Dent Instruments EXCN-I-WI-N, EXCN-I-B-S, EXCN-I-WE-S, EXCN-I-B-F, EXCN-I-N-S User manual

...

Operator’s Guide

ELITEpro™ XC

and

ELOG™ 19

Software

ELITEpro XC

™

/ELOG™ 19

May 1, 2019

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

DENT Instruments

Operator’s Guide: ELITEpro XC and ELOG™ Software ©2019 DENT Instruments, Inc. All rights reserved.

This manual may not be reproduced or distributed without written permission from DENT Instruments.

Congratulations!

You now own one of the world’s most versatile, accurate, feature-rich, and lowest priced power/energy

loggers, the ELITEpro XC™. The ELITEpro XC logger contains many features, some of which enable you to

measure data across multiple platforms, view and graph real-time data, and retrieve data remotely.

In addition, this manual describes the features and functionality of the accompanying ELOG™ Software,

which is designed to be user-friendly, intuitive, and an easy-to-use component of your energy measuring

projects.

Thank You for your business!

Trademarks

ELITEpro XC™, ELOG™, and PhaseChek™ are trademarks of DENT Instruments, Inc.

Windows®, Windows® 7, Windows® 8, Windows® 10, and Notepad® are registered trademarks of

Microsoft Corporation.

Bluetooth® wireless technology is a registered trademark of the Bluetooth SIG. If your unit is equipped

with Bluetooth wireless technology, look for the following trademark symbol:

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

ii

DENT Instruments

TABLE OF CONTENTS

Congratulations! ................................................................................................................. ii

Trademarks ......................................................................................................................... ii

Table of Contents .............................................................................................................. iii

Introduction ....................................................................................................................... 7

ELITEpro XC SAFETY SUMMARY and SPECIFICATIONS ..................................................................... 8

ELITEpro XC RÉSUMÉ DE SÉCURITÉ ET SPÉCIFICATIONS................................................................ 12

ELITEpro XC CONNECTIONS ........................................................................................................... 15

Quick Start to Using the ELITEpro ..................................................................................... 16

Install the ELOG Software on the Computer.................................................................................. 16

Mount the ELITEpro XC .................................................................................................................. 17

ELITEpro XC Connections ......................................................................................................... 18

Complete the Wiring Connections ................................................................................................. 19

CT Connections ........................................................................................................................ 19

Connecting Split-Core Style Millivolt CTs to a Load .......................................................... 20

Connecting RōCoil CTs to a Load ...................................................................................... 22

Voltage Connections ............................................................................................................... 23

Analog Channel Connections ................................................................................................... 23

Current Loop Connection .................................................................................................. 24

Voltage Connection........................................................................................................... 25

Power In/Out Connection ....................................................................................................... 27

Digital Channel Connections ................................................................................................... 27

Connecting the USB Cable ....................................................................................................... 29

Other Communication Connections ........................................................................................ 30

Communicating with the ELITEpro XC ................................................................

Terminating the ELITEpro XC to Computer Connection .......................................................... 33

........................... 31

In depth Use of the ELITEpro XC and ELOG ........................................................................ 34

Creating and Using the Logger Setup Tables ................................................................................. 34

Create a New Setup Table ....................................................................................................... 34

Open an Existing Setup Table on Your PC ............................................................................... 35

Retrieve an Existing Setup Table from the ELITEpro XC .......................................................... 36

Configure the Setup Table ....................................................................................................... 37

Data Logging Controls ............................................................................................................. 38

Start Options ..................................................................................................................... 38

Stop Options ..................................................................................................................... 38

Memory Capacity .................................................................................................................... 38

Quick Setups ............................................................................................................................ 39

Physical Power Channels ......................................................................................................... 41

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

iii

DENT Instruments

Table of Contents

Calculated Power Channels ..................................................................................................... 45

Combining Channels ......................................................................................................... 45

Analog Output Channels (ELITEpro XC Only) ........................................................................... 46

Send a Setup Table to the Logger ............................................................................................ 47

Save a Setup Table on the Computer ...................................................................................... 48

LED Diagnostics .............................................................................................................................. 48

PhaseChek™ LEDs .................................................................................................................... 48

COMM—Communications LED ............................................................................................... 49

Power Measurement—Connecting Sensors & Configuring Channels ........................................... 50

Wiring Label Conventions ........................................................................................................ 51

Current Transformer (CT) Selection ........................................................................................ 51

CT Selection Examples ............................................................................................................. 53

Connecting CTs and Configuring Channels .............................................................................. 53

ELOG Quick Setup Wiring Diagrams ........................................................................................ 55

Using the ELOG Software ............................................................................................................... 59

ELOG Speed Buttons ................................................................................................................ 59

File Menu ................................................................................................................................. 61

Edit Menu ................................................................................................................................ 63

View Menu .............................................................................................................................. 63

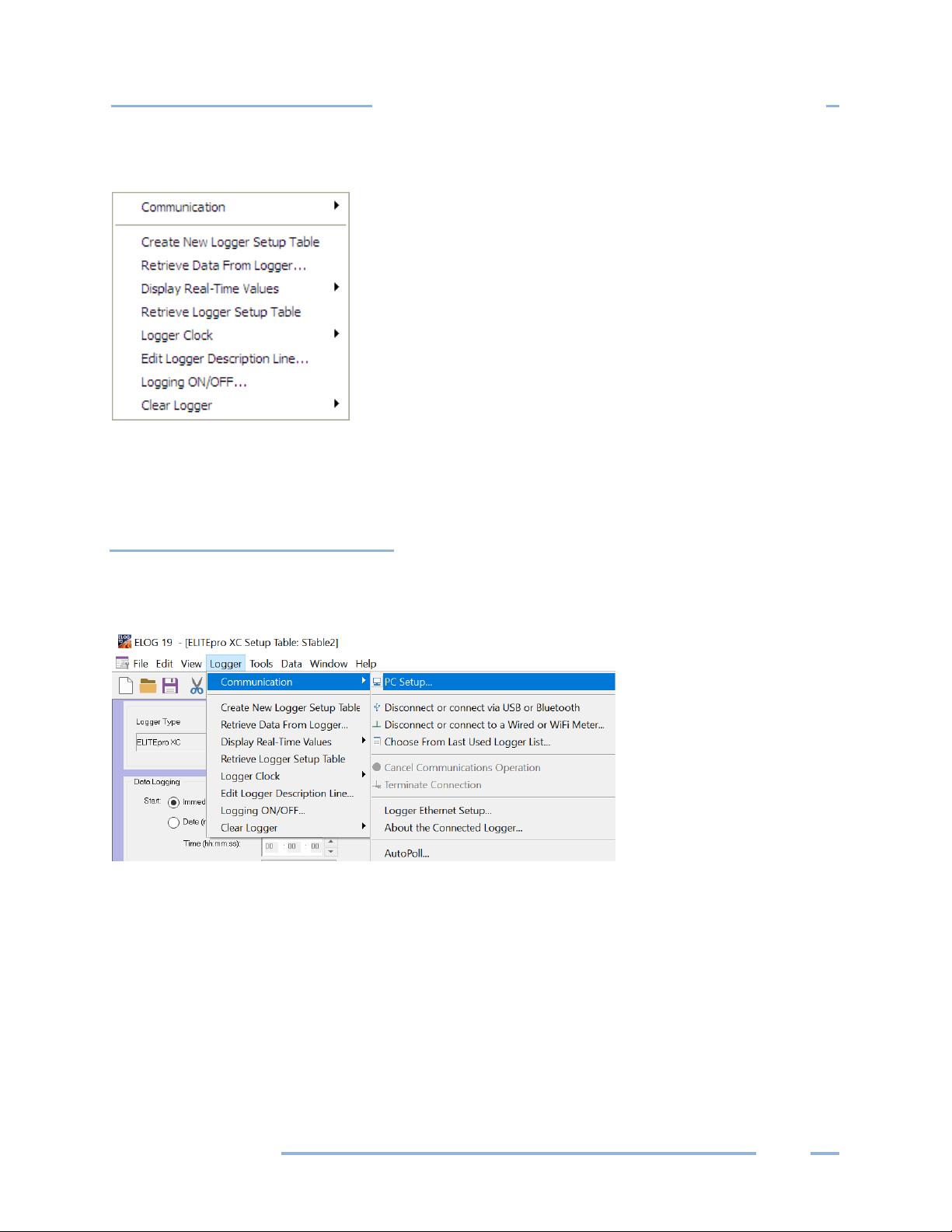

Logger Menu ........................................................................................................................... 64

Communication Sub-Menu ............................................................................................... 64

Retrieve Data From Logger ............................................................................................... 69

Display Real-Time Values Sub-Menu ................................................................................ 71

Retrieve Logger Setup Table ................................................................

L

ogger Clock Sub-Menu .................................................................................................... 77

Edit Logger Description Line ............................................................................................. 78

Logging ON/OFF ................................................................................................................ 78

Clear Logger Sub-Menu..................................................................................................... 79

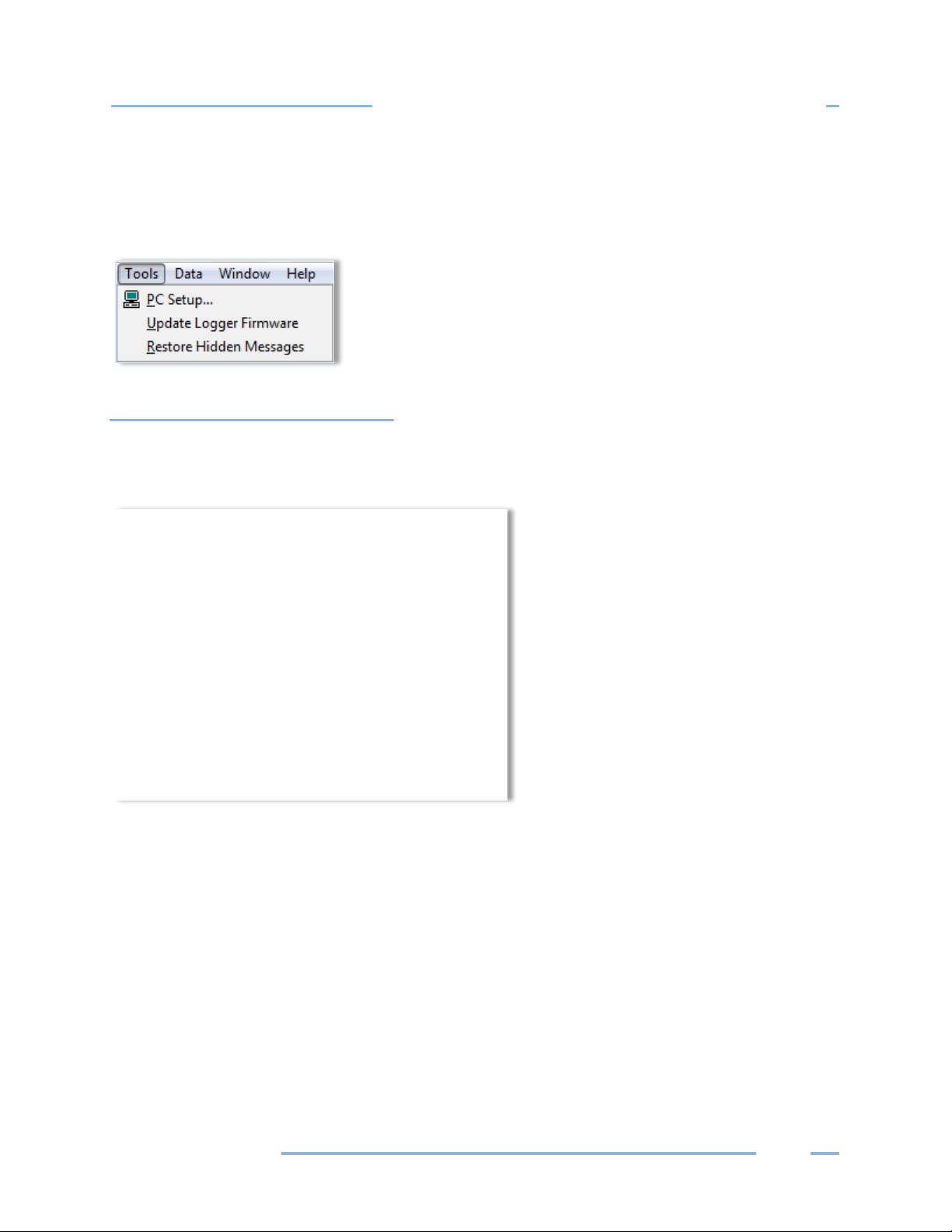

Tools Menu .............................................................................................................................. 80

PC Setup ............................................................................................................................ 80

Update ELITEpro XC Firmware .......................................................................................... 81

Restore Hidden Messages................................................................................................. 81

Data Menu ............................................................................................................................... 82

Create New Graph ............................................................................................................ 82

Graph Options ................................................................................................................... 85

Retrieve Data From Logger ............................................................................................... 86

Open Data File .................................................................................................................. 86

Export Data File ................................................................................................................. 86

Import CSV File .................................................................................................................. 87

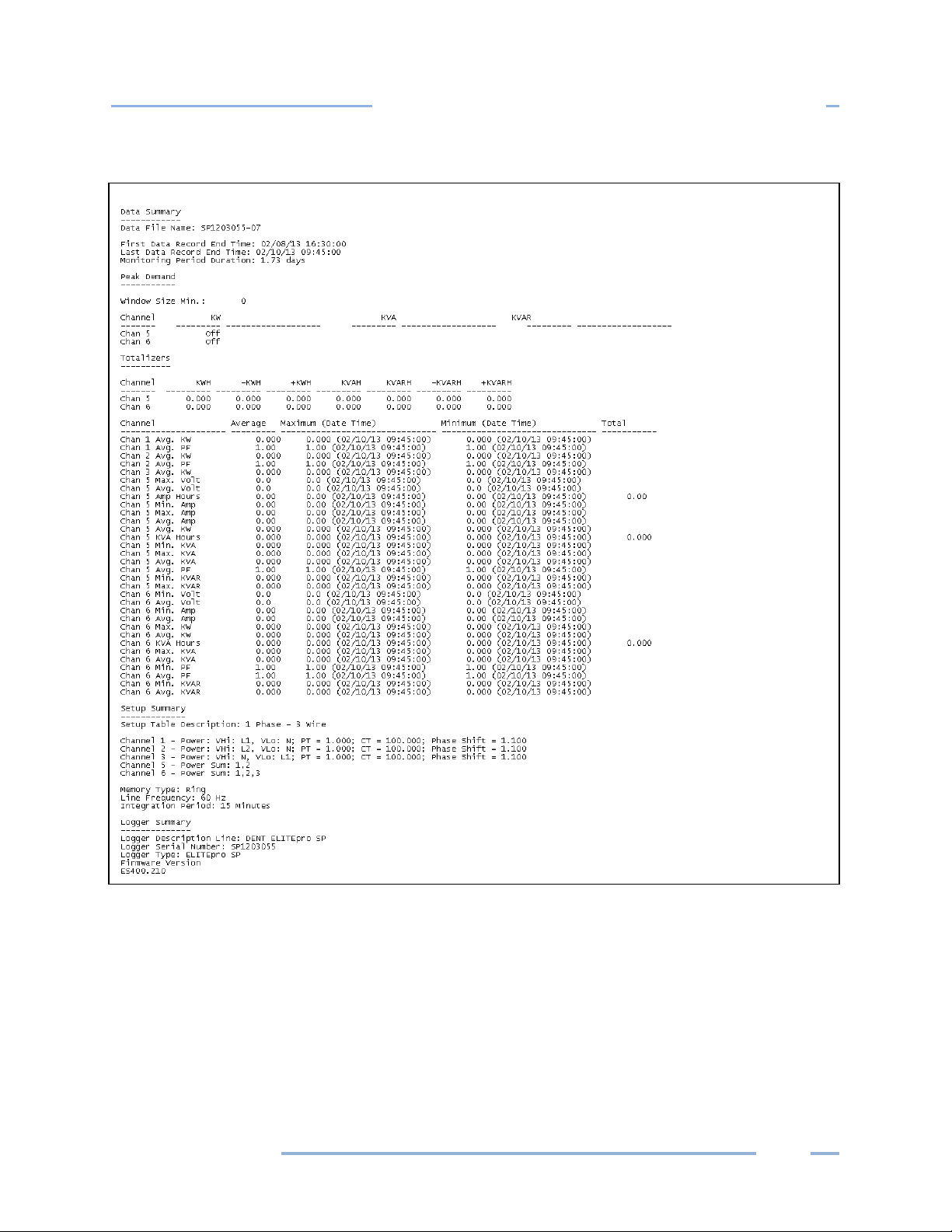

Data File Statistics ............................................................................................................. 88

............................. 77

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

iv

v

DENT Instruments

Table of Contents

Analyze a Selected Data Range ......................................................................................... 90

Extract a Range of Data ..................................................................................................... 91

Check Data for Errors ........................................................................................................ 92

Fill Missing Records with Zeros ......................................................................................... 92

Fill missing Records with Blanks ....................................................................................... 92

Appendices ...................................................................................................................... 93

Appendix A—Installing Firmware Updates .................................................................................... 93

Firmware Updates ................................................................................................................... 93

Downloading and Installing Firmware .............................................................................. 93

Appendix B—Unusual Metering Systems ...................................................................................... 94

3-Phase Delta with a “Wild” (Red) Leg .................................................................................... 94

2–½ Element Meters ............................................................................................................... 95

Using The 2-Watt Element (2 Ct) Method On A 3-Wire Delta Service .................................... 96

Using The 3-Watt Element (3 Ct) Method On A 3-Wire Delta Service .................................... 97

Appendix C—Troubleshooting ELITEpro XC Driver Installation ..................................................... 99

Appendix D—Calculated Power Channel Formulas ..................................................................... 102

Wye Configuration L1-N, L2-N, L3-N ..................................................................................... 102

DELTA Configuration: L1-L2 and L3-L2 .................................................................................. 103

Appendix E—Communication Options on the ELITEpro XC ......................................................... 104

USB (Standard) ...................................................................................................................... 104

Ethernet LAN (Standard) ....................................................................................................... 105

Wi-Fi and Wireless Access Point-to-Point Connection (Optional) ........................................ 108

ELITEpro XC as its own Access Point ............................................................................... 109

ELITEpro XC Connected to a Wireless Network .............................................................. 110

Accessing the ELITEpro ................................................................................................... 113

T

roubleshooting Wi-Fi Connections ............................................................................... 115

Bluetooth (Optional) .............................................................................................................. 116

Appendix F—Meter Installation Final Checklist ........................................................................... 119

Appendix G – ELITEpro XC Technical Specifications .................................................................... 122

Appendix H – DENT Instruments Warranty Statement ............................................................... 124

Index ............................................................................................................................. 126

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

7

DENT Instruments

INTRODUCTION

The ELITEpro XC is a powerful and versatile tool for pinpointing electric usage and quantifying energy

usage. It is capable of measuring, storing, and analyzing consumption data including Volts, Amps, Watts,

Volt-Amps (VA), Volt-Amps reactive (VAR), Kilowatts (kW), Kilowatt Hours (kWh), KVAh, kVARh, and

Power Factor (PF) of an electrical load or an entire building. Analog input channels are especially helpful

when used in conjunction with power measurements to correlate the consumption of electricity with

environmental, HVAC plant performance or other process conditions. The ELITEpro XC also offers some

power quality features such as the ability to view in real-time voltage, current, and power waveforms

and calculate harmonics to the 63

The ELITEpro XC is line-powered from the service being measured, eliminating the need for external

power or space-consuming batteries at the job site. The measurements are stored in on-board,

non-volatile memory in a time series format at an interval selected by the user. The ELITEpro XC can be

mounted anywhere with its magnetic mounting feet and is small enough to be secured inside the

electrical panel.

The Windows-based ELOG software package is used to set up the meter, display metered values, and

retrieve and analyze the collected data. ELOG graphically displays recorded data, performs analysis and

facilitates automatic remote data collection. Data is also easily exported to popular spreadsheet and

database programs for additional analysis.

rd

order.

The ELITEpro XC requires a computer and ELOG™ software for setup, data retrieval, and data analysis.

Download and test the software prior to the field installation of the logger.

If your installation is using ELOG with legacy devices, contact DENT Instruments for a prior version of this

manual.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

8

DENT Instruments

Introduction

E186827

The ELITEpro XC is an Over-Voltage Category III device. Use approved rubber gloves with mechanical

protection and goggles when operating the device.

CAUTION: This LOGGER may contain life-threatening voltages. QUALIFIED PERSONNEL MUST disconnect all high

voltage wiring before using or servicing the LOGGER.

impair its means of protection.

SYMBOLS ON EQUIPMENT

voltages monitored.

personnel only.

of 600V. The ELITEpro XC is a 600 volt Over-Voltage Category III device.

ELITEpro XC SAFETY SUMMARY and SPECIFICATIONS

This general safety information is to be used by both

the Logger operator and servicing personnel. DENT

Instruments, Inc. assumes no liability for user’s

failure to comply with these safety guidelines.

4RH8

Conforms to UL Std 61010-1

Certified to CSA Std C22.2 No.

61010-1

Warning: Use of this device in a manner for which it is not intended may

Denotes caution. See manual for a description of the meanings.

When connecting the ELITEpro XC to an AC load, follow these steps in

sequence to prevent a shock hazard.

1. If possible, de-energize the circuit to be monitored.

2. Connect the CTs to the phases being monitored.

3. Connect the voltage leads to the different phases. Use proper safety

equipment (gloves, mask, and protective clothing) as required for the

Risk of electric shock. Life-threatening voltages may be present. Qualified

DO NOT EXCEED 600V Phase to Phase. This logger is equipped to monitor

loads up to 600V. Exceeding this voltage will cause damage to the logger and

danger to the user. Always use a Potential Transformer (PT) for loads in excess

Dispose of properly.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

9

Introduction

DENT Instruments

OUT: 6 VDC, 200 mA maximum

The use of any other CT will invalidate the UL Listing of the ELITEpro XC.

shock hazard to the user. Wiring must meet 600V AC CAT III rating.

is specific to DC systems. Values reported for voltage, current, KW, KWH will be

IN: 6-10 VDC, 500 mA

SENSOR LIMITATIONS

USB port

USE ONLY SHUNTED CURRENT TRANSFORMERS (CTs).

Do not use other CTs. Only use shunted CTs with a 333mV maximum output only.

Serious shock hazard and logger damage can occur if unshunted CTs are used.

The UL listing covers the use of the following DENT Instruments CTs that are UL

Recognized and have been evaluated to IEC 61010-1:

CT-RGT12-XXXX (solid core), CT-SRS-XXX (split core), CT-HSC-020-X (20A Mini),

CT-HSC-050-X (50A Mini), CT-HMC-0100-X (100A Midi), CT-HMC-0200-X (200A

Midi), CT-RXX-1310-U (RōCoil), CTRXX-A4-U (RōCoil), CT-CON-1000-X, CT-CON0150EZ-X and the CT-SRL-XXX or CT’s that are UL listed to UL2808.

Pulse: Use only "dry contact" non-energized pulse inputs (ELITEpro SP only).

Use of energized pulse initiators can cause damage to the logger and a potential

DC VOLTAGES

The meter is designed to measure AC voltages for installations up to 600

VAC. The meter is also capable of measuring DC voltages up to 600 VDC with the

following caveats.

1) The internal fuse installed in meters with serial numbers before XC1703xxx are

not a suitable disconnect for voltages above 80 VDC. Customers using the meter

for high voltage DC systems must install a UL listed inline 600 volt DC fuse with a

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

rating of 1 amp or less. These fuses are commonly available in the solar power

market.

2) UL testing of the meter was conducted on AC systems only. DC results are

comparable but not tested.

3) DENT Instruments ELOG software does not currently have a configuration that

www.GlobalTestSupply.com

Introduction

DENT Instruments

correct however it should be noted that the meter will also report values that

CAT III 80-600 VAC 125mA 50/60 Hz

pertain to AC systems (such as VARs and Power Factor) that should be ignored.

The equipment is protected throughout by double insulation (IEC 536 Class II).

FCC COMPLIANCE

This device has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at user’s own expense.

Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause

undesired operation.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

10

Introduction

DENT Instruments

MAINTENANCE

There is no required maintenance with the ELITEpro XC. Abide by the following items:

Cleaning: No cleaning agents, including water, shall be used on the ELITEpro XC.

Battery Life: The lithium battery is only used to maintain the date and clock settings during power

failure and has a life expectancy of greater than 10 years. Contact DENT Instruments for service.

No accessories are approved for use with the ELITEpro XC other than those specified in the DENT

Instruments product literature and price sheets.

If the logger appears damaged or defective, first disconnect all power and sensors. Call or email

technical support for assistance.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

11

Introduction

DENT Instruments

ELITEpro XC Top End View

Power In/Out

Terminal Block for

Analog

Connections

Logging On/Comm LED

USB Connection

PhaseChek

LEDs

Magnetic Mounting Feet

Ethernet connection

Optional Wi

5

CT Connections

ELITEpro XC CONNECTIONS

Input

™

Voltage Lead

Connections

-Fi—External

dbi antenna

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

15

DENT Instruments

QUICK START TO USING THE ELITEPRO

IMPORTANT: DO NOT CONNECT THE ELITEpro XC TO YOUR COMPUTER UNTIL YOU HAVE INSTALLED ELOG

Install the ELOG Software on the Computer

Complete this step prior to installation and ascertain that communication between the ELITEpro XC and

PC is established before going into the field.

NOTE: The new path for Data files in ELOG is: C:\Users\UserName\Documents\DENT\ELOG\Data

ELOG is compatible with Windows® 7, Windows® 8, or Windows® 10.

1) Insert the ELOG USB memory stick into the USB port. Browse to the memory stick and locate the

ELOGInstaller.exe file. Start the installer by double-clicking ELOGInstaller.exe.

2) Follow the directions on the screen to install the software.

NOTE: When ELOG is installed, another program, AutoPoll, is also installed. AutoPoll may be used for

unattended and automatic data retrieval from a number of remote loggers where the computer calls the

loggers. See Appendix D—AUTOPOLL: Unattended Calling from the PC to the Logger.

3) Install the ELITEpro XC Driver on your computer.

a) Connect the USB cable to a USB port on your computer, inserting the other end in the USB port

on the ELITEpro XC

NOTE: If a USB cable is used inside an electrical panel it must be rated to the appropriate voltage or

wrapped in an appropriately rated insulating sleeve. The DENT-supplied cable does not meet this

requirement without an insulating sleeve.

b) Perform the setup steps onscreen. You must allow ELOG to install the USB driver for the

ELITEpro XC to work correctly.

c) If the driver installation fails, see Appendix: Troubleshooting ELITEpro XC Driver Installation.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

16

DENT Instruments

Quick Start to Using the ELITEpro

Mount the ELITEpro XC

The ELITEpro XC must be installed in an approved electrical panel or enclosure, following proper

installation practices according to the local electrical codes.

WARNING! Remove the LOGGER from all sources of voltage before mounting.

AVERTISSEMENT! ENLEVEZ L'ENREGISTREUR DE TOUTES LES SOURCES DE TENSION AVANT DE

MONTER.

1) Mount the ELITEpro XC using the black tab on the end of the case. Use a screw to securely mount

the ELITEpro XC near a dedicated circuit disconnect breaker.

NOTE: Allow adequate space for accessing all ports and connectors. The mounting tab is intended for

short term metering (less than 6 months) and must be subject to monthly monitoring by qualified

personnel to verify the ELITEpro XC or its wiring have not shifted.

To remove the logger, remove the screw and roll the magnets off the cabinet to which it is mounted. In

order to prevent injury upon removal, it is recommended practice to roll the device off, due to the

strength of the magnets.

NOTE: For temporary, spot load monitoring, the four magnets on the back of the ELITEpro XC case can

be utilized to hold the logger on unpainted metal. The maximum combined weight of the logger and any

attachments the magnets can support with a 4 times safety margin is 18oz (500 gm). The logger must be

attended by the electrician when it is temporarily mounted by the four magnets.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

17

DENT Instruments

Quick Start to Using the ELITEpro

It is often easier to connect the CTs and voltage

simply plug the voltage leads and CT connectors into the ELITEpro XC before mounting.

“Roll” the device, as seen below.

2) Mark the dedicated circuit as the disconnect for the ELITEpro XC.

ELITEPRO XC CONNECTIONS

The ELITEpro XC has the following connections:

Four current transformers (CTs).

Four voltage wire leads for connecting to voltage sources (L1, L2, L3, and Neutral).

Four analog input channels can be individually used to record process or environmental correlation

studies with power.

Power In/Out for connecting a DENT-provided external power supply or for powering external

devices. Maintain polarity as marked on the case:

In: 6-10 Vdc, maximum input of 500 mA

Out: 6 Vdc output, up to 200 mA for powering other external devices

USB connector for downloads, setup, and communication with a computer. The ELITEpro XC is also

powered from the USB connection. If a USB cable is to be used inside an electrical panel, it must be

rated to the appropriate voltage or wrapped in an appropriately rated insulating sleeve. The DENTsupplied cable does not meet this requirement without an insulating sleeve.

Ethernet port for connecting the device to a network.

An external coaxial connector for a Wi-Fi antenna may also be present.

leads to the load to be monitored first then

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

18

DENT Instruments

Quick Start to Using the ELITEpro

Complete the Wiring Connections

The following connections must be completed to install the ELITEpro XC. ALL WORK SHOULD BE

PERFORMED BY A QUALIFIED ELECTRICIAN USING PROPER SAFETY EQUIPMENT.

CAUTION: The ELITEpro XC should only be wired by qualified personnel. Hazardous voltages exist.

ATTENTION: LE ELITEpro XC ne doit être branché QUE par un personnel qualifié. TENSIONS

DANGEREUSES sont présentEs.

CT CONNECTIONS

NOTE: Use only inherently safe 333mV output CTs supplied by DENT. Never use current output CTs. The

UL listing covers the use of the following DENT Instruments CTs that are UL Recognized and have been

evaluated to IEC 61010-1:

CT-

HSC-020-X (20A Mini), CT-HSC-050-X (50A Mini), CT-HMC-0100-X (100A Midi), CT-HMC-0200-X (200A

Midi), and CTs that are UL listed to UL2808. The use of any other CT will invalidate the UL Listing of the

ELITEpro XC.

1) C

onnect the CTs to the channel(s) on the ELITEpro XC labeled CH 1, CH 2, CH 3 and CH 4. The CT

leads need to be connected to the terminal block using a small screwdriver. For RōCoils, also

connect the shield (bare) wires to the right-most ground terminal marked “S” (shield).

2) Place the CTs on the phase wires of the load to be monitored and corresponding to the phase of the

voltage loads. The CTs must be placed as follows for each channel:

Left connector pin is the positive or high-side wire

Right pin is the negative or low-side

When using DENT Instruments current transformers, connect them as follows:

Split-core CTs (removable leg)—the white CT wire is (+) and the black wire is (-).

Clamp-on CTs (clothes-pin type)—the red wire is positive (+) and the black wire is negative (-).

RōCoil CTs (flexible, Rogowski-style)—the white CT wire is (+) and the brown wire is (-).

If you are using RōCoil CTs, be sure to connect the bare wire to the “S” (shield) screw terminal. This

reduces interference and improves the accuracy of the CT.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

19

DENT Instruments

Quick Start to Using the ELITEpro

Connecting Split-Core Style Millivolt CTs to a Load

1) Open the CT by holding on to the removable leg and pulling it apart.

2) Connect CT around the load conductor to be measured. Make sure the maximum current of the

conductor does not exceed the maximum CT rating listed on the CT data sheet.

3) Carefully re-connect the removable leg while ensuring the CT core alignment matches. The

conductor should be in the inside of the CT window.

Repeat Steps 1-3 if you are using more than one CT.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

20

DENT Instruments

Quick Start to Using the ELITEpro

Correct orientation of a CT is required to ensure proper measurement. If an arrow is shown on

the CT label, it shou

the CT.

“

See

Physical Power Channels.

connections

connections

4) Connect the white wire on the CT to the positive terminal on the measuring device.

5) Connect the black wire on the CT to the negative terminal on the measuring device.

Current

Transformer

Voltage lead

CT 1 must be placed on the phase listed as V High for Channel 1 in the ELOG setup table. CT2, CT3 and

CT4 must also correspond to the appropriate phase as shown in Channels 2, 3, and 4 in the ELOG setup

table.

ld be pointed toward the load. Otherwise, use the instructions printed on

If the CT was accidently installed backwards and access to reverse it is not possible, the

CT Flipper” function can be accessed by clicking the CT “Type” in the “Logger Setup Table.”

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

21

DENT Instruments

Quick Start to Using the ELITEpro

Shield Wires from DENT RōCoil

CTs connected to ELITEpro XC

Negative

Positive

Shield

Connecting RōCoil CTs to a Load

1) Open the CT by squeezing the connector latch and pulling it apart.

2) Connect the CT around the load conductor to be measured. Orient the CT so that the arrow on the

CT case points towards the load. Make sure the maximum current of the conductor does not exceed

5,000 amps.

3) Push the connector back together with the conductor within the loop of the CT.

Repeat the above three steps if you are using more than one RōCoil CT.

4) Connect the CTs brown wire to the negative terminal on the

connector. See photo below.

5) Connect the CTs white wire to the positive terminal on the

connector.

6) Twist together the bare shield wires from the RōCoils and

connect to the “S” shield terminal that is part of the CH 4

connector. This reduces interference and improves accuracy

of the CT.

Connecting RōCoil CTs to an ELITEpro XC

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

22

DENT Instruments

Quick Start to Using the ELITEpro

The ELITEpro XC is rated for 600V Over-Voltage Category III. Cat III is for measurements

performed in the building. Examples are measurements on distribution boards, circuit

breakers, wiring including cables, bus bars, junction boxes, switches, and socket outlets in a

fixed installation, and equipment for industrial use. Other equipment could include stationary

motors with a permanent connection to the fixed installation.

CAUTION: Ensure that the sensor current/voltage is within range and the channel is correctly

elevated signals may damage the ELITEpro XC and this will void your warranty.

VOLTAGE CONNECTIONS

1) Before connecting voltage leads L1, L2, L3, & N to the meter, first connect them to dedicated circuit

breakers using either Croc-clips or lead adapters from DENT.

a) Refer to the wiring diagrams in Section 2 for wiring connection specifics. Follow local electrical

codes during this installation.

b) IMPORTANT: Verify the breaker is marked as the disconnect breaker for the ELITEpro XC.

2) Connect lead adapters to the banana sockets at the end of the voltage leads.

3) Connect the voltage leads (L1, L2, L3, and N, as necessary) to the ELITEpro XC.

-

ANALOG CHANNEL CONNECTIONS

Analog inputs are especially helpful when used in conjunction with power measurements to correlate

the consumption of electricity with environmental, HVAC plant performance or other process

conditions. Typical uses might include logging ambient temperature, building temperatures, solar

insolation, tank pressures, duct flows, etc.

The ELITE XC has four analog input channels that can be configured for voltage or current input used in

any combination among channels. The limiting specifications for analog input are shown in the

Appendix.

The following sensor types are supported and selected through the ELOG software interface.

0/4–20 mA externally powered current loop

0–30* VDC single ended, non-isolated

NOTE: The ELITEpro XC can measure input voltages up to 30.0 volts. However, the polarity protection

circuitry can only withstand 15 volts of reverse-applied polarity without permanent damage to the

meter. The maximum allowable current flowing into the analog input terminal is 23 mA.

configured using ELOG software before connecting external sensors. Sustained exposure to

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

23

DENT Instruments

Quick Start to Using the ELITEpro

CAUTION: Observe the correct signal polarity when connecting voltage sensors to the ELITEpro XC

above 10 volts. Damaging currents may flow from the connected sensor in the event of reverse

polarity or misconfiguration and this will void your warranty.

Channel types (voltage or current) should be configured using the ELOG software prior to connecting

external sensors. This sequence will prevent the unexpected/unpredictable combinations of voltage

transducers connected to low impedance loads (499 ohm) or current transducers with an open circuit.

The first set of Sensor and Output fields on the screen represent the Physical Range. This is where the

user enters the low and high process values from the sensor. This data can typically be found on the

data plate or data sheet of the sensor (typical sensor image below). The second set of Sensor and

Output fields represent the Electrical Output. This is where the user enters the minimum and maximum

electrical output values of the sensor, also listed on the data plate or data sheet.

Example Sensor Data Plates

Current Loop Connection

Sensors using current loops are widely used in industry to communicate analog signals in the presence

of electromagnetic interference. Both 2- and 3-wire current loops (often referred to as loop powered or

separately excited, respectively) are commonly used in industry. Both types of current sensors are

illustrated in this section. Internally, the ELITEpro XC uses 0.1% precision 499 ohm resistors to measure

the voltage drop impressed by the external current source. Current loop sensors will typically be

powered from a 24-volt DC supply. The ELITEpro XC has four measurement channels. The negative

terminals of each channel are common to each other and connected to the reference plane for power

measurements. For this reason, it is imperative that the ELITEpro XC be connected as the last

component in the current loop, rather than the first, if multiple channels are used. Best practices are to

use a single power supply for all sensors to reduce the occurrence of ground loop current between

supplies.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

24

www.GlobalTestSupply.com

DENT Instruments

Quick Start to Using the ELITEpro

L1

L2

G

+

-

Sensor

Pow er Sup pl y

2-Wire Current Loop Configuration

Voltage Connection

Voltage output sensors and 3-wire current loops will typically use one voltage for powering the sensor

and a second voltage (or current) for sending an output signal. Sometimes the power supply ground and

signal reference conductor is shared between two circuits resulting in a three wire device. This economy

usually comes at the installer’s expense of having to form a junction at the power supply, sensor, or

meter. Sensors having four terminals are also popular and are simply connected to the meter by

observing the indicated polarity between sensor and meter.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

25

DENT Instruments

Quick Start to Using the ELITEpro

L1

L2

G

+

-

Senso r

Power Supply

Separately Excited Current or Voltage Loop Configuration

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

26

DENT Instruments

Quick Start to Using the ELITEpro

POWER IN/OUT CONNECTION

The Power In/Out connection can be used with the ELITEpro XC to measure loads where the line voltage

is less than 80 VAC and the internal power supply will not operate (a small battery bank, for example) or

where AC line voltages are not available and you want to use current transformers to record amps only.

It can also be used as a 6V output to power any outside devices.

To power the ELITEpro XC using an external supply, contact DENT Instruments for an

appropriately-rated power supply.

The ELITEpro XC can also supply 6V DC at up to 200mA to an external device when the ELITEpro XC

voltage leads are connected to mains power between 80 and 600 VAC.

DIGITAL CHANNEL CONNECTIONS

Digital channel connections are part of the ELITEpro SP, a legacy product produced before ELITEpro XC.

Users of ELOG connected to legacy products will see digital channels instead of analog channels on the

screen. The Digital channels provide users with a way to export kWh, kVAh, and kVARh pulses to

external devices. The ports are grounded when closed, and floating when open. For example, if the

setup table Digital 1 is configured to output KWh pulses with a Scale of 1.0, Digital channel 1 will output

a pulse for each kilowatt-hour of energy measured by the meter on Power Channel 1.

In Digital 2 the Scale is set to .001 (kWh), so a pulse would be generated for each Watt-hour of energy

measured on Power Channel 2. See below.

For example, in the Digital Channels setup below: A desk lamp with a 100W bulb will use 0.1 kWh every

hour; the meter produces a pulse once every 10 hours on Power Channel 1 and 100 pulses every hour

on Power Channel 2. In contrast, a 1,000W heater will use 1 kWh every hour; the meter produces a

single pulse once an hour on Power Channel 1 and 1,000 pulses every hour on Power Channel 2.

Digital 1/2: Turns the channels on/off by choosing an option from the drop-down list.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

27

DENT Instruments

Quick Start to Using the ELITEpro

1) Connect the wires of your pulse input measuring device to the +/- pulse output connection points on

the ELITEpro SP.

2) Using an existing setup table (or follow the steps in Section 2 of this manual to create a new one),

turn on the Digital 1 and/or Digital 2 channels.

3) Enter a descriptive name in the Name field to identify your logger (optional).

4) Choose which Power Channel (CT) will be used to generate pulses from the drop-down list.

NOTE: The Power Channel drop-down list displays any enabled channel, allowing users to choose which

one(s) to use as a source for the pulses.

For example, if the setup table is only configured to measure one power channel, no other options will

be available in the Power Channel drop-down list. If the setup table is configured to measure two power

channels, you may choose either “1” or “2” from the drop-down list.

Users may wish to output different pulse variables on each channel. The Power Channels for Digital 1

and Digital 2 may both be set to “1,” or set to “1” and “2” in order to output pulses of two Physical

Power Channels, or both may be set to “2.” This enables users to output pulses with different data in the

Value and Scale described in the following sections.

5) Select a parameter (kWh, kVARh, or kVAh) to be used as the source for pulses from the Value

drop-down list.

The ELITEpro SP is capable of outputting pulses for KWh, KVAh, or KVARh. Only one may be outputted at

a time if a single digital output channel is turned on, but users have the option of outputting two

different values concurrently from the same Power Channel if both Digital 1 and Digital 2 are in use.

6) Enter a scale in the Scale field to assign a significance to the pulses.

For example, if 22 is entered in the Scale field and kWh is selected for the Value, then each pulse

generated by the meter is equal to 22 kWh on the selected Power Channel.

7) Click SEND SETUP TABLE to Logger.

NOTE: The maximum output rate is five (5) pulses per second, or 5Hz, with a maximum current of 75mA

and 30V DC.

NOTE: When logging is turned on or a new setup table is sent, pulse outputs start at the integration

period relative to the hour that logging starts. For example, if you have a 5-minute integration period

and you turn logging on at 1:05:01 PM (5 minutes and 1 second after the hour), logging AND pulse

output accumulation will NOT start until 1:10:00 PM.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

28

DENT Instruments

Quick Start to Using the ELITEpro

USB Port

Power In/Out

CONNECTING THE USB CABLE

1) Connect the USB cable to an available USB port on the computer and insert the other end in the USB

port of the ELITEpro XC.

If a USB cable is used inside an electrical panel, it must be rated to the appropriate voltage or wrapped

in an appropriately-rated insulating sleeve. The DENT-supplied cable does not meet this requirement

without an insulating sleeve.

2) Turn on the breaker to begin metering.

ELITEpro

Power End Panel Connections

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

DENT Instruments

Quick Start to Using the ELITEpro

OTHER COMMUNICATION CONNECTIONS

The RJ-45 Connector is for Ethernet Network connections.

NOTE: The Ethernet connector accommodates high speed downloads, setup, and

communication with a computer. If an Ethernet cable is to be used inside an electrical panel, it

must be rated to the appropriate voltage or wrapped in an appropriately-rated insulating sleeve.

The Coaxial connector, if present, is for an optional external Wi-Fi antenna.

NOTE: If an antenna is used inside an electrical panel, it must be at least 2" away from any live

wiring or bus bars.

NOTE: An internal Bluetooth module is an optional communication interface.

External Antenna—

for Wi-Fi (optional)

Ethernet port

Communication Connections

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

30

DENT Instruments

Quick Start to Using the ELITEpro

Communicating with the ELITEpro XC

1) Plug the USB cable into the logger and the PC. ELOG should auto-launch and connect to the ELITEpro

XC automatically. If not, double-click the ELOG icon on the PC desktop.

The ELOG window

opens, displaying the

menus and a row of

speed buttons to

quickly access frequently used ELOG functions.

The ELITEpro XC and ELOG software should connect automatically. If not, proceed with Step 2

below. If the automatic connection is made, proceed with Step 6 below.

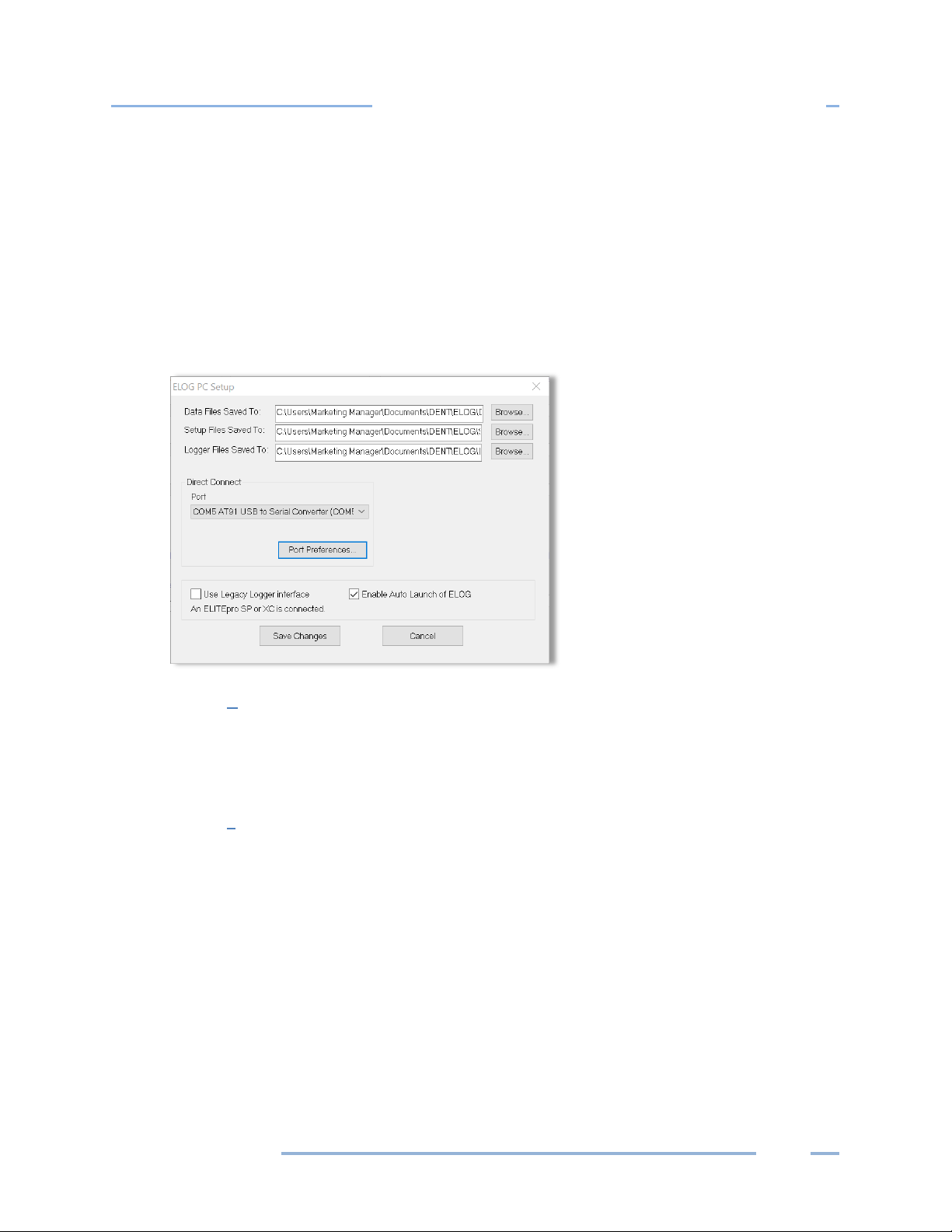

2) Select Tools > PC Setup to open the ELOG PC Setup dialog box.

3) In the middle section of the dialog box labeled Direct Connect, select the Port from the menu that

corresponds to the computer’s COM port where the USB cable is connected.

Port Preferences: This option is used to hide COM Ports from ELOG, to change the order of COM

Ports as they appear in the drop-down control, and the order they are searched when ELOG can't

connect to a logger on the desired port.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

31

DENT Instruments

Quick Start to Using the ELITEpro

Ports that are unchecked will be hidden from ELOG. Ports are listed and searched in the order

shown. The order can be changed by selecting a port and moving it up or down.

Every time ELOG connects to a logger, its port is moved to the top of this list.

4) Check the Use Legacy Logger interface checkbox to enable legacy menu items for customers using

legacy products (ELITEpros). The default is unchecked, and the ELOG only displays features and

menu items relevant to the current software release.

5) Click Save Changes.

For more information on the other ELOG PC Setup options see the Tools Menu content in Section II.

6) Select Logger > Communication > Direct Connect to connect the computer to the ELITEpro XC.

The Logger Connection information displays along the bottom of the window, providing a status

message as the computer connects to the ELITEpro XC. Simultaneously, the logger’s COMM LED will

begin to flash.

ELOG fills the information fields of the Logger Connection

Logger serial number/firmware

version number

7) Create and send a setup table to the logger. See Creating and Using the Logger Setup Tables for a

complete description.

window when the computer establishes communication

with the ELITEpro XC. For more information on using ELOG,

see Using the ELOG Software.

8) Use Logger > Display Real-Time Values to verify installation.

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

32

DENT Instruments

Quick Start to Using the ELITEpro

TERMINATING THE ELITEPRO XC TO COMPUTER CONNECTION

Select Logger > Communication > Terminate Connection to end the connection between the computer

and the ELITEpro XC.

-or-

Use the Disconnect speed button to quickly terminate the connection.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

33

DENT Instruments

IN DEPTH USE OF THE ELITEPRO XC AND ELOG

Creating and Using the Logger Setup Tables

The ELITEpro XC is a flexible meter that can monitor a wide variety of parameters over a wide range of

currents, voltages and service types. This requires that you determine what is recorded and at what

intervals. The ELITEpro XC requires that it be configured for use by first creating a “Setup Table” file and

then loading the file into the meter.

Setup Tables are created using the ELOG software and saved to the computer with a .sut file extension

appended to the name. A .sut file may be:

Loaded into the ELITEpro XC immediately or at a later time but prior to beginning a monitoring

session

Sent to any number of loggers

Retrieved from an ELITEpro XC, modified and saved, and resent to the logger

CREATE A NEW SETUP TABLE

A new setup table can be created for any of the devices compatible with the current version of ELOG.

This includes a variety of DENT Instruments legacy products in addition to the ELITEpro XC.

If the logger is not connected and communicating with the computer, setup tables can still be created

and saved to the computer.

1) Select File > New > Setup Table File and click OK.

If your computer is currently communicating to an ELITEpro XC, the ELOG software assumes the new

setup file is for the connected device. Selecting New displays a setup table with the default parameters.

If no ELITEpro XC or other logger is communicating with the computer, the Select A Setup Table Type

dialog box displays.

2) Select ELITEpro XC from the drop-down menu.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

34

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

3) Click OK.

OPEN AN EXISTING SETUP TABLE ON YOUR PC

Existing setup tables on the computer can be opened, modified, and saved.

1) Select File > Open to display the Open dialog box.

2) Select Setup Table File and click OK.

3) The Open dialog box displays. Select the desired setup table file or navigate to a folder containing

additional files. The default folder is set to C:\Users\User Name\Documents\DENT\ELOG\Setups.

4) Select the file name and click Open.

-orDouble-click the file name to open.

The setup table file can be reviewed, edited, and saved to disk or sent to the logger. For instructions on

sending the file to the logger see Send a Setup Table to the Logger.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

35

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

RETRIEVE AN EXISTING SETUP TABLE FROM THE ELITEPRO XC

Existing setup tables on the ELITEpro XC can be retrieved once the computer and the logger are

connected and communicating.

Select Logger > Retrieve Logger Setup Table.

The setup table stored in the logger is retrieved and displayed, with the name of the file above the ELOG

menu bar. The file can be modified and saved to disk or resent to the logger.

NOTE: Sections of this window are used in the following text to highlight only those areas under

discussion.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

36

www.GlobalTestSupply.com

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

CONFIGURE THE SETUP TABLE

The setup table consists of several sections where the attributes of the ELITEpro XC are defined.

Logger Type Setup Table Name

ELITEpro XC is the default

entry. This field cannot

be edited once you are in

the Setup Table window.

Logger type is chosen

from the Select A Setup

Table Type window.

Enter a name for the

setup table. 20-character

limit. This is helpful for

identifying different

setup tables. NOTE: The

setup table name need

not be the same as the

.sut file name.

Data Interval Line Frequency

The default integration

period is fifteen minutes.

The choices are 1, 3, 15,

30 seconds; 1, 2, 5, 10,

15, 20 and 30 minutes; 1

and 12 hours; 1 day. This

tells the logger at what

time intervals data is to

be stored in the memory.

For example, if the

integration period is set

for 30 minutes and

average watts is being

monitored, then every 30

minutes the logger

records the average

power use (watts) for

that channel over the

preceding 30-minute

interval, based on

approximately 14,400

measurements of the

monitored power draw. If

Maximum (and/or

Minimum) values are

being recorded the

highest (and/or lowest)

of those 14,400 readings

are also saved.

Auto, 60 Hz, or 50Hz.

Default is 60 Hz.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

37

www.GlobalTestSupply.com

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

DATA LOGGING CONTROLS

The Data Logging section controls when the logger starts and stops collecting data. The default values

are Start Immediately and Stop Never (Ring Memory). Additional data logging options are defined

below.

Start Options

Immediately Logging starts as soon as the setup table is sent to the logger.

Date (mm/dd/yy)

Time (hh:mm:ss)

Peak Demand Window

Time should be set in a 24-hour format, e.g., 2:30PM should be entered as

The default is 15 Minutes. Choices are Off, 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, and

Logging starts at the designated date and time.

14:30.

60 minutes.

Stop Options

Never (Ring Memory) Logging is continuous, meaning when memory fills, the oldest records are

replaced with the newest records, allowing for long term metering projects.

When Memory Is Full Logging stops when the memory is full.

Date (mm/dd/yy)

Time (hh:mm:ss)

Time should be set in a 24-hour format, e.g., 2:30 pm should be entered as

Logging stops at the designated date and time.

14:30.

MEMORY CAPACITY

ELOG provides a convenient feature that calculates

the approximate length of time required to fill the

memory for any setup table. The feature is dynamic

so that any time any parameter in a setup table

affecting the memory duration is changed, the Memory Capacity field is updated, providing the (new)

length of time the logger’s memory will last. The ELITEpro XC has 16 MB internal non-volatile memory.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

38

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

The Millivolt default is 100 amps. Enter the value printed on the CT if it is not 100. If RōCoil

(Rogowski) is selected, the CT Amps are set to 5,000 and the CT Phas

may not be changed. All DENT RōCoils, regardless of size, use the same settings.

Power Channel Setup Help: The Power Channel Assistant can be opened to guide a new user

through the Setup Table step

well as a key to recording flag abbreviations. The Power Channel Assistant can be accessed by

starting a new Setup Table and going to Help > Power Channel Setup Help.

QUICK SETUPS

The Quick Setups section of the window provides four buttons to quickly configure the ELITEpro XC.

1) Click the Quick Setup

button that represents

your monitoring scenario.

Each button opens the CT

Selection dialog window.

See ELOG Quick Setup Wiring

Diagrams within this section for more detail.

The View Typical Setup button

is only visible after a Quick

Setup selection is made.

2) Select View All to choose a CT from the CT selection list.

-orSelect Millivolt and enter the CT Amps, the primary current rating of the current transformer, and

the CT Phase Shift.

-orSelect RōCoil.

e Shift is set to 0.0 and

-by-step. It includes helpful explanations of each parameter as

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

39

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

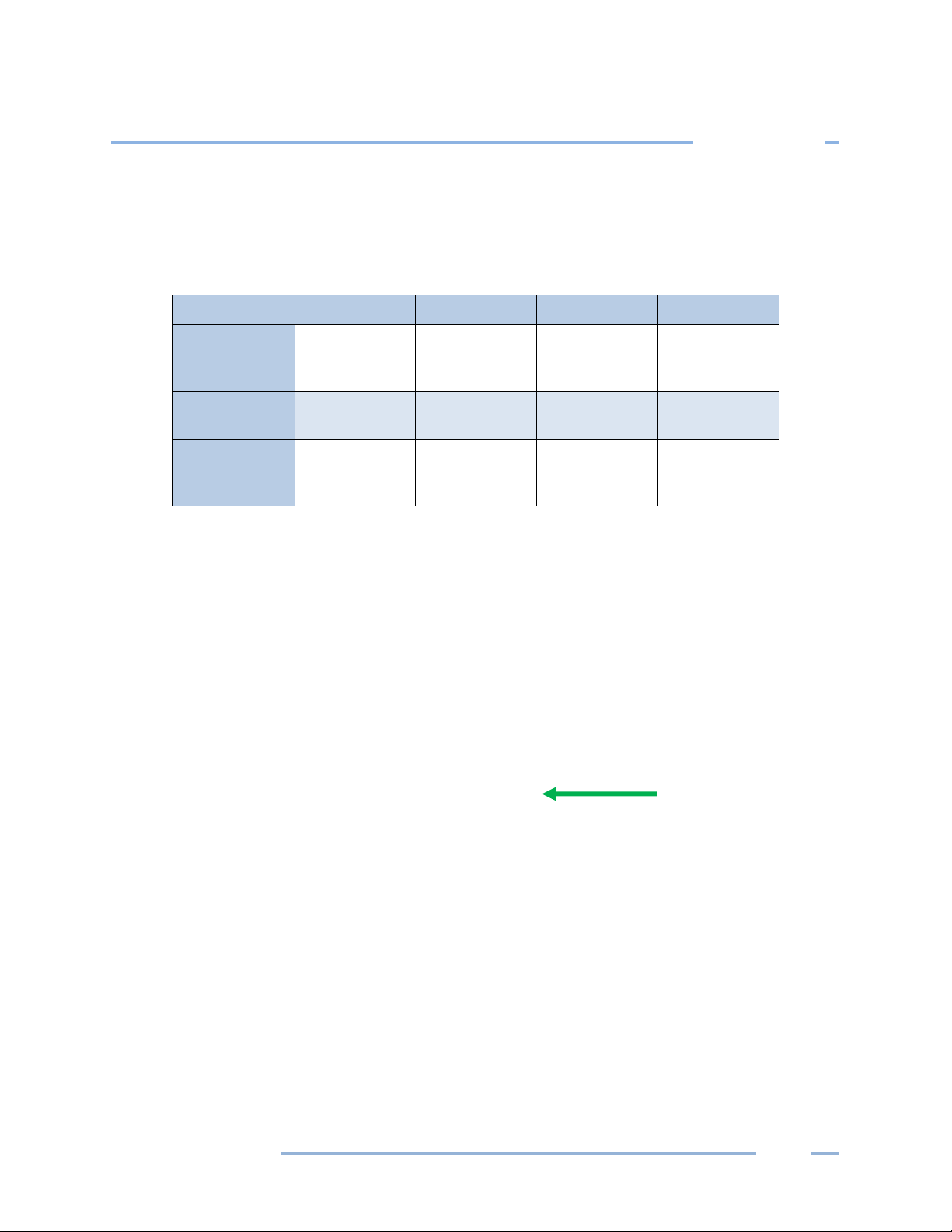

Current Transformers Recommended CT Phase Shift Values

Clamp On CT-CON-0150EZ

CT-CON-1000

Split Core Small CT-SCS-0050

CT-SCS-0100

Split Core

Medium

Split Core Large CT-SCL-0600

Hinged Mini CT-HSC-020

Hinged Midi CT-HMC-0100

Revenue Grade

Toroidal Solid

Core

CT-SCM-0100

CT-SCM-0200

CT-SCM-0400

CT-SCM-0600

CT-SCL-1000

CT-HSC-050

CT-HMC-0200

CT-RGT12-0005

CT-RGT12-0020

CT-RGT12-0050

CT-RGT12-0100

1.10°

0.20°

2.20°

2.20°

1.75°

1.50°

1.30°

1.30°

0.00°

0.00°

0.75°

0.75°

0.12°

0.30°

0.00°

0.00°

0.00°

0.00°

Revenue Grade

Split Core

CT-SRS-005

CT-SRS-050

CT-SRL-100

CT-SRL-200

CT-SRL-400

-0.10°

-0.23°

0.06°

0.06°

-0.06°

Recommended CT Phase Shift Values

3) Click OK.

4) Check the Enable THD checkbox if you want total harmonic distortion to appear as a percentage in

the Data File Summary report. Selecting this option automatically populates any required value field

necessary to determine distortion.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

40

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

Once the Quick Setup is completed, the View Typical Setup button appears in the Quick Setup area of

the screen. Clicking this button displays a wiring diagram showing how to connect the CTs and the

voltage leads of the ELITEpro XC corresponding to the selected setup. The diagram can be printed and

carried into the field for easy reference during installation. Refer to ELOG Quick Setup Wiring Diagrams

for detailed information of each Quick Setup option.

Additionally, depending on the setup, Calculated Power Channels with configuration options display in

the lower section of the Setup Table screen.

HYSICAL POWER CHANNELS

P

The ELITEpro XC has four configurable hardware channels corresponding to the current.

1) Click on the maximize button in the upper right-hand corner of the Setup Table window to display as

much of the full screen as possible.

2) Click on the down arrow next to each channel you want to configure.

CT 1 must be placed on the phase listed as V High for Channel 1 in the ELOG setup table. CT2, CT3

and CT4 must also correspond to the appropriate phase as shown in Channels 2, 3, and 4 in the

ELOG setup table.

3) Select Power to turn on any channel. These channels refer to the current transformer inputs from

the ELITEpro XC. Selecting Power displays the options for configuring the channel.

4) Enter a name for the channel, then select the Voltage References, Current Transformers, and any

Recorded Values.

NOTE: The PT Ratio is used when monitoring voltages greater than 600 VAC (maximum rating of the

ELITEpro XC). Use an instrument grade transformer with low phase shift and high accuracy since errors

in the transformer will translate directly into errors in the recorded data. The PT Ratio value put into the

Setup Table in the logger should be the transformer primary:secondary ratio. This feature is useful when

monitoring high voltage loads such as found at a substation or on transmission lines.

For example, a potential transformer is used to monitor a 4160 VAC load. The transformer steps the

voltage down from 4160 to 120 VAC. The PT equals the transformer ratio or 4160/120 = 34.667. Thus,

34.667 would be used for the PT value in the channel Setup Table.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

41

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

CT Flipper: Quickly change the order of voltage references for a particular channel by clicking

the CT Flipper button. The CT Flipper can be found by clicking on the CT Type dropdown in the

Setup Table and clicking the CT Flipper button. A

been flipped.

The drop-down list in the Type field of the Current Transformers section contains a View All option that

opens the Select a CT from the list window displaying images of CTs with their recommended amps and

phase shift. Selecting a CT from that window automatically populates the Amps and Phase Shift fields

with the CT’s recommended values.

Double-click on any image.

-orSelect an image and click OK.

CAUTION: IF A PT (POTENTIAL

TRANSFORMER) IS NOT USED ON SERVICE

VOLTAGES GREATER THAN 600V, THE

ELITEPRO XC MAY OVERHEAT (OR

WORSE) CAUSING IRREPARABLE DAMAGE

AND EXTREME DANGER TO THE USER.

The Recorded Values of a power channel tell the logger what parameters you wish to record and can be

configured by selecting any combination of Volts, Amps, power (kW), volt-amps (kVA), power factor

(PF), and volt-amps-reactive (kVAR) as desired for each channel you turned on.

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

pop-up window alerts you when the CT has

42

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

Copy Button: Clicking the “C” (copy) button at the end of the Recorded Values Row can be used

to quickly copy a

For a description of the Recorded Values and their formulas for the Calculated Power Channels, see

Calculated Power Channels.

set of recording flags from one channel to another.

The following options are available for configuring Physical Power Channels.

Physical Power Channel Options

Name

V High High-side voltage. This is the “high” reference

V Low Low-side voltage; reference for AC voltage. Choices are: L1, L2, L3, Neutral.

PT Ratio Potential Transformer turns ratio. This is used

Type This is the type of CT connected to the

Amps Depends on the type of CT selected. Displays

Phase Shift Compensate for CT Phase Shift with this setting.

Volts

Amps

KW

KVA

PF

KVAR

Name the channel so it describes the location or

item being monitored, such as "Water Heater"

or "Pump L1 Phase.” A maximum of 20

characters is allowed.

voltage that will be measured with respect to

the reference “low” voltage, V Low.

when a step-down transformer is needed to

measure AC voltages greater than 600V. The

default is 1.000.

ELITEpro XC

the value entered in the CT Size screen.

Default setting is 1.1 degrees.

To record any or all of these values use the

menu to select an option.

Optional

Choices are: L1, L2, L3, Neutral.

Choices are: MilliVolt or RōCoil.

Choices are: Average, Minimum, or

Maximum. In addition, the integrated

hourly value in an option where

appropriate.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

43

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

See Power Measurement—Connecting CTs and Configuring Channels for information on how to

properly configure the Setup Table for single-phase 2-wire, single-phase 3-wire, 3-phase 3-wire, and

3-phase 4-wire services.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

44

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

CALCULATED POWER CHANNELS

Channels 5 and 6 are the Calculated Power Channels. They combine the data from two or more power

channels (also called "hardware” or “physical channels") and are used primarily for calculating total

system volts, amps, kW, kVA, power factor, and kVAR in polyphase or multiple single-phase systems.

The Calculated Power Channels are frequently used to:

Record total system power parameters on three phase loads.

Optimize the logger’s memory by collecting and combining data from two or more channels instead

of collecting data from two (or more) separate channels.

For a description of the formulas used to compute channels 5 & 6 based on the CT input channels 1–4,

see Appendix D—Calculated Power Channel Formulas.

Combining Channels

To combine channels and maximize memory use:

1) Depending on your setup table configuration, ensure that the Physical Power Channels you wish to

combine are set to Power.

It is recommended that the Recorded Values flags of Volts, Amps, kW, kVA, PF, and kVAR for the

individual channels be left on. However, if maximum use of the memory is required, they can be

turned off.

Default recording flags may have the Average checkbox selected in each drop-down menu for the

Recorded Values.

2) Under Calculated Power Channels, turn on the channel by selecting Power Sum from the Channel 5

menu. Perform the same function for Channel 6, if desired.

3) Enter a name for the Calculated Power Channels (optional).

4) Select the Physical Power Channels to be added together in the Combine Channels box.

5) Set each recording flag for Volts, Amps, kW, kVA, PF, and kVAR as desired.

6) Click Send Setup Table to Logger to send the setup table to the logger and make it the active table.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

45

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

The following graphic is an example of a Setup Table for a 3-phase 4-wire connected load using a

Calculated Power Channel with Combine Channels 1, 2, and 3 selected to optimize memory usage on

the ELITEpro XC.

NOTE: The Recorded values listed to the right of the Current Transformers section on the Setup Table

are not shown in this graphic.

ANALOG OUTPUT CHANNELS (ELITEPRO XC ONLY)

NOTE: Turn the analog channels on/off by choosing an option from the drop-down list.

1) Select Current/Voltage/Off from the drop-down menu for the channel type. Additional fields display

on the Setup Table screen when an analog channel current or voltage is selected.

2) Enter a descriptive name in the Name field to identify your measurement. This name appears in the

retrieved logger data header.

3) Enter the raw sensor output minimum/maximum values. This data is typically found on the data

plate or data sheet of the sensor. Typical values for voltage devices are 0-5, 1-5, 0-10, 0-15, 0-30 for

voltage devices and 0–20, 4-20 for current loop devices.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

46

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

To troubleshoot or calibrate a current or voltage sensor, it is convenient to set the physical

range fields to be equal to the electrical output values. The Real Time Values readings

be compared directly with voltage or current measurements taken from a DVM. Offset or gain

errors can be corrected by adjusting the minimum value or span (max-min).

4) Enter the corresponding engineering value to the sensor range (i.e., psig), the units, and the

average, minimum, and/or maximum record.

5) Click Send Setup Table to Logger to load the configuration into the data logger.

Best practices are to confirm the operation of all sensors. Use Logger > Display Real Time Values > Show

as Text or click the Display Real Time Text Values speed button before commissioning the logger for

prolonged data logging projects.

can then

SEND A SETUP TABLE TO THE LOGGER

When you’ve finished selecting the configuration options, the setup table needs to be sent to the

ELITEpro XC.

1) After connecting to the logger, click on one of the SEND

SETUP TABLE to Logger command buttons on the Setup

Table screen. Separate buttons are available at the top

and lower left of the Setup Table screen. Sending a new

setup table to the logger deletes any data still stored in the logger. ELOG displays the following

dialog box to ensure desired data is not lost:

2) Click Send SUT and Delete Data. This loads the new setup table into the meter and clears the data in

the logger. The Logging is now ON dialog box briefly displays.

-orClick Download Data then Send SUT. The Select A Directory and A Name… dialog box displays.

Enter the name and location for the data file. After the data is downloaded to the PC and saved,

ELOG automatically sends the new setup table to the meter and starts logging.

-orClick Cancel.

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

47

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

ELOG automatically initiates logging when a setup table is downloaded to the logger unless the Data

Logging delayed start time is being used.

3) Select Logger > Display Real-Time Values > Show As Text to view the real-time values measured by

the logger.

SAVE A SETUP TABLE ON THE COMPUTER

When you’ve finished selecting the configuration options, the setup table can also be saved for

downloading to the ELITEpro XC at a later time.

Select File > Save to save the setup file to the hard drive or Save As to save to the hard drive using a

different file name or folder location.

Monitoring can begin once the ELOG software is configured and the ELITEpro XC is connected. The

following sections of this chapter provide assistance in making sure the logger is performing correctly.

LED Diagnostics

PHASECHEK™ LEDS

PhaseChek is a unique feature of DENT meters that simplifies installation by ensuring proper CT-tovoltage phase installation and avoiding faulty data collection.

The ELITEpro XC has four tri-color PhaseChek LEDs, one green/red/blue LED for each CT input. These

LEDs provide the following information:

All LEDs are green—the system power factor is greater than 0.55 and the CTs are properly placed on

the corresponding voltage phases and the CT is oriented properly (arrow toward the load).

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

48

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

If the total system power factor is less than 0.55, the LEDs will be red even if connected

properly. This situation is rare but could occur if, for example, the load

lightly loaded electric motor. It is common for an individual phase power factor to be less than

0.55 and the corresponding LED will be red.

If the Physical Power Channel (CT) is turned off in the setup table, the corresponding

PhaseChek LED will be dark.

LED is red—there is a CT voltage phase placement error (or the Power Factor is less than 0.55)

LED is blue—the CT is on backwards (-kW) with the arrow pointed away from the load

LED flashes red and blue—CT is on backwards and on the wrong voltage phase

to be monitored is a

COMM—COMMUNICATIONS LED

The ELITEpro XC COMM LED flashes different colors (green, blue, red) to indicate that the logger is

connected, logging information, and communicating with the computer. Green will flash approximately

once per second when the ELITEpro XC is logging and communicating with the computer.

Find Quality Products Online at: sales@GlobalTestSupply.com

ELITEpro

www.GlobalTestSupply.com

49

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

Power Measurement—Connecting Sensors & Configuring Channels

The ELITEpro XC can monitor AC power loads ranging from 1-phase, 2-wire to 3-phase, 4-wire systems

and up to 600 VAC at 50 or 60Hz.

Read all warning symbols described in the Safety section AT THE BEGINNING OF THIS MANUAL.

Use the proper Current Transformers (CTs) for the load being monitored. For a complete discussion on

this, see the section Current Transformer (CT) Selection below.

CAUTION: DO NOT USE UNSHUNTED CTs. ONLY USE SHUNTED CTS FROM DENT INSTRUMENTS

WITH 333 mVAC OUTPUT. ALL DIAGRAMS IN THIS SECTION SHOW THE CT PHASING ARROW

POINTING TOWARD THE LOAD.

Always orient the arrow on the CT towards the load or as otherwise indicated on the CT. All diagrams in

this section will show the CT phasing arrow oriented towards the load. If the CT was accidently

installed backwards and access to reverse it is not possible, the “CT Flipper” function can be accessed

by clicking the CT “Type” in the “Logger Setup Table.” See Physical Power Channels

.

WARNING: Use of this device in a manner for which it is not intended may impair its means of

protection. Do not exceed 600 VAC voltage inputs!

When connecting the ELITEpro XC to an AC load, follow these steps in sequence to prevent a shock

3. Connect the voltage leads to the different phases. Use proper safety equipment (gloves,

mask, and protective clothing) as required for the voltages monitored.

hazard.

1. If possible, de-energize the circuit to be monitored.

2. Connect the CTs to the phases being monitored.

ELITEpro

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

50

DENT Instruments

In Depth Use of the ELITEpro XC and ELOG

U.S. color conventions are used in the document’s diagrams. ELITEpro XC meters supplied for

international markets are provided with 5 colors of voltage leads: red, black, blue, white, and

yellow. The voltage lead sockets on the meter are all black in color

N.