Desa Tech 44-PH Owner's Manual

INSTRUCTIONS AND PARTS LIST

National-Riverside

Universal

Model 44-PH

ALL PURPOSE

PROPANE

HEATER

MODEL SPC-44PH

SPC

ALL-PRO

40,000 BTU/HR

Type of Gas.................For use with Propane Only

Input rating........................................40,000 BTU/hr

Manifold Pressure....................................11" W.C.

Orifice Size.................................................1.90mm

Max. Supply Inlet Pressure.........................100 psi

Min. Supply Inlet Pressure...............................5 psi

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

WARNING: For Outdoor Use Only

!

GENERAL HAZARD WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE INJURY OR PROPERTY DAMAGE. READ THE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

INSTALLER - LEAVE THESE INSTRUCTIONS WITH CONSUMER

SCHEU PRODUCTS COMPANY, INCORPORATED

Mail: P.O. Box 250, Upland, CA 91785

Plant: 8855 Baker Ave., Rancho Cucamonga, CA 91730

Telephone: 909 981-5343

8339

September 2001

OPERATING INFORMATION

SAFETY PRECAUTIONS

This is a propane, direct-fired heater.

Propane is heavier than air. If propane leaks from a connection

or fitting, it sinks to the floor, collecting there with the

surrounding air, forming a potentially explosive mixture. Obviously, propane leaks should be avoided, so set up the

propane supply with utmost care. Leak check new connections or reconnections with a soap and water solution and

follow all connection instructions herein. Also, ask your

propane dealer for advice on the propane supply installation

and ask him to check it if there are any questions.

Direct-fired means that all of the combustion products enter

the heated space. Even though this heater operates very

close to 100 percent combustion efficiency, it still produces

small amounts of carbon monoxide. Carbon monoxide (called

CO) is toxic.

CO can build up in a heated space and failure to provide

adequate ventilation could result in death. The symptoms of

inadequate ventilation are:

headache

dizziness

burning eyes and nose

nausea

dry mouth or sore throat

So, be sure to follow advice about ventilation in these operating

instructions.

!

WARNING: FIRE, BURN, INHALATION, AND EX-

PLOSION HAZARD. KEEP SOLID COMBUSTIBLES, SUCH

AS BUILDING MATERIALS, PAPER OR CARDBOARD, A

SAFE DISTANCE AWAY FROM THE HEATER AS RECOMMENDED BY THE INSTRUCTIONS. NEVER USE THE HEATER

IN SPACES WHICH DO OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS

GASOLINE, SOLVENTS, PAINT THINNER, DUST PARTICLES

OR UNKNOWN CHEMICALS.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, immediately call

your gas supplier.

Tools Required

8 mm Socket and Driver or Screwdriver

#2 & #3 Philips Head Screwdriver

Open End Wrenches: 10mm, 11mm, 12mm, 3/4"

Teflon Tape - Pipe Thread Sealer

1. Check the heater thoroughly for damage. DO NOT

operate a damaged heater.

2. DO NOT modify the heater or operate a heater which

has been modified from its original condition.

3. Use only propane gas.

4. Use only VAPOR WITHDRAWAL propane supply. If

there is any question about vapor withdrawal, ask your

propane dealer.

5. Never use the heater if the ballast weight is not assembled onto the base. The base must be weighted to avoid

tipping.

6. Use only the hose and regulator assembly provided

with the heater. Inspect hose assembly before each

use of the heater. If there is excessive abrasion or

wear, or hose is cut, replace with hose assembly listed

on parts list before using heater.

7. This heater is for outdoor use only, even so make sure

that there is ample fresh air ventilation. Do not use in

buildings, garages or other enclosed spaces.

8. If at any time gas odor is detected, IMMEDIATELY

DISCONTINUE operation until the source of gas has

been located and corrected.

9. Install the heater such that it is not directly exposed to

water spray, rain and/or dripping water or wind.

10. Maintain minimum clearance to people or normal

combustible material (like paper) of 3 feet from top, 2

feet from the reflector.

11. Operate only on a stable, level surface.

12. Do not move, handle or service while hot or burning.

13. Use only in accordance with local codes or, in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1.

14. Do not hang or attach clothing or any other combustible

materials from, on or near the heater.

15. Check control compartment burners and circulation air

passageways for free air passage, make sure that there

are no obstructions. These areas are a common location

for spider webs, which can present a dangerous condition, damage the heater and render it unsafe for use. The

heater must be checked if any of the following conditions

exist:

a) Gas smell along with predominate yellow tipping of

the burner flames.

b) Heater does not reach temperature.

c) Uneven burner glow.

d) Burner makes popping noises during normal use,

other than during shutdown.

16. Care must be taken for the supervision of children in the

vicinity of an operating heater.

17. Due to high surface termperatures adults and children

must observe clearances to avoid burns or clothing

ignition.

Page 2

GAS REQUIREMENTS

The heater comes with a regulator/hose assembly for

hook-up to a standard 20 pound LP gas tank (18- 1.4" high,

12- 1/4" diameter). The LP tank is not included. A

dented or rusty LP tank may be hazardous and

should be checked by your LP supplier. Never use an

LP tank with a damaged valve. The LP tank must be

arranged to provide for vapor withdrawal from the operating

cylinder. Never connect an unregulated LP tank to the

heater. The heater is shipped from the factory for LP use,

never substitute gases

LP Gas Hook-up:

The heater is designed to house a 20 pound gas cylinder

in the base assembly. Lift the cylinder cover, and place the

LP cylinder into the housing. The regulator can then be

screwed into the LP cylinder, the regulator and the tank

have right-handed threads (clockwise to tighten. No teflon

tape is required). When tightening be careful not to put too

much force on the LP cylinder valve.

ASSEMBLY INSTRUCTIONS

NOTE: Assembly of this heater requires basic

mechanical skills. Proper assembly is the

responsibility of the installer Installation and

repair should be done by a qualified service

person.

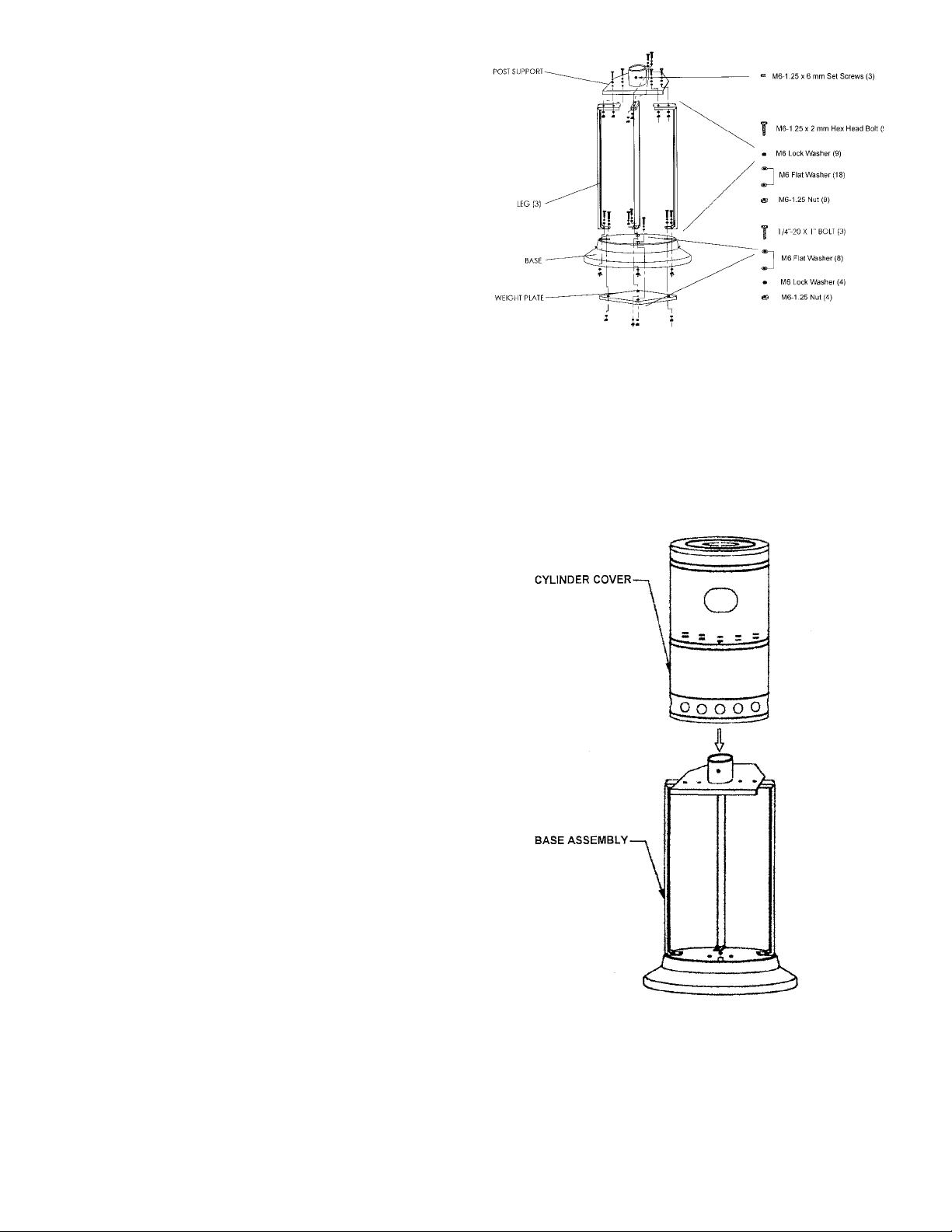

STEP 1:

Attach the three base support legs on the base using three (3)

M6-1.25 x 20mm hex head bolts, three (3) M6 lock washers,

six (6) flat washers, and three (3) M6-1.25 nuts.

Figure 1: Step 1, 2 & 3

STEP 4:

Slide the cylinder cover over the base module assembled

in the previous steps. See figure 2.

STEP 2:

Place the ballast weight plate under the base. Tighten the

weight and base together using four (4) M6-1.25 x 25mm hex

head bolts, four (4) M6 lock washers, eight (8) M6 flat washers

and four (4) M6-1.25 nuts.

STEP 3:

Place the post support on the base support legs (see figure 1).

Tighten the post support and the base support legs together

using six (6) M6-1.25 x 20mm hex head bolts, six (6) M6 lock

washers, twelve (12) M6 flat washers, and six (6) M6-1.25 nuts.

NOTE: Make sure that all bolts are tightened before proceed-

ing to the next assembly step.

Figure 2: Step 4

Page 3

Loading...

Loading...