Page 1

CANADIAN PROPANE CONSTRUCTION FORCED AIR HEATER

OWNER’S MANUAL

MODEL RCLP100V

VARIABLE 65,000, 85,000, AND 100,000 BTU/HR

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide

poisoning and/or electrical shock.

Only persons who can understand and follow the instructions should use or service this heater.

If you need assistance or heater information such as an instructions manual, labels, etc. contact the manufacturer.

TABLE OF CONTENTS

Safety Information ............................................... 2

Unpacking ........................................................... 3

Product Identification ........................................... 3

Propane Supply ................................................... 3

Theory of Operation ............................................ 4

Ventilation ............................................................

Installation ........................................................... 4

Operation ............................................................. 5

Storage ................................................................ 6

Maintenance ........................................................ 6

Save this manual for future reference.

For more information, visit www.desatech.com

Service Procedures ............................................. 6

Troubleshooting ...................................................

Illustrated Parts Breakdown and Parts List ....... 10

Specifications ....................................................

Technical Service ..............................................

4

Replacement Parts ............................................ 12

Accessory .......................................................... 12

Wiring Diagram .................................................. 13

Warranty and Repair Service ............................

9

12

12

14

Page 2

SAFETY INFORMATION

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

WARNING: Fire, burn, inhalation and explosion hazard.

Keep solid combustibles, such

as building materials, paper or

cardboard, a safe distance away

from the heater as recommended by the instructions. Never

use the heater in spaces which

do or may contain volatile or

airborne combustibles or prod

ucts such as gasoline, solvents,

paint thinner, dust particles or

unknown chemicals.

WARNING: Not for home or

recreational vehicle use.

The heater is designed for use as a construction

heater in accordance with ANSI Z83.7/CGA

2.14. Other standards govern the use of fuel

gases and heating products for specific uses.

Your local authority can advise you about these.

The primary purpose of construction heaters is

to provide temporary heating of buildings under

construction, alteration or repair. Properly used,

the heater provides safe economical heating.

Products of combustion are vented into the area

being heated.

We cannot foresee every use which may be made of

our heaters. Check with your local fire safety au

thority if you have questions about heater use.

Other standards govern the use of fuel gases and

heat producing products for specific uses. Your

local authorities can advise you about these.

Carbon Monoxide Poisoning: Some people are

more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness, and/or

nausea. If you have these signs, the heater may not

be working properly. Get fresh air at once! Check

for proper ventilation and have heater serviced.

-

www.desatech.com

Propane Gas: Propane gas is odorless. An odor-

making agent is added to propane gas. The odor

helps you detect a propane gas leak. However, the

odor added to propane gas can fade. Propane gas

may be present even though no odor exists.

Make certain you read and understand all warn

ings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

1. Install and use heater with care. Follow all

local ordinances and codes. In the absence

of local ordinances and codes, refer to the

Standard for Storage and Handling of Liq

uefied Petroleum Gas, ANSI/NFPA 58 and

the Propane Installation Code, CAN/CGA

B149.2. This instructs on the safe storage and

handling of propane gases.

2. Use only the electrical voltage and frequency

specified on model plate. The electrical con

nections and grounding of the heater shall fol

low the National Electric Code, ANSI/NFPA

70 or the Canadian Electrical Code, Part 1.

3. Electrical grounding instructions — This

appliance is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong recep

tacle or extension cord.

4. Use only the hose and factory preset regulator

provided with the heater.

5. Use only propane gas set up for vapor with

drawal.

6. Provide adequate ventilation. Before using

heater, provide at least a 3 ft

of fresh, outside air for each 100,000 Btu/Hr

of rating.

7. For indoor use only. Do not use heater out

doors.

8. Do not use heater in occupied dwellings or in

living or sleeping quarters.

9. Do not use heater in basement or below ground

level. Propane gas is heavier than air. If a leak

occurs, propane gas will sink to the lowest

-

possible level.

10. Keep appliance area clear and free from com

bustible materials, gasoline, paint thinner, and

other flammable vapors and liquids. Dust is

combustible. Do not use heater in areas with

high dust content.

11. Minimum heater clearances from combustible

materials: Outlet: 8 Ft. (2.40 m), Sides: 2 Ft. (60

cm), Top: 6 Ft. (1.80 m), Rear: 2 Ft. (60 cm)

12. Keep heater at least 6 ft. (1.80 m) from pro

pane tank(s). Do not point heater at propane

tank(s) within 20 ft. (6 m).

2

(2.7 m2) opening

103908-01E2

-

-

-

-

-

-

-

-

-

Page 3

SAFETY INFORMATION

Continued

13. Keep propane tank(s) below 100° F (38˚ C).

14. Check heater for damage before each use. Do

not use a damaged heater.

15. Check hose before each use of heater. If highly

worn or cut, replace with hose specified by

manufacturer before using heater.

16. Locate heater on stable and level surface if

heater is hot or operating.

17. Never block air inlet (rear) or air outlet (front)

of heater.

18. Keep heater away from strong drafts, wind,

water spray, rain, or dripping water.

19. Keep child ren and animals away from

heater.

20. Never move, handle, or service a hot or operat

ing heater. Severe burns may result. You must

wait 15 minutes after turning heater off.

21. To prevent injury, wear gloves when handling

heater.

22. Never attach duct work to heater.

23. Do not alter heater. Keep heater in its original

state.

24. Do not use heater if altered.

25. Turn off propane supply to heater and unplug

when not in use.

26. Use only original replacement parts. This

heater must use design-specific parts. Do

not substitute or use generic parts. Improper

replacement parts could cause serious or fatal

injuries.

UNPACKING

1. Remove all packing items applied to heater for

shipment. Keep plastic cover caps (attached to

inlet connector and hose/regulator assembly)

for storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater

is damaged, promptly inform dealer where you

bought heater.

103908-01E 3

www.desatech.com

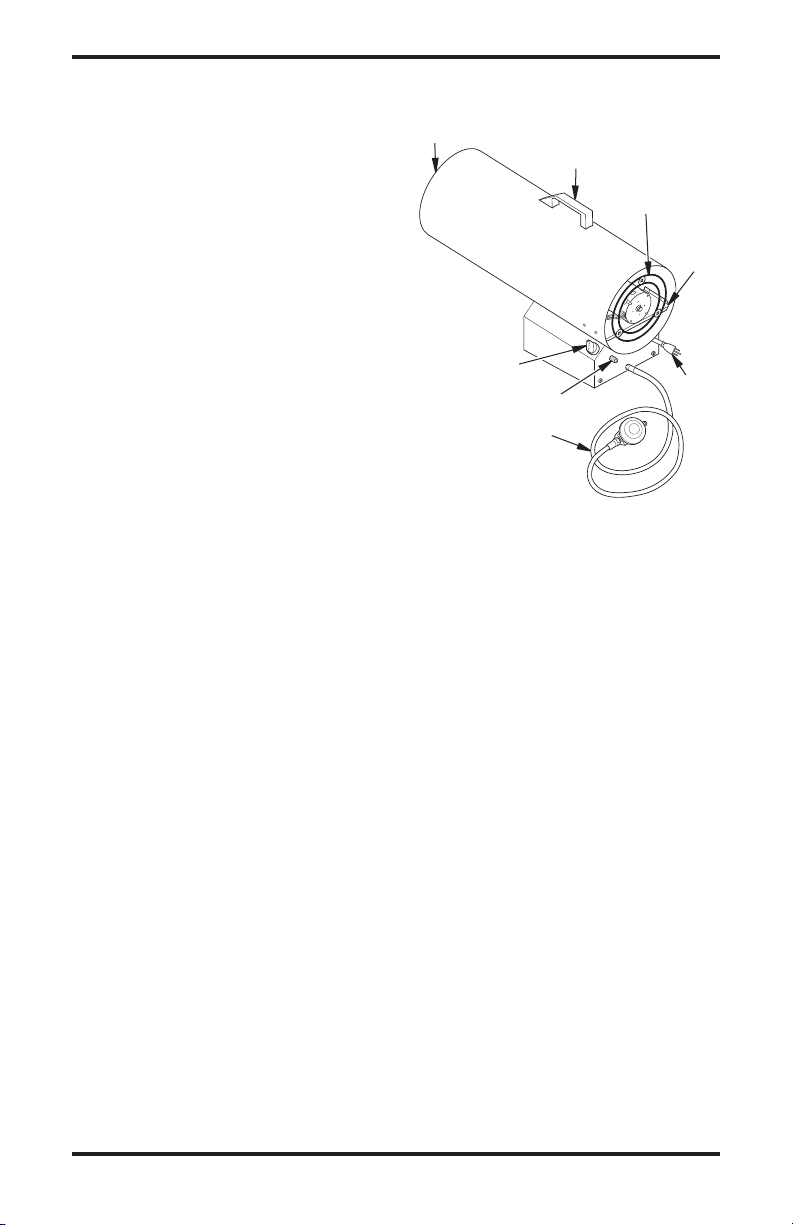

Hot Air Outlet (Front)

Control Knob

-

Hose /Regulator

Assembly

Propane gas and propane tank(s) are to be furnished by the user.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5 of the

Standard for Storage and Handling of Liquefied

Petroleum Gas, ANSI/NFPA 58 and the Propane

Installation Code CAN/CGA B149.2. Your local

library or fire department will have this booklet.

The amount of propane gas ready for use from

propane tanks varies. Two factors decide this

amount:

1. The amount of propane gas in tank(s)

2. The temperature of tank(s)

The chart below shows the number of 100 lb. (45

kg) pound tanks needed to run this heater.

Average Temperature Number Of Tanks

At Tank (100 lb/45 kg)

Above 20° F (-6.7° C) 2

20° F (-6.7° C) to 0° F (-18° C) 3

Below 0° F (-18° C) Use larger tank

Less gas is vaporized at lower temperatures. You

may need two or more 100 lb. (45 kg) tanks or one

larger tank in colder weather. Your local propane

gas dealer will help you select the proper supply

system. The minimum surrounding air temperature

rating for each heater is -20° F (-29° C).

Smaller tanks can be used for limited run times

but it is recommended to use larger tanks for

optimum performance.

PRODUCT

IDENTIFICATION

Handle

Fan Guard

Inlet Connector

Figure 1 - 100,000 Btu/hr Model

PROPANE SUPPLY

Motor

Mount

Power

Cord

Page 4

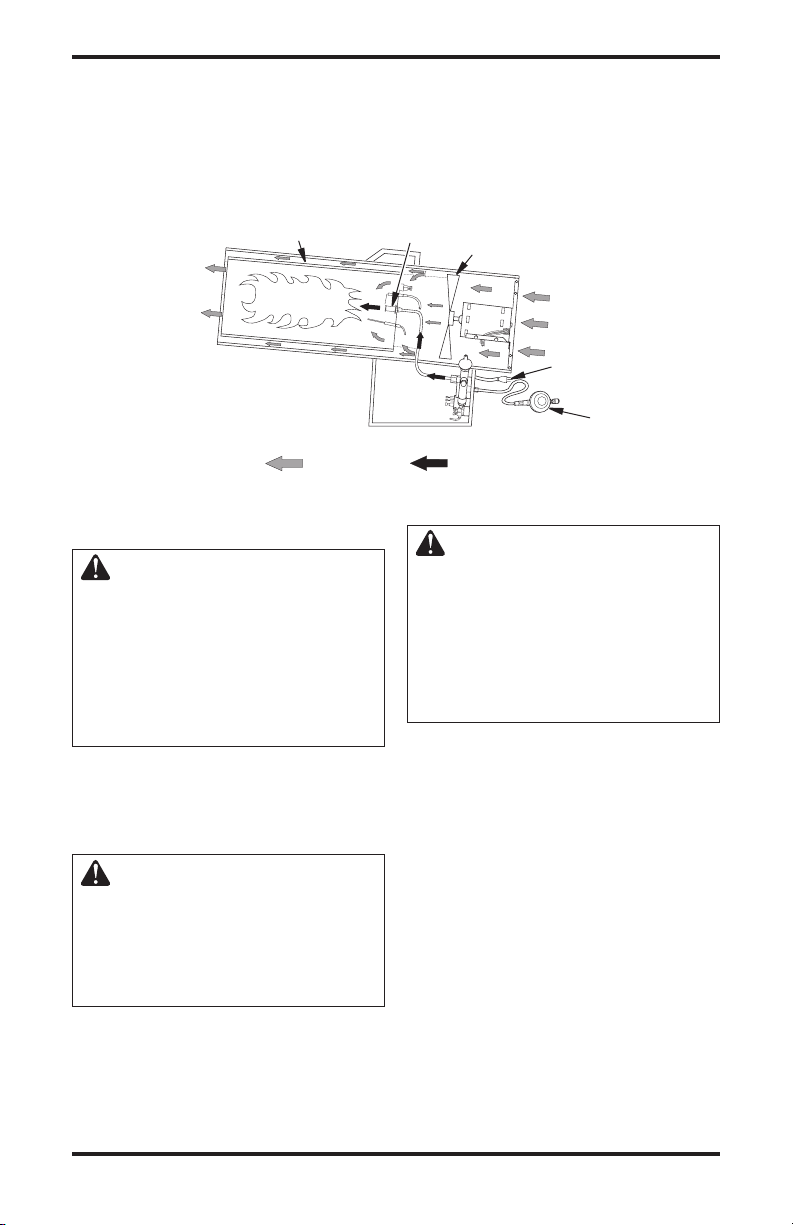

Air For Combustion

And Heating

Fuel

THEORY OF OPERATION

The Fuel System: The hose/regulator assembly attaches to the propane gas supply. The propane gas

moves through the automatic control valve and out the nozzle.

The Air System: The motor turns the fan. The fan pushes air into and around the combustion chamber.

This air is heated and provides a stream of clean, hot air.

The Ignition System: The spark transformer ignitor lights the main burner.

The Safety Control System: This system causes the heater to shut down if the flame goes out.

Combustion Chamber

Clean

Heated

Air Out

(Front)

Nozzle

Fan

Cool

Air In

(Back)

Power Cord

Note: Some parts are located

differently on some models.

Figure 2 - Cross Section Operational View

Air for

Combustion

and Heating

VENTILATION

WARNING: Follow the minimum fresh, outside air ventilation requirements. If proper

fresh, outside air ventilation is

not provided, carbon monoxide

poisoning can occur. Provide

proper fresh, outside air ventilation before running heater.

Provide a fresh air opening of at least 3 ft2 (0.28 m2)

for each 100,000 Btu/Hr rating. Provide extra fresh

air if more heaters are being used.

INSTALLATION

WARNING: Review and understand the warnings in the

Safety Information section, page

2. They are needed to safely operate this heater. Follow all local

codes when using this heater.

Hose/Regulator

Assembly

Fuel

WARNING: Test all gas piping

and connections for leaks after

installation or servicing. Never

use an open flame to check for

a leak. Apply a mixture of liquid

soap and water to all joints.

Bubbles forming show a leak.

Correct all leaks at once.

1. Provide propane supply system (see Propane

Supply, page 3).

2. Connect fuel gas connector fitting on hose/

regulator assembly to propane tank(s). Turn

counterclockwise into threads on tank valve.

Tighten firmly using wrench. IMPORTANT:

Tighten regulator with vent pointing down.

Pointing vent down protects regulator from

weather damage.

3. Connect hose to inlet connector. Tighten

firmly using a wrench. IMPORTANT: Extra

hose or piping may be used if needed. Install

extra hose or piping between hose/regulator

assembly and propane tank. You must use the

regulator supplied with heater.

4. Open propane supply valve on propane tank(s)

slowly.

Note: If not opened slowly, excessflow check valve on propane tank will stop

gas flow. If this happens, close propane supply

valve and open again slowly.

www.desatech.com

103908-01E4

Page 5

INSTALLATION

Continued

5. Check all connections for leaks.

6. Close propane supply valve.

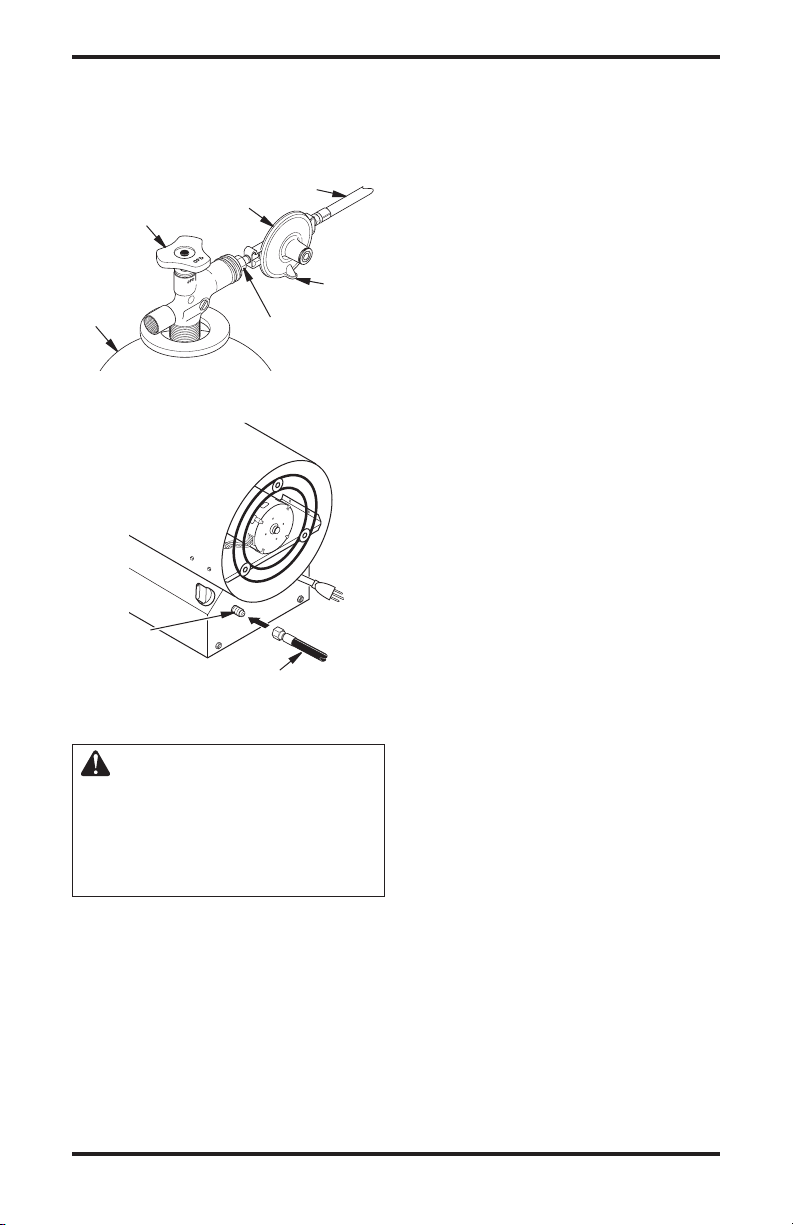

Supply Valve

Regulator

Propane

Tank

Figure 3 - Regulator With Vent Pointing

Down

100,000 Btu/Hr

Model Shown

Inlet

Connector

Figure 4 - Hose and Inlet Connector

Hose

Vent

(pointing

down)

Fuel Gas

Connector

Hose

OPERATION

WARNING: Review and understand the warnings in the

Safety Information section, page

2. They are needed to safely op

erate this heater. Follow all local

codes when using this heater.

TO START HEATER

1. Follow all installation, ventilation and safety

information.

2. Locate heater on stable and level surface.

Make sure strong drafts do not blow into front

or rear of heater.

3. Make sure the control knob is in the OFF

position.

-

4. Plug power cord of heater into a three-prong,

grounded extension cord. Extension cord must

be at least 6 ft. (2 m) long, UL/CSA listed, and

of a proper size.

Extension Cord Size Requirement

Up to 100 ft. (30 m) long, use 16 AWG rated

cord.

101 to 200 ft. (31 to 60 m) long, use 14 AWG

rated cord.

5. Plug extension cord into a 120 volt/60 hertz,

3-hole, grounded outlet. Motor will start. Fan

will turn, forcing air out front of heater.

6. Open propane supply valve on propane tank(s)

slowly.

Note: If not opened slowly, excessflow check valve on propane tank will stop

gas flow. If this happens, close propane supply

valve and open again slowly.

7. Press and hold in control knob. Turn counter

clockwise to the LOW position. Heater should

ignite within a few seconds.

Note: If heater fails to ignite, hose may have

air in it. If so, keep automatic control valve

button pressed and wait 20 seconds. Release

automatic control valve button and wait 20

seconds for unburned fuel to exit heater.

Repeat step 7.

8. After heater ignites, wait 30 seconds then

release the control knob. This activates the

automatic control system.

9. When burner remains lit, set heater at the

desired heat level by turning the control valve

counterclockwise. If burner goes out, turn off

gas. Turn control knob fully clockwise to the

lowest position. Check fuel supply. If adequate

fuel is available, restart heater beginning at

step #1.

TO STOP HEATER

1. Tightly close propane supply valve on propane

tank(s).

2. Wait a few seconds. Heater will burn gas left

in supply hoses.

3. Turn control knob to the OFF position.

4. Unplug heater.

-

103908-01E 5

www.desatech.com

Page 6

STORAGE

CAUTION: Disconnect heater

from propane supply tank(s).

1. Store propane tank(s) in safe manner. See

Chapter 5 of Standard for Storage and Han

dling of Liquefied Petroleum Gases, ANSI/

NFPA 58 and the Propane Installation Code

CAN/CGA B149.2. Follow all local codes.

Always store propane tanks outdoors.

2. Place plastic cover caps over brass fittings on

inlet connector and hose/regulator assembly.

3. Store in dry, clean, and safe place. Do not

store hose/regulator assembly inside heater

combustion chamber.

4. When taking heater out of storage, always

check inside of heater. Insects and small

animals may place foreign objects in heater.

Keep inside of heater free from combustible

and foreign objects.

MAINTENANCE

WARNINGS

• Never service heater while it

is plugged in, connected to

propane supply, operating, or

hot. Severe burns and electri

cal shock can occur.

• Keep heater clear and free

from combustible materials,

gasoline, and other flammable

vapors and liquids.

• Do not block the flow of combustion or ventilation air.

1. Keep heater clean. Clean heater annually or as

needed to remove dust and debris. If heater is

dirty or dusty, clean heater with a damp cloth.

Use household cleaners on difficult spots.

2. Inspect heater before each use. Check connec

tions for leaks. Apply mixture of liquid soap

and water to connections. Bubbles forming

show a leak. Correct all leaks at once.

3. Inspect hose/regulator assembly before each

use. If hose is highly worn or cut, replace with

one specified by manufacturer.

4. Have heater inspected yearly by a qualified

service agency.

-

5. Keep inside of heater free from combustible

and foreign objects. Remove motor and other

internal parts if needed to clean inside of

heater (see Service Procedures).

6. Clean fan blades each season or as needed (see

Fan, page 7).

-

SERVICE PROCEDURES

WARNING: Never service

heater while it is plugged in,

connected to propane supply,

operating, or hot. Severe burns

and electrical shock can occur.

MOTOR

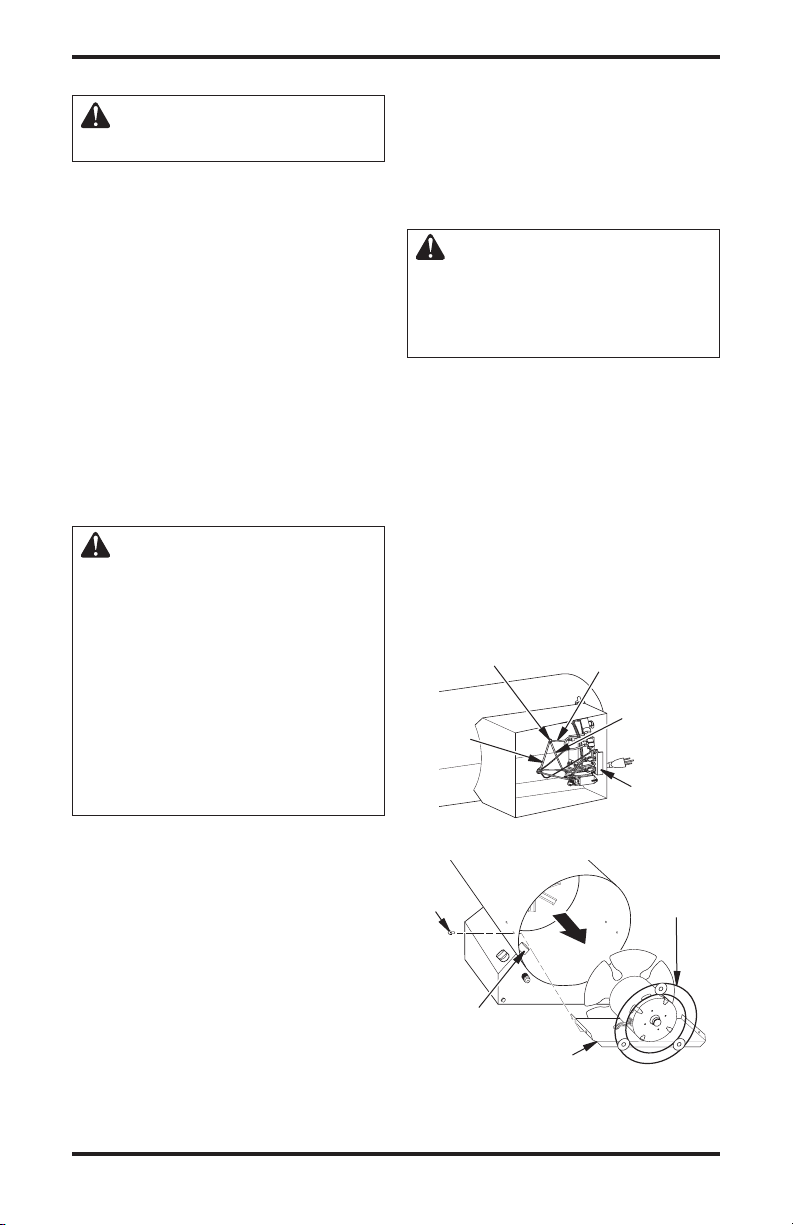

1. With heater on its side, remove base tray.

2. Access ground screw through underside of

heater base. Remove ground screw. Disconnect

the green motor wire and the green power cord

wire from underside of shell (see Figure 5).

3. Remove black and white motor wires from

terminal board (see Figure 5).

4. Carefully push motor wires through hole in

bottom of shell.

5. Remove screws holding motor mount to shell.

Use nut-driver (see Figure 6).

Ground Screw

Motor

Green

Lead

Figure 5 - Location of Ground Screw

Motor

Mount

Screw

-

Hole in Shell

for Wires

Motor Mount

Figure 6 - Removing Motor, Motor Mount,

and Fan Guard from Heater

Transformer

Green Lead

Power Cord

Green Lead

Terminal

Board

Fan

Guard

www.desatech.com

103908-01E6

Page 7

SERVICE PROCEDURES

Continued

6. Carefully pull motor and fan out of shell.

IMPORTANT: Be careful not to damage fan.

Do not set motor and fan down with the weight

resting on fan. This could damage fan pitch.

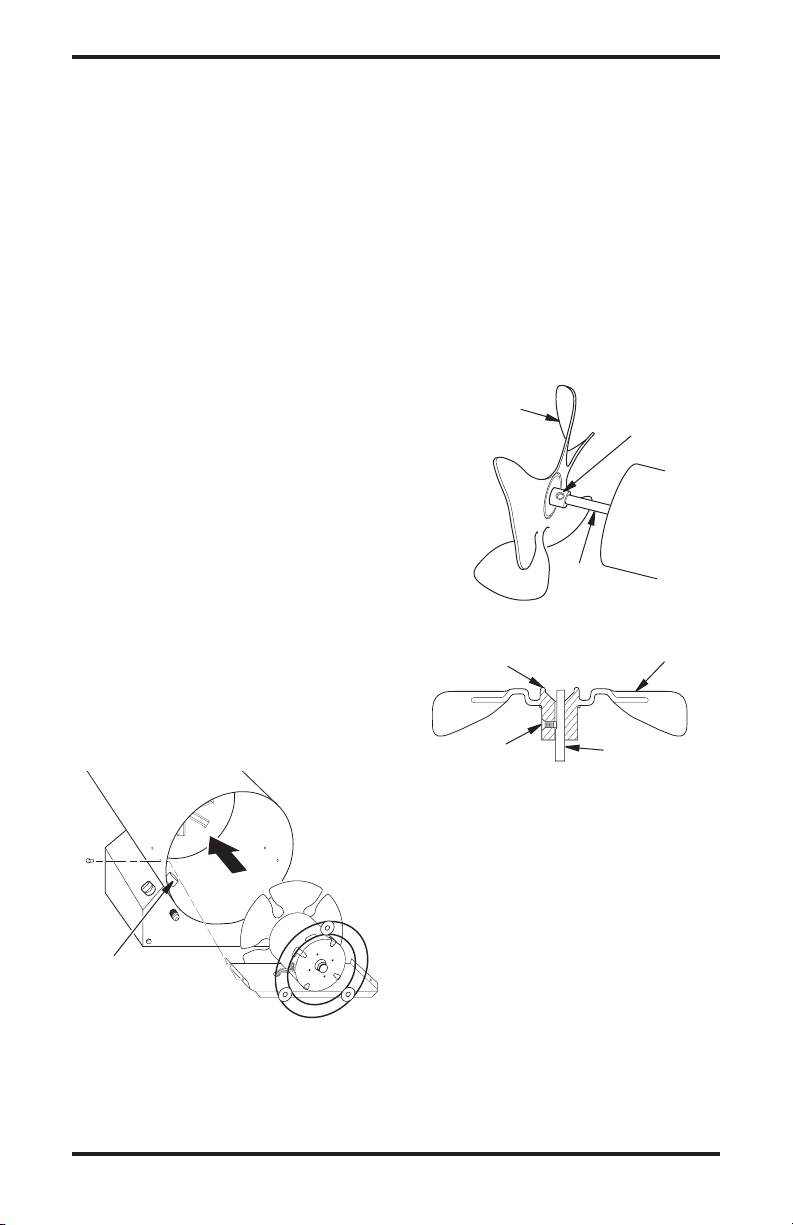

7. Use hex wrench to loosen setscrew which

holds fan to motor shaft.

8. Remove fan. Be careful not to damage the fan

blade pitch.

9. Use nut driver to remove two nuts that attach

motor to motor mount.

10. Discard old motor.

11. Attach motor to motor mount with two nuts.

Tighten nuts firmly.

12. Replace fan on motor shaft. Make sure set

screw contacts flat surface on motor shaft.

13. Tighten set screw firmly (40-50 inch-pounds)

(4.5192-5.649 N•m).

14. Carefully route motor wires through hole

in shell (see Figure 7). Place motor, motor

mount, and fan guard into rear of heater

shell.

15. Insert screws through heater shell and into

motor mount. Tighten screws firmly.

16. Turn heater on its side to access opening in

bottom of base. Connect green wires from

motor, transformer, and power cord to heater

shell using ground nut (see Figure 5, page 6).

17. Attach black and white wires to terminal board

(see Wiring Diagram, page 13, for correct

locations).

18. Replace base tray.

FAN

1 Remove motor, motor mount, and fan (see

Motor, page 6, steps 1 through 8).

2. Clean fan using soft cloth moistened with

kerosene or solvent.

3. Dry fan thoroughly.

4. Replace fan on motor shaft. Make sure set

screw is touching back of flat surface on motor

shaft (see Figure 8).

5. Place setscrew on flat of shaft. Tighten set

screw firmly (40-50 inch-pounds) (4.5192-

5.649 N•m).

6. Place motor, motor mount, and fan guard

into rear of heater shell (see

through 18).

Fan

Motor

Shaft

Figure 8 - Fan, Motor Shaft, and

Setscrew Location

Hub

Setscrew

Figure 9 - Fan Cross Section

Motor, steps 14

Setscrew

Fan

Motor Shaft

-

-

Hole in Shell for

Motor Wires

Figure 7 - Replacing Motor, Motor Mount,

and Fan Guard into Heater

103908-01E 7

www.desatech.com

Page 8

SERVICE PROCEDURES

Continued

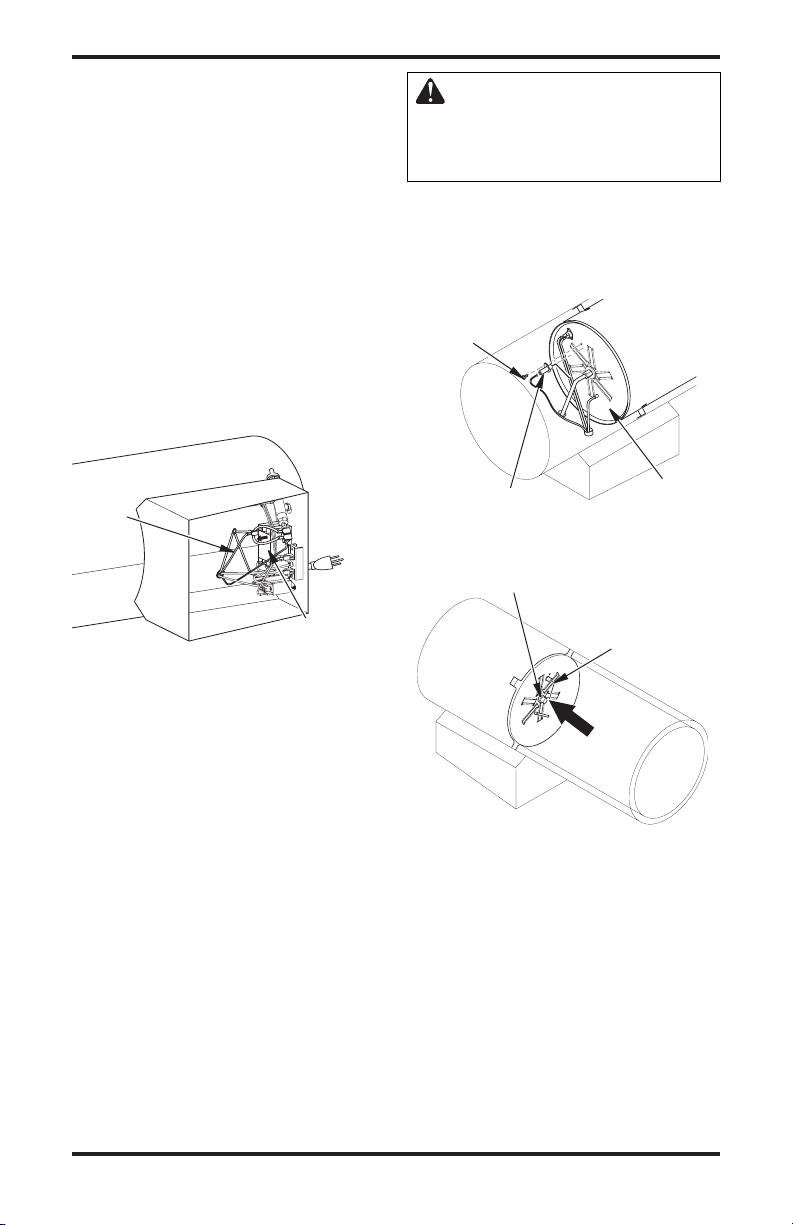

SPARK TRANSFORMER

1. Remove base tray.

2. Locate and disconnect white, black, and

orange wires from spark transformer.

3. Remove two screws holding spark trans

former to base. Remove sheet metal nuts on

transformer and install on new transformer.

Discard spark transformer.

4. Install new spark transformer. Position new

spark transformer in same manner as old

transformer.

5. Connect white, black, and orange wires to new

spark transformer. Connect wires to correct

terminals as noted in step 2.

6. Replace base tray.

WARNING: Make sure heater

is disconnected from propane

supply. Heater could ignite causing severe burns.

Plug into extension cord and watch for spark

between ignitor electrode and target plate.

-

9. Place motor, motor mount, and fan guard

into rear of heater shell (see

through 18, page 7).

Ignitor

Mounting

Screw

Motor, steps 14

Ignitor

Wire

Spark

Transformer

Figure 10 - Removing Ignitor Wire from

Spark Transformer

IGNITOR

1. Remove motor, motor mount, and fan guard

(see Motor, page 6, steps 1 through 6) .

2. Remove orange ignitor wire from ignitor.

3. Remove ignitor mounting screw from rear

head using nut-driver or standard screwdriver

(see Figure 11).

4. Remove ignitor from rear head.

5. Install new ignitor. Attach ignitor to rear head

with ignitor mounting screw.

6. Attach ignitor wire.

7. Check gap between ignitor electrode and

target plate to 0.13"/0.15" (3.3/3.8 mm) (see

Figure 12).

8. Test for spark.

Ignitor

Figure 11 - Removing Ignitor Mounting

Screw and Ignitor

Burner Nozzle

Gap

Area

Figure 12 - Clearance between Ignitor

Electrode and Target Plate

Rear

Head

Ignitor

Electrode

www.desatech.com

103908-01E8

Page 9

TROUBLESHOOTING

WARNING: Never service heater while it is plugged in, connected

to propane supply, operating, or hot. Severe burns and electrical

shock can occur.

OBSERVED FAULT

Fan does not turn when heater is

plugged in

Heater will not ignite

Heater shuts down while run

ning

POSSIBLE CAUSE

1. No electrical power to heater

2. Fan hitting inside of heater

shell

3. Fan blades bent

4. Defective motor

1. User did not follow installa

tion or operation instructions

properly

2. No spark at ignitor. To test for

spark, follow step 8 under Ig-

nitor, page 8. If you see spark

at ignitor, have heater serviced

by qualified service person. If

no spark seen:

A) Loose or disconnected

ignitor wire

B) Wrong spark gap

C) Bad ignitor electrode

D) Bad spark transformer

-

1. Propane supply may be inad

equate

2. High surrounding air tem

perature causing thermal limit

device to shut down heater.

3. Restricted air flow

4. Damaged fan

5. Excessive dust or debris in

surrounding area

REMEDY

1. Check voltage to electrical

outlet. If voltage is good, check

heater power cord for breaks

2. Adjust motor/fan mount to

keep fan from hitting inside of

heater shell. Bend fan mount

if necessary

3. Replace fan. See Fan, page 7

4. Replace motor. See Motor

page 6

1.

Repeat installation and operation

instructions. See Installation,

page 4 and Operation, page 5

2. A) Check ignitor wire. Tighten

or reattach loose ignitor wire.

See Figure 10, page 8 for

ignitor wire location

B) Assure gap between ignitor

electrode and target plate is

0.13"/0.15" (3.3/3.8 mm). Do

not bend electrode. Doing so

may cause it to break

C) Replace ignitor electrode.

See Ignitor, page 8

D) Replace spark transformer.

See Spark Transformer, page 8

1. A) Refill tank

B) Provide additional and/or

larger tanks. See Propa ne

Supply, page 3

2. This can happen when running

-

heater in temperatures above

85°F (29˚C). Run heater in

cooler temperatures

3. Check heater inlet and outlet.

Remove any obstructions

4. Replace fan. See

5. Clean heater. See Mainte

nance, page 6

Fan, page 7

,

-

WARNING: Use only in areas

free of high dust content.

103908-01E 9

www.desatech.com

Page 10

ILLUSTRATED PARTS BREAKDOWN

2

5

6

7

21

NOTE: Screws are standard

hardware items

14

15

2

12

13

16

2

8

9

10

18

19

20

21

4

11

26

3

1

2

22

23

17

29

30

32

34

35

33

26

25

31

32

33

27

28

28

31

27

24

11

MODEL RCLP100V

www.desatech.com

103908-01E10

Page 11

PARTS LIST

MODEL

RCLP100V

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 12 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY

1 102362-01 Base Tray 1

2 M11084-26 Hex TPG Screw, 10-16 X .38 15

3 103917-01AA Base 1

4 099138-02 Nozzle 1

5 098511-216 Shell Kit 1

6 M11084-29 Hex TPG Screw, 10-16 X .75 2

7 M51104-01 Handle 1

8 ** Combustion Chamber Kit 1

9 099538-01 Thermocouple 1

10 099237-01 Thermocouple Clip 1

11

099334-02 Fuel Tube Kit 1

12 M51153-01 Fan 1

13 102366-01 Motor 1

14 102380-01 Motor Bracket 1

15 NTC-4C Hex Lock Nut, 1/4"-20 2

16 102315-02 Fan Guard 1

17 099393-03 Control Knob 1

18 101732-04 Thermal Switch Kit (Incl. Wire Assemblies) 1

19 102487-01 lgnitor Electrode 1

20 097806-02 lgnitor Cable 1

21 M11084-38 Screw, Hex TPG, 8-18 X .38 2

22 098219-17 Power Cord 1

23 M11143-1 Strain Relief Bushing 1

24 103846-01 Valve Kit 1

25 102601-01 Ignition Control 1

26 079010-30 Wire Assembly (Relay) 1

27 079010-19 Wire Assembly (Relay) 1

28 097951-14 Wire Assembly (Relay) 1

29 103847-01 Relay Kit 1

30 102602-01 U-Clip Nut, #6 X .12 2

31 M9900-170 Wire Assembly (lgnition Control) 1

32 M16841-56 Wire Assembly (lgnition Control) 1

33 M16841-68 Wire Assembly (lgnition Control) 1

34 099125-11 Terminal Board 1

35 099157-01 Break Mandrel Rivet, 3/16" 1

079231-01 Service Center List 1

109111-03 Tradename Decal, Reddy

105350-08 Operation Decal 1

105351-02 Warning Decal 1

102599-02 Electrical Decal 1

111632-09

LPA3100 Regulator and Hose Assembly

LPA4020

** Not a field replaceable part.

PARTS AVAILABLE—NOT SHOWN

2

Model Decal 1

1

Fuel Gas Connector 1

103908-01E 11

www.desatech.com

Page 12

SPECIFICATIONS

At LOW setting

• Output Rating - 65,000 Btu/Hr (61,000 kJ/Hr)

• Fuel Consumption - 0.7 Gal/Hr (2.6 Litres/Hr)

• Fuel Consumption - 3.0 lb/Hr (1.36 kg/Hr)

At MED setting

• Output Rating - 85,000 Btu/Hr (80,570 kJ/Hr)

• Fuel Consumption - 0.93 Gal/Hr (3.5 Litres/Hr)

• Fuel Consumption - 3.9 lb/Hr (1.8 kg/Hr)

At HIGH setting

• Output Rating - 100,000 Btu/Hr (94,800 kJ/Hr)

• Fuel Consumption - 1.1 Gal/Hr (4.2 Litres/Hr)

• Fuel Consumption - 4.6 lb/Hr (2.1 kg/Hr)

For all settings

• Propane Vapor Fuel Only

• Supply Pressure To Regulator:

Minimum (for purposes of input adjustment)

10 psi (69 kPa)

Maximum - Tank Pressure

• Regulator Outlet Pressure - Factory Preset

• Manifold Pressure - 10" (25.4 cm) WC

• Hot Air Output (CFM Approx) - 475 (13.45 m)

• Motor - 3,200 RPM, 1/10 HP

• Electric Input - 120 V/60 Hz

• Amperage - 2.9

• Ignition - Continuous

• Ignitor Gap - 0.13"/0.15" (3.3/3.8 mm)

TECHNICAL SERVICE

You may have further questions about this heater.

If so, contact DESA Heating Productsʼ Technical

Service Department at 1-866-672-6040. When

calling, please have your model and serial numbers

of your heater ready.

You can also visit DESA Heating Productsʼ Techni

cal Service web site at www.desatech.com.

REPLACEMENT PARTS

WARNING: Use only original

replacement parts. This heater

must use design-specific parts.

Do not substitute or use generic

parts. Improper replacement

parts could cause serious or fatal injuries. This will also protect

your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), call

DESA Industries at 1-905-826-8010.

When calling DESA Industries, have ready

• your name

• your address

• model number of your heater

• how heater was malfunctioning

• purchase date

In most cases, we will ask you to return the part

to the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If

they canʼt supply original replacement part(s),

call DESA Industriesʼ Parts Department at

1-905-826-8010.

When calling DESA Industries, have ready:

• model number of your heater

• the replacement part number

-

ACCESSORY

Purchase accessories and parts from your nearest

dealer or service center. If your dealer or service

center can not supply an accessory or part, call DESA

Industriesʼ Parts Department at 1-905-826-8010. You

can also write to the address listed on the back page

of this manual.

FUEL GAS CONNECTOR - LPA4020

Connects regulator to all standard propane tanks.

U.L. and A.G.A. listed.

www.desatech.com

103908-01E12

Page 13

WIRING DIAGRAM

Black

Green

White

Motor

Ignitor

Orange

Blue

Blue

Auto Control

Va

lve

Thermocouple

1 2

3 4

5 6

87

Thermal Switch

Te

rminal Board

Blue

Black

Ignition

Control

White

Relay

Green

Green

Black

Black

White

White

Green

Power

Cord

Electrical Connection Diagram

www.desatech.com

103908-01E 13

Page 14

WARRANTY AND REPAIR SERVICE

KEEP THIS WARRANTY

Model

Serial No.

Date of Purchase

LIMITED WARRANTY

DESA Industries warrants this product and any parts thereof, to be free from defects in materials and workmanship

for one (1) year from the date of first purchase when operated and maintained in accordance with instructions. This

warranty is extended only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of proper mainte

nance, normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts, or repair by

anyone other than an authorized dealer or service center. Routine maintenance is the responsibility of the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

DESA Industries assumes no responsibility for indirect, incidental or consequential damages. Some states do not

allow the exclusion or limitation of incidental or consequential damages, or limitations or exclusions may not

apply to you. This Limited Warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our

standard written warranty. We make no other warranty, expressed or implied.

-

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase must be

presented with the heater. The heater will be inspected. A defect may be caused by faulty materials or workmanship.

If so, DESA Industries will repair or replace the heater without charge.

REPAIR SERVICE

Return your heater to your nearest authorized service center. Repairs not covered by the warranty will be billed at

standard prices. Each Service Center is independently owned and operated. We reserve the right to amend these

specifications at any time without notice.

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

2220 Argentia Road, Unit #4

Mississauga, Ontario L5N2K7

905-826-8010

ATTN: Customer Service Department

Page 15

APPAREIL DE CHAUFFAGE À AIR FORCÉ DE CHANTIER AU

GAZ PROPANE POUR LE CANADA

MANUEL D'UTILISATION

MODÈLE RCLP100V

PUISSANCE VARIABLE DE 65 000, 85 000 ET 100 000 BTU/H

IMPORTANT : lisez et comprenez ce manuel avant d'assembler,

d'allumer ou de réparer l'appareil de chauffage. Une mauvaise

utilisation de l'appareil de chauffage peut causer des blessures

graves. Conservez ce manuel pour référence future.

AVERTISSEMENT DE RISQUE GÉNÉRAL :

Tout manquement aux précautions et aux instructions fournies avec cet appareil de chauffage peut causer la mort, des

blessures corporelles graves ainsi que des pertes matérielles

et des dommages causés par les risques associés au feu, à

une explosion, aux brûlures, à l'asphyxie, à l'empoisonnement au monoxyde de carbone et par les chocs électriques.

Seuls les individus qui comprennent et qui respectent ces instructions peuvent utiliser ou réparer cet appareil de chauffage.

Si vous avez besoin d'assistance ou de renseignements concernant l'appareil de chauffage tels que le mode d'emploi, des

étiquettes, etc., communiquez avec le fabricant.

Information relative à la sécurité ......................... 2

Déballage ............................................................ 3

Identification du produit ....................................... 3

Approvisionnement en propane .......................... 3

Théorie de fonctionnement .................................. 4

Ventilation ............................................................

Installation ........................................................... 4

Fonctionnement ................................................... 5

Entreposage ........................................................ 6

Entretien .............................................................. 6

Pour plus de détails, visitez le site www.desatech.com

TABLE DES MATIÈRES

Procédures d'entretien ........................................ 6

Dépannage .......................................................... 9

Vue détaillée et liste des pièces ........................ 10

Spécifications .................................................... 12

Service technique .............................................. 12

4

Pièces de rechange ........................................... 12

Accessoire ......................................................... 12

Diagramme de câblage ..................................... 13

Service de garantie et de réparation ...............Dos

Conservez ce manuel pour consultation future.

Page 16

INFORMATION RELATIVE

À LA SÉCURITÉ

AVERTISSEMENT : cet appareil

contient ou produit des produits

chimiques déterminés par l'État de

Californie comme cancérigènes et

pouvant causer des malformations

congénitales et d'autres troubles

liés à la reproduction.

AVERTISSEMENT : danger d'incendie, de brûlure, d'inhalation et

d'explosion. Gardez les produits combustibles solides comme les matériaux

de construction, le papier et les cartons

à une distance sûre de l'appareil de

chauffage tel que recommandé dans

les instructions. N'utilisez jamais l'appareil de chauffage dans des espaces

susceptibles de contenir des combustibles volatils ou atmosphériques ou

des produits tels que de l'essence,

des diluants, du solvant à peinture,

des particules de poussières ou des

produits chimiques inconnus.

AVERTISSEMENT : n'utilisez

pas à la maison ou dans un véhicule de camping.

Cet appareil de chauffage est conçu comme appareil de

chauffage de chantier en conformité avec les normes ANSI

Z83.7/CGA2.2.14. D'autres normes régissent l'utilisation

des gaz combustibles et des produits de chauffage pour des

utilisations particulières. Les autorités locales peuvent vous

conseiller à propos de ces normes. La fonction principale

des appareils de chauffage de chantier est la production

temporaire de chaleur pour des édifices en construction ou

en cours de modification ou de réparation. Utilisés correctement, ces appareils de chauffage représentent une source

de chaleur économique et sûre. Les produits de combustion

sont évacués dans l'espace qui est chauffé.

Nous ne pouvons pas prévoir toutes les utilisations

possibles de nos appareils de chauffage. Vérifiez

auprès de votre responsable local de la sécuritéincendie si vous avez des questions relatives à

l'utilisation de l'appareil de chauffage.

D'autres normes régissent l'utilisation des gaz combustibles et des produits de chauffage pour des utilisations particulières. Les autorités locales peuvent

vous conseiller à propos de ces normes.

www.desatech.com

Empoisonnement au monoxyde de carbone :

taines personnes sont plus sensibles au monoxyde de

carbone que d'autres. Les premiers symptômes d'un

empoisonnement au monoxyde de carbone ressemblent

à la grippe avec des maux de tête, du vertige ou de la

nausée. Si vous avez ces symptômes, il se pourrait que

l'appareil de chauffage ne fonctionne pas bien. Respirez

tout de suite de l'air frais ! Vérifiez si la ventilation est

suffisante et faites réviser l'appareil de chauffage.

Gaz propane :

odorant est ajouté au gaz propane. Cette odeur vous permet de détecter une fuite de gaz. Cependant, cette odeur

ajoutée au propane peut se dissiper. Du gaz propane peut

être présent même s'il n'y a pas d'odeur.

Lisez et comprenez tous les avertissements. Conservez ce manuel pour consultation future. Il vous permettra de faire fonctionner cet appareil de chauffage

correctement et en toute sécurité.

1. Installez et utilisez l'appareil de chauffage avec

2. N'utilisez que la tension et la fréquence élec-

3. Instructions de mise électrique à la terre : cet

4. N'utilisez que le tuyau et le détendeur réglé en usine

5. N'utilisez que du gaz propane composé pour le

6. Assurez une ventilation suffisante. Avant

7. Usage à l'intérieur seulement. N'utilisez pas

8.

9. N'utilisez pas l'appareil de chauffage dans les sous-

10. Gardez l'espace libre autour de l'appareil et ne

le gaz propane est sans odeur. Un produit

précaution. Respectez tous les règlements et codes

locaux. En l'absence de codes ou de règlements locaux, consultez la Norme pour l'emmagasinage et

la manipulation du gaz de pétrole liquéfié (ANSI/

NFPA58) et le Code d'installation du propane

(CAN/CGA B149.2). Ces documents décrivent

les précautions à prendre pour l'entreposage et la

manutention du gaz propane.

trique indiquées sur la plaque signalétique.

Les connexions électriques et la prise de terre

de l'appareil de chauffage doivent respecter le

Code national de l'électricité, ANSI/NFPA 70

ou le Code canadien de l'électricité, partie 1.

appareil est muni d'une fiche de terre trifilaire

pour vous protéger des décharges électriques;

elle devrait être branchée directement dans une

rallonge ou prise trifilaire avec mise à la terre.

qui ont été fournis avec l'appareil de chauffage.

retrait de vapeur.

d'utiliser l'appareil de chauffage, aménagez une

ouverture sur l'extérieur d'au moins 2,7 m² (3 ft2)

pour chaque 100 000 Btu/h de puissance.

l'appareil de chauffage à l'extérieur.

N'utilisez pas l'appareil de chauffage dans un édifice

habité ou dans des endroits où l'on vit et dort.

sols ou sous le niveau du sol. Le gaz propane est

plus lourd que l'air. Si une fuite se produit, le gaz

propane s'écoulera au niveau le plus bas possible.

placez pas de matériaux combustibles, d'essence,

de solvant à peinture ou d'autres vapeurs ou

liquides inflammables à proximité. La poussière est combustible. N'utilisez pas l'appareil de

chauffage là où il y a beaucoup de poussière.

cer-

103908-01E2

Page 17

INFORMATION RELATIVE

À LA SÉCURITÉ Suite

11.

Distances minimales entre lʼappareil de chauffage et

les combustibles : sortie : 2,4 m (8 pi), côtés : 60 cm

(2 pi), dessus : 1,80 m (6 pi), arrière : 60 cm (2 pi)

12.

Placez l'appareil de chauffage à au moins 1,80 m

(6 pi) des réservoirs de propane. Ne dirigez pas

l'appareil de chauffage vers des réservoirs de

propane qui se trouvent à moins de 6 m (20 pi).

13. Conservez les réservoirs de propane à moins de

38° C (100° F).

14. Vérifiez l'appareil de chauffage avant chaque

utilisation. N'utilisez pas d'appareil de chauffage

endommagé.

15. Avant chaque utilisation de l'appareil de chauffage, vérifiez que le tuyau n'est pas endommagé.

S'il est très usé ou fendu, remplacez le tuyau par

le type de tuyau spécifié par le fabricant avant

d'utiliser l'appareil de chauffage.

16. Placez l'appareil de chauffage sur une surface

stable et de niveau si l'appareil est chaud ou en

fonctionnement.

17.

Ne bloquez jamais lʼentrée dʼair (à lʼarrière) ou la

sortie dʼair (à lʼavant) de lʼappareil de chauffage.

18. Éloignez l'appareil de chauffage des courants

d'air, du vent, des éclaboussures, de la pluie ou

de l'eau ruisselante.

19. Ne laissez pas les enfants et les animaux s'approcher de l'appareil de chauffage.

20.

Ne déplacez, ne manipulez et ne révisez jamais un

appareil de chauffage brûlant ou en opération. Vous

risqueriez de vous brûler gravement. Attendez 15

minutes après avoir éteint l'appareil de chauffage.

21. Pour ne pas vous blesser, portez des gants lorsque

vous manipulez l'appareil de chauffage.

22. N'installez jamais de tuyauterie de ventilation

sur l'appareil de chauffage.

23. Ne modifiez pas l'appareil de chauffage. Maintenez l'appareil de chauffage dans son état initial.

24. N'utilisez pas l'appareil de chauffage s'il a été

modifié.

25. Lorsque l'appareil de chauffage n'est pas utilisé,

fermez la vanne d'approvisionnement en propane

et débranchez l'appareil.

26. Utilisez seulement des pièces de rechange

d'origine. Cet appareil de chauffage utilise des

pièces conçues spécifiquement pour lui. N'utilisez pas de substituts ou de pièces génériques.

L'utilisation de pièces de rechange inadéquates

peut causer des blessures graves ou fatales.

DÉBALLAGE

1. Enlevez tout matériau d'emballage appliqué

sur l'appareil de chauffage pour son expédition.

Conservez les bouchons en plastique (sur le

raccord d'entrée et l'assemblage du tuyau et du

détendeur) pour l'entreposage.

2. Retirez toutes les pièces de l'emballage.

3. Inspectez toutes les pièces pour voir si elles ont

103908-01E 3

www.desatech.com

été endommagées pendant l'expédition. Si l'ap

pareil de chauffage est endommagé, informez-en

au plus vite le revendeur où vous l'avez acheté.

IDENTIFICATION DU

PRODUIT

Sortie d'air chaud (avant)

Poignée

Bouton de

réglage

Raccord d'entrée

Assemblage

du tuyau et du

détendeur

Figure 1 - Modèle à 100 000 Btu/h

Grille de

protection du

ventilateur

Montage

du moteur

Cordon

électrique

APPROVISIONNEMENT

EN PROPANE

Le gaz propane et les réservoirs de propane doivent

être fournis par l'utilisateur.

N'utilisez cet appareil de chauffage qu'avec un système

d'approvisionnement à élimination de vapeurs de propane.

Consultez le chapitre 5 de la Norme pour l'emmagasinage et

la manipulation du gaz de pétrole liquéfié, ANSI/NFPA 58 et

le Code d'installation du propane, CAN/CGA B149.2. Votre

bibliothèque ou votre service d'incendie a cette publication.

La quantité de gaz propane utilisable dans les réservoirs varie. Deux facteurs influencent cette quantité :

1. La quantité de gaz propane contenue dans les

réservoirs

2. La température des réservoirs

Le tableau ci-dessous indique le nombre de réservoirs

de 45 kg (100 lbs) à utiliser pour faire fonctionner

cet appareil de chauffage.

Température moyenne Nombre de réservoirs

Au réservoir (45 kg/100 lbs)

Supérieure à -6,7°C (20°F) 2

Entre 6,7°C (20°F ) et -18°C (0°F) 3

Inférieure à -18° C (0° F) utilisez un réservoir

plus grand

Moins de gaz se vaporise à basse température. Vous

aurez peut-être besoin d'au moins deux réservoirs de

45 kg (100 lbs) ou d'un réservoir plus grand s'il fait

plus froid. Votre fournisseur de gaz propane local vous

aidera à choisir le système d'approvisionnement qui

convient. La température ambiante minimale nominale

de ces appareils de chauffage est de -29°C (-20°F).

Des réservoirs plus petits peuvent être utilisés pour

des durées de fonctionnement limitées mais il est

recommandé d'utiliser de grands réservoirs pour

une performance optimale.

-

Page 18

Air For Combustion

And Heating

Fuel

THÉORIE DE FONCTIONNEMENT

Système d'approvisionnement en carburant :

en gaz propane. Le gaz propane passe par la vanne de contrôle automatique et sort par la buse d'aération.

Système d'admission d'air :

autour de la chambre de combustion. L'air est chauffé et fournit un courant d'air propre et chaud.

Système d'allumage :

Système de contrôle de sécurité :

de la flamme.

Sortie

d'air

chaud

propre

(avant)

le moteur fait tourner le ventilateur. Le ventilateur pousse l'air à l'intérieur et

l'allumeur du transformateur d'étincelle allume le brûleur principal.

Chambre de combustion

l'assemblage de tuyau et de détendeur est relié à l'approvisionnement

ce système provoque l'arrêt de l'appareil de chauffage en cas d'extinction

Buse

d'aération

Ventilateur

Entrée

d'air frais

(arrière)

Cordon électrique

Remarque : certaines pièces

sont disposées différemment sur

certains modèles.

Figure 2 - Vue opérationnelle en coupe transversale

Air pour la

combustion et

le chauffage

VENTILATION

AVERTISSEMENT : respectez les exigences minimales en

matière d'apport en air frais de

l'extérieur. Si aucun apport en air

frais de l'extérieur n'est fourni, un

empoisonnement au monoxyde de

carbone peut se produire. Il doit

y avoir une entrée d'air frais de

l'extérieur adéquate pour utiliser

l'appareil de chauffage.

Aménagez une ouverture d'air extérieur d'au moins

0,28 m² (3 ft

sance. Fournissez davantage d'air extérieur si plus

d'un appareil de chauffage est utilisé.

2

) pour chaque 100 000 Btu/h de puis-

INSTALLATION

AVERTISSEMENT : lisez et

comprenez les avertissements de

la section Information relative à la

sécurité, page 2. Ils sont requis

pour faire fonctionner cet appareil de chauffage sans danger.

Respectez tous les codes locaux

lors de l'utilisation de cet appareil

de chauffage.

www.desatech.com

Assemblage

du tuyau et du

détendeur

Carburant

AVERTISSEMENT : testez

toutes les conduites de gaz et les

connexions pour détecter les fuites

après l'installation ou la révision.

N'utilisez jamais de flamme nue pour

rechercher une fuite. Appliquez une

solution de savon liquide et d'eau

sur tous les joints. La présence de

bulles indique une fuite. Réparez

toutes les fuites immédiatement.

1. Vous devez fournir le système d'approvisionnement en propane (voir Approvisionnement

en propane, page 3).

2. Branchez le raccord de gaz à l'assemblage

du tuyau et du détendeur sur le réservoir de

propane. Tournez-le dans le sens inverse des

aiguilles d'une montre dans le filetage de la

vanne du réservoir. Resserrez fermement avec

une clef. IMPORTANT : serrez le détendeur

en dirigeant la prise d'air vers le bas. Cela le

protégera des intempéries.

3. Connectez le tuyau au raccord d'entrée. Resser

rez fermement avec une clef. IMPORTANT : un

tuyau ou une canalisation supplémentaire peut

être employé au besoin. Installez tout tuyau ou

toute canalisation supplémentaire entre l'assem

blage du tuyau et du détendeur et le réservoir

de propane. Vous devez employer le détendeur

fourni avec l'appareil de chauffage.

103908-01E4

-

-

Page 19

INSTALLATION

Suite

4. Ouvrez lentement la vanne d'approvisionnement

en propane du ou des réservoirs de propane. Re

marque

: si on ne l'ouvre pas lentement, la vanne

de limitation de débit du réservoir de propane

coupera le gaz. Si cela se produit, fermez la vanne

d'approvisionnement et rouvrez-la lentement.

5. Vérifiez les fuites à chaque branchement.

6.

Fermez la vanne d'approvisionnement en propane.

Raccord

de gaz

Tuyau

Tuyau

Prise d'air

(dirigée

vers le

bas)

Vanne

d'approvisionnement

Réservoir de

propane

Figure 3 - Détendeur avec prise d'air

Modèle de 100 000

Btu/h illustré

Raccord

d'entrée

Figure 4 - Tuyau et raccord d'entrée

Détendeur

dirigée vers le bas.

FONCTIONNEMENT

AVERTISSEMENT : lisez et

comprenez les avertissements de la

section Information relative à la sécu

rité, page 2. Ils sont requis pour faire

fonctionner cet appareil de chauffage

sans danger. Respectez tous les

codes locaux lors de l'utilisation de

cet appareil de chauffage.

POUR ALLUMER L'APPAREIL DE

CHAUFFAGE

1. Suivez toutes les consignes d'installation, de

ventilation et de sécurité.

2.

Placez l'appareil de chauffage sur une surface

stable et de niveau. Assurez-vous qu'il n'y a pas

de courants d'air forts à l'avant ou à l'arrière de

l'appareil de chauffage.

103908-01E 5

www.desatech.com

3. Assurez-vous que le bouton de réglage est à la

position OFF.

4. Branchez le cordon électrique de l'appareil de

chauffage dans une rallonge à trois broches mise

-

à la terre. . La rallonge doit être d'au moins 2 m

(6 pi), respecter les normes UL/CSA et être d'un

calibre approprié.

Exigences des dimensions de la rallonge

électrique

Jusqu'à 30 m (100 pi), employez un cordon de

calibre 16 AWG.

Entre 31 et 60 m (101 et 200 pi), employez un

cordon de calibre 14 AWG.

5. Branchez la rallonge électrique dans une prise de

terre à trois branches de 120 volt/60 hertz. Le moteur démarre. Le ventilateur tourne pour pousser

l'air à la sortie avant de l'appareil de chauffage.

6. Ouvrez lentement la vanne d'approvisionnement

en propane du ou des réservoirs de propane.

Remarque : si on ne l'ouvre pas lentement,

la vanne de limitation de débit du réservoir de

propane coupera le gaz. Dans ce cas, fermez

la vanne d'approvisionnement en propane et

rouvrez-la lentement.

7.

Appuyez sur le bouton de réglage et gardez-le

enfoncé. Tournez dans le sens inverse des aiguilles

d'une montre à la position LOW. L'appareil de chauffage devrait s'allumer après quelques secondes.

Remarque : si l'appareil de chauffage ne

s'allume pas, le tuyau peut contenir de l'air. Si

c'est le cas, maintenez le bouton du robinet de

contrôle automatique enfoncé et attendez 20

secondes. Relâchez le bouton du robinet de

contrôle automatique et attendez 20 secondes

pour laisser le combustible imbrûlé s'échapper

de l'appareil de chauffage. Répétez l'étape 7.

8. Lorsque l'appareil de chauffage s'allume, attendez

30 secondes avant de relâcher le bouton de réglage.

Cela active le système de contrôle automatique.

9. Quand le brûleur reste allumé, réglez l'appareil

de chauffage au niveau de chaleur désiré en

tournant la vanne de contrôle dans le sens inverse

des aiguilles d'une montre. Si le brûleur s'éteint,

coupez le gaz. Tournez complètement le bouton

-

de réglage dans le sens des aiguilles d'une montre

à son niveau le plus bas. Vérifiez l'approvisionnement en gaz. Si l'approvisionnement en

combustible est conforme, redémarrez l'appareil

de chauffage en commençant par l'étape 1.

POUR ARRÊTER L'APPAREIL DE

CHAUFFAGE

1. Fermez hermétiquement la vanne d'approvisionnement en propane du ou des réservoirs de

propane.

2. Attendez quelques secondes. L'appareil de

chauffage brûlera le gaz qui reste dans les tuyaux

d'approvisionnement.

3. Tournez le bouton de réglage à la position OFF.

4. Débranchez l'appareil de chauffage.

Page 20

ENTREPOSAGE

ATTENTION : débranchez l'appareil de chauffage des réservoirs

de propane.

1. Entreposez les réservoirs de propane avec les

précautions de sécurité nécessaires. Consultez

le chapitre 5 de la Norme pour l'emmagasinage

et la manipulation du gaz de pétrole liquéfié,

ANSI/NFPA 58 et le Code d'installation du

propane, CAN/CGA B149.2. Respectez tous les

codes locaux. Entreposez toujours les réservoirs

de propane à l'extérieur.

2. Replacez les bouchons en plastique sur les

raccords en laiton d'entrée et de l'assemblage

du tuyau et du détendeur.

3.

Entreposez l'appareil de chauffage dans un endroit

sec, propre et sans danger. N'entreposez pas l'assemblage du tuyau et du détendeur à l'intérieur de la

chambre de combustion de l'appareil de chauffage.

4.

Avant d'utiliser un appareil de chauffage qui a été entreposé, vérifiez toujours l'intérieur de l'appareil. Des

insectes et de petits animaux peuvent avoir introduit

des corps étrangers dans l'appareil de chauffage. Enlevez les produits combustibles et les corps étrangers

qui se trouvent dans l'appareil de chauffage.

ENTRETIEN

AVERTISSEMENTS

• Ne réparez jamais l'appareil de

chauffage lorsqu'il est branché,

connecté à la source d'approvi

sionnement en gaz, en marche

ou brûlant. Des brûlures et

des chocs électriques graves

peuvent se produire.

• Ne placez pas de matériaux

combustibles, d'essence ou

d'autres vapeurs ou liquides

inflammables à proximité de

l'appareil de chauffage.

• Ne bloquez pas la circulation du

combustible ou la ventilation.

1.

Gardez l'appareil de chauffage propre. Nettoyez l'appareil de chauffage chaque année ou selon les besoins

pour enlever la poussière et les débris. Si l'appareil

de chauffage est sale ou poussiéreux, nettoyez-le

avec un chiffon humide. Employez des produits de

nettoyage domestique sur les taches tenaces.

2. Inspectez l'appareil de chauffage avant chaque utilisation. Vérifiez si les branchements ne fuient pas.

Appliquez une solution de savon liquide et d'eau

aux raccords. La présence de bulles indique une

fuite. Réparez toutes les fuites immédiatement.

-

www.desatech.com

3. Inspectez l'assemblage du tuyau et du détendeur

avant chaque utilisation. Si le tuyau est très usé

ou fendu, remplacez-le par le type de tuyau

spécifié par le fabricant.

4. Faites inspecter l'appareil de chauffage une fois

l'an par une entreprise de service qualifiée.

5. Enlevez les produits combustibles et les corps

étrangers qui se trouvent dans l'appareil de chauf

fage. Retirez le moteur et toute autre pièce interne

au besoin pour nettoyer l'intérieur de l'appareil de

chauffage (voir Procédures d'entretien).

6. Nettoyez les pales de ventilateur chaque saison

ou au besoin (voir Ventilateur, page 7).

PROCÉDURES D'ENTRETIEN

AVERTISSEMENT : ne réparez

jamais l'appareil de chauffage

lorsqu'il est branché, connecté à

l'approvisionnement en gaz, en

marche ou brûlant. Des brûlures

graves et des chocs électriques

peuvent se produire.

MOTEUR

1. Déposez l'appareil de chauffage sur le côté et

retirez le plateau de la base.

2. Vous avez accès à la vis de mise à la terre en

passant par le dessous de la base de l'appareil

de chauffage. Retirez la vis de mise à la terre.

Débranchez le fil vert du moteur et le fil vert

du cordon électrique situé sous l'habillage

(voir figure 5).

Vis de mise à la terre

Fil vert du

moteur

Figure 5 - Emplacement de la vis de mise

Vis du

support

du moteur

Orifice de

l'habitacle

pour le

passage

des fils

Figure 6 - Retrait du moteur, du support du

moteur et de la grille du ventilateur de l'appareil

à la terre

Montage

du moteur

Fil vert du

transformateur

Fil vert du

cordon

électrique

Bornier

Grille de

protection du

ventilateur

103908-01E6

-

Page 21

PROCÉDURES D'ENTRETIEN

3. Retirez du bornier les fils noir et blanc du moteur

(voir figure 5).

4. Faites passer délicatement les fils du moteur à

travers l'orifice du fond de l'habillage.

5. Retirez les vis qui retiennent le support du

moteur à l'habillage. Employez un tourne-écrou

(voir figure 6).

6. Retirez délicatement le moteur et le ventilateur

de l'habillage. IMPORTANT : prenez garde de

ne pas endommager le ventilateur. Ne déposez

pas le moteur et le ventilateur de façon à faire

reposer leur poids sur ce dernier. Cela pourrait

endommager l'angle des pales du ventilateur.

7. Utilisez une clef hexagonale pour desserrer la vis

d'arrêt qui retient le ventilateur à l'arbre moteur.

8. Retirez le ventilateur. Prenez garde de ne pas

endommager le pas des pales du ventilateur.

9. Employez un tourne-écrou pour retirer les deux

écrous qui retiennent le moteur à son support.

10. Jetez l'ancien moteur.

11. Fixez le moteur à son support en employant les

deux écrous. Resserrez les écrous fermement.

12. Replacez le ventilateur sur l'arbre moteur. Assurez-vous que la vis d'arrêt est vis-à-vis la surface

plate de l'arbre du moteur.

13. Serrez bien la vis (4,5192 à 5,649 N.m) (40 à 50

pouces-livres).

14. Acheminez soigneusement les fils du moteur

à travers l'orifice de l'habillage (voir figure 7).

Installez le moteur, le support du moteur et la

grille de protection du ventilateur à l'arrière de

l'habillage de l'appareil de chauffage.

15. Insérez les vis à travers l'habillage de l'appareil

de chauffage et dans le support du moteur. Res

serrez les vis fermement.

Suite

-

16. Tournez l'appareil de chauffage sur le côté pour

accéder à l'ouverture du fond de sa base. Raccordez les fils verts du moteur, du transformateur

et du cordon électrique à l'habillage avec l'écrou

de mise à la terre (voir figure 5, page 6).

17. Raccordez les fils noir et blanc au bornier (voir

Diagramme de câblage, page 13, pour les emplacements exacts).

18. Replacez le plateau de la base.

VENTILATEUR

1 Retirez le moteur, le support du moteur et le

ventilateur (voir Moteur, page 6, étapes 1 à 8).

2. Nettoyez le ventilateur à l'aide d'un chiffon doux

humecté avec du kérosène ou du diluant.

3. Séchez le ventilateur complètement.

4. Replacez le ventilateur sur l'arbre moteur. Assurezvous que la vis d'arrêt touche l'arrière de la surface

plane de l'arbre du moteur (voir figure 8).

5. Placez la vis d'arrêt sur le côté plat de l'arbre.

Serrez bien la vis d'arrêt (4,5192 à 5,649 N.m)

(40 à 50 pouces-livres).

6. Installez le moteur, le support du moteur et la

grille de protection du ventilateur à l'arrière

de l'habillage de l'appareil de chauffage (voir

Moteur, étapes 14 à 18).

Ventilateur

Figure 8 - Emplacement du ventilateur,

de l'arbre moteur et des vis d'arrêt

Moyeu

Vis d'arrêt

Arbre

moteur

Ventilateur

Orifice pour le

passage des fils

du moteur

Figure 7 - Remplacement du moteur,

du support du moteur et de la grille du

ventilateur de l'appareil

103908-01E 7

www.desatech.com

Vis d'arrêt

Figure 9 - Coupe transversale du

ventilateur

Arbre moteur

Page 22

PROCÉDURES D'ENTRETIEN

Suite

TRANSFORMATEUR D'ÉTINCELLE

1. Retirez le plateau de la base.

2. Repérez et débranchez les fils blanc, noir et

orange du transformateur d'étincelle.

3. Retirez les deux vis retenant le transformateur

d'étincelle à la base. Retirez les écrous à métal

de l'ancien transformateur et installez-les sur le

nouveau. Jetez le transformateur d'étincelle.

4. Installez le nouveau transformateur d'étincelle.

Disposez le nouveau transformateur d'étin

celle de la même façon que l'ancien.

5. Branchez les fils blanc, noir et orange au

nouveau transformateur d'étincelle. Raccordez

les fils aux bornes correspondantes du bornier

tel que mentionné à l'étape 2.

6. Replacez le plateau de la base.

Fil de

l'allumeur

8. Effectuez un test de détection d'étincelles.

AVERTISSEMENT : assurezvous que l'appareil de chauffage

est débranché de la source d'approvisionnement en propane.

L'appareil de chauffage pourrait

s'allumer et causer des brûlures

graves.

Branchez la rallonge et vérifiez si des étincel-

les apparaissent entre l'électrode d'allumage et

-

la plaque.

9. Installez le moteur, le support du moteur et la

grille du ventilateur à l'arrière de l'habillage

(voir Moteur, étapes 14 à 18, page 7).

Vis de

montage de

l'allumeur

Transformateur

d'étincelle

Figure 10 - Retrait du fil de l'allumeur du

transformateur d'étincelle

ALLUMEUR

1. Retirez le moteur, le support à moteur et la

grille de protection du ventilateur (voir Mo-

teur, page 6, étapes 1 à 6) .

2. Retirez le fil orange de l'allumeur.

3. Retirez la vis de fixation de l'allumeur de

la borne arrière avec un tourne-écrou ou un

tournevis standard (voir figure 11).

4. Retirez l'allumeur de la borne arrière.

5. Installez le nouvel allumeur. Fixez l'allumeur

à la borne arrière avec la vis de fixation de

l'allumeur.

6. Fixez le fil d'allumage.

7. Vérifiez si l'écart entre l'électrode d'allumage

et la plaque est de 3,3 à 3,8 mm (0,13 à 0,15

po) (voir figure 12).

www.desatech.com

Allumeur

Figure 11 - Retrait de l'allumeur et de la

vis de montage

Buse d'aération

Espace

Figure 12 - Espace entre l'électrode

d'allumage et la plaque

Borne

arrière

Électrode

d'allumage

103908-01E8

Page 23

DÉPANNAGE

AVERTISSEMENT : ne réparez jamais l'appareil de chauffage lorsqu'il

est branché, connecté à l'approvisionnement en gaz, en marche ou brûlant.

Des brûlures et des chocs électriques graves peuvent se produire.

PROBLÈME OBSERVÉ

Le ventilateur ne tourne pas

quand l'appareil de chauffage

est branché

L'appareil de chauffage ne s'al

lume pas

L'appareil de chauffage s'éteint

lorsqu'il fonctionne

AVE RTI SSE -

CAUSE POSSIBLE

1. Aucun courant ne se rend à

l'appareil de chauffage

2. Le ventilateur frappe l'intérieur

de l'habillage de l'appareil de

chauffage

3. Les pales du ventilateur sont

tordues

4. Moteur défectueux

-

1. L'utilisateur n'a pas suivi correctement les instructions d'installation ou de fonctionnement

2. Aucune étincelle à l'allumeur.

Pour effectuer un test d'étincelle,

suivez l'étape 8 de la rubrique Al-

lumeur, page 8. Si vous percevez

une étincelle sur l'allumeur, faites

réparer l'appareil de chauffage par

un technicien qualifié. Si vous ne

percevez aucune étincelle :

A) Le fil d'allumage est desserré

ou débranché

B) L'espace ne permet pas

d'étincelles

C) L'électrode d'allumage est

défectueuse

D) Le transformateur d'étincelle

est défectueux

1. L'approvisionnement en propa

ne peut ne pas être adéquat

2. La température de l'air ambiant

est trop élevée, ce qui provoque

la fermeture de l'appareil de

chauffage par le limiteur de

température.

3. Circulation d'air limitée

MENT : n'utilisez cet

appareil que dans

un endroit exempt

de poussière.

103908-01E 9

4. Ventilateur endommagé

5. Poussière ou débris excessifs

dans l'environnement immédiat

www.desatech.com

SOLUTION

1. Vérifiez la tension de la prise de

courant. Si la tension est correcte,

inspectez le cordon électrique

2. Réglez le support du moteur ou

du ventilateur pour empêcher

ce dernier de frapper l'intérieur

de l'habillage de l'appareil de

chauffage. Pliez le support du

ventilateur au besoin

3. Remplacez le ventilateur. Voir

Ventilateur, page 7

4. Remplacez le moteur. Voir

Moteur, page 6

1. Répétez les instructions d'installation et de fonctionnement. Voir

Installation, page 4 et Fonction-

nement, page 5

2. A) Inspectez le fil d'allumage.

Resserrez ou reconnectez le fil

d'allumage s'il est mal fixé. Voir

figure 10, page 8, pour l'emplacement du fil d'allumage

B) Assurez-vous que l'écart entre

l'électrode d'allumage et la plaque est de 3,3 à 3,8 mm (0,13 à

0,15 po).Ne pliez pas l'électrode.

Cela pourrait l'endommager

C) Remettez l'électrode d'allumage

en place. Voir Allumeur, page 8

D) Remettez transformateur

d'étincelle en place. Voir Trans-

formateur d'étincelle, page 8

-

1. A) Remplissez le réservoir

B) Fournissez des réservoirs sup

plémentaires ou de plus grande

capacité. Voir Approvisionnement

en propane, page 8

2. Cela peut se produire si l'appareil

de chauffage fonctionne dans

une température ambiante qui

dépasse 29°C (85°F). Faites fonctionner l'appareil de chauffage à

plus basse température

3. Inspectez l'entrée et la sortie

d'air de l'appareil de chauffage.

Retirez toute obstruction

4. Remplacez le ventilateur. Voir

Ventilateur, page 7

5. Nettoyez l'appareil de chauffage. Voir Entretien, page 6

-

Page 24

VUE DÉTAILLÉE DES PIÈCES

2

5

6

7

21

NOTE: Screws are standard

hardware items

14

15

2

12

13

16

2

8

9

10

18

19

20

21

4

11

26

3

1

2

22

23

17

29

30

32

34

35

33

26

25

31

32

33

27

28

28

31

27

24

11

MODÈLE RCLP100V

Note : Les vis sont

de type standard.

www.desatech.com

103908-01E10

Page 25

LISTE DES PIÈCES

MODÈLE RCLP100V

Cette liste contient les pièces de rechange utilisées dans votre appareil de chauffage. Quand vous

commandez des pièces, reportez-vous aux instructions de la section Pièces de rechange à la page 12

de ce manuel.

Nº Nº DE PIÈCE DESCRIPTION QTÉ

1 102362-01 Plateau de la base 1

2 M11084-26 Vis hexagonale TPG, 10-16 X 0,38 15

3 103917-01AA Base 1

4 099138-02 Buse d'aération 1

5 098511-216 Prêt-à-monter de l'habillage 1

6 M11084-29 Vis hexagonale TPG, 10-16 X 0,75 2

7 M51104-01 Poignée 1

8 ** Prêt-à-monter de la chambre de combustion 1

9 099538-01 Thermocouple 1

10 099237-01 Agrafe de thermocouple 1

099334-02 Prêt-à-monter de tuyauterie d'alimentation 1

11

12 M51153-01 Ventilateur 1

13 102366-01 Moteur 1

14 102380-01 Support du moteur 1

15 NTC-4C Contre-écrou hexagonal, 1/4"-20 2

16 102315-02 Grille de protection du ventilateur 1

17 099393-03 Bouton de réglage 1

18 101732-04 Prêt-à-monter d'interrupteur thermique (comprend les fils) 1

19 102487-01 Électrode d'allumage 1

20 097806-02 Câble de l'allumeur 1

21 M11084-38 Vis hexagonale TPG, 8-18 X 0,38 2

22 098219-17 Cordon électrique 1

23 M11143-1 Bride de cordon 1

24 103846-01 Prêt-à-monter de vanne 1

25 102601-01 Commande d'allumage 1

26 079010-30 Assemblage de fils (relais) 1

27 079010-19 Assemblage de fils (relais) 1

28 097951-14 Assemblage de fils (relais) 1

29 103847-01 Prêt-à-monter du relais 1

30 102602-01 Écrou-agrafe en U, n°6 X 0,12 2

31 M9900-170 Assemblage de fils (contrôle d'allumage) 1

32 M16841-56 Assemblage de fils (contrôle d'allumage) 1

33 M16841-68 Assemblage de fils (contrôle d'allumage) 1

34 099125-11 Bornier 1

35 099157-01 Rivet de mandrin, 3/16 po 1

079231-01 Liste des centres de service 1

109111-03

105350-08 Étiquette d'utilisation 1

105351-02 Étiquette d'avertissement 1

102599-02 Étiquette électrique 1

111632-09

LPA3100

LPA4020

** Cette pièce n'est pas remplaçable hors de l'usine.

PIÈCES DISPONIBLES — PAS ILLUSTRÉES

Étiquette de marque de commerce, Reddy 2

Étiquette du modèle 1

Assemblage du tuyau et du détendeur 1

Raccord d'approvisionnement en gaz 1

103908-01E 11

www.desatech.com

Page 26

SPÉCIFICATIONS

À régime BAS

• Capacité - 65 000 Btu/h (61 000 kJ/Hr)

• Consommation de carburant - 2,6 litres/h (0,7

gallon/h)

•

Consommation de carburant - 1,36 kg/h (3,0 lb/h)

À régime MOYEN

• Capacité - 85 000 Btu/h (80 570 kJ/h)

• Consommation de carburant - 3,5 litres/h ( 0,93

gallon/h)

• Consommation de carburant - 1,8 kg/h (3,9 lb/h)

À régime ÉLEVÉ

• Capacité - 100 000 Btu/h (94 800 kJ/h)

• Consommation de carburant - 4,2 litres/h (1,1

gallon/h)

• Consommation de carburant - 2,1 kg/h (4,6 lb/h)

Pour tous les régimes

• Combustible vapeur de propane seulement

• Pression d'approvisionnement du détendeur :

Minimum (pour le réglage de l'entrée d'alimen

tation) 10 lb/po2 (69 kPa)

Maximum - Pression du réservoir

• Pression à la sortie du détendeur : réglée à l'usine

• Pression du collecteur : 25,4 cm (10" CE)

•

Sortie d'air chaud (CFM approx.) : 475 (13,45 m3)

• Moteur : 3 200 tr/min, 1/10 HP

• Entrée d'électricité : 120 V/60 Hz

• Intensité du courant électrique : 2,9

• Allumage : continu

•

Écart de l'allumeur : 3,3 à 3,8 mm (0,13 à 0,15 po)

SERVICE TECHNIQUE

Vous avez peut-être d'autres questions sur cet appareil de chauffage. Si c'est le cas, communiquez

avec le service technique de DESA Heating Pro

ducts au 1-866-672-6040. Lorsque vous appelez,

ayez sous la main les numéros de modèle et de

série de votre appareil de chauffage.

Vous pouvez aussi visiter le site Web du ser

vice technique de DESA Heating Products à

www.desatech.com

.

www.desatech.com

PIÈCES DE RECHANGE

AVERTISSEMENT : n'utilisez

que des pièces de rechange

d'origine. Cet appareil de chauffage utilise des pièces conçues

spécifiquement pour lui. Ne pas

utiliser de substituts ou de pièces génériques. L'utilisation de

pièces de rechange inadéquates

peut causer des blessures graves ou fatales. Ceci protégera

également la garantie des pièces

remplacées sous garantie.

PIÈCES SOUS GARANTIE

Communiquez avec un revendeur autorisé de ce

produit. S'il ne peut vous fournir des pièces de

remplacement d'origine, appelez DESA Industries

au 1-905-826-8010.

Lorsque vous appelez DESA Industries, soyez

prêt à fournir :

• votre nom

• votre adresse

• le numéro du modèle de l'appareil de chauffage

• une description de la panne de l'appareil de

chauffage

• la date de l'achat

En général, nous vous demanderons de retourner

la pièce à l'usine.

PIÈCES QUI NE SONT PAS SOUS

GARANTIE

Communiquez avec un revendeur autorisé de ce

produit. S'il ne peut vous fournir des pièces de rem

placement d'origine, appelez le Service des pièces

de DESA Industries au 1-905-826-8010.

Lorsque vous appelez DESA Industries, soyez

prêt à fournir :

• le numéro du modèle de l'appareil de chauffage

• le numéro de la pièce de rechange

ACCESSOIRE

Achetez les accessoires et les pièces chez un

revendeur ou au centre de service le plus près de

chez vous. Si votre revendeur ou le centre de service

ne peut fournir un accessoire ou une pièce, appelez

le Service des pièces de DESA Industries au 1-905826-8010. Vous pouvez aussi nous écrire à l'adresse

indiquée au dos de ce manuel.

RACCORD DE GAZ - LPA4020

Permet de raccorder le détendeur à tout réservoir

de propane standard. Sur la liste U.L. et A.G.A.

103908-01E12

-

Page 27

DIAGRAMME DE CÂBLAGE

Noir

Vert

Blanc

Moteur

Allumeur

Orange

Bleu

Bleu

Vanne de

contrôle

automatique

Thermocouple

1 2

3 4

5 6

87

Interrupteur

thermique

Bornier

Bleu

Noir

Commande

d’allumage

Blanc

Relais

Vert

Vert

Noir

Noir

Blanc

Blanc

Ve

rt

Cordon

électrique

Diagramme de la connexion électrique