Desa MSRBVN, MSRBVP User Manual

CAST IRON STOVE AND B-VENT

(FREESTANDING FIREPLACE HEATER)

BURNER SYSTEM

OWNER’S OPERATION AND INSTALLATION MANUAL

NATURAL GAS BURNER SYSTEM MODEL MSRBVN

PROPANE/LP GAS BURNER SYSTEM MODEL MSRBVP

REMOTE READY

IMPORTANT: This b-vent burner system must be installed into approved Sun Valley cast iron stove

bodies, models MC(*) series ONLY. See page 3 of this manual.

QUALIFIED INSTALLER: If you encounter problems during installation of this product, please

contact DESA International’s Technical Service Department at 1-800-337-2564.

* Indicates Color Suffix Designation

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

This appliance may be installed in an aftermarket*, permanently located manufactured

(mobile) home, where not prohibited by state or local codes.

WARNING: Improper installation,

adjustment, alteration, service, or

maintenance can cause injury or

property damage. Refer to this

manual for correct installation and

operational procedures. For assistance or additional information

consult a qualified installer, service agency, or the gas supplier.

— Installation and service must

be performed by a qualified installer, service agency, or the gas

supplier.

— This appliance is only for use

with the type of gas indicated on

the rating plate. This appliance is

not convertible for use with other

gases, unless a certified kit is used.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

Save this manual for future reference.

SUN VALLEY STOVE COMPANY

CAST IRON STOVE AND BURNER SYSTEM

SAFETY

INFORMATION

WARNINGS

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate, or service this stove and burner

system. Improper use of this stove

and burner system can cause serious injury or death from burns,

fire, explosions, electrical shock,

and carbon monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

This stove with burner system is a vented

product. If this unit is not properly installed by

a qualified service person with glass door

properly seated and sealed, gas combustion

products can spill into your home.

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning resemble the

flu, with headaches, dizziness, or nausea. If

you have these signs, the stove may not have

been installed properly. Get fresh air at

once! Have stove inspected and serviced by

a qualified service person. Some people are

more affected by carbon monoxide than others. These include pregnant women, people

with heart or lung disease or anemia, those

under the influence of alcohol, and those at

high altitudes.

Propane/LP gas and natural gas are both

odorless. An odor-making agent is added to

each of these gases. The odor helps you

detect a gas leak. However, the odor added

to these gases can fade. Gas may be present

even though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this stove and burner system.

WARNING: Any change to

this stove or burner system or its

controls can be dangerous.

1. This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases unless a certified kit

is used.

2. For propane/LP burner system, do not

place propane/LP supply tank(s) inside

any structure. Locate propane/LP supply tank(s) outdoors. T o prevent performance problems, do not use propane/LP

fuel tank of less than 100 lbs. capacity.

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do

not use any phone in your building

• immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions

• if you cannot reach you gas supplier ,

call the fire department.

4. Never install the stove

• in a recreational vehicle

• where curtains, furniture, clothing, or

other flammable objects are less than

42" from the front, top, or sides of

the fireplace

• in high traffic areas

• in windy or drafty areas

5. This stove reaches high temperatures.

Keep children and adults away from hot

surfaces to avoid burns or clothing ignition. Stove will remain hot for a time

after shutdown. Allow surfaces to cool

before touching.

6. Carefully supervise young children

when they are in the room with stove.

7. Do not modify this burner or stove under any circumstances. Any parts removed for servicing must be replaced

prior to operating stove or burner system.

8. Turn burner system off and let cool

before servicing, installing, or repairing. Only a qualified service person

should install, service, or repair the

stove or burner system. Have burner

system inspected annually by a qualified service person.

9. You must keep control compartments,

burners, and circulating air passages

clean. More frequent cleaning may be

needed due to excessive lint and dust

from carpeting, bedding material, pet

hair, etc. T urn of f the gas valve and pilot light before cleaning stove.

10. Have venting system inspected annually by a qualified service person. If

needed, have venting system cleaned

or repaired. See Cleaning and Mainte-

nance, page 22.

11. Keep the area around your stove clear

of combustible materials, gasoline, and

other flammable vapor and liquids. Do

not run burner system where these are

used or stored. Do not place items such

as clothing or decorations on or around

stove.

12. Do not use this stove to cook food or

burn paper or other objects.

13. Never place anything on top of stove.

14. Do not use any solid fuels (wood, coal,

paper, cardboard, etc.) in this stove. Use

only the gas type indicated on burner

system nameplate.

15. This appliance, when installed, must be

electrically grounded in accordance

with local codes or, in the absence of

local codes, with the National Electri-

cal Code, ANS/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

16. Do not obstruct the flow of combustion and ventilation air in any way . Provide adequate clearances around air

openings into the combustion chamber

along with adequate accessibility clearance for servicing and proper operation.

17. Do not install stove directly on carpeting, vinyl tile, or any combustible material other than wood. The stove must set

on a metal or wood panel extending the

full width and depth of the stove.

18. Do not use stove or burner system if

any part has been exposed to or under

water. Immediately call a qualified ser vice person to arrange for replacement

of the unit.

19. Do not operate burner system if an y

log is broken.

20. Do not use a blower insert, heat exchanger insert, or other accessory not

approved for use with this stove.

21. Do not operate burner system with

glass door removed, cracked, or broken.

22. This burner system must be properly

connected to a vent system. This burner

system is equipped with a vent safety

shutoff system.

For more information, visit www.desatech.com

2

106706

OWNER’S MANUAL

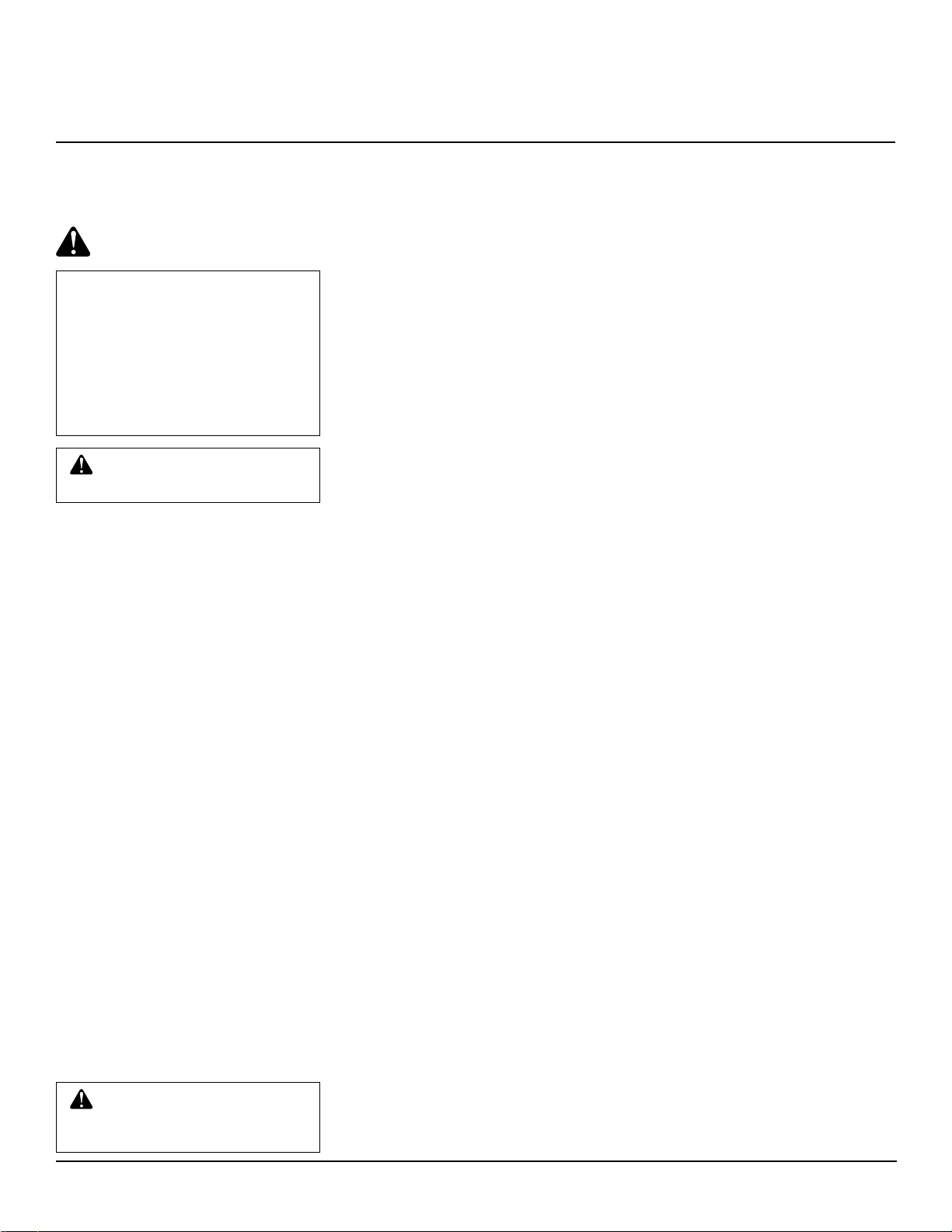

PRODUCT

IDENTIFICATION

Cast Iron

Stove Body

Log Set

ON/OFF Switch

(Opposite Side)

Piezo Ignitor

O

H

L

I

OFF

ON

Control Valve

Cast Iron

Stove Body

LOCAL CODES

Install and use stove and burner system with

care. Follow all local codes. In the absence

to local codes, use the current National Fuel

Gas Code ANS Z223.1, also known as

NFPA 54* (USA) or the current CAN/CGA-

B149[.1 or .2] Installation Codes (Canada).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

PRODUCT

FEATURES

OPERATION

This B-vent freestanding stove with burner

system is clean burning and vents vertically.

Heat is generated by both realistic flames

and glowing embers. When used without

the blower accessory, the stove with burner

system requires no electricity making it

ideal for emergency backup heat.

Venting

System

Draft Hood

Relief

Opening

Pilot Assy

Blower with

Adjustment

Knob (Optional

Installation)

Rear Cover

Glowing Embers

Grate Assembly

Figure 1 - Sun Valley B-Vent Freestanding Fireplace Shown Installed in Approved Sun

Valley Cast Iron Stove Body Models MC Series Only

Burner

Glass Door

Assembly

Lava Rock

PIEZO IGNITOR

This burner system has a piezo ignitor. This

system requires no matches, batteries, or

other sources to light burner system.

106706

3

For more information, visit www.desatech.com

SUN VALLEY STOVE COMPANY

CAST IRON STOVE AND BURNER SYSTEM

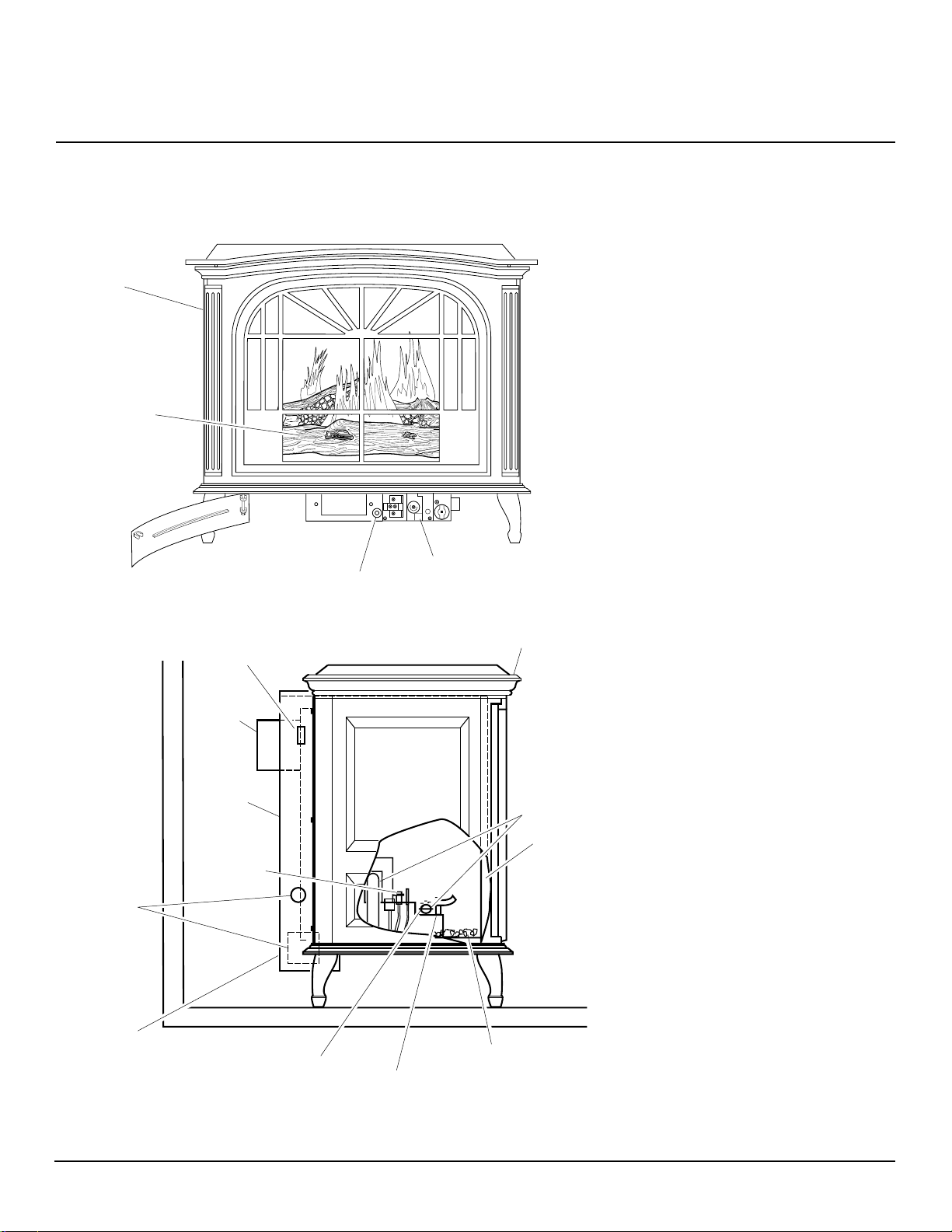

PRE-INSTALLATION

PREPARATION

WARNING: A qualified service person must install stove

and burner system. Follow all local codes.

Corner Installation

CAUTION: This stove creates

warm air currents. These currents

move heat to wall surfaces next

to stove. Installing stove next to

vinyl or cloth wall coverings or

operating stove where impurities

(such as tobacco smoke, aromatic candles, cleaning fluids,

oil or kerosene lamps, etc.) in the

air exist, may discolor walls.

LOCATION AND SPACE

REQUIREMENTS

Determine the safest and most efficient location for your Sun Valley B-vent freestanding

stove. Make sure that rafters and wall studs

are not in the way of the venting system.

Choose a location where the heat output is

not affected by drafts, air conditioning ducts,

windows, or doors. Figure 2 shows some

common locations. Read all venting information in this manual. Be aware of all restrictions and precautions before deciding the

exact location for your stove.

When deciding the location of your stove,

follow these rules:

1. Do not connect this stove and burner

system to a chimney flue serving a

separate solid-fuel burning fireplace or

appliance.

2. Due to high temperatures, do not locate this stove in high traffic areas or

near furniture or draperies.

3. Proper clearances must be maintained,

see Figures 3 and 4.

4. This stove is a freestanding unit designed to set directly on the floor. If

your stove is to be installed directly on

carpeting, vinyl tile, or any combustible

material other than wood, it must be

installed on a metal or wood panel extending the full width and depth of the

stove. See Figure 5.

On Wall with Vertical

Termination Through Ceiling

Figure 2 - Common Freestanding Stove Locations

Ceiling

42"

6"

36"

from

Front

Floor

Figure 3 - Minimum Clearances for Standard Installation

4"

Figure 4 - Minimum Clearance for Corner

Installation

29"

4"

from

Back

Wall

21 1/4"

4"

1

19

/2"

Figure 5 - Freestanding Stove with Burner

System Bottom Dimensions

4"

Front

26"

Front

For more information, visit www.desatech.com

4

106706

CAST IRON STOVE

OWNER’S MANUAL

AND B-VENT

BURNER SYSTEM

ASSEMBLY

STOVE BODY ASSEMBLY

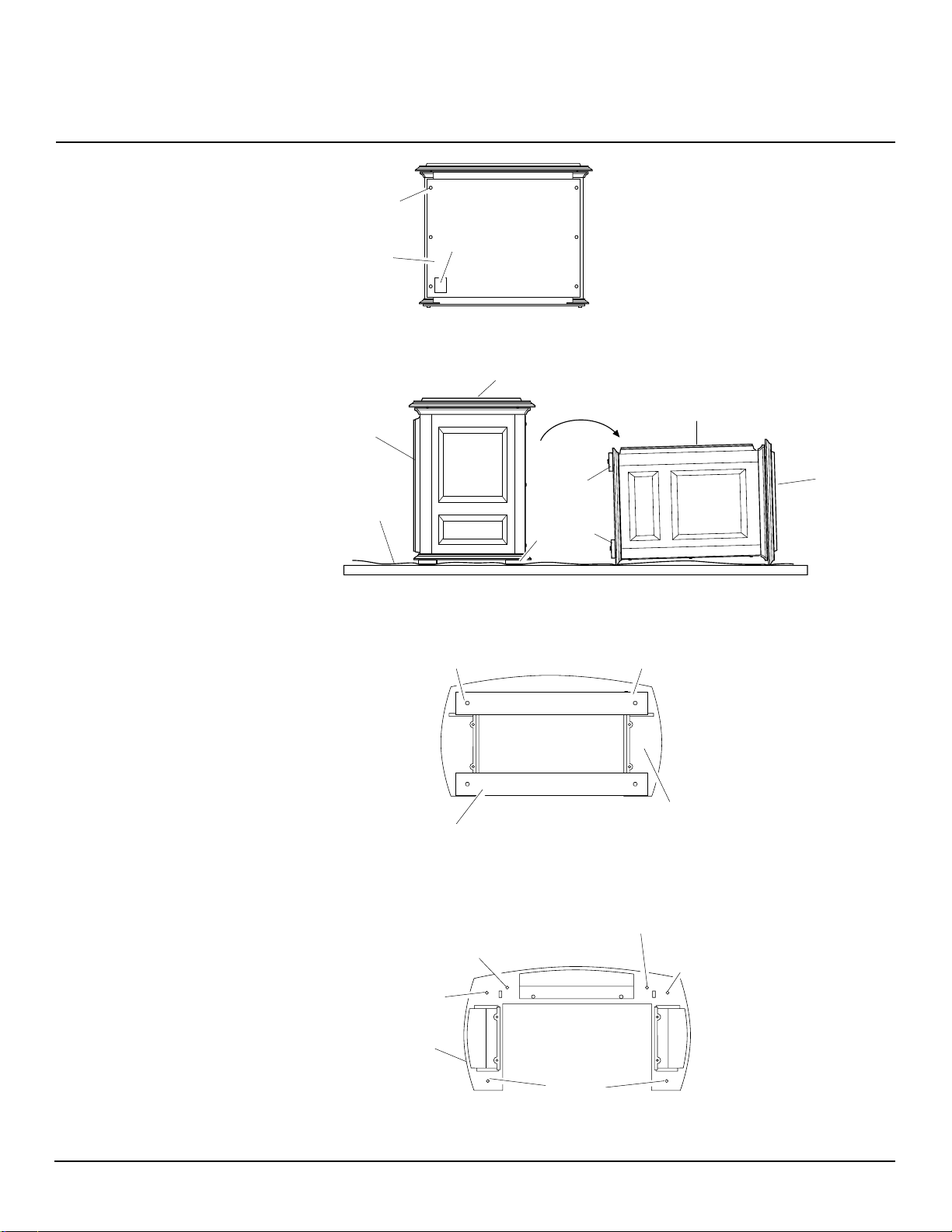

1. Lift off corrugated box enclosing stove

body crating.

2. Remove all screws fastening the wood

frame enclosure. Spread wood frame open

and lift away from plastic-bagged stove

body. The bottom pieces of pallet wood

will remain bolted to the stove body.

3. Remove plastic bag from stove body.

4. Remove back panel from stove and discard (see Figure 6). Use an adjustable

wrench or a 10 mm socket. Remove six

(6) bolts and washers. Keep bolts and

washers to attach rear cover.

5. Remove all contents from inside stove

cavity. Contents include:

(1) - Stove bottom (Discard - Not used

with this application)

(4) - Legs with leg leveler bolts

(1) - Bottom door

(3) - Top grates

(1) - Hardware kit bag with fasteners

6. Carefully lay stove body on back to attach bottom components to stove body

(see Figure 7). Rest stove on drop cloth

or blanket to avoid scratching stove edges.

7. Remove remaining pallet wood attached to bottom of stove body (see

Figure 8). Use an adjustable wrench to

remove bolts.

8. Fasten each leg to stove with four (4)

M8 x 1.25 - 20mm bolts. Use a flat

washer and lock washer with each bolt.

Tighten bolts into threaded holes on

stove body (see Figure 9 and Figure 10,

page 6). Use an adjustable wrench or a

12mm socket.

Bolt

Back

Stove

Panel

Figure 6 - Removing Back Panel

Front of

Stove Unit

Drop

Cloth/

Blanket

Figure 7 - Laying Down Stove On Side

Pallet Wood

Figure 8 - Removing Pallet Wood From The Bottom of The Stove

Door Hinge

Step Bolt Hole

Product

Identification

Label

Top of Stove Unit

Bolt

Leg

Hole

Front of Stove Unit

Pallet

Wood

Bolted to

Bottom of

Stove Body

Front

Door Catch Bolt With

Adjustable Hex Nuts Hole

Front

Pallet Wood

Bottom Of

Stove Unit

Leg

Hole

Stove

Unit

106706

Bottom Of

Stove Unit

Leg Hole

Figure 9 - Locating Threaded Holes for Legs and Door Attachment

5

For more information, visit www.desatech.com

Continued

SUN VALLEY STOVE COMPANY

CAST IRON STOVE AND BURNER SYSTEM

CAST IRON STOVE

AND B-VENT

BURNER SYSTEM

ASSEMBLY

Continued

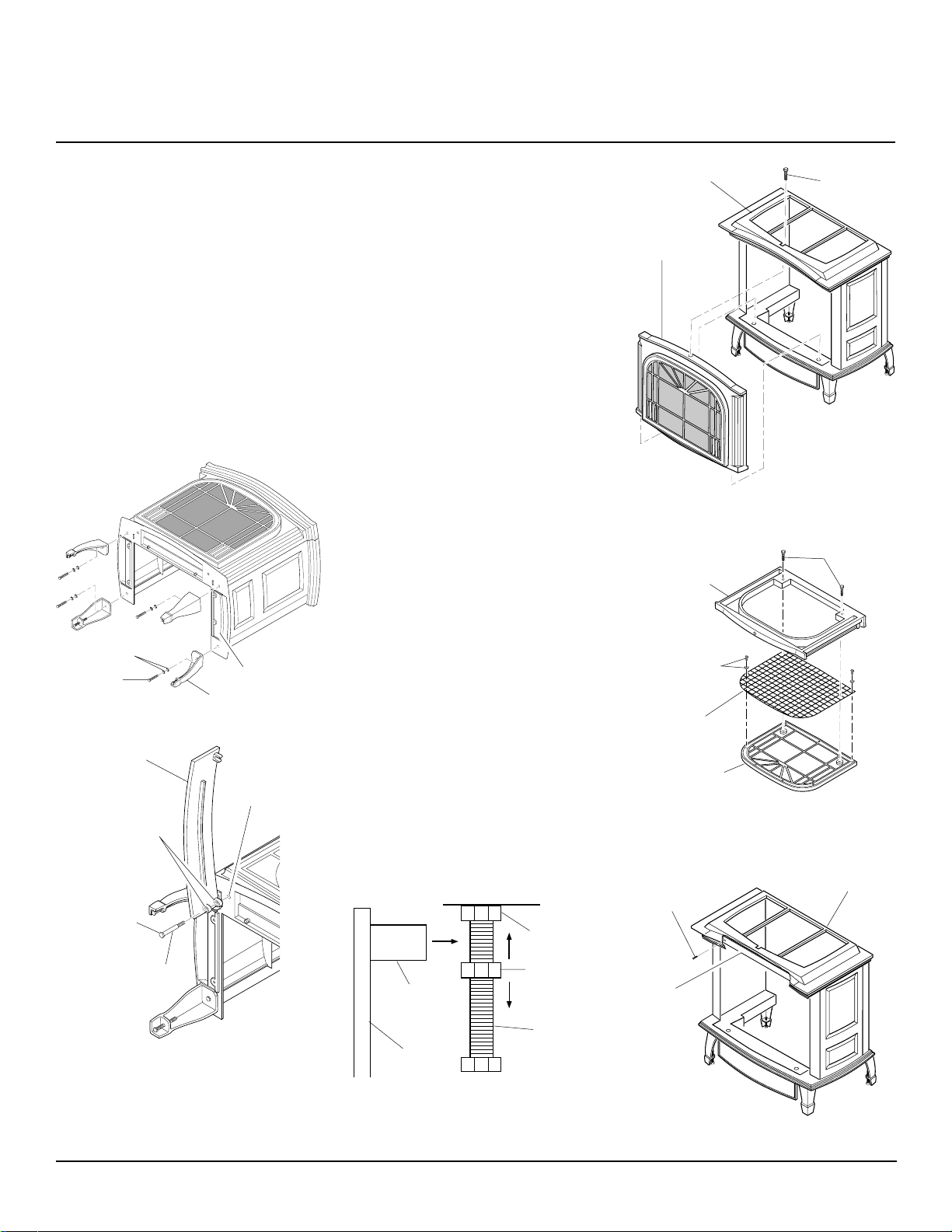

9. Attach stove door by inserting step bolt

through door hinge pivot hole and into

threaded hole in stove body (see Figure 9, page 5 and Figure 11). Use an

adjustable wrench or a 12mm socket

to fasten step bolt. Tighten step bolt

until snug. Make sure door moves

freely.

Washers

Bolt

Figure 10 - Attaching Stove Legs

Stove Door

Panel

Door Hinge

Step

Bolt

Bolt

Shoulder

Figure 11 - Attaching Lower Stove Door

Panel

Bottom Of

Stove Unit

Leg

Threaded

Hole

10. Install door catch bolt (M8 x 1.25-55mm

with two M8 hex nuts) into threaded

hole on stove body (see Figure 9, page

5). Use an adjustable wrench or a 12mm

socket. The catch bolt has two hex nuts

attached to it (see Figure 12). The top

nut is a bolt stop and the bottom nut is

for door leveling adjustment.

11. Check general catch bolt alignment

with door claw. Make final adjustment

and door leveling after stove is in normal standing position (see Figure 12).

12. Carefully lift stove back up on its four

attached legs.

13. Remove 2 bolts from bottom of stove

and one from the top of the stove to

remove the front panel assembly (see

Figure 13). Save bolts.

14. Lay the front panel assembly face down

on a protected surface. Remove the two

screws that hold the front plate onto the

front surround plate (see Figure 14).

Save these screws.

15. Remove the seven screws and washers

that hold the screen onto the front surround plate. Discard these screws,

washers, and screen. They are for ventfree use only (see Figure 14).

16. Replace the two screws from step 14

to reassemble the front plate and the

front surround plate. Set this assembly

aside until stove heater has been installed, logs have been placed inside of

heater, and glass door to heater insert

has been replaced.

17. Remove the two screws that secure the

metal plate located across the front section at the top of the stove body (see Figure 15). Discard these screws and metal

plate. They are for vent-free use only.

Bolt

Stop

Adjusting

Door

Claw

Door

Figure 12 - Catch Bolt and Door Claw

Orientation

Nut

Catch

Bolt

Stove

Body

Front

Assembly

Figure 13 - Removing Front Assembly

Front

Surround

Plate

Screw with

Washer

Screen

Front Plate

Figure 14 - Removing Screen from Front

Assembly

Screw

Metal

Plate

Figure 15 - Removing Metal Plate from

Stove Body

Bolt

Screws

Stove Body

For more information, visit www.desatech.com

6

106706

OWNER’S MANUAL

CAST IRON STOVE

AND B-VENT

BURNER SYSTEM

ASSEMBLY

Continued

INSTALLING B-VENT

BURNER SYSTEM INTO

STOVE BODY

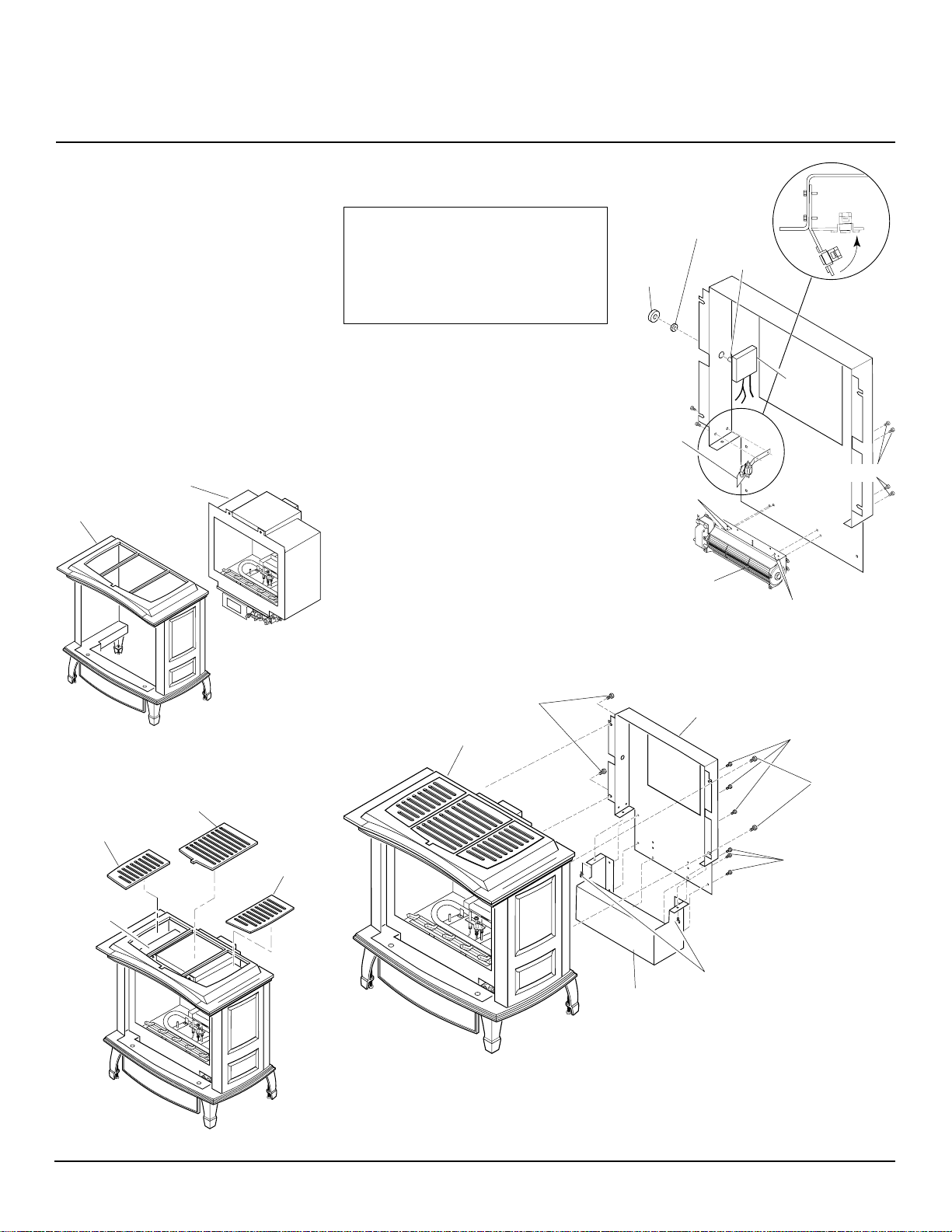

1. Carefully lift burner system and place

into stove body from the rear of stove

(see Figure 16).

2. Place the left, right, and center grate

top into top of stove body.

Burner

Cast Iron

Stove Body

System

O

L

H

I

F

P

F

I

O

L

O

O

T

N

INSTALLING OPTIONAL

BLOWER ACCESSORY

NOTICE: If installing blower in an

existing stove burner system with

gas connections, shut off gas supply and disconnect burner system from gas supply. Contact a

qualified service person to do this.

1. Remove 4 hex screws securing rear cover

to back of stove body (see Figure 18).

2. Separate bottom cover from rear cover

by loosening the 8 mounting screws

(see Figure 18).

3. Align the holes in the top mounting tabs

of blower with the holes in wall of rear

cover. Using the 4 screws provided,

mount blower and tighten screws securely (see Figure 19).

4. Attach thermal switch and bracket to

inside rear cover wall with two hex head

screws provided as shown. After secur ing bracket to rear cover, carefully bend

along existing bend line on bracket to

almost a 90° angle (see Figure 19). This

will allow thermal switch to be positioned against stove rear wall and sense

temperature when in operating mode.

Locknut

Blower

Control

Control

Shaft

Knob

TOP VIEW

Speed

Thermal

Control

Switch

and

Bracket

Screws

Mounting

Holes

Blower

Assembly

Mounting

Holes

Figure 19 - Blower Assembly, Speed

Control, and Thermal Switch Locations

Figure 16 - Installing Burner System into

Cast Iron Stove Body

Center Top Grate

(Included with Stove

Body)

Left Top Grate

Right

Top

Grate

Burner

System

in Stove

Body

Figure 17 - Installing Top Grates

Hex Screws

Rear Cover

Stove Body

Mounting

Screws

Mounting

Screws

Mounting

Screws

Bottom Cover

Figure 18 - Removing Rear Cover and Bottom Cover from Stove Body

Hex

Screws

Continued

106706

7

For more information, visit www.desatech.com

SUN VALLEY STOVE COMPANY

CAST IRON STOVE AND BURNER SYSTEM

CAST IRON STOVE

AND B-VENT

BURNER SYSTEM

ASSEMBLY

Continued

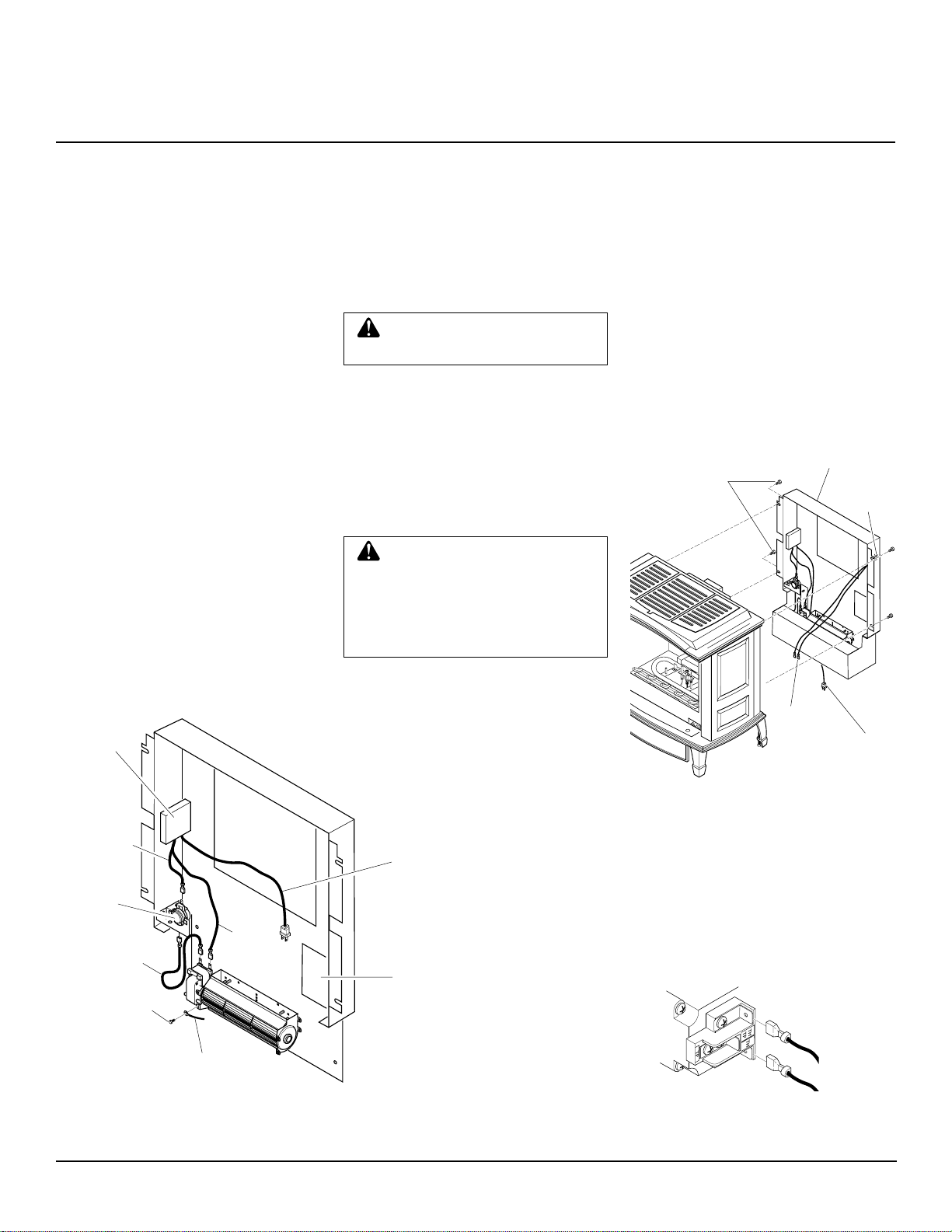

5. Place speed control on left inside of rear

cover and push the plastic control shaft

through opening (see Figure 19).

6. While supporting speed control, secure

control shaft with lock nut by pushing and

turning lock nut with pliers clockwise

until tight against the side of rear cover.

Place control knob provided onto shaft.

7. Place the green ground w ire be tween the

bottom hole on the blower assembly and

the hex screw and tighten (see Figure 20).

8. Connect the blue wire to the blower assembly and one side of the thermal

switch (see Figure 20).

9. Connect the black wire to the other side

of the thermal switch (see Figure 20).

10. Connect the white wire to the other terminal on the blower motor assembly

(see Figure 20). Make sure the thermal

switch has been properly installed to fit

against back of fireplace insert after the

rear cover assembly has been reinstalled.

Speed

Control

Box

11. Make sure all wire connections to terminals on blower motor and thermal switch

are securely attached and that the screw

retaining the green ground wire is tight.

12. Check to make sure that the power cord

is completely clear of the blower wheel

and that there are no foreign objects in

blower wheel.

WARNING: Never touch the

blower wheel while in operation.

13. Peel of f the backing paper and stick the

supplied wiring diagram decal on the

inside of rear cover as shown (see Figure 20).

14. Connect or reconnect gas supply following instructions in Connecting

Stove and Burner System to Gas Supply, page 14.

WARNING: Failure to position

the parts in accordance with supplied diagrams or failure to use

only parts specifically approved

with this heater may result in damage or personal injury.

INSTALLING REAR COVER

1. Place rear cover behind stove body.

Rear cover will rest on the bottom ledge

of the stove body.

2. Place wire harness from ON/OFF

switch under the cast of stove body.

3. Using screws provided, attach rear cover

to back of stove body. See Figure 21.

IMPORTANT:

securely in place before venting pipes

are installed.

4. Open lower door panel on front of stove

to locate valve.

Hex

Screws

This rear cover must be

Rear Cover (Shown

with Optional Blower)

ON/OFF

Switch

ON/OFF

Switch

Wire

Harness

Blower

Power

Cord

Black

Wire

Thermal

Switch

Blue

Wire

Screw

Green Ground Wire

Figure 20 - Blower Wiring Layout

For more information, visit www.desatech.com

White

Wire

Power Cord

(Route Through

Plastic Bushing in

Bottom Cover When

Assembled)

Wiring

Diagram

Decal

8

Figure 21 - Installing Rear Cover (Shown

with Optional Blower Accessory)

5. Connect one wire terminal from ON/OFF

switch to the THTP terminal on the valve.

Connect remaining wire terminal to the

TH terminal on the valve. Make sure that

the wire terminals are in the positions on

the unit as pictured in Figure 22. If wires

are not connected as shown, the ON/OFF

switch will not work.

To Control

Switch

Figure 22 - Control Valve Terminals

106706

OWNER’S MANUAL

CAST IRON STOVE

AND B-VENT

BURNER SYSTEM

ASSEMBLY

Continued

6. Reattach bottom cover to rear cover

with 8 screws removed in step 2 on

page 8 (see Figure 18, page 7). Make

sure that you don’t pinch any wires

during reassembly.

WARNING: A qualified installer or service person must

connect burner system to gas

supply. Follow all local codes.

VENTING

INSTALLATION

WARNING: Read all instructions completely and thoroughly

before attempting installation. Failure to do so could result in serious

injury, property damage, or loss of

life. Operation of improperly installed and maintained venting system could result in serious injury,

property damage, or loss of life.

NOTICE: Failure to follow these

instructions will void the warranty.

INSTALLATION PRECAUTIONS

Consult local building codes before beginning the installation. Only a qualified service person should install venting system.

The installer must follow these safety rules:

• Wear gloves and safety glasses for

protection

• Use extreme caution when using ladders

or when on roof tops

• Be aware of electrical wiring locations

in walls and ceilings

The following actions will void the warranty on your venting system:

• Installation of any damaged venting

component

• Unauthorized modification of the venting system

• Installation of any component part not

manufactured or approved by DESA

International

• Installation other than as instructed by

these instructions

Your burner system is approved for use with

any listed gas vent. A listed gas vent is a factory

made and listed system designed, and installed

exclusively for removing products of combustion, excess air, and dilution air resulting from

burning fuel gas. Metal vents, the most common type of vent, employ double wall construction enclosing an insulating air space.

This air space both helps keep flue gases warm

and reduce heat transferred to nearby combustibles. This appliance is equipped with a safety

control system designed to protect against

improper venting of combustion products.

It is very important that the venting system

maintain its balance between the combustion air intake and the flue gas exhaust.

Certain limitations apply to vent configurations and must be strictly followed.

WARNING: This gas stove with

burner system and vent assembly

must be vented directly to the outside. The venting system must

NEVER be attached to a chimney

serving a separate solid fuel burning appliance.

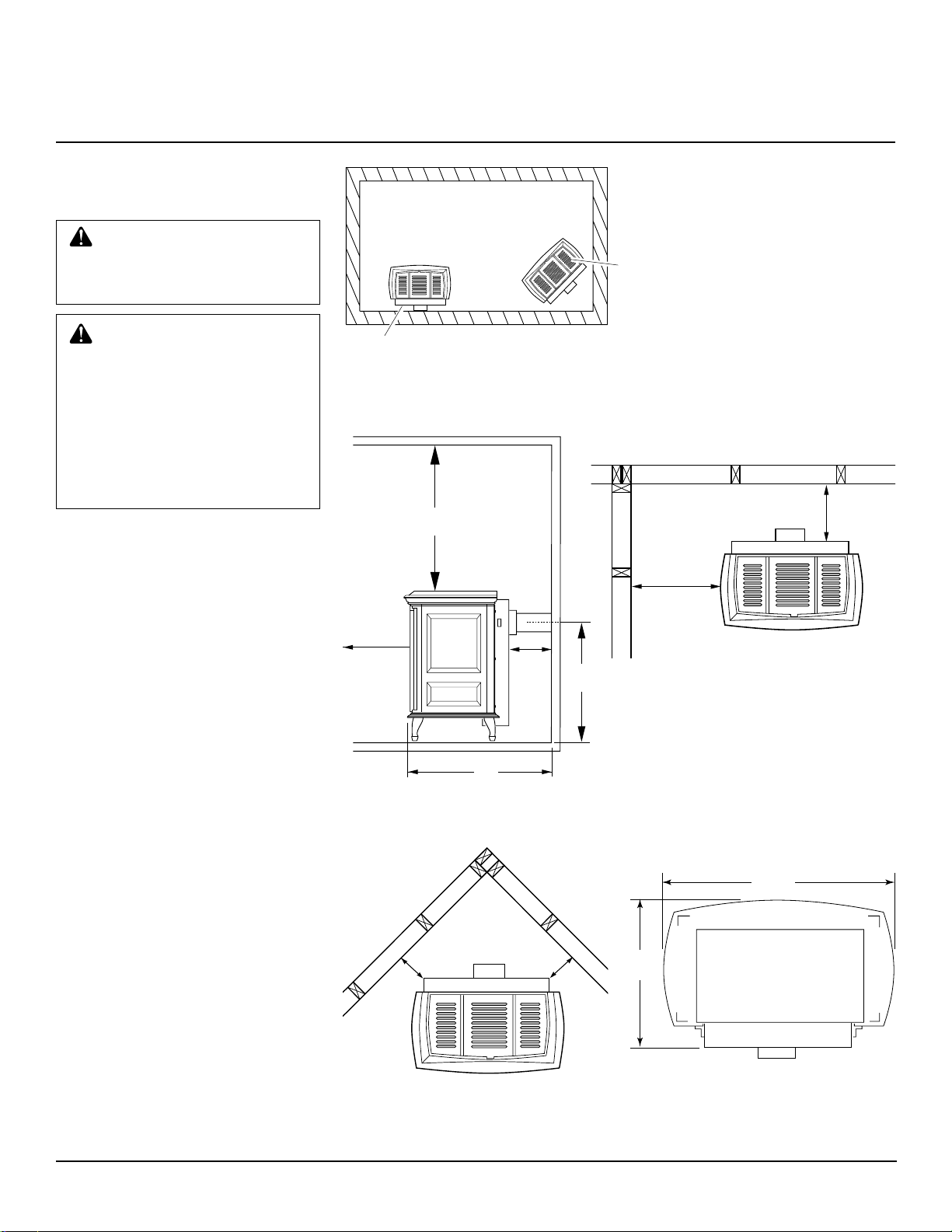

TYPE B-VENT INSTALLATION

(Listed B-0 or Greater)

Before beginning installation be sure that the

overall height and gas vent size conform to

building code requirements. Gas vents extending through pitched roofs can extend a

minimum height of at least 600 mm (2')

higher than any obstruction within 3m (10').

Gas vents extending through flat roofs are

required to extend at least 600 mm (2') above

the roof and at least 600 mm (2') higher than

any portion of the building or adjoining building within 3m (10') of the gas vent.

• Venting instruction contained in this

manual may or may not apply to your

area. Consult your local authority for requirement in your area.

• Where the gas vent extends through accessible spaces, it should be enclosed to

avoid personal contact and damage. Enclosure walls should have a fire rating

equal to or greater than the floors through

which the gas vent passes except in single

or two-family dwellings.

• Situate the gas vent in the structure so

that it can be installed without cutting

joists, sills, plates, or major load bearing

partitions or members. It is also important to locate the base of the gas vent as

near as possible to the heating appliance.

• This heater must be properly connected to

a venting system. This heater is equipped

with a vent safety shutoff system.

• Use only vents labeled "FOR EXTERIOR USE" above the roofline.

• Consult the authority having jurisdiction to select the correct gas vent diameter. Avoid using a larger than necessary diameter.

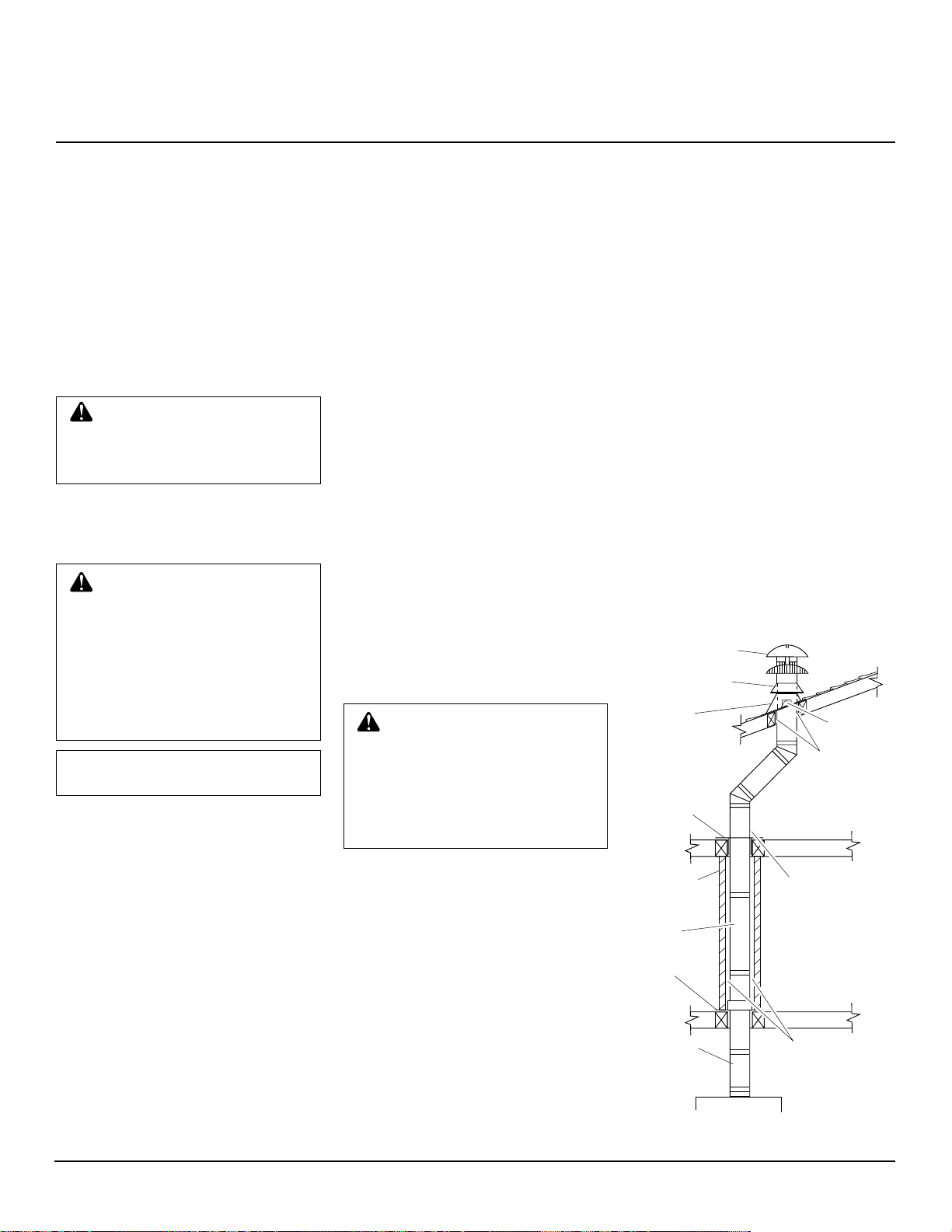

Round Top

Storm Collar

Flashing

Firestop

Spacer

Enclosure

Wall

Gas Vent

Length

Support

Plate

Adjustable

Length

Figure 23 - Typical B-Vent Installation

Keep Electrical

Wires and Building

Insulation Away

from Gas Vent and

Out of the Required

Air Space

Roof

Support

25mm (1")

Clearance to

Combustible

Material

25mm (1")

Clearance to

Combustibles

Continued

106706

9

For more information, visit www.desatech.com

SUN VALLEY STOVE COMPANY

CAST IRON STOVE AND BURNER SYSTEM

VENTING

INSTALLATION

Continued

INSTALLATION OF LISTED

B-1 VENT

WARNING: Installation should

only be made by qualified persons who are familiar with the

safety procedures required for

the installation of the product,

who are equipped with the proper

tools and testing instruments,

and who have achieved proper

certification of licensing. Installations made by unqualified persons can result in the risk of injury or electrical shock which can

be serious or even fatal.

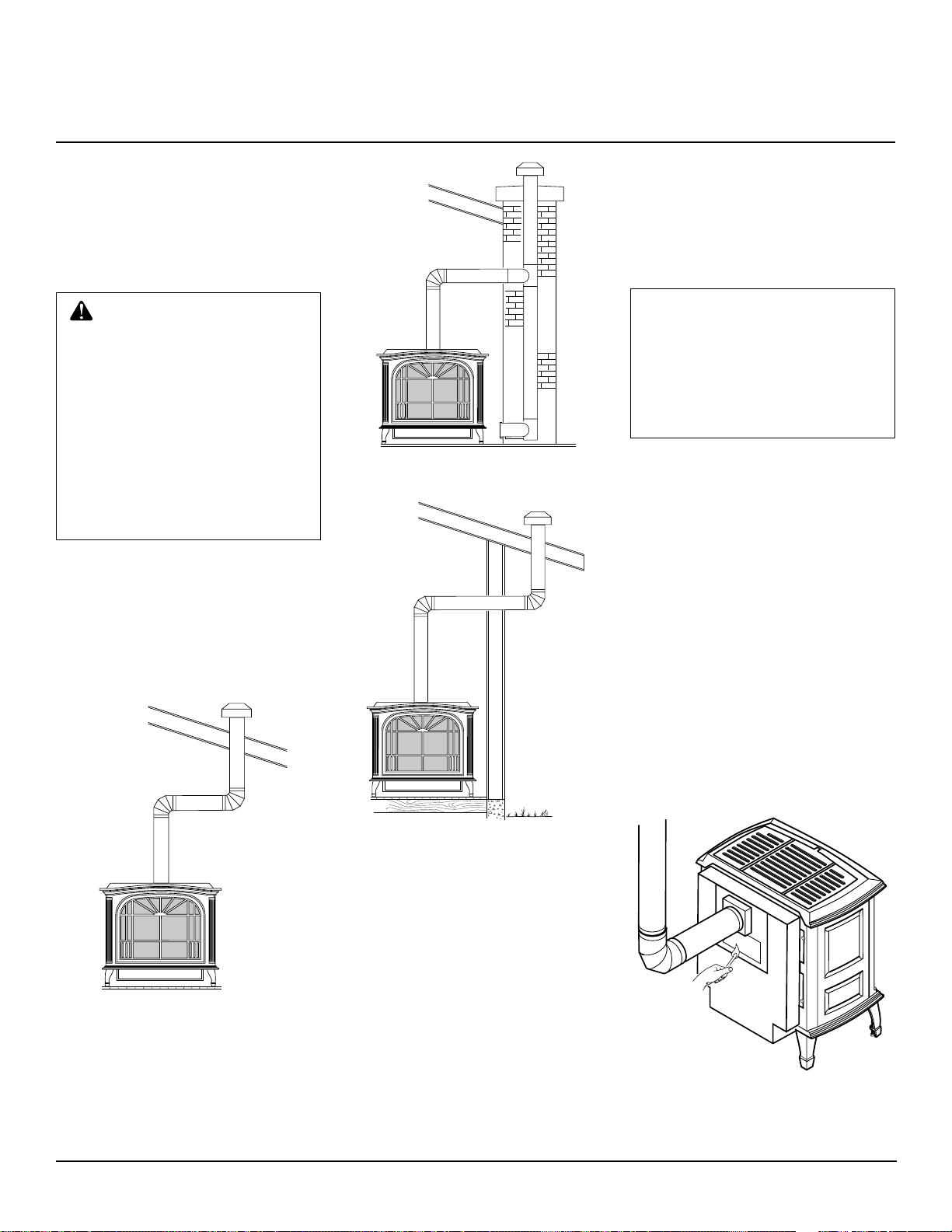

Figures 24, 25 and 26, show other options

for the gas vent. When venting through a

side wall your vent pipe must have the

proper temperature rating (see Figure 26).

Manufacturer’s clearances must also be

maintained. Consult the authority having

jurisdiction in your area regarding venting

through side wall.

Figure 25 - Vertical Venting Configuration

Through Chimney

INSTALLING VENT SYSTEM

IN A CHASE

A chase is a vertical boxlike structure built

to enclose venting that runs along the outside of a building. A chase is not required for

such venting.

NOTICE: Treatment of firestops

and construction of the chase

may vary from building type to

building type. These instructions

are not substitutes for the requirements of local building

codes. You must follow all local

building codes.

Note:

When installing in a chase, you should

insulate the chase as you would the outside

walls of your home. This is especially important in cold climates. Minimum clearance between vent pipes and combustible

materials such as insulation is 1".

CHECKING VENT CAPACITY

Complete all gas piping, electrical, and vent

connections. After adjusting the fireplace

and lighting the main burners, allow a couple

of minutes for warm-up. Hold a lighted

match just under the rim of the draft hood

relief opening. Proper venting will draw the

flame toward or into the draft hood. Improper venting, indicated by escape or spillage of burned gas, will cause match to

flicker or go out. Smoke from a cigarette

will also be pulled into the draft hood if the

vent is drawing properly.

Figure 26 - Venting Through a Side Wall

Figure 24 - Vertical Venting Through

Ceiling Using Two 90° Elbows

For more information, visit www.desatech.com

10

Figure 27 - Test for Proper Venting

106706

Loading...

Loading...