No.C48431 00604A

INSTRUCTION MANUAL

ENGINE-DRIVEN AC GENERATOR

DCA-600P

IMPORTANT: READ AND UNDERSTAND THIS MANUAL

CAREFULLY BEFORE USE OF THIS MACHINE.

KEEP THIS MANUAL FOR YOUR FUTURE REFERENCE.

2-8-5 Nihonbashi-horidomecho, Chuo-ku, Tokyo, 103-8566 Japan

CONTENTS

A

pp

g

g

p

y p

g

g

g

g

p

y p

g

g

g

g

g

p

g

g op

pping

g

g

SAFETY PRECAUTIONS FOR GENER

TORS .................................................................... 2

1. DCA series ........................................................................................................................ 8

1-1 General ................................................................................................................... 8

1-2 Machine structure ................................................................................................... 8

1-3 Machine a

earance and internal component devices ........................................... 8

1-4 Control switches and meters ................................................................................... 10

1-4-1 En

1-4-2 En

ine start/stop controls ....................................................................................... 10

ine indicators .................................................................................................... 12

1-4-3 Generator controls and indicators ........................................................................... 19

2. Trans

2-1 Safet

ortation, storage and installation ............................................................................ 20

recautions for transportation, storage and installation ............................... 20

2-2 Transportation ......................................................................................................... 21

2-3 Stora

2-3-1 Stora

2-3-2 Preparin

e ................................................................................................................... 21

e method ...................................................................................................... 21

for operation ........................................................................................... 22

2-4 Installation ............................................................................................................... 23

2-4-1 Installation ............................................................................................................... 23

2-4-2 Checkin

3. O

eration .......................................................................................................................... 29

3-1 Safet

3-2 Connectin

3-2-1 Precautions in connectin

after installation ....................................................................................... 26

recautions for operation ............................................................................. 29

the load ................................................................................................ 31

the load ......................................................................... 31

3-2-2 Non-liner and sensitive loads .................................................................................. 31

3-2-3 Selection of cables .................................................................................................. 32

3-2-4 connectin

3-3 Groundin

3-4 Before startin

3-4-1 Checku

the load ................................................................................................ 33

............................................................................................................... 34

......................................................................................................... 34

before start-up ......................................................................................... 34

3-4-2 Instruction for Fuel Device ...................................................................................... 36

3-5 Startin

3-6 Durin

3-7 Sto

3-7-1 Stoppin

3-7-2 Emer

.................................................................................................................... 37

eration ..................................................................................................... 38

.................................................................................................................. 38

method ..................................................................................................... 38

ency stop ...................................................................................................... 38

3-7-3 Protection device .................................................................................................... 38

4. Fuel, coolant and lubricants ..............................................................................................40

5. Periodic checkup and maintenance .................................................................................. 43

5-1 Safety precautions for periodic checkup and maintenance ..................................... 43

5-2 Periodic chechup ..................................................................................................... 44

5-2-1 Maintenance schedule ............................................................................................ 44

5-2-2 Checking/every 250 hours ...................................................................................... 45

5-2-3 Checking/every 500 hours ...................................................................................... 46

5-2-4 Checking/every 1000 hours .................................................................................... 51

5-2-5 Table of periodical maintenance and checking ....................................................... 52

6. Troubleshooting .................................................................................................................. 53

7. Principal data ...................................................................................................................... 54

7-1 Readings on gauges ...............................................................................................54

7-2 Setting of switches .................................................................................................. 54

7-3 Reference conditions .............................................................................................. 54

7-4 Limitations ............................................................................................................... 54

7-5 General specifications ............................................................................................. 55

7-6 Conversion list of SI units into UK/US units ............................................................ 56

FOREWORD

• We are very thankful for your special choice of our MACHINE in the market.

• Please read this manual carefully and understand for proper use this machine.

• Please keep this manual at your prescribed location where operator can always take this manual.

• If you have any question or problem on this operation, please contact your nearest Distributors.

• Pay special attention to statements preceded by the following word.

DANGER: indicates an imminently hazardous situation which, if not heeded, will result in

WARNING: indicates a potentially hazardous situation which, if not heeded, could result in

death or serious injury.

death or serious injury.

CAUTION: indicates a hazardous situation which, if not heeded, may result in minor or

moderate injury or damage to the machine.

[ NOTE ]: indicates useful information for the machine operations.

- 1 -

SAFETY PRECAUTIONS FOR GENERATORS

In order to ensure safe operation, the following symbols are used for explanation of the

machine operation.

The following symbols, found throughout this manual, alert you to potentially dangerous

conditions to the operator, service personnel, or the equipment.

WARNING: This symbol refers to a hazard or unsafe practice which can result in severe

personal injury or death.

CAUTION: This symbol refers to a hazard or unsafe practice which can result in personal

injury or product or property damage.

[ NOTE ]: This symbols show handling precautions for effective operation and many years

of satisfactory operation.

Some of the items shown by “

CAUTION” may also cause death or serious injury.

Be sure to observe all the items, as they are important for safe operation.

• If the machine is used by an outsider, you are requested to explain him correct handling and

advise him to read this instruction manual carefully.

• Do not modify the machine at your discretion, as it affects the safety, performance or the life of

the machine.

• If the machine is modified or it is used incorrectly against this manual or unauthorized parts are

used, the warranty of manufacturer will become invalid.

- 2 -

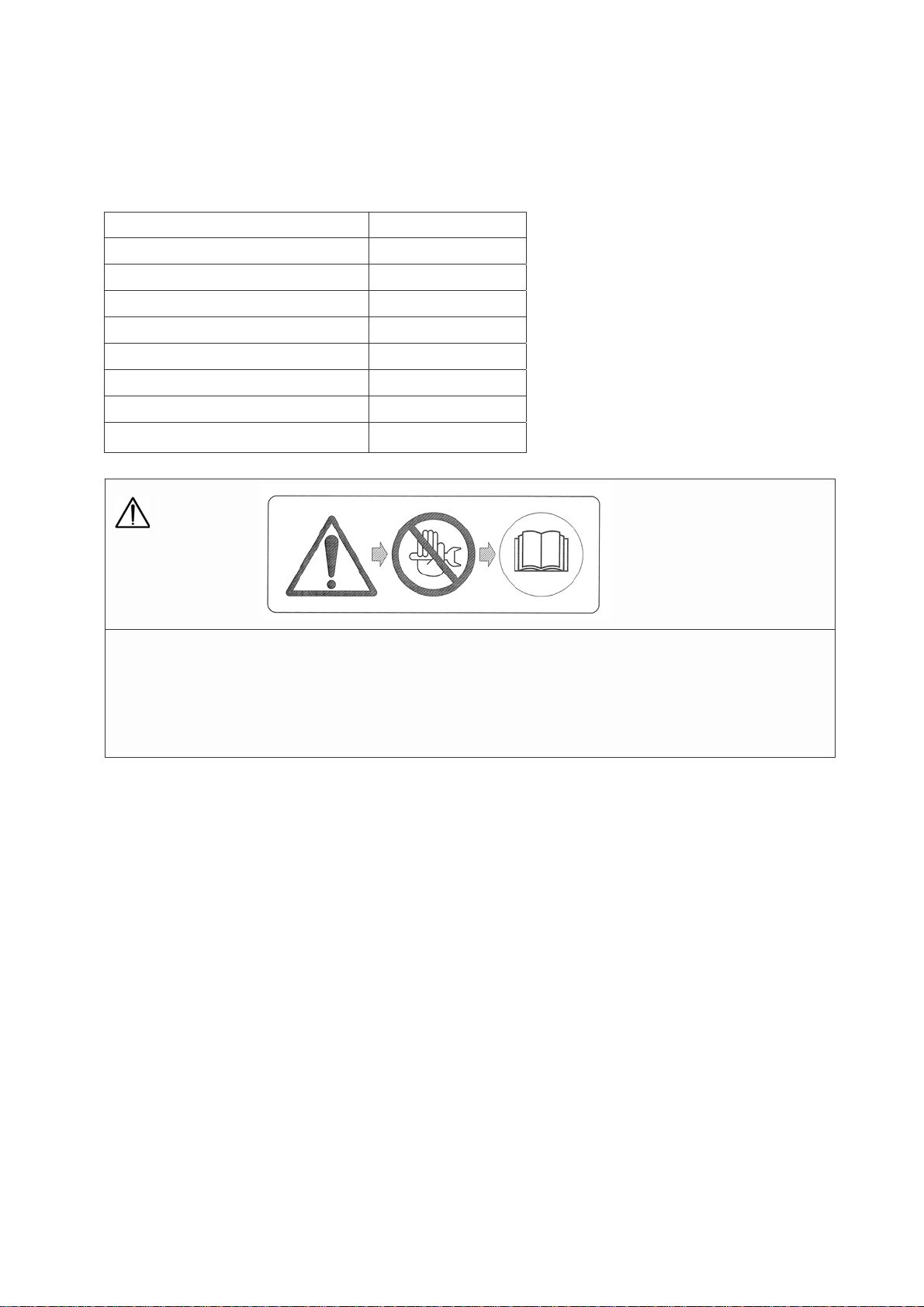

SAFETY LABEL

Safety labels are attached to the following positions of the machine.

• Keep these safety labels clean at all times.

• When safety labels are spoiled or lost, contact distributor or our office specifying the nameplate

No. shown below and ask for new ones.

Parts name Parts number

CAUTION : Instruction manual B9111 0220

DANGER : Electric shock B4510 0250

WARNING : Fire/explosion B9045 0100

CAUTION : Burn B9111 0240

CAUTION : Moving parts B9040 0050

CAUTION : Hot coolant B9041 0020

CAUTION : Engine fan B9040 0060

WARNING : Engine exhaust B9042 0020

CAUTION:

Instruction manual

• Do not use machine before reading the instruction manual.

• Do access to machine in accordance with the instruction manual when machine is in fault.

• Do consult to authorized person for repair or maintenance to avoid incidents.

- 3 -

Do not touch the output terminals during operation to prevent decease due to electric shock.

DANGER: ELECTRIC SHOCK can kill.

• Never touch the output terminals during operation. If your hands or the machine are wet, it will result in

a death or serious injury.

• When a wiring work is required, be sure to turn OFF the circuit breaker and stop the machine.

• Keep the output terminal cover closed and the terminal bolts tightened while the machine is running.

• A low voltage is generated even when the machine is in low speed idle operation. Be sure to stop the

machine completely.

Do not touch the electrical parts in the machine during operation, as it may lead to death due to electric

shock.

• Always close the control panel and tighten the fixing bolts before operating the machine.

• Always close the side door and lock it before operating the machine.

• When opening the control panel for voltage selection, etc., turn OFF the circuit breaker and stop the

machine.

DANGER:

ELECTRIC SHOCK

by leak can kill.

Improper grounding may lead to death due to

electric shock.

• Be sure to execute the grounding of the machine

and the load according to the local rule.

CAUTION:

MOVING PARTS can

cause severe injury.

Rotary unit which runs at a high speed is located in

the machine. (Note that it is very dangerous if you

touch it.)

• Be sure to close the door and lock it during

operation.

• When the door needs to be opened during operation, do not get your hands and head in the

machine to prevent them from being caught in

the machine which may lead to injury.

• When making check or maintenance of the machine, be sure to stop the machine in advance.

- 4 -

Fuel and oil are flammable. Incorrect handling

results in danger of ignition or fire.

• When fuel needs to be supplied to the machine,

be sure to stop the engine. Refrain from smoking.

Keep the machine away from fire.

• Do not leave flammable objects (paper, wood

chips, etc.) and hazardous objects (oil, powder,

etc.) near the machine.

• Wipe off spilt fuel and oil.

WARNING: DIESEL

FUEL can cause fire

or explosion.

CAUTION:

HOT PARTS can burn

skin.

High temperature units are located in the machine.

(Note that these units are very dangerous if they are

used incorrectly.)

• Be sure to close the door and lock it during

operation.

• If the door needs to be opened during operation,

do not get your hands and head in the machine to

prevent unexpected burns.

• When making check or maintenance of the

machine, be sure to stop the machine.

• The bonnet is still hot even after the machine is

stopped. Be careful until the engine is completely

cooled.

CAUTION: ENGINE

EXHAUST can kill.

Insufficient ventilation may lead to death due to

lack of oxygen or poisoning by exhaust gases.

• Do not use the machine in a place of poor ventilation or in a place where exhaust gases stays.

• Do not use the machine indoors or in storehouse,

tunnel, ship hold, tank, etc. of poor ventilation.

• If it becomes necessary to use the machine in

the above places, the exhaust pipe should be

extended to a well ventilated place. In this case,

use a ventilator to ensure proper ventilation.

• Do not direct the exhaust outlet to nearby

pedestrians and houses.

CAUTION:

HOT COOLANT can

cause severe scalds.

If the radiator cap is opened while the water

temperature is high, steam or hot water will spout

out.

• During operation or immediately after stopping

the machine, do not open the radiator cap while

the water temperature is high.

• When cooling water needs to be checked or supplied, wait until the engine is cooled (50°C or less

as measured with the water temperature gauge).

CAUTION: Battery.

Battery generates flammable gases. Improper

handling may lead to explosion or serious injury.

• Battery should be charged in a well ventilated

location. Otherwise, flammable gases are accumulated which may be ignited and exploded.

• When connecting a booster cable, do not jumper

the terminals (+ and -). Otherwise, the flammable

gases generated from the battery may be ignited

and exploded by sparks.

• For maintenance of the machine, disconnect the

ground cable on the ground side.

The battery acid is dilute sulfuric acid. Improper

handling will cause unexpected burns.

• When the battery acid gets on your clothes or skin,

wash it out with a large volume of water immediately. If it gets in your eyes, wash with a large volume

of water immediately and consult your doctor.

In the worst case, it will put out your eyes.

• For checking or handling of the battery, be sure to

stop the engine and turn OFF the battery switch in

advance.

- 5 -

CAUTION: Operator.

Do not operate the machine if operator is tired too

much or drinks some alcohol or take some drugs.

• Otherwise, it may cause unexpected accidents or

injury.

During checking or maintenance, be sure to put on

suitable clothes and protectors.

• Do not put on baggy clothes, necklace, etc.,

because they are easily caught by projections

which may cause injuries.

CAUTION: Connection to house

Before connecting this machine to any building’s

electrical system, a licensed electrician must install

an isolation(transfer) switch.

• Serious injury or death may result without this

transfer switch.

wiring.

CAUTION:

Noise.

This machine generates large noise if the door is

open. Surrounding to large noise may cause hearing

trouble.

• Close and lock the door during operation.

• If opening the door is necessary during operation,

be sure to put on the ear protector.

CAUTION: Transportation.

Do not lift the machine except hanger of base

because it is not strong enough for lifting and

may cause a falling accident.

• When lifting the machine, use the hanger located

at the roof center.

• Keep out under the lifted machine.

Do not lift or do not transport the machine during

operation, as it may cause damage to the fan or

serious trouble.

• When loading the machine on the truck or the

like, fix the machine firmly by hanger on the

both side.

- 6 -

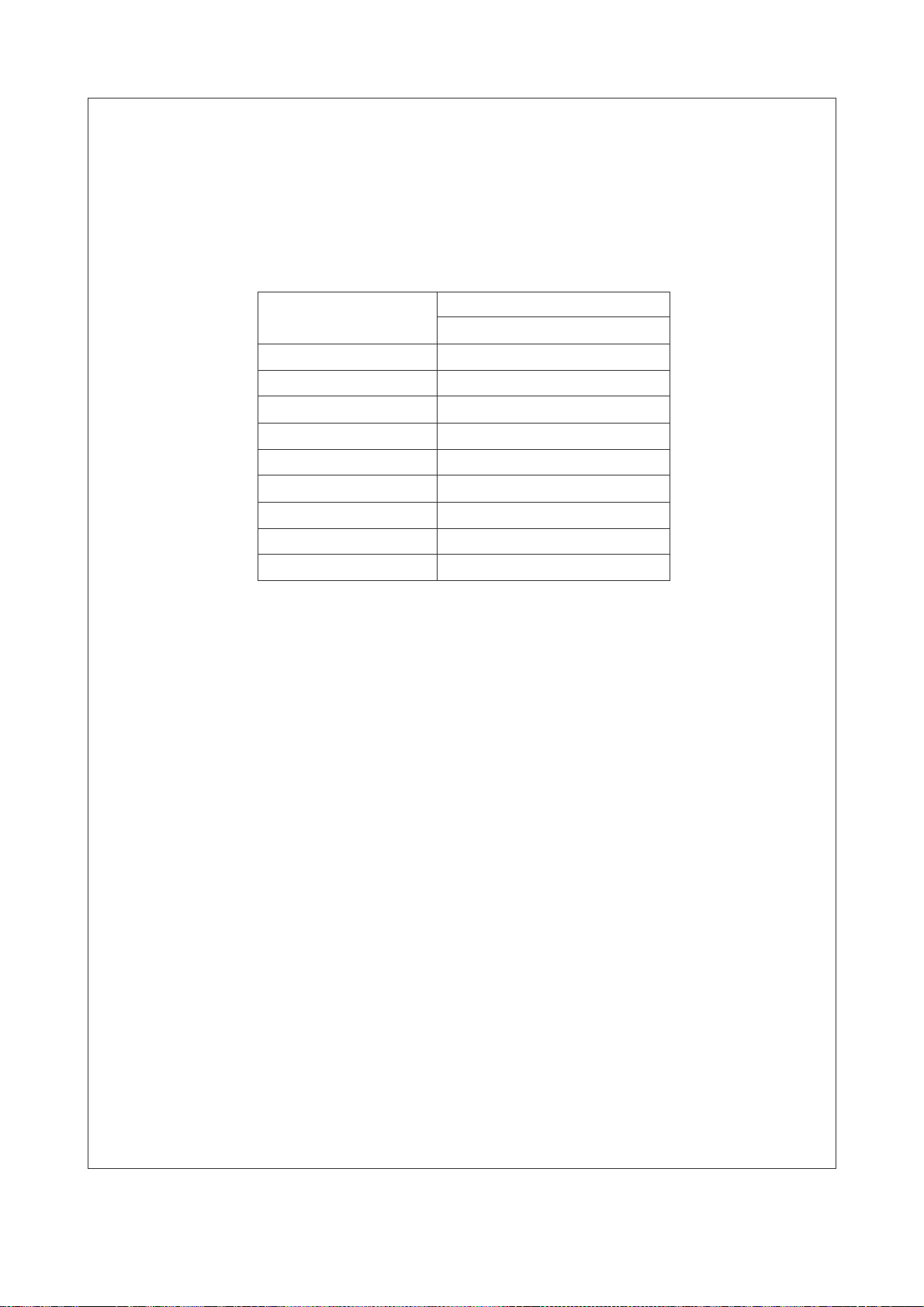

SAFETY LABEL

Model DCA-600P

Parts number

1 DANGER: Electric shock

2 WARNING: Fire/explosion

3 CAUTION: Burn

4 CAUTION: Moving parts

5 CAUTION: Instruction manual

6 CAUTION: Hot coolant

7 CAUTION: Engine fan

8 WARNING: Engine exhaust

This instruction manual

describes how to handle the

machine with a view to

promising safety run, maximum

efficiency and long durability.

Read the manual attentively

before starting the machine

operation for correct handling,

operation and appropriate

maintenance from the beginning.

The maintenance schedule

consists of a procedure of

keeping the machine in good

condition.

For the user, keep the manual

carefully for machine operation

and maintenance according to

the instructions. Observe all the

safety precautions including

ones stated in the manual.

Entrust the repair to trained

personnel of Denyo or its

distributor who are capable of

contacting us as required.

When consulting us, specify

the model and serial number

indicated on the nameplate.

For data not specified in the

manual, see “Principal data”.

The company reserves the right

to make changes without prior

notice.

- 7 -

SAFETY PRECAUTION:

• The user must carry out all safety precautions stated in the manual.

• If any statement in this book, especially with regard to safety, does not comply

with local legislation, the stricter of the two shall apply.

1. DCA SERIES

1-1 General

• DCA series generator is intended for generating power source where there is no power source.

• For further details, see “7 Principal data”.

1-2 Machine structure

• The generator which is directly driven by Perkins water-cooled diesel engine is mounted on

the common frame along with control equipment, radiator, battery(option), fuel tank(option)

and other auxiliary equipment. See Fig. 1.

1-3 Machine appearance and internal component devices

• There are the hanger at the base on its both sides. When lifting the machine, use the hanger.

Do not resort to winding rope because it is not strong enough. See Fig. 2.

• The engine cooling water refilling port and fuel refilling port(option) are located on the top

surface of the machine.

• The drain plugs for engine oil, cooling water and fuel(option) are located at the base side

under the machine. Tags of their respective names are attached there.

Fig. 1 Model DCA-600P

Parts number

1. AC generator

2. Diesel engine

3. Control box

4.

Fuel tank

5. Radiator

6.

Battery

7.

Muffler

8. Intercooler

(option)

(option)

(option)

- 8 -

Fig. 2 Model DCA-600P

Parts number

Parts number

1. Hanger 6. Radiator cooling water drain plug

2. Radiator cooling water refilling port 7. Engine exhaust port (without muffler)

3. Fuel tank refilling port (with fuel tank) 8. Engine exhaust port (with muffler)

4. Fuel drain plug (with fuel tank) 9. Fuel inlet (only without fuel tank)

5. Oil drain plug 10. Fuel outlet (only without fuel tank)

- 9 -

1-4 Control switches and meters

• The control panel is mounted on the bodywork with hinges and is fastened by screws.

Loosening the screws has access to repairing or replacing electrical parts in the control

box.

1-4-1 Engine start/stop controls

Fig. 3 Model DCA-600P

Parts number

Parts number

1. Frequency meter 8. Pilot lamp

2. Ac ammeter (U) 9. Engine indicator

3.

Ac ammeter (V) 10. Coolant level warning lamp

4. Ac ammeter (W) 11. Operation switch

5. Ac voltmeter 12. Start button

6. Voltage regulator

Speed regulator

13.

7. Circuit breaker (for main) 14. Emergency stop button

- 10 -

1. Operation switch

The switch is 2-position switch which can be operated with its specific key only.

RUNOFF/STOP

1) OFF/STOP

This switch should be set in this position unless the machine is in operation.

The key can be inserted or pulled out in this position.

OPERATION SWITCH

RUNOFF/STOP

2) RUN

This switch should be set in this position when the machine is in operation.

OPERATION SW ITCH

2. Start button

KEEP ON PU SHING

TO START ENGINE .

START BUTTON

3. Emergency stop button

BEFORE STARTING , CHECK

EMERGENCY STOP BUTTON I S RESET

RESET

EMERGENCY STOP BUTTON

4.Speed regulator

HIGH

SPEED REGULATOR

LOW

In this position, the preheating system is energized.

This button keep on pushing to start the engine.

The stop button is a push button to stop the engine in case of an emergency.

When the button is pressed, it must be unlocked by turning it anti-clockwise

before the engine can be re-started.

Turn the switch toward the “HIGH” side to increase the speed and toward the

“LOW” side to decrease it.

- 11 -

1-4-2 Engine indicators

5. Engine monitor

(1) Engine indicator

That indicates the numerical values of engine speed, engine oil pressure, run hours,

battery charging voltage, or engine coolant temperature.

Indicated Items Unit

engine speed min

-1

engine oil pressure ×100kPa

battery charging voltage V

engine coolant temperature ºC

1 - Engine Speed

• Revolutions per minute is indicated. 1500/1800 min

2 - Engine Oil Pressure

• 3.0 to 6.0 × 100 kPa should be indicated at normal engine operation.

• Higher value would be indicated in cold condition immediately after engine starts.

• Conduct a warning - up operation until it indicates normal value.

3 - Battery Charging Voltage

• That should indicate more than 26.0V at engine running.

4 - Engine Coolant Temperature

• That should indicate a temperature between 75 to 90°C at engine running.

[ NOTE ]: If that would indicate higher temperature, disconnect all loads, and wait until

the temperature comes down to normal value.

-1

is indicated at 50/60Hz.

- 12 -

(2) Fuel Level Indicator (Only with Fuel Tank)

That Indicates a fuel level in the fuel tank. All the lights are indicated green when the fuel

is full. The green lights stop indicating one by one as the fuel level decrease, finally the

red light will be indicated when it is only one green light is left. Replenish the tank when

there becomes only one lamp turned on. The table below shows the relation between

numbers of turn - on lamps and fuel level.

Numbers of lamps

turned-on

(3) Alarm and Memory at Abnormal Condition

When any abnormal condition occurs in engine oil pressure, battery charging voltage,

or engine coolant temperature, the indication will change as the following;

9

8

7

6

5

4

3

2

1

DCA-600P

Fuel level (L)

450 to full

405 to 450

345 to 405

295 to 345

245 to 295

195 to 245

165 to 195

120 to 165

0 to 120

1 - The Indicator shows its defect with blinking numbers.

2 - When the abnormal condition is corrected, the on - and - off indication will stop.

3 - If engine would stop urgently and automatically or stop manually with the abnormal

condition, the abnormal value will be memorized, and then indicated even after engine

is started again.

In this case, keep on pushing the button “RESET” for more than 5 seconds, and the

abnormal indication will be reset to normal.

- 13 -

(4) Warning Lamps

This monitor indicates the following failures, if any one of them occurs.

① High jacket water temperature (WATER TEMP)

This lamp goes on when the water temperature rises abnormally.

If the lamp goes on during operation, the emergency stop device

immediately operates to shut down the engine automatically.

② Low lubricating oil pressure (OIL PRESS)

If this lamp goes on during operation, the emergency stop device

immediately operates to shut down the engine automatically.

(5) Hour Meter

① When you turn the starter switch to “RUN” position, and push the selector button located

on the right side of the Hour Meter, you can see the numbers mentioned below;

• “ODO” Total running hour

• “TRIP A” Running hours “A” on a certain period

• “TRIP B” Running hours “B” on a certain period

② If you want to reset the Trip Meters, push the selector button for more than 1 second,

after selecting each meters.

- 14 -

(6) The hour meter has an internal battery

The engine monitor incorporates both a rechargeable internal battery as well as a

charging circuit.

While the generator is not in operation, the engine monitor will still indicate the hours

operated via its internal battery.

While the generator is in operation, the internal battery recharges.

When the generator remains unused for a long period of time, the battery will continue to

lose its charge. Once the charge is exhausted, the hour meter will not indicate hours, and

the battery will need to be recharged. From a completely exhausted state, recharging the

battery for 30 minutes will only result in a 30 minute charge to the battery.

However, if charged for 3 hours, the hour meter will indicate hours for more than 10 days

without another charge.

Please refer to the table below to see the relationship between battery time charging

versus length of indication by the hour meter.

6. Coolant level warning lamp

This lamp goes on when the coolant amount become

lower than the fixed amount.

If the lamp goes on during operation, the emergency stop device

Immediately operates to shut down the engine automatically.

7. Controller breaker

COOLANT LEVEL WARNING LAMP

This breaker protects engine hardware.

Before insert the key in the operation switch, switch this breaker to ON.

CONTROLLER

BREAKER

- 15 -

8. Switch and Lamp for Electronic Governor Controller (in the control box)

(1) Isochronous-Droop Change-over switch

The generating set can change the governor control between

”Isochronous Governor Control and Droop Governor Control”

by “Isochronous-Droop Change-over switch” where is equippped

with the control box.

The original position at factory shall be set in “Droop Governor

Control”. Operate the unit in condition of “Droop Control”

in common.

In case of starting with a heavy load, operate the unit in condition

of ” Droop Governor Control” because it is better for starting

efficiency than “Isochronous Governor Control “.

Explanation for the control

① “Isochronous Governor Control “----- Frequency is constant regardless of load.

When the generator is set in a frequency thet will be pointed in condition of NO-LOAD,

the governor controls the frequency constantly regardless of load.

② “Droop Governor Control “----- Frequency will be alternative depending on load.

” Droop Governor Control” means that frequency can be alternative depending on load.

When the rated frequency will be reduced at about 2.0 Hz against NO-LOAD.

Therefore, NO-LOAD frequency should be set at 52.0 to 52.5Hz.

(2) Frequency change – over switch

This is for switching the frequency from 50Hz to 60Hz or 60Hz to

50Hz.

SHUTDOWN LAMP ACTION AL ERT L AMP F AULT R ESE T

WARNING LAMP DIAGNOSTICS L AMP

FREQUENCY

CHANGE- OVE R S WITCH

50Hz ISOCHRONOUS

60Hz

DROOP

ISOCHRONOUS-DROOP

CHANGE-OVER SWITCH

ISOCHRONOUS-DROOP

CHANGE-OVER SWITCH

FREQUE NCY

CHANGE-OVER SWITCH

ISOCHRONOUS

DROOP

50Hz

60Hz

- 16 -

(3) Diagnostic Lamp

This lamp is sometimes called the check engine light.

The diagnostic lamp is used to warn the operator of the presence

of an active diagnostic code. The lamp may not be included in all

applications.

(4) Fault Reset

In case turn off the Diagnostic Lamp, push this button.

(5) Engine Monitoring

This engine monitoring system monitors the following parameters.

・ Engine oil pressure

・ Coolant temperature

・ Intake manifold air temperature

・ Engine speed

・ Boost pressure

・ Fuel temperature

The monitoring system has three levels of operation.

The levels are described below.

Warning Operation (lev el 1)

In the Warning condition, the ECM causes the warning lamp to

come ON. The warning lamp indicates that a fault has been

detected by the engine monitoring system. No further action by

the ECM or the engine occurs.

Action Alert Operation (level 2)

In the Action Alert condition, the ECM causes the action alert

lamp to come on. The Action Alert lamp indicates that a fault has

been detected by the engine monitoring system. This condition is

normally wired in order to cause a shutdown and the shutdown is

controlled by the control panel on the machine.

Shutdown Operation (level 3)

If the fault reaches the Shutdown condition, the ECM causes the

shutdown lamp to come on. Unless the engine is in a Critical

Override condition, the engine will shut down.

DIAGNOSTICS LAMP

FAULT RESET

WARNING LAMP

ACTION ALERT LAMP

SHUTDOWN LAMP

- 17 -

Settings for the Monito ring Sy stem

Parameter State Trip Point Delay Time

Low Engine Oil Pressure

Warn Operator On

Action Alert Always On

Engine Shutdown Always On

300 kPa

(43.5 psi)

250 kPa

(36.3 psi)

200 kPa

(29.0 psi)

60 seconds

2 seconds

2 seconds

High Engine Coolant Temperature

Warn Operator On 104°C (219°F) 60 seconds

Action Alert Always On 105°C(221°F) 10 seconds

Engine Shutdown Always On 108°C(226°F) 10 seconds

Engine Overspeed

Warn Operator On 2000 RPM 1 second

Action Alert Always On 2050 RPM 0 second

Engine Shutdown Always On 2140 RPM 0 second

High Intake Manifold Air Temperature

Warn Operator On 75°C (167°F) 60 seconds

Action Alert Always On 78°C (172°F) 10 seconds

High Fuel Supply Temperature

Warn Operator On 60°C (140°F) 60 seconds

Action Alert Always On 68°C (154°F) 60 seconds

High Boost Pressure

Warn Operator On

300 kPa

(43.5 psi)

60 seconds

Action Alert Always On Map 5 seconds

- 18 -

1-4-3 Generator controls and indicators

9. Frequency meter

This meter indicates the frequency of the outputted voltage. Make sure that it reads

50Hz or 60Hz when running.

10. Ammeter (U, V, W)

This meter indicates the current going to the connected load. It must not exceed the

rated current.

11. Voltmete r (Include voltmeter change-over switch)

The voltmeter indicates the outputted line voltage.

12. Three-phase circuit breaker

The circuit breaker is a safety device interrupting the mains when an overload or a

short circuit occurs at the load side connected to the receptacles. It also serves

as a main switch for supplying energy from the generator to the load connected to the

output receptacles.

Do not use this circuit breaker to turn on or off the load.

When tripped, the breaker must be reset manually by switching it to OFF and then to

ON after eliminating the cause of the trouble.

13. Voltage regulator knob

The output voltage is controlled by a regulator with rotating knob. Turning clockwise

increases the voltage and vice versa.

14. Pilot lamp

The lamp will be turned on if a dynamo generates electricity.

- 19 -

2. TRANSPORTATION, STORAGE AND INSTALLATION

2-1 Safety precautions for transportation, storage and installation

WARNING

• When lifting or transporting the machine, use only appropriate devices which comply with

the local safety codes and regulations.

• When lifting the machine, use the hanger of base.

• Do not resort to rope winding because it is not strong enough.

• Before lifting, close and fix covers and other moving parts and clear away the machine

interior and top.

• Do not slip under a lifted machine.

• The electrical connections shall comply with the local codes.

• Earth the machine properly.

• The engine exhaust gas is lethal and toxic. Do not operate in places where the aeration is

poor. Discharge the exhaust sufficiently by a ventilating system. Never direct the engine

exhaust towards passers-by.

• Do not operate the machine in an atmosphere containing toxic or combustible gas. Otherwise,

fire or explosion might occur in the machine. (Example: Near volatilizing paint solvent.)

• Fuel and oil are combustible and undiluted anti-freeze solution is inflammable. Do not

smoke while handling or refilling them. Do not get fire or heated objects near them. Do not

spill or leave fuel, oil, anti-freeze solution or cleansing agent in or around the machine.

If spilled, be sure to wipe off properly.

• If necessary, provide a spark arrestor to trap incendiary exhaust sparks.

CAUTION

• Install the machine on a well ventilated, horizontal, flat, dry and solid floor. If the floor is

not horizontal enough to keep the machine leveled, consult your sales distributor. When

installing the machine on a trailer, fasten the trailer and fix the wheels by stoppers.

• Do not remove or unduly modify safety devices, guards, covers or insulating materials from

the machine.

• When servicing batteries, always wear protecting clothing and glasses. The battery electrolyte is

a diluted sulphuric acid which can cause severe burns. Get it away from eye, skin and clothing.

• When charging batteries, an explosive gas forms above the cells and escapes through the

vents. Do not smoke near batteries just after having been charged. Never make or break

live circuits or battery terminals, because a spark usually occurs.

• Before checking the machine, stop the engine and wait for at least 10 minutes so that it will

cool down completely. If done while running or immediately after shutdown, you might get

burnt or injured.

- 20 -

2-2 Transportation

• When lifting or transporting the machine, use only appropriate devices which comply with

the local safety codes and regulations.

For dimensions and weight of the machine, refer to “7 Principal Data”.

See Fig 5 for the center of gravity. (without optional parts)

Fig. 5

Model L W H

DCA-600P 1970 mm 20 mm 700 mm

• When lifting the machine, use the hanger of base.

Never use the rope hanger because it is not strong enough to lift.

• Before lifting, close and fix the covers, and other moving parts and clear away the machine

interior and top.

• Do not slip under a lifted machine.

• Before transporting by truck or others, wind ropes on the machine to fasten it securely.

• Put covers so as to protect the machine from rain or moisture when transporting.

2-3 Storage

2-3-1 Storage method

1. Store the generator in a sufficiently ventilated, dry room which is free from frost, salt and dust.

Storage environment: Atmospheric temperature -15 to 55°C, humidity 95% or lower.

2. Run the engine once a week until warm.

- 21 -

3. If it is impossible to run the engine regularly, extra precautions must be taken.

1) Consult the instruction manual for the engine.

2) Remove the battery. Store it in the same environment as for the machine. Keep the

battery clean and coat its terminals lightly with petroleum jelly. Recharge the battery

regularly.

3) If the electrolyte has dropped to the specified level, refill it.

4) Clean the generator. Oil or fuel spillage is not allowed. Protect all electrical components

against penetration by moisture.

5) Enclose the generator, except the bottom, with a plastic bag.

2-3-2 Preparing for operation

Before operating again the generator kept unused for a long time, remove the plastic bag,

VCI paper from the openings and silica gel from inside and check the generator thoroughly.

Further maintain the following items.

1. Consult the instruction manual for the engine.

2. Measure the insulation resistance of the generator with a 500-V insulation resistance tester.

The resistance must exceed 1 MΩ.

In case of measuringwith an insulation resistance tester over 500VDC current, disconnect

all connectors from the AVR located in the control box before measuring.

3. Replace the fuel filter cartridge and fill the fuel tank.

Vent the fuel system.

4. Reinstall and connect the battery. If necessary, recharge it.

5. Check the fan belt condition and tension; adjust if required.

6. Check and, if required, refill cooling water and oil.

7. Submit the generator to a test run.

- 22 -

2-4 Installation

2-4-1 Installation

1. Install the generator on a well ventilated, horizontal, even and solid floor. If the floor is not horizontal

enough to keep the machine leveled, consult your sales distributor. When installing the machine on a

trailer, fasten the trailer and fix the wheels by stoppers. Avoid a site exposed to rain or high temperature.

The operating ambient conditions are atmospheric temperature of

-5 to 46°C, humidity of 85% or lower and altitude of 1000m or ower.

If the machine do not conform with the above conditions, consult your sales distributor.

2. Avoid a dusty site. If it is inevitable, provide protective devices.

3. Do not operate the machine in an atmosphere containing toxic or combustible gas. Otherwise

fire or explosion might occur in the machine. (Example: Near volatilizing paint solvent.)

4. Leave space for operation, inspection and maintenance; at least 1200 mm each on machine

front and rear and sides. See Fig. 6

Fig. 6

[ NOTE ]: If the machine is operated in a smaller space than that shown above, the room

temperature will rise. Please reduce the generator output in such condition. Therefore

proper power reduction is necessary.

If the space required above the machine is not uniform, make a decision so that:

• The radiator can be refilled with cooling water.

• The exhaust pipe can be introduced.

• The exhaust can smoothly be discharged.

- 23 -

5. Do not direct the exhaust towards passers-by or residences, etc.

6. Install an exhaust pipe of sufficient diameter to let the engine exhaust gas out directly.

7 . Check for sufficient ventilation and position the ventilator so that the exhaust from the machine

will not be re-circulated in the room even if the ventilation is proper.

8. Check that the inner earthing system is in compliance with the local regulations.

9. Also connect the load bodyworks to ground.

- 24 -

Model DCA-600P

Fig. 7

1. Oil level gauge 6. Alternator

2. Oil refilling port cap 7. Fuel pre filter

3. Oil drainr 8. Fuel filter

4. Expansion tank cooling water 9. Air cleaner

5. Fan belt

- 25 -

.

2-4-2 Checking after installation

(1) Check engine oil

(Read the instruction manual for the engine furnished separately.)

①

[ NOTE ]: Oil is consumed gradually during operation. When the ma-

Check the level of engine oil by the dipstick. Make sure the oil level

is always between H and L.

② When it is below the low limit, supply oil immediately.

③ At the same time, check condition of oil by the dipstick

chine is to be used continuously for a long time, be careful

with lack of oil.

(2) Check engine cooling water

(Read the instruction manual for the engine furnished separately.)

①

② Maintai the coolant level at the bottom of the filler pipe.

③.Clean the filler cap and check the condition of the cap gaskets.

Remove the filler cap from the expansion tank slowly to relieve

the pressure.

Renew the filler cap if the gaskets are damaged. Fit the filler cap.

[ NOTE ]: When closing the radiator cap after water level is checked or

water is supplied, turn the cap fully clockwise so that it can be

firmly tightened.

Otherwise, cooling water is evaporated which results in serious

damage to the engine.

(3) Check fan belt

(Read the instruction manual for the engine furnished separately.)

①

②

Check the belt for tension and elongation. Also, check it for damage.

Replace if necessary.

For adjustment or replacement of the belt, refer to the instruction

manual for the engine.

Press (about 6kg) the position shown by arrow mark (middle of belt) with

your thumb.

The bend should be within the range of 10 mm.

Parts number of fan belt:

Parts name

Parts number Parts number of manufacture

Fan Belt Y06020 15287 CH11186

Alternator Belt Y06020 15288 CH11037

(4) Check fuel level

①

②

Be sure to check the quantity of fuel prior to operation to

prevent lack of fuel during operation.

Loosen the drain plug of the fuel tank from time to time,

and remove sediment’s and water at the bottom of the tank.

- 26 -

CAUTION

B

attery

• The battery acid is dilute sulfuric acid. Improper handling will cause unexpected burns.

• When the battery acid gets on your clothes or skin, wash it out with a large volume of

water immediately. If it gets in your eyes, wash with a large volume of water immediately

and consult your doctor.

• In the worst case, it will put out your eyes.

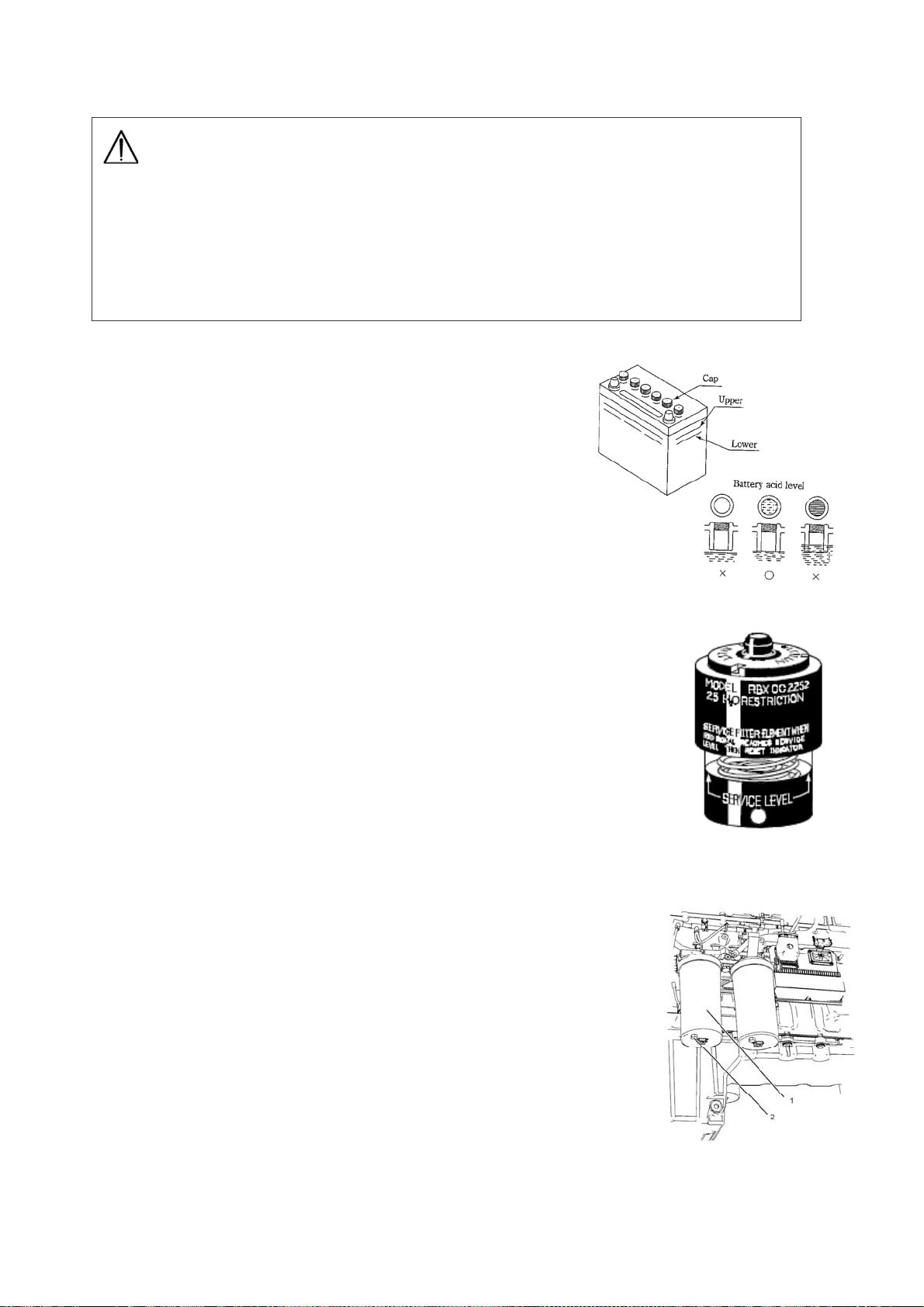

(5) Check battery acid level

Remove the battery acid plug(cap) and check the liquid

level (10-12 mm above the electrodes). Supply distilled

water if necessary.

(6) Check air cleaner service indicator

This engine may be equipped with a different service indicator.

This engine are equipped with a differential gauge for inlet air

pressure. The differential gauge for inlet air pressure displays

the difference in the pressure that is measured before the air

cleaner element and the pressure that is measured after the air

cleaner element. As the air cleaner element becomes dirty, the

pressure differential rises. If your engine is equipped with a different

type of service indicator, follow the OEM recommendations in order

to service the air cleaner service indicator.

The service indicator may be mounted on the air cleaner housing or

in a remote location.

Observe the service indicator. The air cleaner element should be

cleaned or the air cleaner element should be replaced when the

following condition occurs:

・ The red piston locks in the visible position.

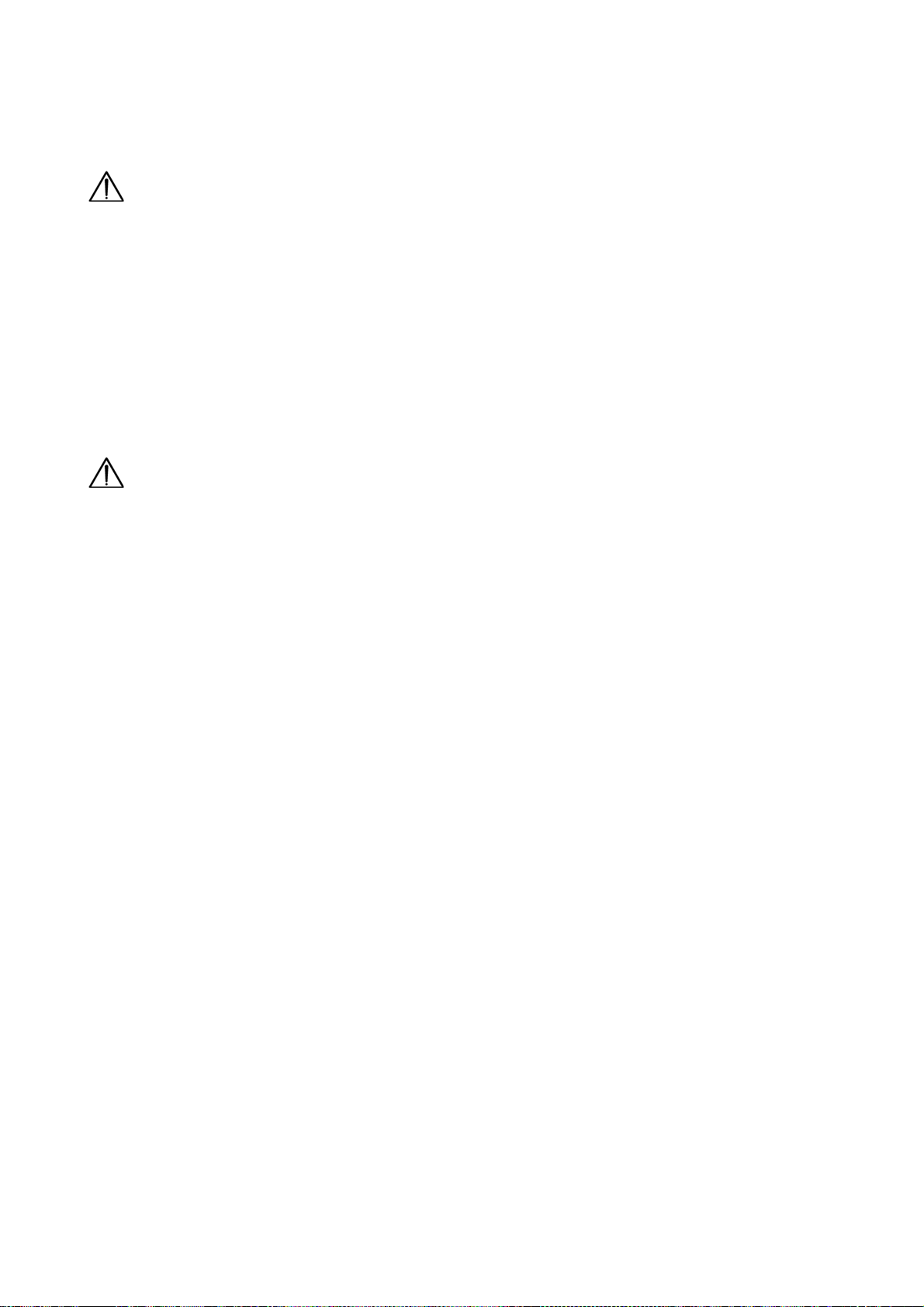

(7) Drain water in fuel primary filter

1. Place a suitable container below the primary fuel filter assembly (1).

2. Remove the drain plug (2). Allow the fluid to drain into the container.

Check the O ring seal on the drain plug for damage. If necessary,

replace the O ring seal.

3. When clean fuel drains from the primary fuel filter install the drain

Plug. Tighten the drain plug to the following torque 1.2 N-m (11 lb in).

Dispose of the drained fluid correctly.

(8) Check for leak of water and oil

Check the machine for the trace of leak of oil or water.

If a leak is found, check the location of leak and stop it.

When the leak cannot be stopped, contact our service

factory.

- 27 -

(9) Check for loose parts

Check for loose bolts and nuts. Loose parts should be tightened firmly. Particularly, make

check on (the fitting of air cleaner, muffler, turbo-charger, etc.), disconnection of electric wiring,

short-circuit and loose terminals.

(10) Removal of foreign objects in machine

• Check that tools and cleaning cloth are not left in the machine. Remove if necessary.

• Check the surroundings of the muffler and engine for presence of dust and flammable

objects. Remove if necessary.

- 28 -

3. OPERATION

3-1 Safety precautions for operation

DANGER

• When the machine is running, never touch output terminals, internal wiring or other electrical

parts.

• Do not use the machine in a humid place. An excessive humidity is very dangerous.

Never touch the machine if the machine or your body is wet.

• The electrical connections shall comply with the local regulations.

• Use cables which are not damaged. Make sure that all electrical connections are securely

fastened. Damaged cables or loose connections might cause electric shocks.

WARNING

• The engine exhaust gas is lethal and toxic. Do not operate in places where the aeration is poor.

Discharge the exhaust by a ventilation facility. Do not direct the engine exhaust towards passersby, residences, etc.

• Do not operate the machine in an atmosphere containing toxic or combustible gas. Otherwise,

fire or explosion might occur in the machine. (Example: Near volatilizing paint solvent.)

• Do not refill fuel or oil while the machine is running but after stopping the engine.

• Fuel and oil are combustible and undiluted anti-freeze solution is inflammable. Do not smoke

while handling or refilling them. Do not get fire or heated object near them.

• Do not spill or leave fuel, oil, anti-freeze solution or cleansing agent in or around the machine.

• Never remove the cover of the output terminals during operation. Before connecting or

disconnecting the cables, switch off the load and machine circuit breakers, stop the machine

and make sure that the machine cannot be started inadvertently.

• Eelectric shock by leak can kill.

Improper grounding may lead to death due to electric shock.

*Be sure to execute the grounding of the machine and the load according to the local rule.

- 29 -

CAUTION

• Avoid overloading the generator.

The generator is provided with circuit breakers for overload protection. When a circuit breaker

has tripped, reduce the concerned load before re-starting.

• Do not connect the output voltage from the machine to facilities wired to the commercial power

supply.

• Before connecting a load, turn off a corresponding circuit breaker and make sure that the

frequency, voltage and power factor of the load to connect match the generator ratings.

• Before checking the machine, stop the engine and wait for at least 10 minutes so that it will cool

down completely. If done while running or immediately after shutdown, you might get burnt or

injured.

• Do not operate the machine beyond the range given in the main specification table.

• In room or environment where the sound pressure level reaches or exceeds 90 dB (A), use ear

protectors.

• During the operation, keep all panels closed.

• Periodically check that:

1. All guards are in place and securely fastened.

2. All hoses and/or pipes are in good condition, not bent and not rubbing.

3. There are no leaks of fuel, oil, cooling water, etc.

4. All fasteners are tight.

5. All electrical leads are secure and in good order.

6. The electrical cables are not damaged.

[ NOTES ]: • Do not remove any of, or tamper with, the sound-damping material.

• Whenever an abnormal condition arises, e.g., excessive vibration, noise, odour,

etc., switch the circuit breakers to OFF and stop the engine. Correct the faulty

condition before re-starting.

- 30 -

3-2 Connecting the load

3-2-1 Precautions in connecting the load

• The switchgear, switching equipment, load and generator in the plant must be connected in

compliance with local codes of low voltage power installation (1000 or less).

• Before starting or before connecting a new load, make sure that the generator is earthed.

Use the earthing rod or, if effective, use an existing earthing installation. Any protective devices

against electric shock and leakage would be useless if earthing is poor.

• Avoid overloading the generator. The generator is provided with circuit breakers for overload

protection when a breaker has tripped, reduce the concerned load before restarting.

• Never connect the generator output voltage to an installation which is also connected to a

commercial power supply.

• Before connecting a load, turn off the corresponding circuit breaker, and check whether

frequency, voltage and power factor comply with the ratings of the generator.

• Distribution board

If the outlets provided on the machine are insufficient, provide an auxiliary switchgear and

connect it with the output terminals. The distribution board must comply with the local rule of

power installation.

• Be sure to provide a load ON/OFF switch between the power outlets and load. Do not use the

generator circuit breaker to turn on/off the load.

• Before connecting the load, stop the engine and turn off the generator circuit breaker.

• The load connecting cable must not get in contact with other output terminals on the terminal

board.

3-2-2 Non-linear and sensitive loads

Non-linear loads draw currents with high contents in harmonics causing distortion in the wave form

of the voltage generated by the synchronous generator.

In general, non-linear type loads generate a high frequency current which adversely affects the

performance of inverters used to feed power voltage to variable speed motors or loads such as

thyristor/rectifier controlled UPS.

Loads most sensitive to voltage distortion include incandescent lamps, discharge lamps,

computers, X-ray equipment, audio amplifiers and elevators.

Consult your sales distributors for measures against the adverse influence of non-linear and

sensitive loads.

- 31 -

3-2-3 Selection of cables

Use cables having sufficient size in consideration of the allowable current of the cables and the

distance between the machine and the load.

If the load current exceeds the allowable current of cables, the cable may be damaged by overheat.

Also, if the cables are too small in size for the length, the input voltage of the load drops which

lowers the working efficiency or causes failure in operation.

Select the length and size of cable so that the voltage drop “e” obtained by the following equation

is within 5% of the rated voltage.

* Equation to obtain 3-phase, 3-wire system voltage drop “e” from the length and size of cable

and operating current is as follows.

L = Length of one wire (m)

I = Generator rated current (A)

S = Cable thickness (mm

e = Voltage drop (V)

2

)

- 32 -

3-2-4 Connecting the load

1. Check whether frequency, voltage and current conform with the ratings of the generator.

2. Install for the load cable, without excessive length, and lay it out in a safe way without forming

coils.

1. Cable clamp

2. Cable outlet

3. Ground terminal(for bonnet)

4. Output terminal U

5. Output terminal V

6. Output terminal W

7. Output terminal O

Fig. 8

3. When connecting output terminals (See Fig. 8.)

• Remove the protection cover of output terminals.

• Loosen the cable clamp and push the wire ends of the load cable through the clamp and cable

outlet.

• Connect the wires to the proper terminals: U/V/W, and if

required O, for 3-phase load

O/U, O/V and O/W for single-phase load

• Tighten the bolts securely.

• Reinstall the protecting cover in front of the output terminal board.

• Tighten the clamp to fasten the cable.

- 33 -

3-3 Grounding

Execute the grounding certainly to prevent the electric shock by leak.

1. Case grounding of the machine

Use the grounding wire which sectional area conforms to the local rule.

Provide the grounding resistance which conforms to the local rule.

2. Case grounding of the load

Execute the grounding for the load similarly.

Provide the grounding rod to satisfy the grounding resistance which conforms to the local rule.

3. Precaution in grounding

1) Select a shady and highly moist place, and burry the grounding rod in such way

that its top end is completely hidden in the ground.

2) If burying the grounding rod on the place that many pedestrians walk on, clamp

the lead wire to prevent catching on it.

3) If the lead wire is not long enough for the connection, connect it as directed below:

* Connect the lead wire and the extension wire by soldering or sleeve coupling

securely and apply insulating tape to the connection.

* Do not burry the connection in the ground.

4) Avoid the places within 2m of lighting conductor grounding location for burying of grounding rod.

5) Do not use a telephone set grounding conductor.

3-4 Before starting

The generators are factory-adjusted to operate at 50/60 Hz, i.e. 1500/1800 min-1.

3-4-1 Checkup before start-up

1. Checking the oil level

• Check the engine oil level or contamination by the dipstick. The oil level must be near to,

but not exceed, the high mark on the dipstick. If required, refill or change the oil.

• If necessary, pour oil up to the specified level through the oil refilling port provided on the

engine.

• For oil change, loosen the oil drain plug from the generator base to drain and, thereafter, pour

oil the same as refilling. Dispose of the discharged oil in compliance with the local regulations.

• After supplying oil, run for several minutes, then stop the engine and make sure that the oil level is

between the high and low marks.

• For the oil volume, see the lubricant volume in the specification table.

- 34 -

2. Checking the cooling water in engine radiator

• Remove the filler cap and check that the water level is bottom of the filler pipe. Refill if short.

• Use soft water as engine cooling water. Use anti-freeze solution where the atmospheric tem- perature is

low.

Mixing volume of anti-freeze solution = total cooling water volume×mixing anti-freeze solution

concentration. For the total cooling water volume, see the engine specification table.

For anti-freeze solution concentration at the temperature, see “Fuel coolant and lubricants”.

• For making up water, remove the radiator cap. Thereafter, securely install the cap so as to be airtight.

3. Checking the fan belt tension

• Check the fan belt tension and elongation. By a thumb, depress (approx. 6kg) the middle point

of the belt. The deflection must be 10-15 mm. At the same time, check whether the belt is

scratched or not. If abnormal, adjust or replace it. For belt checkup, adjustment and

replacement.

4. Checking the fuel (The fuel tank of this machine is the option.)

• Check the fuel level. Refill if required.

• If the fuel remainder is small, dew might be formed in the tank and mix with the fuel.

To avoid such inconvenience, it is recommended to refill the tank fully after the day’s work.

• Loosen the drain plug from the fuel tank to drain water and sediment from the tank.

Dispose of the sediments, etc. in compliance with the local codes.

5. Checking the battery (The battery of this machine is the option.)

• Check whether the electrolyte level is within the specified range or not. If short, add distilled

water.

• If plates are exposed to air for a long time, the battery life would shorten. Keep them dipped.

• Do not pour battery electrolyte beyond the UPPER LEVEL.

• After refilling, securely tighten the caps.

• Give attention to the connection of battery plus (+) and minus (-) terminals. Reverse wiring of

the terminals will cause damage to generator instruments.

6. Checking the wiring

• Check whether the wiring is securely tightened or rubbed.

If abnormal, repair or replace.

7. Checking the piping

• Check whether the piping is securely tightened or leaky. Make sure that the hoses are not

worn. If abnormal, repair or replace.

- 35 -

8. Checking the bolts and nuts

• Check whether bolts and nuts are securely tightened or not especially for the air cleaner,

muffler mounting section. If loose, retighten them.

3-4-2 Instruction for Fuel Device

(1) Setting Procedure for Separate Tank

Where fuel source is a separate tank placed outside the machine, disconnect the tank

connection plug and change the connection as shown in the Fig.9.

(2) Caution on Setting

① For the piping, use oil-resistant hose of 9.6 mm or more internal diameter. Under Cold environ- ment,

use the hose of lager diameter.

② Install the separate fuel tank as near the machine as possible.

③ Set the suction end in the separate tank at the position of 15 to 20 mm upper than the bottom

level (as shown in Section-A of the Fig.9), so that water or sediment may not come into the

suction.

④ While feeding the fuel into the separate tank, do not allow water or dust to come in.

Fig. 9

- 36 -

3-5 Starting

1. Insert the key in the operation switch. Turn the key to RUN keep on pushing start button to

start engine.

• Do not engage the starter for more than 10 seconds at a time; if the engine does not fire, wait

2 minutes before restarting.

• Consult your sales distributor if starting is in extremely cold conditions.

• If the engine would not start after several tries, check whether the fuel level is too low, air is

not bled sufficiently or the battery is discharged.

2. Make sure that the engine warning lamps is extinguished. If alight, stop the engine, check the

item for which it is alight and eliminate the cause.

• Check the engine indicator for normal readings.

3. Check whether the frequency meter read as shown below or not.

Frequency

50Hz operation 50.0Hz 51.3~51.8Hz

60Hz operation 60.0Hz 61.5~62.1Hz

Isochronous Droop

• Check the voltmeter indication and, when the voltage is deviated from the rated voltage,

please contact your nearest Distributor.

4. Check the voltmeter indication and, if required, adjust with the voltage regulator knob.

Turning clockwise increases the voltage and vice versa.

5. When three-phase voltage is supplied, switch the three-phase circuit breaker to ON.

6. Switch on the load and check the frequency meter and voltmeter once more.

Adjust voltage if necessary.

Frequency (3-phase) Voltage

50Hz operation 50 Hz 190~220V or 380~440V

60Hz operation 60 Hz 190~240V or 380~480V

- 37 -

3-6 During operation

1. Periodically check that

• Indications of the engine monitor, indicator lamps and meters are normal.

• Oil, fuel and cooling water do not spill.

• The engine exhaust color is normal. There are no unusual sound and vibration.

• A light load is not applied for a long time. Otherwise, the engine output might drop.

• Each single-phase load is connected in balance whenever it is used.

• The engine oil level checked daily is normal. Refill if necessary.

[ NOTE ]: If the circuit breakers are tripped during operation, switch off the load and stop the

engine. Check and, if necessary, decrease the load.

3-7 Stopping

3-7-1 Stopping method

1. Switch the load circuit breakers to OFF.

2. Switch the generator circuit breaker to OFF.

3. Let the engine run for about 5 minutes to cool down.

4. Stop the engine by turning the key to STOP.

5. If the machine is not used any longer, withdraw and keep the key.

3-7-2 Emergency stop

To stop the engine in an emergency, press the emergency stop button.

3-7-3 Protection device

Protection devices and emergency stop devices are provided for protection of the machine against

trouble during operation.

When the warning lamp lights, stop the engine immediately. Check and remove the cause of

trouble.

- 38 -

Table of protection device

warning

oil pressure failure

(OIL PRESS.)

high jacket water

temperature

(WATER TEMP.)

Battery charging

failure

overcurrent of

generator

fuel level failure

(FUEL LEVEL)

(Optional apparatus)

air filter blinding

(AIR FILTER)

over speed of engine

(OVER SPEED)

coolant level failure

action

turn OFF

the circuit

breaker

– –

– stop

– –

–

– – ※

– –

– – –

– stop – set point: 2140 min

– stop

※

Abnormal value and unit will be indicated lighting on and off.

Stop the

engine

stop

indicate by

warning

lamp

※

※

function

set point: 300kPa

set point: 200kPa

set point: 103°C

set point: 108°C

set point: 26.0V

– –

When overcurrent flows, the

device acts.

When fuel supply is necessary

because of fuel shortage, the

device acts.

When replace or cleaning of

air filter is necessary because

of blinding of filter, the device

acts.

-1

When coolant supply is

necessary because of coolant

shortage, the device acts.

- 39 -

B

4. FUEL, COOLANT AND LU

RICANTS

Engine oil selection:

For engine oil, use API grade : CG-4, ACEA grade : E5 or EMA grade : DHD-1.

The brands/types of oil described PERKINS’s instruction manual can be used regardless

of specified API, ACEA or EMA grade above.

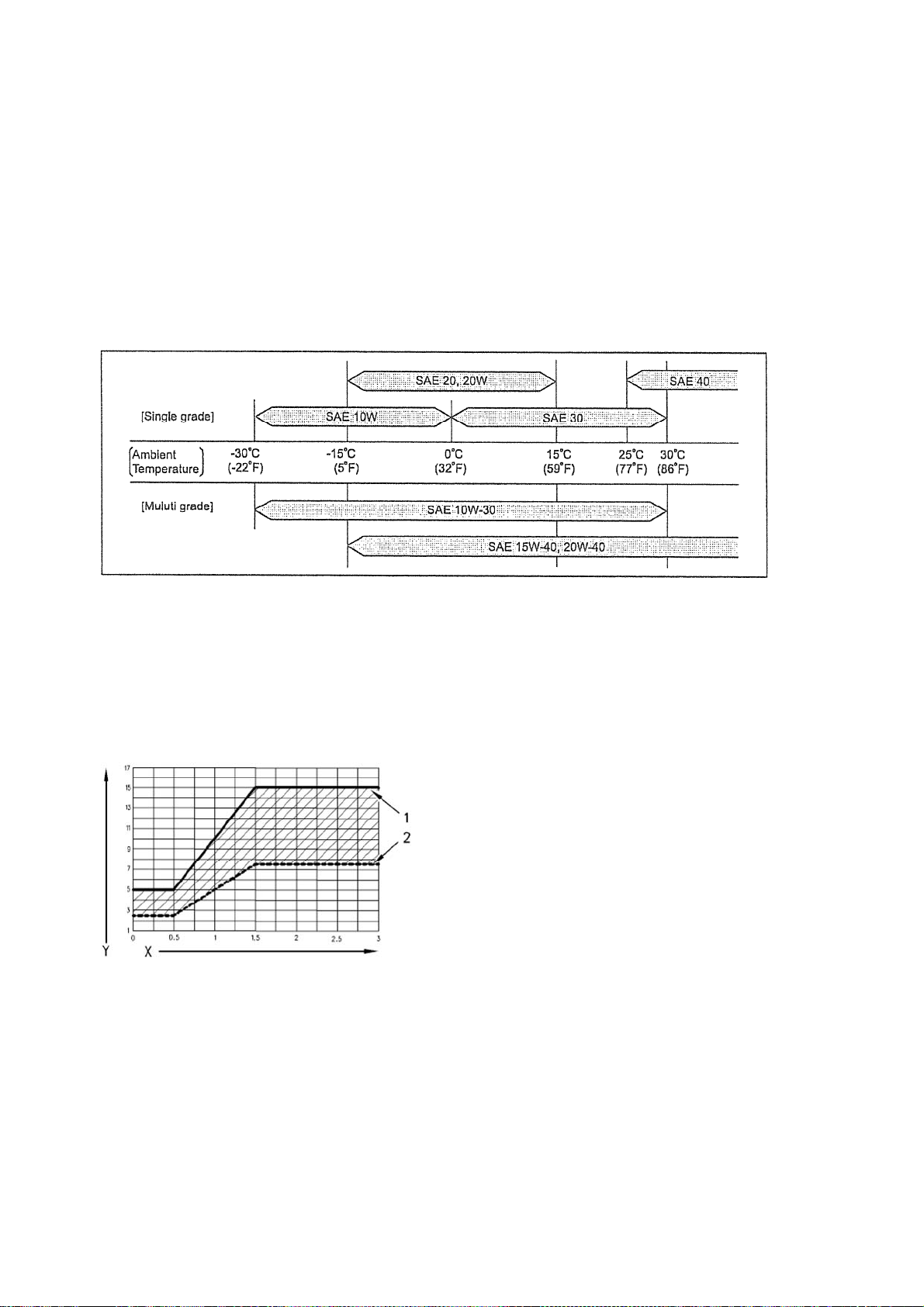

Oil viscosity:

Engine oil viscosity largely affect engine startability, performance, oil consumption, speed of

wearing and occurrence of seizure, etc. Using lubricants whose viscosity selected according to

the atmospheric temperature is important.

Total Base Number (TBN) and Fuel Sulfur Levels for Direct Injection (DI) Diesel Engines

The Total Base Number (TBN) for an oil depends on the fuel sulfur level. For direct injection

engines that use distillate fuel, the minimum TBN of the new oil must be 10 times the fuel sulfur

level. The TBN is defined by “ASTM D2896”. The minimum TBN of the oil is 5 regardless of fuel

sulfur level. Illustration 19 demonstrates the TBN.

(Y) TBN by “ASTM D2896”

(X) Percentage of fuel sulfur by weight

(1) TBN of new oil

(2) Change the oil when the TBN deteriorates to

50 percent of the original TBN.

Use the following guidelines for fuel sulfur levels that exceed 1.5 percent:

• Choose an oil with the highest TBN that meets one of these classifications:

API CG-4, ACEA E5 and EMA DHD-1.

• Reduce the oil change interval. Base the oil change interval

on the oil analysis. Ensure that the oil analysis includes the condition of the oil and a wear

metal analysis.

Excessive piston deposits can be produced by an oil with a high TBN. These deposits can

lead to a loss of control of the oil consumption and to the polishing of the cylinder bore.

- 40 -

[ NOTE ]: Operating Direct Injection (DI) diesel engines with fuel sulphur levels over

0.5 percent will require shortened oil change intervals in order to help maintain

adequate wear protection.

Percentage of Sulfur in the fuel

Lower than 0.5 Normal

0.5 to 1.0 0.75 of normal

Greater than 1.0 0.50 of normal

Fuel selection:

The following specific advantages are required for the diesel fuel.

1) Must be free from minute dust particles.

2) Must have adequate viscosity.

3) Must have high cetane value.

4) Must have high fluidity at low temperature.

5) Must have low sulfur content.

6) Must have little residual carbon.

Applicable Standard

Recommendation

Oil change interval

JIS (JAPANESE INDUSTRIAL STANDARD)

ASTM D975

BS2869-1997

BS EN590 1997

In fuel other than the specified one is used, engine function will be lowered.

NO. 2

No. 1-D or 2-D

Class A-2

- 41 -

The modern, high pressure fuel injection system used on the 2800 Series engines

a high level of fuel cleanliness to ensure correct operation and reliability.

The fuel must conform to all aspects of the ASTM D975 specification, but in

particular to the requirement for number 2-D to have less than 0.05% water and

sediment. The fuel should also be free biological growth. For long term storage of

fuel, the recommendations given in ASTM D975 must be followed where

appropriate.

The use of fuels which do not conform to the above standards can cause: difficully

with starting, poor combustion, deposits in the fuel injectors or combusiton

chamber, reduced service life of the fuel system and filters, reduced engine life

and could affect the warranty.

Cooling water :

Always refer to the chart to determine the correct cooling water to antifreeze solution

mixing ratio.

- 42 -

5. PERIODIC CHECKUP AND MAINTENANCE

5-1 Safety precautions for periodic checkup and maintenance

WARNING

• Before checking or maintaining the machine, stop the engine, wait for it to cool down and

remove all loads from the machine. Make sure that the machine would not accidentally start.

Otherwise, you might be dead or injured by electric shock, burn, catching of hand or clothing,

etc.

• Do not carry out work which will produce heat near fuel, oil, anti-freeze solution or combustible

substances. If such is absolutely required (steam washing, for example), keep away combustible

substances. Keep a fire-extinguisher in the vicinity.

• Take safety precautions against fire. Fuel, oil and anti-freeze solution are combustible. Handle

them with care. When handling them, do not smoke or do not get naked flame near them. Keep

a fire-extinguisher in the vicinity.

CAUTION

• Do not use combustible solvents or carbon tetrachloride for cleaning the machine or parts. Take

safety precautions against toxic fumes of cleansing agent.

• When checking or maintaining, protect the air filter, electrical parts, meters, etc. from moisture or

humidity. Pay attention so that moisture humidity will not penetrate any part.

• When checking or maintaining, cover the replacing parts and generator openings with clean

cloth, paper, tape, etc. so that the parts and generator interior will not he contaminated or moistened. Particularly, the air cleaner, electrical parts and terminals shall not be splashed with water.

• Before removing the radiator cap, stop the engine and wait for at least 10 minutes for it to cool

down. If done while, or immediately after the end of, running, you might get burnt or injured.

• When servicing batteries, always wear protection clothing and glasses. The electrolyte is a

sulphuric acid which can cause severe burns. Get it away from eye, skin and clothing.

• When charging batteries, an explosive gas forms above the cells and escapes through the vents.

Do not smoke near batteries being, or just after having been charged. Never make or break live

circuits or battery terminals, because a spark usually occurs.

• Do not leave tools, parts, rags etc. in or on the machine. Do not leave rags, paper, etc. near the

air intake port of the machine.

• All sound-damping materials of the machine shall be normal. If damaged, repair them to prevent

the sound pressure level from rising. Do not remove or tamper with them.

[ NOTES ]: • Do not reuse gaskets, O-rings, packings, etc. removed for checkup or maintenance.

• Do not remove, tamper with or remodel covers, protective devices, etc. without our

permission. Use only genuine parts for replacement, repair, supply, etc.

- 43 -

• Use only the correct tools for maintenance and repair work. After checkup or

maintenance, carry out a test run to make sure that the generator, controls, circuit

breakers, etc. operate properly.

The periodic checkup and maintenance are outlined. Read the relevant section

beforehand. Only personnel so qualified are allowed to carry out checkup and

maintenance.

• Routine checkup and maintenance items for the engine are described here.

For further details, see the instruction manual for the engine.

• The “Long Interval” checks must include the “Shorter Interval” checks.

• For checkup and maintenance, wear protecting clothing, glasses, etc.

5-2 Periodic checkup

5-2-1 Maintenance schedule

250 hours: Checking/every 250 hours

• Cleaning of air cleaner element

• Measurement of generator insulation resistance (once a month)

• Checking on battery specific gravity

500 hours: Checking/every 500 hours

• Inspection, adjustment and replacement of alternator and fan belt.

• Replacement of engine oil

• Replacement of engine oil filter element

• Replacement of fuel filter element (primary filter and secondary filter)

• Cleaning of radiator and intercooler

• Inspection and replacement of air cleaner element

• Checking for terminal and connection of the circuit

• Checking/every 250 hours is also required.

• Checking on rubber suspension

• Inspection and replacement of the coolant hose, air hose and hose clips.

1000 hours: Checking/every 1000 hours

• Cleaning inside fuel tank (only with fuel tank)

• Checking/every 250 and 500 hours are also required.

On the engine system, main checking items only are shown in this manual.

For details, refer to the instruction manual for the engine furnished separately.

- 44 -

5-2-2 Checking/every 250 hours

(1) Cleaning of air cl eaner element

This element should be cleaned, regardless of operating

time, when the red piston of service indicator locks in the visible position.

- Dry dust clings on element Remove the air cleaner element and clean the element

with dry and clean compressed air.

• While it is being cleaned, check the element for any

damage. Replace if necessary.

• Before installing the air cleaner, wipe off dirt on the

element cover.

• When insert the element, insert the element completely pressing equal edge of element.

(2) Measurement of insulation resistance

A 500-V insulation resistance tester is required to

measure the insulation resistance of the generator.

In case of measuring with an insulation resistance

tester over 500VDC current, disconnect all connectors

from the AVR located in the control box before measuring.

Remove the load cables and earthing cable for the leakage relay.

Turn on the 3-phase circuit breaker, connect the insulation resistance tester between

bodywork earthing terminal and output terminal for measurement.

The result must be more than 1

Consult the distributor.

MΩ.

Otherwise, there is a risk of electric shock or fire.

(3) Check on battery specific gravity

Measure the battery gravity if there is a suspicion that battery leakage has occurred especially

where there have been instances where the machine would not start.

The relationship between Battery Gravity and Battery Charging at 20℃.

battery Gravity battery Charging

Over 1.28 Over charged (need adjustment)

1.25 – 1.28 Optimal charging

1.24 – 1.25 Average

Below 1.24 Low charged (need adjustment)

In determining the specific gravity at a temperature other than 20℃, use the following formula:

S

= St + 0,0007 (t-20)

20

where S

20

St : is the measured specific gravity

t : is the battery solution temperature reading.

: is the calculated specific gravity at 20℃.

- 45 -

5-2-3 Checking/every 500 hours

Checking/every 250 hours is also required.

(1) Inspection, adjustment and replacement of alternator and fan belt

1. Inspection

Check all drive belts and replace a belt if it is worn or damaged.

Where more than one belt is used between two pulleys, all of the

belts must be replaced together. Maximum belt life will be obtained

only if the belts are kept at the correct tensions. Where more than

one belt is used, check/adjust the tension on the tightest belt.

2. Fan Belt Adjustment

Remove the fan guards and proceed as follows.

Use a Borroughs belt tension gauge to check the tension at position

(1). It should be 714 N (160 lbf). To adjust the tension, proceed as

follows:

① Loosen the large lock nut on the belt tensioner and turn the

adjustment setscrew (2) until the correct tension is obtained. Fully

tighten the large lock nut to 280 Nm (207 lbf ft) and check the

tension of the belts again. If the tension is correct, loosen the adjustment setscrew (2) just enough to

release the tension.

② Fit the fan guards and run the enginr for 15 minutes. With the engine stopped, remove the guards

and check again the tension.

③ When the correct tension is obtained, fit the fan guards.

3. Alternator Belt Adjustment

Remove theaccess panel in the fan guard and proceed as follows.

Use a Borroughs belt tension gauge to check the tension at (5). It should be 625 N (461 lbf). To

Adjust the tension, proceed as follows:

① Loosen the alternator to obtain the correct belt tension and tighten the bolt/setscrews to 70 Nm

(51.63 lbf ft).

② Fit the access panel to the guard and run the engine for 15 minutes. Remove the access panel and

check again the tension.

③ When the correct tension is oftained, fit the access panel to the fan guard.

4. Replacement of the Fan Drive Belt

① Remove the belt guard.

② Remove the six setscrews which secure the fan and hub assembly to the pulley and remove the

assembly.

Caution: Take care during the removal of the fan; ensure that the radiator dose not become damaged.

③ Loosen the belt tensioner and remove the old belts. Ensure that the grooves of the pulley are

free from grease and dirt and fit a new set of belts.

④ Fit the fan and tighten the setscrews securely to 46 Nm (33.93 lbf ft). Adjust the fan belts to the

correct tension, see “Fan Belt Adjustment”, and fit the fan guards.

5.Replacement of the Alternator Belt

① Remove the fan guards.

② Remove the six setscrews which secure the fan and hub assembly to the pulley and remove the

assembly.

Caution: Take care during the removal of the fan; ensure that the radiator dose not become damaged.

③ Loosen the adjustment bolt/setscrews to selease the tension on the alternator belt and remove

the old belt. Check that the pulley grooves are clean and fit new belt.

④ Fit the fan and tighten the setscrews securely to 46 Nm (33.93 lbf ft). Adjust the alternator belts

to the correct tension, see “Alternator Belt Adjustment”, and fit the fan guards.

- 46 -

(2) Replacement of engine oil

① Remove the engine oil drain plug and discharge oil completely.

It can be discharged easily when the engine is warm.

② After engine oil is discharged, tighten the plug firmly.

③ Charge new engine oil from the oil filler until it reaches

the notched line of the "H" on the dipstick.

④ After engine oil is supplied, run the engine for a few minutes.

Check that oil is supplied to the level between H and L .

(3) Replacement of engine oil filter element

① Ensure that the oil filter assembly is clean before the procedure

for removing the filter element is carried out.

② Use a suitable container in order to drain the oil filter. Remove

the drain plug (2) and drain the oil. Check the O ring seal on the