HIGH PRESSURE

PORTABLE

FORCED

AIR HEATERS

OWNER’S MANUAL

600 SIDE

350 SIDE

Heater Sizes: 350,000 and 600,000 Btu/Hr

Models: SB350D and SB600D

IMPORTANT: Read and understand this manual before assembling, starting, or servicing heater. Improper use of heater can cause serious injury.

Keep this manual for future reference.

PV 027

PV 026

ARL LOGO

®

G 004

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

SAFETY

INFORMATION

WARNINGS

WARNING ICON G 001

IMPORTANT: Read this Owner’s

Manual carefully and completely

before trying to assemble, operate, or service this heater. Improper use of this heater can

cause serious injury or death from

burns, fire, explosion, electrical

shock, and carbon monoxide

poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early

signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness,

and/or nausea. If you have these signs, the

heater may not be working properly. Get

fresh air at once! Have heater serviced.

Some people are more affected by carbon

monoxide than others. These include pregnant women, persons with heart or lung

disease or anemia, those under the influence

of alcohol, and those at high altitudes.

Make certain you read and understand all

Warnings. Keep this manual for reference.

It is your guide to safe and proper operation

of this heater.

• Use only kerosene or No. 1 fuel oil to

avoid risk of fire or explosion. Never

use gasoline, naphtha, paint thinners,

alcohol, or other highly flammable fuels.

• Fueling

a) Personnel involved with fueling shall

be qualified and thoroughly familiar

with the manufacturer's instructions

and applicable federal, state, and local regulations regarding the safe

fueling of heating units.

b)Only the type of fuel specified on the

heater's data plate shall be used.

c) All flame, including the pilot light,

if any, shall be extinguished and the

heater allowed to cool, prior to fueling.

d)During fueling, all fuel lines and fuel-

line connections shall be inspected

for leaks. Any leaks shall be repaired

prior to returning the heater to service.

e) At no time shall more than one day's

supply of heater fuel be stored inside

a building in the vicinity of the heater.

Bulk fuel storage shall be outside the

structure.

f) All fuel storage shall be located a

minimum of 25 feet from heaters,

torches, welding equipment, and

similar sources of ignition (exception: the fuel reservoir integral with

the heater unit).

g)Whenever possible, fuel storage shall

be confined to areas where floor penetrations do not permit fuel to drip

onto or be ignited by a fire at lower

elevation.

h)Fuel storage shall be in accordance

with the federal, state, or local authority having jurisdiction.

• Never use heater where gasoline, paint

thinner, or other highly flammable vapors are present.

• Follow all local ordinances and codes

when using heater.

• Heaters used in the vicinity of tarpaulins, canvas, or similar enclosure materials shall be located a safe distance

from such materials. The recommended

minimum safe distance is 10 feet. It is

further recommended that these enclosure materials be of a fire retardant nature. These enclosure materials shall be

securely fastened to prevent them from

igniting or from upsetting the heater

due to wind action.

• Use only in well vented areas. Before

using heater, provide at least a threesquare-foot opening of fresh, outside

air for each 100,000 Btu/Hr of rating.

This heater produces carbon monoxide,

which is listed by the State of California as a reproductive toxin under Proposition 65.

• Use only in places free of flammable

vapors or high dust content.

• Use only with the electrical voltage and

frequency specified on model plate.

• Use only a three-prong, grounded extension cord.

• Minimum heater clearances from combustibles:

Outlet: 8 Ft. Sides: 4 Ft.

Top: 4 Ft. Rear: 4 Ft.

• Locate heater on a stable and level surface while hot or running or a fire may

occur.

• When moving or storing heater, keep

heater in a level position or fuel spillage may occur.

• Keep children and animals away from

heater.

• Unplug heater when not in use.

• This heater has a built-in thermostat.

Plugged-in heater may start at anytime.

• Never use heater in living or sleeping

areas.

• Never block air inlet (rear) or air outlet

(front) of heater.

• Never move, handle, refuel, or service

a hot, operating, or plugged-in heater.

• Never attach duct work to front or rear

of heater.

• Warning to New York City Residents

For Use Only At Construction Sites

in accordance with applicable NYC

codes under NYCFD certificate of approval #4803, #4899, #4908, #4909, or

#4934.

2

106029

OWNER’S MANUAL

PRODUCT

IDENTIFICATION

Hot Air Outlet

Lower Shell

Fuel Cap

Thermostat

Figure 1 - 350,000 Btu/Hr Model

Hot Air Outlet

Upper Shell

Flame-Out Control

Reset Button

UNPACKING

1. Remove all protective packing applied

to heater for shipment.

2. Remove heater from shipping container.

3. Check heater for any shipping damage.

If heater is damaged, promptly inform

dealer where you bought heater.

Motor and

Pump

Assembly

Power Cord

Fuel Tank

Lower

Shell

Fuel Cap

Thermostat

Figure 2 - 600,000 Btu/Hr Model

106029

Upper Shell

Flame-Out Control

Reset Button

3

Motor and

Pump

Assembly

Power Cord

Fuel Tank

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

THEORY OF

OPERATION

The Fuel System: The motor turns the

fuel pump. The fuel pump pulls fuel from

the fuel tank. The fuel pump pushes fuel

through a filter and a solenoid valve and out

the burner head nozzle. A fine mist of fuel is

sprayed into the combustion chamber.

The Air System: The motor turns the fan.

The fan pushes air into and around the

combustion chamber. This air is heated and

provides a stream of clean, hot air.

The Ignition System: The electronic ignitor sends voltage to the spark plug. The

spark plug ignites the fuel and air mixture.

The Flame-Out Control System: This

system causes the heater to shut down if the

flame goes out. It also allows the fan to

continue running after normal shutdown of

heater. This cools the combustion chamber.

Combustion

Chamber

FUELS

WARNING: Use only kerosene

or No. 1 fuel oil to avoid risk of fire

or explosion. Never use gasoline, naphtha, paint thinners, alcohol, or other highly flammable

fuels.

Do not use heavy fuels such as No. 2 fuel oil or

No. 2 diesel. Using heavy fuels will result in:

• clogged fuel filter and nozzle

• carbon build-up on spark plug

• the need of non-toxic anti-icer in fuel

during very cold weather

IMPORTANT:

storage container. Be sure storage container

is clean. Foreign matter such as rust, dirt, or

water will cause flame-out control to shut

down heater. Foreign matter may also require you to clean fuel system often.

Spark

Plug

Burner

Head

Use a KEROSENE ONLY

Solenoid

Valve

Fan

Fuel Pump/

Fuel Filter

Motor

VENTILATION

WARNING: Follow the minimum fresh, outside air ventilation requirements. If proper fresh,

outside air ventilation is not provided, carbon monoxide poisoning can occur. Provide proper

fresh, outside air ventilation before running heater.

Fresh Air Opening

Requirements

Square Feet

Heater Size Opening

350,000 Btu/Hr 10.5

600,000 Btu/Hr 18.0

Note:

If you use more than one heater,

provide extra fresh air. Provide a fresh air

opening of at least three square feet for each

100,000 Btu/Hr rating.

Clean

Heated

Air Out

Fuel Tank

Figure 3 - Cross Section Operational View

Nozzle

Fuel Line To

Solenoid Valve

Air for Combustion

and Heating

Electronic Ignitor

Fuel

4

Cool

Air In

Fuel

Pickup

Line

Fuel

Filter

106029

OPERATION

WARNING: Review and un-

derstand the warnings in the

Safety Information

2. They are needed to safely operate this heater.

To Start Heater

1. Follow all ventilation and safety information.

2. Fill fuel tank with kerosene or No. 1

fuel oil.

3. Attach fuel cap.

4. Set thermostat dial to desired temperature.

Note:

Thermostat setting must be

higher than surrounding air temperature.

5. Plug power cord of heater into threeprong, grounded extension cord. Extension cord must be at least six feet long.

WARNING: Use only a threeprong, grounded extension cord.

Use cord with proper wire size to

assure 120 volt operation. See

Extension Cord Wire Size Requirements

Extension Cord Wire Size

Requirements

6 to 100 feet long, use 14 AWG rated cord

101 to 200 feet long, use 12 AWG rated cord

201 to 300 feet long, use 10 AWG rated cord

301 to 400 feet long, use 8 AWG rated cord

401 to 500 feet long, use 6 AWG rated cord

6. Plug extension cord into standard 120

volt/60 hertz, three-hole, grounded outlet.

7. The motor will start when extension

cord is plugged into outlet. The heater

should ignite at once. If heater does not

ignite, restart heater. To restart heater,

wait 60 seconds, then push in flameout control reset button. Flame-out control reset button is at rear of heater near

power cord (see Figure 4).

Note:

A cold heater may affect the thermostat setting. This thermostat is a generalheating control. It is not intended for precise

temperature control. Adjust thermostat until heater cycles at the desired setting.

below.

section, page

OWNER’S MANUAL

Note:

If starting heater for first time, you

may need to restart heater several times

before heater ignites. You may also have to

do this after taking heater out of storage. To

facilitate starting, remove the canister bottom from the pump's fuel filter and fill with

fuel. Reassemble filter (see Pump Fuel

Filter, page 12).

Flame-Out Control

Reset Button

Figure 4 - Flame-Out Control Reset Button

To Stop Heater

CAUTION: Never unplug

heater while heater is running.

Heater must go through purge

cycle. The purge cycle cools the

combustion chamber. Damage to

heater can occur if combustion

chamber is not cooled. Do not

restart heater until purge cycle is

complete.

1. Turn thermostat dial to lowest tempera-

ture setting. This will cause heater

flame to go out. The motor will continue to run during the purge cycle. This

allows the fan to cool the combustion

chamber. When the purge cycle is

finished, the motor will stop. Do not

unplug heater until purge cycle is finished.

2. Unplug extension cord from outlet.

3. To temporarily stop heater, set thermo-

stat at a temperature lower than air

around heater. Heater will cycle back

on if air temperature around heater

matches thermostat setting.

To Restart Heater

CAUTION: Do not restart

heater until purge cycle is

finished. The purge cycle cools

the combustion chamber.

1. Wait until purge cycle is finished after

stopping heater.

2. Repeat steps under To Start Heater.

STORING,

TRANSPORTING,

OR SHIPPING

Note:

If shipping transport companies re-

quire fuel tanks to be empty.

1. Drain all fuel from fuel filters, fuel

lines, and pump (see Fuel Filters [Tank

Fuel Filter], page 12).

2. Clean and flush fuel filter and canister

attached to fuel pump (see Fuel Filters

[Pump Fuel Filter], page 12).

3. Remove drain plug and drain fuel tank.

4. Replace drain plug.

5. If any debris is noted in old fuel, add 1

or 2 quarts of clean kerosene to tank,

stir, and drain again. This will prevent

excess debris from clogging filters during future use.

6. Replace fuel cap or drain plug. Properly dispose of old and dirty fuel. Check

with local automotive service stations

that recycle oil.

7. Add two gallons (350,000 Btu/Hr) or

three gallons (600,000 Btu/Hr) of clean

kerosene or No. 1 fuel oil to fuel tank.

8. Replace fuel cap.

9. Operate heater for 5 minutes (see Op-

eration).

10. Stop heater and let cool completely.

11. Remove drain plug and drain fuel tank.

12. Replace drain plug.

13. Properly dispose of old and dirty fuel.

14. If storing, store heater in a dry location. Make sure storage place is free of

dust and corrosive fumes.

IMPORTANT:

summer months for use during next heating

season. Using old fuel could damage heater.

Do not store kerosene over

106029

5

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

PREVENTATIVE

MAINTENANCE

SCHEDULE

Item

Fuel tank

Filler neck screen

Fuel filter assembly (Fuel tank)

Fuel filter lines

Fuel filter (Pump)

Spark plug

Fan blades and air deflectors

WARNING: Never service

heater while it is plugged in, operating, or hot. Severe burns and

electrical shock can occur.

How Often

Flush every 150-200 hours of operation or

as needed

Check for particles in fuel when filling fuel

tank. Clean when dirty

Clean twice a heating season or replace as

needed

Check and tighten loose connections occasionally

Clean fuel filter element every 250 hours

Clean and regap every 300 hours of operation or replace as needed

Clean each season or as needed

How To

See Storing, Transporting, or Shipping, page 5

Lift out of fuel tank and rinse with clean

kerosene

See Fuel Filters, page 12

See Fuel Lines, Page 12

See Fuel Filters, page 12

See Spark Plug, page 10

See Fan Blades and Air Deflectors, page 10

Air passages around burner head

Motor

Check each season for dirt and debris

Not required, permanently lubricated

Remove debris and trash with a clean, soft

cloth

6

106029

OWNER’S MANUAL

TROUBLESHOOTING

Note:

For additional help, visit DESA

International’s Technical Service web

site at www.desatech.com.

OBSERVED PROBLEM

Motor does not start when heater is plugged

in and thermostat setting is higher than

surrounding air temperature

WARNING: Never service heater while it is plugged in, operating, or

hot. Severe burns and electrical shock can occur. Only a qualified service

person should service and repair heater.

POSSIBLE CAUSE REMEDY

1. No power or low voltage at heater due to:

A) Damaged power cord or extension

cord

B) Wrong size extension cord

C) Heater plugged into outlet with voltage lower than 120 volt

2. Loose electrical connections

3. Motor overload protector tripped due to:

A) Dirty fan

B) Debris pulled into fan area by fan

C) Binding pump

D) Low voltage

1. A) Check condition of power cord or

extension cord. Repair or replace if damaged

B) Use extension cord with proper wire

size (see To Start Heater, page 5)

C) Make sure heater is plugged into 120

volt/60 hertz outlet

2. Check connections. Tighten if loose

3. A) See Fan Blades and Air Deflectors,

page 10

B) Remove debris from fan and fan

guard area

C) Turn fan by hand. If fan is hard to

turn, see Pump, page 11

D) See steps B and C under item 1 above

Note:

Be sure to reset motor overload

protector by pressing reset button on top

of motor

4. Flame-out control not reset

5. Damaged flame-out control

6. Damaged power relay

7. Damaged thermostat

8. Binding pump

4. Press and release flame-out control reset button. See Figure 4, page 5 for button location

5. Replace flame-out control

6. Replace power relay

7. Replace thermostat

8. Turn fan by hand. If fan is hard to turn,

see Pump, page 11

106029

www.desatech.com

7

Continued

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

TROUBLESHOOTING

Continued

OBSERVED PROBLEM

Heater will not ignite, but motor runs for a

short period of time.

POSSIBLE CAUSE REMEDY

1. A) Fuel tank empty

B) Water in fuel

C) Wrong fuel

2. Dirt in nozzle

3. Very low temperature may cause fuel to

thicken and not flow

4. Dirty fuel filters

5. Wrong pump pressure

6. Spark plug wire disconnected from plug

7. Spark plug problems due to:

A) Wrong gap

B) Plug wet with fuel

C) Carbon deposits on plug

D) Damaged plug

1. A) Add fuel to tank

B) Check fuel tank for bubbles of water

in bottom. If found, remove fuel (see

Storing, Transporting, or Shipping, page

5). Clean tank and fuel filters (see Fuel

Filters, page 12). Fill with clean fuel

C) Remove wrong fuel (see Storing,

Transporting, or Shipping, page 5).

Clean tank and fuel filters (see Fuel Fil-

ters, page 12). Fill with correct fuel

2. Replace nozzle (see Nozzle, page 10)

3. Move heater to warmer place until fuel

flows freely

4. Clean fuel filters (see Fuel Filters, page 12)

5. Adjust pump pressure (see Pump Pres-

sure Adjustment, page 11)

6. Connect spark plug wire to spark plug

7. A) Adjust electrode gap to .075" (see

Spark Plug, page 10)

B) Clean fuel from spark plug with

clean, soft cloth

C) Replace plug if heavily coated with

carbon (see Spark Plug, page 10)

D) Inspect plug for worn or eroded electrodes. If found, replace plug (see Spark

Plug, page 10)

8. Solenoid valve not opening

9. Damaged electronic ignitor

www.desatech.com

8

8. Check electrical connections and voltage to solenoid. If good, replace solenoid valve

WARNING: High Voltage!

9. Replace electronic ignitor

106029

TROUBLESHOOTING

Continued

OWNER’S MANUAL

OBSERVED PROBLEM

Heater ignites, but flame-out control shuts

off heater after a short period of time

Heater burns, but puffs of smoke can be seen

Heater does not burn steady

Heater burns with odor

Heater smokes continuously

POSSIBLE CAUSE REMEDY

1. Wrong pump pressure

2. Dirty fuel filters

3. Dirt in nozzle

4. Dirty photocell lens

5. Open or damaged photocell

6. Bad flame-out control

7. Damaged fan switch

1. Wrong pump pressure

2. A) Heater almost out of fuel

B) Water condensation in fuel tank

C) Wrong fuel

1. Adjust pump pressure (see Pump Pres-

sure Adjustment, page 11)

2. Clean fuel filters (see Fuel Filters, page 12)

3. Replace nozzle (see Nozzle, page 10)

4. Clean photocell lens with clean cotton swab

5. Replace photocell

6. Replace flame-out control

7. Replace fan switch

1. Adjust pump pressure ( see Pump Pres-

sure Adjustment, page 11)

2. A) Add fuel to tank

B) Check fuel tank for bubbles of water

in bottom. If found, remove fuel (see

Storing, Transporting, or Shipping, page

5). Clean tank and fuel filters (see Fuel

Filters, page 12). Fill with clean fuel

C) Remove wrong fuel (see Storing,

Transporting, or Shipping, page 5).

Clean tank and fuel filters (see Fuel Fil-

ters, page 12. Fill with correct fuel

106029

3. Dirty fuel filters

4. Air leak in suction system

5. Dirty nozzle

6. Low voltage causing motor to operate

below rated speed

7. Loose fuel line

www.desatech.com

9

3. Clean fuel filters (see Fuel Filters, page 12)

4. Tighten all fuel line connections (see

Fuel Lines, page 12)

5. Replace nozzle (see Nozzle, page 10)

6. Check voltage at heater. Voltage at heater

should be not less than 90% of rated voltage (108V minimum for 120V heaters)

7. Check and tighten all fuel line connections (see Fuel Lines, page 12)

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

SERVICE

PROCEDURES

WARNING: Never service

heater while it is plugged in, operating, or hot. Severe burns and

electrical shock can occur. Only

a qualified service person should

service and repair heater.

Upper Shell Removal

1. Remove screws along each side and top

of heater using 5/16" nut-driver. These

screws attach upper and lower shells

together (see Figure 5).

2. Lift upper shell off.

Upper Shell

Figure 5 - Upper Shell Removal, 600,000

Btu/Hr Model

Fan Blades and Air Deflectors

1. Remove upper shell (see column 1).

2. Clean fan blades and air deflectors with

clean, soft cloth moistened with kerosene or solvent (see Figure 6).

3. Dry fan blades and air deflectors thoroughly.

4. Replace upper shell.

Air Deflector

Fan Blade

Figure 6 - Fan Blades and Air Deflectors

Spark Plug

1. Remove upper shell (see column 1).

2. Remove spark plug wire from spark

plug (see Figure 7).

3. Remove spark plug from burner head

using 13/16"

open-end wrench (see Figure 7).

4. Replace spark plug if damaged or

heavily coated with carbon.

5. Clean and regap spark plug electrodes

to .075 inch (see Figure 8).

6. Install spark plug in burner head.

7. Attach spark plug wire to spark plug.

8. Replace upper shell.

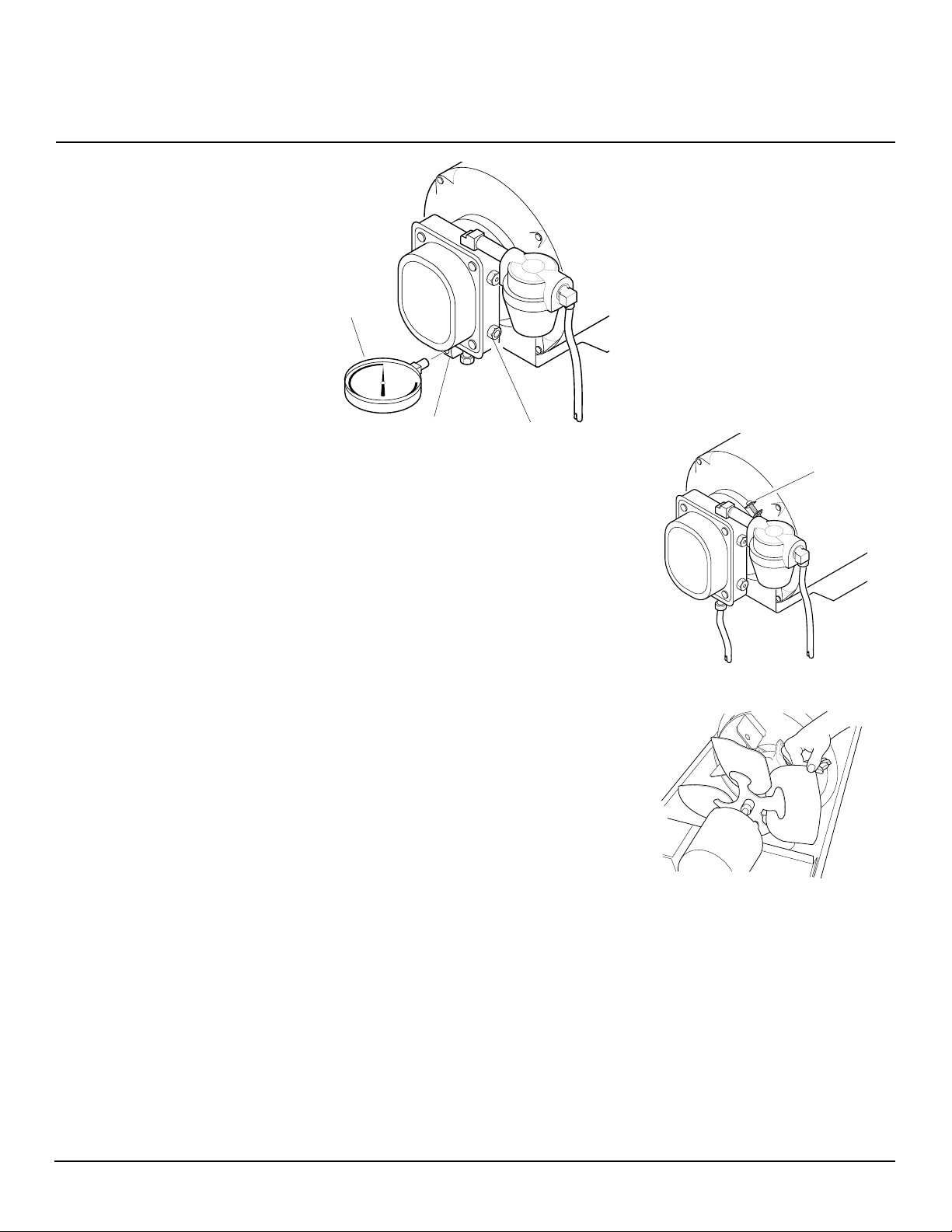

Burner Head

Spark Plug

Nozzle

1. Remove upper shell (see column 1).

2. Remove fuel line from solenoid valve

using 7/16" wrench.

3. Remove spark plug wire from spark

plug.

4. Remove spark plug from burner head

using 13/16" open-end wrench.

5. Remove five screws using

5/16" nut-driver and remove burner

head from combustion chamber.

6. Place burner head into vise and lightly

tighten.

7. Carefully remove nozzle from burner

head using 5/8" socket wrench (see Figure 9).

8. Inspect nozzle for damage. If damaged

or clogged, replace nozzle.

9. Make sure plug is in place on burner

head.

10. Replace nozzle into burner head and

tighten firmly (175-200 inch-pounds).

11. Attach burner head to combustion

chamber.

12. Install spark plug in burner head.

13. Attach spark plug wire to spark plug.

14. Attach fuel line to solenoid valve.

Tighten firmly.

15. Replace upper shell.

Nozzle

Plug

Burner

Head

Figure 9 - Replacing Nozzle

Fuel

Line

Spark

Plug

Spark

Plug

Wire

Solenoid

Valve

Spark

Plug Wire

Figure 7 - Spark Plug Removal

Figure 8 - Spark Plug Gap

10

.075

inch

106029

OWNER’S MANUAL

SERVICE

PROCEDURES

Continued

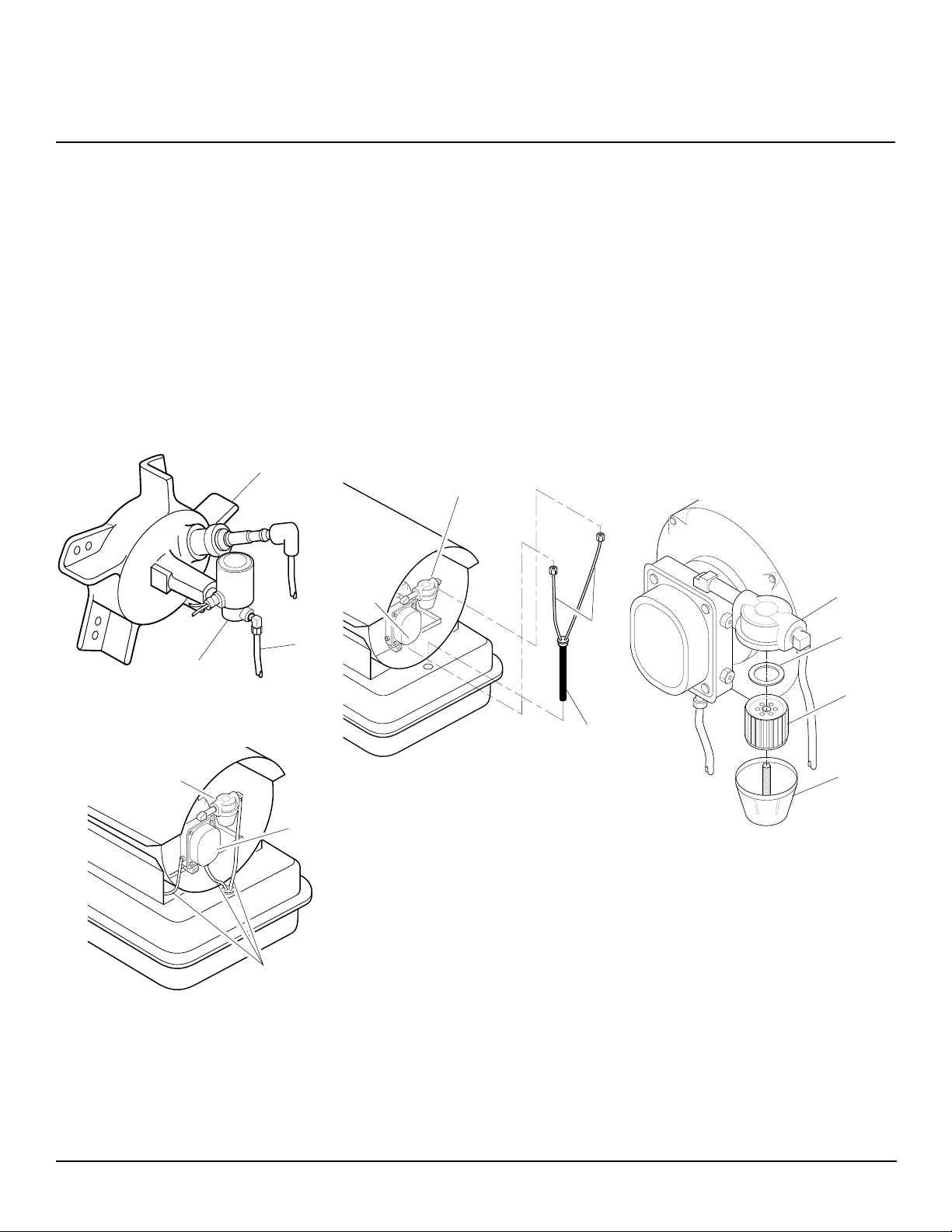

Pump Pressure Adjustment

1. Remove pressure gage plug from fuel

pump port marked “GAGE.”

2. Install accessory pressure gage (part

number M4574) to fuel pump port

marked “GAGE” (see Figure 10).

3. Start heater (see Operation, page 5).

Allow motor to reach full speed.

4. Adjust pressure. Use small flat blade

screwdriver to turn slotted screw at fuel

pump port marked “PRESS ADJ.” Turn

screw clockwise to increase pressure.

Turn screw counterclockwise to decrease pressure. See specifications at

right for correct pressure for each model.

5. Stop heater (see page 5).

6. Remove pressure gage. Replace pressure gage plug in fuel pump port

marked “GAGE.”

Pressure

Gage

psi

Fuel Pump Port

Marked “GAGE”

Model Pump Pressure

350,000 Btu/Hr 100 PSI

600,000 Btu/Hr 110 PSI

Figure 10 - Adjusting Pump Pressure

Fuel Pump Port

Marked “PRESS

ADJ”

Pump

(Procedure if Pump is Binding)

1. Remove upper shell (see page 10).

2. Loosen hex screw on flange clamp at

rear of motor with

5/16" nut-driver (see Figure 11).

3. Turn fan with hand (see Figure 12).

4. If fan turns freely, tighten screw on

flange clamp.

5. If fan does not turn freely, replace

pump.

6. Replace upper shell.

Hex Screw

On Flange

Clamp

Figure 11 - Location of Screw on Flange

Clamp

Figure 12 - Turning Fan with Hand

106029

Continued

11

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

SERVICE

PROCEDURES

Continued

Fuel Lines

(Procedure for tightening fuel lines)

1. Remove upper shell (see page 10).

2. Use an adjustable wrench as a backup

on 90° fittings.

3. Use 7/16" wrench and tighten fuel lines

at solenoid valve (see Figure 13), pump,

and pump fuel filter assembly (see Figure 14).

Burner Head

Fuel Filters

A. Tank Fuel Filter

1. Disconnect fuel lines from pump and

pump fuel filter assembly with 7/16"

wrench (see Figure 15).

2. Carefully pry fuel filter loose from fuel

tank with flat end of screwdriver.

3. Inspect fuel filter for water or dirt.

4. Rinse fuel filter and fuel lines with

clean kerosene.

5. Replace fuel filter into fuel tank.

6. Connect fuel lines to pump and pump

fuel filter assembly.

Pump Fuel

Filter

Assembly

B. Pump Fuel Filter

1. Unscrew canister bottom from canister top with adjustable pliers.

2. Remove fuel filter and gasket from canister bottom (see Figure 16).

3. Inspect canister bottom and fuel filter

for water droplets or dirt.

4. Rinse canister bottom in clean kerosene.

5. Wipe inside of canister bottom dry with

clean cloth.

6. Rinse fuel filter in clean kerosene.

7. Put clean fuel filter and gasket back in

canister bottom.

8. Screw canister bottom into canister top.

9. Tighten securely.

Canister Top

Fuel

Line

Solenoid

Valve

Figure 13 - Fuel Line at Solenoid Valve

Pump

Fuel Filter

Assembly

Pump

Fuel

Lines

Figure 14 - Fuel Lines at Pump and Pump

Fuel Filter Assembly

Fuel

Lines

Fuel Filter

Figure 15 - Removing Tank Fuel Filter

Gasket

Fuel Filter

Canister

Bottom

Figure 16 - Fuel Pump Filter and Canister

12

106029

OWNER’S MANUAL

SPECIFICATIONS

350,000 Btu/Hr 600,000 Btu/Hr

Output Rating (Btu/Hr) 350,000 600,000

Fuel Use Only Kerosene or No. 1 Fuel Oil

Fuel Tank Capacity (U.S. Gallons) 30 36

Fuel Consumption (Gallons Per Hr) 2.5 4

Electric Requirements 120V/60 Hz 120V/60 Hz

Amperage (Normal Run) 7.1 11

Motor RPM 1725 1725

Fuel Pump Pressure (PSI) 100 110

Spark Plug Gap .075" .075"

Weight (approx. lbs.) Dry 180 285

With Full Fuel Tank 390 550

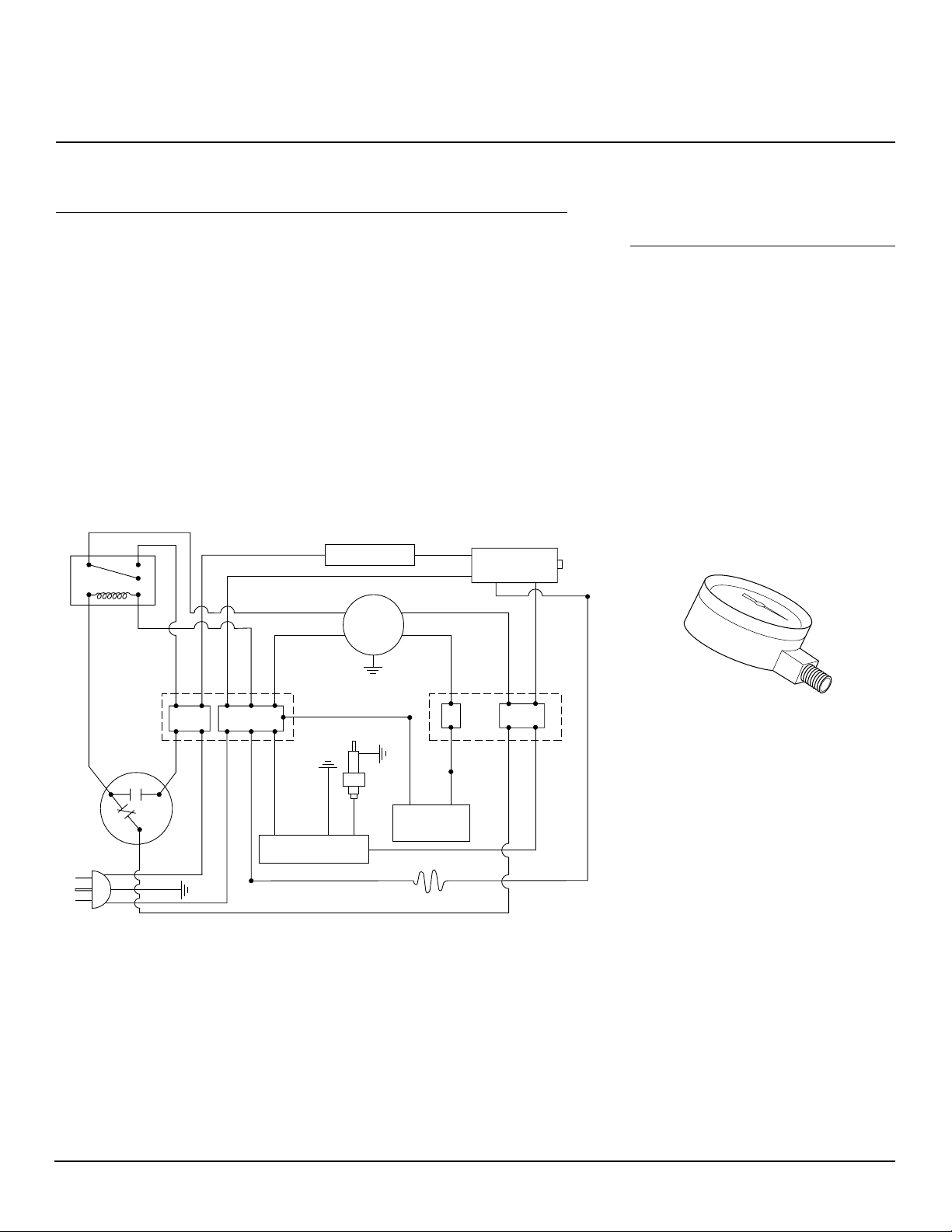

WIRING DIAGRAM

75

BA

RELAY

WHITE

BLACK

RED

BLACK

PLUG

120V

60Hz

132

BLACK

GREEN

WHITE

FAN

SWITCH

Figure 17 - Wiring Diagram

BLACK BLACK

RED ORANGE

WHITE

WHITE

ELECTRONIC

THERMOSTAT B

WHITE

WHITE

MOTOR

WHITE

SPARK

PLUG

WHITE

TERMINAL

BOARD

IGNITOR

ORANGE

TERMINAL

BOARD

SOLENOID

VALVE

PHOTOCELL

WHITE

FLAME-OUT

YELLOW

YELLOW

YELLOW

BLUE

CONTROL

R

RED

RED

RESET

BUTTON

BLUE

MAINTENANCE

KITS

Kit Part Number

Flame-Out Control HA3003

Spark Plug HA3012

ACCESSORY

Purchase this heater accessory from your

nearest dealer or service center. If they cannot supply this accessory, either contact

your nearest Parts Central or DESA

International's Parts Department at 1-800972-7879 for information. Parts Centrals

are listed in the Authorized Service Center

booklet supplied with heater. You can also

write to the address listed on the back page

of this manual.

FUEL PRESSURE GAGE M4574

Special tool to check fuel pump pressure

TECHNICAL

SERVICE

You may have further questions about installation, operation, or troubleshooting.

If so, contact DESA International’s Technical Service Department at 1-800-323-5190.

You can also visit DESA International’s

Technical Services web site at

www.desatech.com.

106029

13

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

ILLUSTRATED

PARTS

BREAKDOWN

SB350D

350,000 BTU/HR

1

2

3

2

4

5

21

2

6

7

8

9

20

25

31

21

32

34

19

26

27

33

28

22

13

29

10

4

13

11

23

30

20

34

2

39

12

16

24

14

15

17

18

41

36

35

37

37

38

14

2

4

40

106029

OWNER’S MANUAL

PARTS LIST

SB350D

350,000 BTU/HR

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions listed

under Repair Service on the back page of this manual.

REF.

NO. PART NO. DESCRIPTION QTY.

1 099329-02 Upper shell model SB350D (Yellow) 1

2 M11084-27 Screw, #10-16 x 1/2" 15

3 M50542-01 Combustion chamber & shield 1

4 M30865-02 Bushing 7

5 M50086 Air deflector 5

6 † Burner head assembly 1

7 M16656-18 Photocell assembly 1

8 M50121 Fan 1

9 M50097-01AA Fan guard 1

10 M51336-02 Fan switch 1

11 M51160-01 Fan switch cover 1

12 M50278 Sleeve 1

13 M11084-26 Screw, #10-16 x 3/8" 13

14 † Motor & pump assembly 1

15 099896-01 Power cord 1

16 M50295 Fuel line 1

17 M50050 Ignition boot 1

18 102482-04 Electronic Ignitor 1

19 099329-01 Lower shell model SB350D (Yellow) 1

20 M11271-8 Clip nut 16

21 M11084-3 Screw, #12-14 x 1/2" 14

22 M50104-02 Bushing 2

23 099509-01 Wire harness 1

24 M50115-01 Fuel line assembly 1

25 M50062-03 Front handle 1

26 097702-01 Fuel cap 1

27 HA2210 Filler neck screen 1

28 HC4-18C Screw, 1/4-20 x 2 1/4"6

29 M51043-01 Screw, 1/4-20 x 1 1/2"2

30 M50062 Rear handle 1

31 098513-05 Fuel tank 1

32 M50063 Wheel support frame 1

33 M18774 Axle 1

34 NTC-4C Hex lock nut, 1/4-20 8

35 M50389 Wheel 2

36 C5-10C Cotter pin, 5/32 x 1 1/4"2

37 WP-10C Flatwasher, 5/8" 4

38 M50296 Wheel spacer 2

39 M27417 Drain plug 1

40 099895-01 Thermostat 1

41 M11084-29 Screw, #10-16 x 3/4" 2

106029

†Not available as complete assembly. See page 18.

15

HIGH PRESSURE PORTABLE FORCED AIR

1

2

2

3

4

5

13

6

7

45

46

8

9

10

11

13

14

21

18

17

15

16

23

22

24

25

33

2

4

28

30

26

27

34

25

16

2

35

36

41

42

15

43

43

44

39

38

37

15

29

12

40

2

19

20

2

4

31

32

47

HEATER 350,000 AND 600,000 BTU/HR

ILLUSTRATED

PARTS

BREAKDOWN

SB600D

600,000 BTU/HR

16

106029

OWNER’S MANUAL

PARTS LIST

SB600D

600,000 BTU/HR

This list contains replaceable parts used in

your heater. When ordering parts, follow

the instructions listed under Repair Service

on the back page of this manual.

REF.

NO. PART NO. DESCRIPTION QTY.

1 099329-04 Upper shell model SB600D (Yellow) 1

2 M11084-27 Screw, #10-16 x 1/2" 28

3 M50543-01 Combustion chamber & shield 1

4 M30865-02 Bushing 5

5 M50157 Air deflector 5

6 † Burner head assembly 1

7 104679-01 Photocell assembly 1

8 M50194 Fan 1

9 M50186-01AA Fan guard 1

10 M51336-02 Fan switch 1

11 M51160-01 Fan switch cover 1

12 M50278 Sleeve 1

13 M11084-26 Screw, #10-16 x 3/8" 15

14 † Motor & pump assembly 1

15 NTC-4C Hex nut, 1/4-20 18

16 M11271-8 Clip nut 18

17 M11084-3 Screw, #12-14 x 1/2" 4

18 M50104-02 Bushing 2

19 099329-03 Lower shell model SB600D (Yellow) 1

20 M50119-01 Fuel line 1

21 099896-01 Power cord 1

22 M50388AB Support bracket model SB600D (Yellow) 2

23 HC4-3C Screw, 1/4-20 x 3/8" 4

24 M50224 Front handle 1

25 M51043-01 Screw, 1/4-20 x 1 1/2"6

26 097702-01 Fuel cap 1

27 HA2210 Filler neck screen 1

28 099509-02 Wire harness 1

29 M28872-01 Rear handle 1

30 M50115-02 Fuel line assembly 1

31 M50050 Ignition boot 1

32 102482-04 Electronic Ignitor 1

33 098513-07 Fuel tank 1

34 HC4-22C Screw, 1/4-20 x 2 3/4"8

35 M28140-02 Wheel support frame 1

36 M18774 Axle 1

37 M27417 Drain plug 1

38 RC1-3C Screw, #6-32 x 3/8" 2

39 099895-01 Thermostat 1

40 M25121B Thermostat bracket (Black) 1

41 M50389 Wheel 2

42 C5-10C Cotter pin, 5/32 x 1 1/4"2

43 WP-10C Flatwasher, 5/8" 4

44 M50296 Wheel spacer 2

45 104413-01 Photocell Bracket 1

46 M10908-2 Screw, #6-32 x 3/8" 2

47 M11084-29 Screw, #10-16 x 3/4" 2

** Internal lockwasher No. 6 2

NPC-1C Nut, 6-32 2

106029

† Not available as complete assembly. See page 18.

Not shown.

** Standard hardware item

17

HIGH PRESSURE PORTABLE FORCED AIR

HEATER 350,000 AND 600,000 BTU/HR

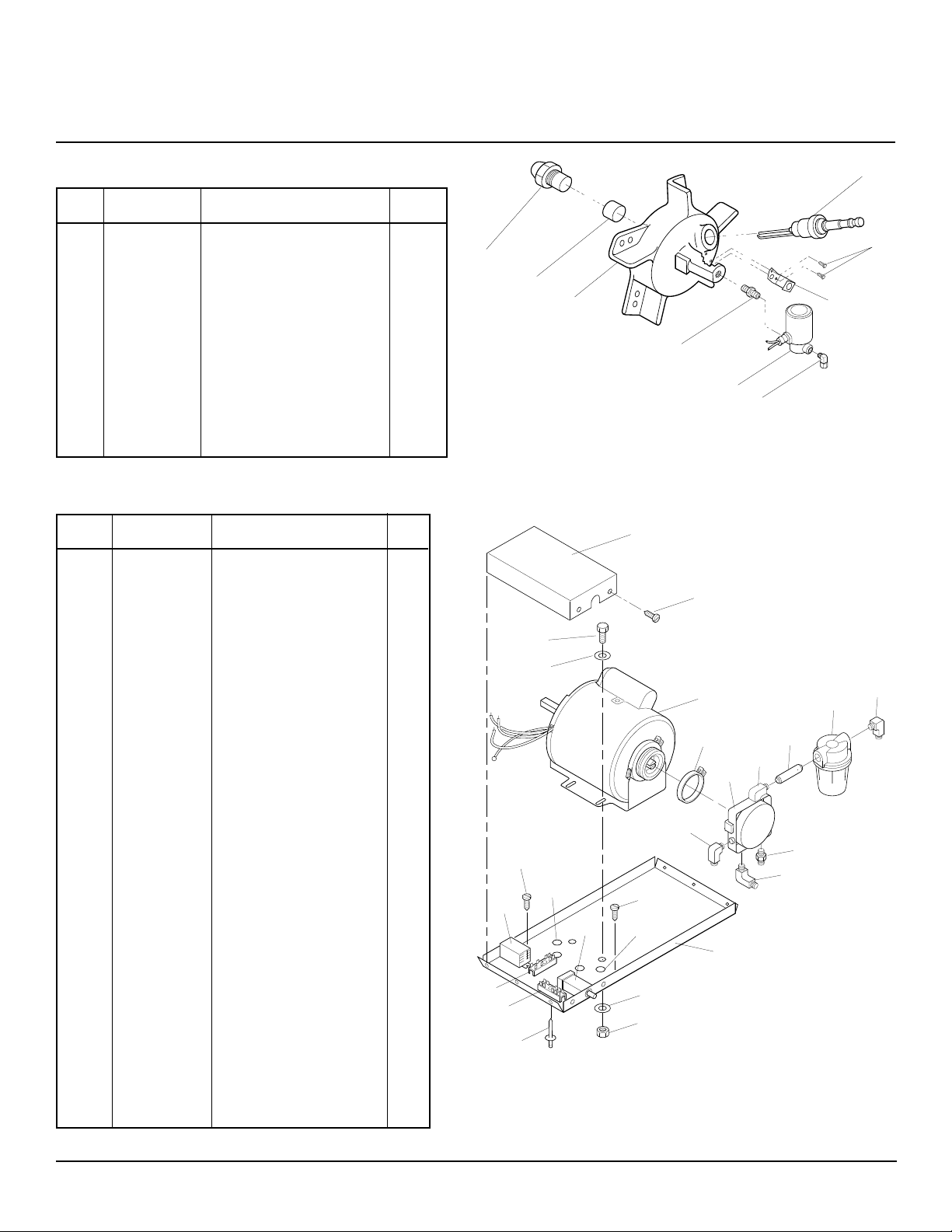

Burner Head Assembly 350,000 and 600,000 Btu/Hr

REF

NO. PART NO. DESCRIPTION QTY.

1 M10908-2 Screw, #6-32 x 3/8"

(350,000 Btu/Hr Only) 2

2 099229-01 Photocell bracket

(350,000 Btu/Hr Only) 1

3 HA3012 Spark plug 1

4 M50112 Nozzle (350,000 Btu/Hr) 1

M30765 Nozzle (600,000 Btu/Hr) 1

5 M51170-01 Plug 1

6 M50924-02 Burner head body 1

7 69246 Straight nipple 1

8 M50077 Solenoid valve 1

9 M50297 Compression elbow 1

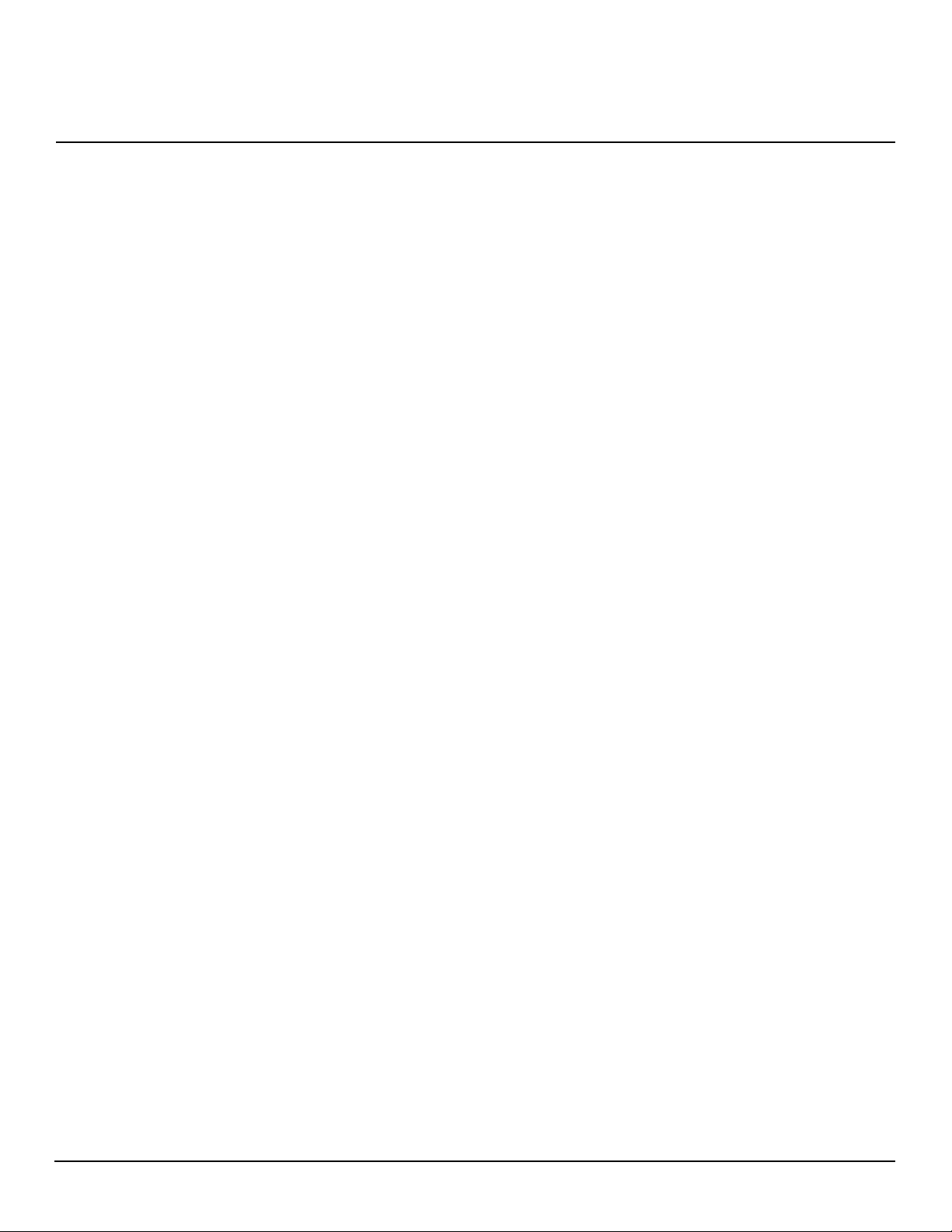

Motor and Pump Assembly 350,000 and 600,000 Btu/Hr

REF.

NO. PART NO. DESCRIPTION QTY.

1 097495-02AA Wiring cover 1

2 HF5-5C Screw, 5/16-24 x 5/16" 4

3 WLE-5 External lockwasher, 5/16" 4

4 M11084-26 Screw, #10-16 x 3/8" 3

5 099562-01 Motor (350,000 Btu/Hr) 1

099562-02 Motor (600,000 Btu/Hr) 1

6 M50116 Flange clamp

(holds pump to motor) 1

7 099520-01AA Motor support

(350,000 Btu/Hr) 1

101552-01 Motor support

(600,000 Btu/Hr) 1

8 57413 Street elbow 2

9 M17499-2 Pipe nipple 1

10 098102-01 Fuel filter assembly 1

098103-01 Filter element

(inside fuel filter

assembly, includes

rubber gaskets) 1

11 M50114-02 90˚ Male elbow 1

12 M50297 Compression elbow 1

13 M50113-02 Straight fitting 1

14 098560-01 Fuel pump 1

15 ** Lockwasher, 5/16" 4

16 NPF-5C Hex nut, 5/16-24" 4

17 HA3003 Flame-out control 1

18 097491-01 Power relay 1

19 101547-01 Snap bushing 3

20 M10908-2 Screw, #6-32 x 3/8" 2

21 101504-01 Strain relief bushing 1

22 M10908-14 Screw, #8-32 x 3/8" 1

23 099125-05 Terminal board 1

24 099125-04 Terminal board 1

25 099157-01 Rivet 2

4

5

6

7

Figure 18 - Burner Head Assembly

1

4

2

3

5

6

12

20

19

(3)

18

17

24

23

25

(2)

22

21

7

15

16

Figure 19 - Motor And Pump Assembly

3

1

2

8

9

11

10

9

8

14

13

8

** Standard hardware item

18

106029

OWNER’S MANUAL

NOTES

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

106029

19

WARRANTY AND REPAIR SERVICE

LIMITED WARRANTY

DESA International warrants this product and any parts

thereof, to be free from defects in materials and workmanship for one (1) year from the date of first purchase when

operated and maintained in accordance with instructions.

This warranty is extended only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse,

abuse, negligence, accidents, lack of proper maintenance,

normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts, or repair by anyone

other than an authorized dealer or service center. Routine

maintenance is the responsibility of the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF

ANY OTHER WARRANTY EITHER EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

DESA International assumes no responsibility for indirect,

incidental or consequential damages. Some states do not

allow the exclusion or limitation of incidental or consequential damages, or limitations or exclusions may not apply to

you. This Limited Warranty gives you specific legal rights

and you may also have other rights which vary from state to

state.

PARTS AND SERVICE UNDER WARRANTY

Should your heater require service, return it to your nearest

authorized service center. Proof of purchase must be presented

with the heater. The heater will be inspected. A defect may be

caused by faulty materials or workmanship. If so, DESA International will repair or replace the heater without charge. If they

cannot supply original replacement part(s), either contact your

nearest Parts Central or call DESA International’s Technical

Service Department at 1-800-323-5190.

When calling DESA International, have ready

• your name

• your address

• model and serial numbers of your heater

• how heater was malfunctioning

• proof of purchase

Usually, we will ask you to return the defective part to the factory.

PARTS AND REPAIR SERVICE

Return your heater to your nearest authorized service center.

Repairs not covered by the warranty will be billed at standard

prices. If they cannot supply original replacement part(s), either

contact your nearest Parts Central or call DESA International’s

Parts Department at 1-800-972-7879 for information.

When calling DESA International, have ready

• model number of your heater

• the replacement part number

A service manual may be purchased from the address listed

below. Send a check for $5.00 payable to DESA International.

When writing for information regarding your heater, be sure to include

the model number and serial number as shown on the model plate.

Each service center is independently owned and operated.

We reserve the right to amend these specifications at any time

without notice.

KEEP THIS WARRANTY

Model No. _______________________________

Serial No. _______________________________

Date of Purchase _________________________

(To be filled in by purchaser)

INTERNATIONAL

Corporate Headquarters

2701 Industrial Drive

P.O. Box 90004

Bowling Green, Kentucky 42102-9004

www.desatech.com

For information, write: DESA International, P.O. Box 90004

Bowling Green, Kentucky 42102-9004 ATTN: Customer Service Department

When writing, always include Model number and Serial number.

106029 01

NOT A UPC

106029-01

Rev. A

06/99

Loading...

Loading...