Desa Tech 160-IF, 280-IF Owner's Manual

VENTED PORTABLE FORCED AIR HEATER

OWNER’S MANUAL

MODELS 160-IF AND 280-IF

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater.

Improper use of heater can cause serious injury. Keep

this manual for future reference.

TABLE OF CONTENTS

Safety Information ............................................... 2

Unpacking .......................................................... 3

Product identification ........................................... 3

Fuels .................................................................... 4

To Start Heater ....................................................

Stop Heater .................................................... 4

To

Thermostat Operation ......................................... 4

Moving and Transporting Heater ......................... 4

Save this manual for future reference.

For more information, visit www.desatech.com

Preventative Maintenance ................................... 5

Troubleshooting ...................................................

Diagrams ............................................................. 7

Illustrated Parts Breakdown and Parts List ....... 10

Specifications ....................................................

4

Technical Service ..............................................

Accessories ....................................................... 15

Warranty and Repair Service ............................ 16

5

15

15

SAFETY INFORMATION

WARNING: This product contains and/or generates chemicals

known to the State of California

to cause cancer or birth defects

or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble,

operate or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of carbon

monoxide poisoning resemble the flue, with head

aches, dizziness and/or nausea. If you have these

signs, the heater may not be working properly. Get

fresh air at once! Have heater serviced. Some people

are more affected by carbon monoxide than others.

These include pregnant women, persons with heart

or lung disease or anemia, those under the influence

of alcohol and those at high altitudes.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

1. Use only kerosene, #1#2 diesel/fuel oil, JET A

or JP-8 fuels to avoid risk of fire or explosion.

Never use gasoline, naphtha, paint thinners,

alcohol or other highly flammable fuels.

2. Fueling

a) Personnel involved with fueling shall be

qualified and thoroughly familiar with the

manufacturerʼs instructions and applicable

regulations regarding the safe fueling of

heating units.

b) Only the type of fuel specified on the

heaterʼs data plate shall be used.

c) All flame, including the pilot light, if any,

shall be extinguished and the heater al

lowed to cool, prior to fueling.

d) During fueling, all fuel lines and fuel-line

connections shall be inspected for leaks.

Any leaks shall be repaired prior to return

ing the heater to service.

2

www.desatech.com

e) At no time shall more than one dayʼs supply

of heater fuel be stored inside a building in

the vicinity of the heater. Bulk fuel storage

shall be outside the structure.

f) All fuel storage shall be located a minimum

of 25 feet (762cm) from heaters, torches,

welding equipment and similar sources

of ignition (exception: the fuel reservoir

integral with the heater unit).

g) Whenever possible, fuel storage shall be

confined to areas where floor penetrations

do not permit fuel to drip onto or be ignited

by a fire at lower elevation.

h) Fuel storage shall be in accordance with

the authority having jurisdiction.

3. Use only the electrical voltage and frequency

specified on model plate.

4. Heater must be grounded. Use only a properly

grounded three-wire extension cord. Plug into

grounded outlet only.

5. Use only in areas free of flammable vapors or

high dust content.

6. Minimum clearance from any combustible

materials: 8 feet (244 cm) from hot air outlet;

4 feet (122 cm) from top; and 4 feet (122 cm)

from sides and inlet.

7. Locate heater on a stable and level surface

while hot or operating or a fire may occur.

8. Use only in well-vented areas. Before using

heater, provide at least a three-square-foot

(2800 square cm) opening of fresh, outside air

for each 100,000 Btu/Hr (30 kw) of rating.

9. Keep children and animals away from heater

at all times.

10. Never start heater when combustion chamber

is hot or if fuel has accumulated in combustion

chamber.

11. When used with thermostat, heater may start

at anytime.

12. When heater is moved or stored, it must be in

a level position or fuel spillage may occur.

13. Use heater only in accordance with local

ordinances and codes.

14. Never use gasoline, crankcase drainings,

naphtha, paint thinners, alcohol or other highly

flammable fuels.

15.

Never use heater where gasoline, paint thinner

or other highly flammable vapors are present.

-

16. Never use heater in living or sleeping areas.

17. Never leave a heater plugged in without adult

supervision if children or animals are likely to

be present.

-

114909-01C

SAFETY INFORMATION

Continued

18. Never move, handle, refuel or service a hot,

operating or plugged-in heater.

19. Never attach heater to external fuel tank.

20. Heaters used in the vicinity of tarpaulins,

canvas or similar enclosure materials shall be

located a safe distance from such materials.

The recommended minimum safe distance is

10 feet (304.8 cm). It is further recommended

that these enclosure materials be of a fire

retardant nature. These enclosure materials

shall be securely fastened to prevent them

from igniting or from upsetting the heater due

to wind action.

21. Unplug heater when not in use.

22. Never block air inlet (rear) or air outlet (front)

of heater.

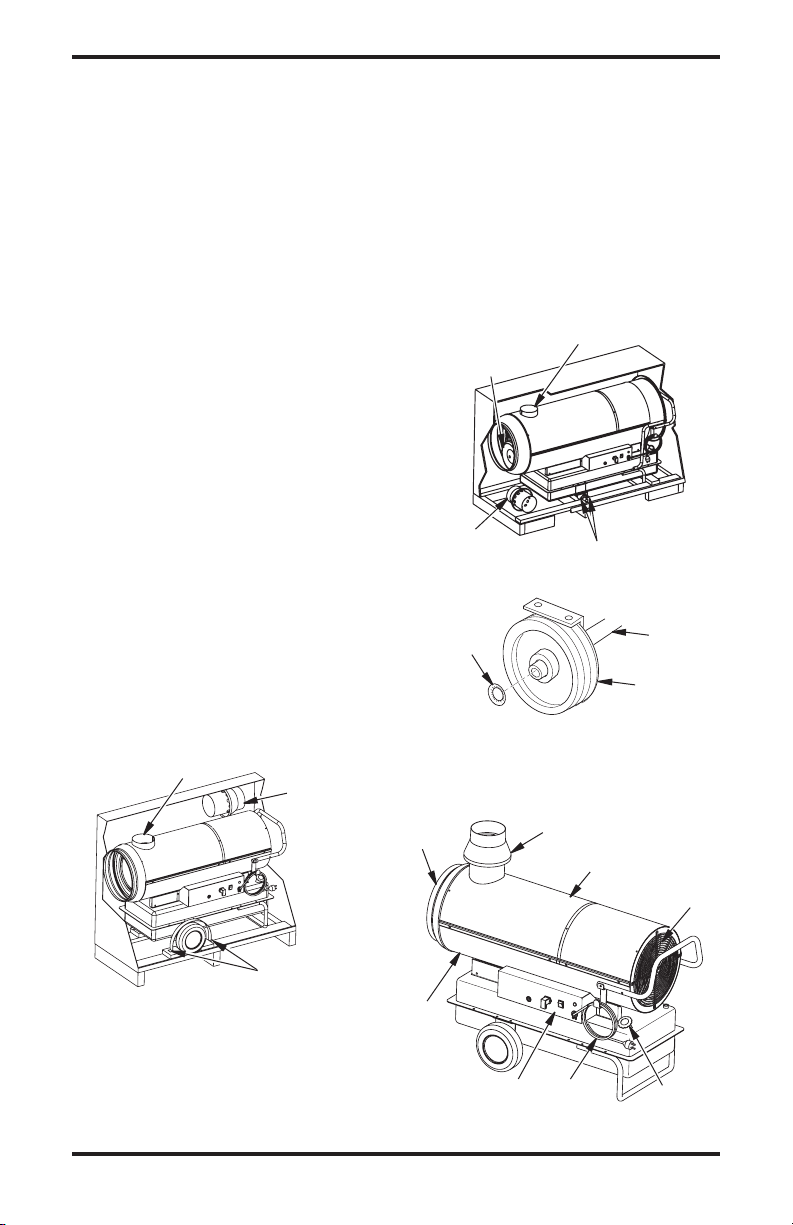

UNPACKING

MODEL 160-IF

1. Remove all the materials used to package the

heater for shipment.

2. Open the carton from the top.

3. Remove the flue connection from carton (see

Figure 1).

4. Lift up and remove cardboard packaging.

5. Unscrew the locking screws on wheel-lock

straps (see Figure 1).

6. Insert the flue connection onto the flue outlet

tube (see Figure 4).

7. Carefully lower the heater from pallet.

Flue Outlet

Tube

Flue

Connection

4. Unscrew the locking screws on hub locking

bar (see Figure 2).

5. Remove the wheels from the hot air outlet

(stored for shipping).

Lift the heater from the air outlet end.

6.

7. Insert the wheels onto the axle.

8. Insert the locking washer (which is in the

documentation envelope) with the convex side

towards the exterior of the machine; using a

hammer and an appropriate-sized spanner, tap

it gently to fix it into position (see Figure 3).

9. Carefully lower the heater from pallet.

Wheels Stored

for Shipping

Flue

Connection

Figure 2 - Removing 280-IF from Carton

Lock

Washer

Figure 3 - Wheel/Axle Assembly for 280-IF

Flue Outlet Tube

Locking Screws

Axle

Wheel

PRODUCT

IDENTIFICATION

Hot Air

Output

Flue Connection

Upper Shell

Fan

Guard

Locking Screws

Figure 1 - Removing 160-IF from Carton

MODEL 280-IF

1. Remove all the materials used to package the

heater for shipment.

2. Open the carton from the top.

3. Lift up and remove cardboard packaging.

www.desatech.com

Lower

Shell

Power

Control

Cable

Panel

Figure 4 - Vented Portable Forced Air Heater

Fuel Tank

Cap

3114909-01C

FUELS

WARNING: Use only kerosene, #1/#2 diesel/fuel oil, JET A

or JP-8 fuels to avoid risk of fire or

explosion. Never use gasoline, oil

drained from crankcases, naphtha, paint thinners, alcohol or

other highly flammable fuels.

Use only kerosene, #1/#2 diesel/fuel oil, JET A

or JP-8 fuels. Heavier fuels such as No. 2 fuel

oil or No. 2 diesel fuel may also be used but will

result in:

• noticeable odor

• additional fuel filter maintenance

• the need for nontoxic, anti-icer additives in very

cold weather

Do not use fuels heavier than No. 2 grade or

heavy oils such as oil drained from crankcases.

These heavy oils will not ignite properly and will

contaminate the heater.

IMPORTANT: Use a KEROSENE ONLY (blue)

or DIESEL ONLY (yellow) storage container. Be

sure storage container is clean. Foreign matter

such as rust, dirt or water will cause the ignition

control assembly to shut down heater. Foreign

matter may also require heaterʼs fuel system to

be frequently cleaned.

TO START HEATER

IMPORTANT: Review and understand the warnings in the

Information section, page 2. They

are needed to safely operate

this heater. Follow all local ordinances and codes when using

this heater.

1. Fill tank with fuel (see Fuels).

2.

Plug heater power cord into approved, grounded,

120V/60Hz, 3 prong outlet or extension cord.

Extension Cord Size Requirements

6 to 10 feet (1.8 to 3 meters) long, use 18 AWG

(0.75 mm2) rated cord

11 to 100 feet (3.3 to 30.5 meters) long, use

16 AWG (1.0 mm

101 to 200 feet (30.8 to 61 meters) long, use

14 AWG (1.5 mm

3. If a thermostat is connected, adjust it to the

maximum temperature.

2

) rated cord

2

) rated cord

Safety

4.

Flip switch (3 on Electric Control Panel,

page 7) to the position with the symbol:

- the fan should start and after several

seconds the heater should ignite.

The first time the heater is used or after the fuel

circuit has been completely drained, the flow of

fuel oil to the nozzle may be insufficient and may

activate the flame control, which will turn off the

heater; if this happens, wait for about a minute and

then press the reset button (1

Panel, page 7

) to start the heater again.

on Electric Control

TO STOP HEATER

1.

Move switch (3 on Electric Control Panel, page

7) to the “0” position or adjust the control mech

anism, for example turning the thermostat to a

lower position. The flame will go out and the fan

will continue to function until the combustion

chamber has cooled down completely.

2. Wait until fan stops before unplugging heater.

Unplug heater when not in use.

THERMOSTAT

OPERATION

The heater can only work automatically when a

thermostat is connected to it by attaching the cable

to terminals 2 and 3 of plug (4

Panel, page 7

).

on Electric Control

MOVING AND

TRANSPORTING HEATER

WARNING: Before moving

the heater you must turn the

heater off (see To Stop Heater),

disconnect the plug from the

power supply and wait for the

heater to cool.

Before lifting or moving the heater, make sure that

the fuel tank cap is firmly in place.

The heater may be supplied in a portable version,

with wheels or a suspended version, mounted on a

support structure and fixed in place with wires or

chains. In the former case, to move the heater, sim

ply grasp the support handle and move the heater.

In the latter case, the heater must be lifted with a

fork-lift truck or a similar piece of equipment.

-

-

4

www.desatech.com

114909-01C

PREVENTATIVE

MAINTENANCE

To ensure that the heater continues to work

properly, it is necessary to periodically clean the

combustion chamber, the burner and the fan.

WARNING The following

steps must be carried out before

servicing the heater: turn the

heater off, following the instruc

tions in the previous section;

disconnect the plug from the

power supply and wait for the

heater to cool.

TROUBLESHOOTING

OBSERVED FAULT

The fan does not come on and

the flame does not light

POSSIBLE CAUSE

1. No electric current

2. Incorrect setting on the thermo

stat (if fitted)

3. Faulty thermostat

4. Motor winding burnt out or

broken

5. Bearings of motor have seized

up

6. Motor capacitor has burned

out

7. Thermostat plug not connected

Every 50 hours of use it is necessary to:

• Dismantle the filter cartridge, remove it and

clean it with clean fuel oil.

• Remove the exterior cylindrical casing and

clean the inside and the blades of the fan.

• Check the condition of the cables and the high

voltage connections on the electrodes.

• Dismantle the burner, clean the parts, then clean

the electrodes and adjust them, if necessary, to

the distance indicated in Electrode Spacing on

page 7.

SOLUTION

1 A) Check the characteris-

tics of the electrical system

(120 V - 60 Hz)

B) Check that the sw itch

works and is in the correct

position

C) Check that the fuse has not

blown

-

2. Check that the thermostat

setting is correct (e.g. the

temperature setting on the

thermostat must be higher than

the ambient temperature)

3.

Replace the thermostat

4. Replace the motor

5. Replace the bearings

6. Replace the capacitor

7. Connect thermostat plug

www.desatech.com

5114909-01C

OBSERVED FAULT

The fan comes on but the

flame does not light or does

not remain lit

TROUBLESHOOTING

Continued

POSSIBLE CAUSE

1. Ignitor is not functioning

2.

Faulty flame control

3.

Non-functioning photoelectric

cell

4. Fuel is not reaching the burner

or a sufficient amount is not

arriving

5.

Solenoid valve is not working

SOLUTION

1. A) Check the connections

of the ignition cables to the

electrodes and transformer

B) Check the position of the

electrodes and the distance

between them, in accordance

with the diagram on page 7

C) Check that the electrodes

are clean

D) Replac e the ignit ion

transformer

2. Replace the flame control

3. Clean or replace the photoelectric cell

4. A) Check that the connection

between the pump and the

motor is intact

B) Check that air has not filtered into the fuel circuit, check

the tubes and the filter seal

C) Clean or, if necessary,

replace the nozzle

5. A) Check the electrical con

nection

B) Check the LI thermostat

C) Clean or, if necessary,

replace the solenoid valve

-

The fan comes on and the flame

lights, but produces smoke

The heater does not turn off

The fan does not switch off

6

1.

Insufficient air for combustion

2. Too much air for combustion

3. Fuel is dirty or contains water

4. Air has filtered into the fuel

circuit

5. Inadequate quantity of fuel in

burner

6. Too much fuel in burner

1. Faulty fan thermostat

www.desatech.com

1. A) Remove anything block

ing or obstructing the aspiration and/or airflow ducts

B) Check the position of the

air regulation ring

C) Clean the burner disc

2. Check the position of the air

regulation ring

3. A) Replace the fuel with

clean fuel

B) Clean the fuel filter

4. Check the condition of the

tubes and the seal of the fuel

filter

5. A) Check the pump pressure

B) Clean or replace the nozzle

6.

A) Check the pump pressure

B) Replace the nozzle

1. Replace the solenoid valve

1. Replace the FA thermostat

114909-01C

-

DIAGRAMS

1 2 3 6 8 9

12

13

11

4

5 7

10

0.08" - 0.12"

(2-3 mm)

!

C

A

UT

IO

N

:

H

o

t

w

h

i

le

i

n

o

pe

rati

o

n

.

D

o

n

o

t

to

u

c

h.

Ke

e

p

c

h

il

d

ren,

a

n

im

a

ls

,

c

lo

th

in

g

a

n

d

c

o

m

b

us

t

i

bl

e

s

aw

a

y.

!

P

R

E

CA

UC

I

Ó

N:

C

al

ie

n

te

cu

a

nd

o

e

s

t

á

en

o

p

e

r

ac

ió

n

.

No

t

ocar

.

M

a

n

te

n

g

a

a lo

s

n

iñ

o

s

,

a

ni

m

a

l

e

s

,

v

e

s

t

im

e

nt

a

y

c

om

b

u

s

ti

b

l

es

a

le

-

j

ad

o

s.

!

AT

T

E

N

T

IO

N

:

L’

ap

pa

re

i

l

de

c

hauffage

e

s

t

b

rû

la

n

t

p

en

d

a

n

t

l

e

fo

n

c

t

i

o

n

ne

m

e

nt.

N

e

le

to

u

c

he

z

p

a

s

.

T

e

n

e

z

l

es

e

n

fa

n

ts

, les

a

nim

a

u

x

e

t

l

es

vê

t

e

m

e

n

t

s

à

l’

é

c

ar

t

d

e

c

e

t

ap

p

a

re

il

.

O

P

E

R

A

T

IN

G

I

N

S

T

R

U

C

T

IO

N

S

ST

A

RT

1

.

Fill

t

a

nk

U

se

o

nl

y

ke

ro

se

n

e

,

#

1

&

#

2

d

ie

se

l

a

n

d

f

u

el

o

il

,

JE

T

A

o

r

JP

8

f

ue

l

s.

2

.

P

lu

g

p

ow

e

r

cord

i

n

to

12

0V

/6

0

Hz

outl

et

.

Po

w

e

r

in

d

icator

lig

h

t

sh

o

ul

d

be

on

.

3

.

If

e

q

u

ip

pe

d

, ad

j

us

t th

e

r

m

o

s

ta

t

k

no

b

to

t

he wa

rm

es

t

sett

i

ng

.

4

.

P

u

s

h

ON

/

OF

F

sw

itch

t

o

O

N

( )

.

F

a

n

m

o

to

r

sh

ou

ld

s

t

ar

t

i

mm

e

d

ia

t

e

ly

.

He

a

te

r

wi

l

l

i

gn

i

te

wi

th

i

n

1

0

s

econds

.

5

.

If

eq

ui

p

pe

d,

ad

j

u

s

t

th

e

rm

osta

t to desired

s

etti

n

g

.

ST

OP

Pu

s

h

O

N

/

O

F

F

sw

it

c

h

to

OF

F

(

O).

F

a

n

m

o

to

r

wi

l

l

cont

i

n

u

e

to

r

u

n.

Do

n

o

t

un

plug he

a

te

r

u

n

t

i

l

c

o

o

l

in

g

c

y

cl

e

i

s

c

o

mp

l

e

te.

S

e

e

m

o

d

e

l

d

e

c

a

l

o

r

o

w

n

er

’s

m

a

n

u

a

l

f

or

a

d

d

i

t

io

n

a

l

o

p

e

r

a

t

i

n

g

i

n

s

t

r

u

c

-

t

io

n

s

,

s

a

fe

t

y

r

e

q

u

i

r

e

m

e

n

t

s

,

a

n

d

s

p

e

c

i

fi

c

a

t

i

o

n

s

.

O

PE

R

A

T

I

N

G

I

N

S

T

R

U

C

T

I

O

N

S

ST

A

R

T

1

.

Fill

t

a

n

k

U

se

o

nl

y

ker

os

e

n

e

,

#

1

&

#

2

d

ie

s

el

a

n

d

f

u

e

l

o

i

l

,

JE

T

A

o

r

JP

8

f

u

e

l

s.

2

.

P

lu

g

p

o

we

r

co

r

d

in

t

o

1

2

0V

/

6

0

H

z

o

u

t

le

t.

P

ow

er

i

n

d

icator

ligh

t

should

be

on

.

3

.

If

e

q

u

ip

pe

d

, adju

s

t

t

he

r

m

os

ta

t kn

o

b

to

t

he

warmes

t

se

t

t

i

n

g

.

4

.

P

u

sh

ON

/OFF

sw

it

ch

t

o

ON

(

)

. Fa

n

mo

t

or

s

h

o

u

ld

st

a

r

t

i

mm

e

di

-

a

tely

. He

a

te

r

wi

l

l

i

gn

i

te

wi

th

i

n

1

0

se

co

n

ds

.

5

.

If

eq

ui

p

pe

d, ad

j

us

t

ther

m

o

st

at

to desir

e

d sett

i

ng

.

ST

OP

Pu

s

h

O

N

/

O

F

F

s

w

i

t

c

h

to OF

F

(

O

)

.

F

an

mo

t

or

wi

l

l

co

n

ti

n

u

e

to

r

u

n.

Do

n

o

t

u

n

plug

h

e

a

te

r

u

nt

i

l co

o

l

in

g

c

y

cl

e

i

s

c

om

p

l

e

te

.

Se

e

mo

d

el

d

e

c

a

l

or

o

w

n

er

’

s

m

a

n

u

a

l

f

or

a

d

d

it

i

o

n

a

l

o

p

er

at

i

n

g

in

st

r

u

c

-

t

io

n

s

,

s

a

fe

t

y

r

e

q

u

i

r

e

m

e

n

t

s

,

an

d

s

p

e

c

i

fi

c

a

t

i

o

n

s

.

O

PE

R

A

T

I

N

G

IN

S

TR

U

C

T

IO

NS

ST

A

RT

1.

Fi

l

l

t

a

n

k

Us

e

o

nl

y

ke

r

ose

ne

,

#

1

&

#

2

d

iese

l

a

n

d

f

u

el

o

il

,

JET

A

o

r

JP-8

f

u

e

ls

.

2.

P

lu

g

p

ow

e

r

co

rd

in

t

o

1

2

0

V

/

6

0

Hz

o

u

t

le

t

.

Po

w

e

r

i

n

d

i

ca

to

r

li

gh

t

s

h

ou

l

d

be

o

n.

3.

If

eq

ui

p

pe

d

,

a

d

ju

s

t

the

rm

os

t

at

k

n

ob

to the

wa

r

m

es

t

sett

i

ng

.

4

.

P

us

h

ON

/

OF

F

sw

it

ch

t

o

ON ( )

.

F

an

mo

t

or

should

st

a

r

t

i

mm

e

d

i

-

ate

l

y

. He

at

e

r

wi

l

l

i

g

n

i

te

wi

t

hi

n

1

0

s

econ

d

s

.

5

.

I

f

e

q

u

i

p

pe

d,

ad

j

us

t

t

he

r

m

os

tat

t

o

d

esired

s

e

tt

i

n

g

.

S

T

OP

Pu

s

h

ON/O

F

F

swit

c

h

to

OFF

(

O

).

F

a

n

moto

r

wi

l

l

c

o

n

t

in

u

e

t

o

r

u

n.

Do

no

t

u

np

l

u

g

he

at

e

r

un

ti

l

c

o

ol

i

n

g

cy

c

le

is

c

o

mp

l

e

t

e

.

S

e

e

m

o

d

e

l

d

e

c

a

l

or

o

w

ne

r

’

s

m

a

n

u

a

l

f

or

a

d

d

it

io

n

a

l

o

pe

r

a

t

i

ng

i

n

s

t

r

u

c

-

t

i

o

n

s

,

s

a

fe

ty

r

e

qu

i

r

e

m

e

n

t

s,

a

n

d

s

pe

c

i

fic

a

t

i

o

n

s

.

2

7

0

0

1

I

n

d

us

t

ri

a

l

D

ri

v

e

P.

O

.

B

o

x

9

00

4

Bo

wl

i

n

g

G

r

e

en

,

K

y

4

2

1

0

2

w

ww

.

d

e

s

at

e

c

h

.

co

m

1

13

3

44

-0

8

U

N

PL

U

G

HE

A

T

E

R

B

E

F

O

R

E

R

E

M

O

V

I

NG

CO

VE

R

U

N

P

LU

G

HE

A

T

E

R

B

E

F

O

RE

R

E

M

O

V

I

N

G

CO

V

ER

U

N

P

L

U

G

HE

A

T

E

R

B

E

F

O

R

E

RE

M

OV

I

N

G

C

OV

E

R

Ma

de

i

n

I

t

a

l

y

FLA

M

E

C

O

N

TRO

L

R

E

S

E

T

F

LA

M

E

CO

N

TR

O

L

R

E

S

E

T

FLA

M

E

C

O

N

T

RO

L

R

E

S

E

T

M

a

n

uf

ac

t

u

re

d

f

o

r

:

HEATER FUNCTIONING DIAGRAM

1. Combustion chamber

2. Anti-wind flue connection

3. Burner

4. Nozzle

5. Fuel circuit

6. Fuel pump

7. Electric fuel valve

8. Motor

9. Fan

10. Cable winding bracket

11. Fuel filter

12. Fuel tank

13. Control panel

ELECTRIC CONTROL PANEL

1. Reset button

6

1

2

4

2. Operation label

3. Main switch

4. Socket for ambient ther

mostat

5. Power cable

6. Power indicator

7. Thermostat plug (must be

secure if no control device

is used)

-

7

3

5

FLUE CONNECTIONS DIAGRAM

Pipe 6" Diameter

Flue

Connector

www.desatech.com

ELECTRODE SPACING

7114909-01C

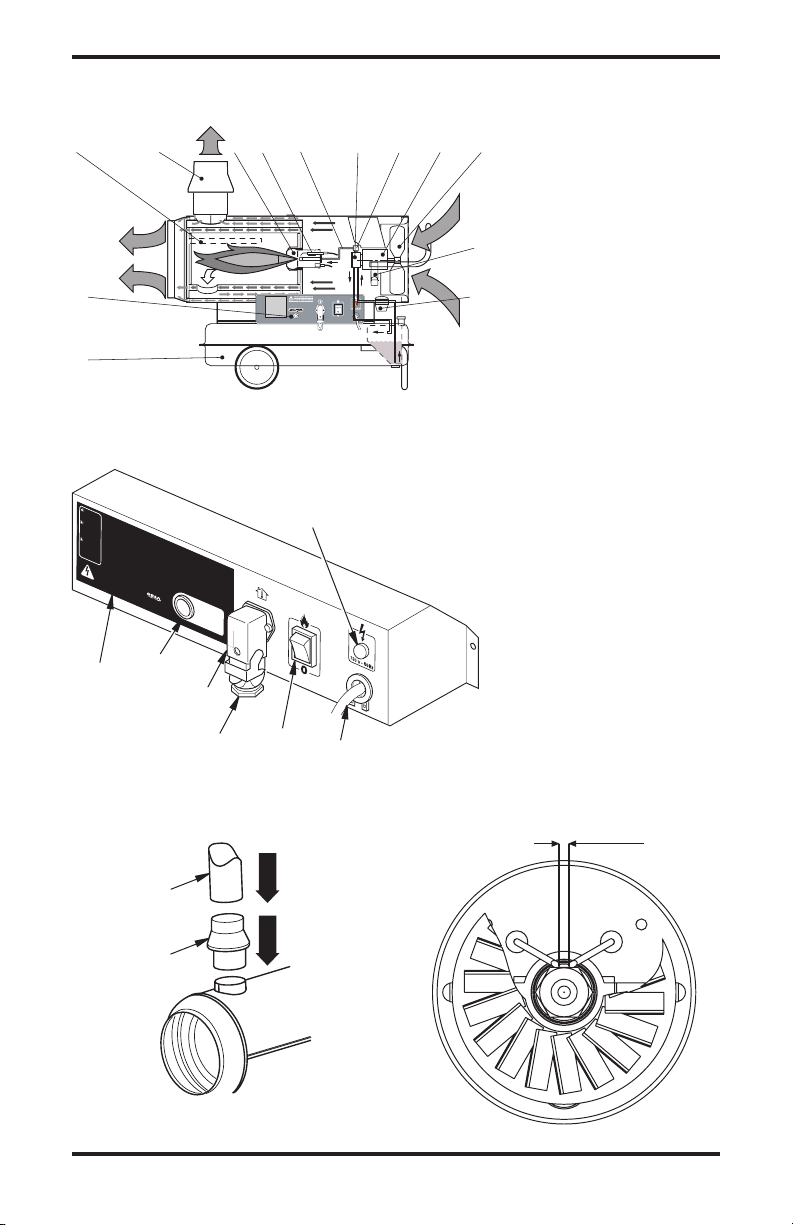

DIAGRAMS

5

4

A

3

2

D

C

1

B

A

6

2

D

C

1

B

5

E

Continued

EXHAUST PIPE POSITIONING DIAGRAM

WARNING: The diagrams are typical; the installation of the flue

must meet current legal norms.

A. Minimum 3 ft.

B. Minimum 3 ft.

C. As short as possible

D. Equal to or greater than the diameter of

the burner’s flue output

E. Minimum 3 ft.

1. Anti-wind device fitted with the heater

2. Horizontal crosspiece with a minimum

upwards angle of at least 5°, minimum 1"

up for every 12" of horizontal travel

3. Flue with minimum internal dimensions

of 8" x 8"

4. Anti-explosion/flue inspection shutter

5. External buffer wall

6. H-shape draw activator

8

www.desatech.com

114909-01C

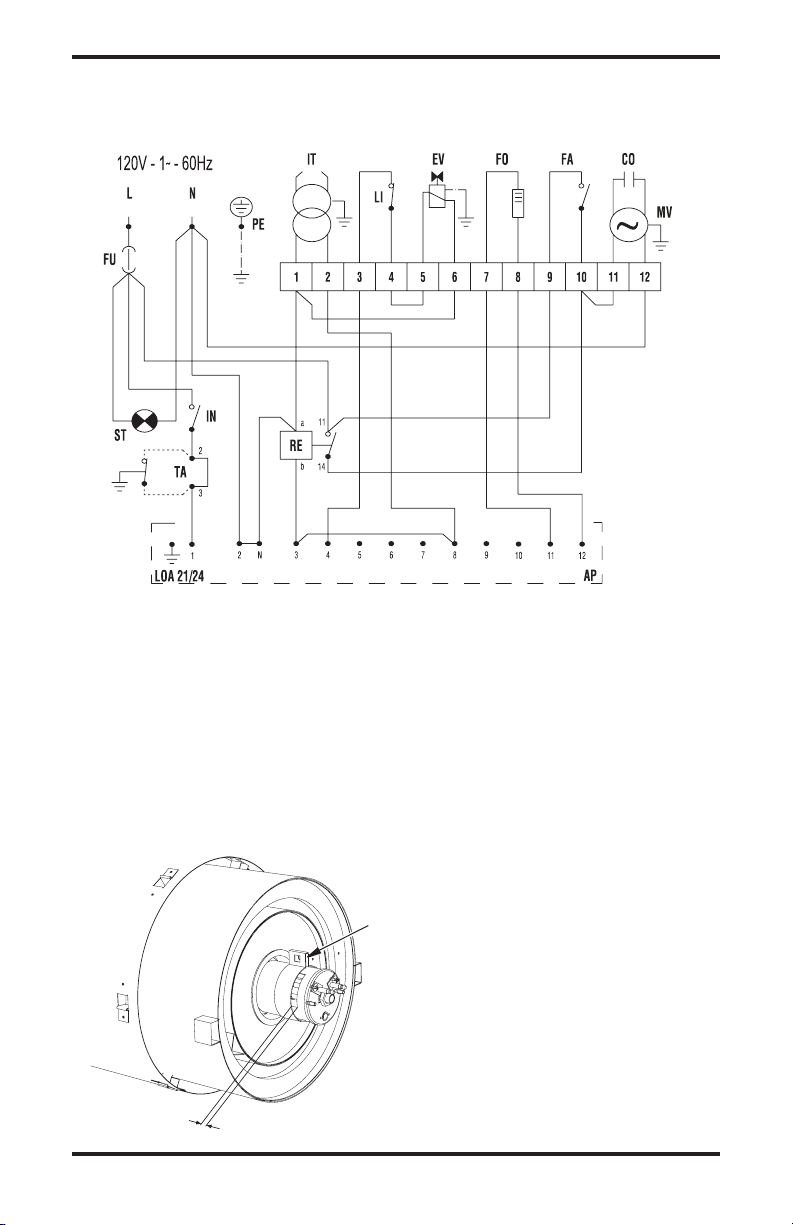

ELECTRIC WIRING DIAGRAM

A

DIAGRAMS

Continued

FU Fuse

6A 160-IF

10A 280-IF

IT High voltage transformer

LI Safety thermostat

EV Solenoid valve

FO Photocell

FA Fan thermostat

CO Capacitor

MV Fan motor

ST Power light

IN Switch

TA Ambient thermostat socket

RE Relay

AP Control box

REGULATION OF COMBUSTION AIR SHUTTER ADJUSTMENT

Air Shutter

160-IF A=19/32" (15 mm)

280-IF A=5/16" (8 mm)

www.desatech.com

9114909-01C

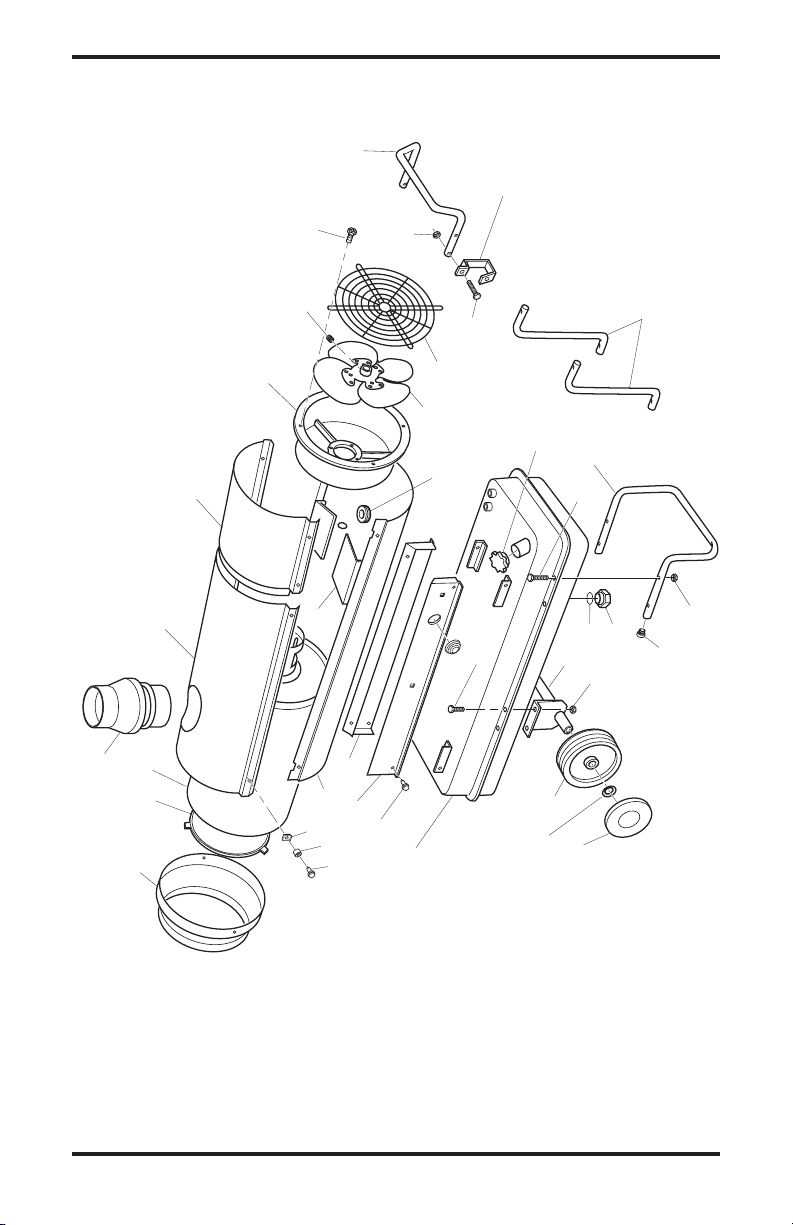

ILLUSTRATED PARTS BREAKDOWN

1

2

33

3

4

8

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

35

30

34

26

27

28

29

30

31

36

7

6

28

10

9

28

5

32

MODELS 160-IF AND 280-IF

10

www.desatech.com

114909-01C

This list contains replaceable parts used in your heater. When ordering parts, be sure to provide the correct

PARTS LIST

model and serial numbers (from the model plate), then the part number and description of the desired part.

KEY PART NUMBER

NO. 160-IF 280-IF DESCRIPTION QTY.

1 115130-01 115130-02 Rear Handle 1

2 115131-01 115131-02 Frame Support 1

3 115132-01 115132-02 Outlet Cone 1

4 115133-01 115133-01 Cap Plug 2

5 115134-01 115134-02 Axel 1

6 115135-01 115135-02 Wheel 2

7 115136-01 115136-02 Wheel Lock Washer 2

8 115137-01 115138-01 Fuel Tank 1

9 115139-01 115139-01 Drain Plug 1

10 115140-01 115140-01 Drain Plug O-Ring 1

11 115141-01 115141-01 Fuel Cap 1

12 115142-01 115142-02 Fan Guard 1

13 115143-01 115144-01 Fan 1

14 115145-01 115145-01 Fan Set Screw 1

15 115146-01 115147-01 Motor Support 1

16 115148-01 115148-02 Air Deflector 3

17 115149-01 115150-01 Combustion Chamber 1

18 115151-01 115152-01 Flame Guard Shield 1

19 115153-01 115154-01 Shell Support, Right 1

20 115155-01 115156-01 Shell Support, Left 1

21 115157-01 115158-01 Lower Shell 1

22 115159-01 115160-01 Upper Shell 1

23 115161-01 115162-01 Upper Shell, Rear Cover 1

24 115163-01 115163-01 Flue Connector 1

25 115164-01 115164-01 Cable Bushing 1

26 115165-01 115165-01 Screw, M5 x 16 4

27 115166-01 115166-01 Screw, 10 x 1/2" 6

28 115248-01 115248-01 Nut, M6 10

29 115249-01 115249-01 Sleeve Screw 6

30 115250-01 115250-01 Screw, M6 x 16 4

31 115251-01 115251-01 Screw, 14 x 1/2" 4

32 115167-01 115167-01 Clip Nut 6

33 115168-01 115168-01 Screw, M6 x 30 4

34 115169-01 115169-01 Power Cord Hook 2

35 ----- 115170-01 Handle Support Bar 2

36 115171-01 115171-02 Yellow Wheel Plug 2

114909-01C

www.desatech.com

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14-1

14-2

14-3

14-4

15

16

17

18

19

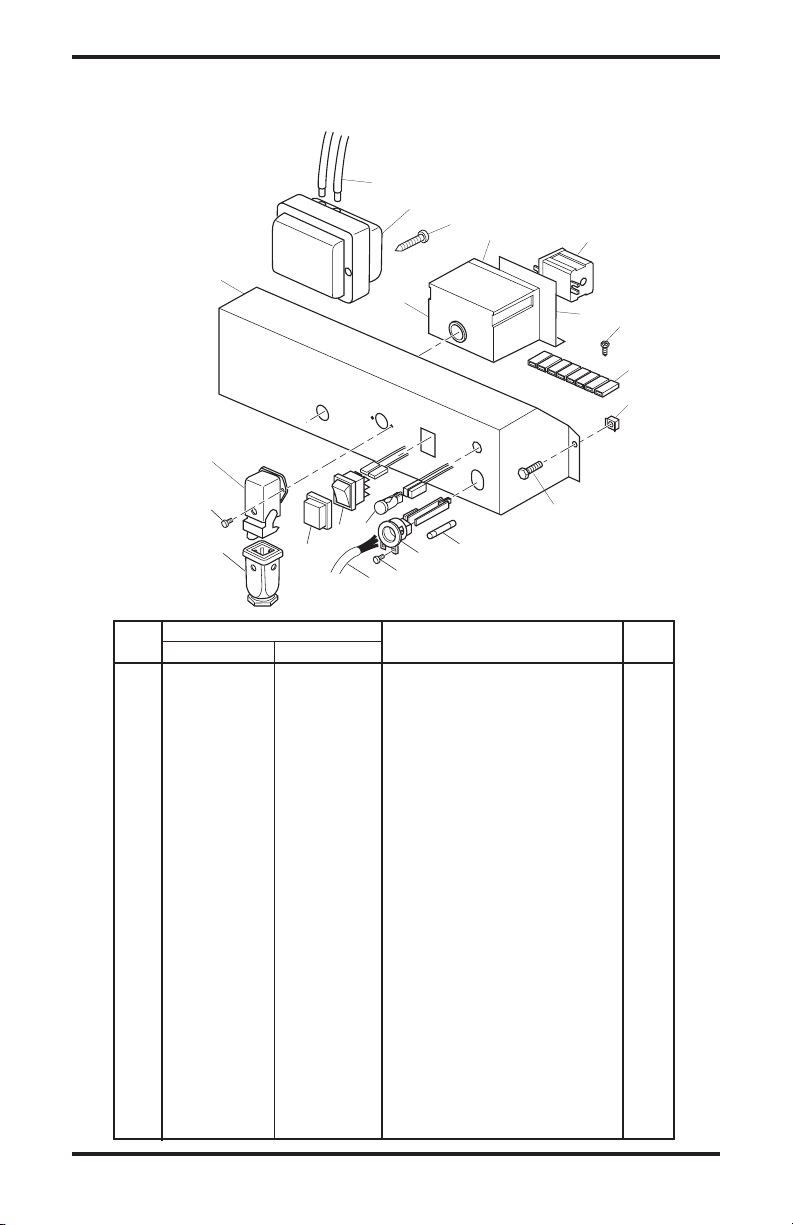

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST

CONTROL BOX FOR 160-IF, 280-IF

KEY PART NUMBER

NO. 160-IF 280-IF DESCRIPTION QTY.

1 115172-01 115172-01 Control Box Support 1

2 Control Box Base 1

3 115173-01 115173-01 Control Box 1

4 115174-01 115174-01 Transformer 120V 1

5 115175-01 115175-02 High Tension Cable 2

6 115176-01 115176-01 Relay 1

7 115177-01 115177-01 Terminal Board 1

8 115178-01 115178-01 Electrical Component Cover 1

9 115179-01 115179-01 Power Light 1

10 115180-01 115180-01 Switch Cover 1

11 115181-01 115181-01 Switch 1

12 115182-01 115182-01 4-Pin Socket 1

13 115183-01 115183-01 Plug 1

14 115184-01 115184-01 Electric Wire with Plug and

Cable Fastener 1

14-1 115185-01 115185-01 Cable Fastener 1

14-2 115186-01 115186-02 Fuse 1

14-3 115187-01 115187-01 Electric Wire with Plug 1

14-4 115188-01 115188-01 Screw 8 x 3/8" 2

15 115189-01 115189-01 Screw 8 x 1

16 115190-01 115190-01 Screw 4 x 1/2" 2

17 115191-01 115191-01 Clamp Nut M6 2

18 115250-01 115250-01 Screw M6 x 16 mm 2

19 115192-01 115192-01 Screw 4 x 3/8" 2

12

www.desatech.com

1

/2" 2

114909-01C

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST

1

1

2

3

4

5

6

7

8

11

11

9

10-1

10-2

10-3

10-4

10-5

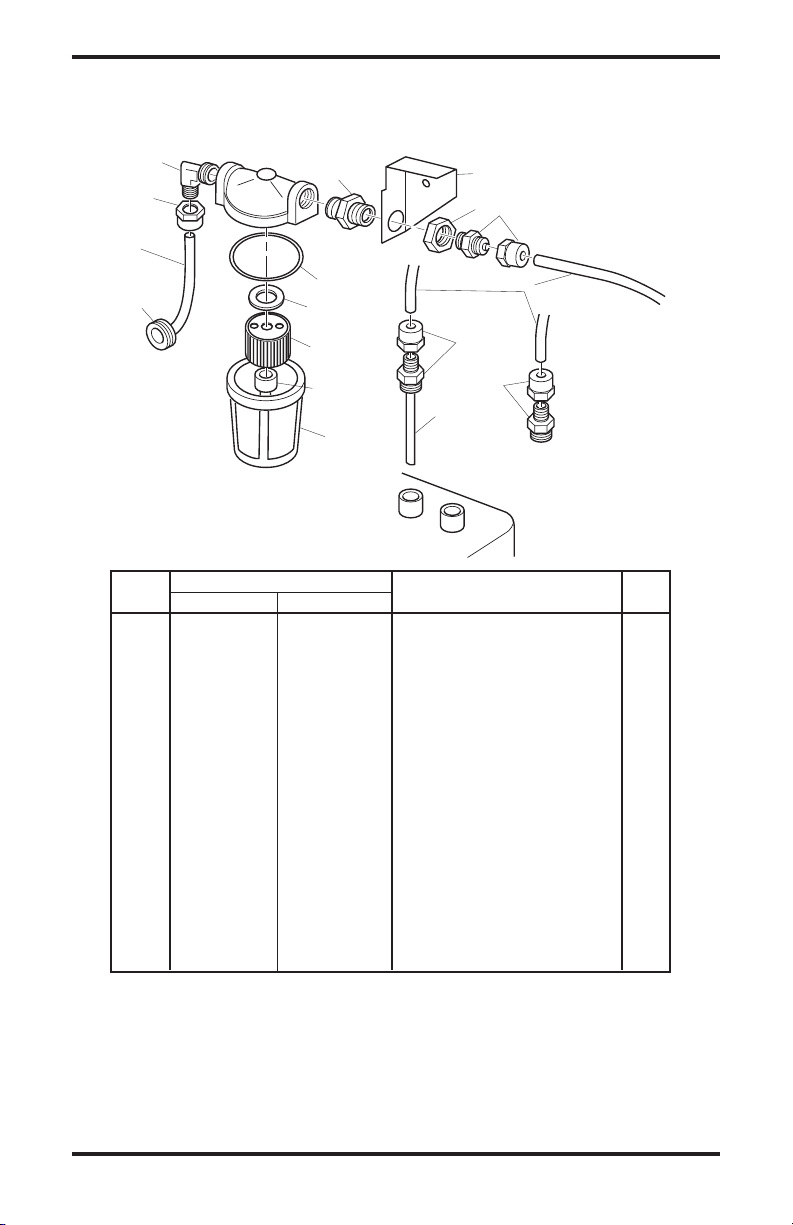

FUEL FILTER ASSEMBLY FOR 160-IF, 280-IF

KEY PART NUMBER

NO. 160-IF 280-IF DESCRIPTION QTY.

1 115252-01 115252-01 Flex Fuel Tube 1

2 115253-01 115253-01 Cable Bushing 1

3 115193-01 115193-02 Fuel Pickup Tube 1

4 115194-01 115194-01 Straight Connection 1/4" 1

5 115195-01 115195-01 Nut 3/8" x 5 1

6 115196-01 115196-01 Filter Support Bracket 1

7 115197-01 115197-01 Double Male Connector 1

8 115198-01 115198-01 90˚ Elbow 1

9 115199-01 115199-01 Straight Connector 1

10 115200-01 115200-01 Filter Assembly 1

10-1 115201-01 115201-01 Filter O-Ring 1

10-2 115202-01 115202-01 Top Fuel Filter Seal 1

10-3 115203-01 115203-01 Filter Element 1

10-4 115204-01 115204-01 Filter Housing 1

10-5 115205-01 115205-01 Lower Oil Filter Seal 1

11 115206-01 115206-01 Straight Connector 1/8" 2

www.desatech.com

13114909-01C

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST

2

1

3

4

5

6

7-1

7-2

14

9

8

12

11

1516

26

17

18

29

25

25

30

19

20

10

11

12

27

13

21

24

28

23

22

Blue Mark

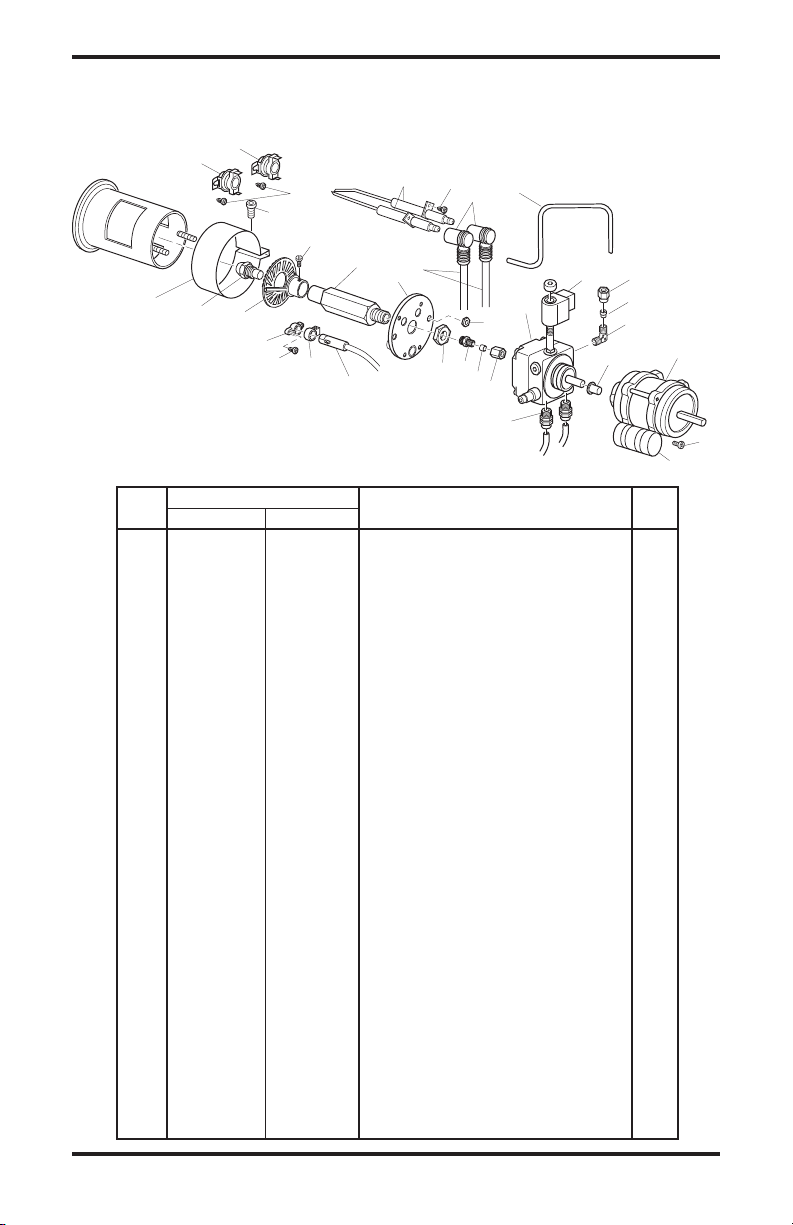

MOTOR, FUEL PUMP AND BURNER COMPONENTS FOR 160-IF, 280-IF

KEY PART NUMBER

NO. 160-IF 280-IF DESCRIPTION QTY.

1 115207-01 115207-02 Electrode Wire 2

2 115208-01 115208-01 Cool Off Thermostat (Fan) 1

3 115209-01 115209-01 Overheat Thermostat (Blue Dot) 1

4 115210-01 115210-01 Ceramic Electrode 2

5 115211-01 115211-01 Cable Connector (90˚) 2

6 115212-01 115212-01 Fuel Line 1

7 115213-01 115213-01 High Pressure Pump 1

7-1 115214-01 115214-01 Solenoid Valve 1

7-2 115215-01 115215-01 Pump Body/Housing 1

8 115216-01 115216-01 Connector 1/4" 2

9 115217-01 115217-02 Coupling, Motor/Pump 1

10 115218-01 115218-01 Connector 90˚ 1/8" 1

11 115219-01 115219-01 Ferrule 4 mm 2

12 115220-01 115220-01 Ferrule Nut 2

13 115221-01 115222-01 Motor 1

14 115223-01 115223-01 Fuel Line Fitting 1

15 115224-01 115224-01 Connector 1/8" 1

16 115225-01 115225-01 Nut, M14 1

17 115226-01 115226-01 Burner Flange 1

18 115227-01 115227-01 Nozzle Support 1

19 115228-01 115228-01 Diffuser 1

20 115229-01 115229-02 Nozzle, 80˚ 1

21 115230-01 115230-01 Air Regulation Strap 1

22 115231-01 115231-01 Photocell 1

23 115232-01 115232-01 Photocell Clamp 1

24 115233-01 115233-01 Photocell Flange 1

25 115234-01 115234-01 Screw 8 x 3/8" 3

26 115235-01 115235-01 Nut, M5 1

27 115236-01 115236-01 Screw, Allen 1

28 115237-01 115237-01 Screw 6 x 1/2" 1

29 115238-01 115238-01 Screw M4 x 8 mm, Allen 1

30 115239-01 115239-01 Screw M6 x 25 mm, Allen 1

14

www.desatech.com

114909-01C

SPECIFICATIONS

Model 160-IF 280-IF

Maximum Output Rating (Btu/Hr) 158,000 278,000

Net Output Rating (Btu/Hr) 133,000 234,400

Fuel Use only kerosene, #1/#2 diesel/fuel oil, JET A or JP-8 fuels*

Fuel Tank Capacity (U.S. Gal./Liters) 17/65 28/105

Fuel Consumption

(Gal. Per Hr/Liters Per Hr) 1.27/4.81 2.22/8.40

Pump Pressure (psi) 145 174

Electric Requirements 120 V/60 HZ 120 V/60 HZ

Amperage (Normal Run) 4.8 8.5

Motor RPM 2850 1750

Hot Air Output (CFM) 1,060 1,940

Shipping Weight (Approximate) 190 lbs/86 kg 320 lbs/145 kg

Heater Weight without Fuel (Approximate) 161 lbs/74 kg 273 lbs/124 kg

* Use of #2 diesel & fuel oil will result in noticeable odor and could require additional fuel filter main

tenance. Use in extreme cold temperatures may require nontoxic anti-icer additives.

TECHNICAL SERVICE

You my have further questions about installation,

operation or troubleshooting. If so, contact DESA

Heating Productsʼ Technical Service Department

at 1-866-672-6040. When calling please have your

model and serial numbers of your heater ready. You

can also visit DESA Heating Productsʼ technical

services web site at www.desatech.com.

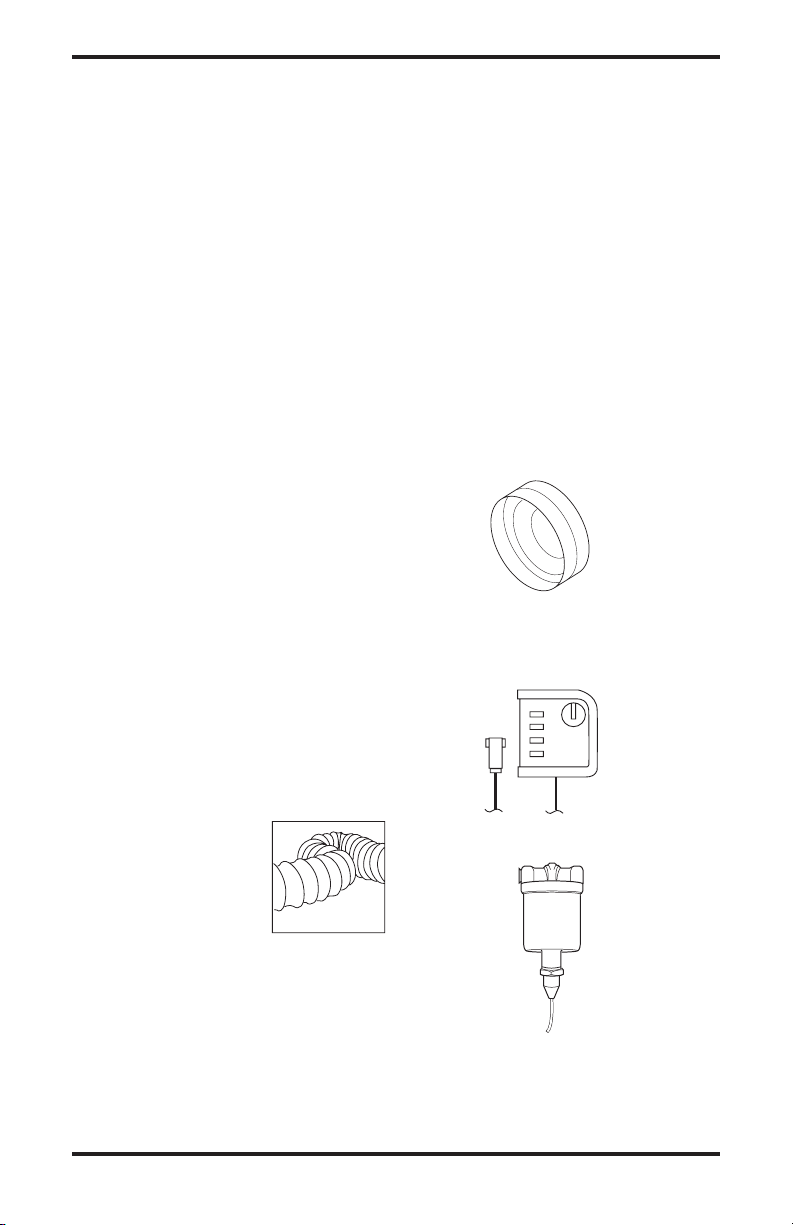

ACCESSORIES

Purchase accessories and parts from your nearest

dealer or service center. If they can not supply

these accessories or parts, either contact your

nearest parts dealer or DESA Heating Products

at 1-866-672-6040 for referral information. Parts

Centrals are listed in the Authorized Service Center

booklet supplied with heater.

FLEXIBLE VENT

HOSE

HA3220 for Model 160-IF

Model 160-IF can only con

nect one 20' section of vent

hose. Must be used with hose

connector kit HA3230.

HA3221 for Model 280-IF

Model 280-IF can connect up to two 20' sections

of vent hose. Must be used with hose connector

kit HA3231.

-

HOSE CONNECTOR KIT

HA3230 for Model 160-IF

HA3231 for Model 280-IF

EXTERNAL THERMOSTAT - HA3210

EXTREME COLD FUEL OIL PRE-HEATER

HA3211

-

www.desatech.com

15114909-01C

Loading...

Loading...