Page 1

TYPE OF GAS...........................For use with Propane Only

INPUT RATING....................................12-IR 11,000 BTU/hr

.............................24-IR/24-IRP 22,000 BTU/hr

........................................36-IR 33,000 BTU/hr

........................................48-IR 44,000 BTU/hr

MANIFOLD PRESSURE..........................28" Water Column

ORIFICE SIZE....................................................No. 69 Drill

!

WARNING: Improper installation, alteration,

service or maintenance can cause property damage,

injury, or death. Read the installation operating and

maintenance instrucitons thoroughly before installing or

servicing this equipment.

OPERATING INFORMATION

This is a propane, direct-fired, heater. It's intended use is

primarily temporary heating of buildings under construction,

alteration or repair.

WARNING:

!

NOT FOR HOME OR RECREATIONAL VEHICLE USE

Propane is heavier than air. If propane leaks from a connection or fitting, it sinks to the floor, collecting there with the

surrounding air, forming a potentially explosive mixture.

Obviously, propane leaks should be avoided, so set up the

propane supply with utmost care. Leak check new connections or reconnections with a soap and water solution and

follow all connection instructions herein. Also ask your

propane dealer for advice on the propane supply installation

and ask him to check it if there are any questions.

Direct-fired means that all of the combustion products from

burning propane enter the heated space. Even though this

heater operates very close to 100 percent combustion efficiency, it still produces small amounts of carbon monoxide.

Carbon monoxide (called CO) is toxic.

CO can build up in a heated space and failure to provide

adequate ventilation could result in death. The symptoms of

inadequate ventilation are:

headache

dizziness

burning eyes and nose

nausea

dry mouth or sore throat

So, be sure to follow advice about VENTILATION in these

operating instructions.

SCHEU PRODUCTS COMPANY, INCORPORATED

Mail: P.O. Box 5050, Upland, CA 91785-5050

Plant: 8855 Baker Ave., Rancho Cucamonga, CA 91730

ASSEMBLY AND OPERATING INSTRUCTIONS

UNIVERSAL MODELS 12-IR, 24-IR, 24-IRP, 36-IR, 48-IR

ALL PRO MODELS SPC-12, SPC-24, SPC-24P, SPC-36, SPC-48

!

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN RESULT IN DEATH,

SERIOUS BODILY INJURY AND PROPERTY LOSS OR DAMAGE

FROM HAZARDS OF FIRE, EXPLOSION, BURN, ASPHYXIATION,

AND CARBON MONOXIDE POISONING.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE

INSTRUCTIONS SHOULD USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS

AN INSTRUCTIONS MANUAL, LABELS, ETC. CONTACT THE

MANUFACTURER.

TELEPHONE: 909 981-5343

INFRA-RED HEATERS

GENERAL HAZARD WARNING:

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT operate a

damaged heater.

2. Do not modify the heater or operate a heater which has

been modified from its original condition.

3. Use only propane gas.

4. Use only VAPOR WITHDRAWAL propane cylinders. If there

is any question about vapor withdrawal, ask your propane

dealer.

5. Mount propane cylinders vertically (shutoff valve up). Secure

them from falling or being knocked over and protect them

fromdamage.

6. Do not direct heat toward propane cylinders.

7. Use only the hose and regulator assembly provided with the

heater. Inspect hose assembly before each use of the

heater. If there is excessive abrasion or wear, or hose is

cut, replace with hose assembly listed on parts list before

using heater. The hose and fittings shall be protected

from damage and deterioration.

8. For indoor or outdoor use. AREA MUST BE WELL VENTILATED. Provide minimum openings of 1 sq. ft. near the floor

and 1 sq. ft. near the ceiling (also see "Operating Information").

9. If at any time gas odor is detected, IMMEDIATELY DISCONTINUE operation until the source of gas has been located

and corrected.

10. Install the heater such that it is not directly exposed to water

spray, rain, dripping water and/or wind.

11. Maintain minimum clearance from normal combustible

materials (like paper) as follows: rear-2 ft.; sides-3 ft.;

front-6 ft. Locate 10 ft. from canvas or plastic tarpaulins or

similar coverings and secure them to prevent flapping or

movement due to wind action.

12. Operate only on a stable, level surface.

13. Since permanent skin tissue damage can occur, avoid

contact with the unit while it is operating or shortly after it

has been shut off.

14. Operate the unit in a draft-free area or protect the heater

fromdrafts.

15. Do not move, handle or service while hot or burning.

16. Use only in accordance with local codes or, in the absence

of local codes, with the Standard for the Storage and

Handling of Liquefied Petroleum Gases ANSI/NFPA 581998, and National Fuel Gas Code ANSI Z223.1/NFPA

Page 2

!

WARNING; FIRE, BURN, INHALATION, AND EXPLOSION HAZARD. KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING MATERIALS,

PAPER OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE HEATER AS RECOMMENDED BY THE INSTRUCTIONS NEVER USE THE

HEATER IN SPACES WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR UNKNOWN CHEMICALS.

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

1. Inspect the heater for possible shipping damage. If any

is found, immediately notify the dealer.

2. Follow all of the “Safety Precautions” and “Operating

Information" on page 1, and “Propane Fuel Information” on page 4.

3. Refer to the exploded view on page 3 for general

assembly layout. Regulator: Heater is to be hooked up

to the regulator (set at 28” water column) supplied with

the heater.

4. HEATER ASSEMBLY:

a) Lay the heater reflector down down on a flat level

surface (the manifold mounting lug will be up).

b) Attach the manifold to the burner/reflector assem-

bly as shown in the exploded view.

c) Be sure that the neck(s) of the manifold are

pushed al l of t h e w ay i n t o t he o n e ( 1) inch tube(s)

of the burner assembly(s).

d) Position and tighten the adapter clamp(s).

e) The manifold mounting lug (the rectangular piece

of 1/8” thick steel that is welded to the manifold)

must face the direction shown in the exploded

view.

f) Attach the loose thermocouple end to the connec-

tion at the thermoelectric valve.

g) Tighten the connection finger tight, then tighten an

additional maximum ¼ turn using a 3/8” open end

wrench.

5. If you have the 24,000 BTU w/Piezo (all others go to

step7):

a) Place the piezo mounting bracket with the attach

ment surface on the left side of the manifold

mounting lug, the piezo bracket will cross over the

lug.

b) Lineup the mounting holes on the piezo bracket

and the lug, then securely attach the piezo bracket

to the lug with the two 10-24x3/8 machine screws

and hex nuts provided.

c) Insert the loose end of the electrode wire onto the

terminal on the piezo igniter.

6. HEATER MOUNTING (for Quad Heater go to step 7):

a) Assemble the flattened end of the heater support

to the manifold mounting lug with a lock bolt (3/816 x 1 ¼ bolt).

b) Place the 3/8-16 whiz nut onto the remaining 3/8-

16 x 1 ¼ bolt, with the nut serrations away from the

bolt head.

c) Attach the lock bolt assembly into the remaining

base support weld nut, making sure that the nut

serrations face the base support.

d) Mount the heater onto a standard 20 or 40 #

propane cylinder by placing the slot in the heater

support over the propane cylinder flange. Tighten

the lock bolt assembly, then secure with the nut.

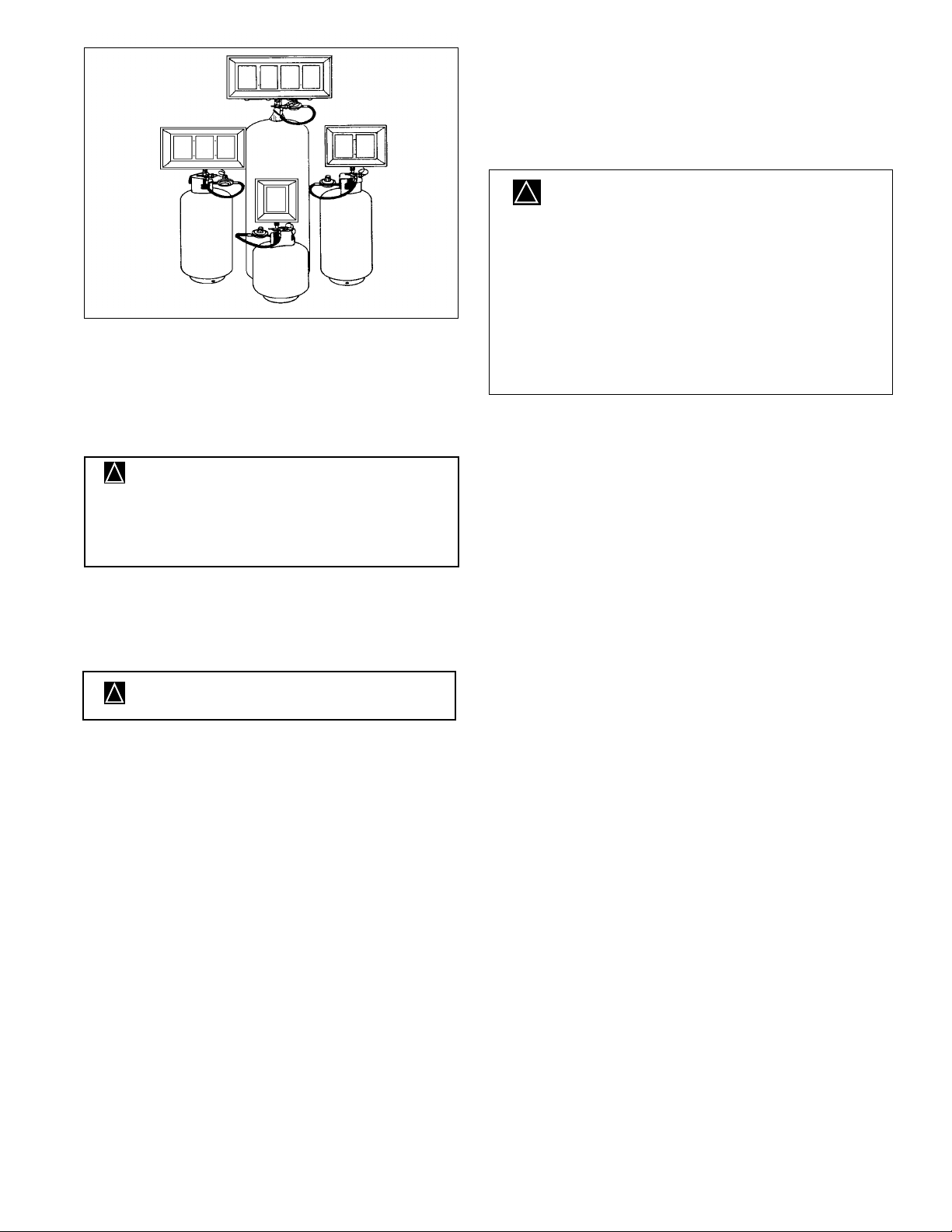

7. QUAD-HEAD HEATER MOUNTING

a) Mount the quad-head heater onto a 100# cylinder

Page 2

by placing the collar assembly over the threaded

neck (for cylinder valve cover) and tighten the wing

nut.

b) Place the slot in the heater support over the propane

cylinder flange.

c) Tighten the lock bolt assembly, then secure with the

nut.

8. Check the ‘O’ ring on the POL before each use (see page

4). Replace the ‘O’ ring if there is any sign of ware or

damage.

9. After the heater is securely attached to the propane

cylinder connect the POL fitting of the hose and regulator

assembly to the propane cylinder by rotating the POL nut

counterclockwise into the propane cylinder’s valve outlet. Securely tighten with a wrench.

10. Securely tighten all gas connections.

11. Open the cylinder’s gas valve and check all gas connections with a soap and water solution. DO NOT USE A

FLAME.

!

WARNING: DO NOT LOOK OVER TOP OF

HEATER (REFLECTOR) DURING IGNITION.

This heater may produce a small puff of flame

during ignition, which could result in serious

bodily injury.

START

1. Fully open the valve on the propane cylinder.

2. Depress the red button on the safety valve admitting gas

to the heater. Place a lighted match near the face of the

ceramic element using the hole located on the side of the

reflector. If the hose is filled with air, allow a few seconds

for gas to reach element. DO NOT LIGHT AT THE

ORIFICE.

3. 24-IRP: Depress the red button on the safety valve

admitting gas to the heater. Push and release the

piezo ignition button until the gas on the surface of the grid

ignites. this may take several strikes of the piezo.

Ignition may be observed using the holes located on the

sides of the reflector. DO NOT LOOK OVER TOP OF

REFLECTOR! If the hose is filled with air allow a few

seconds for the gas to reach the grids.

4. When the gas on the face of the ceramic element lights,

continue to hold the button depressed for 30 seconds,

then release. On multiple head units, check to see that

all elements are burning.

5. If the flame goes out, wait 5 minutes and repeat the

lighting procedure.

STOP

1. Securely close valve at propane cylinder.

2. Do not attempt to relight for 5 minutes.

RESTART AFTER SAFETY SHUTDOWN

1. Securely close valve at propane cylinder.

2. Wait 5 minutes.

3. Restart following "Start" procedure.

Page 3

INSTRUCTIONS FOR ORDERING PARTS -

All parts orders must show Heater Model No., Item No., Part

No. and Description. Only parts supplied by the manufacturer

should be used on this unit. A locally purchased part may

appear to be identical, although in reality it might endanger the

heater or the persons operating the heater.

Item

No. Description 12IR Qty. 24IR Qty. 24IRP Qty. 36IR Qty. 48IR Qty.

1 Burner Assembly w/ceramic grid 1010 1 1010 2 1010 2 1010 3 1010 4

2 Hose Assembly 1016 1 1016 1 1016 1 1016 1 1016 1

3 Support Tube Assembly 1017 1 1017 1 1017 1 1017 1 1017 1

4 Reflector Assembly 1009 1 1019 1 1019 1 1022 1 1025 1

5 Manifold Assembly 1014 1 1021 1 1021 1 1024 1 1027 1

6 Bracket, Thermocouple 3003 1 3003 1 3003 1 3003 1 3003 1

7 Orifice, LP #69 Drill 3008 1 3008 2 3008 2 3008 3 3008 4

8 Keeper, Grid 3017 2 3017 3 3017 2 3017 4 3017 5

9 Bracket, Electrode Ground 3645 1

10 Bracket, Piezo Mounting 4291 1

11 Bracket, Label 4292 1

12 Nut, flange Lock 3/8-16 6042 2 6042 2 6042 2 6042 2 6042 2

13 Clip, Thermocouple 6045 1 6045 1 6045 1 6045 1 6045 1

14 Clamp, Loop 1" Dia. 6069 1 6069 2 6069 2 6069 2 6069 2

15 Thermocouple, 12" 6233 1 6233 1 6233 1 6233 1 6233 1

16 Regulator 28" W.C. 1/4 x 3/8 FPT 6257 1 6257 1 6257 1 6257 1 6257 1

* Manual, Operating Instructions 6326 1 6326 1 6326 1 6326 1 6326 1

* Label, Warning, Fuel 6369 1 5369 1 6369 1 6369 1 6369 1

19 POL, Excess Flow 1/4 MPT 6433 1 6433 1 6433 1 6433 1 6433 1

20 Piezo Igniter 6473 1

* Label, Hangtag 6712 1 6712 1 6712 1 6712 1 6712 1

22 Nut, Piezo 7161 1

23 Valve, Thermoelectric 7285 1 7285 1 7285 1 7285 1 7285 1

24 Electrode 7395 1

* Label, Mode/Opr. Instructions 7608 1 7608 1 7608 1 7608 1 7608 1

* Label, Light Here 7609 1 7609 1 7609 1 7609 1 7609 1

* Label, Warning/Ignition Flash 8186 1

28 Screw, Machine 3/8-16 x 1 1/4 Grd 5 8190 2 8190 2 8190 2 8190 2 8190 2

29 Collar, Assembly, 48IR 1028 1

The heater should be serviced only by a trained, experienced

service person.

Read the section on "Servicing" before ordering parts.

For parts order, call (909) 981-5343.

Page 4

SERVICING

A hazardous condition may result if a heater is used that

has been modified or is not functioning properly. When the

heater is working properly:

The flame is contained near the surface of the

ceramic grid(s).

The flame is essentially blue.

There is no strong disagreeable odor, eye burning or

other physical discomfort.

There is no smoke or soot internal or external to the

heater.

There are no unplanned or unexplained shutdowns of

the heater.

The parts list shows the heater as it was constructed. Do

not use a heater which is different from that shown. In

this regard, use only the hose, regulator and cylinder

connection fitting (called a POL fitting) supplied with the

heater. Do not use alternates. For this heater, the

regulator must be set to supply 28" water column (W.C.)

outlet pressure (1.0 psig). If there is any uncertainty

about the regulator setting, have it checked.

A heater which is not working right must be repaired, but

only by a trained, experienced service person. Contact

the factory for the service center closest to you, phone

number (909) 981-5343.

WARNING

Local codes for installation of propane systems may vary

considerably. Therefore, ask your local propane supplier

for advice on propane system installation in your particular

area. In the absence of local codes, install in accordance

with American National Standards Institute (ANSI)/National Fire Protection Association (NFPA) publication 581998 Standard for the Storage and Handling of Liquefied

Petroleum Gases and ANSI Z223.1/NFPA 54 National Fuel

Gas Code. Your supplier, fire marshal or library should

have copies of these standards.

The propane supply system must be arranged for vapor

withdrawal. Propane cylinders must be secured in the

upright position to keep them from falling or being knocked

over.

MINIMUM RECOMMENDED PROPANE CYLINDER SIZE:

HEATER MODEL CYLINDER SIZE OPERATING TIMES

@60

12IR/SPC-12IR 20# (5- Gallons) 30 - hours

24IR/SPC-24IR 20# (5 - Gallons) 15 - hours

24IR/SPC-24IRP 20# (5 - Gallons) 15 - hours

36-IR/SPC-36IR 40# (10 - Gallons) 20 - hours

48IR/SPC-48IR 100# (25 - Gallons) 35 - hours

o

F*

You may also obtain in-warranty or out-of warranty service

by returning the product freight prepaid to:

Scheu Products Company

8855 Baker Avenue

Rancho Cucamonga, CA 91730

In-warranty products returned to the Service Department

will be repaired with no charge for either parts or labor and

will be returned to you freight prepaid. Please include a brief

statement indicating date, place of purchase, the nature of

the problem and proof of purchase.

Out of warranty products returned to the Service Department will be repaired with a charge for parts and labor and

will be returned to you freight collect.

MAINTENANCE AND STORAGE

1. The heater should be inspected before each use, and at

least annually by a qualified person.

2. Before each use, check the soft "O" ring seat at the

bullnose of the POL fitting. If the "O" ring is cut, scuffed,

or otherwise damaged, replace it with part number 6681.

3. Turn off the gas at the LP-gas supply cylinder(s) when

the heater is not in use.

4. When the heater is to be stored indoors, the connection

between the LP-gas supply cylinder(s) and the heater

must be disconnected and the cylinder(s) removed from

the heater and stored outdoors and in accordance with

Chapter 5 of the Standard for Handling of Gases ANSI/

NFPA 58-1998.

* If ambient temperatures will be less than 60oF increase

propane supply accordingly.

PROPANE FUEL INFORMATION

During use, liquid propane in a container vaporizes. As it

vaporizes, the propane cools itself. This cooling process

is known as the refrigeration effect. If it continues long

enough and proceeds fast enough, the propane temperature and pressure will fall so low that heater operation may

be improper or even impossible even though plenty of

propane remains in the container. Often frost forms on the

outside of the propane container as a warning of excessive

refrigeration.

Recommendations to reduce the ill effects of refrigeration

effect are:

Provide considerable more propane than you plan to

consume. As a rule of thumb, provide twice as much.

Fill containers frequently, especially in cold weather.

Never allow propane to fall below one-third of container capacity.

If possible, keep containers in a warm area (under

no circumstances should the heater exhaust be

directed toward the propane container).

Page 4

SEPTEMBER 2000

6326P

Loading...

Loading...