Desa VCB36NE, VCB36PE User Manual

VENTED GAS FIREPLACE

INSTALLATION AND OWNER’S OPERATION MANUAL

4" B-VENT DECORATIVE GAS FIREPLACES

MODELS

(V)CB36N(E) AND (V)CB36P(E)

WARNING: If the information in this manual is not fol-

lowed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

— Installation and service must be performed by a quali-

ed installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance

CONSUMER: Retain this manual for future reference.

For more information, visit www.desatech.com

Safety Information ............................................... 2

TABLE OF CONTENTS

Product Identication ........................................... 4

Local Codes......................................................... 4

Product Features ................................................. 5

Pre-Installation Preparation ................................. 5

Installation Precautions ....................................... 8

Venting Installation .............................................. 8

Installing Optional Controls.................................11

Fireplace Installation.......................................... 14

Operating Fireplace ........................................... 19

SAFETY INFORMATION

Inspecting Burners............................................. 22

Cleaning and Maintenance ................................ 23

Specications .................................................... 24

Troubleshooting ................................................. 25

Illustrated Parts Breakdown and Parts List........ 30

Replacement Parts ............................................ 34

Service Hints ..................................................... 34

Technical Services ............................................. 34

Accessories ....................................................... 34

Warranty Information ...........................Back Cover

WARNING: Improper installation, adjustment,

alterati on , service or

maintenance can cause

injury or property damage. Refer to this manual

for correct installation

and operational procedures. For assistance or

additional information

consult a qualified installer, service agency or

the gas supplier.

This appliance may be in-

stalled in an aftermarket,*

per manentl y loc ate d,

manufactured (mobile)

home, where not prohibited by local codes.

This appliance is only for

use with the type of gas

indicated on the rating

plate. This appliance is

not convertible for use

with other gases.

* Aftermarket: Completion of sale, not for

purpose of resale, from the manufacturer

State of Massachusetts:

The in stall ation must

be made by a licensed

plumber or gas tter in

the Commonwealth of

Massachusetts.

WARNING: This product

contains an d / o r generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate or service this replace.

Improper use of this replace

can cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

www.desatech.com

117437-01B2

SAFETY INFORMATION

Continued

This replace is a vented product. This replace

will not produce any gas leakage into your home if

properly installed. This replace must be installed

by a qualied (certied or licensed) service person.

If this unit is not properly installed by a qualied

service person gas and/or carbon monoxide leakage (spillage) can occur.

Carbon Monoxide Poiso ning: Early signs of

carbon monoxide poisoning resemble the u, with

headaches, dizziness or nausea. If you have these

signs, the replace may not be working properly.

Get fresh air at once! Have replace serviced.

Some people are more affected by carbon monoxide

than others. These include pregnant women, people

with heart or lung disease or anemia, those under the

inuence of alcohol and those at high altitudes.

Natural and Propane/LP Gas: Natural and propane/

LP gases are odorless. An odor-making agent is

added to these gases. The odor helps you detect a gas

leak. However, the odor added to the gas can fade.

Gas may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

Do not place clothing or other

ammable material on or near

the appliance. Never place any

objects on or around replace.

Fireplace reaches high temperatures. Keep children and adults

away from hot surface to avoid

burns or clothing ignition. Fireplace will remain hot for a time

after shutdown. Allow surfaces

to cool before touching.

Do not operate replace with

glass door removed, cracked

or broken.

Carefully supervise young chil-

dren when they are in the room

with the replace.

Keep the appliance area clear

and free from combustible materials, gasoline and other am-

WARNING: Any change to

this replace or its controls can

be dangerous.

WARNING: Do not use a blower insert, heat exchanger insert

or other accessory not approved

for use with this replace.

WARNING: Do not allow fans

to blow directly into the replace.

Avoid any drafts that alter burner

ame patterns. Ceiling fans can

create drafts that alter burner

ame patterns. Altered burner

patterns can cause sooting.

Due to high temperatures, the

appliance should be located out

of trafc and away from furniture

and draperies.

117437-01B 3

www.desatech.com

mable vapors and liquids.

This product is intended only

as a supplement to your central

heating system and is not to be

installed as a primary source of

heat. You may use this product

for emergency heating during a

power outage.

1. This appliance is only for use with the type

of gas indicated on the rating plate. This appliance is not convertible for use with other

gases unless a certied kit is used.

2. Do not place propane/LP supply tank(s) in-

side any structure. Locate propane/LP supply

tank(s) outdoors (propane/LP units only).

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not use

any phone in your building

• immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions

• if you cannot reach your gas supplier, call

the re department

SAFETY INFORMATION

Continued

4. Never install the replace

• in a recreational vehicle

• in windy or drafty areas where curtains or

other combustible (ammable) objects can

make contact with the replace front

• in high trafc areas

5. Do not modify this replace under any circum-

stances. Any parts removed for servicing must

be replaced prior to operating replace.

6. Turn replace off and let cool before servicing,

installing or repairing. Only a qualied service

person should install, service or repair this

replace.

7. You must keep control compartments, burn-

ers and circulating air passages clean. More

frequent cleaning may be needed due to excessive lint and dust from carpeting, bedding

material, etc. Turn off the gas valve and pilot

light before cleaning replace.

8. Have replace and venting system inspected

annually by a qualied service person. If needed,

have venting system cleaned or repaired. See

Cleaning and Maintenance, page 23.

9. Do not use this replace to cook food or burn

paper or other objects.

10. Do not use any solid fuels (wood, coal, paper,

cardboard, etc.) in this replace. Use only the

gas type indicated on the nameplate.

11. This appliance, when installed, must be electrically grounded in accordance with local

codes or, in the absence of local codes, with

the National Electric Code, ANSI/NFPA 70,

or the Canadian Electric Code, CSA C22.1.

12. Do not use fireplace if any part has been

exposed to or under water. Immediately call

a qualied service technician to arrange for

replacement of the unit.

13. Do not operate replace if any log is broken

or missing.

14. To prevent performance problems, do not

use propane/LP fuel tank of less than 100 lb.

(45 kg) capacity (propane/LP units only).

15. Prov ide adequa te clearance s around air

openings.

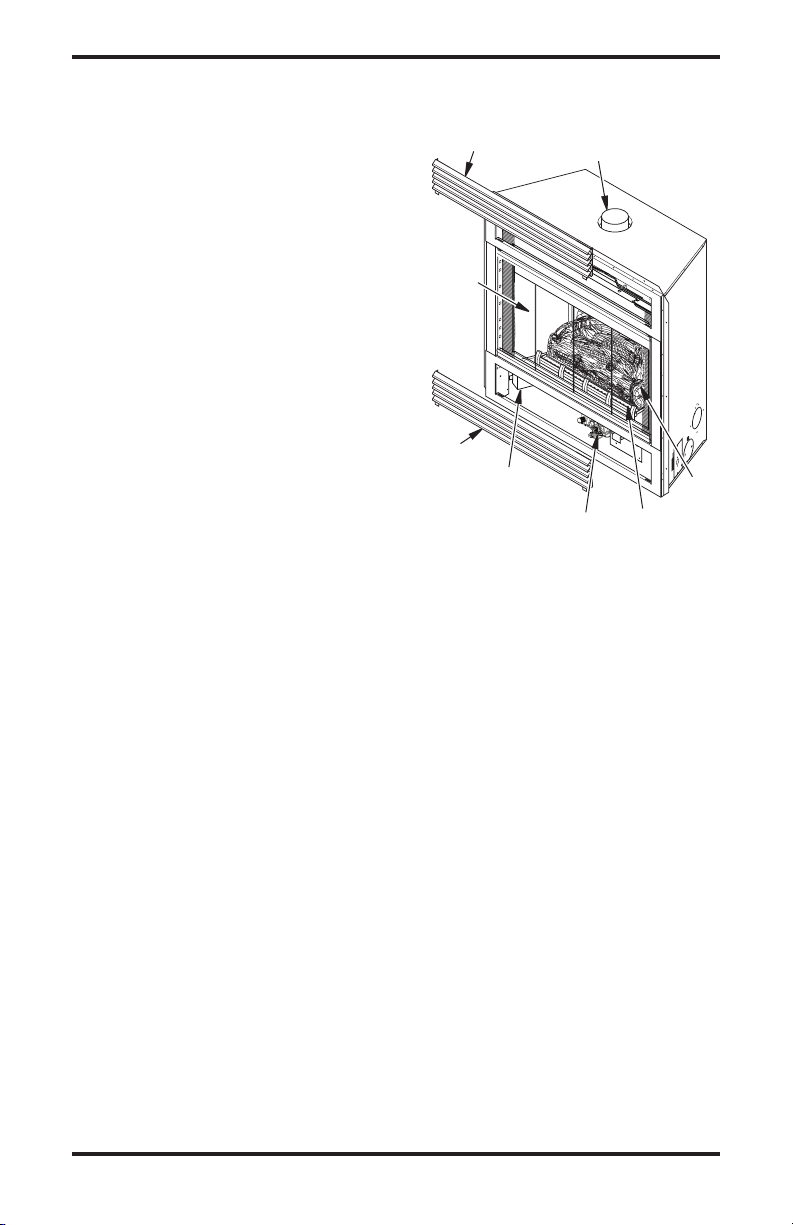

PRODUCT

IDENTIFICATION

Top Louver Panel

Glass

Door

Assembly

Bottom

Louver

Panel

Junction Box

(Electronic

Ignition Only)

Figure 1 - B-Vent Fireplace

4" B-Vent

Flue Collar

Control

Valve

Ember

Tray

Nailing

Flange

Log

Set

LOCAL CODES

Install and use replace with care. Follow all

local codes. In the absence of local codes, use

the latest edition of The National Fuel Gas Code

ANSI Z223.1/NFPA 54* (USA) or the current CSA-

B149.1 Installation Code (Canada).

*Available from:

American National Standards Institute, Inc.

National Fire Protection Association, Inc.

1430 Broadway

New York, NY 10018

Batterymarch Park

Quincy, MA 02269

www.desatech.com

117437-01B4

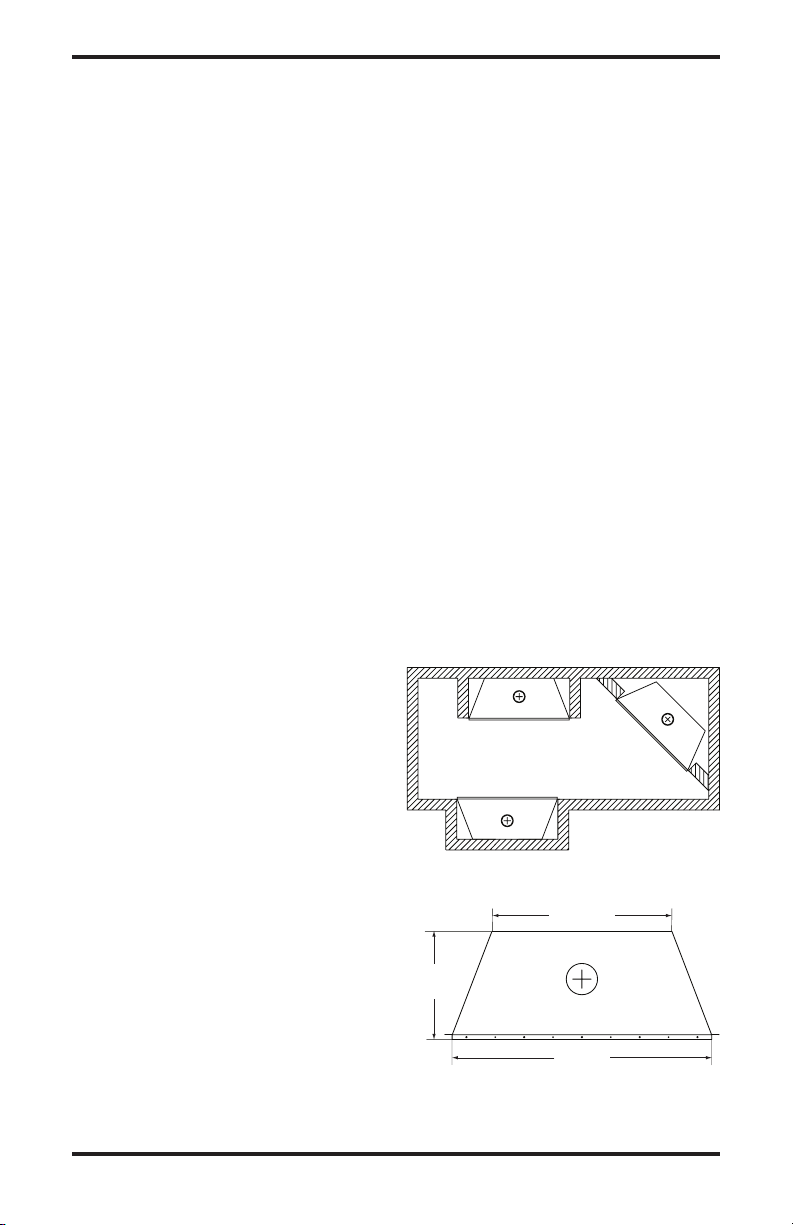

PRODUCT FEATURES

25"

(63.5 cm)

36"

(91.4 cm)

36"

(91.4 cm)

These are a few facts that can help you understand

and enjoy your vented decorative replace:

• The (V)CB36N(E) and (V)CB36P(E) series

of vented decorative replaces may be recessed

into an exterior chase, an interior ush wall

enclosure or a framed-in corner installation.

• Mod e ls (V)C B 36N an d (V ) CB3 6 P ar e

equipped with a millivolt gas control system

that does not require electricity to operate.

A piezo ignitor is provided to light the pilot

without using matches or lighters.

• Models (V)CB36N(E) and (V)CB36P(E) are

equipped with an electronic ignition system

that requires 120 VAC to operate. An electrode

ignitor automatically lights the pilot ame when

the replace is turned on.

• These replaces can accept any approved 4"

B-Type venting system and must be terminated

vertically through the roof using a listed type

vent cap only. See venting instructions starting

on page 8 for proper venting requirements.

• These vented replaces require indoor air for

combustion and must be installed in a room of

sufcient size to provide adequate fresh air for

safe and proper operation. The room intended

for installation must be of sufcient size to

meet the requirements for an unconned space

as dened in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, Section 5.3, Air for

Combustion and Ventilation. If sufcient air

for combustion is not available a makeup air kit

model AK4 may be required to provide outside

air to this appliance. Check your local codes as

to specic requirements for make up air.

• This replace may be installed in any room of

the house provided all local codes and these

installation instructions are followed.

When deciding the location of your replace,

follow these rules:

• Do not connect this replace to a chimney ue

servicing a separate solid fuel burning replace

or appliance.

• Do to high temperatures, do not locate this

replace in high traffic areas, windy or drafty

areas, or near furniture or draperies.

• Proper clearances must be maintained.

• If your replace is to be installed directly on

carpeting, vinyl, tile or any combustible material other than wood, it must be installed on a

metal or wood panel extending the full width

and depth of the replace (see Figure 3).

• Only trim kits supplied by DESA shall be used

in the installation of this replace, see Acces-

sories, page 34.

• Do not install aftermarket vent dampers.

Manual or automatic vent dampers are not approved for use with this appliance.

• Your replace is designed to be used in zero

clearance installations. Wall or framing material

can be placed directly against any exterior sur-

face on the back, sides or top of your replace,

except when clearances are required from ue

vent pipe, see Clearances on page 6.

• If recessed into a wall, you can avoid extra

framing by positioning your replace against

an already existing framing member.

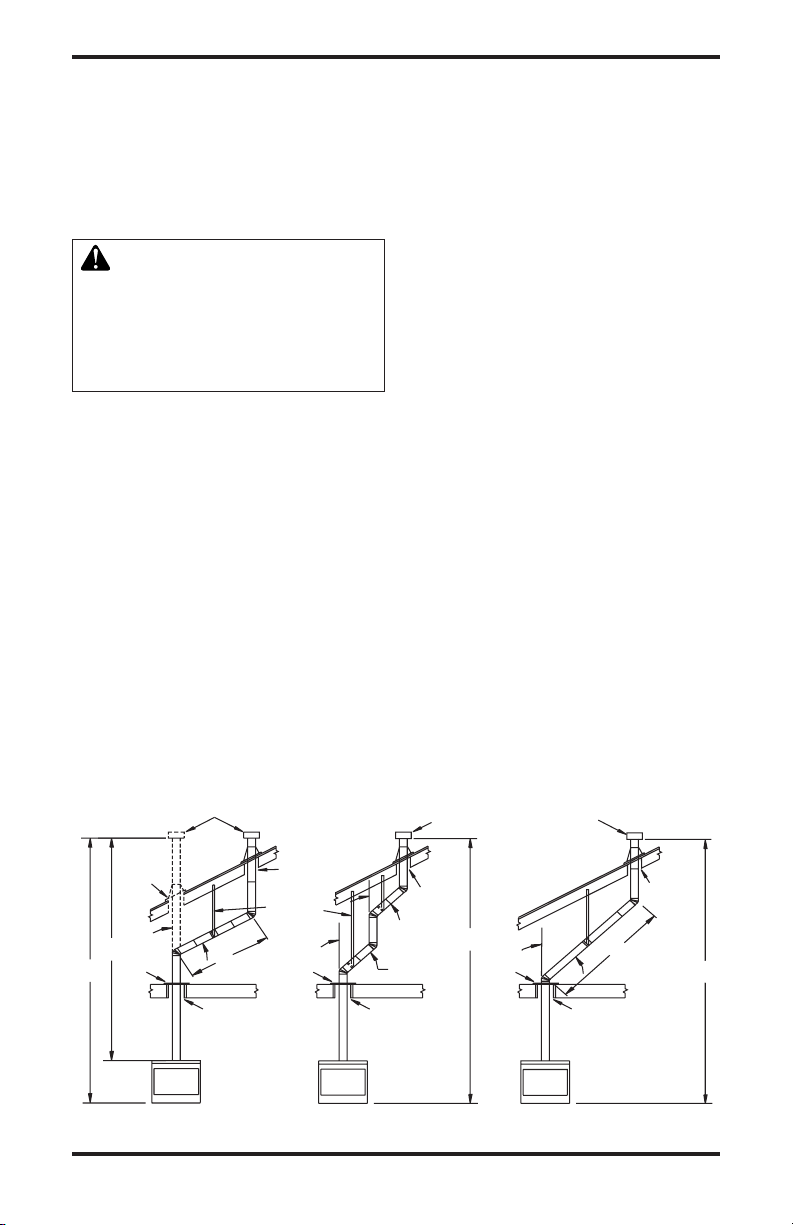

Flush with a wall

Through exterior wall

enclosed in a chase

Corner

Installation

PRE-INSTALLATION

PREPARATION

LOCATION AND SPACE

REqUIREMENTS

Determine the safest and most efcient location

for your DESA direct-vent replace. Make sure

that rafters and wall studs are not in the way of the

venting system. Choose a location where the heat

output is not affected by drafts, air conditioning

ducts, windows or doors. Figure 2 shows some

common locations. Be aware of all restrictions and

precautions before deciding the exact location for

your replace and termination cap.

117437-01B 5

www.desatech.com

Figure 2 - Common Fireplace Locations

Figure 3 - Fireplace Bottom Dimensions

PRE-INSTALLATION

PREPARATION

Continued

• A hearth extension is not required with this

appliance. If one is installed, it is for aesthetic

purposes only and does not have to meet standard requirements for hearth extensions.

• If you plan on installing a television or entertain-

ment center recessed above your replace, it is

recommended that you maintain a minimum 18"

(45.7 cm) above the top of louver opening.

• When locating the termination cap, it is important to observe the minimum vent height and

clearances required under code, see Venting

Installation Instructions, page 8.

• Do not recess termination cap into a wall or

siding.

• You may paint the termination cap with 450° F

(232° C) heat resistant paint to coordinate with

the exterior nish.

PACKAGING AND REMOVAL

The (V)CB36 vented decorative gas replaces are

packaged with the following items:

• one box containing a 4 piece log set located on

the burner in the rebox.

• one bag containing the owner’s manual with

installation instructions, operator’s guide, and

warranty information.

• one bag of glowing ember material.

• one bag of vermiculite hearth treatments.

1. Remove shrink wrap securing 2 carton trays

to unit.

2. Lift top carton tray off and remove four corner

posts.

3. Discard bottom tray once unit is moved into

position.

Note: To prevent damage to ceramic logs and

glass panels you may want to remove them before

positioning and framing the unit. To access rebox,

see Louver Panels and Glass Door, page 16.

CLEARANCES

Minimum clearances to combustibles for replace:

Back, Sides, Floor and Top

Perpendicular walls 10" (25.4 cm)

Ceiling to Louver & Front 36" (91.4 cm)

B-Vent Surfaces 1" (26 mm) (See

venting instructions

Mantel Clearances (See Mantel Clear-

Combustible material with a maximum thickness

of 5/8" (16 mm) may be ush with top and sides

of front face of replace.

0" (0 mm)

for specics on vent

clearances.)

ances, page 7, for

specic clearances to

combustible mantels.)

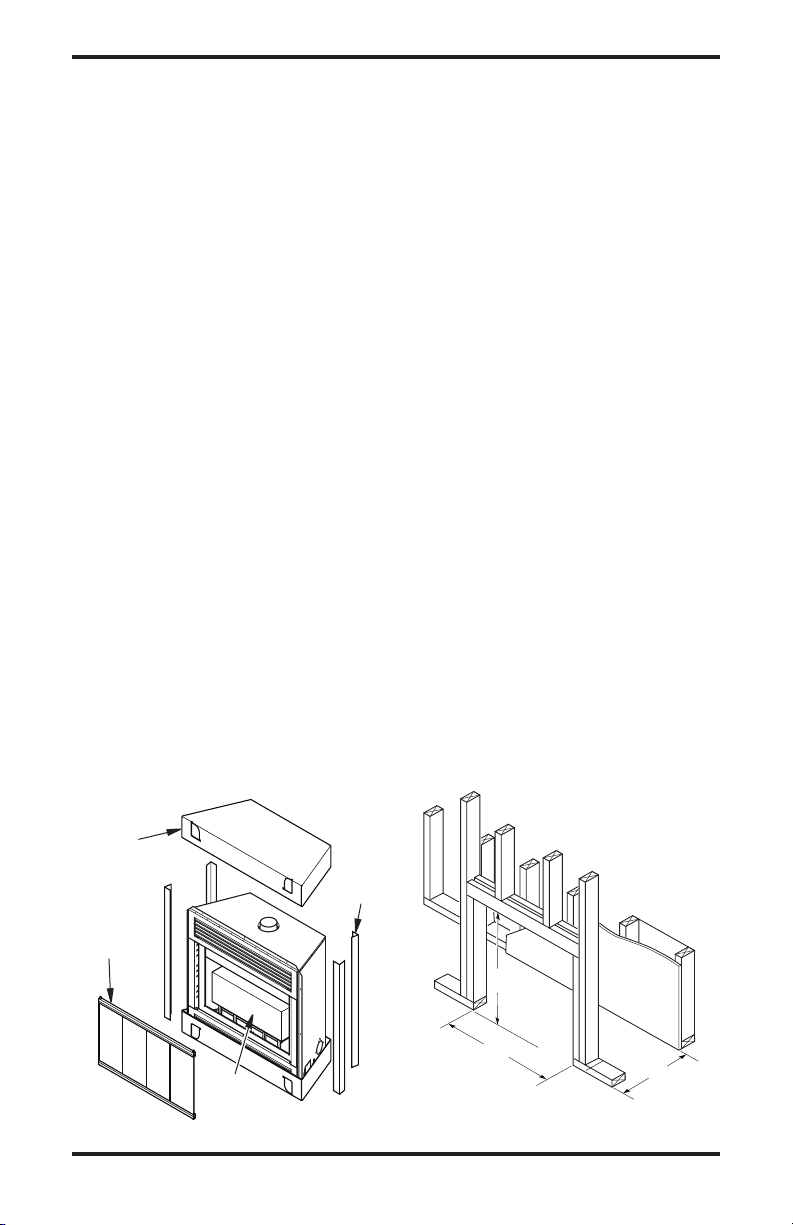

FRAMING AND FINISHING

Figure 5 shows typical framing of this replace.

Figure 6, page 7, shows framing for corner installation. All minimum clearances must be met.

For overall unit dimensions, framing allowances

and vent collar locations, see Unit Dimensions,

Figure 7 on page 7.

For available accessories for this replace, see

Accessories, page 34. If you are using a separate

combustible mantel piece, refer to Figures 8 and

9, page 8, for proper height and clearances. You

can install a noncombustible mantel at any height

above the replace opening.

Note: Noncombustible mantels may discolor!

Carton

Tray

Glass

Panel

Log

Carton

Figure 4 - Unpacking Fireplace

Corner

Post

36 1/4"

(92.1 cm)

Figure 5 - Framing Clearances for Flush

www.desatech.com

36"

(91.4 cm)

14 3/4"

(37.5 cm)

Wall Installation

117437-01B6

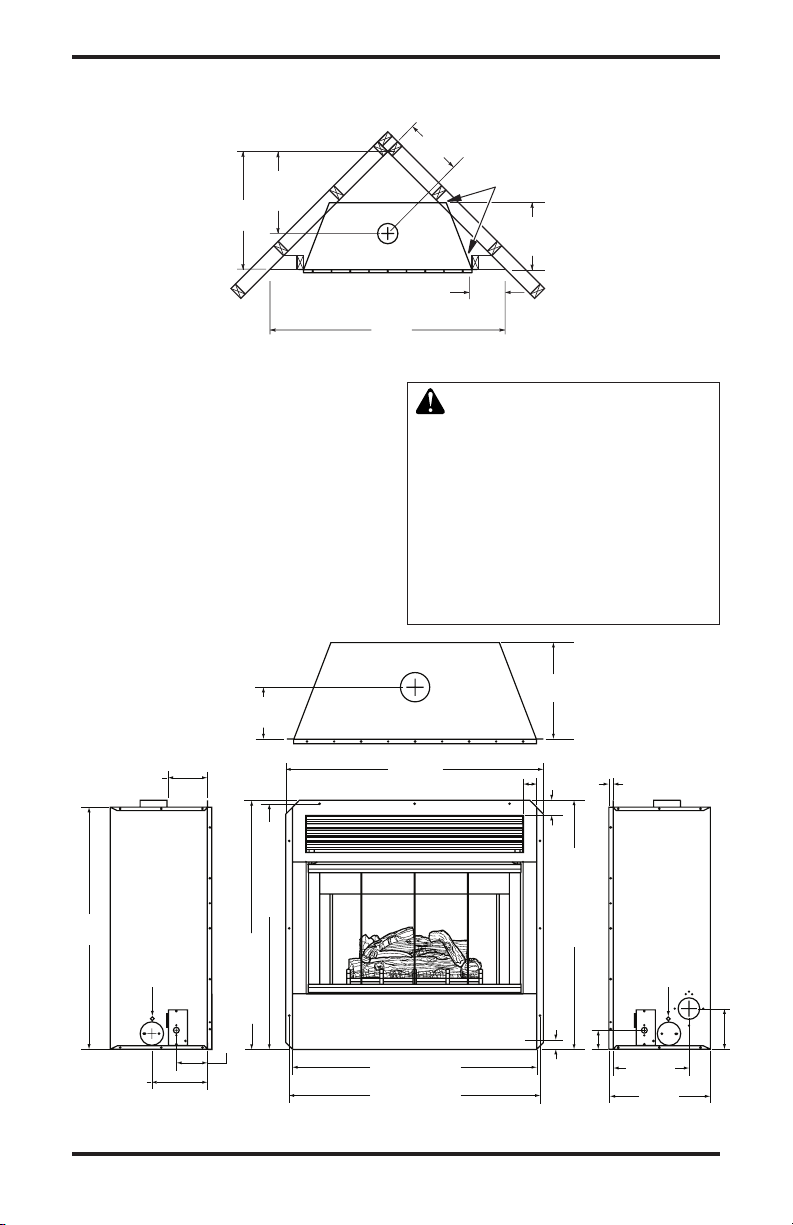

28 5/8"

(72.7 cm)

21" (53.3 cm)

To Center of

Top Vent

14 3/4"

(37.5 cm)

14 3/4" (37.5 cm)

to Nailing

Flanges

56 3/4"

(144 cm)

12 1/4"

(31 cm)

to Opening

PRE-INSTALLATION PREPARATION

14 3/4" (37.5 cm)

to Nailing Flanges

7 7/8" (20 cm) to

Center of 4" B-Vent

5 7/8"

(15 cm) to

Nailing

Flange

36

1

/

4

" (92.1 cm)

to Nailing Flange

36 1/4" (92.1 cm)

Face Dimensions

1

1

/

2

" (3.8 cm)

2

1

/

2

" (6.4 cm)

6" (15.2 cm)

5/8"

(16 mm)

11 1/8"

(28.3 cm)

Air Kit Location

1 1/4"

(3.2 cm)

2"

(5.1 cm)

38"

(96.5 cm)

15 3/8"

(39 cm)

36" (91.4 cm)

Face Dimensions

37" (94 cm)

to Nailing Flange

35 3/4"

(90.8 cm)

4

1

/

2

" (11.4 cm) Electrical Inlet

36

3

/

4

" (93.4 cm)

Wall Switch

Wireway

Wall Switch

Wireway

8" (20.3 cm)

Gas Supply

Inlet

Continued

Figure 6 - Framing Clearances for Corner Installation

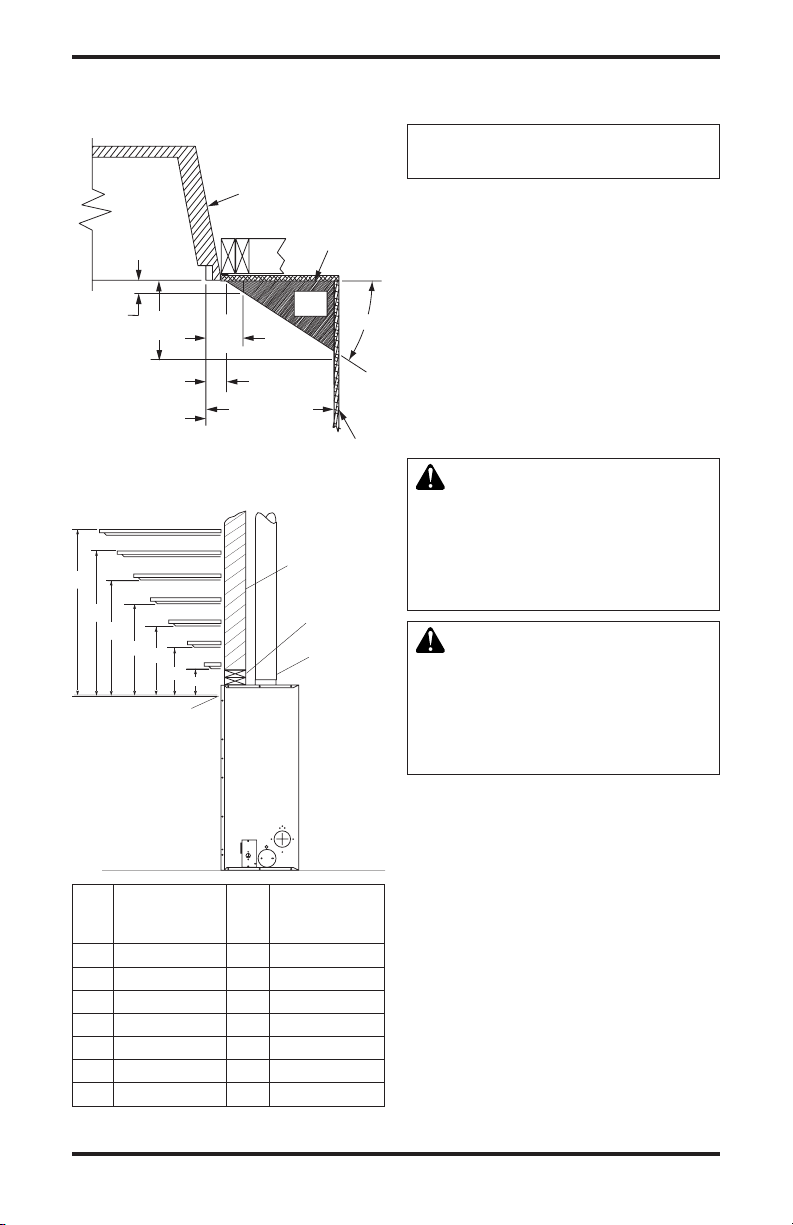

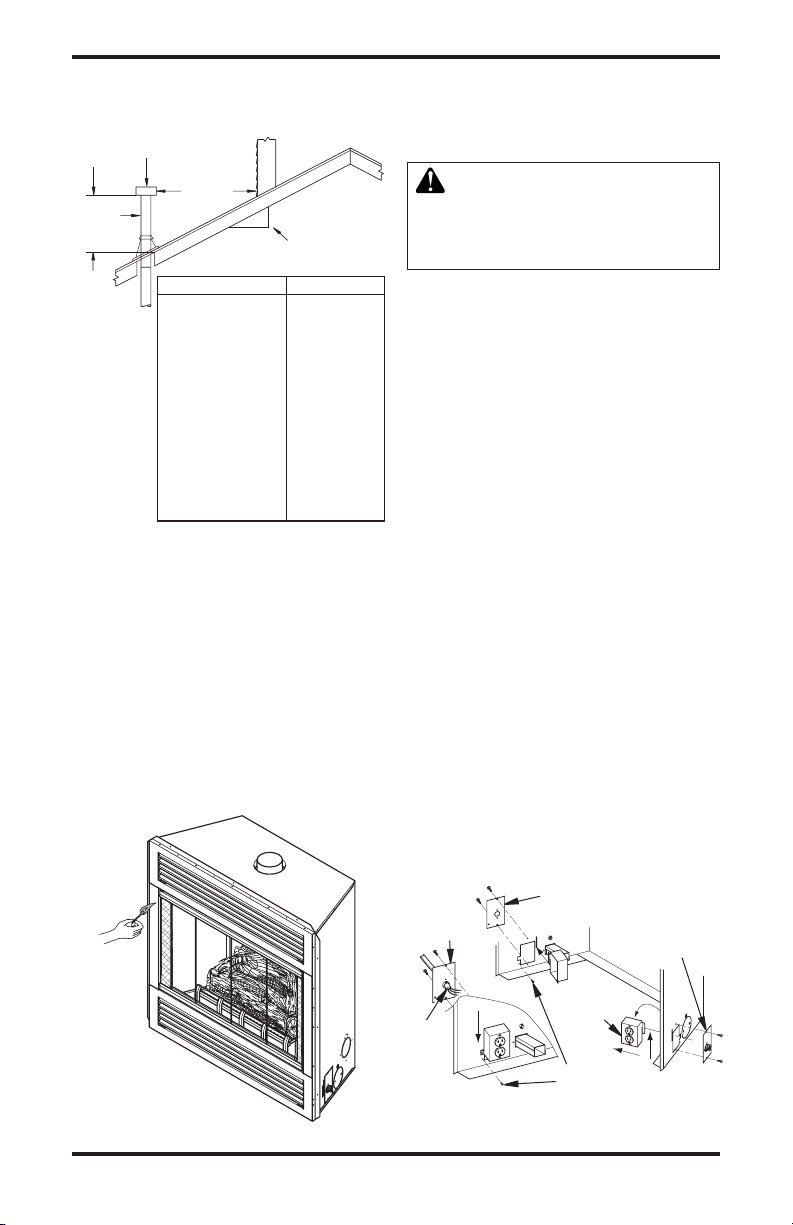

MANTEL CLEARANCES

Figure 8, page 8, shows projected mantel depths

at various heights above top of louver opening.

Figure 7 shows minimum allowable distances

from various mantel components in relation to

both sides of replace opening.

These dimensions allow for 1"

clearance at sides and back of

replace.

However, 0" clearance is also

permitted at all sides when framed.

WARNING: When nishing

appliance do not overlap combustible materials onto the black

front face. Brick, tile or other

noncombustible materials may be

applied to the face provided that

any replace openings are not

blocked and gaps in the material

used and the face are sealed with

a noncombustible caulking.

117437-01B 7

Figure 7 - Unit Dimensions

www.desatech.com

1 1/2"

(3.8 cm)

3 1/2"

(8.9

cm)

Outer

Surround

Combustible

Material May

Be Used

Perpendicular

Side Wall

5 1/4"

(13.3 cm)

1 3/4"

(4.4 cm)

To Fireplace

Opening

10" (25.4 cm)

33°

Safe

Zone

C

B

A

D

E

F

G

Top of Louver

Opening

3

2

1

4

5

6

7

Stud Wall

4" B-Vent

Flue Pipe

2 x 4 Header

at 1" Min.

Clearance

PRE-INSTALLATION

PREPARATION

Continued

Figure 8 - Side Clearances for

Combustible Mantels

Ref. Mantel Depth Ref.

1 16" (40.6 cm) A 18" (45.7 cm)

2 14" (35.6 cm) B 16" (40.6 cm)

3 12" (30.5 cm) C 14" (35.6 cm)

4 10" (25.4 cm) D 12" (30.5 cm)

5 8" (20.3 cm) E 10" (25.4 cm)

6 4" (10.2 cm) F 8" (20.3 cm)

7 2" (5.1 cm) G 6" (15.2 cm)

Figure 9 - Clearances for Combustible

Mantels

Mantel from

Top of Louver

Opening

www.desatech.com

INSTALLATION PRECAUTIONS

NOTICE: Failure to follow these in-

structions will void the warranty.

• Wear gloves and safety glasses for protection

• Use extreme caution when using ladders or

when on roof tops

• Be aware of electrical wiring locations in walls

and ceilings

The following actions will void the warranty on

this product:

• Installation of any damaged venting component

• Unauthorized modication of the venting system (Do not cut or alter vent components)

• Installation of any component part not manufactured or approved by DESA.

• Installation other than as instructed by these

instructions

WARNING: Read all instruc-

tions completely and thoroughly

before attempting installation.

Failure to do so could result in

serious injury, property damage

or loss of life.

WARNING: B-type vent pipe airspace clearance to combustibles

is 1" on all sides. Where the vent

pipe passes through a vertical wall

a listed thimble approved for use

with B-type vent must be used.

VENTING INSTALLATION

A 4" B-type venting system must be connected to the

appliance for venting to the outside of the building.

The following section is provided as a guide to

install a standard B-type vent installation.

Standing code requirements concerning B-type

vent installations may vary within your state,

province or local codes jurisdiction. Therefore,

it is recommended that you check with your local

building code authority for specic requirements

or in absence of local codes, follow Section 7.0

of the current National Fuel Gas Code NFPA

54/ANSI Z223.1 or in Canada with CAN/CSA

B149 for Category I systems using double wall

B-1 vent pipe.

This gas appliance must be vented to the outdoors

only and may not be terminated into an attic space

or into a chimney ue servicing a solid fuel burning appliance.

117437-01B8

Maintain

Listed

Clearance

Maintain

Listed

Clearance

12' Min.

12' Min.

45°

45

6'

8'

12' Min.

60

45

Position

Firestop

Position

Firestop

Position

Firestop

Listed

Vent Cap

Listed

Vent Cap

Listed

Vent Cap

Maintain

Listed

Clearance

Maintain

Listed

Clearance

Maintain

Listed

Clearance

Maintain

Listed

Clearance

Support Each

Lateral At

Least Every

6 Feet

Maintain

Listed

Clearance

10'

EXAMPLE 3EXAMPLE 2

EXAMPLE 1

VENTING INSTALLATION

Continued

This appliance may be vented through a manufactured chimney liner system if all are listed,

inspected and approved by local codes and/or

building authorities.

The examples shown in Figure 10 are typical of

most B-vent installations and code practices.

WARNING: This gas replace

and vent assembly must be vented

directly to the outside. The venting

system must NEVER be attached

to a chimney serving a separate

solid fuel burning appliance.

Example 1: Shows the minimum allowable system

height and lateral offset for a 60° or greater inclina-

tion. Code species that offsets at 60° or greater

are considered horizontal and must follow the 75%

rule for lateral to total vertical system height. Codes

also allows only one offset in the total system when

at 60° or greater. The total vertical height in this

example represents the minimum height of 8 feet

and therefore the allowable lateral is 6 feet when the

75% rule applies. If the lateral length must exceed

75% then the system must be sized in accordance

with the Category I venting tables.

Example 2: Shows multiple offsets each at 45°

of inclination. Multiple offsets are permitted if

they do not exceed 45° of inclination. The total

lengths of the two offsets are not required to meet

the 75% rule.

Example 3: Shows a single offset at 45° of inclina-

tion and therefore the lateral length at 10 feet of offset

does not have to meet the 75% allowable rule.

In each case the offsets must be supported and

restops must be positioned wherever the vent

must pass through a sub-oor, ceiling joist or

an attic overhang. The vent pipe must terminate

vertically into a listed type vent cap and extend a

sufcient height through an approved roof ashing, roof jack or a roof thimble. At all points the

listed clearances must be maintained.

Vent terminations must be located in accordance

with height and proximity rules of NFPA No. 54 or

CAN/CSA B149. These rules apply to vents at 12"

diameter or less and require a minimum height in

accordance with the roof pitch and a minimum of

8 foot distance from a vertical wall or obstruction

(see Figure 11, page 10).

If venting horizontally through a side wall becomes necessary, a listed thimble approved for use

with B-type vent must be used. Check with your

local codes before venting through a side wall.

Some codes areas allow the use of existing B-type

vent systems if the system is at or above the recom-

mended diameter of the ue.

The ue connection must be made using listed B-type

connectors and the existing system must be code

inspected for damage and proper installation.

It is not recommended that this appliance be

common vented with and existing gas burning

appliance. However, if it becomes necessary to

common vent the appliance. The venting system

must be sized and congured in accordance with

the common venting guides Appendix G of the current National Fuel Gas Code NFPA No. 54/ANSI

Z223.1 and in Canada with CAN/CSA B149.

Note : Before connecting this appliance to an

existing vent system or a common venting system consult with your local architect planner, or

building ofcial.

Figure 10 - Typical B-Vent Conguration

117437-01B 9

www.desatech.com

Lowest

Discharge

Opening

Listed

Vent Cap

8 Ft. Min.

Roof Pitch x/12

Listed Clearance

12

x

Listed

Gas

Vent

H (Min)

Height

From Roof

VENTING INSTALLATION

Continued

Roof Pitch H (Min.)

Flat to 6/12 1.0 ft (0.3 m)

6/12 to 7/12 1.25 ft (0.38 m)

Over 7/12 to 8/12 1.5 ft (0.46 m)

Over 8/12 to 9/12 2.0 ft (0.61 m)

Over 9/12 to 10/12 2.5 ft (0.76 m)

Over 10/12 to 11/12 3.25 ft (0.99 m)

Over 11/12 to 12/12 4.0 ft (1.22 m)

Over 12/12 to 14/12 5.0 ft (1.52 m)

Over 14/12 to 16/12 6.0 ft (1.83 m)

Over 16/12 to 18/12 7.0 ft (2.13 m)

Over 18/12 to 20/12 7.5 ft (2.27 m)

Over 20/12 to 21/12 8.0 ft (2.44 m)

Figure 11 - B-Vent Termination

CHECKING FOR PROPER VENTING

After completing and checking the electrical, gas

and vent connections, follow the lighting instructions and allow the main burner to run for approximately 5 minutes. Hold a match or butane lighter

ame, near the opening between the glass and the

replace face and play it along the entire length

of the opening (Smoke may also be used). Proper

venting will tend to draw ame or smoke into the

appliance. Improper venting, escaping or spillage

of burned gas, is indicated when the match ickers

or goes out (see Figure 12). Smoke will also tend

to disperse away from the appliance.

If the appliance is not venting properly, shut it

off and notify your installer or a qualied service

agency to inspect the venting system.

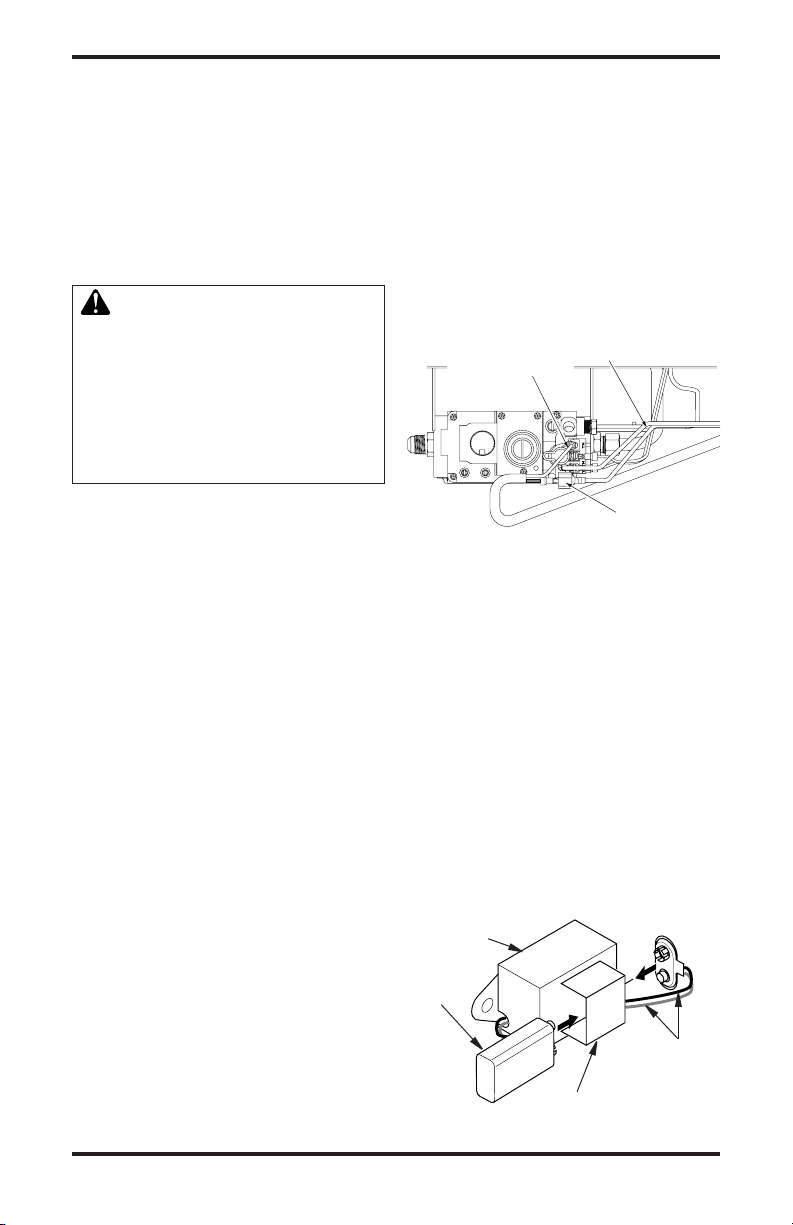

ELECTRICAL SUPPLY CONNECTION

CAUTION: Disconnect the

electrical power to the supply

circuit before attempting to connect or service this appliance.

A prewired junction box receptacle with strain

relief is provided on the right side of the cabinet for

hard wiring the unit to a 15 Amp, 120 VAC, 60 Hz

grounded branch circuit. If the installation demands

that the electrical supply be connected from the left

side, the entire receptacle box can be relocated to the

left side by following these instructions:

Note: If you do not need to relocate the junction

box, to connect the electric supply follow steps 8

through 11 only:

1. Remove 2 screws and outer cover with strain

relief bushing on right side of cabinet (see

Figure 13).

2. Remove inner retaining screw on junction box

mounting tab.

3. Slide junction box up until screw mounting

tab is lined up to notch in outer cabinet.

4. Swing junction box out and slip retaining

ange out through slot in outer cabinet.

5. Remove 2 screws and outer cover on left side

of outer cabinet.

6. Reinsert junction box retaining ange through

slot now on left side and swing screw mount-

ing tab back through notch as before.

7. Slide junction box down till mounting tab holes

line up and replace inner retaining screw.

8. With junction box cover removed, pull end

of 3-wire Romex supply line through uni-

versal strain relief bushing on cover. (see

Figure 13).

J-Box

Cover

with Strain

Relilef

J-Box

Cover

J-Box Cover

with Strain

Relief

Figure 12 - Checking for Spillage

Romex

Cable

Figure 13 - Relocating Junction Box Recep-

tacle and Electrical Supply Connection

www.desatech.com

J-Box with

Receptacle

Screw/Tab

Retainer

117437-01B10

Remote Receiver

or Wall Switch to

Terminal Marked “TH”

Wire Harness From

High Limit Switch

Male Connector to

Remote Receiver

or Wall Switch

VENTING INSTALLATION

Continued

9. Strip back outer Romex to about 4" and connect black, white and green wires accordingly

using 3 wire nut connectors.

10. Tuck tailing wires into junction box and replace

junction box cover using 2 remaining screws.

11. Tighten adjustment on universal strain bush-

ing to secure Romex sheathing and complete

supply connection.

WARNING: This appliance,

when installed must be electri-

2. Route 15 foot wire through hole openings with

bushings provided on either side of replace

cabinet.

3. Connect one bare wire end to each of terminals

of GWMS2 wall switch.

4. Install wall switch and cover in wall.

IMPORTANT: Do not use any other wire than that

provided with GWMS2 wall switch kit. Do not

exceed 15 feet of distance from valve connection.

Using wire of higher gauge or turns or exceeding

minimum distance will increase resistance at

control valve causing unreliable performance of

replace controls.

cally grounded in accordance

with local code or in the ab-

sence of local code, with the

current National Electric Code,

ANSI/NFPA 70, or the Canadian

Electric Code, CSA C22.1.

HIGH ALTITUDE INSTALLATION

Your DESA direct-vent replace has been tested

and approved in the USA for elevations from

0-2,000 feet (610 m) and in Canada at elevations

from 0-4,500 feet (1,372 m).

When installing a non-high altitude replace at an

elevation above 2,000 feet (610 m) (in the USA),

you may need to decrease the input rating by

changing the existing burner orice to a smaller

size. Reduce input 4% for each 1,000 feet (305 m)

above sea level. Check with your local gas company for proper orice size identication.

When installing this replace in Canada at an

elevation above 4,500 feet (1,372 m), Check with

local or provincial code authorities.

Consult your local gas company to help determine

the proper orice for your location.

For assistance with any high altitude installation

contact DESA’s Customer Service Department at

1-866-672-6040.

Figure 14 - Connecting Remote Receiver

or Wall Switch to the Gas Control Valve

INSTALLING OPTIONAL WIRELESS

HAND-HELD REMOTE CONTROL

MODEL HRC100

Installing Remote Receiver

1. O pen bottom louv er an d locat e swi tch

bracket on right side.

2. Locate battery clip mount ed on back of

receiver. Slide a 9-volt alkaline battery (not

included) through clip.

3. Attach terminal wires to battery (see Figure 15).

4. Connect one wire from receiver to male con-

nector on high limit harness and one to “TH”

on control valve (see Figure 14).

5. Locate two plastic mounting clips provided

with kit.

INSTALLING OPTIONAL

CONTROLS

INSTALLING OPTIONAL WALL

MOUNT SWITCH - GWMS2

1. Connect one terminal of 15 foot wire from

wall switch to male connector on high limit

harness. Connect remaining wire terminal to

TH terminal on valve. Make sure that wire

terminals are in positions on unit as pictured

in Figure 14. If wires are not connected as

shown switch will not work.

117437-01B 11

www.desatech.com

Receiver

9-Volt

Alkaline

Battery

Terminal

Wires

Battery Clip

Figure 15 - Attaching Alkaline Battery to

Receiver

Loading...

Loading...