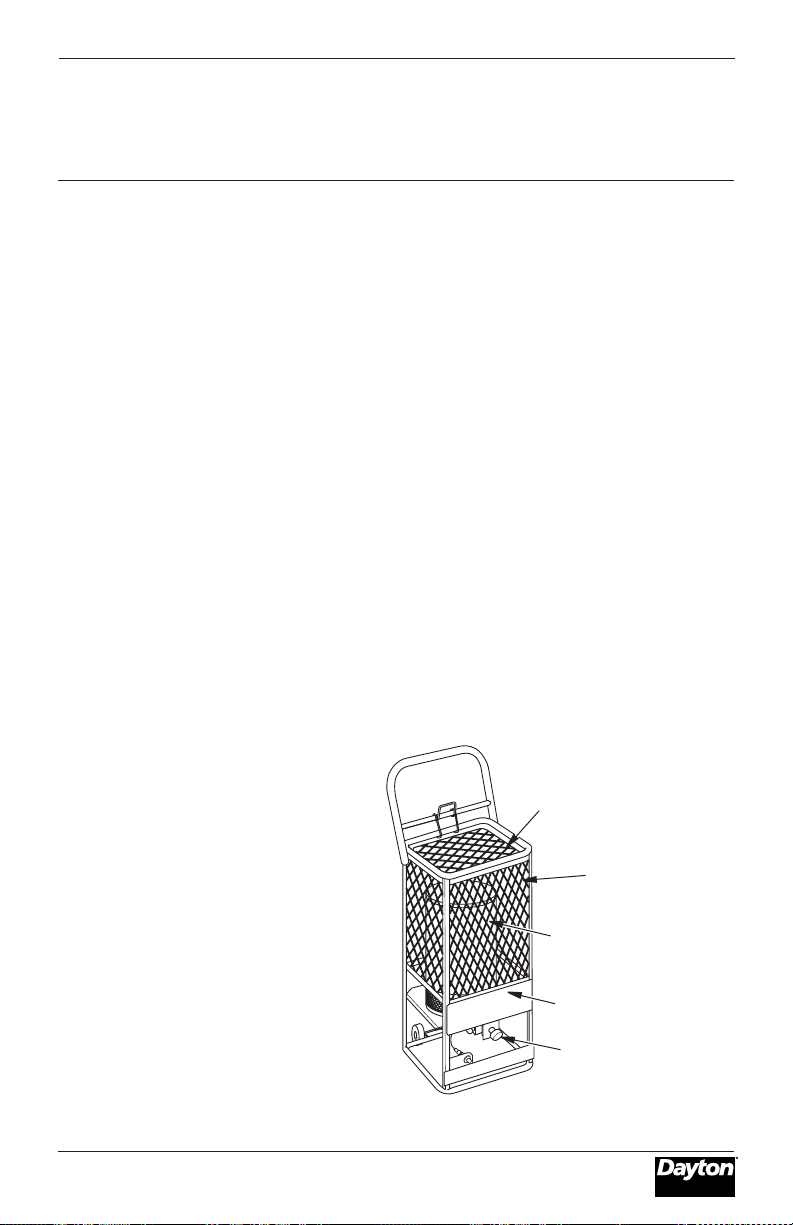

Product Identification

Figure 3 - 125,000 Btu/Hr Model (6BY70)

handle before operating

heater (6BY70 only).

service a hot or operating

heater. Severe burns may

result. Wait 20 minutes

after turning heater off.

To prevent injury, wear gloves

when handling heater.

heater.

heater in its original state.

altered.

heater when not in use.

ment parts. This heater must

use design-specific parts. Do

not substitute or use generic

parts. Improper replacement

parts could cause serious or

fatal injuries.

Top

Protective

Screen

Combustion

Chamber

Cover

Lighting

Port

Control Knob

3

Dayton Operating Instructions and Parts Manual

Dayton

®

Natural Gas Radiant

Construction Heaters

6BY70 and 6BY72

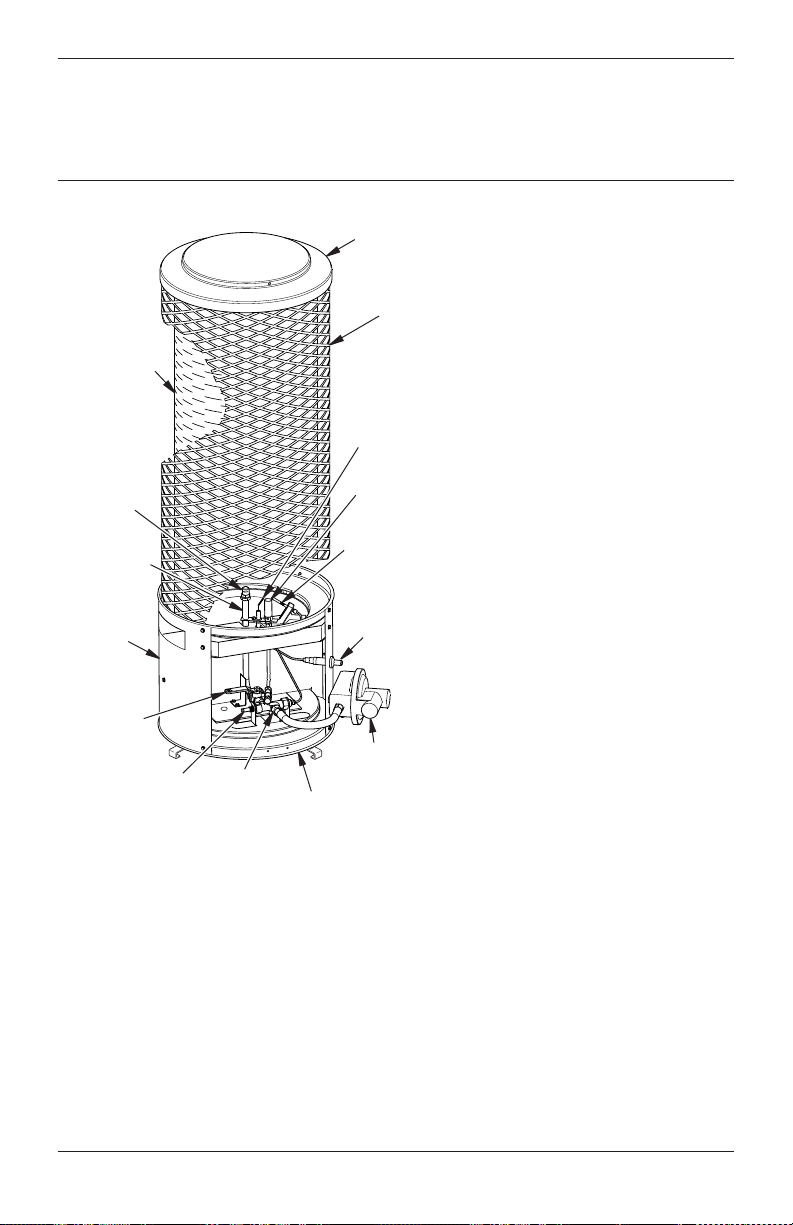

Product Identification (Continued)

Top

Shell

Emitter

Ignitor

Electrode

Thermocouple

Base

Pilot Burner

Ignitor

Regulator/Fuel

Tube Assembly

Installed

Nozzle

Main

Burner

Tube

Base

Shell

Main

Burner

Valve

Handle

Automatic

Control

Valve Button

Figure 4 - 250,000 Btu/Hr Model (6BY72)

Valve Inlet

(1/2" SAE

Flare)

Theory of Operation

The Fuel System: The gas supply

attaches to the heater through

user supplied hose or pipe. This

provides fuel to the heater.

The Ignition System: The ignitor

lights the burner fuel supply.

The Automatic Control System:

This system causes the heater to

shut down if the flame goes out.

Natural Gas Supply

The user must furnish the natural gas supply and the connections to the heater.

For 125,000 Btu/Hr models,

regulate the natural gas supply

between a minimum 7" w.c. to a

maximum of 1/2 psi (14" W.C.).

The natural gas supply capacity should be able to supply a

minimum of 125 cubic feet of gas

at pressure for each heater connected to the system.

For 250,000 Btu/Hr models,

regulate the natural gas supply to min. 4 psi. If over 4 psi is

supplied, then use the supplied

regulator on the heater. The natural gas supply capacity should

be able to supply a minimum of

250 cubic feet of gas at pressure

for each heater connected to the

system.

Consult your natural gas supplier

for proper sizing of the natural

gas supply lines.

Follow all local ordinances and

codes. In the absence of local

ordinances and codes, refer

to the National Fuel Gas Code

Handbook, NFPA 54/ANSI Z223.1.

4

Dayton Operating Instructions and Parts Manual

Models 6BY70 and 6BY72

Specifications

Model 6BY70

• Rating: 125,000 Btu/Hr

• Fuel: Natural Gas Only

• Fuel Consumption: 3.5 m3/hr (125 ft3/hr)

• Manifold Pressure: 1.5 kPa (6" W.C.)

• Min Temperature: -29 °C (-20° F) Surrounding Air Temperature

• Ignitor Gap: 0.195"

Model 6BY72

• Rating: 250,000 BTU/Hr

• Fuel: Natural Gas Only

• Fuel Consumption: 243 ft3/hr

• Supply Pressure: Max. (to regulator) - 200 psi

Min. (to heater) - 4 psi

Max. To Heater Without Regulator - 4 psi

• Manifold Pressure: 3.5 psi

• Ignitor Gap: 0.195"

Ventilation

Provide at least a 0.28 m2

(3 ft2) opening of

fresh, outside air for

each 100,000 Btu/Hr of

rating while running

heater. If proper fresh,

outside air ventilation

is not provided, carbon

monoxide poisoning can occur. Provide

proper fresh, outside

air ventilation before

running heater.

Installation

Test all gas piping and

connections for leaks

after installation or

servicing. Never use an

open flame to check for

a leak. Apply a mixture

of liquid soap and water

to all joints. Bubbles

forming show a leak.

Correct all leaks at once.

Read these instructions

carefully. Read and

adhere to these instructions. Do not allow anyone who has not read

these instructions to

assemble, light, adjust

or operate this heater.

Do not attempt to

operate the heater with

any gas other than that

indicated on the heater

nameplate.

5

The installation of this appliance must comply with local

and/or Provincial codes or, in

the absence of these codes,

with the National Fuel Gas

Code, ANSI Z223.1 – Latest

Edition or with the current

installation codes.

This heater (including hose and

regulator) must be inspected

before each use and at least

annually by a qualified service

person. If the hose shows evidence of excessive abrasion or

wear or if the hose is cut, it must

be replaced prior to the heater

being put into operation.

LOCATING HEATER

The heater must be located

on a hard, flat, level surface to

minimize the risk of accidental

tipping.

This appliance must be

installed only in locations

where the potential for physical damage to the appliance

(i.e., due to physical contact) is

reduced to a minimum.

The installer must inform the

owner/operator of this appliance that precautions must be

taken to protect the appliance

from physical damage.

This appliance produces radiant heat. Therefore, it must be

located at least 1.8 m (6 ft) away

from any propane/LP gas container and must not be directed

toward any propane/LP gas container within 6 m (20 ft).

The heater must be installed in a

location such that it will not be

exposed directly to water spray,

rain and/or dripping water.

Use of this heater in a draft/

windy area decreases its efficiency. If possible, operate the

unit in a draft free area.

Loading...

Loading...