Page 1

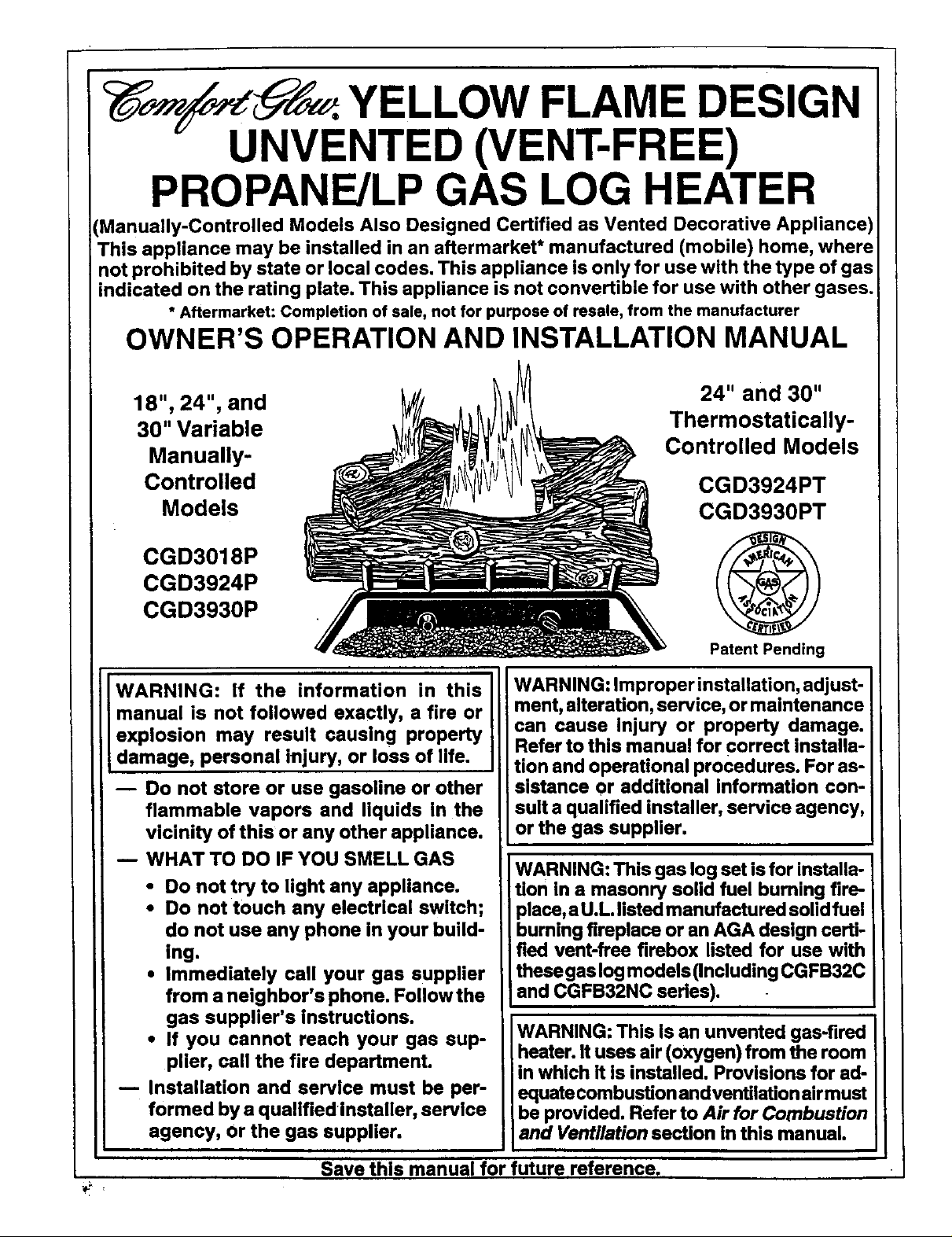

YELLOW FLAME DESIGN

UNVENTED (VENT-FREE)

PROPANE/LP GAS LOG HEATER

IManuaily-Controlled Models Also Designed Certified as Vented Decorative Appliance)

Thin apphance may be installed in an aftermarket* manufactured (mobile) home, where

not prohibited by state or local codes. This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not convertible for use with other gases.

* Aftermarket: Completion of safe, not for purpose of resale, from the manufacturer

OWNER'S OPERATION AND INSTALLATION MANUAL

18", 24", and

30" Variable

Manually-

Controlled

Models

CGD3018P

CGD3924P

CGD3930P

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury, or loss of life.

u Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your build-

ing.

• Immediately call your gas supplier

from a neighbor's phone. Followthe

gas supplier's Instructions.

• If you cannot reach your gas sup-

plier, call the fire department.

Installation and service must be per-

formed by a qualified installer, service

agency, or the gas supplier.

24" and 30"

Thermostatically-

Controlled Models

CGD3924PT

CGD3930PT

Patent Pending

WARNING: Improper installation, adjust-

ment, alteration, service, or maintenance

can cause Injury or property damage.

Refer to this manual for correct installa-

tion and operational procedures. For as-

sistance or additional information con-

sult a qualified installer, service agency,

or the gas supplier.

WARNING: This gas log set is for installa-

tion in a masonry solid fuel buming fire-

plar_, a U.L.listedmanufactured solidfuel

burning fireplace or an AGA design certP

fled vent-free firebox listed for use with

these gas log models (Including CGFB32C

and CGFB32NC series)°

WARNING: This Is an unvented gas-fired

heater. It uses air (oxygen) from the room

in which it is installed. Provisions for ad-

equate combustion and ventilation air must

be provided. Refer to Air for Combustion

and Ventilation section in this manual.

Save this manual for future reference.

Page 2

CONTENTS

SECTION PAGE

Safety Information................................................................................... 2

Product Identification .............................................................................. 4

Local Codes ............................................................................................. 4

Unpacking ................................................................................................ 4

Product Features ...................................................................................... 4

Air for Combustion and Ventilation ........................................................ 5

Installing .................................................................................................. 8

Check Gas Type ............................................................................... 8

Installation and Clearances (Vent-pree Operation Only) ................. 9

Installing Damper Clamp Accessory for Vented Operation ............ 13

Installing Heater Base Assembly ..................................................... 14

Connecting to Gas Supply ................................................................ 15

Checking Gas Connections .............................................................. 17

Installing Logs .................................................................................. 19

Operating Heater (Manually-Controlled Models) ................................... 20

Operating Heater (Thermostatically-Controlled Models) ....................... 22

Inspecting Burners ................................................................................... 24

Cleaning and Maintenance ...................................................................... 25

Troubleshooting ....................................................................................... 25

Optional Positioning of Thermostat Sensing Bulb .................................. 29

Technical Service .................................................................................... 31

Specifications .......................................................................................... 31

Service Hints ........................................................................................... 31

Replacement Parts ................................................................................... 32

PartsCentral ............................................................................................ 32

Accessories .............................................................................................. 33

Illustrated PartsLists ............................................................................... 34

Warranty Information .............................................................................. Back Cover

SAFETY

INFORMATION

IMPORTANT: Read this owner's manual carefully and completely before

trying to assemble, operate, or service this heater. Improper use of this

heater can cause serious injury or death from burns, fire, explosion,

electrical shock, and carbon monoxide poisoning.

A WARNINGS

A DANGER

Carbon monoxide peisoning may lead to deatht

Carbon Monoxide Poisoning: Early signsof carbonmonoxide poisoningresemble

the flu, with headaches, dizziness, or nausea. If you have these signs, the heater may not

be working properly. Get fresh mr at once. Have heater serviced. Some people are more

affected by carbon monoxide than others. These include pregnant wome.n, people with

heart or lung disease or anemia, those under the influence of alcohol, and those athigh

altitudes.

Propane Gas: Propane gas is odorless. An odor-making agent is added to the gas. The

odor helps you detect a gas leak. However, the odor added to the gas can fade. Gas may be

present even though no odor exists.

Make certain you read and understand all Warnings. Keep thismanualfor reference. It is

your guide to safe and proper operation of this heater.

[ _J_ Safety Information continues on next page

10_04

Page 3

SAFETY

INFORMATION

Continued

I0_04

WARNINGS Continued

WARNING: Any change to this heater or its controls can be dangerous. "

1. This appliance is only for use with the type of gas indicated on the rating plate. Thi:

appliance is not convertible for use with other gases,

2. Do not place propane (LP) supply tank(s) inside any structure. Locate propane (LP) supply

tank(s) outdoors.

3. To prevent performance problems, do not use propane fuel tank ofless than 100 lbs. capacity.

4. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not use any phone in your building

• immediately call your gas supplier from a neighbor' s phone. Follow the gas supplier' s

instructions

• if you cannot reach your gas supplier, call the fire department

5. This heater shall not be installed in a bedroom or bathroom unless installed as a vented

appliance (Variable Manually-Controlled Models Only) (see page 13).

6. Never install the heater

• in a recreational vehicle

• where curtains, furniture, clothing, or other flammable objects are less than 36 inches

from the front, top, or sides of the heater

• in high traffic areas

• in windy or drafty areas

7. Before installing in a solid fuel burning fireplace, the chimney flue and firebox must be

cleaned of soot, creosote, ashes and loose paint by a qualified chimney cleaner. Creosote

will ignite if highly heated. Inspect chimney flue for damage. If damaged, operate heater

with flue damper closed.

8. If fireplace has glass doors, never operate this heater with glass doors closed. Ifyou operate

heater with doors closed, heat buildup inside fireplace will cause glass to burst. Also if

fireplace opening has vents at the bottom, you must open the vents before operating heater.

9. You must operate this heater with a fireplace screen in place. Make sure fireplace screen

is closed before running heater.

!0. This log heater is designed to be smokeless. If logs ever appear to smoke, turn off heater

and call a qualified service person. Note: During initial operation, slight smoking could

occur due to log curing and heater burning manufacturing residues.

11. Do not allow fans to blow directly into the fireplace. Avoid any drafts that alter burner

flame patterns. Ceiling fans can create drafts that alter burner flame patterns. Altered

burner patterns can cause sooting.

12, Do not use a blower insert, heat exchanger insert or other accessory not approved for use

with this heater.

13. This heaterneeds fresh, outside air ventilation to run properly. This heater has an oxygen

depletion sensor (ODS) pilot light safety system. The ODS shuts down the heater if not

enough fresh airis available. See Air for Combustion and Ventilation, pages 5 through 8.

If heater keeps shutting off, see Troubleshooting, pages 25 through 28.

14. Do not run heater

• where flammable liquids or vapors are used or stored

• under dusty conditions

15. Do not use this heater to cook food or burn paper or other objects.

16. Never place any objects on the heater.

17. Heater base assembly becomes very hot when running heater. Keep children and adults

away from hot surface to avoid burns or clothing ignition. Heater will remain hot for atime

after shutdown. Allow surface to cool before touching.

18. Carefully supervise young children when they are in the room with heater.

19. Do not use heater if any part has been exposed to or under water. Immediately call a

qualified service technician to inspect the room heater and to replace any part of the conU'ol

system and any gas control which has been under water.

20. Do not operate heater ifany log is broken. Do not operate heater if a log is chipped (dime-

sized or larger).

21. Turn heater off and let cool before servicing. Only a qualified service person should

service and repair heater.

22. Operating heater above elevations of 4,500 feet could cause pilot outage, m_

Page 4

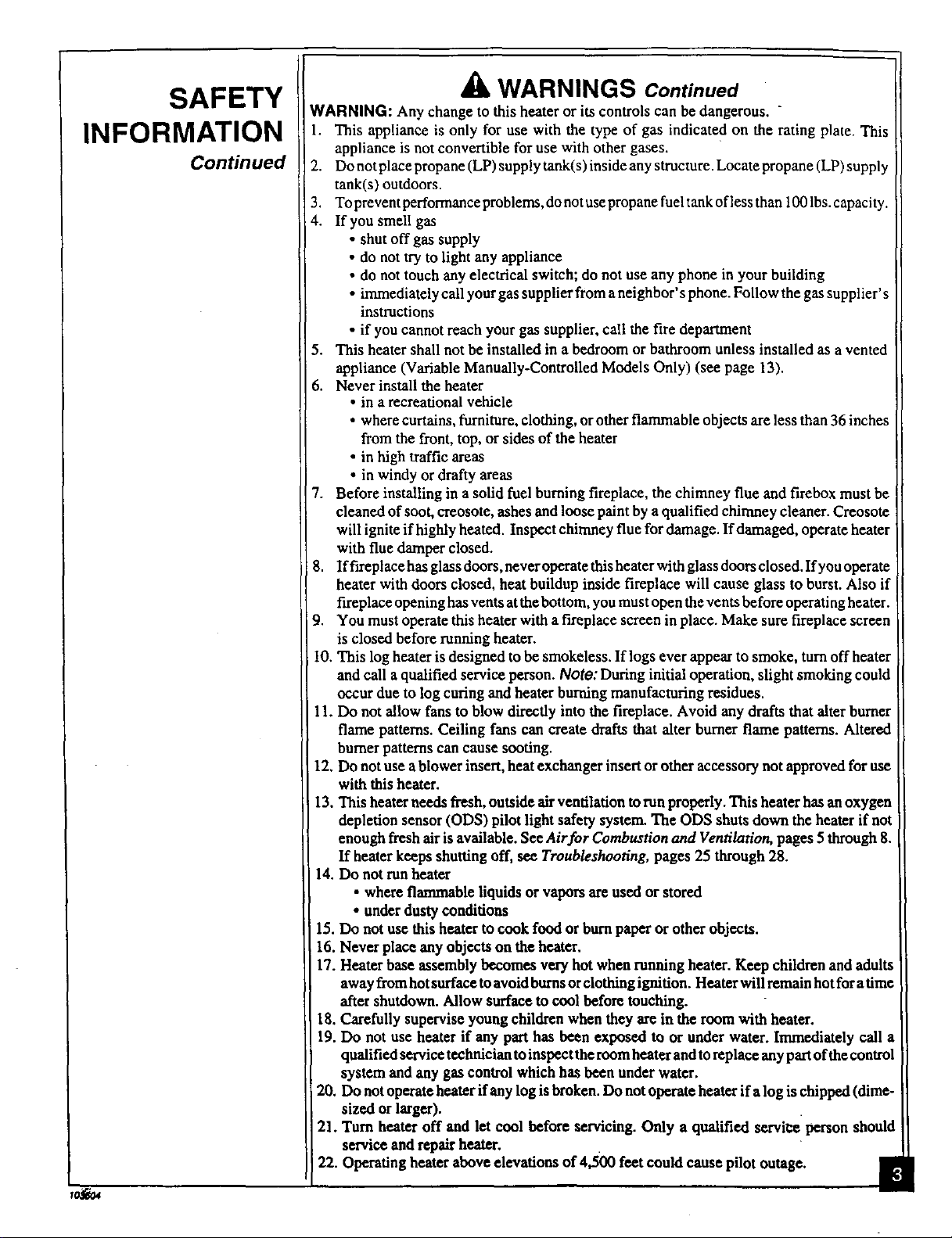

PRODUCT

IDENTIFICATION

LOCAL CODES

Crossover Log Log.

Front Log

Ignitor

Contr¢

Figure 1 - Vent-Free Gas Log Heater

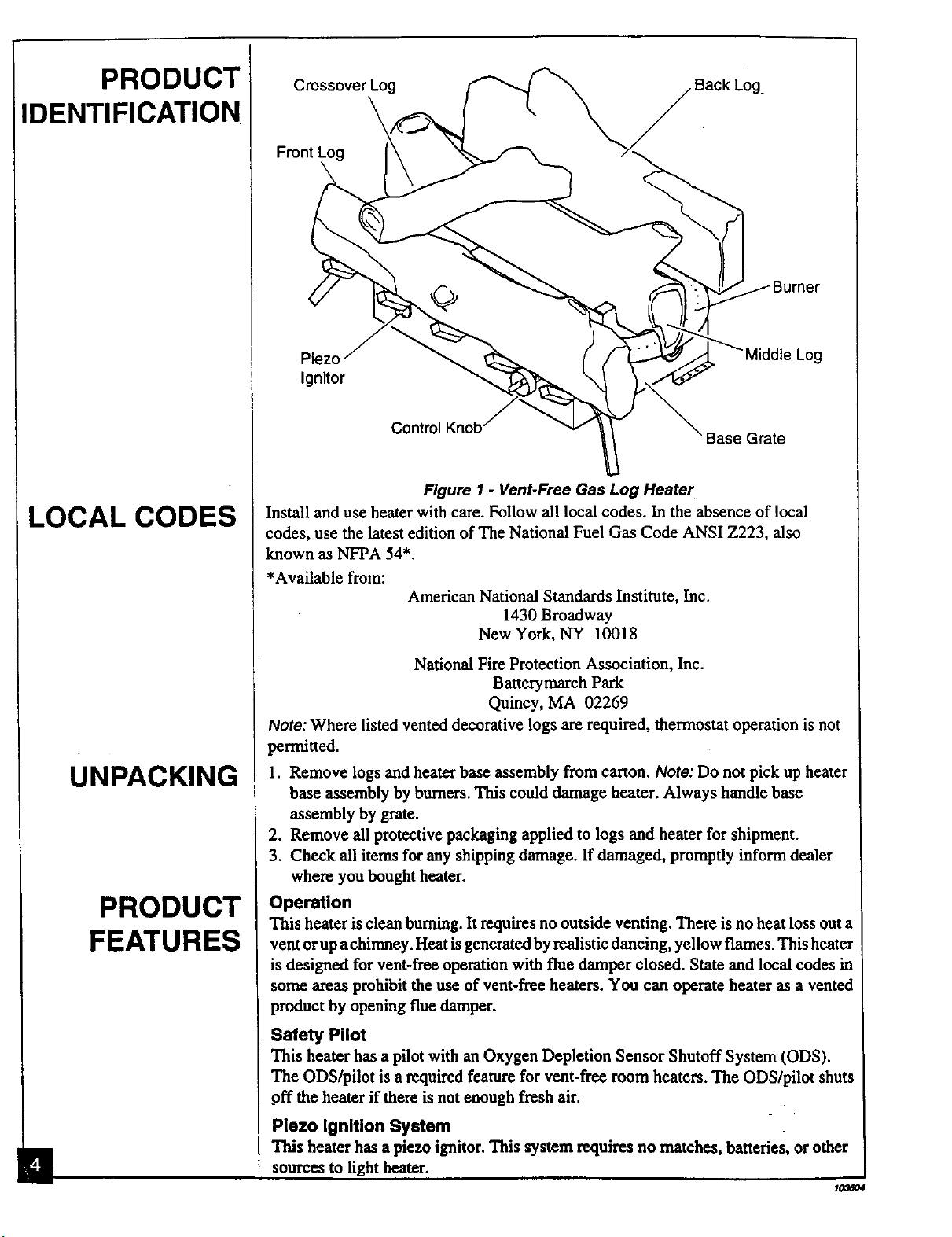

Install and use heater with care. Follow all local codes. In the absence of local

codes, use the latest edition of The National Fuel Gas Code ANSI Z223, also

known as NFPA 54*.

*Available from:

Ameriean National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

UNPACKING

PRODUCT

FEATURES

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

Note: Where listed vented decorative logs are required, thermostat operation is not

permitted.

1. Remove logs and heater base assembly from carton. Note: Do not pick up heater

base assembly by burners. This could damage heater. Always handle base

assembly by grate.

2. Remove all protective packaging applied to logs and heater for shipment.

3. Check all items for any shipping damage. If damaged, promptly inform dealer

where you bought heater.

Operation

This heater is clean burning. It requires no outside venting. There is no heat loss out a

vent or up a chimney. Heat is generated by realistic dancing, yellow flames. This heater

is designed for vent-free operation with flue damper closed. State and local codes in

some areas prohibit the use of vent-free heaters. You can operate heater as a vented

product by opening flue damper.

Safety Pilot

This heater has a pilot with an Oxygen Depletion Sensor Shutoff System (ODS).

The ODS/pilot is a required feature for vent-free room heaters. The ODS/pilot shuts

9ff the heater if there is not enough fresh air.

Piezo Ignition System

This heater has a piezo ignitor. This system requires no matches, batteries, or other

sourcesto light heater.

70a_4

Page 5

AIR FOR

WARNING

COMBUSTION

AND

VENTILATION

This heater shall not be installed in a confined space unless

provisions are provided for adequate combustion and ventilation

air. Read the following instructions to insure proper fresh air for

this and other fuel-burning appliances in your home.

Today's homes are built more energy efficient than ever. New materials, increased

insulation, and new construction methods help reduce heat loss in homes. Home

owners weather strip and caulk around windows and doors to keep the cold air out

and the warm air in. During heating months, home owners want their homes as

airtight as possible.

While it is good to make your home energy efficient, your home needs to breathe.

Fresh air must enter your home. All fuel-burning appliances need fresh air for

proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers, and fuel burning appliances draw air from

the house to operate. You must provide adequate fresh air for these appliances.

This will insure proper venting of vented fuel-burning appliances.

PROVIDING ADEQUATE VENTILATION

The following is excerpts from National Fuel Gas Code. NFPA 54/ANSI Z223.1,

Section 5.3, Air for Combustion and Ventilation.

All spaces in homes fall into one of the three following ventilation classifications:

1. Unusually Tight Construction; 2. Unconfined Space; 3. Confined Space.

The information on pages 5 through 7 will help you classify your space and provide

adequate ventilation.

Unusually Tight Construction

The air that leaks around doors and windows may provide enough fresh air for

combustion and ventilation. However, in buildings of unusually tight construction

you must provide additional fresh air.

Unusually tight construction Is defined as construction where:

a. walls and ceilings exposed to the outside atmosphere have a con-

tinuous water vapor retarder with a rating of one perm (6x10 "11per

pa.aec.m =) or less with openings gasketed or sealed and

b. weather stripping has been added on openable windows and doors and

c. caulking or sealants are applied to areas such as joints around window

and door frames, between sole plates and floors, between wall-ceiling

Joints, between wall panels, at penetrations for plumbing, electrical, and

gas lines, and at other openings.

If your home meets all of the three criteria above, you must provide addi-

tional fresh air. See Ventilation Air From Outdoors, page 7.

If your home does not meet all of the three criteria above, proceed to page 6.

10_604

Confined and Unconfined Space

The National Fuel Gas Code (ANSIZ223.1, 1992 Section 5.3) defines a confinod

space as a space whose volume is less than 50 cubic feet per 1,000 Btu per hour (4.8

m 3 per kw) of the aggregate input rating of all appliances installed in that space and

an unconfined space as a space whose volume is not less than 50 cubic feet per 1,000

Btu per hour (4.8 m 3per kw) of the aggregate input rating of all appliances installed

in that space. Rooms communicating directly with the space in which the appliances

are installed*, through openings not furnished with doors, are considered apart of the

unconfined space.

* Adjoining rooms are communicating only if there are doorless passageways or

ventilation grills between them. Continued _"

Page 6

AIR FOR

COMBUSTION

AND

VENTILATION

Continued

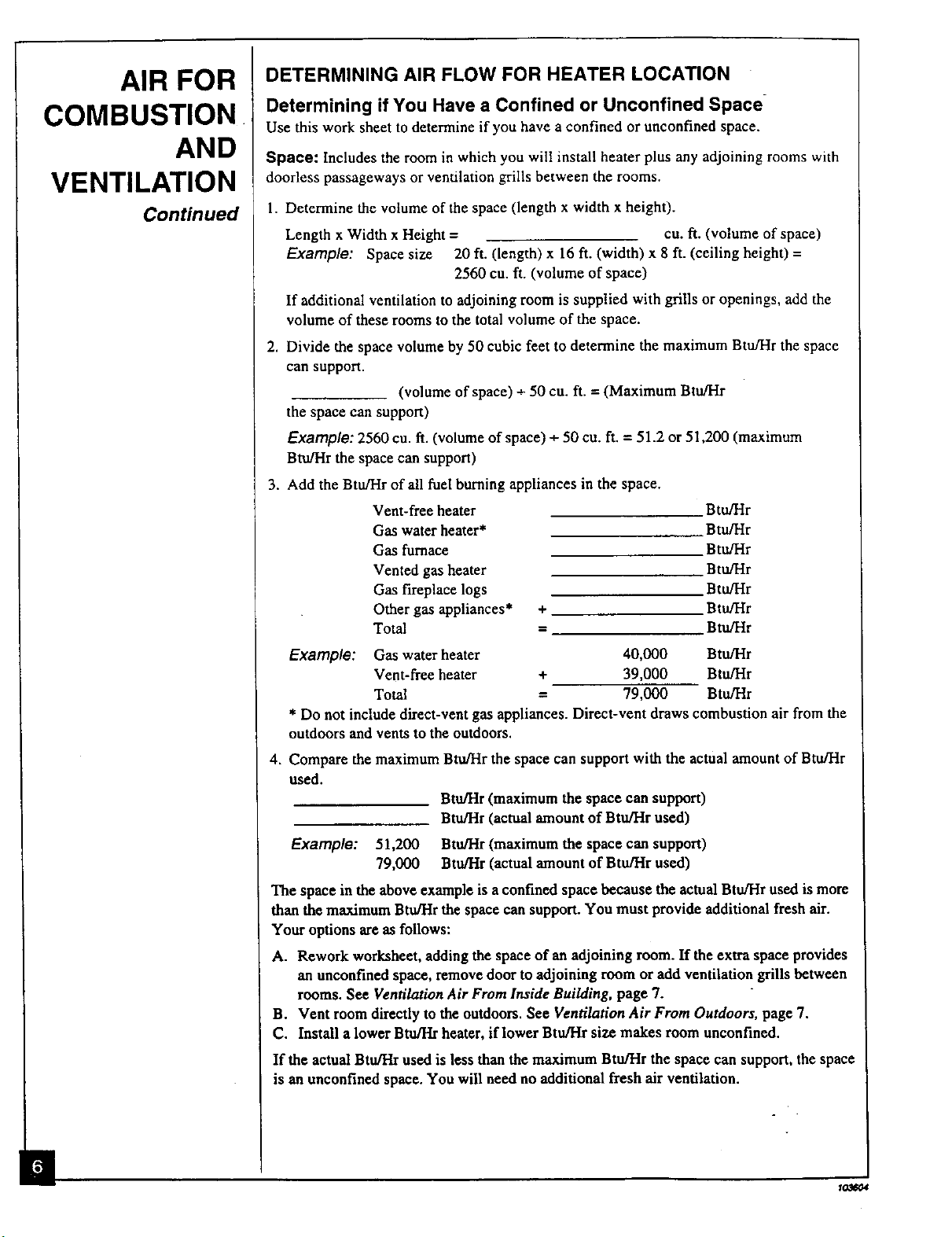

DETERMINING AIR FLOW FOR HEATER LOCATION

Determining if You Have a Confined or Unconfined Space-

Use this work sheet to determine if you have a confined or unconfined space.

Space: Includes the room in which you will install heater plus any adjoining rooms with

doorless passageways or ventilation grills between the rooms.

1. Determine the volume of the space (length x width x height).

Length x Width x Height = cu. ft. (volume of space)

Example: Space size 20 ft. (length) x 16 ft. (width) x 8 ft. (ceiling height) =

2560 cu. ft. (volume of space)

If additional ventilation to adjoining room is supplied with grills or openings, add the

volume of these rooms to the total volume of the space.

2. Divide the space volume by 50 cubic feet to determine the maximum Btu/Hr the space

can support.

(volume of space) + 50 cu. ft. = (Maximum Btu/Hr

the space can support)

Example: 2560 cu. ft. (volume of space) + 50 cu. ft. = 51.2 or 51,200 (maximum

Btu/Hr the space can support)

3. Add the Btu/Hr of an fuel burning appliances in the space.

Vent-free heater Btu/Hr

Gas water heater* Btu/Hr

Gas furnace Btu/Hr

Vented gas heater Btu/Hr

Gas fireplace logs Btu/Hr

Other gas appliances* + .Btu/Hr

Total = Btu/Hr

Example: Gas water heater 40,000 Btu/Hr

Vent-free heater + 39,000 Btu/Hr

Total = 79,000 Btu/Hr

* Do not include direct-vent gas appliances. Direct-vent draws combustion air from the

outdoors and vents to the outdoors.

4. Compare the maximum Btu/Hr the space can support with the actual amount of Btu/Hr

used.

Btu/Hr (maximum the space can support)

Btu/Hr (actual amount of Btu/Hr used)

Example: 51,200 Btu/T-Ir(maximum thespacecansupport)

79,000 Btu/Hr (actualamount of BtuiHr used)

The space in the above example is a confined space because the actual Btu/Hr used is more

than the maximum Btu/Hr the space can support. You must provide additional fresh air.

Your options are as follows:

A. Rework wurksheet, adding the space of an adjoining room. If the extra space provides

an unconfined space, remove door to adjoining room or add ventilation grills between

rooms. See Ventilation Air From Inside Building, page 7.

B. Vent room directly to the outdoors. See Ventilation Air From Outdoors, page 7.

C. Install a lower Btu/Hr heatar, if lowar Btu/Hr size makes room unconfined.

Iftbe actual Btu/Hr used is less than the maximum Btu/I-Irthe space can support, the space

is an unconfined space. You will need no additional fresh air ventilation.

Page 7

AIR FOR

COMBUSTION

AND

VENTILATION

Continued

WARNING

If the area in which the heater may be operated is smaller than

that defined as an unconfined space, provide adequate combus-

tion and ventilation air by one of the methods described in the

National Fuel Gas Code, ANSI Z223.1, 1992, Section 5.3 or appli-

cable local codes.

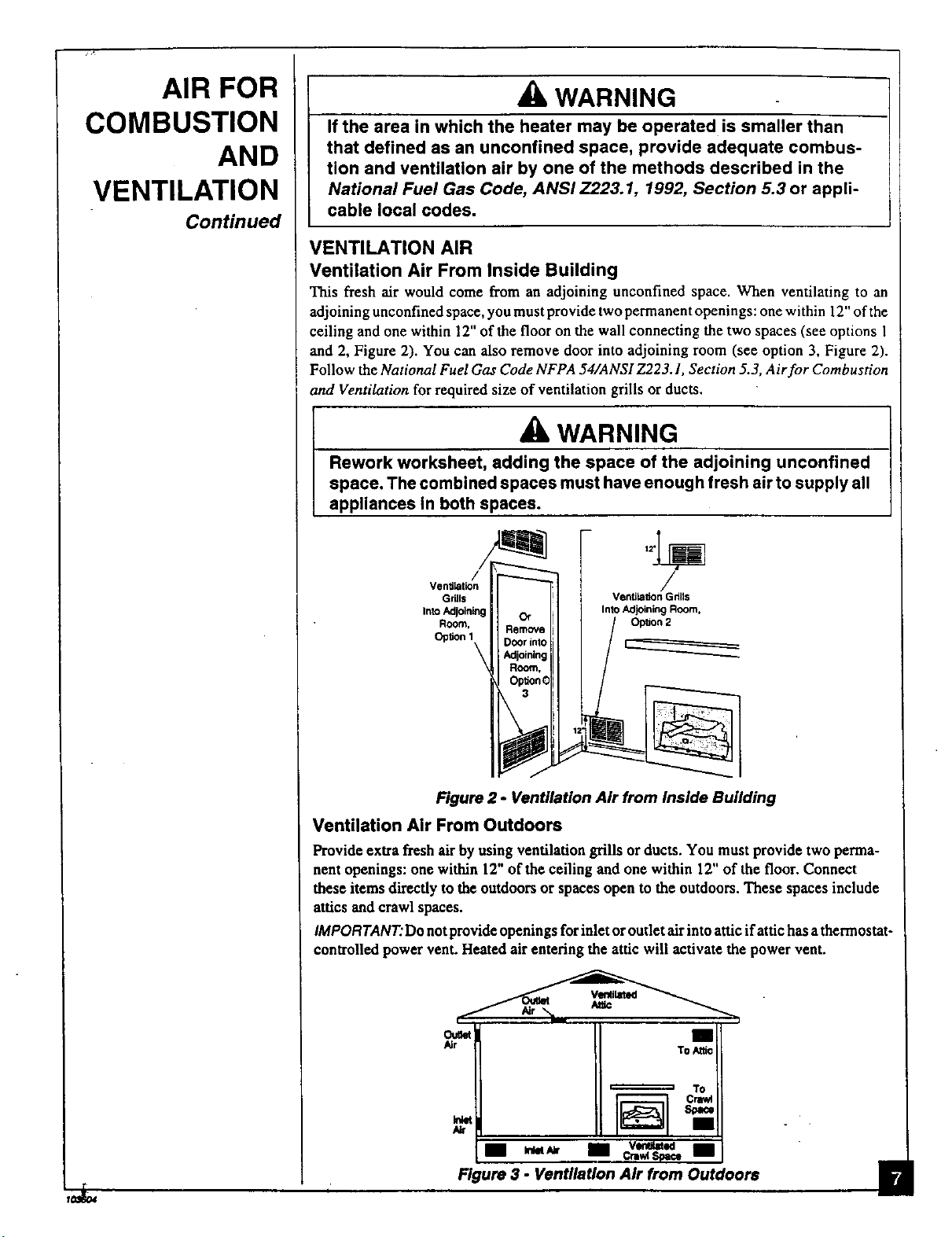

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining unconfined space. When ventilating to an

adjoining unconfined space, you must provide two permanent openings: one within 12" of the

ceiling and one within 12" of the floor on the wall connecting the two spaces (see options 1

and 2, Figure 2). You can also remove door into adjoining room (see option 3, Figure 2).

Follow the National Fuel Gas Code NFPA 54/ANSI Z223.1, Section 5.3, Air for Combustion

2nd Ventilation for required size of ventilation grills or ducts.

WARNING

Rework worksheet, adding the space of the adjoining unconfined

space. The combined spaces must have enough fresh air to supply all

appliances in both spaces.

Ven--

Grills Ventila_on Gdlls

Into Adjoining O_ Into Adjoining Room.

Room, Remove II Op_on 2

Op_on 1 Door into li

Adjoiningil

Room,

OptionOll

Figure 2 - Ventilation Air from Inside Building

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills or ducts. You must provide two perma-

nent openings: one within 12"of the ceiling and one within 12" of the floor. Connect

these items directly to the outdoors or spaces open to the outdoors. These spaces include

attics and crawl spaces.

IMPORTANT: Do not provide openings for inlet oroutlet airinto attic if attic has a thermostat-

controlled power vent. Heated air entering the attic will activate the power vent.

Outer

/_ir

========== To

Inka/U¢ I Verl_llted

'ure 3 - Ventilation Air from Outdoors

n IF4

Cr,_s_= I

I

TO Attic

spa=

c"

I

Page 8

INSTALLING

t NOTICEA qualified service person must install heater. Follow all local codes.

NOTICE

State or local codes may only allow operation of this appliance in a

vented configuration. Check your state or local codes.

WARNING

Before installing in a solid fuel burning fireplace, the chimney flue

and firebox must be cleaned of soot, creosote, ashes and loose paint

by a qualified chimney cleaner. Creosote will ignite if highly heated.

Inspect chimney flue for damage. If damaged, operate heater with

flue damper closed.

WARNING

Seal any fresh air vents or ash clean-out doors located on floor or wall

of fireplace. If not, drafting may cause pilot outage or sooting. Use a

heat-resistant sealant. Do not seal chimney flue damper.

WARNING

Never install the heater

• in a bedroom or bathroom unless installed as ave, nted appli-

• ance (Variable Manually-Controlled Models Only) (see page 13)

• in a recreational vehicle

• where curtains, furniture, clothing, or other flammable objects

are less than 36 inches from the front, top, or sides of the heater

• in high traffic areas

• in windy or drafty areas

CAUTION

This heater creates warm air currents. These currents move heat

to wall surfaces next to heater. Installing heater next to vinyl or

cloth wall coverings or operating heater where impurities in the air

(such as tobacco smoke) exist, may discolor walls.

IMPORTANT: Vent-free heaters add moisture to the air. Although this is beneficial,

installing heater in rooms without enough ventilation air may cause mildew to form

from too much moisture. See Air for Combustion and Ventilation, pages 5 through 7.

CHECK GAS TYPE

Use only propane gas. If your gas supply is not propane, do not install heater. Call

dealer where you bought heater for proper type heater.

Page 9

INSTALLING

Continued

INSTALLATION AND CLEARANCES (Vent-Free Operation Only)

Maintain the minimum clearances. If you can, provide greater clear-

ances from floor, ceiling, and adjoining wall.

MINIMUM FIREPLACE CLEARANCE

TO COMBUSTIBLE MATERIALS

Log Size

18,24,30

Log Minimum Firebox Size

Size Height Depth Front Width

18" 17" 14" 20"

24" 17" 14= 26"

30" 17" 14" 32"

Carefully follow the instructions below. This will ensure safe installation into a

masonry, U.L. listed manufactured fireplace, or AGA design certified vent-free

firebox listed for use with these models.

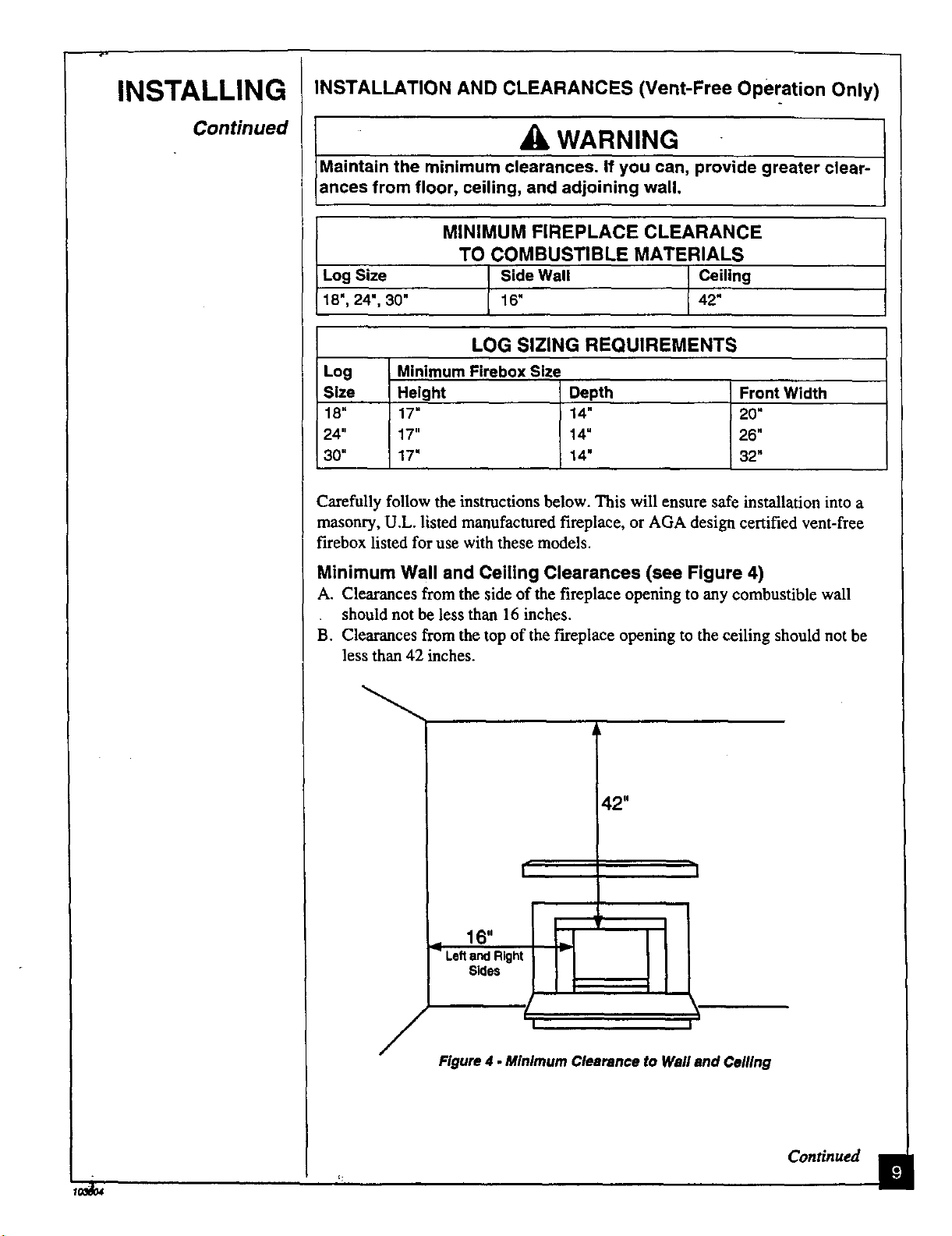

Minimum Wall and Ceiling Clearances (see Figure 4)

A. Clearances from the side of the fireplace opening to any combustible wall

should not be less than 16 inches.

B. Clearances from the top of the fireplace opening to the ceiling should not be

less than 42 inches.

Side Wall Ceiling

16• 42"

LOG SIZING REQUIREMENTS

WARNING !

/

42"

i

Left and Right

Sides

16

/

I

Figure 4. Minimum Clearance to Well end Ceiling

Continued

Page 10

INSTALLING

NOTICE

Continued

You may use this heater as a vented product. If so, you must

always run heater with chimney flue damper open. If running

heater with damper open, non-combustible material above fire-

place opening is not needed. Go to Installing Damper Clamp

Accessory for Vented Operation, page 13.

Minimum Non-Combustible Material Clearances

If Not Using Mantel

Note: If using a mantel, go to page 11. If not using a mantel, follow the informa-

tion on this page.

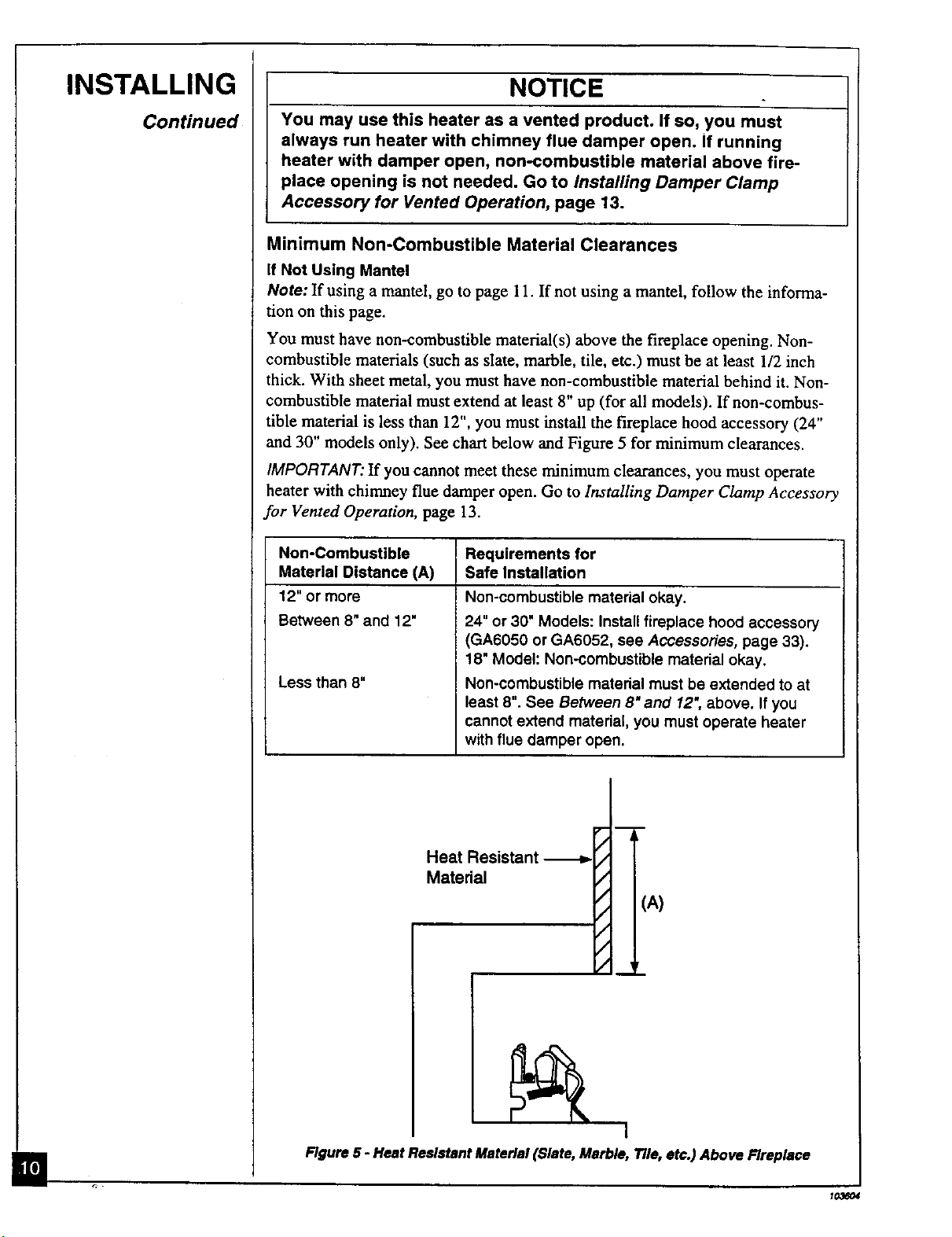

You must have non-combustible material(s) above the fireplace opening. Non-

combustible materials (such as slate, marble, tile, etc.) must be at least 1/2 inch

thick. With sheet metal, you must have non-combustible material behind it. Non-

combustible material must extend at least 8" up (for all models). If non-combus-

tible material is less than 12", you must install the fireplace hood accessory (24"

and 30" models only). See chart below and Figure 5 for minimum clearances.

IMPORTANT: If you cannot meet these minimum clearances, you must operate

heater with chimney flue damper open. Go to Installing Damper Clamp Accessory

for Vented Operation, page 13.

Non-Combustible

Material Distance (A)

12" or more

Between 8" and 12"

Less than 8"

Requirements for

Safe Installation

Non-combustible material okay.

24" or 30" Models: Install fireplace hood accessory

(GA6050 or GA6052, see Accessories, page 33).

18" Model: Non-combustible matedal okay.

Non-combustible matedal must be extended to at

least 8". See Between 8"and 12", above. If you

cannot extend material, you must operate heater

with flue damper open.

ml

Heat Resistant -_

Material

I

Figure 5 - Heat Resistant Material (Slate, Marble, Tile, etc.) Above Fireplace

I03604

Page 11

INSTALLING

Continued

Minimum Non-Combustible Material Clearances (Continued)

If Using Mantel

You must have non-combustible material(s) above the fireplace opening. Non-

combustible materials (such as slate, marble, tile, etc.) must be at least 1/2 inch

thick. With sheet metal, you must have non-combustible material behind it. Non-

combustible material must extend at least 8" up (for all models). If non-combus-

tible material is less than 12", you must install the fireplace hood accessory (24"

and 30" models only). Even if non-combustible material is more than 12", you

may need the hood accessory to deflect heat away from your mantel shelf. See

chart below and Figures 6 and 7 for minimum clearances.

IMPORTANT." If you cannot meet these minimum clearances, you must operate

heater with chimney flue damper open. Go to Installing Damper Clamp Acces-

sory for Vented Operation, page 13.

Non-Combustible

Material Distance (A)

12" or more

Between 8" and 12"

Requirements for

Safe Installation

Non-combustible material okay.

24" or 30" Models: Install fireplace hood accessory

(GA6050 or GA6052, see Accessories, page 33).

18" Model: Non-combustible material okay.

Less than 8"

Non-combustible material must be extended to at

least 8". See Between 8" and 12", above. If you

cannot extend material, you must operate heater

with flue damper open.

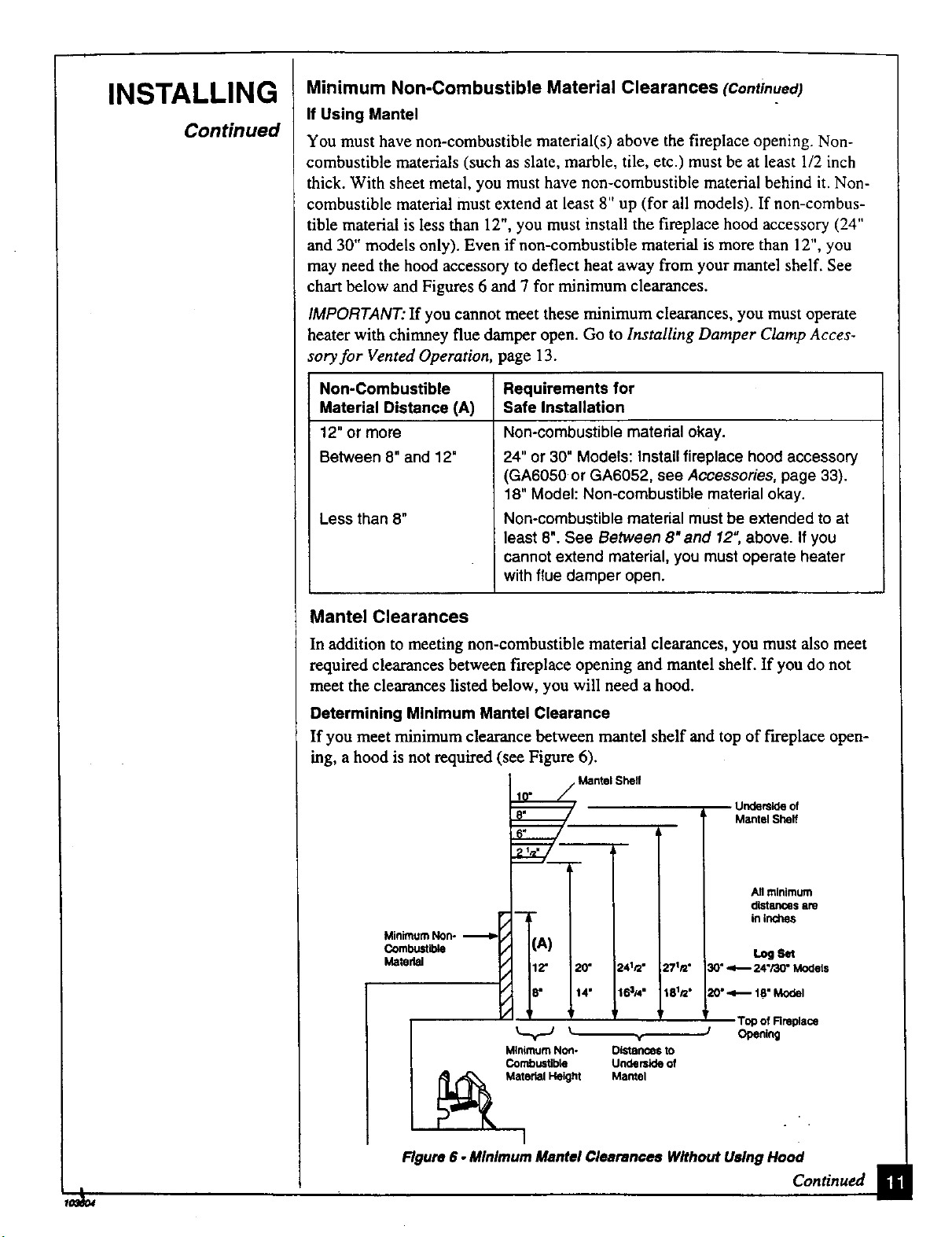

Mantel Clearances

In addition to meeting non-combustible material clearances, you must also meet

required clearances between fireplace opening and mantel shelf. If you do not

meet the clearances listed below, you will need a hood.

Determining Minimum Mantel Clearance

If you meet minimum clearance between mantel shelf and top of f'weplace open-

ing, a hood is not required (see Figure 6).

Mantel Shelf

Mantel Shelf Underside of

,,,k

All minimum

j m_

MinimumNon- _ i

Combustiblfl ,, (A)

Matedal / 12" 20" 241,2• 271,2 •

#

/ 8" 14" 163/4, 181Q"

/

MinimumNon. Distancesto

Combustible Undersideof

MaterialHeight Mantel

_ / Opening

distances are

in inches

Log Set

30" _ 24"/30" Models

20" _ 18" Model

Top of Fireplace

I

Figure 6. Minimum Mantel Clearances Without Using Hood

Continued _l_

i

I

Page 12

INSTALLING

Continued

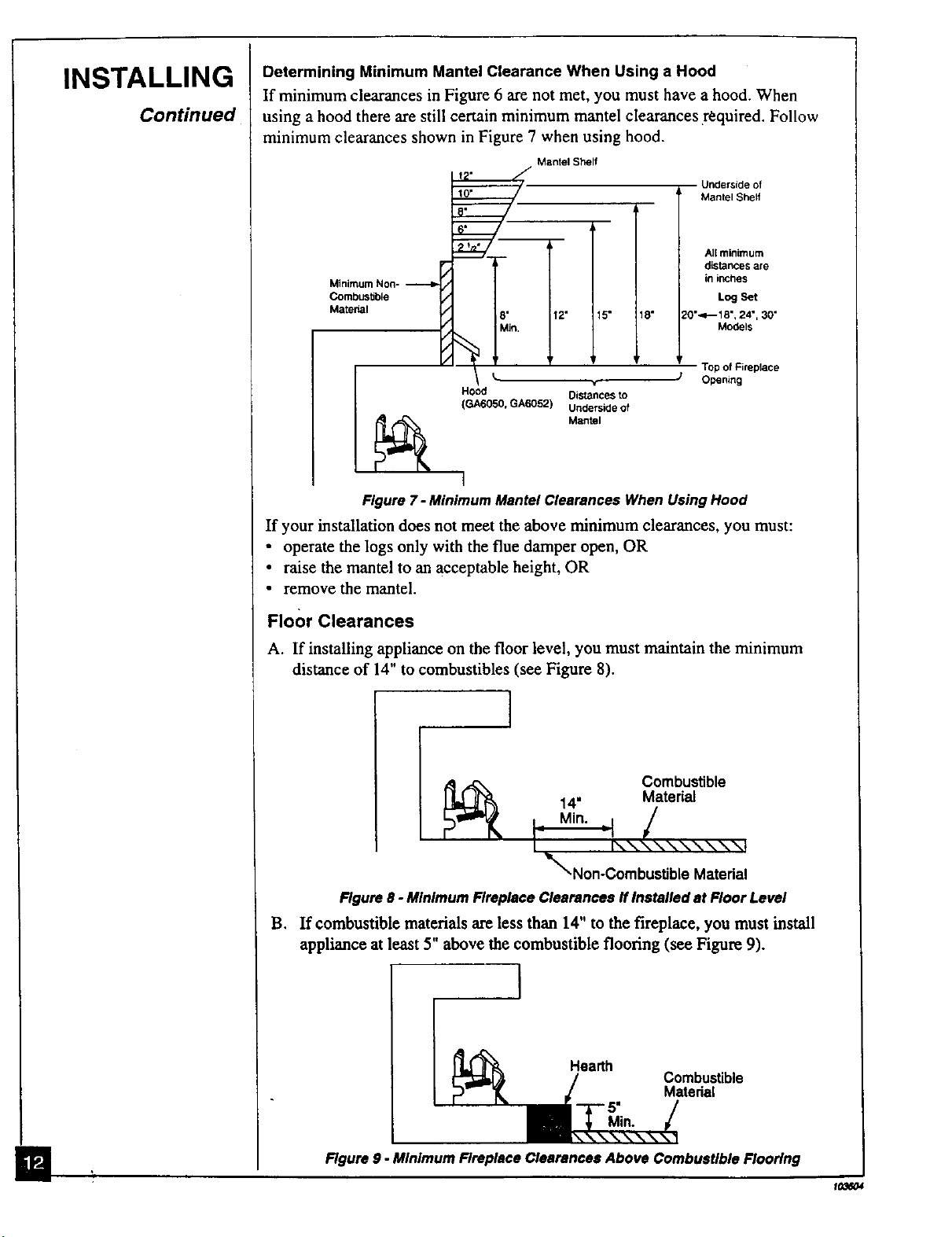

Determining Minimum Mantel Clearance When Using a Hood

If minimum clearances in Figure 6 are not met, you must have a hood. When

using a hood there are still certain minimum mantel clearances required. Follow

minimum clearances shown in Figure 7 when using hood.

Mantel Sheff

Underside of

Mantel Sheff

L

Minimum Non-

CombuslJble

Material

m'_m

12" 15" 18"

All minimum

distances are

in inches

Log Set

!0"<--18", 24", 30"

Models

r

k

HOOd Distances to

(GA6050, GA6052) Underside of

Mantel

Figure 7- Minimum Mantel Clearances When Using Hood

r Top of Fireplace

Opening

If your installation does not meet the above minimum clearances, you must:

• operate the logs only with the flue damper open, OR

• raise the mantel to an acceptable height, OR

• remove the mantel.

Floor Clearances

A. If installing appliance on the floor level, you must maintain the minimum

distance of 14" to combustibles (see Figure 8).

]

Combustible

14" Material

\\\\\\\\\1

_"_'Non-Combustible Material

Figure 8 - Minimum Fireplace Clearances ff Installed at Floor Level

B. If combustible materials are less than 14" to the fireplace, you must install

appliance at least 5" above the combustible flooring (see Figure 9).

Hearth

Combustible

Matede[

Min.

_l_ ,, Figure 9 - Minimum Fireplace Clearances Above Combustible Flooring

1O36O4

Page 13

INSTALLING

ContMued

INSTALLING DAMPER CLAMP ACCESSORY FOR

VENTED OPERATION

Note: When used as a vented heater, appliance must be installed only in a solid-

fuel burning fireplace with a working flue and constructed of non-combustible

material.

If your heater is a manually controlled model, you may use this heater as a vented

product. There are three reasons for operating your heater in the vented mode.

1. The fireplace does not meet the clearance to combustibles requirements for

vent-free operation.

2. State or local codes do not permit vent-free operation.

3. You prefer vented operation.

If reasons number 1or 2 above apply to you, you must permanently open chimney flue

damper. You must install the damper clamp accessory (to order, seeAccessories, page

33). This will insure vented operation (see Figure 10). The damper clamp will keep

damper open. Installation instructions are included with clamp accessory.

See chart below for minimum permanent flue opening you must provide. Attach

damper clamp so the minimum permaneni flue opening will be maintained at all times.

Chimney Minimum Permanent

Height (ft.) Flue Opening ($q. ins.)

6' to 15' 39 sq. inches

15' to 30' 29 sq. inches

Area of Various Standard Round Flues

Diameter (ins.) Area (sq. ins.)

5" 20 sq. inches

6" 29 sq. inches

7" 39 sq. inches

8" 51 sq. inches

Damper F

Clamp

Damper

Oon,por

,o_04_

Masonry Fireplace Manufactured Fireplace

Figure 10- Attaching Camper Clamp m

Continued

Ill

Page 14

INSTALLING

INSTALLING HEATER BASE ASSEMBLY

Continued

WARNING

You must secure this heater to fireplace floor. If not, heater will move

when you adjust controls. Moving heater may cause a gas leak.

WARNING

if installing in a sunken fireplace, special care is needed. You

must raise the fireplace floor to allow access to heater control

panel. This will insure adequate air flow and guard against soot-

ing. Raise fireplace floor with non-combustible material. Make

sure material is secure.

CAUTION

Do not pick up heater base assembly by the burner. This could

damage heater. Only handle base assembly by grates.

IMPORTANT: Make sure the heater burners are level. If heater is not level, heater

will not work properly. For thermostat models, avoid damage to thermostat bulb.

Avoid nicks or sharp bends in thermostat bulb wire. Keep thermostat bulb in

mounting bracket.

Installation Items Needed

• hardware package (provided with heater)

• approved flexible gas hose (not provided) (if allowed by local codes)

• sealant resistant to propane (propane/LP) gas, not provided

• electric drill with 3/16" drill bit

1. Apply pipe joint sealant lightly to male threads of the fitting to be threaded into

gas regulator. Connect approved flexible gas hose to gas regulator of heater

(see Figure 11).

IMPORTANT:Hold gas regulator with wrench when connecting flexible gas hose.

2. Locate masonry screws in hardware package.

3. Position heater base assembly in fireplace.

4. Mark screw locations through holes in mounting brackets (see Figure 12, page

15). If installing in a brick-bottom fireplace, mark screw locations in mortar

joint of bricks.

5. Remove heater base from fireplace.

6. Drill holes at marked locations using 3/16" drill bit.

7. Attach base assembly to fireplace floor using two masonry screws (in hardware

package) (see Figure 12, page 15).

8. Connect to gas supply. See Connecting To Gas Supply, page 15.

(_ Regulator

_ __eeter Gas

Flexible Gas Hose

(if allowed by local codes)

Fitting

! _L_ Figure 11 - Attaching Flexible Gas Hose to Heater Gas Regulator

,, ,,_

Page 15

INSTALLING

Continued

Mo2g

Figure 12 - Attaching Base Assembly to Fireplace Floor

CONNECTING TO GAS SUPPLY

NOTICE

A qualified service person must connect heater to gas supply.

Follow all local codes.

CAUTION

Never connect heater directly to the propane supply. This heater

requires an external regulator (not supplied). Install the external

regulator between the heater and propane supply.

Installation Items Needed

Before installing heater, make sure you have the items listed below.

• external regulator (supplied by

installer, see page 16)

• piping (check local codes)

• sealant (resistant to propaneJLP gas)

• manual shutoff valve *

* An A.G.A. design-certified manual shutoffvalve with 1/8" NFFtap is an acceptabh

alternative to test gauge connection. Purchase the optional A.G.A. design-eertifiex

manual shutoff valve from your dealer. See Accessories, page 33.

• test gauge connection *

• sediment trap

• tee joint

• pipe wrench

Continue

Page 16

INSTALLING

Continued

The installer must supply an external regulator. The external regulator will reduce

incoming gas pressure. You must reduce incoming gas pressure to between 11 and

14 inches of water. If you do not reduce incoming gas pressure, heater regulator

damage could occur. Install external regulator with the vent pointing down as

shown in Figure 13. Pointing the vent down protects it from freezing rain or sleet.

Propane

Supply Tank

\

T

E erna,

Reou,ator

*<o*"-_ Vent Pointing

6"000 €

.-, L • Down

Figure 13 - External Regulator With Vent Pointing Down

CAUTION

Use only new, black iron or steel pipe. Internally-tinned copper

tubing may be used in certain areas. Check your local codes. Use

pipe of 1/2" diameter or greater to allow proper gas volume to

heater. If pipe ts too small, undue loss of pressure will occur.

Installation must include a manual shutoff valve, union, and plugged 1/8" NPT tap.

Locate NPT tap within reach for test gauge hook up. NPT tap must be upstream

from heater (see Figure 14, page 17).

Apply pipe joint sealant lightly to male threads. This will prevent excess sealant

from going into pipe. Excess sealant in pipe could result in clogged heater valves.

CAUTION

Use pipe joint sealant that is resistant to liquid petroleum (LP) gas.

Install sediment trap in supply line as shown in Figure 14, page 17. Locate sedi-

ment trap where it is within reach for cleaning. Locate sediment trap where trapped

matter is not likely to freeze. A sediment trap traps moisture and contaminants.

This keeps them from going into heater controls. If sediment trap is not installed or

is installed wrong, heater may not run properly.

Page 17

INSTALLING

Contmued

CAUTION

Avoid damage to regulator. Hold gas regulator with wrench when

connecting it to gas piping and/or fittings.

A.G.A. Design-Certified

Manual Shutoff Valve

From

Gas Meter

(5"W.C*** to

10.5" W.C,

Pressure)

Sediment Figure 14 - Gas Connection

Trap

* Purchase theoptional A.G.A. design-certified manual shutoff valve from your dealer

See Accessories, page 33.

_'* Minimum inlet pressure for purpose of input adjustment.

With 1/8" NPT Tap*

// Gas Hose (if allowed

,_ / by local codes)

3" Minimum

// Approved Flexible

/

CHECKING GAS CONNECTIONS

WARNING

Test all gas piping and connections for leaks after installing or

servicing. Correct all leaks at once.

WARNING

Never use an open flame to check for a leak. Apply a mixture of

liquid soap and water to all joints. Bubbles forming show a leak.

Correct all leaks at once.

CAUTION

Make sure external regulator has been Installed between propane

supply end heater. See guidelines under Connecting to Gas Sup-

ply, page 15.

Pressure Testing Gas Supply Piping system

Test Pressures In Excess Of 1/2 PSIG

1: DisconneCt heater and its individual manual shutoff valve from gas supply

piping system. Pressures in excess of 1/2 psig will damage heater regulator.

2. Cap off open end of gas pipe where manual shutoff valve was connected.

Ia_6_

Continued I

Page 18

INSTALLING

Con_nued.

3. Pressurize supply piping system by either using compressed air of

opening propane supply tank valve.

4. Check all joints of gas supply piping system. Apply mixture of liquid soap and

water to gas joints• Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect heater and manual shutoff valve to gas supply. Check reconnected

fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG

1. Close manual shutoff valve (seeFigure 15).

2. Pressurize supply piping system by either using compressed air or opening

propane supply tank valve.

3. Check all joints from propane supply tank to manual shutoff valve (see Figure

16). Apply mixture of liquid soap and water to gas joints. Bubbles forming

show a leak.

4. Correct all leaks at once.

Pressure Testing Heater Gas Connections

1. Open manual shutoff valve (see Figure 15).

2. Open propane supply tank valve.

3. Make sure control knob of heater is in the OFF position.

4. Check all joints from manual shutoff valve to control valve (see Figure 16).

Apply mixture of liquid soap and water to gas joints. Bubbles forming show a

leak.

5. Correct all leaks at once.

6. Light heater (see Operating Heater, pages 20 through 22 [manually-controlled

models] or pages 22 through 24 [thermostatically-controlled models]). Check

all other internal joints for leaks.

7. Turn offheater (see To Turn OffGas to Appliance, page 21 [manually-con-

trolled models] or page 24 [thermostatically-controlled models]).

Shutoff

Valve

Figure

Propane

Supply Ta__. __

_ ,L_, ,ff*_.._.... -,-_,..._.._,

sed

15 - Manual Shutoff Valve

Manual

•"_ Shutoff

,//

.... Valve

,,_

///,

"/ /

• //

:_._ --

To;..-=

Figure 16. Checking Gas Joints

i i i , i i i i _ i _ i

Thermostat Gas Valve or

Control Valve Location

/

Page 19

INSTALLING

INSTALLING LOGS

Continued

WARNING

Failure to position the parts in accordance with these diagrams or failure

to use only parts specifically approved with this heater may result in

property damage or personal injury.

Each log is marked with a number. These numbers will help you identify the log

when installing. It is very important to install these logs exactly as instructed. Do

not modify logs. Only use logs supplied with beater.

1. Locate pegs on the bottom of back log (#1). Slide these pegs into the holes in

the grate base behind the burner (see Figure 17).

2. Place the base ofthe middle log (#2) in the U-shaped slots of the grate base in front

of the back log. The cutout on the right of the middle log should fit over the burner

(see Figure 18), Make sure the front of the middle log is resting on the tabs of the

grate base and the cutout area is centered over the burner "U" bend.

3. Locate the recesses on the back of the front log (#3). Fit these recesses between

the posts of the grate base (see Figure 19).

4. Locate the notches in the bottom of the crossover log (#4). Place the crossover

log on top of the middle log and front log. Make sure the notches of the cross-

over log lines up with rectangular knobs on top of the middle and front logs

(see Figure 20).

/_"_Back Log (#1) (_J_j Middle Log (#2)

Peg _.... _ "(<.:""-.1..

Hole in _ '-.. _ _ _ . _.'.-., _

GrateBase<_._.._ , :1 "at -

_,,,,.____ " L_'_---%_,_"_%_.._. j ' Cut°ut._./

_I "_"_I U-Shaped

_J td Slot

Figure 17- Installing Back Log (#1) Figure 18 - Installing Middle Log (#2)

Front Log (#3) Notches _ Crossover

"_1<_'_ Rectangular _-,_p.,_ f

Flgure19 . lnstalllng_Front :;#3) Fl:::: . lnstalllng Cr "_o_ver Log (#_

Page 20

OPERATING

1 FOR YOUR SAFETY READ BEFORE LIGHTING /

HEATER.

Manually-

Controlled Models

WARNING

If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury or loss of life,

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell

next to the floor because some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the

knob will not push in or turn by hand, don't try to repair it, call a qualified service

technician or gas supplier. Force or attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a

qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

WARNING

• If fireplace has glass doors, never operate this heater with glass doors

closed. If you operate heater with doors closed, heat buildup inside

fireplace will cause glass to burst. Also if fireplace opening has vents at

the bottom, you must open the vents before operating heater.

• You must operate this heater with a fireplace screen in place. Make sure

fireplace screen is closed before running heater.

NOTICE

During initial operation of new heater, burning logs will give off a paper-

burning smell. Orange flame will also be present. Open damper or

window to vent smell. This will only last a few hours.

Note: Homeowners generally prefer to operate their heater with the chimney damper

closed. This will put all the heat into the room. However there may be times you will

desire the full flames of the Hi heat setting but will find the heat output excessive. You

can open the chimney damper (if you have one) fully or partially to release some of

the heat. WARNING: Damper handle will be hot ff heater has been running.

1. STOP! Read the safety information above.

2. Make sure manual shutoff valve is fully open.

3. Press in and turn control knob clockwise _ to the OFF position.

IgnitorButlon\ _Control Knob

Figure21 - Control Knob and Ignitor Button Location

4. Walt five ($) minutes to clear out any gas. Then smell for gas, including near the

floor. I!you smell gas, STOP! Follow "B" in the safety information above. If you

don't smell gas, go to the next step.

Page 21

OPERATING

HEATER

Manually-

Controlled Models

Continued

5. Slightly depress and turn control knob counterclockwise _ to the PILOT

position. Press in control knob for five (5) seronds (see Page 20).

Note: You may be running this heater for the first time after hooking up to gas

supply, If so, the control knob may need to be pressed in for 30 seconds. This

will allow air to bleed from the gas system.

6. With control knob pressed in, press and release ignitor button. This will light

pfloL The pilot is attached to the burner. If needed, keep pressing ignitor button

until pilot lights.

Note: ff pilot does not stay lit, contact a qualified service person or gas supplier

for repairs. Until repairs are made, light pilot with match. To light pilot with

match, see Manual Lighting Procedure, page 22.

7. Keep control knob pressed in for 30 seconds after lighting pilot. After 30 seconds,

release control knob.

Note: If pilot goes out, repeat steps 3 through 7.

Pilot Bumer

lo_o_

Figure 22 - Pilot

• If control knob does not pop out when released, contact a qualified service

person or gas supplier for repairs.

8. Slightly depress and turn control knob counterclockwise _ to desired

heating level The burner should light. Set control knob to any heat level between

HI and LO.

WARNING

Do not operate heater between PILOT and HIGH positions.

VARIABLE CONTROL OPERATION

The variable control valve can be set to any heat setting and flame height desired, by

simply turning the control knob until that setting is attained. Even the lowest setting

provides realistic, dancing yellow flames. Selecting higher settings produces greater

heat output. This results in increased heating comfort.

CAUTION

Do not try to adjust heating levels by using the manual shutoff valve.

TO TURN OFF GAS TO APPLIANCE

Shutting Off Heater

1. Press in and turn control knob clockwise _ to the HIGH position.

2. Turn control knob clockwise _ to the pilot position.

3. Press in control knob and turn clockwise _ to the OFF position.

Shutting Off Burners Only (pilot stays lit)

1. Turn control knob clockwise _ to the HIGH position.

2. Press in and turn control knob clockwise _ to the pilot position.

Continued U

Page 22

OPERATING

HEATER

Continued

MANUAL LIGHTING PROCEDURE

1. Follow steps 1 through $ under Lighting Instructions, pages 20 and 21.

2. Depress control knob and light pilot with match.

3. Keep control knob pressed in for 30 seconds after lighting pilot. After 30 seconds,

release control knob. Now follow step 8 on page 21.

OPERATING

HEATER

Thermostatically-

Controlled Models

• FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

if you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot_

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell

next to the floor because some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the

knob will not push in or turn by hand, don't try to repair it, call a qualified service

technician or gas supplier. Force or attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a

qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

WARNING

• If fireplace has glass doors, never operate this heater with glass doors

closed. If you operate heater with doors closed, heat buildup inside

fireplace will cause glass to burst. Also iffireplace opening has vents at the

bottom, you must open the vents before operating heater.

• You must operate this heater with a fireplace screen in place. Make sure

fireplace screen is closed before running heater.

NOTICE

During Initial operation of new heater, burning logs will give off a paper-

burning smell. Orange flame will also be present. Open damper or window

to vent smell. This will only last a few hours.

Note: Homeowners generally prefer to operate their heater with the chimney damper

closed. This will put all the heat into the room. However there may be times you will

desire the full flames of the Hi heat setting but will find the heat output excessive. You

can open the chimney damper (if you have one) fully or partially to release some of

the heat. WARNING: Damper handle will be hot if heater has been running.

Page 23

OPERATING

HEATER

Thermostatically-

Controlled Models

Continued

1. STOP! Read the safety information above.

2. Make sure manual shutoff valve is fully open.

3. Turn control knob clockwise _ to the OFF position.

. g!LniW

ignitor Button.__" _ _ _COntrOI KnOb

Figure23 - Control Knob and Ignitor Button Location

4. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the

floor. If you smell gas, STOP! Follow "B" in the safety information above. If you

don't smell gas, go to the next step.

5. Turn control knob counterclockwise _ to the PILOT position. Press in

control knob for five (5) seconds (see above).

Note: You may be running this heater for the first time after hooking up to gas

supply. If so, the control knob may need to be pressed in for 30 seconds or less.

This will allow air to bleed from the gas system.

• If control knob does not pop out when released, contact a qualified service

person or gas supplier for repairs.

6. With control knob pressed in, press and release ignitor button. This will light pilot.

The pilot is attached to the front burner. If needed, keep pressing ignitor button

until pilot lights.

Note: If pilot does not stay lit, contact a qualified service person or gas supplier

for repairs. Until repairs are made, light pilot with match. To light pilot with

match, see Manual Lighting Procedure on page 24.

7. Keep control knob pressed in for 30 seconds after lighting pilot. After 30 seconds,

release control knob.

Note: If pilot goes out, repeat steps 3 through 7. This heater has a safety inter.

lock system. Walt one (1) minute for system to reset before lighting pilot again.

Electrode

Ignitor

Thermocouple_ _ mer

10_04

_

Figure24 - Pilot

8. Turn control knob counterclockwise _ to desired heating level. The

burners should light. Set control knob to any heat level between HI and LO.

CAUTION

Do not try to adjust heating levels by using the manual shutoff.valve.

• i

Continued I

Page 24

OPERATING

TO TURN OFF GAS TO APPLIANCE "

HEATER

Thermostatically-

Controlled Models

Continued

Shutting Off Heater

1. Turn control knob clockwise _ to the OFF position.

Shutting Off Burners Only (pilot stays lit)

1. Turn control knob clockwise _ to the PILOT position.

THERMOSTAT CONTROL OPERATION

(Thermostat-Controlled Models Only)

The thermostat control knob can be set to any comfort level between Hi and Lo. The

thermostat will gradually modulate the heat output and flame height from higher to

lower settings, or pilot, in order to maintain the comfort level you select. The ideal

comfort setting will vary by household depending upon the amount of space to be

heated, the output of the central heating system, etc.

Note: Selecting the Hi setting with the control knob will cause the burner to remain

fully on, without modulating down in most cases.

MANUAL LIGHTING PROCEDURE

1. Follow steps 1 through 5 under Lighting lnstruclions, page 23.

2. Depress control knob and light pilot with match.

3. Keep control knob pressed in for 30 seconds after lighting pilot. After 30 seconds,

release control knob. Now follow step 8, page 23.

INSPECTING

BURNERS

Check pilot flame pattern and burner flame patterns often.

PILOT FLAME PA'I'rERN

Figure 25 shows a correct pilot flame pattern. Figure 26 shows an incorrect pilot flame

pattern. The incorrect pilot flame is not touching the thermocouple. This will cause the

thermocouple to cool. When the thermocoupl¢ cools, the heater will shut down.

Pilot Burner

Figure 25. Correct Pilot

Flame Pattern

If pilot flame pattern is incorrect, as shown in Figure 24

• turn heater off (see To Turn OffGas to Appliance, page 21 [manually-con-

trolled models] or above [thermostat-controlled models])

• see Troubleshooting, pages 25 through 28

Figure 26 - Incorrect Pilot

Flame Pattern

Page 25

CLEANING

AND

MAINTENANCE

WARNING

Turn off heater and let cool before cleaning.

CAUTION

You must keep control areas, burner, and circulating air passage-

ways of heater clean. Inspect these areas of heater before each

use. Have heater inspected yearly by a qualified service person.

Heater may need more frequent cleaning due to excessive lint

from carpeting, bedding material, etc.

ODS/PILOT AND BURNER

• Use a vacuum cleaner or small, soft bristled brush to clean.

LOGS

• If you remove logs for cleaning, refer to Installing Logs, page 19, to properly

replace logs.

• Replace log(s) if broken or chipped (dime-sized or larger).

TO_

TROUBLE-

SHOOTING

Note: All trouble-

shooting items are

listed in order of

operation.

WARNING

Turn off and unplug heater and let cool before servicing. Only a

qualified service person should service and repair heater.

CAUTION

'Never use a wire, needle, or similar object to clean ODS/pilot. This

can damage ODS/pilot unit.

OBSERVED POSSIBLE

PROBLEM CAUSE REMEDY

When ignitor button

ts pressed, there is no

spark at ODS/pilot

1. Ignitor electrode not con-

neeted to ignitor cable

2. Ignitor cable pinched or

wet

3. Piezo ignitor nut is loose

4. Broken ignitor cable

5. Bad piezo ignitor

6. Ignitor electrode broken

7. Ignitor electrode posi-

tioned wrong

1. Reconnect ignitor cable

2. Free ignitor cable if

pinched by any metal or

tubing. Keep ignitor

cable dry

3. Tighten nut holding

piezo ignitor to base

panel of log set. Nut is

located behind base

panel.

4. Replace ignitor cable

5. Replace piezo ignitor

6. Replace piezo ignitor

7. Replace pieze igniter

Continued _,

Page 26

TROUBLE-

SHOOTING

Continued

OBSERVED POSSIBLE

PROBLEM CAUSE REMEDY

When ignitor button

is pressed, there is

spark at ODS/pilot

but no ignition

1. Gas supply turned off or

manual shutoff valve

closed

2. Control knob not in

PILOT position

3. Control knob not

pressed in while in

PILOT position

4. Air in gas lines when

installed

5. Depleted gas supply

6. ODS/pilot is clogged

7. Gas regulator setting is

1. Turn on gas supply or

open manual shutoff

valve

2. Turn control knob to

PILOT position

3. Press in control knob

while in PILOT position

4. Continue holding down

control knob. Repeat

igniting operation until

air is removed

5. Contact local propane

gas company

6. Clean ODS/pilot (see

Cleaning and Mainte-

nance, page 25) or

replace ODS/pilot

assembly

7. Replace gas regulator

not correct

ODS/pilot lights but

flame goes out when

control knob is

released

1. Control knob not fully

pressed in

2. Control knob not

pressed in long enough

3. Manual shutoff valve

not fully open

4. Pilot flame not touching

thermocouple, which

allows thermocouple to

cool, causing pilot flame

to go out. This problem

could be caused by one

or both of the following:

A) Low gas pressure

B) Dirty or partially

clogged ODS/pilot

5. Thermocouple connec-

tion loose at control

valve

6. Thermocouple damaged

7. Control valve damaged

1. Press in control knob

fully

2. After ODS/pilot lights,

keep control knob

pressed in 30 seconds

3. Fully open manual shut-

off valve

4. A) Contact local pro-

pane gas company

B) Clean ODS/pilot (see

Cleaning and Mainte-

nance, page 25) or

repl_e ODS/pilot

assembly

5. Hand tighten until snug,

then tighten 1/4 mm

more

6. Replace thermocouple

7. Replace control valve

Page 27

TROUBLE-

SHOOTING

Continued

OBSERVED POSSIBLE

PROBLEM CAUSE REMEDY

Burner does light

after ODS/pilot is lit

1. Burner orifice clogged

2. Inlet gas pressure is

too low

3. Burner orifice diameter

is too small

1. Clean burner (see

Cleaning and Mainte-

nance, page 25) or

replace burner orifice

2. Contact local propane

gas company

3. Replace burner orifice

Delayed ignition of

bumer

Bumer backfiring

during combustion

Slight smoke or

odor during initial

operation

Moisture!condensa- 1. Not enough combus- 1. Refer to Air for Com-

tion noticed on tion/ventilation air bustion and Ventilation

windows requirements (page 5)

1. Manifold pressure is

too low

2. Burner orifice clogged

1. Burner orifice is

clogged or damaged

2. Damaged burner

3. Gas regulator defective

1. Not enough air

2. Gas regulator defective

3. Residues from manu-

facturing processes

and logs curing

1. Contact local natural gas

company

2. Clean burner (see

Cleaning and Mainte-

nance, page 25) or

replace burner orifice

1. Clean burner (see

Cleaning and Mainte-

nance, page 25) or

replace burner orifice

2. Replace damaged burner

3. Replace gas regulator

1. Check burner for dirt

and debris. If found,

clean burner (see

Cleaning and Mainte-

nance, page 25)

2. Replace gas regulator

3. Problem will stop after a

few hours of operation

Heater produces a

whistling noise

when burner is lit

I.Turningcontrolknob

toHI positionwhen

burneriscold

2. Air in gas line

3. Air passageways on

heater blocked

4. Dirty or partially

clogged burner orifice

1. Turn control knob to LO

position and let warm up

for a minute

2. Operate burner until air

is removed from line.

Have gas line checked

by local natural gas

company

3. Observe minimum

installation clearances

(see pages 9-12)

4. Clean burner (see

Cleaningand Maintenance,

page 25) or replace

burner orifice

Page 28

TROUBLE-

WARNING

SHOOTING.

Continued

If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• if you cannot reach your gas supplier, call the fire department.

IMPORTANT: Operating heater where impurities in air exist may create odors.

Cleaning supplies, paint, paint remover, cigarette smoke, cements and glues, new

carpet or textiles, etc., create fumes. These fumes may mix with combustion air

and create odors. These odors will disappear over time.

OBSERVED POSSIBLE

PROBLEM CAUSE REMEDY

Heater produces a

clicking/ticking noise

ust after burner is lit

or shut off

Heater produces

unwanted odors

1. Metal expanding while

heating or contracting

while cooling

1. Heater burning vapors 1.

from paint, hair spray,

glues, cleaners, chemi-

cals, new carpet, etc.

(SeeIMPORTANT

statementabove)

2. Gas leak. See Warning 2.

statement at top of

page

1. This is common with

most heaters. If noise is

excessive, contact

qualified service person

Open window and

ventilate room. Stop using

odor causing products

while heater is running

Locate and correct all

leaks (see Checking Gas

Connections, page 17)

Heater shuts off in use

(ODS operates)

Gasodoreven when

controlknob isin OFF

)osition

Gasodorduring

combustion

Logs set cycles m

pilot, but room

temperature drops to a

lower than ideal level

before log set comes

backon

1. Not enough fresh air is

available

2. Low line pressure

3. ODS/pilot is partially

clogged

1. Gas leak. See Warning

statement at top of

page

2. Control valve defective

1. Foreign matter between

control valve and burner

2. Gas leak. See Warning

statement at top of

page

1. Thermostat sensing bulb

needs to be repositioned.

1. Open window and/or door

for ventilation

2. Contact local natural gas

company

3. Clean ODS/pilot (see

Cleaning and Mainte-

nance, page 25)

I. Locate and correct all

leaks (see Checking Gas

Connections, page 17)

2. Replace control valve

1. Take apart gas tubing and

remove foreign matter

2. Locate and correct all

leaks (see Checking Gas

Connections, page 17)

1. Reposition thermostat

sensing bulb (see instruc-

tionsfor Optional

Positioning of Thermostat

Sensing Bulb, page 29.

Page 29

OPTIONAL

POSITIONING

OF

THERMOSTAT

SENSING BULB

For Masonry and

If your log set cycles to pilot, but the room temperature drops to a lower than

ideal comfort level before the log set comes back on, you maywant to

reposition the thermostat sensing bulb.

The thermostat sensing bulb is located near the gas valve assembly on the mounting

bracket. This location allows the thermostat to keep the room temperature at an ideal

comfort level for most fireplace applications. For positioning the thermostat sensing bulb

elsewhere, an adhesive-backed mounting clip has been provided.

Tools needed: 1/4" hex driver or socket

l. Remove logs. Locate the gas valve assembly and thermostat sensing bulb (see Figure 27).

Factory-built

Metal Fireplace

Gas Valve

Assembly

Mounting Thermostat

Bracket Sensing Bulb

Figure 27- Location of Gas Valve Assembly and Thermostat Sensing Bulb

2. The adhesive-backed mounting clip (see Figure 28) is attached to the thermostat sensing

bulb. Remove the adhesive-backed mounting clip.

Figure28 - Adhesive-backed Mounting Clip

3, With 1/4" hex driver or socket, loosen the thermostat screw. Carefully slide the thermo-

stat sensing bulb out of the retaining clamp (see Figure 29).

Note: Do not remove the screw. Make sure you tighten the screw after removing the

thermostat sensing bulb.

iMPORTANT: Do not force or bend the thermostat sensing bulb or capillary,

ICGd04

Screw

Retaining Claml:

Sensing Bulb

Figure 29 - Removing Thermostat Sensing Bulb

4. The thermostat sensing bulb may be located to the lower fight front sid_ of fireplace.

Determine location of sensing bulb, but do not mount sensing bulb until step 5. If you

have a masonry fireplace, see Figure 30 on page 30 for location. Continued I

Page 30

OPTIONAL

POSITIONING

OF

THERMOSTAT

SENSING BULB

For Masonry and

Factory-built

Metal Fireplace

Continued

Thermostat L.

Sensing Bulb

Mounting Clip

Figure 30 - Locating Thermostat Sensing Bulb on Masonry Fireplace

If you have a factory-built metal fireplace, see Figure 31 for location.

Thermostat

Sensing Bulb

Adhesive-backed

Mounting Clip

Figure 31 - Locating Thermostat Sensing Bulb on Factory-built Metal Fireplace

I-,

i

/ kl

J

If your ftreplace has glass doors, position sensing bulb directly behind door gap on right

bottom side (see Figure 32).

Thermostat

Sensing Bulb

Mounting Clip

Glass

Doors

Figure 32 - Installing Thermostat Sensing Bulb behind Glass Doors

5. The mounting clip must be a minimum of 3" from bottom of fireplace to

prevent crimping of capillary. Once you have decided on a location, clean the

area thoroughly. Remove the paper backing from the adhesive on back of

mounting clip, Press the clip into the new location so that the thermostat

sensing bulb will be positioned vertically with the capillary at the bottom (see

Figure 33). Slide the thermostat sensing bulb into the clip.

IMPORTANT: Do not crimp capillary. Thermostat

Adhesive-backed

• Mounting Clip

_ Sensing Bulb

Do Not Crimp Capillary

Figure 33. Positioning the Thermostat Sensing Bulb In the Vertical

Position with the Capillary at the Bottom

Page 31

TECHNICAL

SERVICE

You may have further questions about installation, operation, or ti'oubleshooting.

If so, contact DESA International's Technical Service Department at

1-800-DESA LOG (I-800-337-2564).

SPECIFICATIONS

SERVICE

HINTS

18" Model 24" Models 30" Models

Btu (Variable) 16,000/30,000 20,000/39,000 20,000/39,000

Type Gas Propane Only Propane Only Propane Only

Ignition Piezo Piezo Piezo

Manifold Pressure 8.0" W.C. 8.0" W.C. 8.0" W.C.

Inlet Gas

Pressure (in. of water)

Maximum 14" 14" 14"

Minimum* 11" 11" t 1"

Shipping Weight 28 Ibs.

* For the purpose of input adjustment

When gas pressure is too low

• pilot will not stay lit

• burners will have delayed ignition

• heater will not produce specified heat

• propane gas supply may be low

30 lbs. 32 lbs.

When gas quality is bad

• pilot will not stay lit

• burners will produce flames and soot

• heater will backfire when lit

You may feel your gas pressure is too low or gas quality is bad. If so, contact your

local propane gas supplier.

Page 32

REPLACEMENT

PARTS

Note: Use only original replacement parts. This will protect your warranty cover-

age for parts replaced under wan-anty.

Parts Under Warranty

Contact authorized dealers of this product. If they can't supply original replace-

ment part(s), call DESA International's Technical Service Department at

1-800-DESA LOG (1-800-337-2564).

When calling DESA International, have ready

• your name

• your address

• model number of your heater

• how heater was malfunctioning

• type of gas used (propane or natural gas)

• purchase date

Usually, we will ask you to return the defective part to the factory.

Parts Not Under Warranty

Contact authorized dealers of this product. If they can't supply original replace-

ment part(s), call DESA International's Parts Department at 1-800-972-7879 for

referral information.

When calling DESA International, have ready

• model number of your heater

• the replacement part number

PARTS

CENTRAL

These Parts Centrals are privately owned businesses. They have agreed to support

our customer's needs by providing original replacement parts and accessories.

Baltimore Electric

1348 Dixwell Avenue

Hamden, CT 06514

1-800-397-7553

203-248-7553

Parts Department

Portable Heater Parts

342 N. County Rd. 400 East

Valparaiso, IN 46383

All States

219-462-7441

1-800-362-6951

FBD

1349 AdamsStreet

BowlingGreen,KY 42103

502-846-8534

1-800-654-8534

Fax:1-800-846-0090

Four Rags Power Products

1115 Stateline Road

Niles, MI 49120

616-684-2697

Parts Only

Master Service Center

1184 Wilson NW

Walker, MI 49504

616-791-4760

1-800446-1446

Washer Equipment Co.

1715 Main Street

Kansas City, Me 64108

KS, Me, AR

816-842-3911

East Coast Energy

Products

833 Broadway

W. Long Branch, N,J

07764

906-870-8809

1-800-755-8809

Tarantln Tank Co.

• P.O. Box6129

Freehold, NJ 07728

908-780-9340

1-800-922-0724

Albany Ladder

1586-90 Central Avenue

Albany, NY 12205

NY, MA, V'I"

518-869-5335

1-800-354-7368

Dayton Hardware

P.O. Box 275

North Dayton Station

Dayton, OH 45404

All States

513-258-3721

OH 1-800-762-3426

Hal¢o Enterprises

208 Carter Drive, Unit 21

West Chester, PA 19382

215-696-2670

1-800-368-0803

LA Porte's Parts &

Service

2444 N. 5th Street

HartsvUle, SC 29550

803-332-0191

Parts Department

Cans Unlimited, Inc.

P.O. Box 645

Taylor, SC 29687

All States

803-879-3009

1-800-845-5301

103d04

Page 33

ACCESSORIES

Purchase these fireplace accessories from your local dealer. If they can not supply

these accessories, call DESA International's Sales Department at 1-'800-472-7879

for referral information. You can also write to the address listed on the back page

of this manual.

MANUAL SHUTOFF

VALVE - GA5010

For all models. Manual shutoff valve

with 1/8" NPT tap, Fits 112" NPT

pipe.

BLACK FIREPLACE

HOOD - GA6050

For all models.Helps

deflect heataway from

mantel orwall above

fireplace.

BRASS FIREPLACE

HOOD - GA6052

For all models. Helps

deflect heat away from

mantel or wall above

fireplace.

DAMPER CLAMP - GA6080

For variably controlled models.

Permanently opens chimney flue

damper for vented operation (see

Installing Damper Clamp Accessory

for Vented Operation, page 13).

LAVA ROCK - GA6060

For all models. Order when additional

rock is desired. (3 lb. bag)

10_Q04

Page 34

ILLUSTRATED

PARTS

BREAKDOWN

Variable Manually-

Controlled Models

CGD3018P

CGD3924P

CGD3930P

2

12

9

5

21

19

17

15

/o3eo4

Page 35

PARTS LIST This list contains replaceable parts usedin your heater. When ordering parts, follow

the instructions listed under Replacement Parts on page 32 of this manual.

KEY

NO.

1 103008-02

2 103009-02

3 103010-02

4 103011-02

5 102775-04CK

6 102844-02

7 102966-02

8 098887-10

9 102798-01

10 102779-04

11 099056-19

12 102843-01

13 102980-01

14 102568-08

18 098508-01

16 098354-01

17 102445-01

18 099387-08

19 098271-07

20 099059-02

20-1 098594-01

20-2 098593-01

21 Ml1084-38

22 098276-01

23 098248-01

CGD3018P CGD3924P CGD3930P

PART NUMBER PART NUMBER PART NUMBER DESCRIPTION

103005-01

103009-01

103010-01

103011-01

102775-01CK

102844-01

102966-01

098867-10

102798-01

102779-02

099056-17

102843-01

102772-01

102568-06

098508-01

098354-01

102445-01

099387-08

098271-07

099059-02

098594-01

098593-01

Ml1084-38

098276-01

098249-01

103008-03

103009-03

103010-03

103011-03

102775-03CK

102844-01

102966-01

098867-10

102798-01

102779-02

099056-17

102843-01

102772-01

102568-06

098508-01

098354-01

102445-01

099387-08

098271-07

099059-02

098594-01

098893-01

Ml1084-38

098276-01

098249-01

QTY.

Back Log (#1) 1

Middle Log (#2) 1

Front Log (#3) 1

Crossover Log (#4) 1

Painted Base Assembly 1

Lower Bracket 1

Upper Bracket 1

Gas Regulator 1

Inlet Tube 1

Outlet Burner Tube 1

Burner Orifice Injector 1

Burner Clip 1

Burner 1

Control Valve 1

Valve Retainer Nut 1

Control Knob 1

Piezo Ignitor 1

Pilot Tube 1

Ignitor Cable 1

ODS Pilot 1

Ignitor Electrode 1

Thermocouple 1

Hex Screw, #8-18 x .38 11

Hex Head Plug, 1/8 NPT 1

Nut, M5 2

100563-01

101055-02

100565-01

100639-01

101449-04

101137-02

101416-33

GA6060

PARTS AVAILABLE -- NOT SHOWN

100563-01

101055-02

100565-01

100639-01

101449-04

101137-02

101416-33

GA6060

100563-01

101055-02

100565-01

100639-01

101449-04

101137-02

101415-33

GA6060

WarningPlate 1

LightingInstructionsPlate 1

WarningPlate Fastener 1

CautionDecal 1

ControlPositionDecal 1

HardwareKit 1

InformationVideo 1

Lava Rock 1

Page 36

ILLUSTRATED

PARTS

BREAKDOWN

Thermostatically-

Controlled Models

CGD3924PT

CGD3930PT

18

3

20-1

20

A

13

2

23

17

19

L

15

14

_t

\

I

I

I

Page 37

PARTS LIST This list contains replaceable parts used in your heater. When ordering parts, follow

the instructions listed under Replacement Parts on page 32 of this manual.

KEY CGD3924PT CGD3930PT

NO. PART NUMBER PART NUMBER DESCRIPTION

1 103008-01

2 103009-01

3 103010-01

4 103011-01

5 102775-05CK

6 102844-01

7 102966-01

6 098867-10

9 102981-01

10 1102983-02

11 099066-17

12 102843-01

13 102772-01

14 101329-19

15 102979-01

16 098544-01

17 102445-01

18 099387-09

19 098271-07

20 099059-02

20-1 i098594-01

20-2 098593-01

21 Ml1084-38

22 096249-01

23 099211-01

103008-03

103009-03

103010-03

103011-03

102775-07CK